gledhill BMA 200 SP-SOL, BMA 240 SP-SOL, BMA 220 SP-SOL, BMA 260 SP-SOL, BMA 280 SP-SOL Installation & Servicing Instructions Manual

...

Design, Installation

& Servicing

Instructions Addendum

These instructions must be read in conjunction with the

standard Boilermate A-Class SP Design, installation and

servicing instructions before installation

Model Numbers

BMA 200 SP-SOL

BMA 220 SP-SOL

BMA 240 SP-SOL

BMA 260 SP-SOL

BMA 280 SP-SOL

BMA 300 SP-SOL

All models comply with the water heater manufacturers

specification for integrated thermal stores

A sealed system central heating

and mains pressure hot water

supply appliance with thermal

store designed specifically for use

with solar energy

ISSUE 5: 06-08

Page 2

Section Page

DESIGN

Introduction 3

Technical Data 5

INSTALLATION

Wiring Details 10

Typical Pipework Arrangement 12

Controls 13

Filling/Commissioning 16

Short Parts List 17

Terms & Conditions 22

ISSUE 5: 06-08

The code of practice for the installation,

commissioning & servicing of central heating systems

The Gledhill BoilerMate range is a WBS

listed product and complies with the WMA

Specification for integrated thermal storage

products. The principle was developed in

conjunction with British Gas. This product

is manufactured under an ISO 9001:2000

Quality System audited by BSI.

Patents Pending

The Gledhill Group’s first priority is to give a

high quality service to our customers.

Quality is built into every Gledhill product

and we hope you get satisfactory service

from Gledhill.

If not please let us know.

Building Regulations and Benchmark Commissioning

The Building Regulations (England & Wales) require that the installation of a heating

appliance be notified to the relevant Local Authority Building Control Department.

From 1st April 2005 this can be achieved via a Competent Person Self Certification

Scheme as an option to notifying the Local Authority directly. Similar arrangements

will follow for Scotland and will apply in Northern Ireland from 1st January 06.

CORGI operates a Self Certification Scheme for gas heating appliances.

These arrangements represent a change from the situation whereby compliance with

the Building Regulations was accepted if the Benchmark Logbook was completed and

this was then left on site with the customer).

With the introduction of a self certification scheme, the Benchmark Logbook is being

replaced by a similar document in the form of a commissioning check list and a service

interval record is included with all gas appliance manuals. However, the relevant

Benchmark Logbook is still being included with all Thermal Storage products and

unvented cylinders.

Gledhill fully supports the Benchmark aims to improve the standards of installation

and commissioning of central heating systems in the UK and to encourage the regular

servicing of all central heating systems to ensure safety and efficiency.

Building Regulations require that the heating installation should comply with the

manufacturer’s instructions. It is therefore important that the commissioning check

list is completed by the competent installer. This check list only applies to installations

in dwellings or some related structures.

