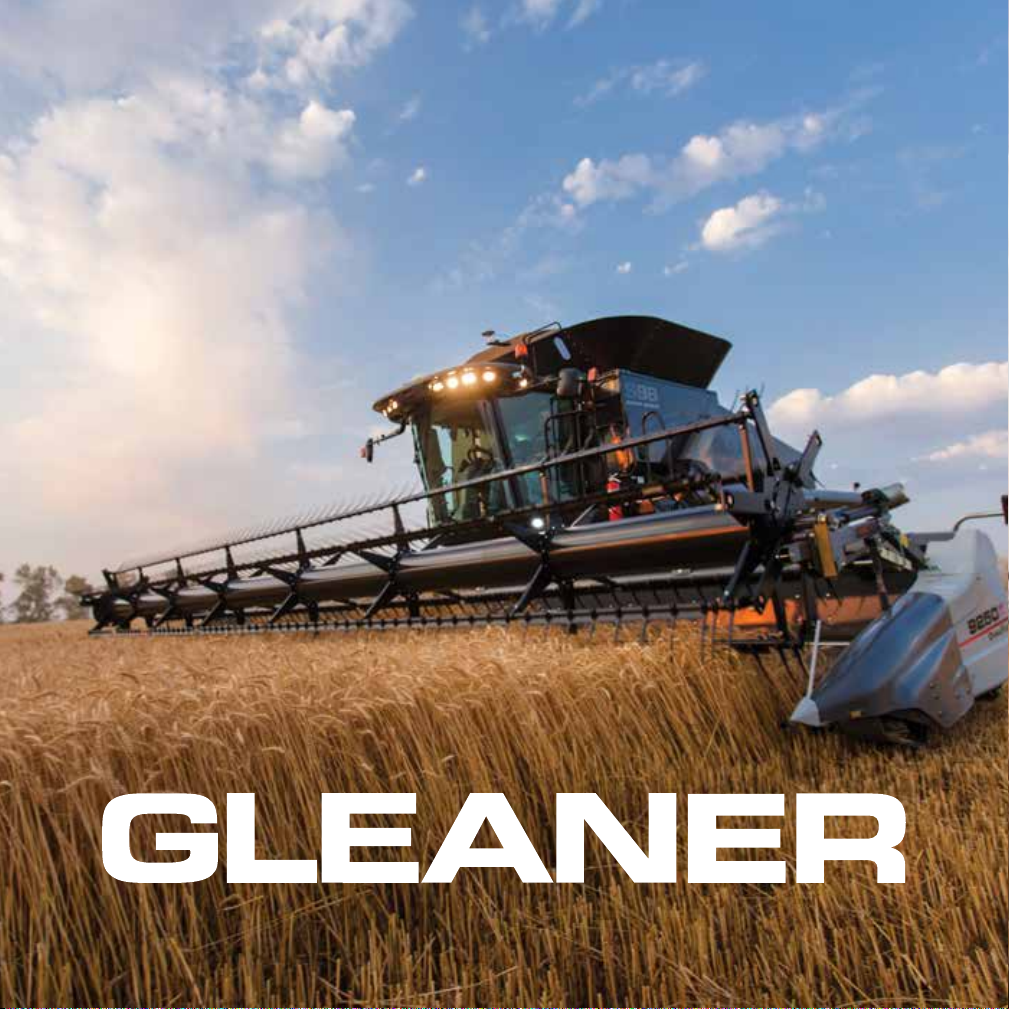

Gleaner GL S68, CIH 6130, CIH 6140, GL S78, CIH 7230 User Manual

...

Transverse vs. Axial Competitive Comparison

New DuraGuard two-speed rotor gearbox

New AGCO Power Engines

The S68 features a new twin turbocharged fuel-efficient, high-torque

8.4L AGCO Power engine delivering 322 rated horsepower and

maximum boost horsepower of 398 horsepower.

The S78 features a new twin turbocharged, fuel-efficient, hightorque 9.8L AGCO Power engine delivering 375 rated horsepower

and an awesome maximum boost horsepower of 451 horsepower.

The S88 features the same twin turbocharged, fuel-efficient high-torque 9.8L

AGCO Power engine delivering 430 rated horsepower and maximum boost

horsepower of 471 horsepower.

New XR two-speed hydro transmission

All S8 models feature an optional XR™ two-speed hydro feature that

provides greater climbing ability on hills and convenient on the go shifts.

