gledhill PULSACOIL III Design, Installation And Servicing Instructions

DESIGN, INSTALLATION AND

SERVICING INSTRUCTIONS

TEL: 0800 14 55 55 7

www.gledhill-pulsacoil-3.co.uk

A mains pressure hot water supply system

incorporang an o peak electric thermal store

PULSACOIL III

DESCRIPTION

INTRODUCTION

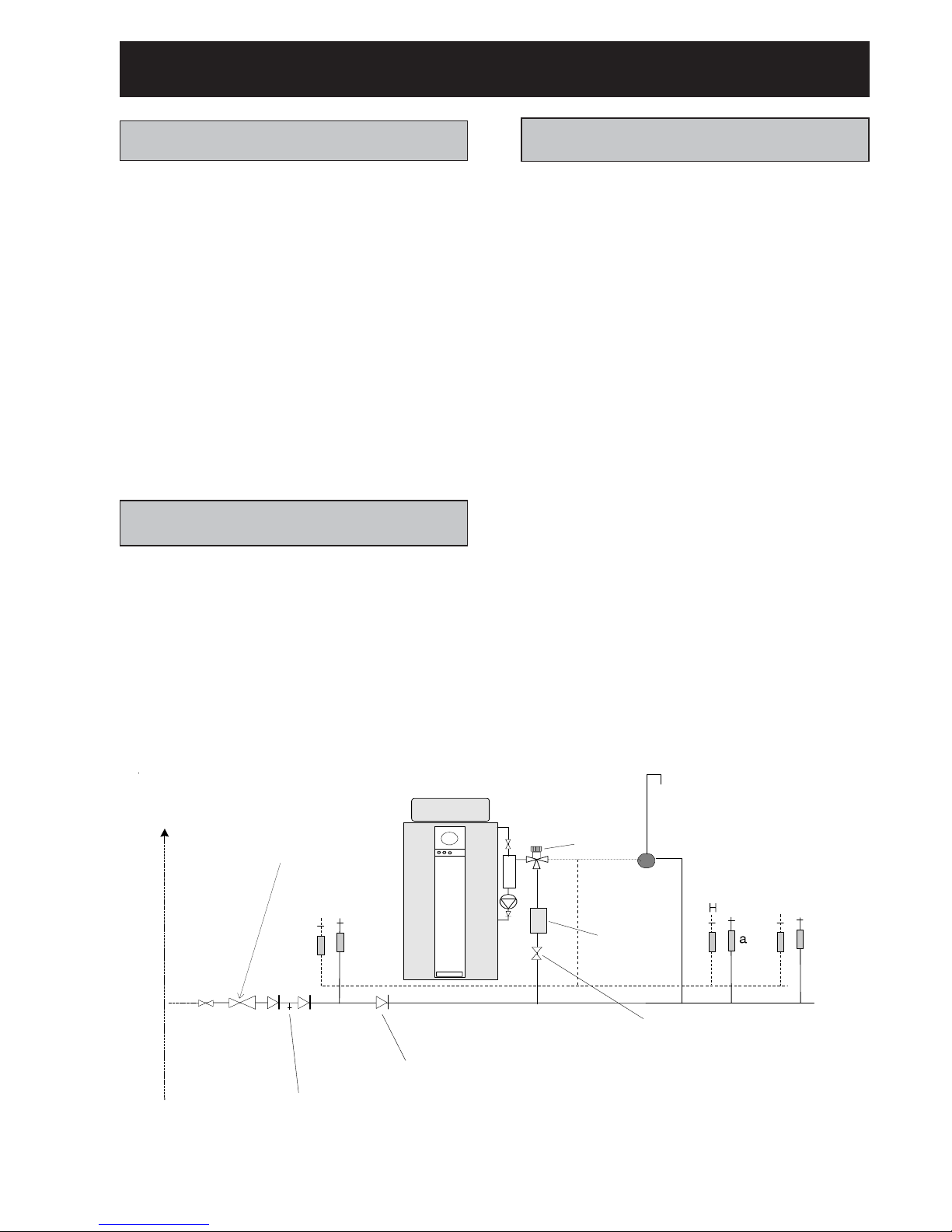

The PulsaCoil III based hot water supply system is shown

schematically in Figure 1.1.