Page 3

INTRODUCTION

DESIGN

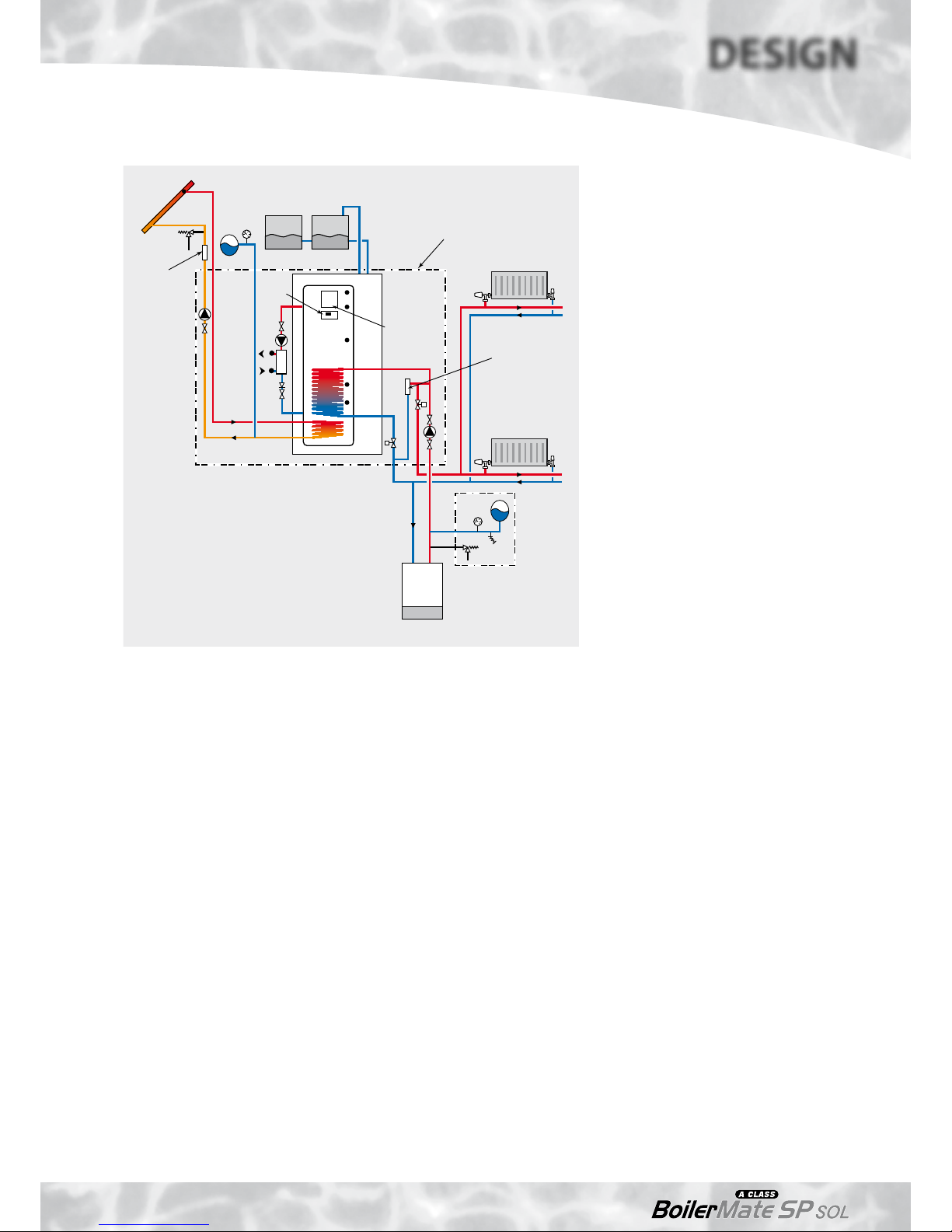

The arrangement of a typical BoilerMate A-Class

SP Solar installation is shown schematically

below. The basic unit which is covered by these

instructions incorporates the Danfoss SH - E01

solar controller.

The appliance generally follows the principles

of the standard BoilerMate A-Class SP appliance

but is fitted with a separate set of coils to

allow it to accept the maximum amount of

heat available from the solar panels/controls.

This is then used to supplement the hot water

system.

Because this product does not require a safety

discharge from a temperature and pressure

relief valve, any installations will be easy to

incorporate into the building and will not suffer

from the problems associated with using PVCu

soil stacks to take the discharge from unvented

cylinders.

The models 200 and 220 are supplied with a

single F&E cistern. All four larger models are

supplied with two F&E cisterns. The single cistern

will fit within the cupboard in a typical storey

height cupboard but when two cisterns are

used, these will need to be located elsewhere.

The operation of the appliance/solar system is

controlled by a number of sensors. The location

and reference numbers of the various sensors

is shown eg 2, S6.

Sensors S1/S2, S3, S4, S5 and S6 are connected

to the appliance control PCB which operates all

the heating and hot water functions as the basic

BoilerMate appliance.

