Page 1

2015 Quick Reference Guide

S67/S68/S77/S78/S88 Models

It is YOUR responsibility to read and understand the safety section in your

Operator’s Manual and the manual for all attachments before operating your

machine. Remember YOU are the key to safety. Good safety practices not only

protect you, but also the people around you.

Study the features in your Operator’s Manual and make them a working part

of your safety program. Keep in mind that the safety section in your Operator’s

Manual is written only for this type of machine. Practice all other usual and

customary safe working precautions, and above all REMEMBER - SAFETY IS

YOUR RESPONSIBILIT Y. YOU CAN PREVENT SERIOUS INJURY OR DEATH.

Page 2

Contents

Combine Setup 1

Cereal Grain - Wheat, Oats, Barley 1

Milo - Grain Sorghum 2

Dry Corn (< 20% moisture) 2

High Moisture Corn (> 24% moisture) 3

Soybeans 4

Canola/Rapeseed 5

Millet 5

Edible Beans 6

Sunowers 7

Flax 7

Grass Seed (Bluegrass, Bentgrass) 8

Alfalfa 9

Clover 10

Rye 10

Troubleshooting 11

Header 11

Feed conveyor 16

Processor 17

Grain quality 19

Grain loss 23

Loss Calculation 25

“Quick check” for combine grain loss 25

Spreading discharge 25

“Next step” for combine grain loss 25

Rotor loss 26

Shoe loss 26

“Advanced” grain loss calculation procedure 27

Advanced rotor loss 27

Advanced shoe loss 27

Standard Payable Moisture & Density Chart 28

Page 3

Combine Setup

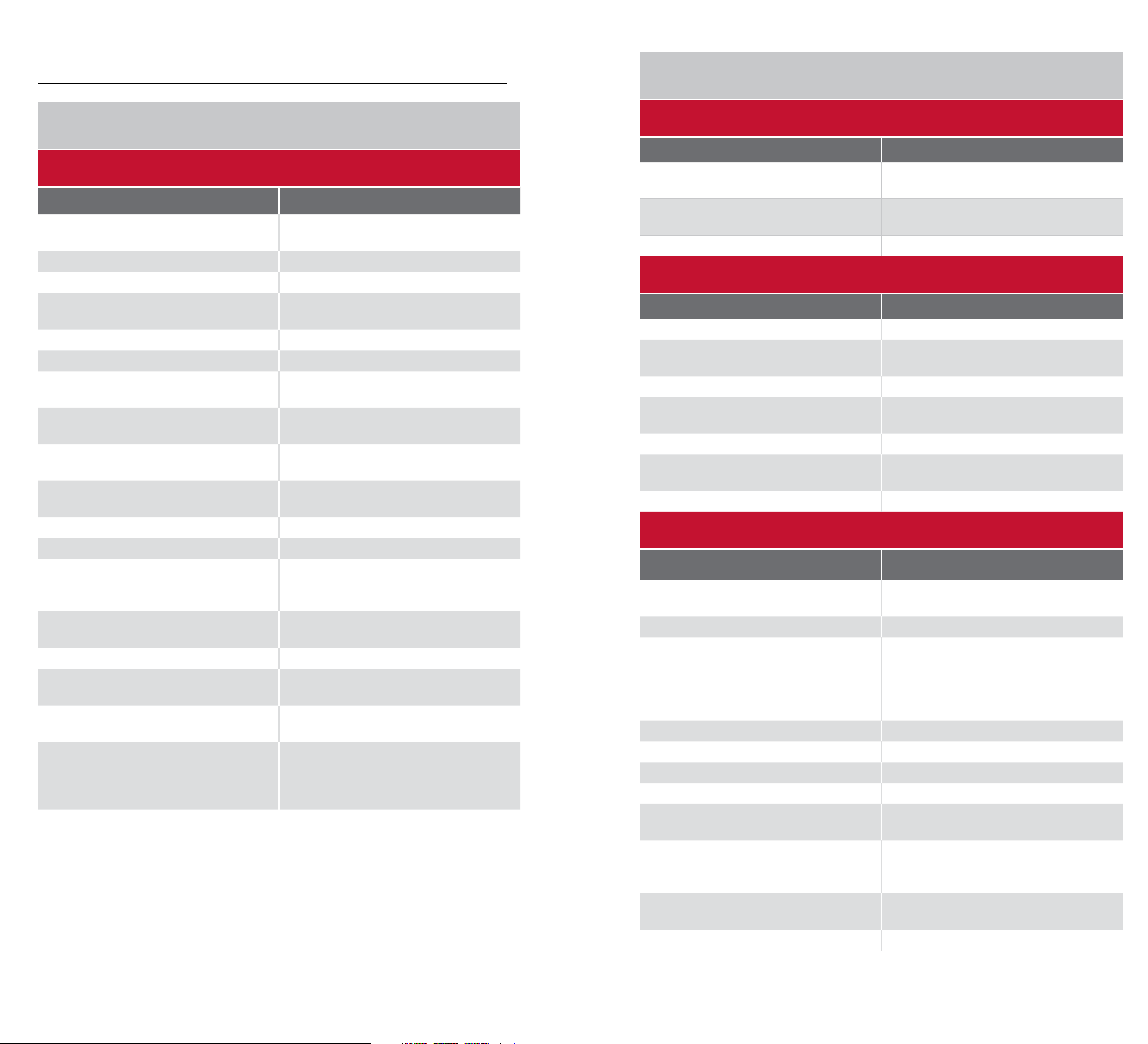

Cereal Grain - Wheat, Oats, Barley

Initial Combine Setup

Milo - Grain Sorghum

Initial Combine Setup

Concave

Rotor RPM

Setting

Fan

Opening

Chaffer

Opening

Sieve

Opening

Chopper

Speed

Elevator

Boots

Concave

0.1” -

0.2”

0.1” -

0.2”

0.1” -

0.2”

Setting *

3 - 6

3 - 6

3 - 6

Fan Opening

Chaffer

0.75”

(19 mm)

0.75”

(19 mm)

0.75”

(19 mm)

Opening

Sieve

0.375”

(10 mm)

0.375”

(10 mm)

0.375”

(10 mm)

Opening

Fast Solid

Fast Solid

Fast Solid

Chopper

Speed

Crop

Wheat 800

Oats 600

Barley

* - As read on the EIP.

Rotor RPM

400 -

600

Initial Header & Header Drive Setup

• Cutterbar locked up on ex headers.

• Variable speed header drive in slowest position.

• Right-hand pivot drive belt positioned on large countershaft drive

sheave and small driven pivot sheave.

Straw Chopper

• Position chopper drive belt so chopper is operating at fast speed.

450-600 0.2” - 0.4” 3 - 6

• Set concave to stem thickness just below head for starting point.

