Page 1

Operation Manual and Parts Directory

LC84

Conquest Post-Mix ReMote soda Line ChiLLeR

Rev. 03-24-14

Glastender, Inc. · 5400 North Michigan Road · Saginaw, MI · 48604-9780

800.748.0423 · 989.752.4275 · Fax 800.838.0888 / 989.752.4444 · www.glastender.com

© 2006 Glastender, Inc.

Page 2

Page 3

index

INSPECTION AND LOCATION

Inspection Upon Arrival .................................................... 1

Location of Remote Cooler ............................................... 1

Removing the Top Cover .................................................. 1

INSTALLATION

Electrical Hook-Up ........................................................... 2

Refrigeration Start-Up....................................................... 2

Connection of Water Supply ............................................. 2

Connection of “Product Out” Lines .................................. 2

Connection of “Product In” Lines .................................... 2

Connection of CO2 Cylinders........................................... 3

Start-Up of Dispensing System......................................... 3

Insulated Conduit .............................................................. 3

CLEANING AND MAINTENANCE

Water Level ....................................................................... 4

Cleaning Hints................................................................... 4

Water Bath Cleaning and Maintenance ............................ 4

Sanitizing Water Circuits .................................................. 4

Sanitizing Syrup Circuits .................................................. 4

Preventative Maintenance Schedule ................................. 5

TROUBLE SHOOTING PROCEDURES

Poor Carbonation .............................................................. 6

Bad Taste in Beverage ...................................................... 6

Noisy Carbonator Pump .................................................... 6

Compressor Will Not Run .................................................6

Compressor Runs But Stops ............................................. 6

Compressor Runs But Will Not Cool ...............................6

Carbonator Pump Motor Will Not Run ............................6

Carbonator Pump Motor Will Not Stop ............................6

Carbonator Pump Running In Wrong Direction ............... 6

Circulating Pump Motor Will Not Run ............................6

Circulating Pump Running In Wrong Direction ............... 6

Pump Leaking Water ......................................................... 6

Warm Beverage ................................................................. 6

Water Bath Freezing Completely ...................................... 6

Noise In Water Bath .......................................................... 6

SPECIFICATIONS .............................................................. 7-8

TYPICAL INSTALLATION DIAGRAMS ........................... 9

WIRING DIAGRAM ............................................................ 10

LC84 COMPRESSOR AND RELATED PARTS ........ 11 - 12

WARRANTY ......................................................................... 13

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 4

insPeCtion and LoCation

RTV TO FORM A FILL

CABINET PLACED UP

1. INSPECTION UPON ARRIVAL

• Immediately upon receipt of the unit, make a visual

inspection of the carton to determine if there is evidence

of damage. Following un-crating, make an inspection for

signs of damage.

• If damage is found, notify the carrier immediately.

• The Transportation Company is liable for damage sustained

during shipment but claims must be made with in 15 days.

2. LOCATION OF REMOTE COOLER

• Unit can be placed up to 150 ft. (45.7m.) from the dispens ing station. The low profile design allows the unit to be

located under counter.

• If unit is installed on the floor:

a) the cabinet must be sealed to the floor with an NSF

listed silicon RTV applied around the entire periph-

ery of the cabinet (see fig.1)

b) optional 6” legs must be installed to the cabinet bottom.