Sensors T1, T2 and T3 are connected to the

Danfoss controller and operate all the solar

functions.

Sensor T3 provides a high temperature interlock

to de-activate the solar pump at a temperature

of 90°C in the store.

Although sensors T3 and T2 are wired in to the

solar controller the cable provided for Sensor T1

(3 metres long) may require to be extended by

the installer dependant on the location of the

solar panels/appliance. (2 x 0.75mm2 double

insulated cable) up to a maximum total length

of 50 metres.

A safety device (pressure relief valve) to control

the risk of over-pressure in system components

should be fitted as shown on the Solar System

diagram. A termination from a safety pressure

device should minimise the risk of damage

to persons or materials. Suitable locations are

a high temperature receptacle, an internal

Schematic Diagram of Typical BoilerMate 260 SP solar system

Figure 1.1

F&E cisterns

Solar

collector

Solar

circuit

Note: V1-

V2-

normally open

(powered closed)

normally closed

(spring return)

Heating

circuit

T1

PRV

Discharge pipe

BoilerMate

A-Class SP Sol

Boiler

Hot out

S1/S2

T3

S6

S5

S4

S3

T2

V1

V2

Mains

cold in

Heating/hot

water controls

(ACB)

Automatic

bypass

valve

Sealed

system kit available as

an optional

extra

Components fitted

within the

appliance case

Commissioning/

filling assembly

Solar

Controls

Page 4

DESIGN

INTRODUCTION

gulley or else issue externally at ground level.