The PulsaCoil III appliance utilizes an off peak electrically

heated thermal store with integral feed and expansion

cistern to produce primary hot water. This is then

circulated by a pump through a plate heat exchanger to

instantaneously heat mains pressure domestic cold water.

This allows mains pressure domestic hot water to be

provided to the taps at high flow rates without the need

for any temperature and pressure relief safety valves or

expansion vessels. The actual temperature of the

domestic hot water is maintained at the pre-set level by

a printed circuit board which controls the speed of the

pump circulating the primary hot water from the store

through the plate heat exchanger.

THERMAL STORE

The thermal store and the top up cistern are constructed

of copper. The thermal store is manually filled with mains

cold water through the feed and expansion cistern. It

should be filled up to the level of the swage mark in the

cistern.

The thermal store is efficiently insulated with Rockwool

CFC free insulation and finished in a painted steel case

to minimise standing losses.

The primary water in the store is heated to a temperature

of approximately 77oC by the immersion heaters.

2

DOMESTIC HOT WATER

Cold Water Supply

The PulsaCoil III units are designed to be fed directly

from the mains water supply as shown schematically in

Figure 1.1. They fulfil the requirements of Water Bylaw

91, and therefore do not require a check valve to be

fitted to the supply pipe. The performance of the PulsaCoil

is directly related to the adequacy of the cold water supply

to the dwelling. This must be capable of providing for

those services, which could be required to be supplied

simultaneously, and this maximum demand should be

calculated using procedures defined in BS 6700.

PulsaCoil will operate at mains pressures as low as 1

bar and this must be available when the local demand is

at its maximum, but the preferred range is between 2

and 3 bar. As a general guideline, although a 15mm

external service may be sufficient for smaller dwellings

with one bathroom, a 22mm service (25mm MDPE) is

preferred and should be the minimum for larger dwellings.

If a water meter is fitted in the service pipe, it should

have a nominal rating to match the maximum hot and

cold water peak demand calculated in accordance with

BS 6700. This could be up to 50

litres/min in some

properties.

The unit must be fitted strictly in accordance with the

requirements of the Local Water Undertaking who should

be consulted prior to the installation. In the event of any

difficulty please contact us as the manufacturers. The

equipment used in the system should be suitable for a

working pressure of 8 bar and approved by the WBS or

other relevant standard. If this is not the case a pressure

limiting valve will be required which is suitable for the

item of equipment with the lowest maximum working

pressure.

Supply

pipe

S

econd

d

welling

H

a

a

C

a

CHaaC

Sink

Hand

basin

Bath

Shower

Check valve NOT REQUIRED unless supply

pipe services more than one dwelling

Check valve NOT REQUIRED unless

chem ica l w a ter trea tm e nt u n it is fitted

Scale inhibitor

NOT REQUIRED

Mixing valve

Lockshield gate valve recom m ende

d

for maintenance/flow control in hig

h

pressure areas.

Figure 1.1 Typical hot and cold wa ter distribution network

‘a’ - flow regulator rec omm e nded for better

balance of h o t an d cold water supply

Pressure limiting valve

NOT R EQ U IRE D at pressures

below 8 bar unless any system

components have a lower

maximum working pressure.

DESCRIPTION

Safety Fittings

It is not necessary to fit control and safety equipment

normally associated with mains pressure hot water

storage appliances e.g. temperature and pressure relief

valves and expansion vessel. PulsaCoil is WBS listed

and a non-return valve is not required. However if the

ancillary equipment fitted in the supply to these appliances

require a non-return valve then the valve must be fitted

directly after the branch to the drinking water i.e. a kitchen

sink as shown schematically in Figure 1.1.

