gledhill GB35C Design, Installation And Servicing Instructions

DESIGN, INSTALLATION

AND SERVICING INSTRUCTIONS

THE GAS SAFETY (INSTALLATION AND USE)

REGULATIONS

In your own interest and that of safety, it is

law that all gas appliances are installed by

competent persons and in accordance with the

above regulations.

ISSUE 5: 06-08

Gledhill High Efficiency

Combination Boiler

Model: GB35C

Page 2

ISSUE 5: 06-08

IMPORTANT NOTES

Gledhill Water Storage Limited

Sycamore Estate

Squires Gate

Blackpool

Lancs

FY4 3RL

GENERAL

The Gledhill GB35C is a fully automatic gas fired wall mounted high efficiency

condensing combination boiler. This room sealed and fan assisted boiler is

designed to provide both central heating and mains pressure domestic hot

water. The boiler GB35C is set to give a maximum output 28.9kW (condensing)

for central heating and 35.6kW for domestic hot water.

The boiler is only suitable for use in fully pumped sealed heating systems and

the controls give priority to domestic hot water.

Once the controls are set, the boiler operates automatically and the boiler

controller will automatically activate the frost protection program to prevent

the boiler from freezing. The boiler is supplied with a filling loop and an integral

central heating programmer.

IMPORTANT NOTES

• This boiler is suitable only for installation in GB and IE and should be

installed in accordance with the rules in force

• This boiler is for use when supplied with Natural Gas (G20) only

at 20mbar in GB &IE only from a governed gas supply meter

• Appliance category: I2H

• Appliance types: C13, C33, C53

These instructions cover the following boiler models and only apply to the

appliances sold and installed in Great Britain (GB) and Ireland (IE). This appliance

has been certified for safety and therefore these instructions must be followed.

Both the appliance and the Installation Instructions must not be modified unless

recommended and approved by Gledhill Water Storage Limited in writing. Any

alteration not approved by Gledhill Ltd., could invalidate the certification as

well as the boiler warranty and may also infringe the current issue of statutory

requirements i.e. “ The Gas Safety (Installation and use) Regulations 1998” in GB

and current addition of I.S. 813 “Domestic Gas Installations” in IE.

“In your own interest, and that of safety, it is law that all gas appliances are

installed by competent persons, in accordance with the above regulations.

Failure to install appliances correctly could lead to prosecution.”

CONTROL OF SUBSTANCES HARMFUL TO HEALTH

When working with insulation materials, avoid inhalation as it may be harmful to

health, Avoid contact with skin, eyes, nose and throat. Use disposable protection.

Dampen the material and ensure that the area is well ventilated.

INSTALLATION INSTRUCTIONS

These instructions are an integral part of the appliance and must be read before

installing or lighting the appliance. Also to comply with the current issue of

the Gas Safety (Installation and Use) Regulations, these instructions must be

handed to the user on completion of the installation.

Page 3

CONDENSING COMBI BOILER

CONTENTS

CONTENTS PAGE

1. IMPORTANT INFORMATION

1.1. Building Regulations and

Benchmark Commissioning 4

1.2. Gas Testing and Certification and CE Mark 4

1.3. Spare parts 4

1.4. Handling and storing the appliance 4

1.5. System Installation 4

1.6. Warnings 5

1.7. Equipment selection 5

1.8. Electricity supply failure 5

1.9. Protection against Freezing 5

1.10. Boiler installation in a compartment

or cupboard 5

1.11. Boiler casing 5

1.12. Condensate drain 5

1.13. Pluming from flue terminal 6

1.14. Cleaning 6

1.15. maintenance and servicing 6

1.16. Replacement parts 6

1.17. Continuous Improvements 6

2. TECHNICAL INFORMATION

2.1. Description 7

2.2. Operation 8

2.3. Technical Data 10

2.4. Principal Dimensions and Fixings 11

3. USER CONTROLS

3.1. Lighting the Boiler 12

3.2. To Turn the Boiler Off 13

3.3. Central heating programmer 13

4. SYSTEM DESIGN AND PLANNING INFORMATION

4.1. Important Notices 14

4.2. Central Heating Circuit & System 15

4.3. Domestic Hot Water Circuit 18

4.4. Site Requirements 19

4.5. Flue Location and Ventilation 22

5. BOILER INSTALLATION

5.1. Unpacking the boiler 24

5.2. Boiler fixing 24

5.3. Connections 24

6. ELECTRICAL WIRING

6.1. General 25

6.2. External Controls 26

7. COMMISSIONING

7.1. General 27

7.2. Commissioning the boiler 28

7.3. Setting central heating timer 28

7.4. Checking boiler functions 29

7.5. Completion 30

CONTENTS PAGE

8. ANNUAL SERVICING

8.1. General 31

8.2. Spark & Flame Sensing Electrodes 31

8.3. Burner 31

8.4. Combustion Chamber & Heat Exchanger 31

8.5. Condensate Drain 31

8.6. Inner Casing Panel Seal Check 31

8.7. Combustion Check 31

8.8. DHW Filter/Flow Regulator 31

9. CHANGING PARTS

9.1. General 32

9.2. Spark and flame sensing electrodes 33

9.3. Spark and flame sensing leads 33

9.4. Burner Sub Assembly 34

9.4.1 Burner 34

9.4.2 Fan/Gas Valve and Venturi Assembly 34

9.5. Heat Exchanger 35

9.6. Heat Exchanger Insulation 36

9.7. Overheat Thermostat 36

9.8. Boiler flow temperature control sensor 36

9.9. Expansion vessel 37

9.10. Flue gas sensor 37

9.11. Controller PCB 38

9.12. Fuse 38

9.13. DHW Flow Rate and Temperature Sensor 38

9.14. Boiler Pressure and

Return Temperature Sensor 39

9.15. Pump 39

9.16. Safety Relief Valve 39

9.17. Plate Heat Exchanger 39

9.18. Hydraulic Monoblock 40

9.19. Drain Off Tap 40

9.20. Divertor Valve Head 40

9.21. Automatic Air Vent

(to Hydraulic Monoblock) 40

9.22. Central Heating Clock 40

9.23. On-Off Switch 40

10. FAULT FINDING

10.1. Initial checks 41

10.2. Appliance controller 41

10.3. Computer software 48

10.4. Internal wiring diagram 48

11. BENCH MARK COMMISSIONING CHECK LIST 51

12. TERMS AND CONDITIONS 53

Page 4

1.0 IMPORTANT INFORMATION

1.1. BUILDING REGULATIONS AND COMMISSIONING

The Building Regulations (England & Wales) require that the installation of a

heating appliance be notified to the relevant Local Authority Building control

Department. From 1st April 2005 this can be achieved via a Competent Person

Self Certification Scheme as an option to notifying the Local Authority directly.

Similar arrangements will follow for Scotland and will apply in Northern Ireland

from 1st January 06.

CORGI operates a Self Certification Scheme for gas heating appliances.

Gledhill fully supports the industries aims to improve the standards of

installation and commissioning of central heating systems in UK and to

encourage the regular servicing of all central heating systems to ensure safety

and efficiency.

Building Regulations require that the heating installation shall comply with the

manufacturer’s instructions. A commissioning checklist is provided on Page

51 and it is important that this is completed by the competent installer. This

check list only applies to installations in dwellings or (some related structures

defined in the Regulations)

1.2. GAS TESTING, CERTIFICATION AND CE MARK

This boiler has been tested and certified for safety and performance. It is

important that no alteration is made to the boiler unless it is approved in writing

by Gledhill Water Storage Ltd. It meets the requirements of Statutory Instrument

‘The Boiler (Efficiency) Regulations 1993 No 3083’ and is deemed to meet the

requirements of Directive 92/42/EEC on the energy efficiency requirements

for new hot water boilers fired with liquid or gaseous fuels.

The boiler has been certified by the Notified body ‘Advantica 0087’ and the

production is certified by the notification body ‘BSI 0086’. The CE mark on the

appliance shows compliance with:

(a) Directive 90/396/EEC on the approximation of laws relating to appliances

burning gaseous fuels.

(b) Directive 73/23/EEC on the harmonisation of laws of the Member States

relating to electrical equipment designed for use within certain voltage

limits.

(c) Directive 89/336/EEC on the approximation of the laws of Member States

relating to electromagnetic compatibility.

1.3. SPARE PARTS

When replacing spare parts on this appliance, remember to use only spare parts

that you can be assured conform to the safety and performance specifications

of the manufacturer. Do not use reconditioned or copy parts that have not

been clearly authorised by Gledhill Water Storage Ltd.

1.4. HANDLING AND STORING THE APPLIANCE

This appliance should be handled carefully to avoid

damage and any manual handling/lifting operations will

need to comply with the requirements of the Manual

Handling Operations Regulations issued by the H.S.E.

During the appliance installation it will be necessary

to employ caution and assistance whilst lifting as the

appliance or component exceeds the recommended

weight for a one man lift.

Take care to avoid trip hazards, slippery or wet surfaces. In

certain situations it may be necessary to use mechanical

handling aids.

If the unit needs to be stored prior to installation it

should be stored upright in a dry environment and on

a level base.

1.5. SYSTEM INSTALLATION

In GB the installation must be carried out by a CORGI

Registered installer and it must be carried out in

accordance with the latest edition of the following

relevant requirements: -

• Gas Safety (Installation and Use) Regulations

• The Building Regulations, The Building Regulations

(Scotland), The Building Regulations (Northern

Ireland) – as appropriate

• The Water Fittings Regulations or Water Byelaws in

Scotland

• Health & Safety Document No. 635 – The Electricity

at Work Regulations 1989.

