Gleason Reel MMD-32 Installation And Maintenance Instructions Manual

INSTALLATION and MAINTENANCE INSTRUCTIONS

MMD-32 GEAR DRIVE ELECTRIC CABLE REELS

All units are provided with right hand rotation unless otherwise

specified. This means that cable is pulled off spool top left or

bottom right (spool rotates clockwise to wind cable) when

viewing spring end of reel. See diagram on parts page.

Clock-type springs provide power for automatic cable take-up.

Spring must be pretensioned at time of installation to

insure that tension is applied to cable at all times. Atension

adjustment spanner wrench is provided with each reel.

WARNING

Some reels with large or multiple springs are equipped with a

ratcheted adjustment wrench. Follow separate instructions

for its use. Failure to use ratcheted wrench, on reels so

equipped, could result in serious personal injury.

WARNING

Do not attempt to relieve spring tension using spanner

wrench. Doing so may result in personal injury.

INSTALLATION

1. Insure that machinery to be serviced by reel is at position

closest to reel.

2. Securely mount reel in desired position using 3/8"(M10)

bolts, Be sure spool is aligned with cable run.

3. Position optional cable guide, if reel is so equipped.

See CABLE INSTALLATION DRA WING.

4. Unspool cable from reel, without allowing spool to rotate, so

that desired length of cable extends from reel. Do not pull

cable directly off reel as this will apply tension to the spring

and may cause overtensioning when the reel is put into

service. Connect free end of cable to junction box on

machine or adjust cable stop

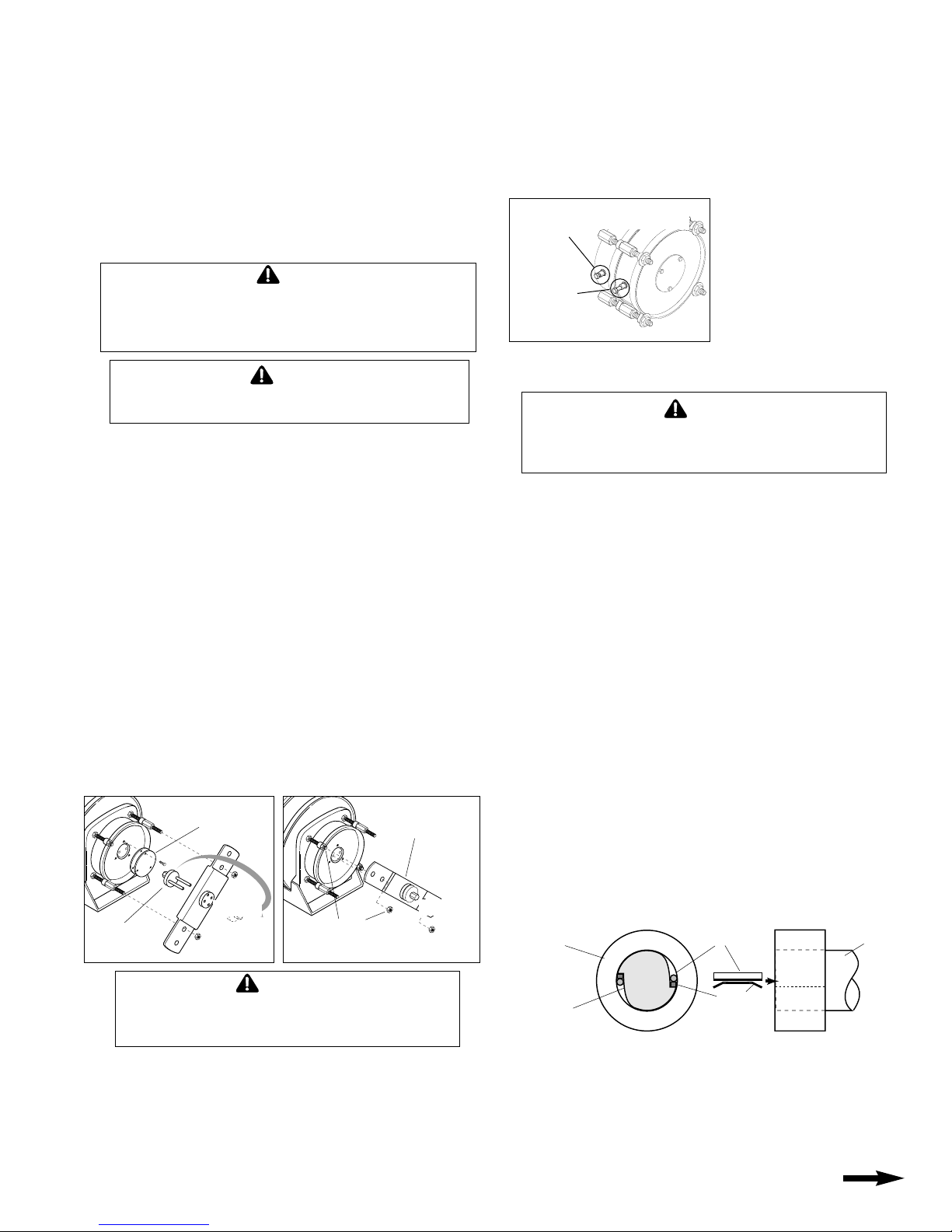

5. Remove ratchet wrench and cover plate on spring housing

to expose shaft and spring hub. (Fig 1).

6. Reinstall ratchet wrench (Fig 2). Use long handled wrench

to rotate arbor driver clockwise (for standard rotation).

Number of 360

number on serial plate.

reel is reverse rotation and wrench must be rotated

counterclockwise.

ARBOR

DRIVER

Do not exceed number of turns indicated on serial plate.