The two-speed on the go shift is operated by a convenient push button

from the right-hand console. The two-speed hydro features a 30% larger

hydro motor.

All S8 models feature a newly designed heavy-duty DuraGuard™ twospeed rotor gearbox with larger sheave, bearings and belt built for

the higher demands of the S88 machine. It features a wider overlap

on rotor speeds and lets operators run on the high side of the

low range in a lot of crops for maximum efficiency. It also features

reversing capability.

New 230-gallon fuel capacity

All S8 models feature a new 230-gallon fuel tank,

a 53% increase to keep you in the field longer

between fill-ups for more productivity.

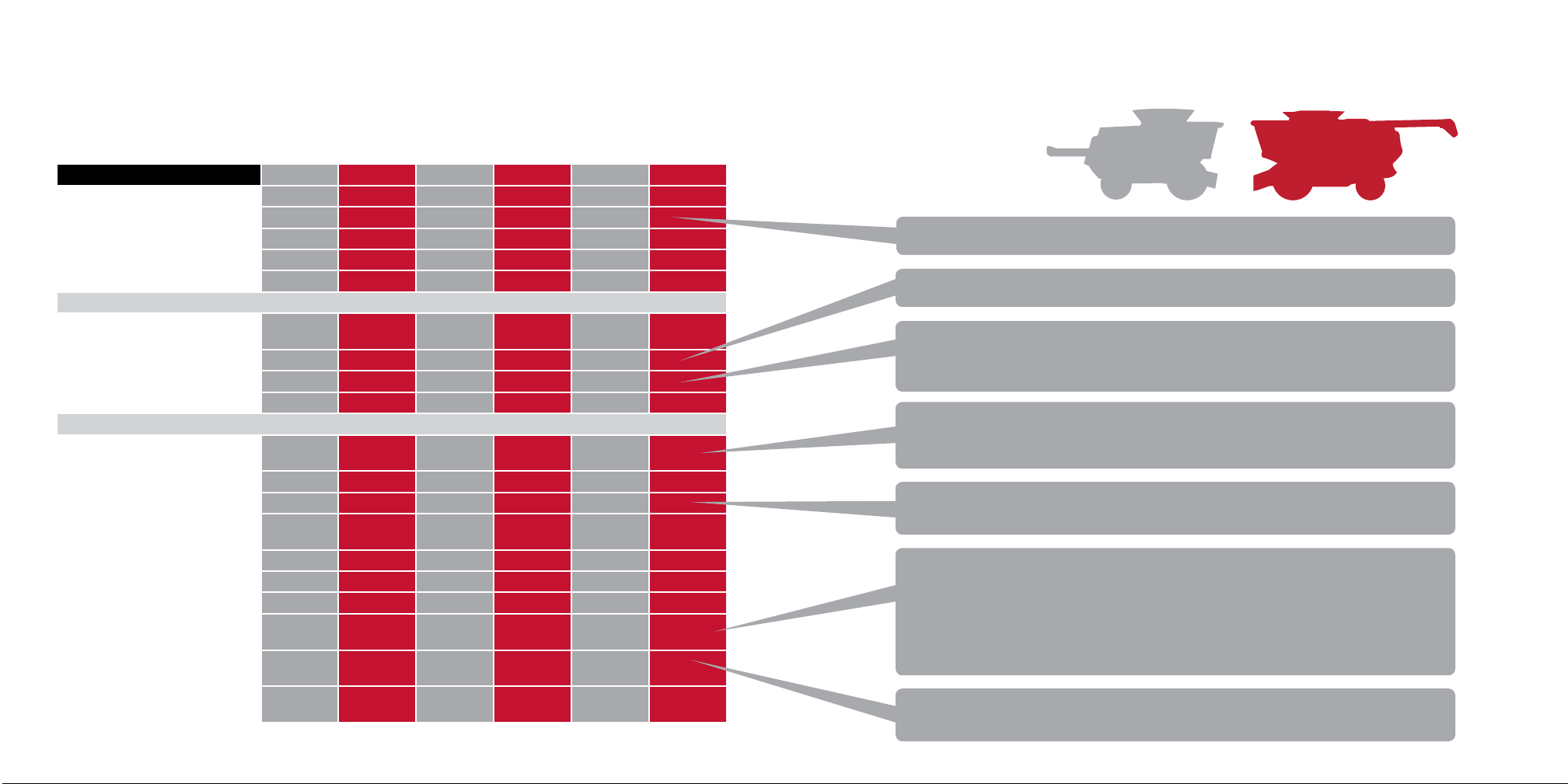

Gleaner vs. Case IH

Make/Model GL S68 CIH 6130 GL S78 CIH 723 0 GL S8 8 CIH 82 30

Class 6 6 7 7 8 8

Horsepower (hp) 322 320 375 380 430 450

Maximum boost horsepower (hp) 398 380 4 51 440 471 510

Engine displacement (L) 8.4 8.7 9.8 8.7 9.8 12.9

Rated speed (rpm) 2,1 0 0 2,1 0 0 2,10 0 2,1 0 0 2,10 0 2,1 0 0

Cooling System

Maintenance

Cleaning required No Yes No Yes No Ye s

Variable fan pitch feature available Yes No Yes No Ye s No

Average power savings @ 80°F (hp) 36 None 36 None 36 None

Processor

Rotor length (in) 90 102.8 90 10 3.3 90 110

Degrees of threshing/separation 360 156 360 180 360 180

Threshing & separation area (in²)

Cleaning area (in²) 7,729 7, 9 4 7 7, 7 2 9 10,075 7,7 2 9 10,075

Cleaning method Two-stage Single-stage Two-stage Single-stage Two-stage Single-stage

Accelerator roll technology Yes No Yes No Yes No

% of cleaning performed on shoe

Slope sensitivity

Approx. power required for straw

chopper (hp)

Reverse

Cooling fan

Natural Flow

Typ e

Feeding

6,0 47 Not

66% @ rolls;

34% @ shoe

No, up to

23+% slopes

40 80-90 40 80-90 40 80-90

Not available Reverse

Axial w/

flighting

Published

100 % @

shoe

Yes No, up to

Cooling fan

Natural Flow

Feeding

6,0 47 Not

66% @ rolls;

34% @ shoe

23+% slopes

Not available Reverse

Axial w/

beater

published

100 % @

shoe

12% No, up to

Cooling fan

Natural Flow

Feeding

6,0 47 Not

66% @ rolls;

34% @ shoe

23+% slopes

Not available

Axial w/

beater

published

100 % @

shoe

12%

Advantages

The higher horsepower rating is lost with higher weight and parasitic loss of the machine.