• The current IEE Wiring Regulations

The installation should also conform to the relevant

requirements of following British Standards and Codes

of Practices: -

• BS 5440 Part 1 - Flues

• BS 5440 Part 2 - Ventilation

• BS 5449 - Forced circulation hot water systems

• BS 5546 - Installation of hot water supplies for

domestic purposes

• BS 7074 - Expansion vessels and ancillary equipment

for sealed water systems

• BS 6798 - Installation of gas fired hot water boiler

• BS 6891 - Gas installation

• BS 7593 - Treatment of water in domestic hot water

central heating systems

• IGE/UP/7/1998

In IE, the installation must be carried out by a competent

Person and installed in accordance with the current

edition of I.S.813 “Domestic Gas Installations”, the current

Building Regulations and reference should be made

to the current ETCI rules for electrical installations.

The following BS standards give valuable additional

information: -

• BS 5449 - Forced circulation hot water systems

• BS 5546 - Installation of hot water supplies for

domestic purposes

• BS 7074 - Expansion vessels and ancillary equipment

for sealed water systems

• BS 7593 - Treatment of water in domestic hot water

central heating systems

Page 5

CONDENSING COMBI BOILER

1.0 IMPORTANT INFORMATION

1.6. WARNINGS

(a) Gas Leak or Fault

If a gas leak or fault exists or is suspected, turn the boiler mains electricity

supply off and turn off the gas supply at the meter. Consult your local gas

company or your local installation/servicing company.

(b) Clearances

If fixtures are positioned close to the boiler, space must be left as shown in

figure 4.3, section 4.4. Enough space must also be left in the front of the boiler

to allow for servicing.

(c) Sheet Metal Parts

This boiler contains metal parts (Case & components) and therefore care should

be taken when handling and cleaning, with particular regard to edges.

(d) Sealed Components

This boiler uses a fully premix burner with an air/gas ratio controller therefore

the burner input i.e. CO and CO2 settings and the burner off set pressure are

factory set and sealed and require no onsite adjustments during installation

or routine servicing.

Under no circumstances should the user should interfere with the sealed

components as this could result in a potentially dangerous situations arising. If

sealed components in the appliance are replaced and/or re-commissioned in

the field then these must be done strictly in accordance with manufacturer’s

instructions and these components must be re-sealed.

1.7 EQUIPMENT SELECTION

This information is provided to assist generally in the selection of equipment.

Responsibility for selection and specification of our equipment must, however,

remain that of our customers and any expert or consultants concerned with the

installation(s). Therefore please note that: -

(a) We do not therefore accept any responsibility for matters of design selection

or specification for the effectiveness of an installation containing one of our

products.

(b) All goods are sold subject to our Conditions of Sale which are set out in the

Appendix to this document.

1.8 ELECTRICITY SUPPLY FAILURE

(a) This boiler must be earthed and the boiler will not work without an electricity

supply (Class I appliance).

(b) Reset any external controls to resume normal operation of the central

heating.

(c) Normal operation of the boiler should resume when the electrical supply

is restored. If the boiler does not resume normal operation turn the mains

switch off and on. If the boiler does not resume normal operation after this,

the overheat thermostat may have operated. The overheat thermostat would

only operate under abnormal conditions and, under these circumstances it

would be advisable to consult your installation/servicing company.

1.9 PROTECTION AGAINST FREEZING

(a) The boiler has a built in frost protection

programme as long as the electricity and

gas are left switched on. The boiler controller

operates the burner and the system pump

when the temperature inside the boiler falls

below 5ºC.

(b) Any other exposed areas of the heating and

hot water system should be protected as

normal by a separate frost thermostat / pipe

thermostat

(c) If the mains electricity and gas supplies to

the boiler system are to be turned off for

any long periods during severe weather,

it is recommended that the whole system

including the boiler should be drained to

avoid risk of freezing. In this case ensure that

the immersion heater in the cylinder (if fitted)

is also switched off.

(d) Contact your installation/service company as

draining, refilling and pressurising of a sealed

heating system MUST be carried out by a

competent person.

(e) As a safety feature, the boiler will stop working

if the condensate drain becomes blocked.

During freezing conditions this may be due

to ice forming in the condensate drain if this

has been installed external to the house. Ice

blockage should be released by use of warm

cloths on the pipe. Contact your installation/

service company if the fault persists.

1.10 BOILER INSTALLATION IN A

COMPARTMENT OR CUPBOARD

If the boiler is fitted into a compartment or

cupboard, it does not require ventilation openings.

However, do not use the compartment or cupboard

for storage.

1.11 BOILER CASING

Do not remove or adjust the casing in any way, as

incorrect fitting may result in incorrect operation

or failure to operate at all.

1.12 CONDENSATE DRAIN

The condensate drain must not be modified or

blocked. See section 4.4 (e) for further details.

Page 6

IMPORTANT INFORMATION

1.13 PLUMING FROM THE FLUE TERMINAL

This is a high efficiency condensing boiler and the flue gas temperature will be

low. Therefore like all condensing boilers this appliance will produce a plume of

condense in cool weather. It is normal and not a fault condition, but this should

be taken into account when positioning the boiler / flue terminal.

1.14 CLEANING

This boiler contains metal parts and therefore care should be taken when

handling and cleaning, with particular regard to edges.

The boiler casing can be cleaned using a mild liquid detergent with a damp

cloth and then a dry cloth to polish. Do not use any form of abrasive or solvent

cleaner as you may damage the finish.

1.15 MAINTENANCE AND SERVICING

This appliance must be serviced and installed by a competent person e.g. CORGI

Registered installer. All CORGI registered installers carry a CORGI ID Card and

have a registration number. You can call CORGI direct on 01256 372300.

For the continued efficient and safe operation of the boiler, it is recommended

that it is checked and serviced at regular intervals. The frequency of service

will depend upon the installation condition and usage, but in general, once a

year is recommended.

If this boiler is installed in a rented property, there is a duty of care imposed on

the owner of the property by the current issue of the Gas Safety (Installation

and Use) regulations, Section 35.

The installation/service engineer should complete the commissioning check list

and service record log on completion of commissioning and service work.

1.16 REPLACEMENT PARTS

Free of charge replacement for any faulty components are available from

Gledhill Ltd during the in-warranty period (normally 12 months).

After this the spares can be obtained direct from Gledhill Ltd using the ‘Speed

Spares’ service. Help and advice is also available from our Technical Help Line

on 08449 310000.

Please quote the name, model and serial number of the appliance as well as

your CORGI registration details when requesting help or ordering spares. The

name and model will be on the name badge on the front of the appliance

and the serial number is shown on the information label on the bottom right

hand side inner panel.

1.17 CONTINUOUS IMPROVEMENTS

In the interest of continuously improving the Gledhill Boiler range, Gledhill

Water Storage Ltd reserves the right to modify the product without notice and

in these circumstances this booklet which is accurate at the time of printing

should be disregarded.

Page 7

CONDENSING COMBI BOILER

2.0 TECHNICAL INFORMATION

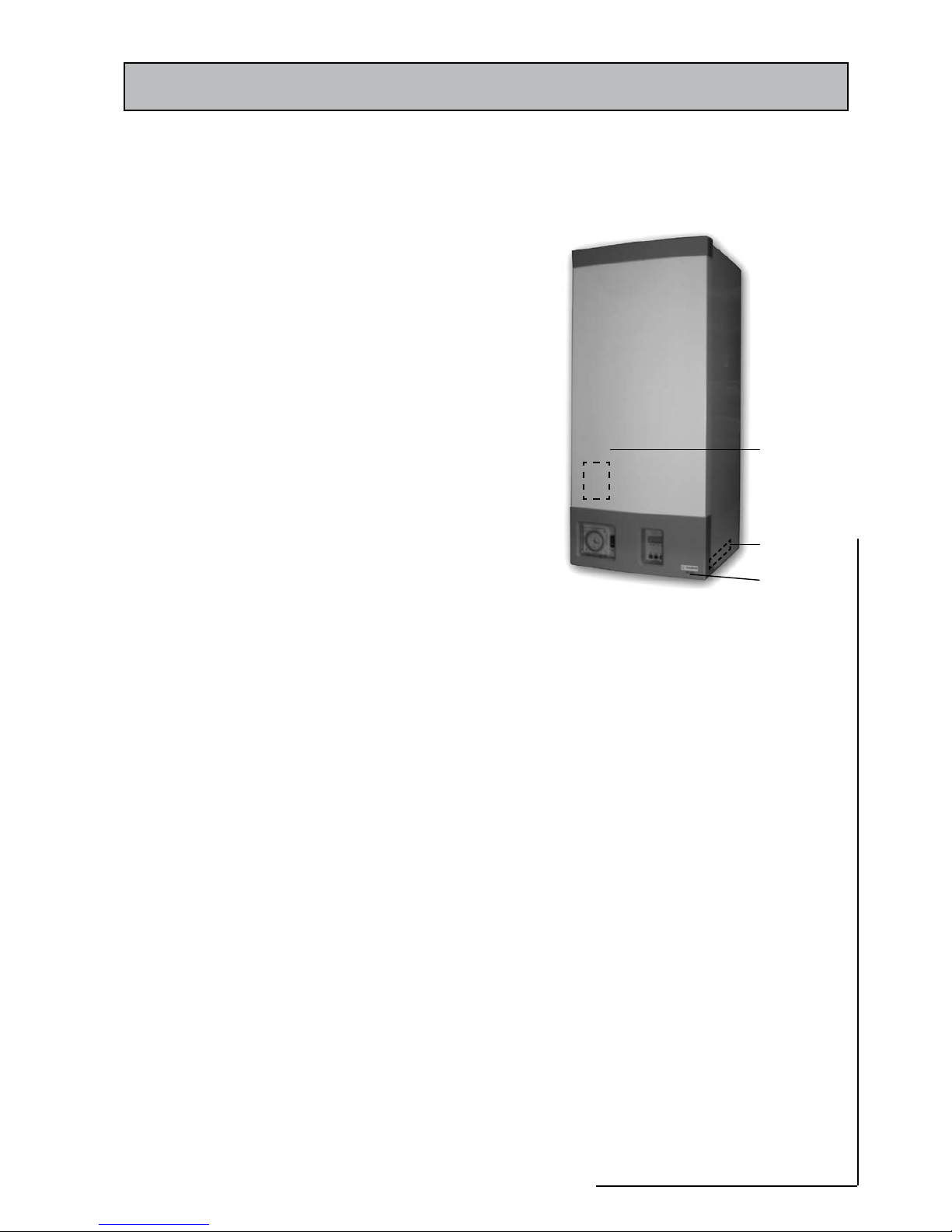

2.1 DESCRIPTION

The Gledhill GB35C is a fully automatic, wall mounted gas fired, high efficiency

condensing combination boiler (Figure 2.1). It is a room sealed fan assisted

appliance and suitable for sealed central heating system and mains pressure

domestic hot water only. The maximum outputs of the boiler are: -

For central heating: 26.0 kW (Condensing) / 28.9kW (Non-Condensing)

For domestic hot water: 35.6 kW

It is designed for use on Natural Gas (G20), and governed meter supply only. It

is only suitable for use on fully pumped sealed heating systems and the controls

give priority to domestic hot water. The boiler is supplied with a filing loop and

a central heating programmer.

