Page 1

Operation Manual and Parts Directory

MF24, MF36, MF48

M

ug Frosters and Plate Chillers

Rev. 11-04-08

MF24-S

MF48-B2

Glastender, Inc. · 5400 North Michigan Road · Saginaw, MI · 48604-9780

800.748.0423 · 989.752.4275 · Fax 800.838.0888 / 989.752.4444 · www.glastender.com

© 2008 Glastender, Inc.

Page 2

Page 3

index

toPiC Page

Terms and Conditions ....................................................................1

Warranty Statement ........................................................................ 1

Installation ...................................................................................... 2

Operation ........................................................................................ 3

Cleaning Instructions ..................................................................... 3

Electrical and Refrigeration Specifications ................................... 4

Wiring Diagram ............................................................................. 4

Compressor and condenser related parts ....................................5-6

Evaporator and related parts .......................................................... 7

Electrical Components ................................................................... 8

Shelving and related parts ..............................................................9

Doors, tops and related parts ....................................................... 10

Refrigeration compartment covers .............................................. 11

220 Volt Electrical Parts ..............................................................12

Installation Notes ......................................................................... 12

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 4

terMs and Conditions

PriCes:

All prices are LIST. Applicable taxes will be added.

uotations:

Q

Unless otherwise stated, quotations are effective for 30 days only.

CCePtanCe:

a

All orders are subject to acceptance by Glastender, Inc.’s headquarters

in Saginaw, Michigan. Possession of the Parts Directory and Price List

is not an offer to sell.

hiPMents:

s

F.O.B. factory in Saginaw, Michigan. Partial shipments will be made

unless otherwise specified by the customer. Orders are shipped via UPS

or DHL unless otherwise specified.

ayMent terMs:

P

Cash should be included with all orders unless credit terms have been

arranged. To establish credit, banking and trade references are required.

A convenient credit application is available upon request. Visa and

MasterCard are also accepted.

Warranty stateMent

delivery:

Varies according to prior production commitments, but parts orders

generally ship within two working days.

eturns:

r

A Return Authorization (RA) number must be issued by the factory in

advance for any items that are returnable. The RA number MUST be

noted on the outside of the returned package. Returns must be received

within 90 days of the RA issue date. Shipping charges must be prepaid.

A 20% handling charge will be applied to all authorized returns if

received in new, unused condition in the original packaging.

oss or daMage:

l

Glastender, Inc. is not responsible for any loss, damage, or delay of

merchandise during shipment. Such transit claims must be filed with

the carrier. Merchandise must be examined on arrival. If shortages

occur, Glastender, Inc. must be notified in writing within five (5) days

of delivery to honor any shortage claim.

NOTE: Glastender, Inc.’s policy of constant quality improvement means

that prices, specifications, and policies are subject to change without

notice.

LABOR: Glastender, Inc. warrants all products to be free of defects in

material and workmanship. In established areas, a start-up and a 90day labor warranty are included with glasswasher models GT-24 and

GT-30. The GT-18 series glasswashers include a 90-day labor warranty.

Self-contained refrigeration models, except beer line chillers, include a

1-year labor warranty, for the duration of one year from date of installation or up to 18 months from date of factory shipment, whichever

occurs sooner. For warranty labor claims beyond 15 months from the

date of factory shipment, proof of date of installation or occupancy must

be provided. Authorization for labor must be obtained from Glastender

within the warranty period and prior to the service being performed.

Labor warranty applies to the United States and Canada only.

PARTS: Within one year from date of installation, or 15 months from

date of factory shipment, whichever occurs sooner, Glastender, Inc.

will replace any part or assembly found defective under normal use and

service. Field replacement parts include a warranty of 90 days from date

of installation. All self-contained refrigeration models include a 5-year

compressor warranty.

A warranty claim form MUST accompany all returned defective parts or

assemblies. This form MUST be completed in full. Failure to do so may

result in delay or denial of credit. Any defective part or assembly must

be returned to Glastender, Inc., Saginaw, Michigan, with all transportation and delivery charges prepaid. Warranty repairs or replacements will

be shipped FOB factory in Saginaw, Michigan.

