gledhill PCA 200 - SOL, PCA 220 - SOL, PCA 240 - SOL Addendum Manual

ADDENDUM INSTRUCTIONS

FOR SOLAR APPLIANCE

PLEASE LEAVE THESE INSTRUCTIONS IN THE POCKET PROVIDED ON

THE BACK OF THE FRONT PANEL

AN OPEN VENTED MAINS PRESSURE HOT WATER

SUPPLY APPLIANCE WITH THERMAL STORE

DESIGNED SPECIFICALLY FOR USE WITH

SOLAR ENERGY

THESE INSTRUCTIONS MUST BE READ IN

CONJUNCTION WITH THE STANDARD

PULSACOIL DESIGN, INSTALLATION AND SERVICING

INSTRUCTIONS BEFORE INSTALLATION

TM

benchmark

The code of practice for the installation,

commissioning & servicing of central heating systems

Models

PCA 200 - SOL

PCA 220 - SOL

PCA 240 - SOL

PulsaCoil SOL

A - C L A S S

Page 2

CONTENTS

Section Page

1.0 Design

1.1 Introduction 3

1.2 Technical Data 4

Terms & Conditions 6

The Gledhill BoilerMate range is a WBS

listed product and complies with the WMA

Specification for integrated thermal storage

products. The principle was developed in

conjunction with British Gas. This product

is manufactured under an ISO 9001:2000

Quality System audited by BSI.

Patents Pending

The Gledhill Group’s first priority is to give a

high quality service to our customers.

Quality is built into every Gledhill product

and we hope you get satisfactory service

from Gledhill.

If not please let us know.

ISSUE : 1: 10-06

Building Regulations and Benchmark Commissioning

The Building Regulations (England & Wales) require that the installation of a heating

appliance be notified to the relevant Local Authority Building Control Department.

From 1st April 2005 this can be achieved via a Competent Person Self Certification

Scheme as an option to notifying the Local Authority directly. Similar arrangements

will follow for Scotland and will apply in Northern Ireland from 1st January 06.

CORGI operates a Self Certification Scheme for gas heating appliances.

These arrangements represent a change from the situation whereby compliance with

the Building Regulations was accepted if the Benchmark Logbook was completed and

this was then left on site with the customer.

With the introduction of a self certification scheme, the Benchmark Logbook is being

replaced by a similar document in the form of a commissioning check list and a service

interval record is included with all gas appliance manuals. However, the relevant

Benchmark Logbook is still being included with all Thermal Storage products and

unvented cylinders.

Gledhill fully supports the Benchmark aims to improve the standards of installation

and commissioning of central heating systems in the UK and to encourage the regular

servicing of all central heating systems to ensure safety and efficiency.

Building Regulations require that the heating installation should comply with the

manufacturer’s instructions. It is therefore important that the commissioning check

list is completed by the competent installer. This check list only applies to installations

in dwellings or some related structures.