The boiler must be installed with one of the purpose designed Gledhill flue

systems such as the standard balanced flue kit part no GT461. Various flue

extensions, bends, vertical flue kits and plume management kits are available

as optional extras. These are detailed in a separate manual.

The boiler data badge gives details of the model, serial number, thermal data

and the Gas Council number and is situated on the inner door panel. It is visible

when the front panel is removed. The unique boiler model is shown on the

front case panel and the serial number is shown on the information label on

the bottom right hand side inner panel (Figure 2.1).

Data Badge On inner panel

behind front

case panel

Serial Number

Name and

Model

Figure 2.1

Page 8

2.0 TECHNICAL INFORMATION

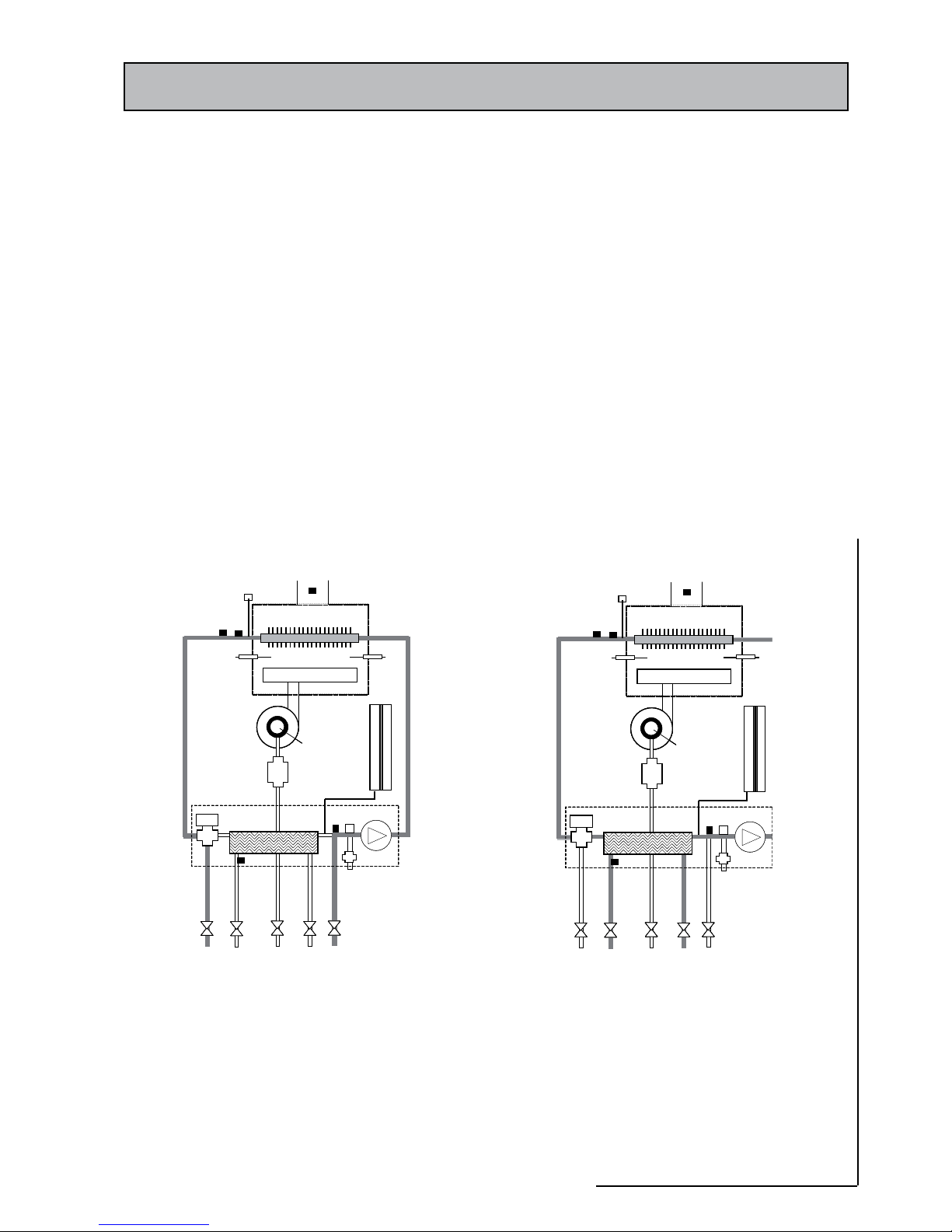

2.2 OPERATION

The main components of the boiler are shown in figures 2.2a and 2.2b. The

status of the boiler and the central heating and hot water demands and the

corresponding boiler functions are indicated on the 4 x 7 segment display as

described in section 2.2.(e).

Flue Gas Sensor

Expansion Vessel

(7 Litre)

Heat Exchanger

Burner Assembly

Window

Spark Electrode

Flame Sensing Electrode

Overheat Thermostat

Boiler Flow Temperature

Control Thermostat Sensor

Fan Assembly

Gas Valve Assembly

Air/Gas Venturi

Figure 2.2a

Condensate Trap Cap

(for cleaning)

Condensate Drain

Connection

Air Vent

Diverter Valve

Modulating Pump

DHW Flow Rate &

Temperature Sensor

CH Bypass Flow

Adjusting Screw

Figure 2.2b

Boiler Pressure & Return

Temperature Sensor

Pressure Relief

Valve

Drain Valve

Page 9

CONDENSING COMBI BOILER

2.0 TECHNICAL INFORMATION

a) Central heating mode (Figure 2.3)

The demand for central heating is generated when both the programmer and

the room thermostat are calling for heat. The demand for central heating ceases

if either the programmer or the room thermostat stops calling for heat. Hot water

has priority and therefore if a hot water heating demand is active, a central heating

demand will not be accepted.

When a central heating demand is sensed and accepted, the 3-port diverter valve is

moved to the central heating mode and the pump circulates the water through the

primary circuit and its speed is regulated to maintain the boiler return temperature

measured by sensor, S4, at a pre-set value (60ºC).

The burner ignition sequence will start when the flow temperature measured by

sensor, S4, is below the pre-set limit. Once the burner ignites the fan speed controls

the gas rate to maintain the heating flow temperature at the preset value of 80oC.

When the boiler flow temperature exceeds the preset value, the burner will switch

off and a minimum 4 min delay occurs (an anti-cycle function) before the burner

will automatically relight. During this period, the pump will continue to run.

When the central heating demand ceases, the burner is switched off and the pump

continues to run for a period of 3 minutes pump overrun period. After the pump

overrun period, the pump is switched off and the 3-port diverter valve moves to

the hot water mode.

(b) Domestic hot water mode (Figure 2.4)

Hot water has priority. A hot water demand at any

hot water terminal fitting will override any central

heating demand.

The controller senses the hot water flow by means

of a solid state (S3) flow switch and moves the

3-way diverter valve to the hot water mode. This

allows the pump to circulate the primary water

through the plate heat exchanger.

The burner will li gh t au to ma ti cally and the

temperature of domestic hot water is controlled by

the DHW flow rate and temperature sensor S3.

When the domestic hot water demand ceases, the

burner will switch off and the diverter valve will

remain in the domestic hot water mode unless

there is a demand for central heating. However

the central heating will not start until a 40 second

delay period has expired.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

25

26

26

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

25

26

26

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Figure 2.4 Domestic hot water circuit

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Figure 2.3 Central heating circuit

25

25

26

26

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Figure 2.4 Domestic hot water circuit

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1. Central heating (CH) flow 2. Domestic hot water (DHW) outlet 3. Gas inlet

4. Cold water (CW) inlet & Filter/Regulator 5. Central heating (CH) return 6. Pressure relief valve discharge

7. Hydro -block assembly 8. 3 port diverter valve assembly 9. Plate heat exchanger

10. Pump 11. Pressure relief valve (PRV) 12. Automatic air vent

13. Expansion vessel 14. Gas valve 15. Fan

16. Venturi assembly 17. Burner 18. Primary heat exchanger

19. Manual air vent 20. DHW temperature & flow sensor (S3) 21. Temperature & pressure sensor (S4)

22. Flue gas temperature sensor (S2) 23. Safety (OHT) sensor 24. Boiler flow temperature sensor (S1)

25. Spark electrode 26. Flame sensing electrode

-block assembly

25

25

26

26

Page 10

2.0 TECHNICAL INFORMATION

(c) Frost protection mode

The boiler has a built in frost protection function. This function can be deactivated by removing the jumper from pins 1 & 9 on connector

J3 on the controller PCB (see section 4). When the boiler is in the frost protection mode, its status is shown on the front panel display.