High level termination from walls or on roofs

could cause injury to people or animals below

if the valve were to release scalding water and

steam.

The pipe leading to the safety device and

the collec tor should be of rigid and nondeformable construction, without any possibility

of restriction or disclosure by any other fitted

component.

In order to meet the Building Regulations

requirement to reduce the rate of accumulation

of scale in hard water areas, it is important

that the installer checks the hardness of the

incoming water supply.

If this exceeds 200ppm (mg/l), we recommend

that the factory fitted scale inhibitor is ordered

as an optional extra.

If it exceeds 300ppm (mg/l), we recommend the

use of a polyphosphate type of scale inhibitor.

This can also be ordered as an optional extra but

will need fitting on site by the installer.

Note:

If the summer towel rail circuit is required, this

will need to be a separate zoned circuit from the

heating circuit complete with its own time and

temperature controls.

The standard manual fill model BoilerMate AClass SP SOL appliance is shown. A ballvalve and

overflow are available as an optional extra at the

time of order. If required, these should be fitted

in the plain F&E cistern in a position to suit the

individual site conditions.

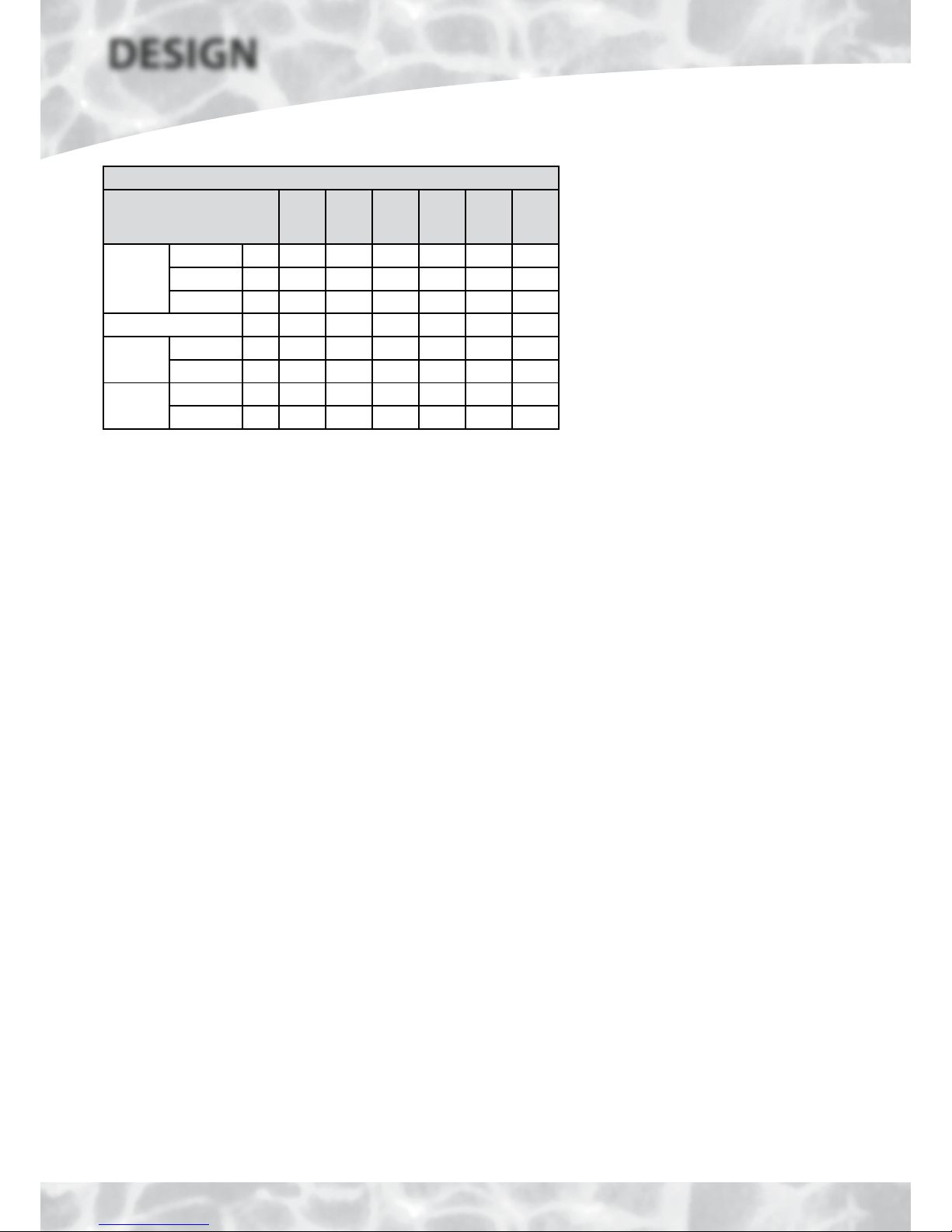

Model Selection Data Table/Weights

Model Reference

BMA

200 SP

SOL

BMA

220 SP

SOL

BMA

240 SP

SOL

BMA

260 SP

SOL

BMA

280 SP

SOL

BMA

300 SP

SOL

Dwelli ng

type

Bedrooms 2-3 2-4 3-5 3-5 4-5 5-6

Bathrooms 1 2 2 2 2 3

En-Suite 2 1 2 3 3 3

Max Floor Area (m2) 80 100 130 170 220 280

Weight

Empty (kg) 73 79 96 104 112 120

Full (kg) 233 260 313 366 411 472

Volume

Total (l) 160 181 217 262 299 352

Solar (l) 82 93 109 127 148 167

Note:

It is important that the maximum floor area is not exceeded to achieve compliance

with the SAP regulations.