The warranty does not cover equipment subjected to accidents, freight

damage, alterations, improper power and/or plumbing hookups, improper chemical use, general misuse, or lack of routine required maintenance

as determined by Glastender, Inc.

No representative, distributor, dealer, or any other person is authorized

to modify this warranty. This warranty replaces all other written or

verbal warranties.

NOTE: Glastender, Inc.’s policy of constant quality improvement

means that prices, specifications, and policies are subject to change

without notice. Questions regarding this warranty should be directed to

Glastender’s Customer Service Representative.

03/01/07

IMPORTANT!!

Attention Refrigeration Service Companies

Please review the important warranty information on this page. If you believe a

service call should be covered by the factory, please call the factory for authorization

between 8AM and 5PM EST, Monday through Friday.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

1

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 5

installation

introduCtion

This manual describes the operational features of Mug Froster/Plate Chiller models MF24, MF36, and MF48. Please review this

information before attempting installation and operation.

Long term, trouble-free service will follow if good housekeeping and maintenance procedures are followed. Thank you for

selecting Glastender, Inc. products.

utility reQuireMents and ConneCtions

Electrical: 115 Volt AC, 1 Phase, 60 Hz, 6.7 Full Load Amps. A separate 15 Amp circuit is recommended. A 6-foot

•

grounded cord is included.

•

Plumbing: None required. Automatic condensate evaporator is included.

unCrating and start-uP instruCtions

All Mug Frosters and Plate Chiller models are shipped in one carton. These steps should be followed:

1. If legs or casters are included, bolt them to the base with the bolts provided.

2. Unwrap power cord from base.

3. Position Mug Froster/Plate Chiller and level and/or seal as required (see page 2).

4. Install shelves.

5. Plug into 115 volt AC outlet.

6. Load with mugs, glasses, plates, etc.

7. Your Glastender Mug Froster/Plate Chiller is now ready for use.

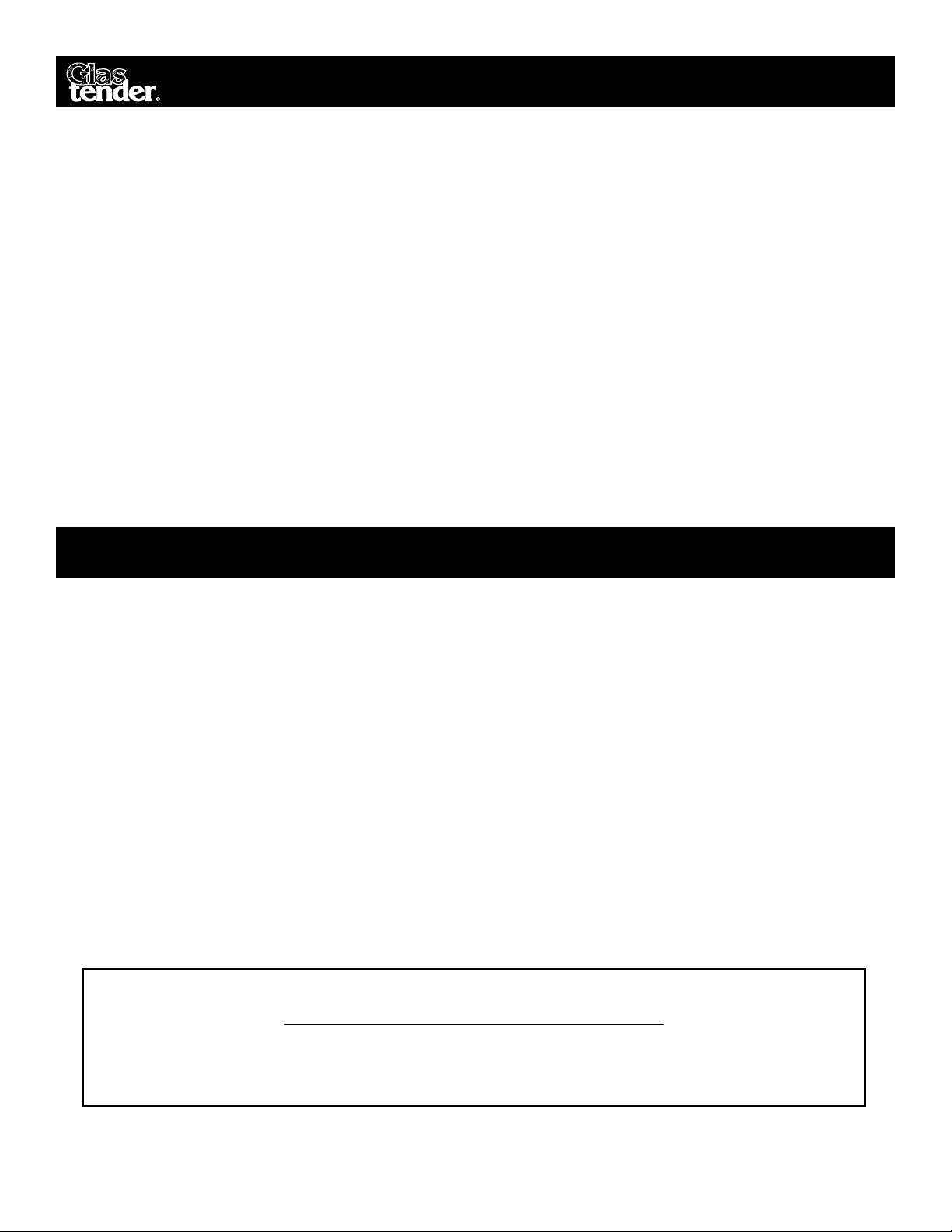

sealing Mug Froster and Plate Chiller Base to Floor

To comply with NSF & health codes. The Mug Froster base must be sealed to the floor using NSF listed sealant.

Place a bead of sealant along outer edges of the base and remove excess with disposable towel.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

2

Page 6

oPeration and Cleaning

oPeration

The Mug Froster/Plate Chiller is designed to chill mugs, glasses, plates, etc. that will appear “frosted” when removed. The

operating temperature range of 0°F (-18°C) to 35°F (2°C).

The Mug Froster/Plate Chiller should be filled with dry, room-temperature mugs, glasses, plates, etc. to allow maximum

chilling. During business hours, the Mug Froster/Plate Chiller can be loaded with additional dry, room-temperature mugs,

glasses, plates, etc. Allow 30 minutes for chilling.

The Mug Froster/Plate Chiller includes an automatic defrost system. Defrosting will occur every six hours for approximately 20 minutes. During the defrost cycle, the fan inside the Mug Froster/Plate Chiller will turn off and a small amount

of mist may appear if the top is opened.

There is also a manual defrost system controlled by a switch located on the front left bottom of the Mug Froster/Plate

Chiller. This is used when there is ice or snow accumulation inside. An end-of-the-day or weekly schedule can be established for the activation of this manual defrost cycle.

When the manual defrost switch is pushed, a light will turn on and the Mug Froster/Plate Chiller will go into a six-hour

defrost. After six hours, the Mug Froster/Plate Chiller will resume normal operation.

If the manual defrost switch is accidentally pushed, the defrost cycle can be terminated by unplugging the power cord

for three seconds.

Cleaning instruCtions

Cleaning is essential to sustaining the integrity of your equipment and preventing corrosion.

ESTIMATED CLEANING TIME: 5 to 10 minutes per unit daily, 30 minutes quarterly

FREQUENCY: Daily cleaning of exterior & door gaskets. Quarterly cleaning of interior, including shelves.

PROCEDURE:

1. A non-chlorine based cleaner or mild detergent and warm water applied with a soft cloth or sponge to all contact surfaces.

2. Immediately rinse off cleaning agent(s), using clean warm water, clean soft cloth or sponge.

3. Dry with a soft clean cloth, removing standing water as soon as possible.

NOTES:

1. Never use hydrochloric acid, wire brushes, steel wool, scrapers, or chlorine based cleaners on stainless steel surfaces,

since they will break down the passivity layer and allow corrosion to occur.