Elevator

Boots

• Run in low range of rotor gearbox for greater torque if possible (S8

Series has greater range to provide ability to run on low side of

gearbox).

0.625”

(16 mm)

0.313”

(8 mm)

Fast Solid

Initial Header & Header Drive Setup

• Lock up cutterbar on ex headers.

• Variable speed header drive in slowest position.

• Right-hand pivot drive belt positioned on large countershaft drive

sheave and small driven pivot sheave.

Straw Chopper

• Position chopper drive belt so chopper is operating at fast speed.

Dry Corn (< 20% moisture)

Initial Combine Setup

Concave

Rotor

RPM

Setting

Fan

Opening

Chaffer

Opening

Sieve

Opening

Chopper

Speed

Elevator

Boots

Tips

• Filler bars may be required for hard threshing cereals to eliminate

white caps. Order Concave Filler Kit #700958588 from your

dealer.

• If white caps persist, dealer should contact Technical Service Support

for additional kits required.

• A narrow wire-4 section concave option may be ordered from the

factory in lieu of the All Crop concave or from AGCO Parts for areas

predominately harvesting harder threshing cereals such as spring

wheat and canola. Order Narrow Wire Concave #71469348 from

your dealer.

1 2

250-300 0.6” - 0.8” 4 - 6

• Feed chains at slow speed for corn

Initial Header & Header Drive Setup

• Variable speed header drive hose and coupler should be connected.

• Right-hand pivot drive belt positioned on small countershaft drive

sheave and large driven pivot sheave.

Tips

• Use round end corn chaffer for higher moisture corn.

• A grain chaffer is optional and can be used for drier corn.

• Removal of lower sieve will increase capacity in corn.

0.625”

(16 mm)

0.4”

(11 mm)

Slow Solid

Page 4

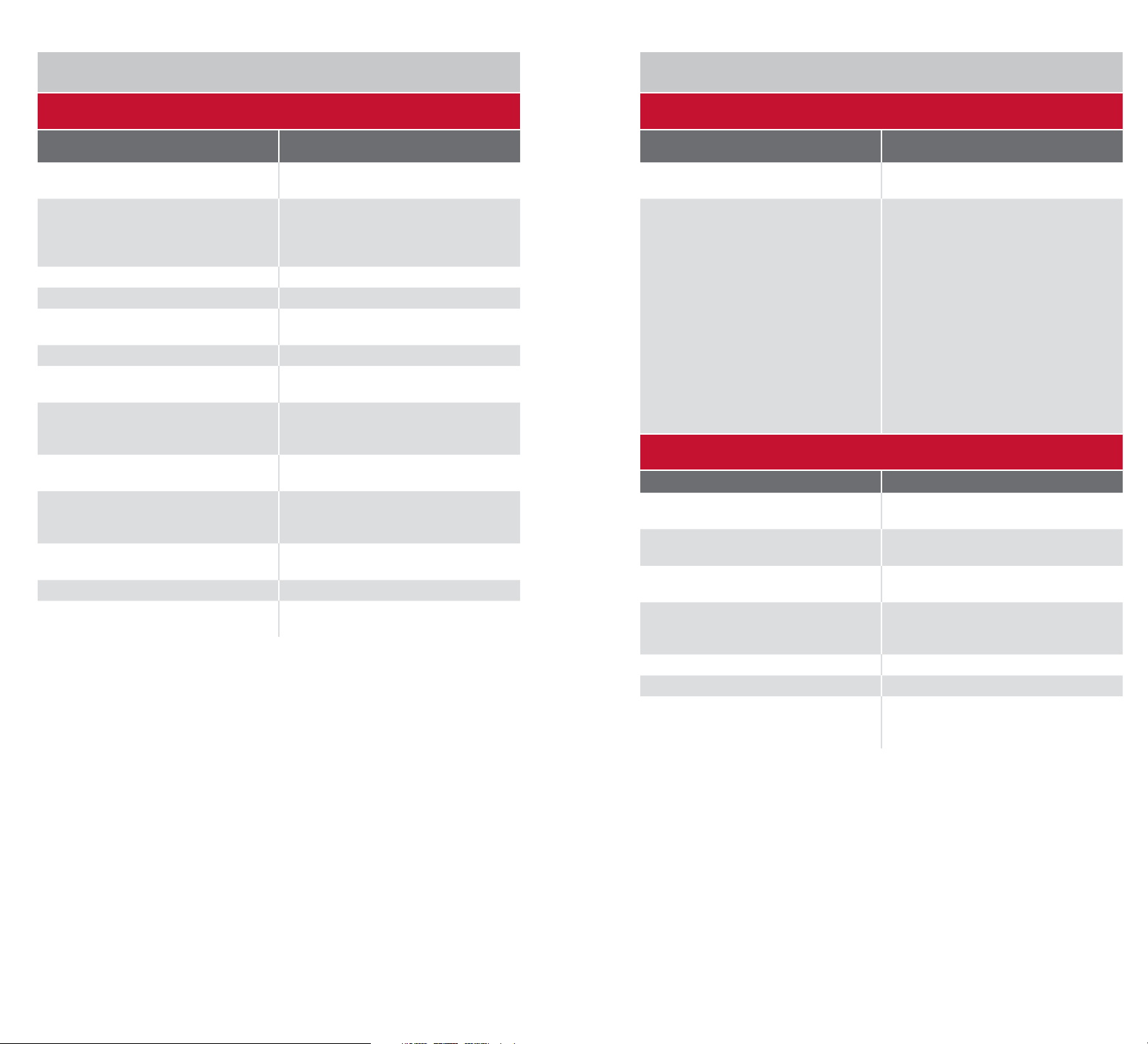

High Moisture Corn (> 24% moisture)

Soybeans

Initial Combine Setup

Concave

Rotor RPM

250-300 0.6” - 0.8” 4 - 7

• * IMPORTANT: Set chaffer to achieve acceptable grain bin sample.

Opening chaffer can be done anytime. However, due to the nature of

the electronics, closing the chaffer should be done at the end of the

eld after cleanout by completely opening and then closing to the

lower number that you desire and then adjusting up to the desired

chaffer setting.

• Feed chains at slow speed for corn.

Setting

Fan

Opening

Chaffer

Opening

0.625”

(16 mm) *

Sieve

Remove

lower

sieve

Opening

Chopper

Speed

Slow Solid

Elevator

Initial Header & Header Drive Setup

• Variable speed header drive hose and coupler should be connected.

• Right-hand pivot drive belt positioned on small countershaft drive

sheave and large driven pivot sheave.

Tips

• Use round end corn chaffer for higher moisture corn.

• Use grain chaffer for drier corn.

Initial Combine Setup

Concave

Boots

Rotor RPM

400 0.2” - 0.4” 3 - 6

Setting

Fan

Opening

Chaffer

0.75”

(19 mm)

Opening

Sieve

0.375”

(16 mm)

Opening

Chopper

Speed

Fast Perf.