Domestic Hot Water Flow Rates

Provided the pipe sizing and the supply pressure is adequate the hot water flow rate should be up to 35 litres/

min for all models (see Table 1.1). The domestic hot

water outlet temperature is regulated to 55oC by the electronic control system and is not user adjustable.

Use in Hard Water Areas

There are two options for the pump speed control. Option

‘H’ must be used in hard water areas above 200ppm.

Option ‘S’ can be used in soft water areas below 200ppm.

A patented control system within the Option ‘H’

microprocessor offers a more sophisticated level of pump

speed control and will help prevent the formation of scale.

Both options (‘H’ and ‘S’) prevent domestic hot water

from exceeding 550C for most of the operational times of

the appliance.

It is not necessary to fit any form of scale inhibiting

equipment in the domestic cold water supply to the

PulsaCoil when using option ‘H’.

If scale should however become a problem the plate heat

exchanger is easily isolated and can be replaced with a

service exchange unit.

3

DESCRIPTION

STANDARD EQUIPMENT

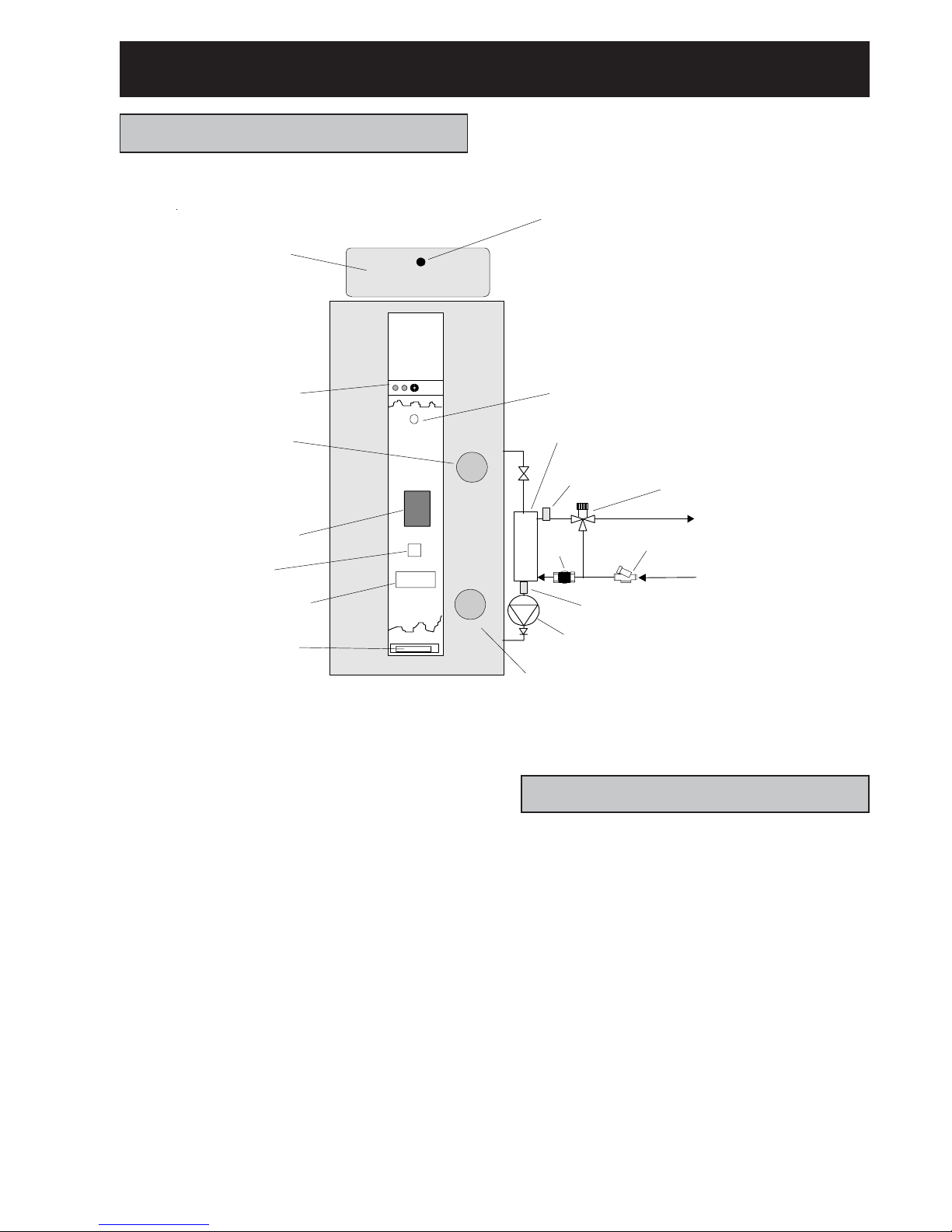

The standard configuration of the PulsaCoil III is shown

in Figure 1.2. It is supplied as a complete factory made

and tested appliance fitted with all the following items of

equipment :-

- Grundfos UPS pump for domestic hot water primary

circuit.

- Domestic hot water temperature controls and PCB.