If the boiler temperature drops below 10ºC, the pump is switched on and the diverter valve is moved to the central heating mode.

If the boiler temperature drops below 5ºC after switching on the pump, then the burner is switched on and modulated to minimum

power level. The burner continues to burn at minimum power level until the boiler temperature rises above 15ºC. After this the burner

is switched off and the pump continues to run for a period of 1 minute, after which the pump is also switched off.

b) Pump protection mode

The pump is switched on for about 1 minute every 36h to prevent it sticking. To allow this to operate the electricity supply and boiler

on/off switch must not be switched off. If the property is left unoccupied unless the system has been drained off

e) 4 x 7 Segment display functions

The 4 digit display is shown and described in section 3. The individual segments of the 1st digit and the dots indicate the status of the

appliance functions. The 2nd, 3rd and 4th digits display the heating system pressure in bars. The push buttons are used for diagnostics

and for setting central heating flow and domestic hot water temperatures. This is described in detail in sections 3 & 6 of this manual.

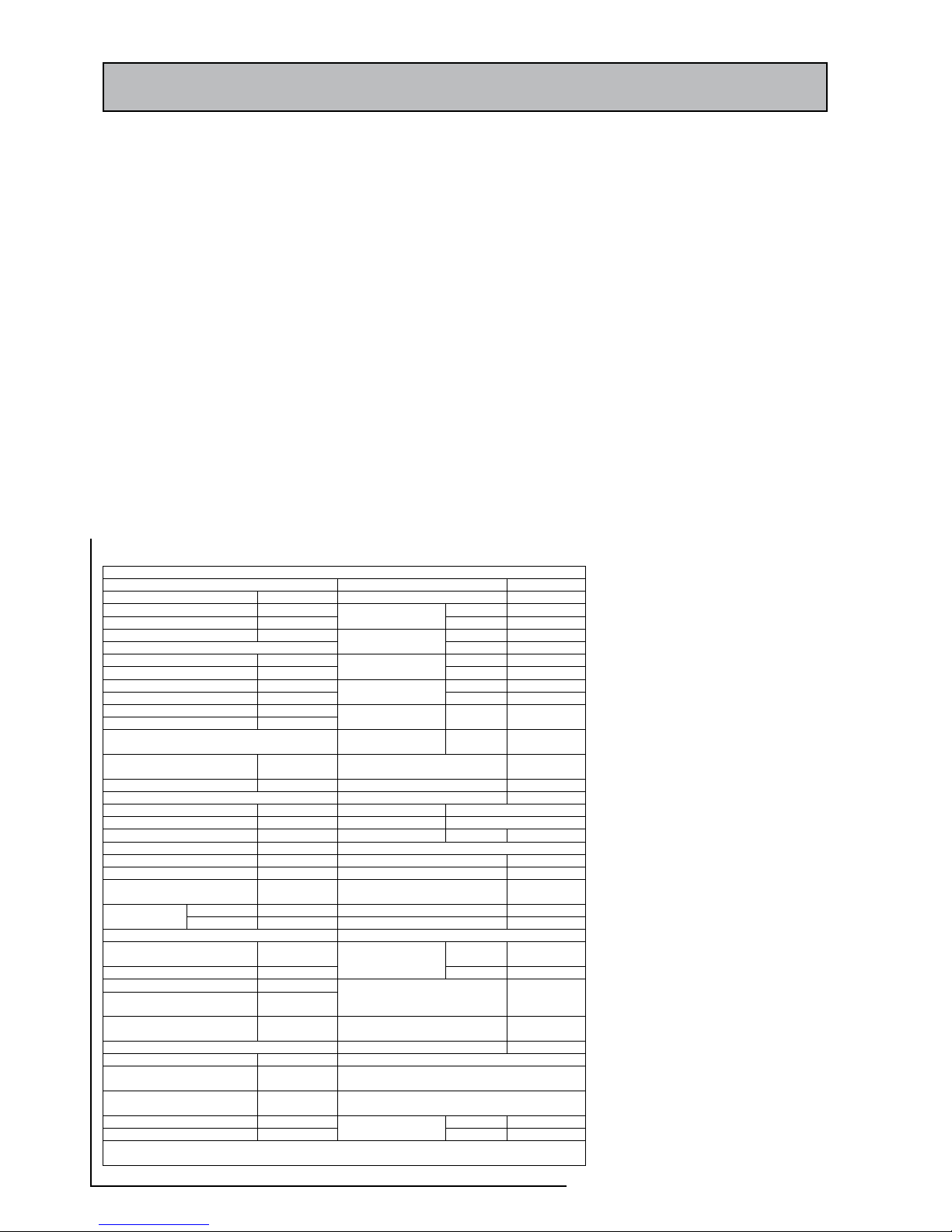

2.3 TECHNICAL DATA (Table 2.1)

Tab le 2.1 : Tech nical data

Out er ca se (O verall dimens ions)

App liance type

C13, C33, C

53

Cas ing h eight

850 mm

App liance category

I

2H

Cas ing h eight incl uding fl ue

100 0 mm

Max imum

26. 3 kW

Cas ing w idth

380 mm

He at in put – C H

( N et )

Min imum

7.5 k W

Cas ing d epth

385 mm

Max imum

29. 2 kW

Min imum cle aranc es

He at in put – C H

( G ross )

Min imum

8.3 k W

Abo ve ca sing

200 mm

Max imum

26. 0 kW

Bel ow ca sing

200 mm

Hea t out put – CH

( No n C on densi ng )

Min imum

7.4 k W

Fro nt (In oper ation)

20 mm

Max imum

28. 9 kW

Fro nt (For ser vicin g)

600 mm

Hea t out put – CH

( C ondensing )

L.H . Sid e

20 mm

R.H . Side

20 mm

Hea t inp ut – D HW

( G ross )

Max imum

40. 0 kW

Wei ghts

Hea t out put DHW

Max imum

35. 6 kW

Packaged bo iler carton

50. 0 kg

Inl et pr essur e (Natural Ga s–

G20 )

20 mbar

Ins talla tion lift weig ht

45. 0 kg

Max ga s rat e (A fter 10 mins )

3.6

[2]m3

/h

Con nections

Flu e gasses mass flow rat e

16. 21 g/s

Gas su pply

22m m cop per

NOXCla ss

5 ( < 70 mg/ kWh t o EN483 )

Cen tral hea ting flo w

22m m cop per

SED BUK R ating

90. 7 %, A Clas s

Cen tral hea ting ret urn

22m m cop per

CW mains inlet

15m m cop per

El ectri cal D ata

DHW fl ow

15m m cop per

Sup ply

230 V~ 50Hz

Pre ssure relief discha rge

15m m cop per

Power con sumpt ion

155 W

Con densate dra in

21/22 mm

pla stic

Ele ctric al prot ectio n

IPX 0 D

Dia meter

100 mm

Ext ernal fu se ra ting

3A

Flu e ter minal

dim ensio ns

Pro jection

125 mm

Int ernal fu se ra ting

F2L

Cen tral Hea ting (Pr imary ) Circu it

DHW Ci rcuit

Saf ety d ischa rge (PRV)

set ting

3.0 ba r

Max imum

8.0 ba r

Max imum ope ratin g pre ssure

2.5 ba r

Ope ratin g pressure

Min imum

<0. 2 bar

Min imum ope ratin g press ure

0.5 ba r

Rec ommen ded o perating

ran ge

1 – 2 bar

DHW fl ow rat e ‘D’ s pecif ied @

30K rise

17. 2 l/min

CH flo w tem perat ure

(ad justa ble)

40 – 8 0oC

Min imum wor king flo w rate

2.0 l/ min

Int egral Ex pansi on Vess el (F or CH on ly)

DHW fl ow te mpera ture

(1 )

35 – 6 5oC

Min imum pre-c harge pres sure

0.5 ba r

Nom inal cap acity of ex p.