Elevator

Boots

Initial Header & Header Drive Setup

• Release and adjust cutterbar on ex headers. Adjust header height

control.

• Variable speed header drive in slowest position.

• Right-hand pivot drive belt positioned on large countershaft drive

sheave and small driven pivot sheave.

Tips

• Round end corn chaffer can remain in combine for soybeans however,

grain quality will be negatively impacted. Standard chaffer will provide

higher grain quality.

3 4

Page 5

Canola/Rapeseed

Initial Combine Setup

Concave

Rotor RPM

Setting

• Feed chains (front and rear) should be in high position and fast speed.

• Angle pickup header down so pickup attachment and pickup header

auger can breakup clumps of crop material and more evenly feed the

feed chains and lower wind board accordingly.

Tips

Fan

Opening

Chaffer

Opening

Sieve

Opening

Chopper

Speed

Elevator

Boots

• During day in dry conditions, slow the rotor down; at night when

conditions are damp speed rotor up

450-600 0.2” - 0.4” 3 - 5

0.75”

(19 mm)

0.375”

(9 mm)

Fast Solid

Initial Header & Header Drive Setup

• Variable speed header drive (if equipped) in slowest position for draper

headers and direct cut headers.

• Right-hand pivot drive belt positioned on large countershaft drive

sheave and small driven pivot sheave.

• For pickup headers, speed up variable speed header drive (if

equipped) by 50%.

• Feed chains (front and rear) should be in high position and fast speed.

• Angle pickup header down so pickup attachment and pickup header

auger can breakup clumps of crop material and more evenly feed the

feed chains. Lower wind board accordingly.

Tips

• During day in dry conditions, slow the rotor down; at night when

conditions are damp speed rotor up

Millet

Edible Beans

Initial Combine Setup

Concave

Rotor RPM

190 - 230 0.3” - 0.4” 5 - 7

• Remove all reverse bars and replace with forward bars and remove

separator knives if installed.

Initial Header & Header Drive Setup

• Cutter Bar - In some crops, the material is direct cut so the header

should be set-up accordingly. In many cases, the crop is windrowed

and the material is harvested from the windrow.

• Variable speed header drive in slowest position.

• Right-hand pivot drive belt positioned on large countershaft drive

sheave and small driven pivot sheave.

Setting

Fan

Opening

Chaffer

0.75”

(19 mm)

Opening

Sieve

0.375”

(10 mm)

Opening

Chopper

Speed

Fast Solid

Elevator

Boots

Initial Combine Setup

Concave

Rotor RPM

525 0.2” - 0.3” 2 - 4

• While you can harvest millet with the All Crop convave, settings

are ideal with Narrow wire concave installed. Order Narrow Wire

Concave #71469348 from you dealer.

Setting

Fan

Opening

Chaffer

0.625”

(16 mm)

Opening

Sieve

0.187 5”

(5 mm)

Opening

Chopper

Speed

Fast Solid

Elevator

Boots

Tips

• Optional perforated boot covers on clean grain and tailings elevators

may be used if desired but, can cause cracking in certain conditions.

• Optional slow speed elevator kit may be used if desired. Order Slow

Speed Elevator Kit #71394759 from your dealer.

Additional Combine Setup

• If cracking of beans still occurs, remove all lugs on front accelerator

roll and leave lugs on rear accelerator roll to move crop. Lugs should

be reinstalled immediately for all other crops.

Initial Header & Header Drive Setup

• Variable speed header drive (if equipped) in slowest position for draper

headers and direct cut headers.

• Right-hand pivot drive belt positioned on large countershaft drive

sheave and small driven pivot sheave.

• For pickup headers, speed up variable speed header drive (if

equipped) by 50%.

5 6

Page 6

Sunowers

Grass Seed (Bluegrass, Bentgrass)

Initial Combine Setup

Concave

Rotor

RPM

350 0.4” 2 - 5

Setting

Fan

Opening

Chaffer

0.625”

(16 mm)

Opening

Sieve

0.25”

(6 mm)

Opening

Chopper

Speed

Fast Solid

Initial Header & Header Drive Setup

• Header must be equipped with sunower attachment to minimize head

and seed loss at the header.

• Variable speed header drive in slowest position.

• Right hand pivot drive belt positioned on large countershaft drive

sheave and small driven pivot sheave.

Additional Combine Setup

• May require additional Separator Blanking Kit #700961967 (3

blanks) will block off separator grates and level out shoe distribution.

Please have your dealer contact Technical Service Support.

Flax

Initial Combine Setup

Initial Combine Setup

Elevator

Boots

Rotor RPM

400 0.0” - 0.1” 0 - 1 **

* - If baling straw is preferred, order impeller if needed.

** - The Light Seed Kit #700959206 can be installed and used for grass

seed harvest but should be removed for any other crop.

Concave

Setting

Fan

Opening

Chaffer

0.75”

(19 mm)*

Opening

Sieve

0.1”

(2.5 mm)

Opening

Fast* Solid

Chopper

Speed

Elevator

Boots

Initial Header & Header Drive Setup

• Variable speed header drive in slowest position.

• Right hand pivot drive belt positioned on large countershaft drive

sheave and small driven pivot sheave.

Additional Combine Setup

• Completley block off leaf screen with plastic or cardboard.

• May require additional Separator Blanking Kit #700961967. This

will block off separator grates and level out shoe distribution.

• 2 additional reverse bars should be removed from separator side of

rotor (LH) and add 2 reverse bars on threshing side of rotor (RH).

• Have your dealer contact Technical Service Support for additional

adjustments required.

Concave

Rotor RPM

800 0.0” - 0.4” 3 - 5

Setting

Fan

Opening

Chaffer

0.625”

(16 mm)

Opening

Sieve

Opening

0.12 5”

(3.18 mm)

Chopper

Speed

Fast Solid

Elevator

Boots

Initial Header & Header Drive Setup

• Flax is generally windrowed and a pickup attachment is used on

header.

• Variable speed header drive in slowest position.

• Right-hand pivot drive belt positioned on large countershaft drive

sheave and small driven pivot sheave.

7 8

Page 7

Alfalfa

Clover

Initial Combine Setup

Concave

Rotor RPM

600 - 800 0.3” - 0.5” 3 - 6 **

* - If baling straw is preferred, order impeller if needed.

** - The Light Seed Kit #700959206 can be installed and used for alfalfa

seed harvest but should be removed for any other crop.

Setting

Fan

Opening

Chaffer

0.25” -

0.925”

(6 mm -

16 mm)

Opening

Sieve

0.1”

(2.5 mm)

Opening

Fast* Solid

Chopper

Speed

Elevator

Boots

Initial Header & Header Drive Setup

• Variable speed header drive in slowest position.

• Right hand pivot drive belt positioned on large countershaft drive

sheave and small driven pivot sheave.