TM

benchmark

The code of practice for the installation,

commissioning & ser vicing of central heating systems

Page 3

PULSACOIL

A-CLASS

SOL

1.0 DESIGN

1.1 INTRODUCTION

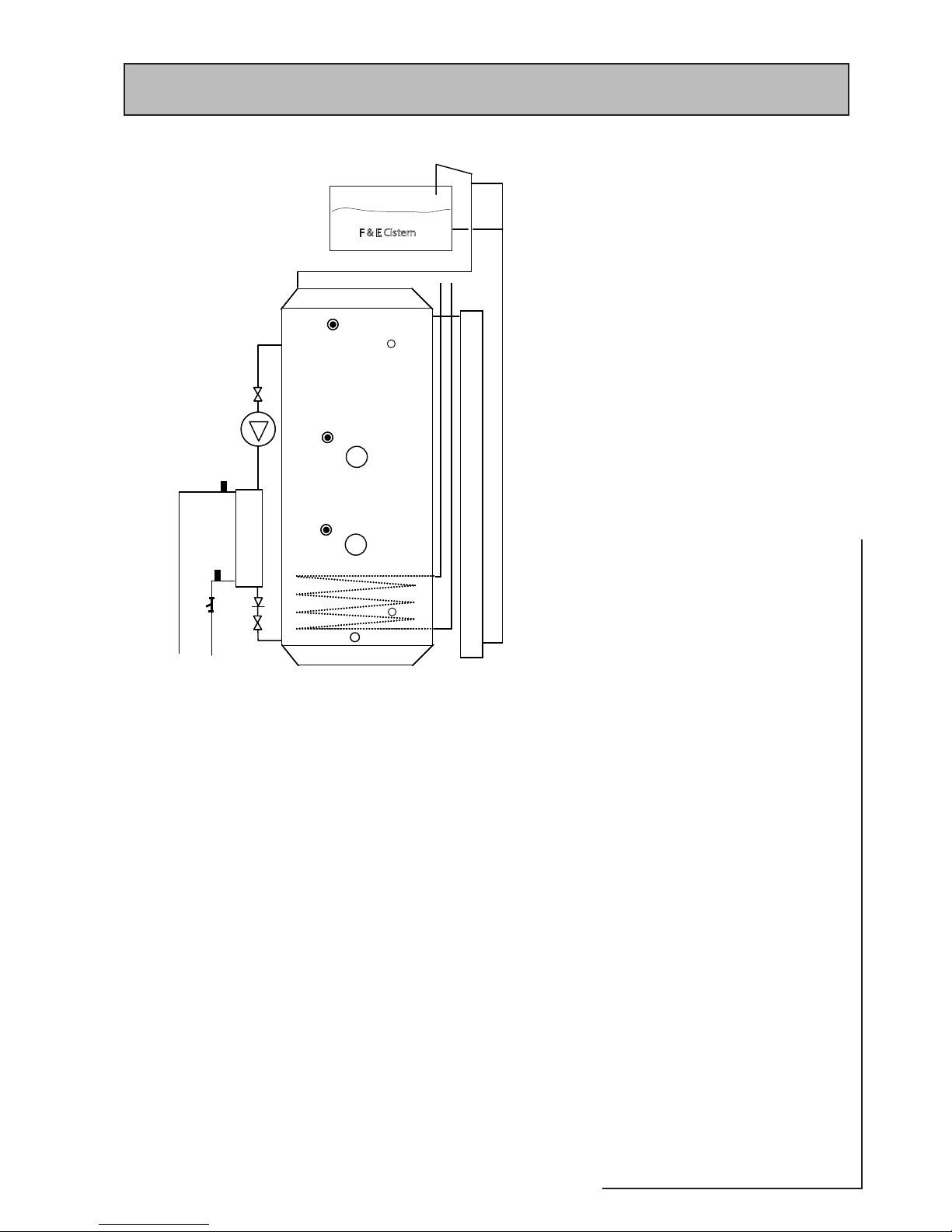

The arrangement and components of a PulsaCoil

A-Class Sol appliance are shown schematically

opposite.

The current solar appliance is based on the

standard PulsaCoil appliance and this addendum

must be read in conjunction with the Design,

Installation and Servicing Instructions provided

for the standard appliance.

The basic differe nce betwee n this and a

standard PulsaCoil appliance is the addition of a

solar coil at the bottom of the thermal store.

All the equipment and controls for the solar

system will need to be designed, supplied

and installed by the Solar installer from

the connec tion provided on to p of the

appliance.

However, a pair of connections are provided on

the PulsaCoil from a sensor (T3) to provide the

facility for a high temperature interlock to be

wired back by the installer to the solar controller.

This needs to be connected to prevent the

solar pump from running in the event that the

thermal store reaches a temperature above

87oC , see page 4 for further details. A 10mm dry

pocket is also provided at low level (T2) for the

installation of a solar control sensor. A further

control sensor will also need to be provided by

the installer adjacent to the solar collector (T1).

See diagram on page 4 for further details.

To obtain maximum benefit from this appliance

it is recommended that it is used in conjunction

with an Economy 7 off peak electrical tariff.

If the appliance is used with an on peak tariff it

is recommended that a time clock is fitted on

the electrical supply to the off peak (bottom)

immersion heater. This should be set to charge

the store overnight and allow the solar to

replenish the store during the day.

A new appliance incorporating most of

the solar equipment and controls will be

available later this year. The controls will be

intelligent and under certain conditions will

hold off input from the electrical supply if a

solar input is available.

The standard man ual fill model is shown

opposite but an automatic fill model with ball

valve and overflow can be provided if ordered

as an optional extra.

If the water hardness exceeds 200ppm (mg/l)

the factory fitted scale inhibitor should be

ordered as an optional extra.

16

17

18

9

6, S3

7, S4

10

5, S5

4, S6

12

11

8

13

25

26

15

14

1

3

S1/S2

11

19

20

2

21

22

23

F & E Cistern

24

Schematic arrangement

T3

T2

1. Bottom (Off-Peak) immersion heater (IH_1)

2. Top (On-Peak) immersion heater (IH_2)

3. Overheat sensor pocket (Sensor S1/S2)

4. Middle sensor pocket (Sensor S6 for IH_2)

5. Bottom sensor pocket (Sensor S5 for IH_1)

6. DHW inlet (CW) sensor, S3

7. DHW outlet sensor, S4

8. Grundfos UPR 15-50 pump

9. Filter & flow regulator (26 l/min)

10. Plate heat exchanger

11. Pump/PHE isolating valves

12. Non-return valve

13. Pre-expansion chamber

14. Open vent/safety

15. Cold feed/expansion

16. CW inlet

17. HW outlet

18. Drain tapping

19. Return from PHE to store

20. Flow from store to PHE

21. Solar coil

22. Bottom solar sensor pocket (10mm tube base) - T2

23. Top solar sensor - T3

24. Feed and expansion cistern

25. Solar coil flow (collector) connection (15mm copper)

26. Solar coil return connection (22mm copper)

Loading...

Loading...