gledhill 120IND, 210IND, 400IND, 300IND Design, Installation & Servicing Instructions

Design, Installation & Servicing Instructions

Models covered in this manual

Stainless Lite Direct Buffer 90-400 litres

Stainless Lite Indirect Buffer 120-400 litres

Stainless Lite Flexible Buffer 90-400 litres

StainlessLite Buffer Store

Stainless steel store for use with heat pumps and boilers

Page 2

These instructions should be read in conjunction with the installation/

servicing instructions issued by the manufacturer of the heat source

being used.

Any installation must be in accordance with the relevant requirements

of the Gas Safety Regulations, Building Regulations, I.E.E. Wiring

Regulations and the Water Fitting Regulations (England and Wales)

or Water Byelaws (Scotland). It should be read in accordance with

the relevant recommendations of the following:

BS 6798; BS EN 12828, BS EN 12831, BS EN 14336; BS 5546;

BS 5440:1; BS 5440:2; CP 331:3

BS EN 806-1 to 5, BS EN 8558:2011: BS EN 1458-1:2011 and BS

7593:2006

It must be installed by a competent person as defined by the relevant

regulations. Manufacturers notes must NOT be taken as over-riding

statutory obligations.

This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge unless they have been given supervision

or instruction concerning use of the appliance by a person responsible

for their safety. Children should be supervised at all times to ensure

they do not play with the appliance.

This information is provided to assist generally in the selection of

equipment.

Responsibility for selection and specification of our equipment must

however remain that of our customer and any experts or consultants

concerned with the installation(s).

PLEASE NOTE: THAT WE DO NOT THEREFORE ACCEPT ANY

RESPONSIBILITY FOR MATTERS OF DESIGN SELECTION OR

SPECIFICATION, FOR THE EFFECTIVENESS OF AN INSTALLATION

OR SYSTEM CONTAINING ONE OF OUR PRODUCTS UNLESS

SPECIFICALLY REQUESTED TO DO SO IN WRITING.

All goods are sold subject to our Conditions of Sale which are set

out at the rear of this specification. In the interest of continuously

improving the Stainless Lite range, Gledhill Building Products

Limited reserve the right to modify the product without notice, and

in these circumstances this booklet, which is accurate at the time of

printing, should be disregarded. An updated set of Instructions will

be produced and supplied with new appliances and will be made

available for other appliances on request.

Stainless Lite Buffer Store is produced under an iso 9001:2008 quality

management system approved by bsi.

ISSUE 7: JANUARY 2014

Section Page

DESIGN

Description 3

Technical Data 4

INSTALLATION

Installation 8

Commissioning 10

APPENDIX

Appendix A 11

Appendix B 12

Notes 13

Benchmark Checklist 16

Benchmark Service Record 17

Terms & Conditions 18

Benchmark places responsibilities on both manufacturers and installers.

The purpose is to ensure that customers are provided with the correct

equipment for their needs, that it is installed, commissioned and serviced

in accordance with the manufacturers instructions by competent

persons and that it meets the requirements of the appropriate Building

Regulations. The Benchmark Checklist can be used to demonstrate

compliance with Building Regulations and should be provided to the

customer for future reference.

Installers are required to carry out installation, commissioning and

servicing work in accordance with the Benchmark Code of Practice

which is available from the Heating and Hot Water Industry Council who

manage and promote the Scheme. Visit www.centralheating.co.uk for

more information.

For further information on the HWA Charter Membership, please refer to

the HWA website hotwater.org.uk.

Page 3

Buffer vessels are simply a duplex stainless steel tank that contains a

volume of water . Buffer vessels are used in heating systems to decouple

the heat sources from the heat demands, in the same way a hot water

cylinder decouples the hot water demands from the boiler .

Buffer stores are recommended by heat pump manufacturers to ensure

trouble free operation of their appliances. They achieve this by presenting

the heat pump with a larger volume of water to heat which reduces

the amount of cycling. This in turn extends the life of the heat pump’s

compressor and by reducing cycling reduce running costs.