CABINET BOTTOM

RTV

ET WHEN

RIGHT

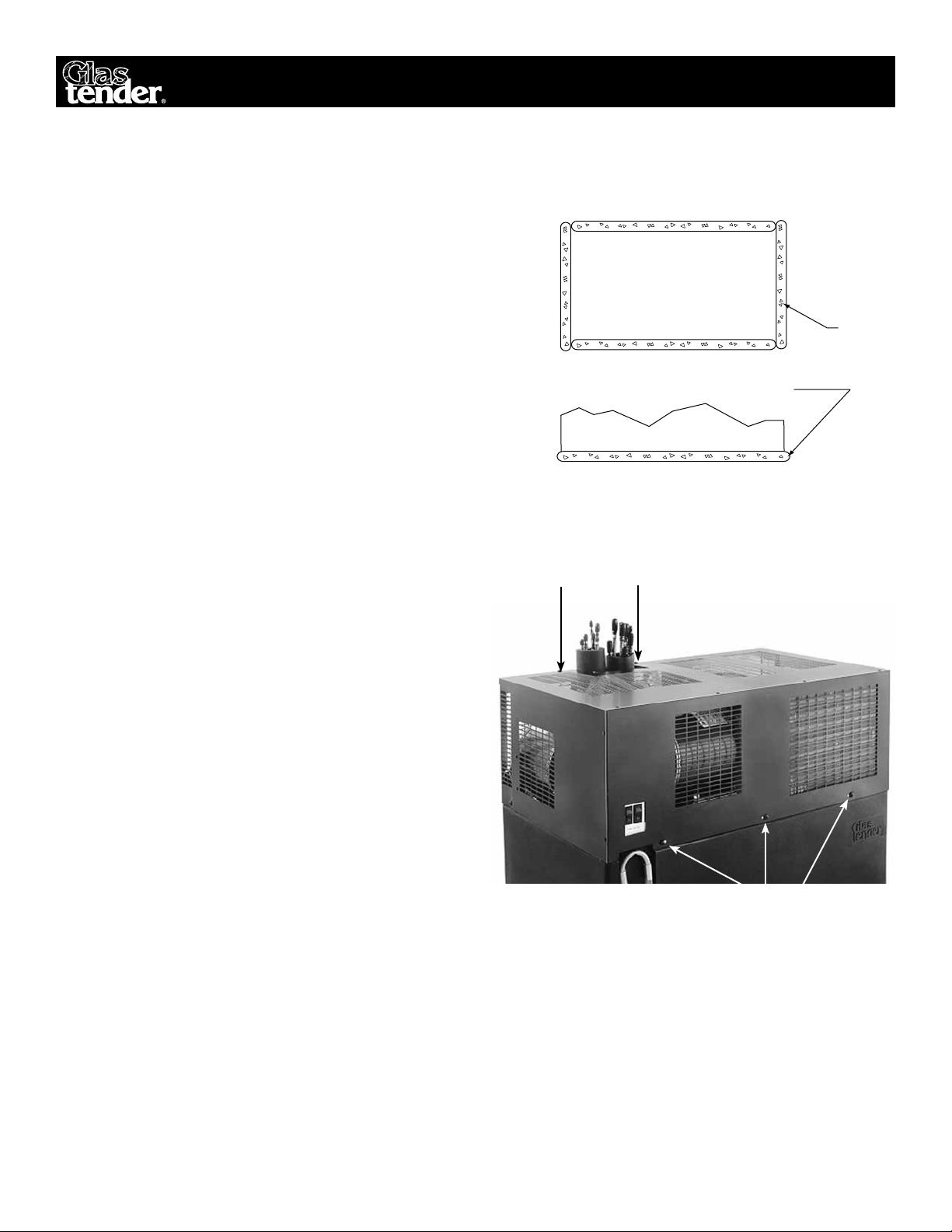

Fig. 1 Sealing Cabinet with RTV

• If unit is installed on a countertop or shelf:

a) the cabinet must be sealed to the countertop or shelf

with an NSF listed silicon RTV applied around the

entire periphery of the cabinet. (see fig.1)

b) optional 4” legs must be installed to the cabinet bottom.

• Any location must have the ability to support the operat-

ing weight of the unit. (261 lbs./118 kg.)

• Avoid obstructions to the air intake and exhaust sections

of the unit.

• Minimum clearance between the top, front, and back of unit

and any obstruction is 12 in. (30.5cm.)

• Proper unrestricted airflow is essential.

• After the unit is in place, check to be sure it is level.

3. REMOVING THE FRONT COVER

• Remove the three-(3) screws in front of the unit, and two-

(2) screws on top rear. (see fig.2)

• Lift cover up to disengage from rear of the unit, then

pull forward.

Fig. 2 Removal of Front Cover

• Do not remove the screws along the sides or back.