Additional Combine Setup

• May require additional Separator Blanking Kit #700961967. This

will block off separator grates and level out shoe distribution. Please

have your dealer contact Technical Service Support.

Initial Combine Setup

Concave

Rotor RPM

700 - 900 0.0” - 0.1” 2 - 6 **

* - If baling straw is preferred, order impeller if needed.

** - The Light Seed Kit #700959206 can be installed and used for clover

seed harvest but should be removed for any other crop.

Setting

Fan

Opening

Chaffer

0.25” -

0.925”

(6 mm -

16 mm)

Opening

Sieve

0.1”

(2.5 mm)

Opening

Fast* Solid

Chopper

Speed

Elevator

Boots

Initial Header & Header Drive Setup

• Variable speed header drive in slowest position.

• Right hand pivot drive belt positioned on large countershaft drive

sheave and small driven pivot sheave.

Additional Combine Setup

• May require additional Separator Blanking Kit #700961967. This

will block off separator grates and level out shoe distribution. Please

have your dealer contact Technical Service Support.

Rye

Initial Combine Setup

Concave

Rotor RPM

600 0.2” 3 - 5

Initial Header & Header Drive Setup

• Variable speed header drive in slowest position.

• Right hand pivot drive belt positioned on large countershaft drive

sheave and small driven pivot sheave.

Setting

Fan

Opening

Chaffer

0.75”

(19 mm)

Opening

Sieve

0.2”

(5 mm)

Opening

Chopper

Fast Solid

Speed

Elevator

Boots

9 10

Page 8

Troubleshooting

Header

Header

Ragged and uneven cutting of crop

Possible Cause Correction

Cutting mechanism not operating at

recommended speed.

Reel speed too slow for ground speed. Increase reel speed.

Reel height too high. Lower reel.

Reel position is either too far forward or

too far back on reel arms.

Header not level. Level header.

Guards are bent or broken. Straighten or replace guards.

Upper lips of guards bent causing poor

shearing action.

Sickle not contacting guards.

Sickle hold down clips worn or not

adjusted properly.

Too much fore and aft looseness

between sickle back and guards.

Bent or twisted sickle. Straighten or replace sickle assembly.

Ground speed too fast. Reduce ground speed.

Flex cutter bar hanging up.

Flex header height sensor on rockshaft

not set the same.

Rockshaft binding (flex header) Free rockshaft.

Insufficient ground pressure from flex

cu t ter b a r.

Flex cutter bar tilted up too much at the

front.

Intermittent signal for automatic header

height control flex header.

Check basic speed of combine and

check header drives.

Adjust reel position so reel bats hold

grain leaning slightly into sickle.

Adjust upper lips of guards so they are

parallel to lower shear edge of guard.

Adjust sickle so tips of sickle sections

rest lightly on guards.

Replace worn hold down clips and

adjust clips.

Adjust wear plates.

Check flex arms, filler panels (at ends

of headers) and stabilizers for freedom

of movement and correct any binding.

Readjust sensor as outlined in header

Operator Manual.

Increase ground pressure by

decreasing spring tension on flex arms.

Tilt cutter bar down so skid pads are

parallel to the ground.

Clean corrosion and paint from

contacts on switches. Check for good

connectiion at harness disconnects.

Check for broken wires in harness.

Shattering of grain ahead of cutter bar

Possible Cause Correction

Reel speed not coordinated with

ground speed.

Ground speed too fast for condition of

crop.

Reel height too low. Raise reel.

Change reel speed to coordinate with

ground speed.

Decrease ground speed.

Loss of grain heads and cut crop at cutter bar

Possible Cause Correction

Reel not low enough. Lower reel.

Conveyor clearance too high from

header bottom.

Conveyor fingers retracting too early. Adjust fingers close to header bottom.

Cutting with header too high, cutting

stalks too short for proper delivery.

Reel speed too low. Increase speed of reel.

Reel incorrectly positioned on reel

arms.

Conveyor flights worn. Replace conveyor flighting.

Lower conveyor.

Lower header.

Position reel closer to header conveyor.

Guards plugging

Possible Cause Correction

Sickle sections not contacting guards.

Missing or worn sickle sections. Replace sickle sections.

Reel not adjusted to provide smooth

flow of material into header conveyor.

Guards bent or broken. Straighten or replace guards.

Cutter bar tilted down too much. Tilt cutter bar up.

Bent or twisted sickle. Straighten or replace sickle assembly.

Ground speed too fast. Reduce ground speed.

Skid pads binding (flex header).

Flex cutter bar too heavy.

Flex header height too low.

Dirt on skid pads (flex header). Clean dirt off skid pads.

Adjust sickle so tips of sickle section

rest lightly on guards.

Refer to Operator Manual for best

starting position and adjust reel

height, reel speed and reel fore and

aft position for even flow. Straighten or

replace guards.

Check that skid pad splice brackets are

not binding skid pads.

Decrease ground pressure by

increasing spring tension on flex arms

where plugging is occurring.

Move selection to higher cutting

position.

11 12

Page 9

Header

Header

Crop bunching on cutter bar

Possible Cause Correction

Reel too high. Lower reel.

Reel too far forward. Set reel back.

Reel speed too slow. Increase reel speed.

Sticky header pan. Remove dirt, gum or rust.

Conveyor too high. Lower header conveyor.

Worn conveyor flighting. Replace flighting.

Conveyor fingers retracting too early.

Conveyor not operating at

recommended speed.

Adjust fingers as close to header

bottom as possible.

Check header drive. Check basic

speed of combine and conveyor.

Excessive vibration of cutting parts

Possible Cause Correction

Cutting mechanism not at

recommended speed.

Excessive looseness of cutting parts

and sickle drive.

Drive idler shock absorber worn. Replace shock absorber.

Pickup reel tines entering sickle. Raise reel with fine height adjustment.

Drive tires improperly inflated.

Header not secured to feeder house.

Stabilizers loose at anchors (flex

header).

Loose or broken cutter bar or flex arm

attaching bolts (flex header).

Check basic speed of combine.

Remove all excessive play from cutter

bar and sickle drive to eliminate

vibration.

Inflate tires to recommended tire

pressure.

Check lower header hooks are secure

and spring latch is properly seated in

hooks.

Tighten bolts holding the stabilizer

anchors to the header guard angle and

to the cutter bar assembly. Tighten

wobble box stabilizer attaching bolts.

Tighten or replace all bolts attaching

cutter bar to header and flex arms.

Reel wrapping in tangled and weedy crops

Possible Cause Correction

Place reel ahead and down. Make sure

Incorrect location of pickup reel.

Reel speed too fast. Reduce speed of reel.

Pickup reel tines pitched too much to

rear.

Pickup reel tines bent. Replace or straighten tines.

Crop not divided at header ends. Install or adjust long dividers.