NOTE: On reels containing more than one spring, the hubs

are connected at the factory. Therefore, by tightening the

outer spring, the inside spring(s) will be tightened.

7. Remove collector cover and connect individual supply

conductors to collector terminals. See ELECTRICAL

CONNECTIONS diagram, on parts page.

O

turns should match last digit in model

If model number includes an “R”,

(See EXPLANATION on parts list page.)

COVER PLATE

AND GASKET

Figure 1

REMOVE THESE

NUTS AND USE TO

MOUNT WRENCH.

RATCHET WRENCH

(ADJUSTING

POSITION)

CAUTION

Over-tensioning can cause a broken spring,

sheared shaft or other damage.

Figure 2

MAINTENANCE

Periodically: A. Use compressed air to clean collector assem-

bly and inside of collector housing. Inspect collector assembly

for brush wear and pitted slip rings.

B. Inspect cable for wear

“IN” with 2/3

cable off reel–

SPRING OK

BROKEN SPRING

INDICATORS

and check mounting bolts and

other hardware for tightness.

C. Check for broken springs

by pulling about 2/3 cable off

“OUT” with 2/3

cable off reel–

SPRING

BROKEN

Figure 3

reel and observing “Broken

Spring Indicators” on sides of

spring canisters. See Fig. 3.

D. Apply grease to gears

through grease fitting on side

of gear housing.

NOTE: Bearings and springs are prelubricated and require no

periodic maintenance.

WARNING

Do not attempt to remove spring from its housing. Clock-

type springs can be dangerous to handle. Removal of

spring from housing could result in personal injury.

SPRING REPLACEMENT

The unique SAFETYCHANGE® spring motor consists of a

spring and hub sealed within a housing. Areplacement spring

is supplied sealed in its housing and the old unit should be discarded completely.

1. Turn off all electric power.

2. Disconnect cable from machine junction box.

3. Relieve all spring tension. following steps under

SPRING DETENSIONING on last page.

4. Remove inspection cover from face of spring housing.

5. Rotate spool clockwise and observe spring shaft. Shaft

should rotate counterclockwise and hub (with spring

attached) should remain stationary.