2. On stainless steel surfaces, you may use a soft bristle brush or Scotch-Brite® pad for more stubborn stains. Always

scrub with the direction of the grain. Follow with a thorough cleaning as described above.

3. Deposits from food preparation must be properly removed. Even hard water deposits will rust stainless steel, if not

removed.

4. Repeated cleaning may dry up black-vinyl-clad steel (exterior) surfaces of the cooler. Armor All® or similar product

can bring back the shine. Apply the product to a cloth and then rub into the surface, rather than spraying it directly onto

the black-vinyl-clad surface.

5. The cooler door gaskets are most often overlooked when cleaning. Failure to clean them regularly will lead to premature failure, since alcohol and moisture build-up breaks down the gasket material.

6. Mug frosters have a manual defrost timer switch on the front near the bottom, which will activate a 6-hour defrost cycle.

Depressing the switch before you close for the evening will remove excess frost build-up on the interior liner. This procedure should be done as often as is necessary. It should also be done the night before the quarterly interior cleaning.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

3

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 7

eleCtriCal

RECOMMENDED

15 AMP. SERVICE

115 VOLT

POWER

NEUTRAL

GROUND

1

2

11

10

6

15

13

5

12

3

16

14

5

7

8

3

4

9

6

COMPRESSOR WIRING

ELECTRICAL RATINGS

TOTAL AMPS

Evaporator Fan Motor

Condensing Unit Fan Motor

Compressor

All wires are 16 Gauge

115V, Single Phase, 60Hz, 3 wire.