Combine requires periodic cleaning of radiator vs. no cleaning on reverse cooling.

Gleaner is the only combine with a variable pitch fan that can save 66% of power at

80°F outside ambient temperature. This translates to a 36 horsepower savings at this

temperature.

Gleaner’s flat, even crop mat means the crop doesn’t have to change direction to

accommodate the rotor. All axial designs have a high wear area as the crop changes direction

into rotor intake. The beater in the CIH 7230 and 8230 can break up cob and damage grain.

The Gleaner 360-degree threshing and separation is substantially greater than CIH’s 156°

or 180° threshing and separator grate wrap at the same 30” rotor diameter.

With Gleaner, 66% of the cleaning is done at the accelerator rolls of our exclusive 2-stage

cleaning system. Our shoe is a secondary means not a primary as in the CIH where 100%

has to be cleaned at the shoe. Our accelerator rolls direct all of the crop through the high

air blast to the front of the cascade pan in the same location every time. Over 40+% of the

7230 and 8230 grain pan is solid at the front and is counted as sieve area which never gets

any air so it does no functional cleaning. With the Gleaner, 100% of the shoe is receiving

air from the upper air blast off of the accelerator rolls and the pneumatic area of the shoe.

The CIH 7230 and 8230 have a self-leveling shoe that is mechanical, can wear out and only

levels to 12% slopes. Gleaner accelerator rolls can reduce slope sensitivity up to 23+%.

Gleaner vs. Case IH

Make/Model GL S68 CIH 613 0 GL S78 CIH 7230 GL S88 CIH 82 30

Grain Handling

Grain bin capacity

Power-fold bin extensions Standard Optional Standard Optional Standard Optional

Average unloading rates 4.0 bu./sec. 3.0 bu./sec. 4.0 bu./sec. 3.6 bu./sec. 4.0 bu./sec. 3.6 bu./sec.

Time to unload grain bin (sec) 98 100 98 87. 5 98 8 7. 5

Unloader design

Construction & Weights

Mainframe construction

Straight-through shafts

Operating weight - 2WD (lbs.)

Power required to move operating

weight difference (hp)

Weight of machine w/header and

full grain bin (lbs.)

† Operating weight is weight of machine with tires; full tank of fuel. ‡ As equipped with 30’ draper header (Class 6), 35’ draper header

(Class 7) and 40’ draper header (Class 8).