Reel ends wrapping.

reel tines clear the sickle with reel in

lowest position.

Adjust tine pitch.

Install reel end shields (Flex header).

Install Reel Divider Kit #700957021

(Dynaflex)

Raise reel to reduce amount of straw

gathered by reel.

Crop wrapping on header conveyor (Flex Header)

Possible Cause Correction

Conveyor too high or too low. Adjust conveyor height.

Uneven feed to conveyor. Adjust reel speed and/or location.

Conveyor finger retracting too early or

conveyor fingers too late

Adjust position of conveyor fingers.

13 14

Page 10

Header

Header conveyor plugging or material not moving from center

of conveyor into front feed chain (Flex Header)

Possible Cause Correction

Straw retarder clearance from conveyor

flight too great.

Reel not adjusted to provide smooth

flow of material into header conveyor.

Conveyor fingers retracting too early or

too late.

Insufficient lean in header conveyor

flighting.

Straw retarder clearance from conveyor

flight too great.

Conveyor too far forward or too far to

rear.

Conveyor too high or too low. Adjust conveyor height.

Feeder chains not moving material.

Crop wrapping on Dynaflex header center conveyor auger

Possible Cause Correction

Wrapping in damp, green-stem

soybeans.

Adjust straw retarder.

Adjust reel height. Adjust reel speed

and flow of material into header

conveyor reel fore and aft position for

even flow.

Adjust position of conveyor fingers for

best material flow.

Conveyor flighting should have slight

lean toward center of conveyor.

Using carpenter’s square against

conveyor tube. Flighting should lean

approximately 0.5” (12.7 mm) toward

center of conveyor.

Adjust straw retarder closer to flight.

Adjust conveyor fore and aft position.

Move front feed chain drum forward

away from header consistently.

Install Auger Filler Kit.

Feed Conveyor

Feeder chains plugging or wrapping

Possible Cause Correction

Refer to previous section on HEADER or

Uneven feed from header.

Improper feed chain speed.

Feeder chain drum stops set too low. Adjust feeder drum stops.

Dirt between front and rear feed chains. Clean out dirt.

Front feeder chain drive slip clutch set

too loose.

Worn or damaged cylinder bars. Replace thresher cylinder bars.

Concave clearance too wide.

Feeder chain slats bowed or missing.

Material entering into the outer ends of

front chain slats.

Front feeder chains plugging in extreme conditions

Possible Cause Correction

Front feed chain grabbing crop, but not

releasing to the rear feed chain.

Too much material entering combine

Possible Cause Correction

Cutting too low in order to get all down

and tangled crops.

CONVEYOR PLUGGING (PG. 15) condition

for header performance checks.

Check feed chain drive sheave

installation with grain header belts

driving off larger sheave diameter. With

corn header, belts driving off smaller

sheave diameter.

Check clutch assembly for worn or

broken parts.

Reduce concave clearance and then

speed if cracking occurs.

Straighten or replace bent or missing

slats.

Adjust straw retarders toward center of

header, then install fairing extensions.

Remove every other center slat.

Use lifting guards or pickup reel in

down and tangled conditions.

Uneven or bunched feeding of crop to cylinder

Possible Cause Correction

Uneven feed to cylinder.

15 16

Refer to previous listed feeding

problems.

Page 11

Processor

Processor

Slugging or overloading of cylinder

Possible Cause Correction

Engine not up to correct speed.

Cylinder drive belt slipping.

Too much material entering cylinder. Reduce ground travel speed.

Cylinder bars worn or damaged. Replace cylinder bars.

Concave twisted, worn excessively or

damaged.

Concave plugged with mud or dirt, etc. Clean concave.

Cage helical bars worn or damaged.

Cage door assembly not aligned.

Cylinder discharge paddles worn or

damaged.

Discharge impeller or straw chopper

drives slipping.

Uneven feed to cylinder.

Crop too damp or green. Wait for crop conditions to improve.

Crop extremely difficult to convey.

Adjust engine high idle to proper

speed.

Check condition of belt and replace or

clean if it becomes worn or oily. Check

and lubricate gearbox input torque

sensor mechanism.

Repair concave.

Repair helical bars and be sure they are

properly aligned.

Align door assembly by adjusting

alignment bolts to form a smooth inner

surface in the cage.

Replace discharge paddles.

Repair by checking and replacing worn

belts and damaged sheaves. Adjust

belt tensions.

Refer to section on UNEVEN OR BUNCHED

FEEDING (PG. 16).

Install edible bean kit across the cage.

(Such as edible beans and sunflowers).

Cylinder vibration

Possible Cause Correction

Dirt and material stuck to inside of

cylinder bars.

Vibration caused by cylinder drive.

Clean material from inside of cylinder

bars.

Place cylinder drive gearbox in neutral

and operate cylinder drive through its

variable speed range to determine if

vibration is still present. If so, check the

following:

1. V/S drive and driven sheaves for

condition and balance.

2. V/S cylinder drive belt.

3. Cylinder drive torque sensor, and

cylinder drive gearbox bearings and

gears.

Make sure to place gearbox back in

High or Low gear.

Grain loss from cylinder

Possible Cause Correction

Engine not up to correct speed.

Insufficient material entering cylinder.

Uneven feed to cylinder.

Cylinder speed too high or too low.

Insufficient threshing at concave. Decrease concave clearance.

Grain not coming out of cage. Install two extra reverse cylinder bars.

Excessive loss out of discharge

Adjust engine high idle to proper

speed.

Increase ground speed for more intake

of material (corn only).

Refer to section on UNEVEN OR BUNCHED

FEEDING (PG. 16).

Try various cylinder speeds to

determine optimal speed for threshing

and separating.

Remove helicals bolted to rear

separator door (milo & high moisture

corn).

17 18

Page 12

Grain quality

Grain quality

Excessive cracked grain in grain tank

Possible Cause Correction

Crop too damp or green. Wait for crop conditions to improve.

Cylinder speed too fast for crop grain

cracking but still do a good job.

Uneven feeding or slugs entering

cylinder.

Engine not up to correct speed. See your dealer.

Concave not level. Level concave to cylinder.

Insufficient material entering cylinder.

Dented conveyor housings, bent

conveyor shafts or worn conveyor

flighting.

Concave clearance too close. Increase concave clearance.

Excessive tailings return.

Grain remains in cage too long. Remove concave filler bars.

Excessive feed chain speed.

Worn cylinder bars. Replace cylinder bars.

Kernel moisture too high. Wait for crop to mature.

Decrease cylinder speed just enough to

stop threshing.

Refer to section on UNEVEN OR BUNCHED

FEEDING (PG. 16).

Increase ground speed for more intake

of material.

Check each conveyor in the combine

and header and correct. Remove

dents from conveyor housings to

achieve adequate clearance with auger.

Straighten or replace bent conveyors.