Page 5

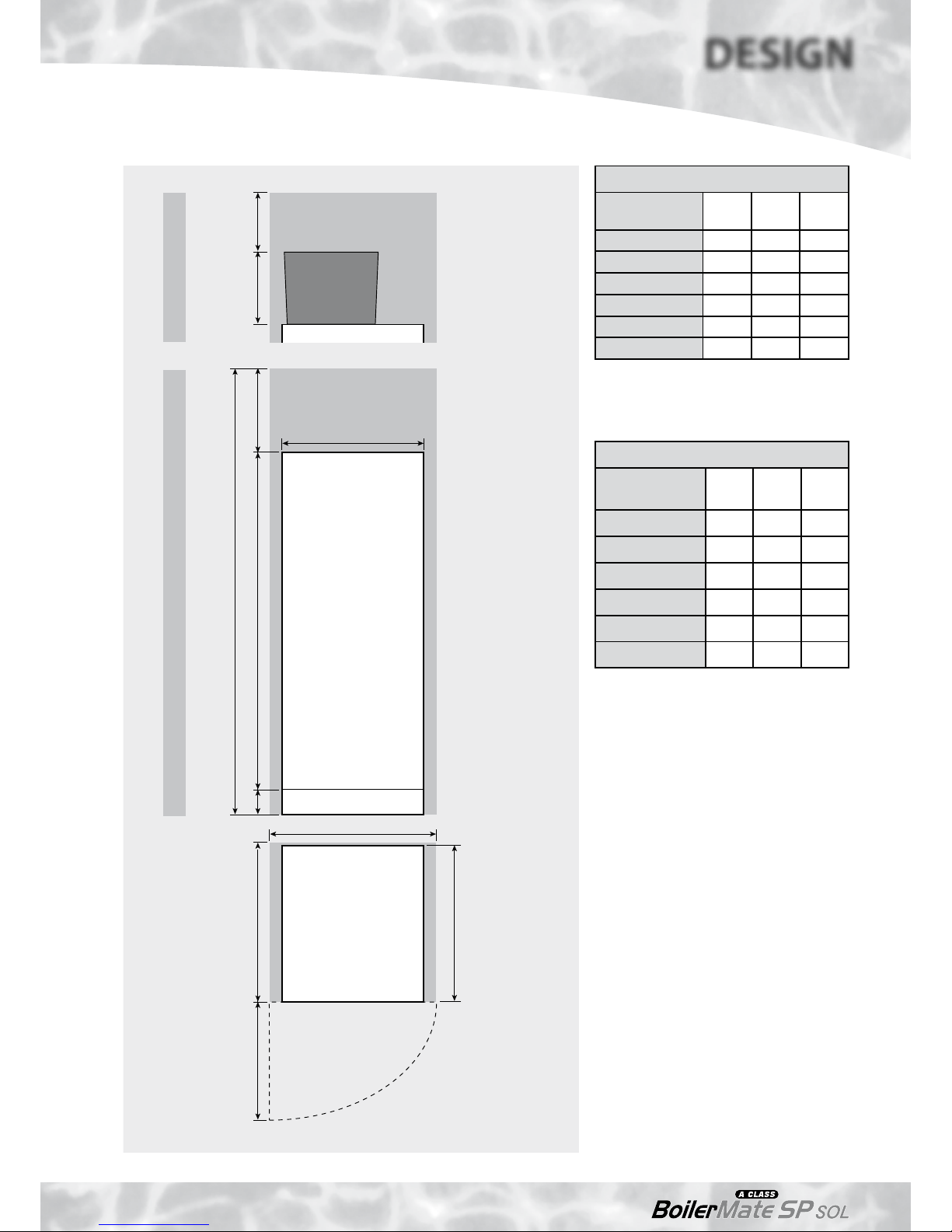

B

E

C

BoilerMate A-Class

SP SOL

300 *250A100 *500

D

F

Maintenance

access

Figure 1.2

*Minimum access /

maintenance access

above the appliance

case.

*If the F&E cistern is

fitted with a ballvalve,

this dimension will

need to increase to

350mm to comply with

the Water Regulations.

The minimum clear

opening in front of

the appliance to be

at least the same as

the depth of the

appliance

plus 50mm.

The cupboard door

opening will need to

take into account the

various sizes of

appliances.

F&E cistern

BMA 200-220 SP SOLBMA 240-300 SP SOL

Appliance Dimensions

Model

Height

(A)

Width

(B)

Depth

(C)

BMA 200-SP SOL 1330 560 620

BMA 220-SP SOL 1330 560 620

BMA 240-SP SOL 1575 560 620

BMA 260-SP SOL 1575 610 670

BMA 280-SP SOL 1575 640 700

BMA 300-SP SOL 1485 710 770

The above dimensions are for the appliance

only and do not include the 100mm high

installation base.

Minimum Cupboard Dimensions

Model

Height

(D)

Width

(E)

Depth

(F)

BMA 200-SP SOL 1980 660 630

BMA 220-SP SOL 1980 660 630

BMA 240-SP SOL 2175 660 630

BMA 260-SP SOL 2175 710 680

BMA 280-SP SOL 2175 740 710

BMA 300-SP SOL 2085 810 780

The above dimensions include the 100mm

high installation base and allow space for

installation/maintenance of the appliance only.

The height shown for the 200-220 models also

allows for the installation of the F&E cistern (with

no ballvalve) as shown opposite.

Note: With the 240-300 models, additional space

will be required for two feed and expansion

cisterns (each 280mm wide x 420mm deep x

300 high). This is NOT included in the minimum

cupboard dimensions shown above. Access

and maintenance space will also be required

for these cisterns.

Options at Extra Cost

• Hot and cold water manifolds for use with

plastic pipework.

• Scale inhibitor for mains water services with

hardness levels above 200ppm (mg/l).

• Ballvalve/overflow connector for automatic

fill model.

• Primary sealed system kit for fitting near

boiler comprising:

- Expansion vessel (size varies with model)