390 bu.

standard

2-auger

swivel

Unitized,

welded

Yes No, 90°

†

33,923 40,276 34,223 43,288 34,233 43,988

N/A 12 N/A 17 N/A 19

63,093 6 4,924 64,233 69,24 9 64,973 72,46 3

‡

300 bu., no

option

3-auger

turret

Bolt-on Unitized,

gearboxes

390 bu.

standard

2-auger

swivel

welded

Yes CVT drive

315 bu., no

option

3-auger

turret

Bolt-on Unitized,

gearboxes

390 bu.

standard

2-auger

swivel

welded

Yes CVT drive

350 bu., no

option

3-auger

turret

Bolt-on

gearboxes

Advantages

30% larger grain tank on S68 vs.CIH 6130 and 23% larger on the S78 vs.CIH 7230. Gleaner

has largest on any class 6/7 combine. S88 is 11% larger vs. CIH 8230.

33% faster unloading rate on S68 vs. CIH 6130; 11% faster unloading on S87/S88 vs.

CIH7230/CIH8230.

Gleaner faster average unloading rate can unload the largest grain bin in the world in just

over a minute and a half.

Less wear, less horsepower required and less grain damage with Gleaner’s shallow 29°

angle from clean grain cross auger to unloading auger.

The Gleaner frame is stronger and lighter due to its exclusive welded unitized frame.

Gleaner is more efficient and drives are easier to ser vice.

Unlike Gleaner, CaseIH combines have a weight issue and consumes 19 hp. of its available

horsepower just moving the bare combine weight difference of the 8230 through the field

on a flat surface. Wet ground and hills compounds this issue. Though smaller, the CIH

7230 platform still consumes 17 horsepower more of its available horsepower versus the

S78 and the 6130 consumes 12 more horsepower .