These buffer stores can be connected to air, water or ground source

heat pumps.

Buffer stores can be connected to either open vented or sealed systems as

they are designed to work at up to 3.5 bar . The systems that are connected

to the buffer store dictate the selection of system and components required

for safe operation, and this is the responsibility of the system designer .

Buffer stores are not suitable for potable water and should not be

used to feed any hot water outlets.

Direct & Indirect buffer stores

Direct buffer stores are heated directly by the main heat source only, eg.

heat pump, and do not incorporate electric heaters and therefore the

heating circuit flow temperature connected to the buffer vessel depends

upon the flow temperature of the heat source. This type of store is ideal

for the combination of a heat pump with under floor heating. Underfloor

heating operating at 30°C - 40°C.

Indirect stores enable connections to be made to the heat pump, heating

system and an additional heat source. This could be an oil or gas boiler

but not a solid fuel heat source because the heat exchanger is not of

the correct type. The additional heat is supplied via a heat exchanger

and therefore is hydraulically separate from the water in the buffer store.

An additional heat source is useful for extreme conditions when the heat

pump may not be able to supply the heat required and when it can top

up the store.

Flexible buffer stores

This type of buffer store has been designed with flexibility in mind. It

enables multiple heat pumps and/or separate domestic hot water and

central heating zones to be connected. For this reason the installation

diagrams in the following pages do not relate to this model. The installer

can choose how to install this product and blank off any unused

connections.

Weather compensation

Some heat pumps can use the external temperature to control the

temperature of the water supplied to the cylinder and therefore the

temperature supplied to the under floor heating. This can produce further

savings by eliminating the need for the thermostatic component of the

under floor heating manifold. Also it enables the heating system to run at

its optimum temperature, rather than running too hot for the conditions

at that time.

DESIGN

DESCRIPTION

Please Note:i) Any heat source, heat pump, boiler or other source used in a sealed

system must incorporate a certified overheat protection device and

the heat source should be certified for use in a sealed heating system.

All heat sources must have two independent temperature control

devices, for example, a control and an overheat thermostat.

ii) Any sealed heating system must have a means for accommodating

the expansion of the whole system volume including the buffer

vessel’s volume.

iii) Any heat source in a sealed heating system must be fitted with a

pressure relief valve (PRV), and there should be no isolating valve

between the PRV and the heat source.

iv) Any sealed heating system should incorporate an approved filling

method.

v) Should it be deemed necessary by the designer or installer to

incorporate a third level of protection against overheat, a manual

reset overheat thermostat can be fitted in the top thermostat pocket.

This coupled with the energy cut off valves for every heat source will

stop the buffer store overheating if all other devices fail.

Page 4

The Buffer store is insulated to a very high standard using high density

HCFC free foam cased in a steel shell and has an ozone depletion potential

(ODP) of zero and a global warming potential (GWP) of 1.

The specification of the models are shown in the following tables.