ves sel

7.0 litre s

Max imum con densa te flow ra te: 2 .94 l/h

Max imum cap acity of CH

sys tem

125 li tres

Pum p Characte ristics: See f igure 4.6

Wat er co ntent of th e boi ler

2.6 li tres

Ca se on

9.25 - 9.85%

CO2at maximu m

DHW he at in put

Cas e off

9.05 - 9.65%

(1) Ad justa ble b ut flow rate depend ent

(2) Based on CV of 40MJ /m

3

Page 11

CONDENSING COMBI BOILER

2.0 TECHNICAL INFORMATION

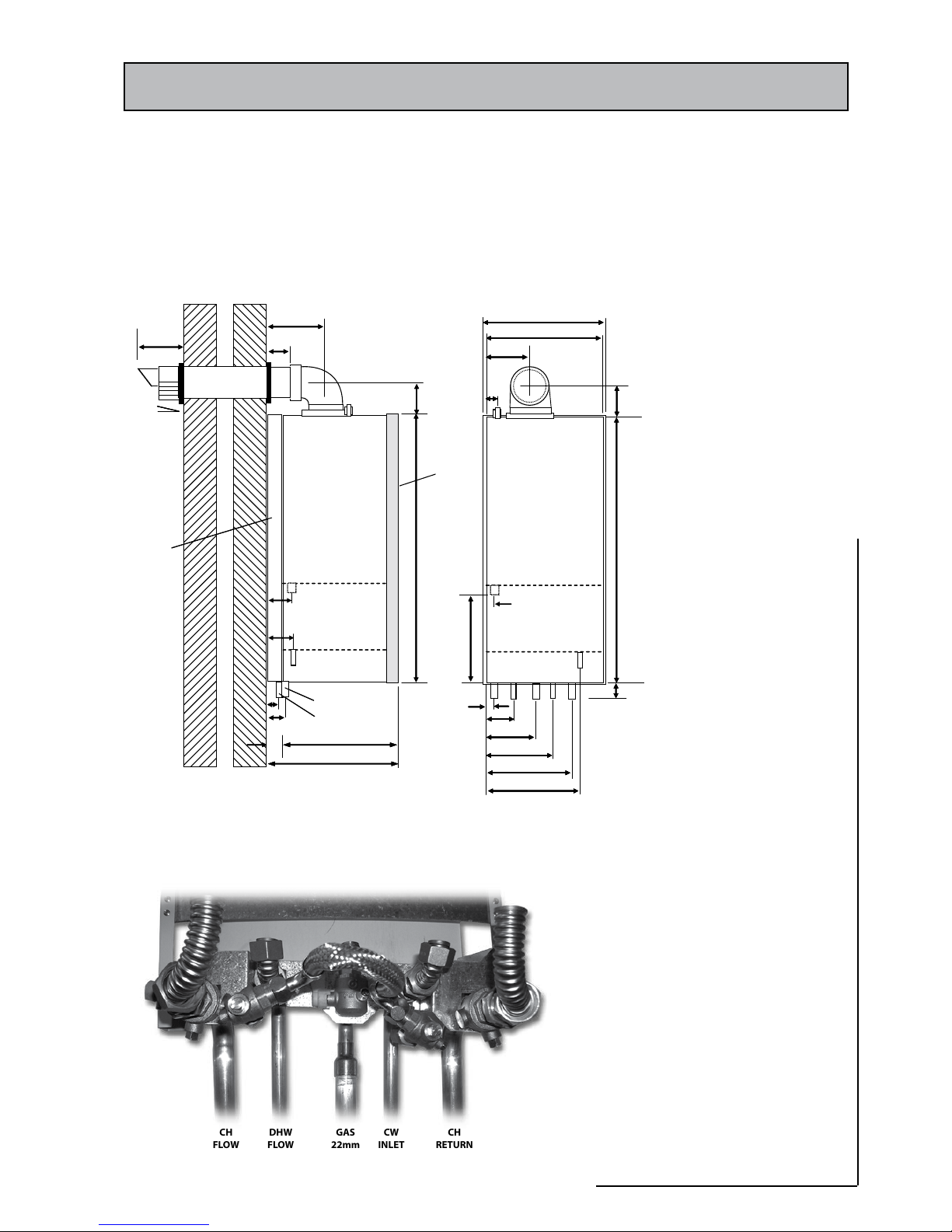

2.4 PRINCIPAL DIMENSIONS AND FIXINGS (FIGURES 2.6 AND 2.7)

The appliance dimensions and positions of pipe connections are shown in

figure 2.6. The back plate connection arrangements is shown in figure 2.7

A

75

40

60

85

G

40

345

385

850

180

66

95

H

380

373

140

37

95

290

30

A

60

123

190

306

333

B

C

D

E

F

G

50

842

H

130

1.5oslope

Towards

boiler

CONNECTIONS

A Condensate drain 21/22mm plastic

overflow pipe

B CH Flow 22mm Copper tail

C DHW out 15mm Copper tail

D Gas supply 22mm Copper tail

E CW inlet 15mm Copper tail

F CH Return 22mm Copper tail

G PRV discharge 15mm Copper tail

60/100mm Concentric

H Manual air vent

J Flue

CLEARANCES

L.H. Side 20mm

R.H. Side 20mm

Top 200mm

Bottom 200mm

Front – Operational 20mm

Front – Service 600mm

B, E, F

Front

cover

Back

plate

Appliance

case

A

75

85

G

850

95

30

A

60

123

190

190

306

333

B

C

D

E

F

G

H

30

A

B

C

D

E

F

G

H

A

C, D

Appliance

case

Front ElevationSide Elevation

CONNECTIONS

A Condensate drain 21/22mm plastic

overflow pipe

B CH Flow 22mm Copper tail

C DHW out 15mm Copper tail

D Gas supply 22mm Copper tail

E CW inlet 15mm Copper tail

F CH Return 22mm Copper tail

G PRV discharge 15mm Copper tail

60/100mm Concentric

H Manual air vent

J Flue

CLEARANCES

L.H. Side 20mm

R.H. Side 20mm

Top 200mm

Bottom 200mm

Front – Operational 20mm

A

Figure 2.6 - Dimensions/Connection Details

Figure 2.7 - Boiler Mounting Back Plate (view from front)

CH

RETURN

22mm

GAS

22mm

CH

FLOW

22mm

DHW

FLOW

15mm

CW

INLET

15mm

Page 12

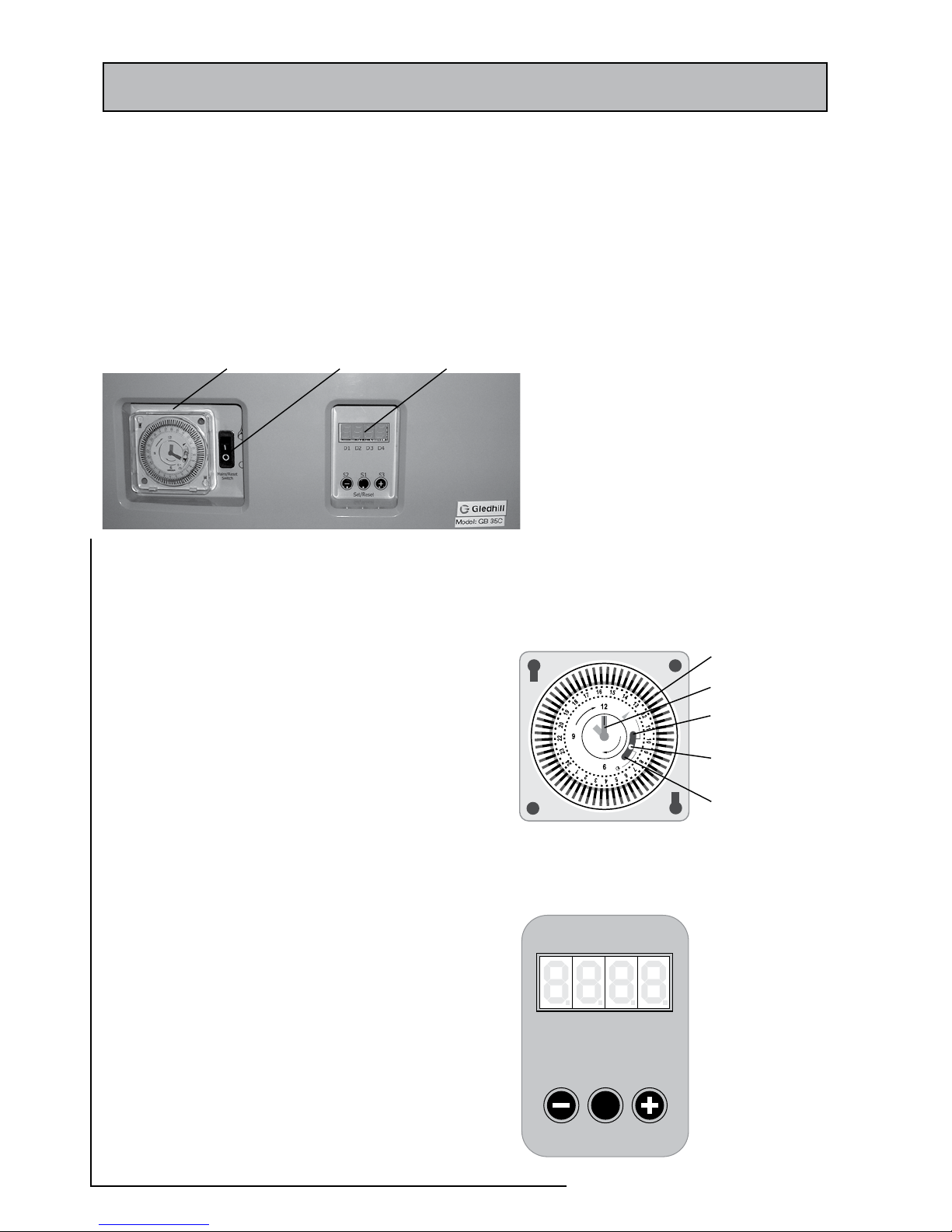

3.0 USER CONTROLS

The user controls consist of a central heating programmer, boiler ‘on-off’ switch

and a 4 digit display as shown in figure 3.1. The boiler ‘on-off’ switch should be

left in the ON position which is indicated by a flame symbol for normal operation,

otherwise the built in boiler frost protection will not function. The four digit

display indicates the status of the boiler and the pressure in the heating system.

The push buttons below the display are used for setting and resetting the

controller and these functions are shown in figures 3.3A and 3.3B. For further

details see the ‘User Instruction Manual’ supplied with this appliance.

3.1 CENTRAL HEATING PROGRAMMER (FIGURE 3.2)

The programmer controls the central heating system only and can be

set to control at 15 minute intervals. The 3 position switch allows the

central heating to be either permanently off, timed or constantly on.

a) Constant (top) position:

The heating will be on constantly irrespective of the position of

the tappets. The central heating will only be controlled by the main

appliance controls and/or any external controls e.g. room thermostat.

b) Timed (Central position):

The heating will operate according to the position of the tappets and

will be controlled during the on period by the main appliance controls

and/or room thermostat.

c) Off (Bottom position):

No central heating available.

Note: Domestic hot water will operate on demand irrespective of the

position of the 3 position switch.

To set the time of day:

Turn the minute hand clockwise to align the pointer with the correct

time to the nearest 15 minutes ensuring that AM/PM is considered.

DO NOT at any time attempt to rotate the bezel anti-clockwise.

To set heating times:

Decide the central heating ‘on’ and ‘off’ times of the day the central heating

is required. Move the 3 position switch to the timed (central) position. The

central heating will operate when the tappets are set to the outer edge of the

bezel. Each tappet represents 15 minutes. Therefore set the tappets towards

the outer edge for the time periods the heating is required to be ‘on’ and set

the tappets towards the centre for the time heating is required to be ‘off’.