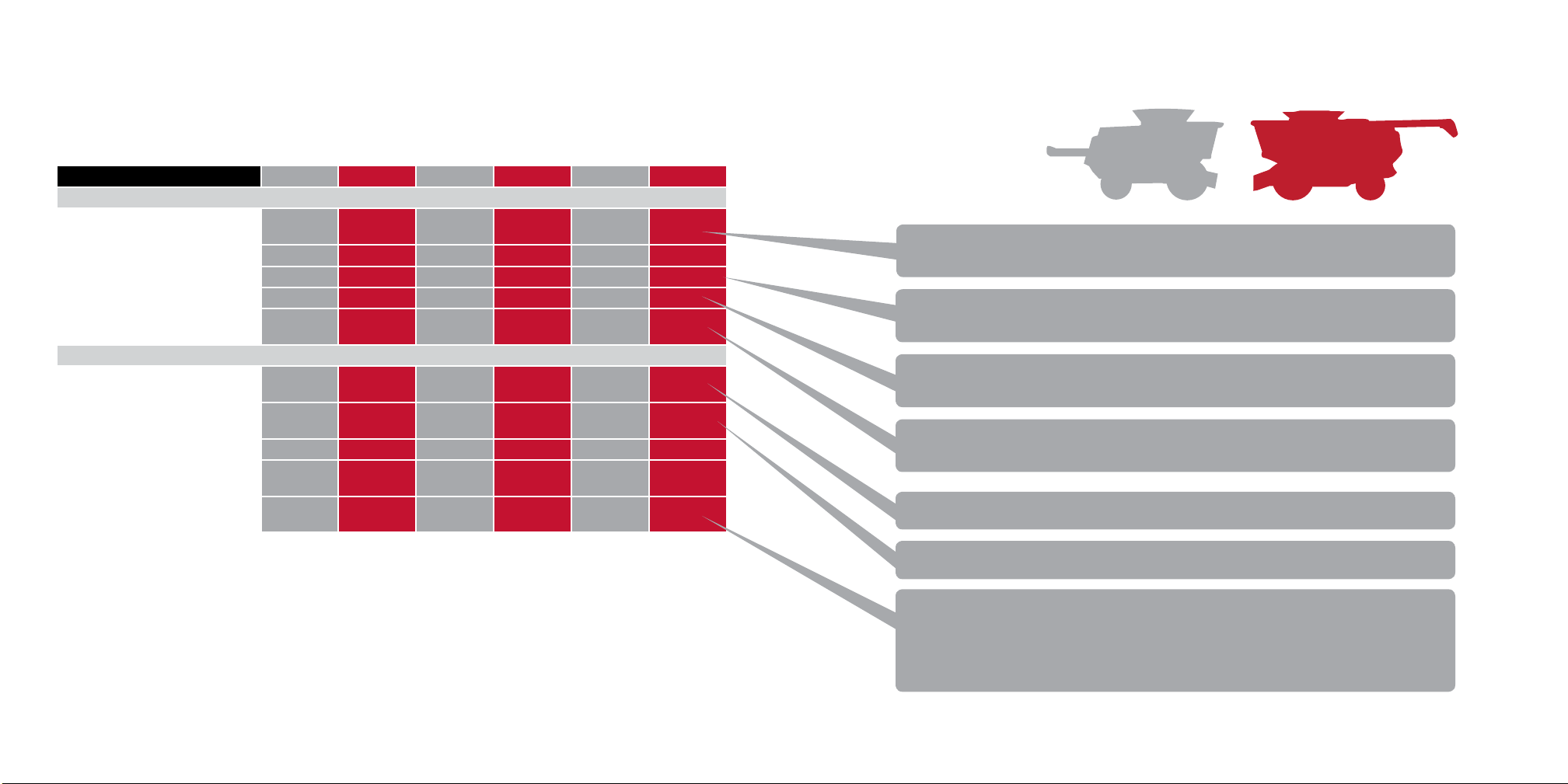

Gleaner vs. John Deere

Make/Model GL S68 JD S660 GL S78 JD S 670 GL S8 8 JD S680

Class 6 6 7 7 8 8

Horsepower (hp) 322 320 375 373 430 473

Maximum boost horsepower (hp) 398 365 451 425 471 540

Engine displacement (L) 8.4 9.0 9.8 9.0 9.8 13 .5

Rated speed (rpm) 2 ,10 0 2,200 2,1 0 0 2,200 2 ,10 0 2 ,10 0

Cooling System

Maintenance

Cleaning required No Ye s No Ye s No Yes

Variable fan pitch feature available Yes No Ye s No Ye s No

Average power savings @ 80°F (hp) 36 None 36 None 36 None

Processor

Rotor length (in) 90 123 90 123 90 123

Degrees of threshing/separation 360 18 0 360 180 360 18 0

Threshing & separation area (in²) 6,0 47 4,095 6,047 4,095 6,047 4,095

Cleaning area (in²) 7,72 9 7, 5 89 7,7 2 9 7, 5 89 7,7 2 9 8 ,711

Cleaning method

Accelerator roll technology Yes No Ye s No Ye s No

% of cleaning on performed on shoe

Slope sensitivity

Approx. power required for straw

chopper (hp)

Reverse

Cooling fan

Natural Flow

Typ e

Feeding

Two-stage Single-

66% @

rolls; 34% @

shoe

No, up to

23+% slopes

40 80-90 40 80-90 40 80-90

Air scoop Reverse

Axial w/

beater

stage

100% @

shoe

Yes No, up to

Cooling fan

Natural Flow

Feeding

Two-stage Single-

66% @

rolls; 34% @

shoe

23+% slopes

Air scoop Reverse

Axial w/

beater

stage

100% @

shoe

Yes No, up to

Cooling fan

Natural Flow

Feeding

Two-stage Single-

66% @

rolls; 34% @

shoe

23+% slopes

Air scoop

Axial w/

beater

stage

100% @

shoe

Yes

Advantages

Gleaner provides a higher percentage of horsepower to the seperator than the Class 6

and Class 7 John Deere combines relative to weight and less efficient drives. The higher

horsepower rating with the John Deere S680 is lost with higher weight and parasitic loss

of the machine.

John Deere’s air scoop requires periodic cleaning of radiator vs. no cleaning with

Gleaner’s reverse cooling.

Gleaner is the only combine with a variable pitch fan which can save 66% of power at 80°F

outside ambient temperature. The savings can amount to 36 horsepower.

Gleaner’s flat, even crop mat means the crop doesn’t have to change direction. All axial

designs have a high wear area as the crop changes direction into rotor intake. The beater

in the John Deere can break up cob and damage grain.

The 360-degree threshing and separation with the Gleaner provides almost 48% more area

than John Deere.

John Deere had to lengthen their shoe to compensate for no self-leveling device.

Gleaner’s cleaning area is not only slightly larger on the S68 and S78, but we don’t rely on

our shoe to do all the cleaning. In fact, we do 66% of our cleaning at the accelerator rolls.

Loading...

Loading...