DESIGN

TECHNICAL DATA

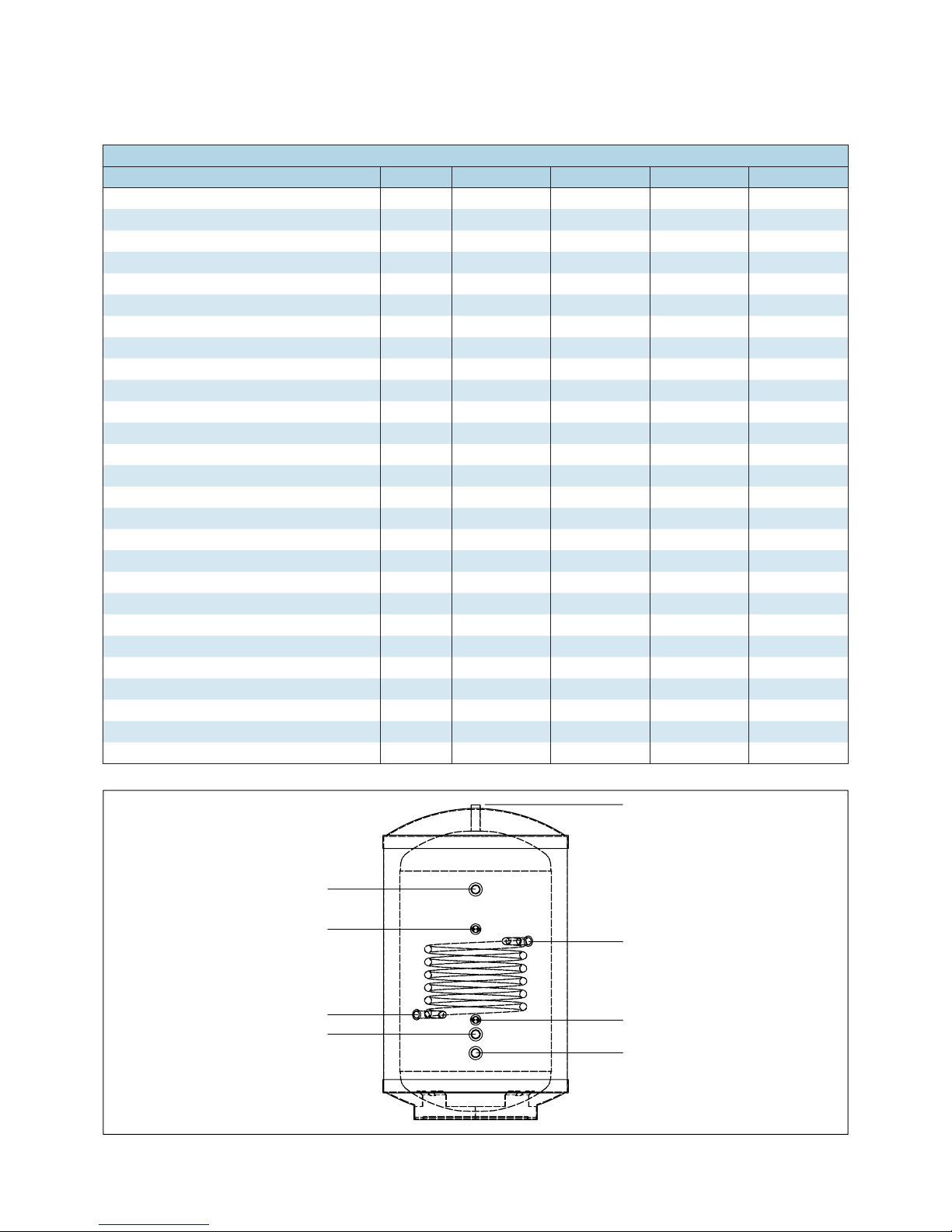

Stainless Lite Direct Buffer Store Technical Specification

Description 90D 120D 210D 300D 400D

Capacity litres 90 120 210 300 400

Height mm 745 930 1495 1992 2030

Diameter mm 550 550 550 550 630

Weight (empty) kg 13 18 28 37 51

Weight (full) kg 103 138 238 337 451

Standing losses kWhr/24hr 0.85 1.06 1.70 2.04 2.82

Maximum working pressure - cylinder bar 3.5 3.5 3.5 3.5 3.5

Maximum working pressure - space heating bar 3.5 3.5 3.5 3.5 3.5

Central heating flow connection mm 28 28 28 35 35

Central heating return connection mm 28 28 28 35 35

Heat pump flow connection mm 28 28 28 35 35

Heat pump return connection mm 28 28 28 35 35

Central heating flow tapping height mm 732 920 1483 2020 2030

Central heating return tapping height mm 200 200 200 200 214

Heat pump flow tapping height mm 690 690 1253 1791 1805

Heat pump return tapping height mm 300 300 300 300 314

Thermostatic pocket size - Bottom mm 22 22 22 22 22

Thermostatic pocket size - Top mm 22 22 22 22 22

Thermostatic pocket height - Bottom mm 245 257 446 607 621

Thermostatic pocket height - Top mm 448 571 937 1287 1201

Heating Flow

Heat Pump Return

Heating Return

Heat Pump Flow

Sensor Pocket

Sensor Pocket

Page 5

DESIGN

TECHNICAL DATA

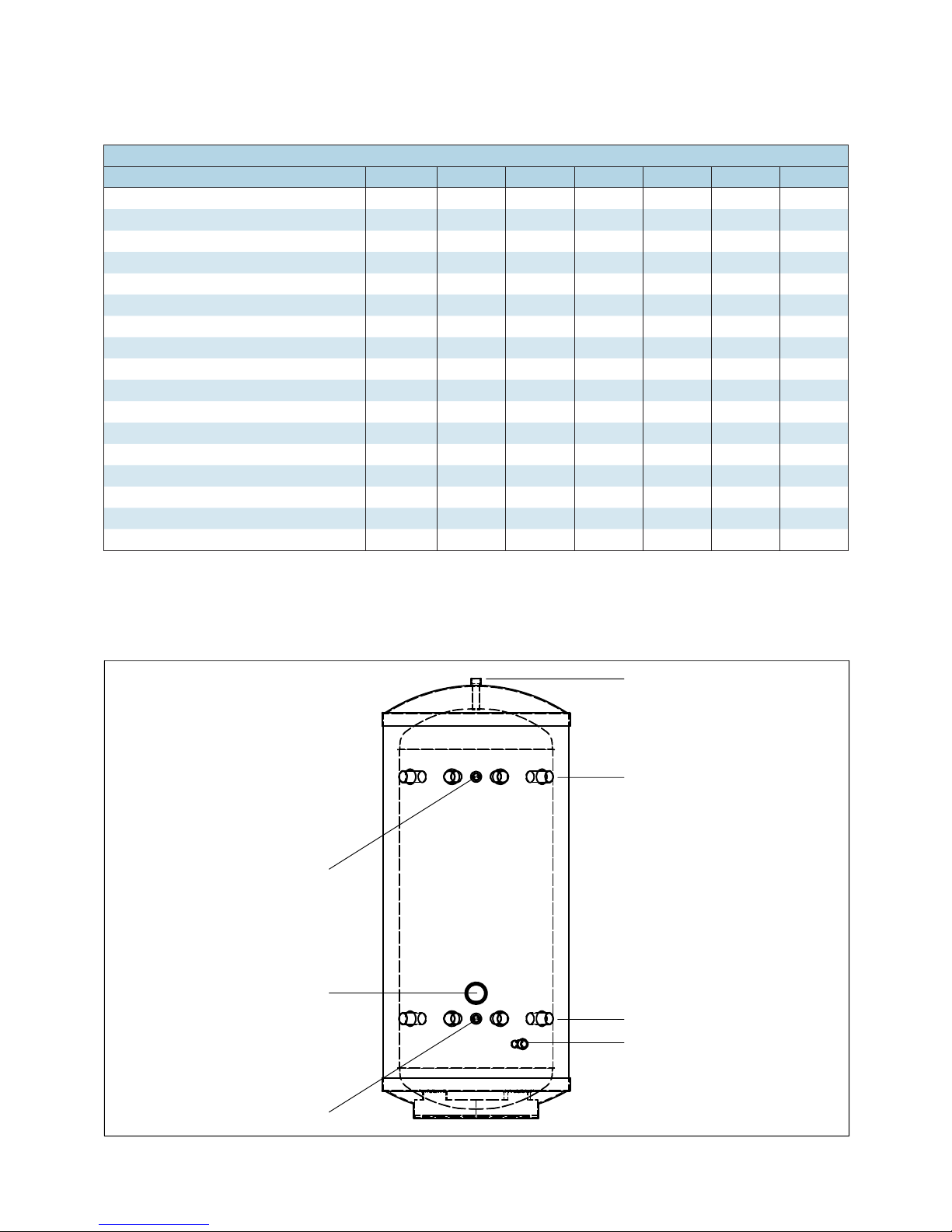

Stainless Lite Indirect Buffer Store Technical Specification