NOTE: Do not attempt to remove spring if resistance

Continue to rotate spool and strike end of shaft with a rubber

mallet until shaft rotates freely and hub remains stationary.

6. Remove (4) nuts which secure spring motor(s) to frame.

7. Slide spring motor(s) off shaft and discard.

NOTE: On multi-spring reels, be sure to remove and save

dowel pins which connect one spring hub with another. Also

8. Install replacement spring motor(s), pawls and pawl springs.

that pawls and pawl springs are inserted flush with ends of

(Spring not

9. Tighten nuts (and extension bolts) securing spring

10. Connect free end of cable to junction box or adjust cord stop.

11. Retighten nut on spring detensioner. See SPRING

12. Tension spring with spanner wrench. Refer to

13. Replace inspection cover and top gear access cover.

is met or hub tends to rotate with shaft.

remove snap rings on shaft between reel housings.

NOTE: Pawl springs must be located between the pawls

and the deepest section of the shaft grooves. Make sure

shaft and hub or they may rub against inspection cover.

SPRING

HUB

shown)

SHAFT

GROOVE

END VIEW

PAWL

SPRING

Install

against flat

SPRING

SHAFT

SIDE VIEW

housing(s) to reel frame.

DETENSIONING, back page.

INSTALLATION section.

CONTINUED ON BACK PAGE

7

11

12

28

ref

11

12

11

12

11

12

28

ref

2

3

9

10

1

1

1

1

2

3

8

8

5

8

16

17

19

21

27

28

29

30

31

33

34

35

3

15

11

11

32

29

28

30

11

11

11

14

15

18

20

32

20

14

20

19

15

27

23

24

25

26

1

4

22

1

6

1