Repair or replace conveyors with worn

or damaged conveyor flighting.

Adjust the cleaning shoe to reduce

tailings. On combines equipped with

optional tailings return, adjust handle to

return tailings to distribution augers.

Check feed chain drive sheave

installation on right-hand end of feeder

countershaft. With grain header, belts

driving off larger sheave diameter. With

corn header, belts driving off smaller

sheave diameter. V/S header drive must

be locked into low speed position when

operating grain header.

Grain not threshed from heads or shelled from cob or pod

Possible Cause Correction

Decrease concave clearance and

Concave clearance too great.

Cylinder speed too slow.

Concave not level. Level concave to cylinder.

Uneven feed to cylinder.

Insufficient material entering cylinder.

Cylinder bars worn or damaged. Replace cylinder bars.

Cylinder not aggressive enough. Replace cylinder bars.

Concave extremely worn or damaged. Replace concave.

Crop very difficult to thresh.

adjust cylinder speed to prevent

cracking.

Increase cylinder speed enough to do

good job of threshing. Do not increase

speed to point where grain cracking is

excessive.

Refer to section on UNEVEN OR BUNCHED

FEEDING (PG. 16).

Increase ground speed for more intake

of material.

Install concave fillers. On combines

equipped with optional tailings return,

adjust handle to return tailings to

cylinder.

Material lodging outside of cage

Possible Cause Correction

Crop condition.

Material not being delivered by

distribution auger.

Cylinder speed too high. Decrease cylinder speed.

Cylinder bars or helical bars worn. Replace cylinder bars or helical bars.

Concave plugged with mud or dirt, etc. Clean concave.

Cylinder discharge metal paddles worn

or missing.

Discharge impeller or straw chopper

drives slipping.

Concave clearance too close.

Separator grate cover needed.

Vertical helical bar closest to chopper.

Plugging only on front top of cage

normal in some conditions.

Check and repair drive for belt

slippage.

Repair discharge.

Repair by checking and replacing worn

belts and damaged sheaves. Adjust

belt tensions.

Increase clearance (maximum

recommended clearance 0.75” (19

mm)).

Install the separator grate cover on the

separator grate.

Remove vertical helical bar closest to

chopper (soybeans & wheat in some

conditions).

19 20

Page 13

Grain quality

Grain quality

Foreign material in clean grain

Possible Cause Correction

Engine not up to correct speed.

Separator drive belt, fan drive belt, or

cleaning shoe drive belt slipping.

Missing or plugged fan inlet screen. Clean or reinstall fan inlet screen.

Uneven feed to cylinder.

Insufficient material entering cylinder.

Incorrect chaffer for crop being

harvested.

Insufficient air blast from cleaning fan. Increase fan choke setting.

Sieve opening too wide.

Uneven opening of sieve or chaffer

louvers.

Chaffer opening too wide.

Finishing sieve required for crop and

crop conditions.

Excessive tailings allowing uneven

distribution of material on the cleaning

shoe.

Cleaning shoe overloaded due to over

threshing.

Excessive cob breakage from cage.

Adjust engine high idle to proper

speed.

Inspect drives, replace any damaged

belts and adjust idlers as required.

Refer to section on UNEVEN OR BUNCHED

FEEDING (PG. 16).

Increase ground speed for more intake

of material.

Round end, shallow tooth 1.125” (28.6

mm) spacing - generally used in corn

but has also been found to provide

desired cleaning in some crops such

as soybeans and high moisture cereal

grains where more air volume is

desired.

Square end, deep tooth 1.625” (41.3

mm) spacing - generally used in high

moisture corn to remove pieces of cob

from the tank sample.

Consider increasing air, then decrease

sieve opening in 0.06” (1.6 mm)

increments.

Straighten louvers or replace sieve or

ch af fer.

Consider increasing air, then decrease

sieve opening in 0.06” (1.6 mm)

increments.

A number of finishing sieves are

available and can be used to provide

best clean in crops such as soybeans

and small or light seeds.

Refer to EXCESSIVE TAILINGS (PG. 23)

condition section.

Refer to remedies listed under

MATERIAL LODGING OUTSIDE OF CAGE (PG.

20).

Optimize concave setting and cylinder

speeds.

Sieves plugging with straw and chaff

Possible Cause Correction

Insufficient air blast from cleaning fan. Increase fan choke setting.

Consider increasing air, then decrease

Sieve opening too wide.

Chaffer opening too wide.

Missing or improperly installed fan inlet

screen.

Shutting down machine before it has

cleaned out.

Incorrect chaffer for crop being

harvested.

Incorrect air pattern.

sieve opening in 0.06” (1.6 mm)

increments.

Decrease chaffer opening in 0.06” (1.6

mm) increments.

Properly install all fan inlet screens.

Allow crop to pass through and clear

machine before disengaging separator.

Round end, shallow tooth 1.125” (28.6

mm) spacing - used in all crops except

corn. Round end, deep tooth 1.625”

(41.3 mm) spacing - generally used

in corn but has also been found to

provide desired cleaning in some crops

such as soybeans and high moisture

cereal grains where more air volume is

desired.

Square end, deep tooth 1.625” (41.3

mm) spacing - generally used in high

moisture corn to remove pieces of cob

from the grain tank sample.

Inspect fan, fan choke, shoe air duct

and splitter location.

21 22

Page 14

Grain loss

Grain loss

Excessive tailings

Possible Cause Correction

Insufficient sieve opening.

Insufficient air blast from cleaning fan. Increase fan choke setting.

Chaffer opening too wide.

Cleaning shoe overloaded due to over

threshing.

Increase sieve opening in 0.06” (1.6

mm) increments.

Consider increasing air, then decrease

chaffer opening in 0.06” (1.6 mm)

increments.

Refer to remedies listed under

MATERIAL LODGING OUTSIDE OF CAGE (PG.

20) condition.

Grain loss over cleaning shoe

Possible Cause Correction

Engine not up to correct speed.

Separator drive belt, fan drive belt or

cleaning shoe drive belt slipping.

Plugged fan inlet screen. Clean screen.

Uneven feed to cylinder.

Insufficient material entering cylinder.

Material plugging fan choke and/or fan.

Insufficient chaffer opening.

Adjust engine high idle to proper

speed.

Inspect drives, replace any damaged

belts as required and adjust idlers.

Refer to section on UNEVEN or BUNCHED

FEEDING (PG. 16).

Increase ground speed for more intake

of material.

Clean fan choke and fan. Be sure fan

inlet screens are installed.

Increase chaffer opening in 0.06” (1.6

mm) increments.

Grain loss can be caused by too little or

too much air volume.

Grain loss over cleaning shoe (cont.)

Possible Cause Correction

Round end, shallow tooth 1.125” (28.6

mm) shoe spacing - used in all crops

except corn.