S2 S1

Set/Reset

S3

D1 D2 D3 D4

Figure 3.3a

Boiler Display

Indicator

Figure 3.1

Central Heating

Programmer

Boiler

On/Off Switch

4 Digit

Display

Figure 3.2

Tappets

Minute Hand

I : Constant

Top Position

3 Position Switch shown at

Timed Central Position

0 : Off

Bottom Position

Page 13

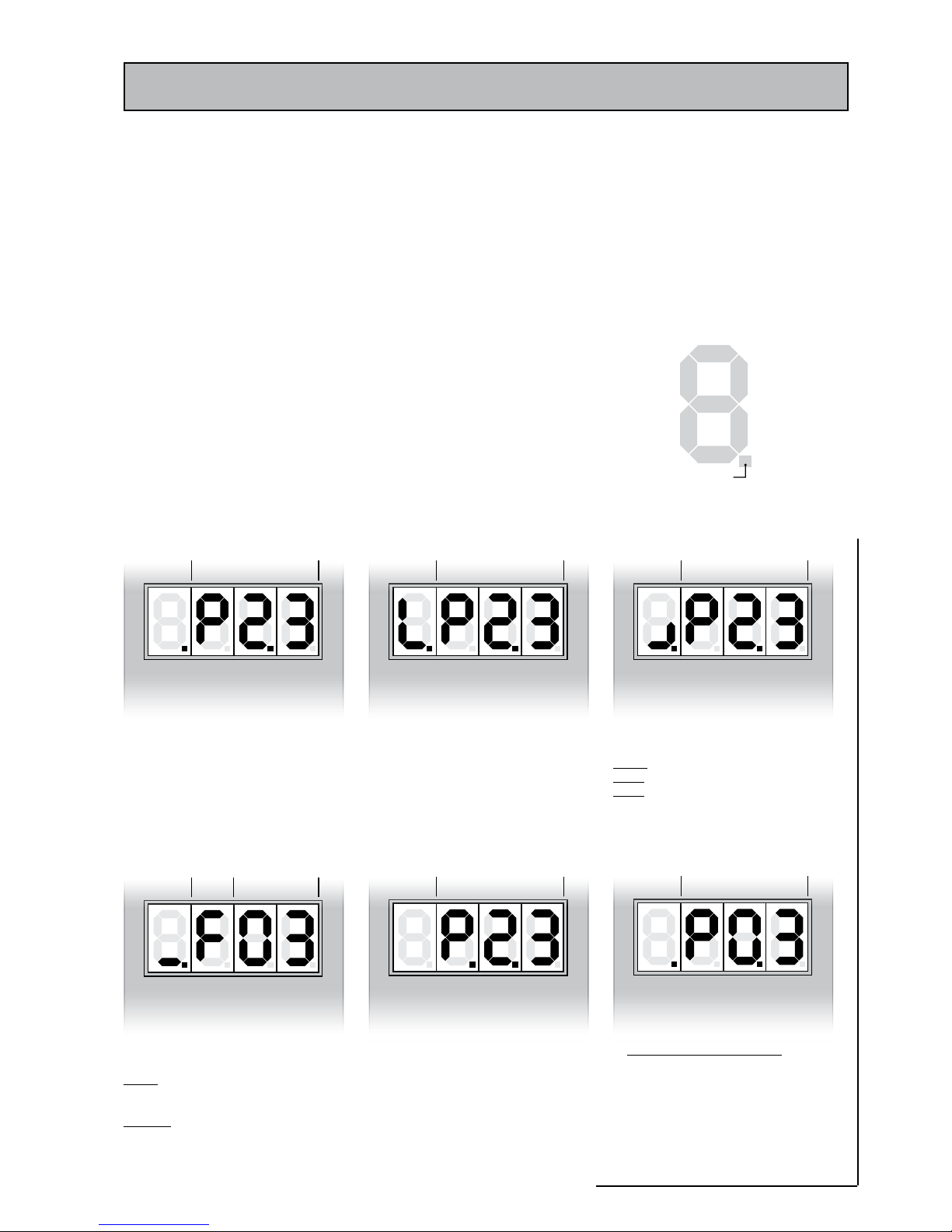

CONDENSING COMBI BOILER

S2 S1

Set/Reset

S3

D1 D2 D3 D4

Boiler Temperature

(e.g. 03)

F: Frost

Protection

3.0 USER CONTROLS

3.2 LIGHTING THE BOILER

Switch the appliance on/off switch to on position. The dot D1 will begin to flash

to indicate that the controller is active and the 2 – 4 digits will show the system

pressure in bar (e.g. P2.1 system pressure is 2.1 bar).

The boiler will light automatically when either a hot water tap is opened or when

the central heating is called on. The central heating is controlled by the programmer

on the boiler and the remote room thermostat. For central heating to function,

both the programmer and the room thermostat must be calling for heat. The hot

water and the central heating demands are indicated by the vertical bars of the

first segment display (D1).

When the burner is lit, the dot D1 will be on constant and the 2 – 4 digits will show

the system pressure in bar (e.g. P2.1).

A fault is indicated by flashing dot ‘D2’ and the fault code is displayed on the digital

display. To reset press ‘Set/Reset’ button S1. The flashing ‘P’ indicates low system

pressure. If the fault persists contact your installer/service provider. The control and

digital display functions are described in detail in section 10.

S2 S1

Set/Reset

S3

D1 D2 D3 D4

System Pressure Reading

(in bar e.g. P 2.3)

(a) Standby Mode

Dot D1: FLASHING In standby mode

Display shows system pressure e.g. P 2.3

(d) Automatic frost protection mode

Dot D1: Flashing - In standby mode

Dot D1: ON - Burner is live

Bar C Lit - Boiler pump on

Display ‘F’: Constant - Frost protection Level 1

Display ‘F’: Flashing - Frost protection Level 2

Display shows boiler temperature e.g. F 03

S2 S1

Set/Reset

S3

D1 D2 D3 D4

System Pressure Reading

(in bar e.g. P 2.3)

(b) Hot Water Draw-Off Mode

Dot D1 : ON - Burner is lit

Bar ‘a’ : ON - Hot water demand active

Bar ‘b’ : ON - Hot water demand active

Bar ‘c’ : ON - Boiler pump on

Display shows system pressure e.g. P 2.3

S2 S1

Set/Reset

S3

D1 D2 D3 D4

System Pressure Reading

(in bar e.g. P 2.3)

(c) Central Heating Mode

Dot D1 : ON - Burner is lit

Bar ‘c’ : Boiler pump on

Bar ‘d’ : Central heating demand active

Display shows system pressure e.g. P 2.3

S2 S1

Set/Reset

S3

D1 D2 D3 D4

System Pressure Reading

(in bar e.g. P 2.3)

(e) Safety Lockouts

Dot D2: Flashing - Lockout error

Press reset button ‘S1’ to clear

Dot D1: ON - Blocking error

Switch appliance off and on to clear

Display shows system pressure e.g. P 2.3

S2 S1

Set/Reset

S3

D1 D2 D3 D4

System Pressure Reading Flashing

(in bar e.g. P 0.3)

(f) Low System Pressure Reading

System pressure display flashing Low system pressure:

Arrange for system to be topped up by a

competent person

3.3 TO TURN THE BOILER OFF

The boiler is fully automatic in operation. However

if necessa ry, the boiler can be swi tched off

permanently by turning the on-off switch to OFF

position. This is not generally recommended as it

will switch off the pump protection facility, which

is likely to lead to the pump being ‘stuck’ when the

boiler is switched back on.