Description 120IND 210IND 300IND 400IND

Capacity litres 120 210 300 400

Height mm 930 1495 1992 2030

Diameter mm 550 550 550 630

Weight (empty) kg 22 33 44 55

Weight (full) kg 142 243 344 455

Standing losses kWhr/24hr 1.06 1.70 2.04 2.82

Maximum working pressure - cylinder bar 3.5 3.5 3.5 3.5

Maximum working pressure - space heating bar 3.5 3.5 3.5 3.5

Maximum working pressure - heat exchanger bar 3.0 3.0 3.0 3.0

Central heating flow connection mm 28 28 35 35

Central heating return connection mm 28 28 35 35

Heat pump flow connection mm 28 28 35 35

Heat pump return connection mm 28 28 35 35

Coil flow connection mm 22 22 22 22

Coil return connection mm 22 22 22 22

Central heating flow tapping height mm 920 1483 2020 2030

Central heating return tapping height mm 200 200 200 214

Heat pump flow tapping height mm 690 1253 1791 1805

Heat pump return tapping height mm 300 300 300 314

Coil flow tapping height mm 535 780 1000 1014

Coil return tapping height mm 315 520 700 714

Thermostatic pocket size - Bottom mm 22 22 22 22

Thermostatic pocket size - Top mm 22 22 22 22

Thermostatic pocket height - Bottom mm 257 446 607 621

Thermostatic pocket height - Top mm 571 937 1287 1201

Coil - loops 6888

Coil - surface area m

2

0.59 0.78 0.78 0.78

Heating Flow

Coil Flow

Sensor Pocket

Heating Return

Heat Pump Flow