13

36

36

37

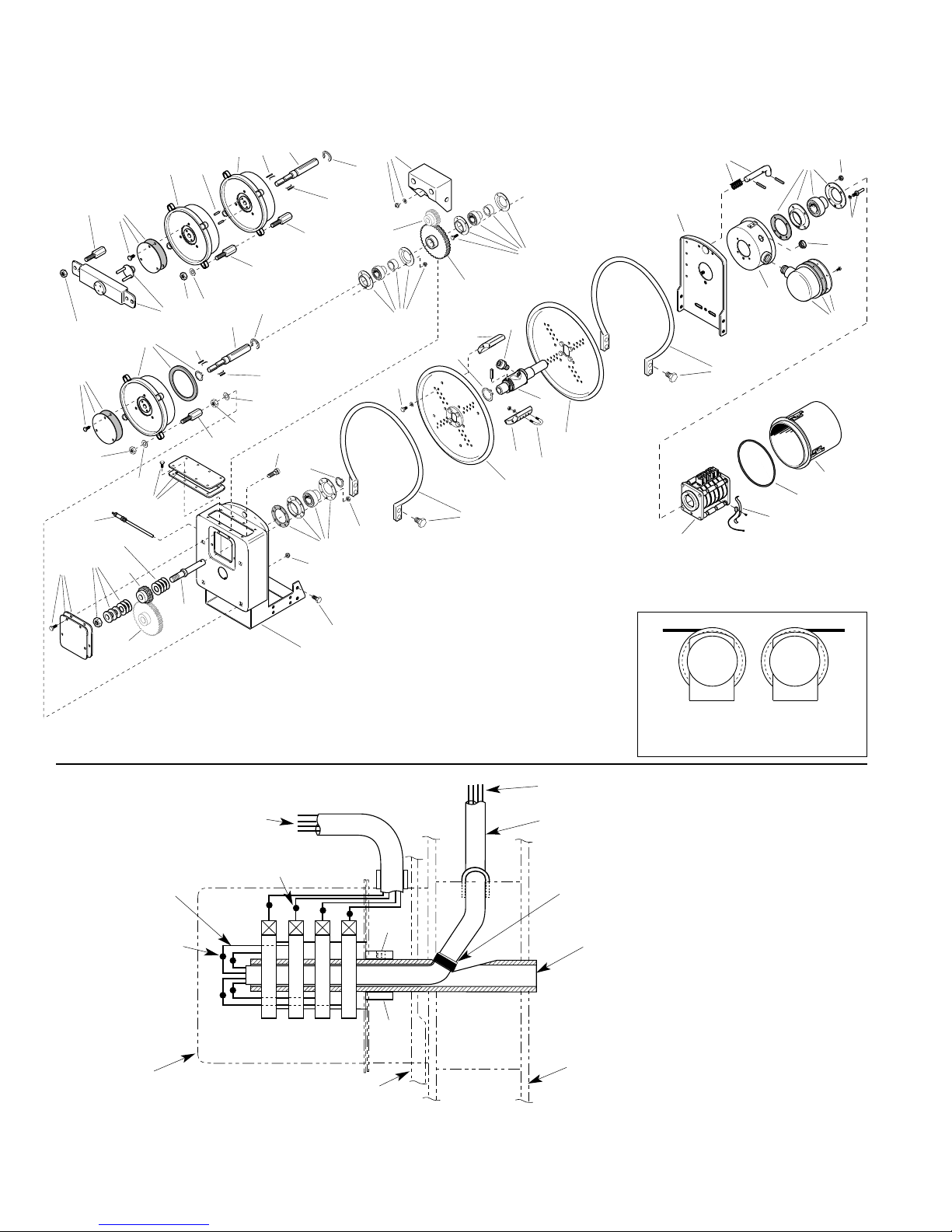

ILLUSTRATED PARTS LIST

MMD-32 GEAR DRIVE ELECTRIC CABLE REELS

ELECTRICAL CONNECTIONS

LEADWIRES ARE

NUMBER TAGGED

SLIP-RING LEAD TO

MOVING CABLE

CONNECTIONS

SLIP–RING

LEADWIRE INPUT FIXED END

(CUSTOMER SUPPLIED)

SLIP-RING

COVER

SLIP–RING ENCLOSURE

•

600 VOLTAC. 250 VOLT DC. WATERTIGHT, DUST TIGHT.

•

DO NOT EXCEED AMPERAGE RATING OF CABLE OR SLIP RING.

• NUMBER OF CIRCUITS MAY VARY FROM TWO (MINIMUM) TO 36 (MAXIMUM). FOUR CIRCUITS SHOWN.

BRUSH TERMINAL

CONNECTIONS

1

1

SLIP–RINGS

Always specify SERIAL NUMBER &

MODEL NUMBER when ordering parts.

SET

SCREW

432

32

4

COLLAR

FRAME

CABLE LEADWIRES

MOVING END

CABLE

WATER–TIGHT

CABLE GRIP

MAINSHAFT

SPOOL

REEL

TO DETERMINE ROTATION OF REEL

STANDARD REVERSE

ROTATION ROTATION

Cable is payed out and retracted as shown

when viewing reel from spring motor side.

NOTE:

Wire size, wire connectors, connection

sequence, and connection methods must comply

with National Electrical code and Local Electrical

ordinances. If in doubt, contact a local electrical

contractor or electrical inspector.

COLOR SEQUENCE FOR TYPE SO CABLE

THREE CONDUCTOR CABLE

# 1 – BLACK

# 2 – WHITE

# 3 – GREEN (ground)

FOUR THRU TWELVE CONDUCTOR CABLE

# 1 – BLACK

# 2 – WHITE

# 3 – RED

# 4 – GREEN (ground)

# 5 – ORANGE

# 6 – BLUE

# 7 – WHITE W/ BLACK TRACER

# 8 – RED W/ BLACK TRACER

# 9 – GREEN W/ BLACK TRACER

#10 – ORANGE W/ BLACK TRACER

#11 – BLUE W/ BLACK TRACER

#12 – BLACK W/ WHITE TRACER

Loading...

Loading...