Figure 3.3b

c

a

b d

dot

Page 14

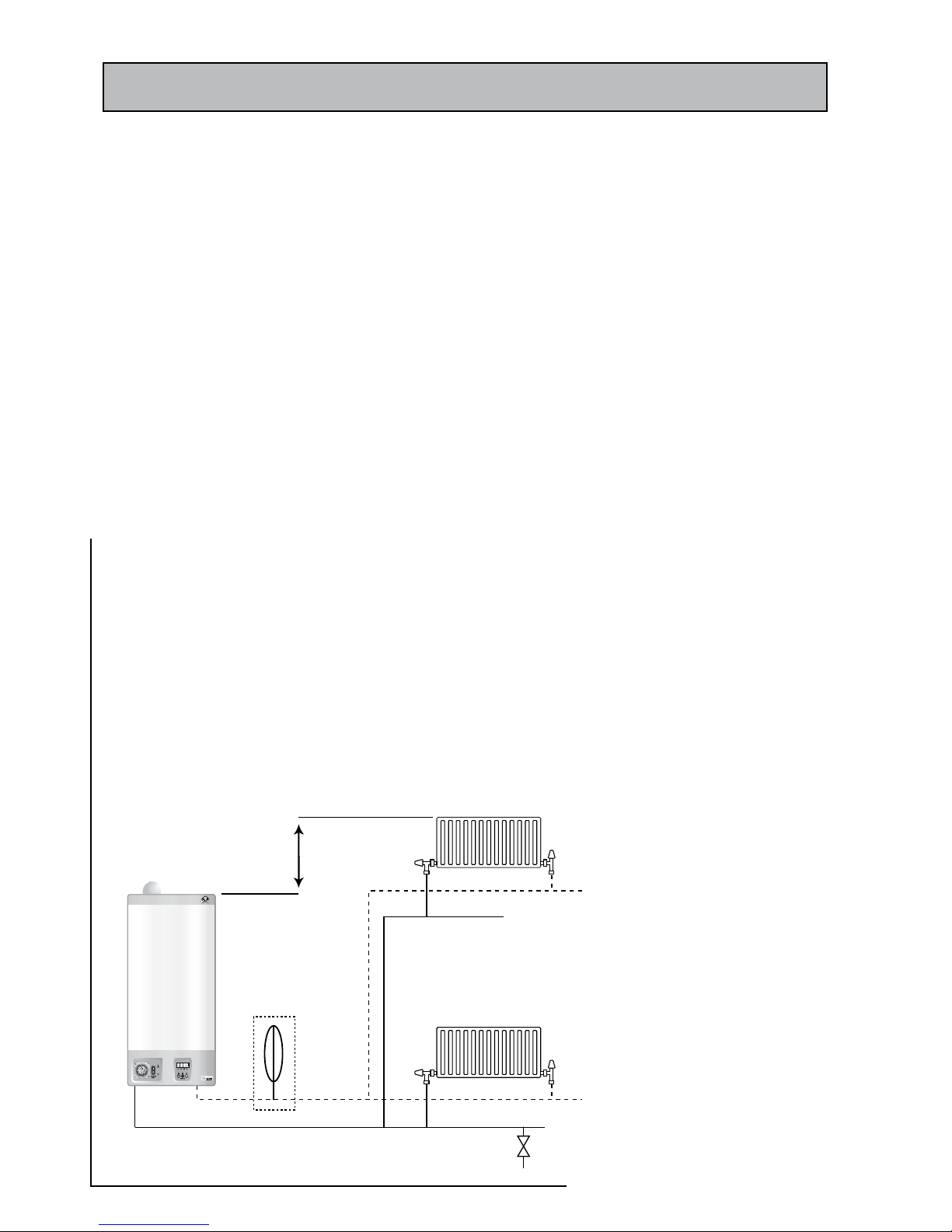

4.0 SYSTEM DESIGN AND PLANNING INFORMATION

4.1 IMPORTANT NOTICES

a) The boiler is supplied in one pack. The flue and fixing jig/brackets are supplied separately.

b) This boiler is for use on G20 natural gas only. The boiler is certified to the current issue of EN483, EN626 and EN 677 for performance

and safety. It is important that no alteration is made to the boiler, without the written permission of Gledhill Ltd.

The Gledhill GB35C Combination Boiler is a ‘Water Bylaws Scheme – Approved Product’.

In GB it is necessary to comply with the Water Supply (Water Fittings) regulations 1999 (or for Scotland, The Water Bylaws 2000,

Scotland).

To comply with the Water Regulations your attention is drawn to ‘The Water Regulations’ guide published by the Water Regulations

Advisory Services ( WRAS) which gives full details of the requirements.

In IE the requirements given in the current edition of the I.S.813 and the current Building regulations must be followed..

c) In GB, the installation of this boiler must be carried out by a competent person e.g. CORGI Registered installer and must comply with

the relevant requirements of : -

Manufacturer’s instructions supplied

The Gas Safety (Installation and use) Regulations, The Building Regulations and local Water Company Bylaws. The Health and Safety at

Work Act, Control of Substances Hazardous to Health, The Electricity at Work Regulations and any other applicable local regulations.

The detailed recommendations are contained in the current issue of BS5440 Pts. 1 & 2; BS 5449; BS 5546; BS 7074 Part 1; BS 6700; BS

6798; BS 6891, BS 7593, IGE/UP/7/1998

d) In IE, the installation must be carried out by a Competent Person and installed in accordance with the current edition of I.S.813 “Domestic

Gas Installations”, the current Building Regulations and reference should be made to the current ETCI rules for electrical installations.

e) When installing the boiler, care should be taken to avoid any possibility of personal injury when handling sheet metal parts.

f) Refer to Manual Handling Operations, 1992 regulations.

Figure 4.1

minimum system & expansion

vessel charge pressure > (0.5 + h/10) bar

Height = h (metres)

Additional

expansion

vessel

(if required)

Drain cock

(lowest point)

NOTE: an air vent(s) will be needed at

the highest point if the pipework system

if this rises above the highest radiator

and subsequently drops to a lower level

Page 15

CONDENSING COMBI BOILER

4.0 SYSTEM DESIGN AND PLANNING INFORMATION

4.2 CENTRAL HEATING CIRCUIT & SYSTEM

a) Central heating system

The Gledhill GB35C combination boiler is suitable for fully pumped sealed systems

only. The sealed heating system is shown schematically in figure 4.1. The sealed

system installation must comply with the appropriate requirements of current

issues of BS5449, BS6759, BS6798 and BS7074.

A draining tap or taps conforming to the current issue of BS 2879, must be

provided at all the low points of the system to allow the entire central heating

system to be drained.

It is recommended that manual air vents are provided at all the high points of

the system.

The minimum initial (cold) system and expansion vessel pressure must be at least

0.5 bar greater than h/10 (see figure 4.1). For example if height of the system high

point above the boiler is 7m, then the minimum charge pressure should be greater

than 1.2 bar (7/10 + 0.5 = 1.2 bar). This will minimise the chances of the system

entraining air and/or ‘kettleing’ noises from the boiler during operation.

b) Treatment of water in the heating system

All central heating systems will be subject to corrosion unless an appropriate

water treatment is applied. This will deteriorate the efficiency of the system as the

corrosion sludge accumulates within the system risking damage to equipment

such as the pump, valves and boiler. It will also give rise to boiler noise and

circulation problems. The system commissioning, cleansing and dosing must

comply with BS7593 requirements.

When upgrading existing systems it is necessary that the system is cleaned prior

to treatment in order to remove any sludge and reduce the likelihood of these

deposits damaging the new components.

When fitting new systems flux may be present within the system, which can lead

to damage of system components.

All systems must be thoroughly drained and flushed out. The recommended

flushing and cleansing agents are Betz-Dearbon Sentinel X300 or X400 and

Fernox Superfloc Universal Cleanser which should be used in accordance with

the manufacturer’s instructions.

The only system additives recommended are Betz-Dearbon Sentinel X100 and

Fernox-Copal and these should be used following the inhibitor manufacturer’s

instructions. It is important to check that the inhibitor concentration after

installation, system modification and at every service is in accordance with the

manufacturer’s instructions.

Important Notes:-

• Failure to flush and add inhibitor correctly to the system at the correct

concentration recommended in the manufacturers instructions will

invalidate the appliance warranty.

• Failure to fit a suitable system filler in existing systems will also invalidate

the appliance warranty.

• In the case of an existing installation, the system MUST be thoroughly flushed

before installing the new boiler. Power flushing is the recommended option

for existing installations because all high efficiency boilers have smaller

waterways than traditional boilers. A suitable system filter (e.g. Spirovent

SV3-025-T ) fitted in the boiler return is STRONGLY recommended in new

systems and must be fitted in existing systems.

• It is imperative when draining down to the primary boiler circuit that any

heating circuit debris is not drawn into the boiler waterways. Before refilling,

the system filter should be cleaned

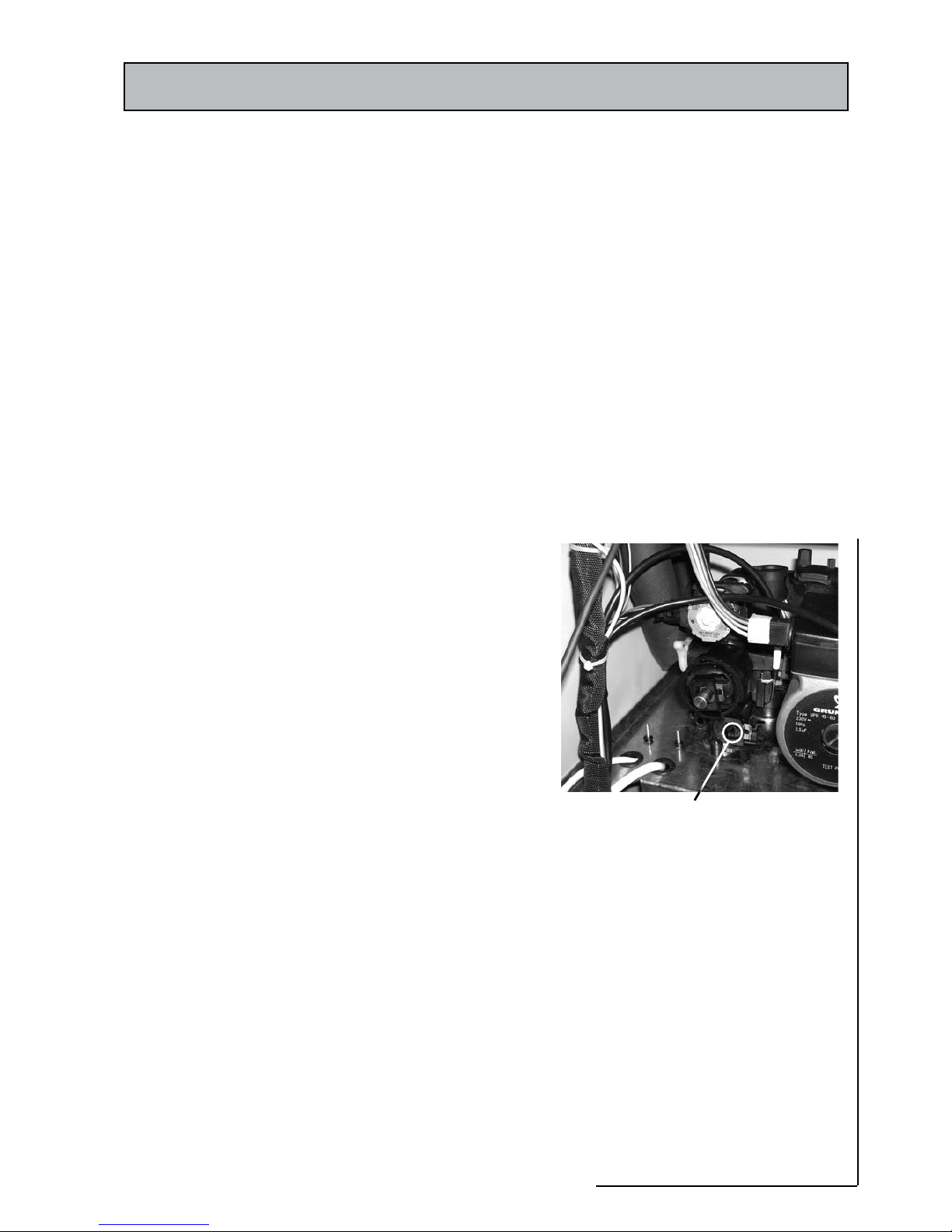

c) System bypass

The boiler is fitted with an integral bypass valve for

the central heating circuit as shown in figure 4.2. The

bypass should be adjusted so that when the boiler is in

the central heating mode, the temperature difference

across the boiler is between 11 and 20ºC. The boiler

flow and return temperature can be measured using

the digital display of the boiler.