Sensor Pocket

Heat Pump Return

Coil Return

Page 6

DESIGN

TECHNICAL DATA

Stainless Lite Flexible Buffer Store Technical Specification

Description 90FLX 120FLX 210FLX 250FLX 300FLX 400FLX

Capacity litres 90 120 210 250 300 400

Height mm 745 930 1495 1745 1992 2030

Diameter mm 550 550 550 550 550 630

Weight (empty) kg 13 18 28 32 37 51

Weight (full) kg 103 138 238 282 337 451

Standing losses kWhr/24hr 0.85 1.06 1.70 1.85 2.04 2.82

Maximum working pressure - cylinder bar 3.5 3.5 3.5 3.5 3.5 3.5

Maximum working pressure - space heating bar 3.5 3.5 3.5 3.5 3.5 3.5

Tappings mm 28 28 35 35 35 35

Upper tapping height mm 470 662 1225 1475 1761 1776

Lower tapping height mm 295 295 295 295 295 310

Vent/relief boss (22mm compression) mm Top/Mid Top/Mid Top/Mid Top/Mid Top/Mid Top/Mid

Drain (1/2” BSP) height mm 220 220 220 220 220 235

Inspection hatch (1 3/4” BSP) height mm 370 370 370 370 370 385

Thermostatic pocket size mm 22 22 22 22 22 22

High level stat height mm 470 662 1225 1475 1761 1776

Low level stat height mm 295 295 295 295 295 310

Upper Plain Pipe Connections

Lower Plain Pipe Connections

High Level Stat

Low Level Stat

Inspection hatch

22mm Compression

½" BSP Fitting for Drain Valve

The 22mm compression connection at the top of the cylinder can be used

as a vent or possible pressure relief position.

Loading...

Loading...