- 2 x 3 kW low watts density Incaloy immersion

heaters.

- Domestic hot water plate heat exchanger.

- Domestic hot water mixing valve.

- Float switch for ‘Dry Firing’ protection.

- Overheat protection.

- Wiring centre.

- System status display.

OPTIONAL EQUIPMENT

a) The appliance is supplied with the components on the

right hand side (as shown in Figure 1.2) as standard but

can be supplied left handed.

b) A 22mm diameter warning pipe/overflow connection.

Any options must be clearly specified at the time of order

or a standard model will be supplied.

4

Plate heat exchange r

On peak I.H.

Ove rheat thermos tat

Off peak I.H.

Plate heat

exchanger pump

T op up

cistern

Float switch

Domestic ho t water

control PCB

S

ystem status displa y

a

nd controls

Grom ets

W iring centre

Relay

Hot water

temperature

sensor

Figure 1.2 Standard PulsaCoil III P acka ge

Primary P.H.E. return temperature sensor

Cold mains supp

ly

In-line ‘Y’strainer

Flow

switch

Mixing valve

DESCRIPTION

ELECTRIC IMMERSION HEATERS

The immersion heaters used are 14” 3kW low watts

density units with incaloy 825 immersion sheaths, and

matching 11” rod thermostats which should be set to

770C. They are BEAB approved and have been chosen

to meet the requirements of the Maxistore specification

produced specially for Ecomony 7 products by the

Electricity Industry.

It is recommended that replacements should be obtained

only from Gledhill Water Storage.