- 15mm 3 bar pressure relief (safety) valve

- Pressure gauge and filling loop

DESIGN

TECHNICAL DATA

Page 6

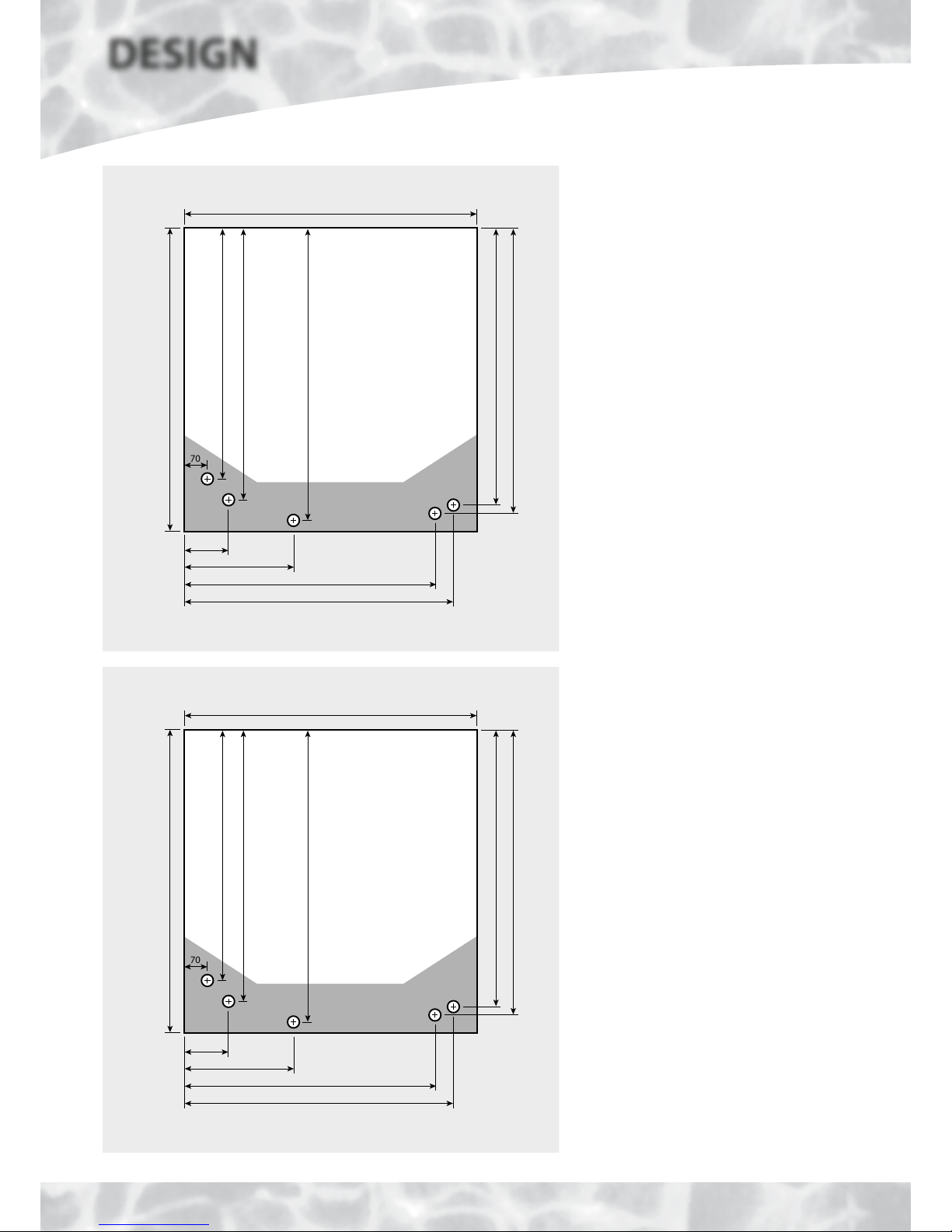

Connection Details/Dimensions - 200 model

Figure 1.3

70

490 - Boiler Flow

525 - Heating Flow

560 - Combined Boiler/Heating Return

620 (including the door/clock)

560

520 - Domestic Hot Water

545 - Incoming Cold Supply

210

490

520

130

Connection Details/Dimensions

Diagrams opposite show the connection details

and dimensions for the BoilerMate A-Class SP

SOL appliance.

The BoilerMate A-Class SP SOL units are supplied

on an installation base to allow the pipe runs

to connect to the appliance from any direction.

It is easier if all pipes protrude vertically in the

cut out area shown. Compression or push fit

connections can be used. All pipe positions

are approximate and subject to a tolerance of

+/-20mm in any direction. A 15mm cold water

supply and a 22mm warning/overflow pipe

may also be required for the separate feed and

expansion cisterns if these are located in the

appliance cupboard.

Note: All dimensions are shown in mm and

are to the centre line of pipework/gland.

Connection Details/Dimensions - 220 model

Figure 1.4

70

490 - Boiler Flow

525 - Heating Flow

560 - Combined Boiler/Heating Return

620 (including the door/clock)