1

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 5

instaLLation

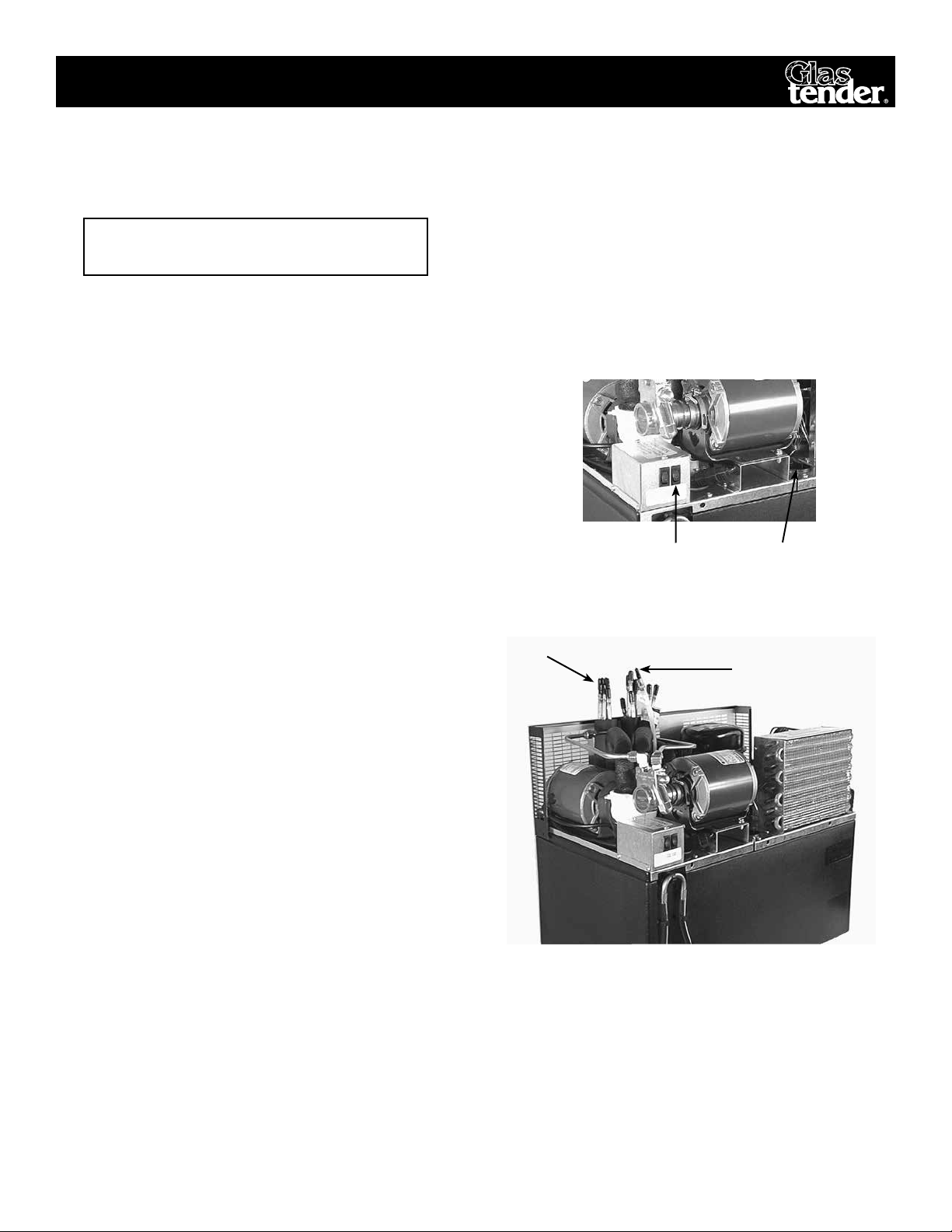

1. ELECTRICAL HOOKUP

• Unit is supplied with a 20-amp line cord on the left rear

of the unit.

NOTE: THIS UNIT REQUIRES 20

AMP CIRCUIT PROTECTION

• The main supply cord comes off the control box, located

on the pump deck. The refrigeration power cord plugs

into the back of the control box, also located on the pump

deck.

• Connect syrup out lines (3/8” male barb) to a color-

• Secure connections with proper sized “O” clamps.

• Connect the recirculating soda line (3/8” tubing) to

• Connect the other 3/8” line to the barbed fitting on the

2. REFRIGERATION START-UP

• Remove top cover. Locate the black plastic water bath

fill-plug and remove it. (see fig.3)

• Fill the unit with clean water until water begins to come

out of the overflow tube.

• Plug in main power cord and the condenser fan and

compressor should start. (see fig. 3) If not, refer to

“TROUBLESHOOTING PROCEDURES”.