Round end, deep tooth 1.625” (41.3

mm) spacing - generally used in corn

but has also been found to provide

Incorrect chaffer for crop being

harvested.

Incorrect air pattern.

Grain loss present when entering and/

or leaving the crop.

desired cleaning in some crops such

as soybeans and high moisture cereal

grains where more air volume is

desired.

Square end, deep tooth 1.625” (41.3

mm) spacing - generally used in high

moisture corn to remove pieces of cob

from the grain tank sample.

Inspect fan, fan choke, shoe air duct

and splitter location.

This situation is usually normal because

the cleaning system should be adjusted

to provide min. grain loss when in a

fully loaded condition.

If grain and material is falling off rear

edge of chaffer in piles or bunches, air

Incorrect fan choke setting.

Harvesting in damp freezing weather. Wait for suitable harvest conditions.

Improper distribution of material on

cleaning shoe - excessive tailings.

Cleaning shoe overloaded due to over

threshing.

23 24

volume is too low and fan choke setting

should be increased.

If grain is being blow out and can be

caught approximately 12” (30.5 mm)

behind end of chaffer, fan choke setting

should be decreased.

Refer to EXCESSIVE TAILINGS (ABOVE)

condition section.

Refer to remedies listed under

MATERIAL LODGING OUTSIDE OF CAGE (PG.

20) condition. Adjust separator grate to

#9 condition.

Page 15

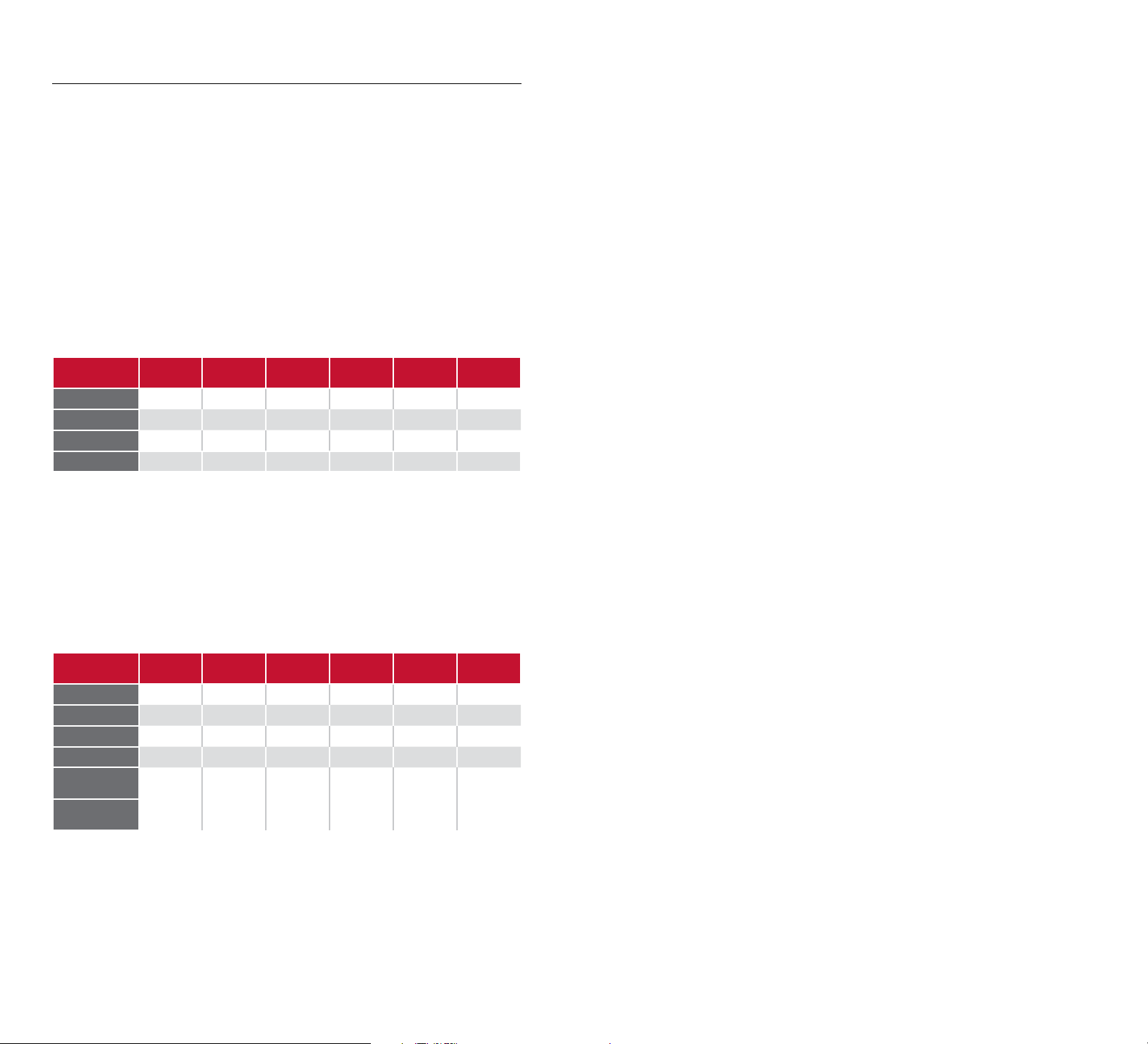

Loss Calculation

“Quick check” for combine grain loss

Spreading discharge

Grain loss calculated per square foot across the entire eld.

To perform a quick estimate for total grain loss from the combine, count

the number of seeds found in a square foot behind the combine. Determine

the quantity of loss in at least three places throughout the eld to arrive at

an average.

• Remember to subtract any pre-harvest loss, grain loss caused by the

header, or loss due to combine leaks in the eld!

Use TABLE 1 below to determine grain loss in bushels per acre.

TABLE 1 - SEED COUNT PER SQUARE FOOT

Rotor loss

1. Remove the straw spreader, the chaff spreader and raise the shoe

tailboard so that shoe and rotor discharge remain separate.

2. Count the grain in a one-foot run of the rotor discharge path, which is

24 inches wide to ensure that all grain is counted.

• Remember to subtract any pre-harvest loss, grain loss caused by

the header, or loss due to combine leaks in the eld!

• Use TABLE 2 on the previous page to determine total grain loss

from the rotor.

ROTOR LOSS EX AMPLE: a wheat farmer has a 40-foot wide header.

He removes the straw spreader, the chaff spreader, and raises the shoe

tailboard. He counts a total of 12 0 kernels of wheat in the rotor discharge

path (2 feet wide and 1 foot long). With a 40-foot header, it takes 760

kernels counted to equal one bushel loss, so 120 ÷ 76 0 = 0 .16 bushels lost

per acre from the rotor.

15 ft. 20 ft. 25 ft. 30 ft. 35 ft. 40 ft.