560

520 - Domestic Hot Water

545 - Incoming Cold Supply

210

490

520

130

DESIGN

TECHNICAL DATA

Page 7

DESIGN

TECHNICAL DATA

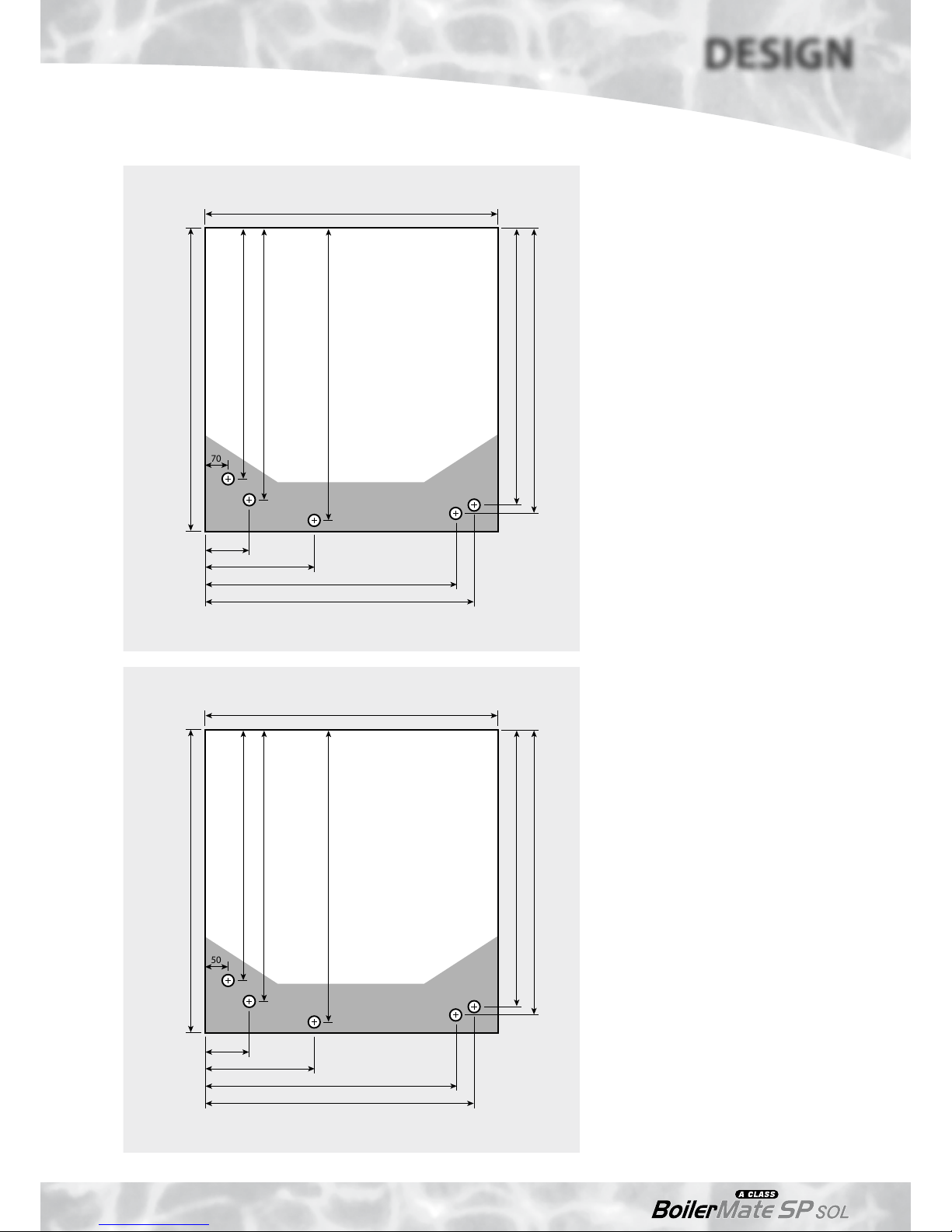

Connection Details/Dimensions - 240 model

Figure 1.5

70

490 - Boiler Flow

525 - Heating Flow

560 - Combined Boiler/Heating Return

620 (including the door/clock)

560

520 - Domestic Hot Water

545 - Incoming Cold Supply

210

490

520

130

Connection Details/Dimensions

Diagrams opposite show the connection details

and dimensions for the BoilerMate A-Class SP

SOL appliance.

The BoilerMate A-Class SP SOL units are supplied

on an installation base to allow the pipe runs

to connect to the appliance from any direction.

It is easier if all pipes protrude vertically in the

cut out area shown. Compression or push fit

connections can be used. All pipe positions

are approximate and subject to a tolerance of

+/-20mm in any direction. A 15mm cold water

supply and a 22mm warning/overflow pipe

may also be required for the separate feed and

expansion cisterns if these are located in the

appliance cupboard.

Note: All dimensions are shown in mm and

are to the centre line of pipework/gland.

Connection Details/Dimensions - 260 model

Figure 1.6

50

535 - Boiler Flow

595 - Heating Flow

625 - Combined Boiler/Heating Return

670 (including the door/clock)