NOTE: A small amount of water will flow out of the over

flow tube until the ice is fully formed.

coded conduit. (Note which numbered line goes to

which colored tube.) (see fig. 4)

the barbed fitting coming from the insulated pump.

(see fig. 4) Labeled “Soda Return”.

soda coil. Labeled “Soda Out”.

Fig. 3

Control Box Switches

Filling the

Water Bath

3. CONNECTION OF WATER SUPPLY

• Glastender, Inc. recommends that a 1/2” water line with

shut-off valve be installed within 10-ft. (3 M.) of the unit.

Incoming water pressure is not to be less that 20 P.S.I.

NOTE: If water pressure exceeds 60 P.S.I. or severely fluc-

tuates, a water pressure regulator is required ahead of the

brass pump to avoid flooding the Carbonator. This regulator

is not supplied as standard equipment

• Before connecting water supply, drain approximately

two gallons of water from supply to flush out foreign

matter.

• It is recommended that a water filtering systems be

installed to reduce “off” tastes and odors. Use a system

that can filter out dirt particles 1 micron and larger.

Also amoebic and giardial cysts, asbestos fibers and

other similar contaminants.

• Connect water supply to the 3/8” barb of the fitting of

the water-in tube. (see fig. 4, Labeled Water Supply)

• Secure with proper sized “O” clamps.

4. CONNECTION OF “PRODUCT OUT” LINES

• Install the insulated bundled tubes on the 3/8” barb fittings.

Syrup and Soda Lines

Water-in Tube

Fig. 4 Connection of Water in Line

5. CONNECTION OF “PRODUCT IN” LINES

• Install the 1/4” I.D. braided tubing from the syrup

supply location to the 1/4” male barb connections on

the unit. Use tie wraps to neatly bundle supply lines.

• Secure lines to product coils with “O” clamps.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

2

Page 6

instaLLation

6. CONNECTION OF CO2 CYLINDERS

• Mount the regulator assembly conveniently near the

product supply and CO2 cylinder.

• Use either a regulator with a wall mounting bracket or

mount directly to the cylinder.

• An extension tube is mounted to the carbonator tank

with 1/4” barb fitting for ease of connection. Measure

and cut a length of 1/4” I.D. braided flexible tubing to

go from the CO2 regulator to the carbonator extension

tube (labeled C02). (Leave enough line to go through

the top cover of the unit.)

• Measure and cut 1/4” I.D. braided flexible tubing for

each syrup gas line. Connect one end to the regulator

manifold and the other end to syrup supply.

7. START-UP OF DISPENSING SYSTEM

Open main water supply valve.

•

Purge air from carbonator by lifting relief valve.

• Turn on “CARB” switch. (see fig. 3)

• Close all CO2 regulators.

Fig. 5 GLASTENDER TEMPLOCK Insulated Conduit

8. INSULATED CONDUIT (Figure 5)

• The GLASTENDER TEMPLOCK insulated tube con duit is recommended for this remote Post-Mix applica tion. This manufactured conduit maximizes the cooling

performance of the system.

• Open the valve on the CO2 cylinder. (The high pres

sure gauge will read about 800 P.S.I.)

• Adjust the carbonator regulator to 100 P.S.I.

• Operate a valve until carbonated water flows freely

(without spurting).

• Adjust the syrup regulator to 50 P.S.I.

• Adjust diet syrup regulator (if used) to 12 P.S.I.

• Check all connections for leaks.

• Insulate and tape all exposed refrigerated conduit lines.

• After refrigeration systems has cycled off once, turn on

recirculating switch. (Full ice bank is required to cool

tower.) Replace top cover.

• Follow standard brixing procedures.

• Conduit may be run under floors, over ceilings, under

the counter or bar, and will not kink in an 18-inch radius

around a corner.

• When conduit is to be run across ceilings or under coun

ters, always place conduit straps every 3-ft. to prevent

sagging.

• On runs through ceilings that are also used for air con ditioning return ducts, check local fire codes. They may

require that the conduit be covered with a fire rated

metal flex duct.

• It is recommended that the chase protrude above the

floor level a minimum of 2 inches and should be sealed

off once the installation has been completed. By sealing

off the floor chase, you eliminate the possibility of for eign matter being spilled into it, which could permeate

the conduit.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

3

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 7

CLeaning and MaintenanCe

1. WATER LEVEL

• Due to evaporation, it is necessary to periodically check

the water level of the bath. Add water as required.