5

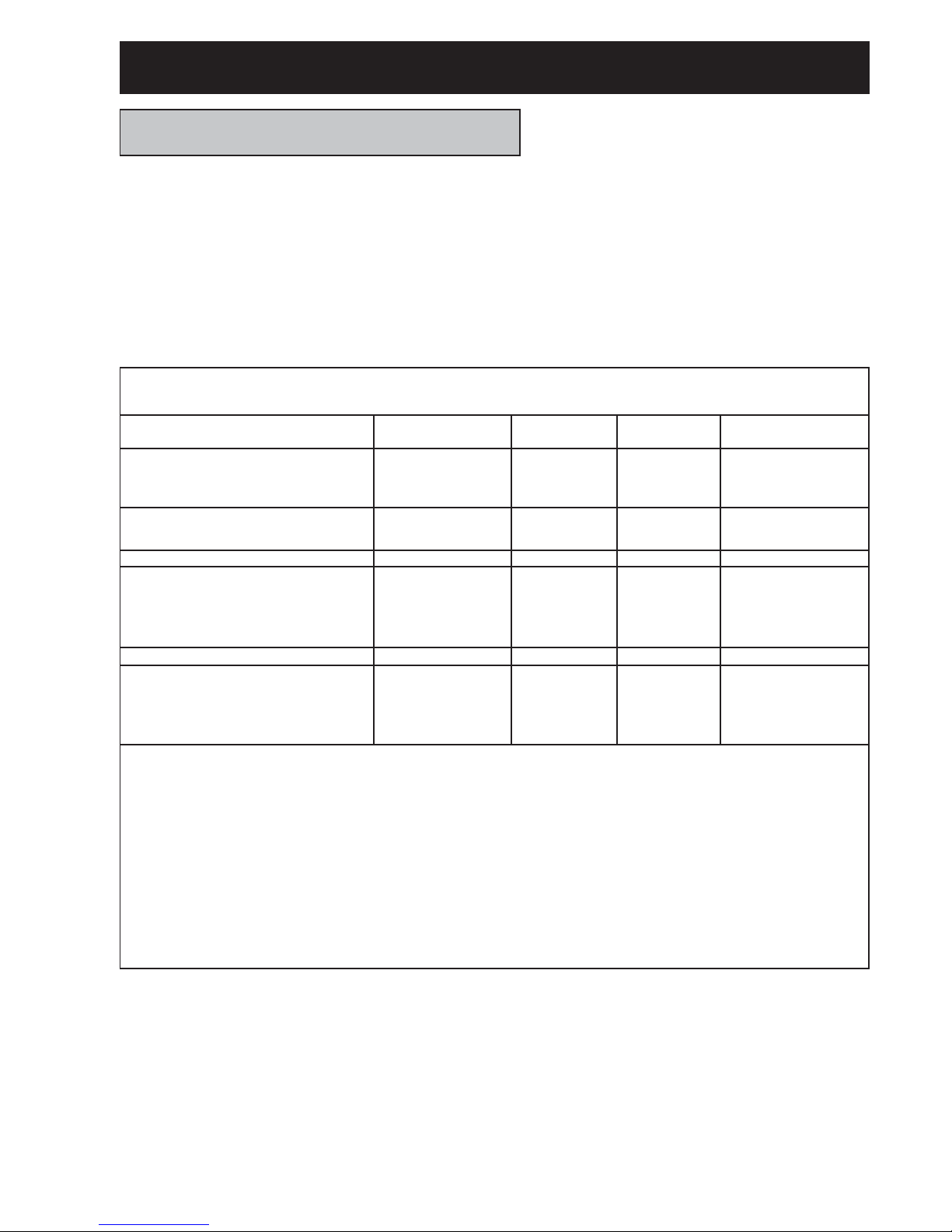

Table 1.1 Technical Specification of PulsaCoil III

MODEL PC144 PC190 PC210 PC245

Overall dimensions of store 1650 x 525 1840 x 550 1840 x 575 1960 x 575

(Height x Diameter)

Minimum cupboard size

(Width x Depth) 700 x 550 715 x 600 750 x 650 750 x 650

Nominal store capacity (litres) 160 205 230 250

Weight (kg)

Empty 39 41 46 52

Full 199 246 276 302

Hot water flow rate (litres/min) 35 35 35 35

Typical dwelling types

Bedrooms 1 - 2 2 - 3 2 - 3 2 - 4

Bathrooms 1 or 1 1 2

En-suite shower rooms 1 1 2 1

NOTES

1. The PC245 model can be installed in a property with greater hot water demand. However this will require

more ‘ON peak’ electricity to recharge the store.

2. The standard pattern is manual fill. If automatic fill patterns are required please speak to our Technical

Sales Office.

3. The flow rates are for 350C average temperature rise and assume normal pressure and adequate flow to

the appliance.

4. For hard water areas use suffix ‘H’, for soft water areas use suffix ‘S’ after the model number, e.g.

PC144H = PulsaCoil mk III model 144 for hard water areas.

5. A minimum of 200mm should be available above the appliance to allow it to be filled and the water level

checked.

.

.

.

.

.