610

600 - Domestic Hot Water

615 - Incoming Cold Supply

240

510

550

130

Page 8

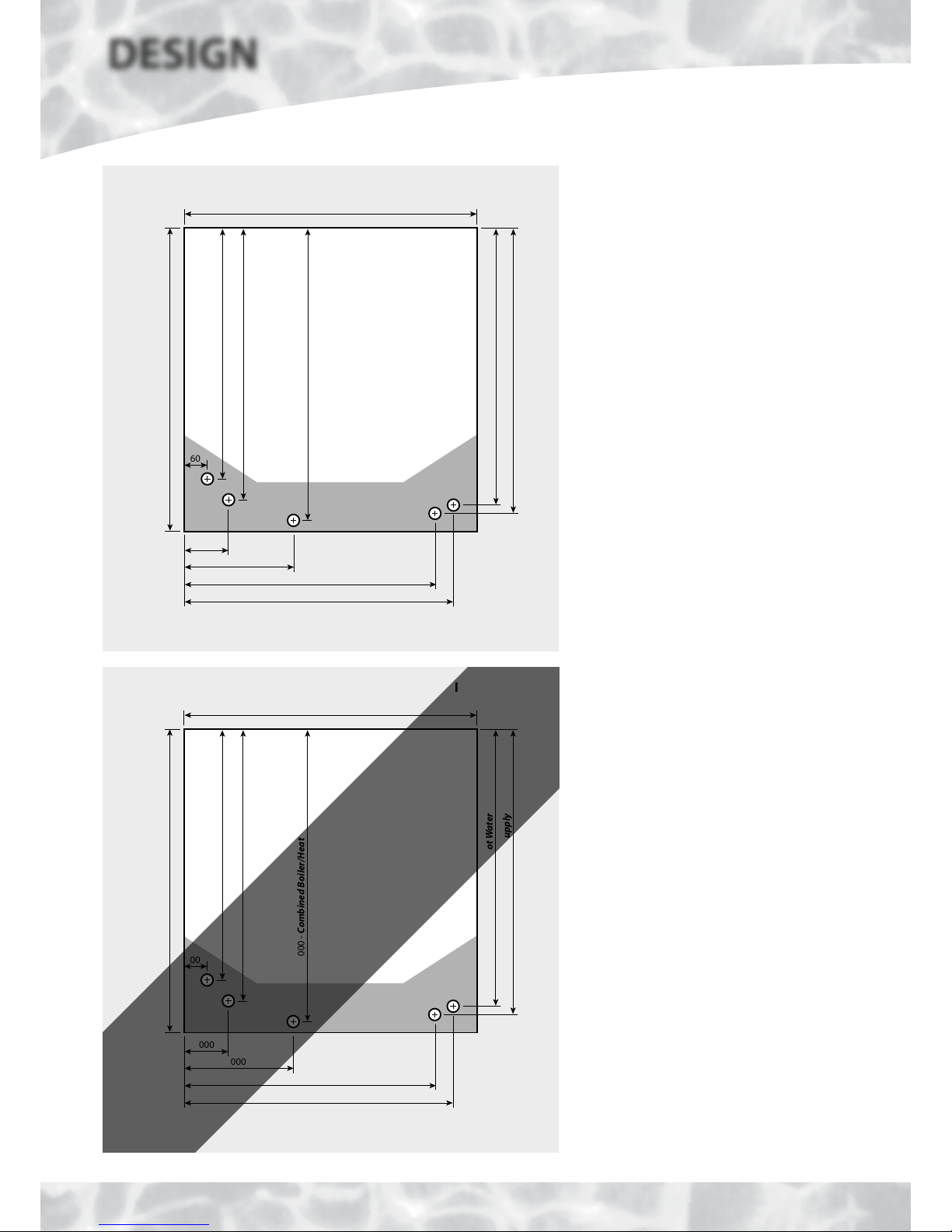

Connection Details/Dimensions - 280 model

Figure 1.7

60

570 - Boiler Flow

605 - Heating Flow

650 - Combined Boiler/Heating Return

700 (including the door/clock)

640

605 - Domestic Hot Water

610 - Incoming Cold Supply

250

570

605

160

Connection Details/Dimensions

Diagrams opposite show the connection details

and dimensions for the BoilerMate A-Class SP

SOL appliance.

The BoilerMate A-Class SP SOL units are supplied

on an installation base to allow the pipe runs

to connect to the appliance from any direction.

It is easier if all pipes protrude vertically in the

cut out area shown. Compression or push fit

connections can be used. All pipe positions

are approximate and subject to a tolerance of

+/-20mm in any direction. A 15mm cold water

supply and a 22mm warning/overflow pipe

may also be required for the separate feed and

expansion cisterns if these are located in the

appliance cupboard.

Note: All dimensions are shown in mm and

are to the centre line of pipework/gland.

Connection Details/Dimensions - 300 model

Figure 1.8

00

000 - Boiler Flow

000 - Heating Flow

000 - Combined Boiler/Heating Return

770 (including the door/clock)

710

000 - Domestic Hot Water

000 - Incoming Cold Supply

000

000

000

000

Details to follow

in later issue

DESIGN

TECHNICAL DATA

Loading...

Loading...