• A low water level results in noisy operation and reduces

cooling capacity.

2. CLEANING HINTS

• Clean external cabinetry with mild soap and warm water.

• Do not use strong bleaches or detergents.

• Do not use steel wool, scouring pads, abrasives, etc.

• Do not use hot water; this may damage certain materials.

• The refrigeration condenser should be cleaned with a soft

bristle brush or a vacuum cleaner.

3.WATER BATH CLEANING AND DRAINING

Disconnect main power.

•

• Remove top cover.

• Remove drain tube holding clamps and drain water from

bath.

Note: Because the water bath tank is well insulated, it may

take hours for the ice to melt naturally. The ice can be melted

faster by refilling the tank with warm water.

• Disconnect the refrigeration deck power cord from the

control box.

• Remove six (6) hold-down screws (shipping screws).

• After ice has melted, lift out the refrigeration deck by its

handles.

• Clean the evaporator coil with soap or detergent using a

soft brush. Rinse with clean water.

• Remove the rear panel for easier access to this base. This

is accomplished by removing 2 screws on each side and 4

screws across the back.

• Make sure CO2, water and syrup supply are all shut off.

• Depressurize the carbonator by lifting its relief valve.

• Remove five (5) hold-down screws (shipping screws).

• Clean coils and inside of tank with soap or detergent and

• Replace motor and pump deck.

• Replace refrigeration deck. Plug cord from refrigeration

• Replace rear panel.

• Replace drain tube in holding clamps making sure hole in

• Refill tank until water comes out of the overflow tube.

• Replace top cover.

4. SANITIZING WATER CIRCUITS

• Turn on water and flush at least five gallons through entire

• Fill a five-gallon pressure tank with a mild cleaning solution

• Flush lines with this cleaning solution by connecting soda

• Fill a five-gallon pressure tank with a chlorine solution

(1-½ oz. Clorox to 5 gallons of water).

• Flush lines with this chlorine solution to prevent mold and

• Flush entire system with potable water (suitable for drink-

5. SANITIZING SYRUP CIRCUITS

• Uncouple syrup line from syrup container.

• Connect syrup line to tank filled with potable water (suit-

• Connect 5-gallon pressure tank containing soda solution (1

• Repeat above procedure using chlorine solution (1-½ oz. Clorox

rinse with water.

deck back into control box.

plastic/copper elbow is on top.

system (plain and carbonated water circuits).

(1 lb. baking soda to 5 gallon of water).

water line to outlet of tank (baking soda) and pressurize with

CO2.

bacteria growth by connecting soda water line to outlet of

tank (chlorine) and pressurizing with CO2 Connect water

lines to the dispenser.

ing) to remove all trace of chlorine solution.

able for drinking). Pressurize at least 2 gallons of water

through each syrup circuit.

lb. Baking soda to 5 gallons of water) and flush through

syrup circuits.

to 5 gallons of water) to prevent mold and bacteria growth.

• Lift out motor and pump deck.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

• Repeat above procedure using potable water (suitable for

drinking) to flush system of all trace of chlorine solution.

4

Page 8

CLeaning and MaintenanCe

PREVENTIVE MAINTENANCE SCHEDULE

Daily Syrup Tank When Cleaning Tanks

Connectors Rinse Both Quick Connects

In Clean Warm Water.

Daily Dispensing Wash Nozzle And Diffuser

Valves In Warm Soapy Water And

Rinse In Warm Water

Daily Dispensing Wash With Mild Detergent

Towers And Warm Water, Then

Wipe Dry. Flush Drain

With Warm Water

Twice Weekly Dispensing Follow Standard Brixing

Tower Brix Instructions

Check

Weekly Remote Cooler Wash With Mild Detergent

And Wipe Dry

Weekly System Review Pressure Gauges

Pressures For Proper Settings

Monthly Remote Cooler Clean Condenser With A

Air Cooled Soft Bristled Brush Or

Condenser Vacuum Cleaner

Every 6 Months Syrup Lines Follow “SANITIZING

SYRUP CIRCUITS”

Instructions

Every 6 Months Water Lines Follow “SANITIZING

WATER CIRCUITS”

Every 6 Months Water Bath Follow “WATER BATH

DRAINING AND CLEANING”

Instructions

Every 6 Months Lubrication Lubricate Circulating And

Carbonator Pump Coupling

With 3-5 Drops Of SAE 20

Non-Detergent Oil

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

5

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 9

tRoubLe shooting PRoCeduRes

1. POOR CARBONATION

• Make sure faucet and nozzle are clean.