W/R = White W/ Red

W = White

P = Purple

R = Red

O = Orange

BR = Brown

BL = Blue

B = Black

LEGEND

P

P

2

1

B

W

P

P

B

W

B

7

A

2

5

P

P

6.67

.28 AMP

4

3

.49 AMP

5.90 AMP

W

C

M

W

M

S

B

1

2

W

OPENS ABOVE +45°F

M

3

5

1

4

2

W/R

BR

R

O

BL

W

W

W

O

W

W

W

eleCtriCal and reFrigeration sPeCiFiCations

design

M

(L-to-R length) eleCtriCal tyPe Charge high loW

24”, 36”, 48” 115V, 1Ph., 60 Hz., 6.7 Amp R404A 8.5oz. 350 175

odel reFrigerant Pressure

Wiring diagraM

ITEM DESCRIPTION PART #

1 6 HR. MANUAL DEFROST LIGHT 07000171

2 EVAPORATOR FAN RELAY 07000166

3 EVAPORATOR FAN 06001445

4 TEMPERATURE CONTROL 07000276

5 COMPRESSOR, TECUMSEH 07000175

6 CONDENSER FAN MOTOR 06001449

7 AUTOMATIC DEFROST 06001397

8 DEFROST THERMOSTAT 07000165

9 DEFROST HEATER 07000169

10 MANUAL DEFROST SWITCH 07000257

11 6 HR. MANUAL DEFROST 07000156

12 OVERLOAD 07000128

13 START RELAY 07000168

14 CAPACITOR 06001380

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

15 CONDENSER FAN BLADE 07000155

16 EVAPORATOR FAN BLADE 09000298

4

Page 8

CoMPressor and Condenser related Parts

20

21

12

4

5

6

13

7

8

10

15

18

14

11

8

16

19

9

1

3

2

17

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

5

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 9

CoMPressor and Condenser related Parts

Part no. old Part no. desCriPtion PriCe

07000258 GT-036350 Condensing Unit, Complete, R404A Aspera $900.00

06001639 GT-036351 Condensing Unit, Complete, R404A Tecumseh 980.00

07000173 GT-035008 1/3 HP Aspera compressor, R404A 450.00

1. 07000151 GT-032203 Start capacitor for 1/3 HP R404A Aspera compressor 25.00

2. 06001675 GT-034115 Relay for 1/3 HP R404A Aspera compressor 15.00

3. 07000

4. 07000175 GT-035026 1/3 HP Tecumseh compressor, R404A (after 1/00) 375.00

5. 06001380 GT-032206 Start capacitor for 1/3 HP R404A Tecumseh compressor 20.00

07000168 GT-034112 Relay for 1/3 HP R404A Tecumseh compressor 18.00

07000128 GT-031207 Overload protector for 1/3 HP R404A Tecumseh compressor 12.00

6. 06001449 GT-035114 Condenser fan motor, 6W 95.00

7. 06001321 GT-031515 Bracket, condenser fan motor mounting 5.00

8. 07000155 GT-032803 Fan blade, condenser, 5 blade 10.00

9. 07000179 GT-035714 Nut, fan blade mounting 1.00

10. 07000152 GT-032302 Fan shroud, condenser 15.00

11. 06004028 Filter dryer with service port 25.00

12. 06001384 GT-032501 Suction line accumulator 40.00

13. 08000078 GT-032607 Condenser coil 145.00

14. 07000230 GT-038016 Pan, condensate, MF24, MF36 and MF48 (after 1998) 70.00

15. 07000260 GT-038001 Pan, condensate, MF36 and MF48 (prior to 1998) 65.00

16. 08000125 GT-038006 Pan, condensate, MF24 (prior to 1998) 60.00

17. 07000237 GT-038207 Wicking material, consists of 14 - 2 1/2” x 6” pieces, 34.00

MF24, 36 & 48 (after 1998)

18. 07000234 GT-038201 Wicking material, consists of 11 9” pieces, MF36 & MF48 24.00

(prior to 1998)

19. 07000235 GT-038203 Wicking material, consists to 11 4” pieces, MF24 14.00

(prior to 1998)

20. 06001461 GT-035290 Elbow, 1/2” x 1/2” plastic barb 2.00

21. 06001345 GT-031716 Tubing, drain, clear plastic. 1/2” ID x 5/8” OD, per foot 1.45

06001313 GT-031400 Condensing unit power cord 20.00

07000154 GT-032508 Cap tube (60” x .036) - all models 20.00

127

Overload protector for R404 Aspera compressor 15.00

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

6

Page 10

evaPorator and related Parts

Part no. old Part no. desCriPtion PriCe

1. 07000310 GT-031514 Bracket, evaporator fan motor $14.00

2. 07000134 GT-031516 Temperature control mounting bracket, prior to

3. 07000153 GT-032303 Evaporator fan box back, prior to

07000362 Cover, evaporator back,

4. 07000380

5. 09000298 GT-032804 Fan blade, evaporator, 5 blade 5.00

6. 07000276 Temperature control, includes knob 50.00

7. 07000165 GT-033413 Defrost sensor 26.00

8. 07000169 GT-034704 Defrost heater 60.00

9. 06001445 GT-035107 Fan motor, evaporator 35.00

10. 07000182 GT-036100 Cover, front, evaporator, MF24, MF36,

07000184 GT-036102 Cover, front, evaporator, MF48, prior to

07000364 Cover, front, evaporator, MF24, MF36, MF48,

07000183 GT-036101 Cover, bottom, evaporator, MF24, MF36, prior to

07000360 Cover, bottom, evaporator, MF24, MF36,

07000185 GT-036103 Cover, bottom, evaporator, MF48, prior to

07000361 Cover, bottom, evaporator, MF48,

11. 07000228 GT-037420 Evaporator housing, prior to

07000365 Drain pan, evaporator MF24, MF36,

07000366 Drain pan, evaporator MF48,

12. 06001573 GT-038725 10-32” x 1/2” thumbscrew (4 required) (2 req prior to

Evaporator coil replacement kit 180.00

SN 404104830N

SN 404104830N

and after 24.00

prior to

SN 404104830N

SN 404104830N

SN 404104830N

SN 404104830N

SN 404104830N

SN 404104830N

24.00

SN 404104830N

54.00

SN 404104830N

SN 404104830N

SN 404104830N

SN 404104830N

and after 42.00

60.00

and after 60.00

and after 60.00

SN 404104830N

10.00

54.00

and after 54.00

42.00

and after 42.00

42.00

) 1.00

6

11

3

1

5

12

4

8

9

2

7

10

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

7

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 11

eleCtriCal CoMPonents

Part no. old Part no. desCriPtion PriCe

1. 06001314 GT-031401 Exterior power cord, 11’ $35.00

07000599

includes (06001572 01000669 06001314)