Wheat

Corn

Soybeans

Canola

19 19 19 19 19 19

2 2 2 2 2 2

5 5 5 5 5 5

111 111 111 111 111 111

“Next step” for combine grain loss

If it is determined in the “quick check” that combine harvest loss is

unacceptable, it is critical to determine the quantity of loss due to the rotor and

the quantity due to the shoe.

Follow the steps below to estimate grain loss from the rotor and the shoe.

TABLE 2 - CALCULATED LOSS IN TOTAL GRAIN PER SWATH

15 ft. 20 ft. 25 ft. 30 ft. 35 ft. 40 ft.

Wheat

Corn

Soybeans

†

Canola

Canola by

Weight (g)

Canola by

Volume (mL)

285 380 475 570 665 760

30 40 50 60 70 80

75 100 125 150 175 200

1665 2230 2775 3330 3885 4440

7.8 10.4 13.0 15.6 18.2 20.8

18 24 30 36 42 48

Shoe loss

1. Remove the straw spreader, the chaff spreader and raise the shoe

tailboard so that shoe and rotor discharge remain separate.

2. Count or weigh the grain in a one-foot run of the shoe discharge path,

which is effectively ve feet, to ensure that all grain is counted.

• Remember to subtract any pre-harvest loss, grain loss caused by

the header, or loss due to combine leaks in the eld!

• Use TABLE 2 on the previous page to determine total grain loss

from the shoe.

SHOE LOSS EXAMPLE: a corn farmer has a 12-row, 30-inch corn head,

which equals a 30 foot swath. He removes the straw spreader, the chaff

spreader, and raises the shoe tailboard. He counts a total of 28 kernels of

corn in the path behind the shoe (5 feet wide and 1 foot long). With a 30foot header, it takes 60 kernels of corn to equal one bushel loss,

so 28 ÷ 60 = 0.47 bushels lost per acre from the shoe.

If time does not allow for quantifying the grain over the full width of the shoe,

individual square foot quantities can be averaged, and multiplied by 5 to

compare with TABLE 2 on the previous page.

† Canola shown in weight and volume due to the large quantity of seeds

required to equal 1 bushel of loss.

25 26

Page 16

“Advanced” grain loss calculation procedure

For the most accurate determination of grain lost through the combine

harvester, grain must be “caught” directly from the rotor discharge separately

from grain “caught” from the shoe discharge, and weighed.

TABLE 3 - CALCULATED LOSS IN TOTAL WEIGHT OF GRAIN PER SWATH

15 ft. 20 ft. 25 ft. 30 ft. 35 ft. 40 ft.

Wheat (g)

Corn (g)

Soybeans (g)

Canola (g)

Canola by

Volume (mL)

Advanced rotor loss

1. Remove the straw spreader, the chaff spreader and raise the shoe

tailboard so that shoe and rotor discharge remain separate.

2. Use a pan, measuring one foot long and six feet wide to “drop” directly

in front of the rotor discharge

• Make sure that the pan dropped does not include any grain lost

3. Sort out the grain from the rest of the material, and weigh the grain.

• Remember to subtract any pre-harvest loss, grain loss caused by

• Use TABLE 3 above to determine total grain loss from the rotor.

ADVANCED ROTOR LOSS EXAMPLE: a canola farmer has a 30-foot wide

header. He removes the straw spreader, the chaff spreader, and raises the shoe

tailboard. He measures a total of 6 grams in the rotor discharge path (from the

“drop” pan). With a 30-foot header, it takes 15.6 grams weighed to equal one

bushel loss, so 6 ÷ 15.6 = 0.38 bushels lost per acre from the rotor.

Advanced shoe loss

1. Remove the straw spreader, the chaff spreader, and raise the shoe

tailboard so that shoe and rotor discharge remain separate.

2. Use a pan, measuring one foot long and six feet wide to “drop” directly

in front of the shoe discharge.

• Make sure that the pan dropped does not include any grain lost

9.3 12.4 15.5 18.6 21.7 24.8

8.4 11. 2 14. 0 16.8 19.6 22.4

9.3 12.4 15.5 18.6 21.7 24.8

7.8 10.4 13.0 15.6 18.2 20.8

18 24 30 36 42 48

from the shoe discharge

the header, or loss due to combine leaks in the eld!

from the rotor discharge.

Standard Payable Moisture & Density Chart

Crop

Alfalfa 12.0 60 27

Barley 14.0 48 22

Canola 10.0 52 24

Corn 15.5 56 25

Edible Beans 14. 5 60 27

Flax 7.0 56 25

Grass Seeds 12.0 22 10

Lentils 10.5 60 27

Millet 11. 0 50 23

Mustard 8.0 60 27

Navy Beans 14. 5 62 28

Oats 14.0 32 15

Peas (Black-Eyed) 12.0 60 27

Peas (Field) 10.5 60 27

Popcorn (Yellow) 14.0 60 27

Popcorn (White) 14.0 60 27

Rape Seed 10.0 52 24

Rice (Long) 14.0 45 20

Rice (Medium) 14.0 45 20

Rye 14.0 56 25

Safflower 6.0 45 20

Sorghum 13.0 56 25

Soybeans 13.0 60 27

Sunflower (Oil) 14.0 25 11

Sunflower (Stripe) 14 .0 28 13

Wheat (Durham) 13.0 60 27

Wheat (HrdRdSpr) 13.0 60 27

Wheat (HrdRdWtr) 13.0 60 27

Wheat (SftRdWtr) 13.0 60 27

Wheat (White) 13.0 60 27

Standard

Moisture (%)

Crop

Density (lbs./

bu.)

Crop

Density (kg/

bu.)

• Sort out the grain from the rest of the material, and weigh the grain.

3. Remember to subtract any pre-harvest loss, grain loss caused by the

header, or loss due to combine leaks in the eld!

• Use TABLE 3 above to determine total grain loss from the rotor.

ADVANCED SHOE LOSS EX AMPLE: a soybean farmer has a 35-foot header.

He removes the straw spreader, the chaff spreader, and raises the shoe

tailboard. He measures a total of 10 grams in the path behind the shoe (from

the “drop” pan). With a 35-foot header, it takes 21.7 grams to equal one bushel

loss, so 10 ÷ 21.7 = 0.46 bushels lost per acre from the shoe.

26 27

Page 17

Page 18

AGCO • 4205 River Green Parkway, Duluth, GA 30 096 • Fax 770.813.6038 • gleanercombines.com

AGCO may at any time, and from time to time, for technical or other necessary reasons, modify any of the

data, specications or warranty of the products described herein. Some equipment shown may be optional.

Attention: Photographs in this publication may show protective shields or guards open or removed for the

purposes of illustration. Be cer tain all shields and guards are in place during operation.

AGCO & Gle aner are registe red tra demar ks of AGCO Co rporation • © 2015 AGCO • GL14P042ST (01) 1.2 PD

Loading...

Loading...