SYSTEM DESIGN

6

HOT AND COLD WATER SERVICES

A schematic layout of the hot and cold water services in

a typical small dwelling is shown in Figure 2.1.

PulsaCoil III will operate at mains pressures as low as

1 bar and as high as 8 bar although the preferred range

is 2-3 bar. It is also important to check that all other

equipment and components in the hot and cold water

system are capable of accepting the mains pressure

available to the property.

If the mains pressure can rise above the maximum

working pressure of any items of equipment or

component to be fitted a suitable pressure limiting

(reducing) valve will be required.

For properties with a higher supply pressure than 8 bar

it is recommended that a pressure limiting valve is

fitted, set at 3 bar.

PulsaCoil III is WBS approved. A non-return valve is not

required. Should ancillary equipment fitted in the supply

to the PulsaCoil require a non-return valve, then this valve

must be fitted directly after the branch to the drinking

water tap (kitchen sink). See Figure 1.1 for details.

Note: The hot and cold water distribution pipework should

be designed and installed to prevent heating of the cold

distribution pipe.

Taps and Valves

Aerated taps are recommended for all mains pressure

systems to prevent splashing.

Pipe Sizing

To achieve even distribution of the available supply of

hot and cold water, it is important in any mains pressure

system that the distribution pipes in a dwelling should

be sized in accordance with BS6700. This is particularly

important in a large property or one with more than one

bathroom. However the following rule of thumb guide lines

should be adequate for most typical property types:

a) A 15mm copper or equivalent external service may

be sufficient for smaller 1 bathroom dwellings

(depending upon the flow rate available), but the

minimum size for larger dwellings must be 22mm

(25mm MDPE).

b) The internal cold feed from the main stop tap to the

PulsaCoil should be run in 22mm pipe. The hot drawoff should also be run in 22mm as far as the branch

to the bath tap.

c) The final branches to the hand basins and sinks

should be in 10mm and to the shower in 15mm.

d) The final branches to taps in existing properties,

which are in 15mm,

should be restricted

to balance

the flow to each outlet.

e) Best results for a balanced system are achieved by

fitting appropriate flow regulators to each hot and

cold outlet (see Appendix 1).

f) For properties where the inlet pressure is high and

the flow rates may exceed 30 l/min at any bath hot

tap the installer must fit a lockshield pattern gate

valve at the cold inlet to the appliance. This should

then be adjusted to restrict the maximum flow rate

to 30 l/min.

On the odd occasion it is felt necessary to provide a

secondary circulation. We would recommend the

use of Raychem HWAT Plus or similar self regulating

trace heating to maintain the temperature in the hot

water distribution system. The system must be

installed and commissioned fully in accordance with

the manufacturers instructions.

Showers

a) Any type of shower mixing valve can be used as

long as both the hot and cold supplies are mains

fed. However PRESSURE COMPENSATING shower

mixing valves are proven to give better control when

more than one fitting are open simultaneously and

are therefore STRONGLY RECOMMENDED.

Thermostatic versions are preferable.

b) The hot water supply to a shower mixing valve should,

wherever practical, be fed directly from the PulsaCoil

III or be the first draw-off point on the hot circuit.

c) The cold supply to a shower mixing valve should be

fed directly from the rising mains via an independent

branch.

d)

Fixed head type showers:

No back-syphonage

arrangements are necessary.

e)

Loose or flexible head type showers:

If a loose

head shower with a flexible hose is used over a bath

then: -

• The hose must be fixed so that the head cannot

fall closer than 25mm above the top edge of the

bath as specified in Model Byelaw 16 of the Water

Supply Byelaws.

Or

• The shower must incorporate or be fitted with an

acceptable means of back-syphonage protection

in accordance with the Model Water Byelaws.

Bidets

a) The supply of hot and cold mains water directly to a

bidet is permitted provided that it is of the over-rim

flushing type and that a type ‘A’ air gap is

incorporated.

b) It must not include either an ascending spray or

provision to attach a hand spray.

Loading...

Loading...