2. 07000246 GT-031608 Decal, control module 7.00

3. 06001397 GT-033000 Automatic defrost 32.00

4. 07000156 GT-033001 Manual defrost timer (6 hr) 90.00

5. 01000547 GT-033301 Receptacle, 3 wire, mate-n-lok 1.00

6. 06001634 GT-033302 Receptacle, 6 wire, mate-n-lok 1.50

7. 06001409 GT-033304 Receptacle, compressor 5.00

8. 07000257 GT-033401 Manual defrost switch 20.00

9. 07000166 GT-034105 Evaporator fan relay 40.00

10. 07000171 GT-034907 Manual defrost light, red 10.00

11. 07000176 GT-035519 Wiring harness, control module 50.00

12. 07000227 GT-037419 Control module, complete 1,090.00

Replacement powercord assembly, 40.00

3

9

2

1

5

8

3

6

10

7

11

4

4

12

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

8

Page 12

shelving and related Parts

Part no. old Part no. desCriPtion PriCe

1. 07000030 GT-031517 10” shelf bracket (MF36 = 1) (MF48 = 2

2. 07000029 GT-031518 20” shelf bracket (MF24 = 3) 12.00

07000371 24” shelf bracket (MF48 = 1

SN 404104830N

3. 07000135 GT-031519 32” shelf bracket (MF36 = 3) 15.00

4. 07000136 GT-031520 44” shelf bracket (MF48 = 3) 18.00

5. 07000159 GT-033104 Shelf, 19-5/8” x 19-5/8” [MF24 = 1 (bottom), 50.00

MF36 = 1 (bottom), MF48 = 2 (bottom)]

6. 07000160 GT-033105 Shelf, 9-13/16” x 19-5/8” [MF24 = 2 (middle), 35.00

MF36 = 2 (middle), MF48 = 2 (middle)]

7. 07000158 GT-033100 Shelf, 4” x 19-5/8” [MF48 = 1 (bottom)] 35.00

8. 07000161 GT-033107 Shelf, 9-13/16” x 12-1/8” 30.00

[MF24 = 2 (top), MF36 = 2 (top), MF48 = 2 (top)]

9. 07000162 GT-033108 Shelf, 12” x 19-5/8” [MF36 = 3 (bottom, middle, top), 40.00

MF48 = 4 (middle, top)]

10. 06001573 GT-038725 10/32” x 1/2” thumbscrew 1.00

Complete Shelf Kits

07000223 GT-036918 Complete shelf kit for MF24 (includes: 1 - 07000159, 180.00

2 - 07000160, 2 - 07000161)

07000224 GT-036919 Complete shelf kit for MF36 (includes: 1- 07000159, 300.00

2 - 07000160, 2 - 07000161, 3 - 07000162)

07000225 GT-036920 Complete shelf kit for MF48 (includes: 2 - 07000159, 425.00

2 - 07000160, 1- 07000158, 2 - 07000161, 4 - 07000162)

prior to SN 404104830N

and after) 14.00

) $6.00

1

19-5/8″

2

9-13/16″

19-5/8″

3

19-5/8″

4

4″

19-5/8″

07000159 07000160 07000158 07000161

MF24 = 1

MF36 = 1

MF48 = 2

5

MF24 = 2

MF36 = 2

MF48 = 2

6

MF24 = 0

MF36 = 0

MF48 = 1

7

8

9-13/16″

MF24 = 2

MF36 = 2

MF48 = 2

10

12″

19-5/8″

12-1/8″

07000162

MF24 = 0

MF36 = 3

MF48 = 4

9

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

9

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 13

doors, toPs, and related Parts

Part no. old Part no. desCriPtion PriCe

07000129 GT-031311 Gasket, wiper, 24” top, 21-1/2” long $10.00

1. 07000130 GT-031312 Gasket, wiper, 36” top, 33-1/2” long 14.00

07000212 GT-036213 Sliding door, 21”, MF24 120.00

(for permanent breaker strip models, 1993 only)