When adjusting the bypass valve, it is important

to ensure that the central heating circuit flow rate

is sufficient to heat all the radiators uniformly and

simultaneously.

Figure 4.2

Bypass Adjuster

d) System Controls

A 24 hour electro-mechanical programmer is supplied

fitted to the boiler. Further external controls e.g. room

thermostat and thermostatic radiator valves should

be fitted to comply with the relevant requirements

of Part L1 of the Building Regulations. For further

information see: -

• The current issues of Approved Documents L1A

& L1B

• The Domestic Heating Compliance Guide

• GIL 59, 2000 : Central heating system specification

(CheSS)

• GPG 302, 2001: Controls for domestic central

heating system and hot water. BRECSU.

Page 16

4.0 SYSTEM DESIGN AND PLANNING INFORMATION

(e) System filling and topping procedure

The appliance is supplied with connections points on the mains cold water

inlet and central heating return isolating taps as shown in figure 4.3 to which

the filling loop kit supplied can be temporarily fitted. The system pressure will

be indicated on the appliance digital display.

If an alternative filling method is used for filling and

topping up the water loss from the system then it must

be fitted in an accessible position and it must be:-

• In accordance with all relevant water supply

regulations and use approved equipment i.e.

Guidance G24.2 and recommendation R24.2

of the ‘Water Regulations Guide’. Typical filling

arrangements are shown in figure 4.4. if installed

in GB

• In accordance with the current edition of I.S. 813.

if installed in IE

In GB, the sealed primar y circuit may be filled or

replenished by means of a temporary connection

between the circuit and the cold water supply, provided

a ‘Listed’ i.e WRAS approved double check valve or some

other no less effective back flow prevention device is

permanently connected at the inlet to the circuit and

the temporary connection is removed after use.

Figure 4.3

Filling loop

Figure 4.4

Sealed System Filling Method - 2

1. Control / Isolating Valve

2. Type C A Backflow Prevention Device

3. Tundish

4. Air Gap

5. Pressure regulator (optional)

CH Return CH Return

Cold Water

Supply Pipe

Cold Water

Supply Pipe

1 1

1

1

23

3

4

2

3

4

5

Sealed System Filling Method - 1

1. Control / Isolating Valve

2. Double check valve

3. Hose unions

4. Temporary connection

Page 17

CONDENSING COMBI BOILER

4.0 SYSTEM DESIGN AND PLANNING INFORMATION

(f) Central heating circuit expansion vessel

The seven litre appliance expansion vessel (see figure 2.2a) is supplied pre-charged

to 1.0 bar. Therefore the minimum cold fill pressure should be 1.0bar. The vessel is

suitable for the correct operation of central heating system capacities up to 70 litres.

For greater system capacities an additional expansion vessel must be fitted (as shown

in Figure 4.1). For guidance, the expansion vessel volumes are given in Table 4.1

In GB: The expansion vessel must conform to the current issues of BS4814 and

BS7074 Parts 1 and 2. It must be connected to the central heating return pipe and

sized according to BS5449 and BS7074 Part 1.

In IE: Refer to the current edition of I.S. 813.

(g) Pressure relief valve/discharge pipe

A non-adjustable system safety valve set at 3 bar is fitted

to the appliance (figure 4.5). All discharge pipework,

fittings, etc should be suitable for pressures greater than

3 bar and temperatures greater than 100ºC.

The pressure relief discharge pipe should not be less than

15mm diameter. It should run continuously downwards

and discharge outside the building, preferably at low

level over a drain. It should be routed and terminated in

such a way that no hazard occurs to people or damage

is caused to wiring or electrical components. The end of

the pipe should terminate facing down and towards the

wall (or be provided with a suitable guard).

The di scharge mus t not be above a windo w, or

other public access way. When choosing a location

consideration should always be given to the possibility

that boiling water/steam could discharge from this

pipe.

(H) Pump characteristics

The boiler is fitted with a modulating Grundfos UPR 1560 pump. The pump operates at maximum speed when

in the boiler is in DHW mode and modulates when the

boiler is in the central heating mode.

The pressure flow characteristics of the pump (available

for the central heating circuit) are shown in figure 4.6.

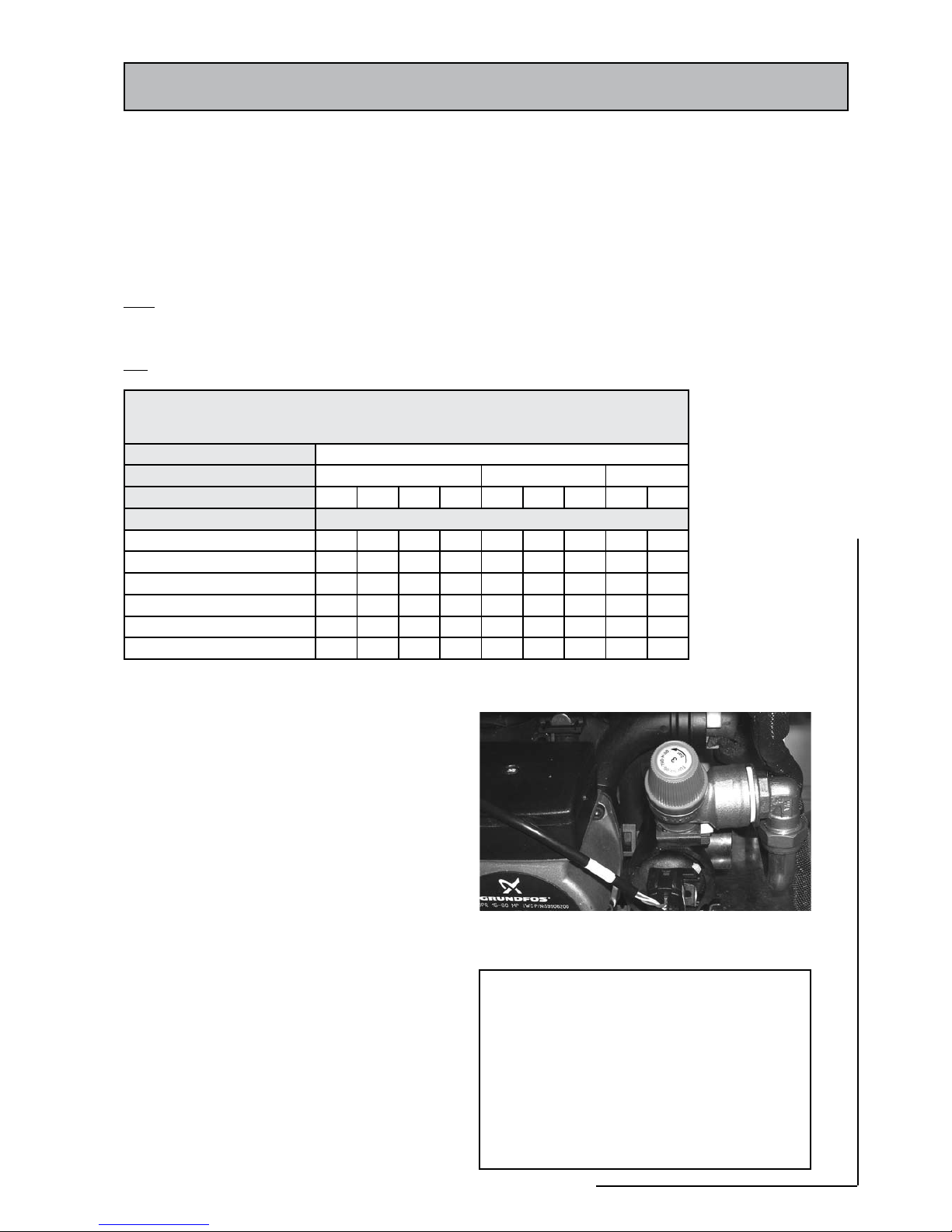

Table 4.1 - Expansion Vessel Volume Required

Safety Valve Setting (bar) 3.0

Vessel Charge Pressure (bar) 0.5 1.0 1.5

Initial (cold) Fill Pressure (bar) 0.5 1.0 1.5 2.0 1.0 1.5 2.0 1.5 2.0

Total System Capacity (l) Expansion Vessel Volume (litres)

25 2.1

3.5 6.5 13.7 2.7 4.7 10.3 3.9 8.3

50 4.2 7.0 12.9 27.5 5.4 9.5 20.6 7.8 16.5

75 6.3 10.5 19.4 41.3 8.2 14.2 30.9 11.7 24.8

100 8.3 14.0 25.9 55.1 10.9 19.0 41.2 15.6 33.1

125

10.4 17.5 32.4 68.9 13.6 23.7 51.5 19.5 41.3

150 12.5 21.0 38.8 82.6 16.3 28.6 61.8 23.4 49.6

Figure 4.5

Figure 4.6 - Pump Characteristics

Loading...

Loading...