07000213 GT-036214 Sliding door, 20-3/16”, MF24 126.00

07000261 GT-036215 Sliding door, 33”, MF36 180.00

(for permanent breaker strip models, 1993 only)

2. 07000214 GT-036216 Sliding door, 32-3/16”, MF36 192.00

07000231 GT-038113 Top, MF24 126.00

3. 07000232 GT-038114 Top, MF36 192.00

07000233 GT-038115 Top, MF48 252.00

07000238 GT-038437 Breaker strip, 24” and 48” sliding door opening, 4 pieces 25.00

4. 07000239 GT-038438 Breaker strip, 36” sliding door opening, 4 pieces 35.00

2

4

3

1

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

10

Page 14

reFrigeration CoMPartMent Covers

Part no. old Part no. desCriPtion PriCe

07000186 GT-036105 Front, black vinyl-clad, MF24 $33.00

07000187 GT-036106 Front, stainless steel, MF24 48.00

07000188 GT-036107 Front, black vinyl-clad, MF36 44.00

07000189 GT-036108 Front, stainless steel, MF36 72.00

1. 07000190 GT-036109 Front, black vinyl-clad, MF48 55.00

07000191 GT-036110 Front, stainless steel, MF48 96.00

07000192 GT-036111 Back, black vinyl-clad, MF24 40.00

07000193 GT-036112 Back, stainless steel, MF24 80.00

07000194 GT-036113 Back, black vinyl-clad, MF36 50.00

07000195 GT-036114 Back, stainless steel, MF36 100.00

2. 07000196 GT-036115 Back, black vinyl-clad, MF48 55.00

07000197 GT-036116 Back, stainless steel, MF48 96.00

3. 07000198 GT-036117 Side, left, black vinyl-clad, all models 40.00

07000199 GT-036118 Side, left, stainless steel, all models 80.00

4. 07000200 GT-036119 Side, right, black vinyl-clad, all models 40.00

07000201 GT-036120 Side, right, stainless steel, all models 80.00

Front view

Front view

3

1

4

Rear view

11

2

Model MF48

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 15

220 volt eleCtriCal Parts

Part no. desCriPtion PriCe

06001438 Compressor, 1/3 HP, 220/50Hz, R404A $510.00

06001793 Start capacitor, for 1/3 HP R404A compressor, 220/50Hz 25.00

06001794 Relay, compressor, 1/3 HP, 220V/50Hz, R404A 10.00

06001795 Overload for 1/3 HP R404A compressor, 220/50Hz 15.00

06001451 Motor, condenser fan, 9 watt, 220V 50/60 Hz 120.00

06001448 Motor, evaporator fan, 220V 50.00

07000170 Defrost heater, 220V 85.00

06001398 Defrost timer, automatic, 220V, 50 cycle 32.00

07000157 Defrost timer, manual, 220V, 50 cycle, 6 hour 132.00

01000591 Light, power, green, 220 VAC 6.00

07000167 Relay, evaporator fan, 220V 72.50

Installation Notes

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

Original System Installer

Company: _____________________________________________

Address: _____________________________________________

_____________________________________________

City, State, Zip: _____________________________________________

Phone Number: _____________________________________________

Fax Number: _____________________________________________

Contact: _____________________________________________

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

12

Page 16

U N P A R A L L E L E D U N D E R B A R D E S I G N & E N G I N E E R I N G

Expect more

more flexibility

more features

Glastender has the most complete line of bar equipment and

the ability to manufacture custom units, giving you virtually

unlimited design exibility. Each piece of equipment is

engineered with features that enhance your efciency, ease

your maintenance, and prolong the life of your investment.

The exibility you want. The features you need.

Glastender. Expect more.

GLASSWA S H ERS • COC K TA I L S TAT IONS • CO OLERS • F ROST ERS • BEER S Y S T EMS

Loading...

Loading...