• Temperature of the soda water in cup affects the amount

of carbonation retained in water. If drink is above 40

degrees F. only 92% is retained. When taking drink

temperature, always dispense at least 16 ounces of

product to get a true reading.

• Flooded carbonator caused by water being supplied at a

higher pressure than the CO2 pressure. Check pressure

regulator system. Make sure it is at least 35 P.S.I. lower

than CO2 pressure. The CO2 pressure should be 100

P.S.I.G.

• Any substance with an oil base will knock out carbona tion. Make sure no pipe dope or compound is on any

fitting. Always use teflon tape.

• Ice that is super cold will cause foaming problems and

a loss of carbonation. Bring ice to melt temperature (28

degrees) before using.

2. BAD TASTE IN BEVERAGE

• Pipe compound or pipe dope can impart a taste to the

water. Remove piping and clean joints. Replace piping

using only teflon tape.

• Carbon dioxide (CO2) gas is odorless, colorless, and

tasteless. If CO2 gas contains any oil or sludge from fill ing tanks, a bad taste could result.

• Soda water reacts to brass or copper and becomes toxic.

Remove any brass or copper object coming in contact

with soda water. Replace with polyethylene or stainless

steel.

3. NOISY CARBONATOR PUMP

• Check to see that filter and/or strainer are not clogged,

and water valve to unit is wires from switch. With

switch in “ON” fully opened.

• Incoming water supply to unit should be 3/8” I.D.

minimums.

• Be sure pump and pump motor are properly aligned and

the clamp is tight.

• Broken vanes in pump requiring pump replacement.

4. NOISY RECIRCULATING PUMP

• Check for restrictions in recirculating lines.

• Be sure pump and pump motor are properly aligned and

clamp is tight.

• Broken vanes in pump requiring pump replacement.

5. COMPRESSOR WILL NOT RUN

• Verify that switch is in “ON” position.

• Check all wire junctions and tighten any loose connections.

• Replace ice-bank control.

6. COMPRESSOR RUNS BUT STOPS

• Air-cooled: Clean condenser

• Water-cooled: Verify adequate water supply.

7. COMPRESSOR RUNS-WILL NOT COOL

• Check for refrigerant leaks

• Replace condenser.

8. CARBONATOR PUMP MOTOR WILL

NOT RUN

• Check fuse and supply switch. Make sure switch is on.

• Check switch on beverage system by disconnecting power

supply. Remove 2 wires from switch. With switch in

“ON”

• Remove 2 wires from switch. With switch in “ON” position,

connect continuity tester to both terminals of switch. If no

continuity, replace switch.

• Check circulating pump to be sure it turns freely by hand.

If not, replace it.

• With pump removed and proper voltage supplied to the

motor and it fails to run, it is defective and must be

replaced.

9. PUMP LEAKING WATER

• Check for worn seal. If so, replace pump

• Pump must be insulated properly to prevent condensation.

10. WARM BEVERAGE

• Check for defective circulating pump. If so, replace it.

• Check water bath temperature (30º +/-2) and level.

• Clean condensor coil at air intake.

11. WATER IN BATH FREEZING COMPLETELY

• Ice-bank control defective and must is be replaced.

12. NOISE IN WATER BATH

• Water level in bath low. Refill to proper level.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

6

Page 10

sPeCifiCations

LC84 CONQUEST

1/3 HP Post-Mix Remote

LC84 CONQUEST

StandaRd FeatuRes

• Modular lift-out refrigeration system for

easy in-field service

• High capacity refrigeration and recirculation

for high volume and remote long distance

installations

• CFC-free R134a refrigerant

• Light-weight, roto-molded water bath with

drain

• Up to six (6) syrup circuits with recirculating

soda and water

• Polyurethane foamed-in-place insulation

• Self-contained carbonation system

SPeCifiCations

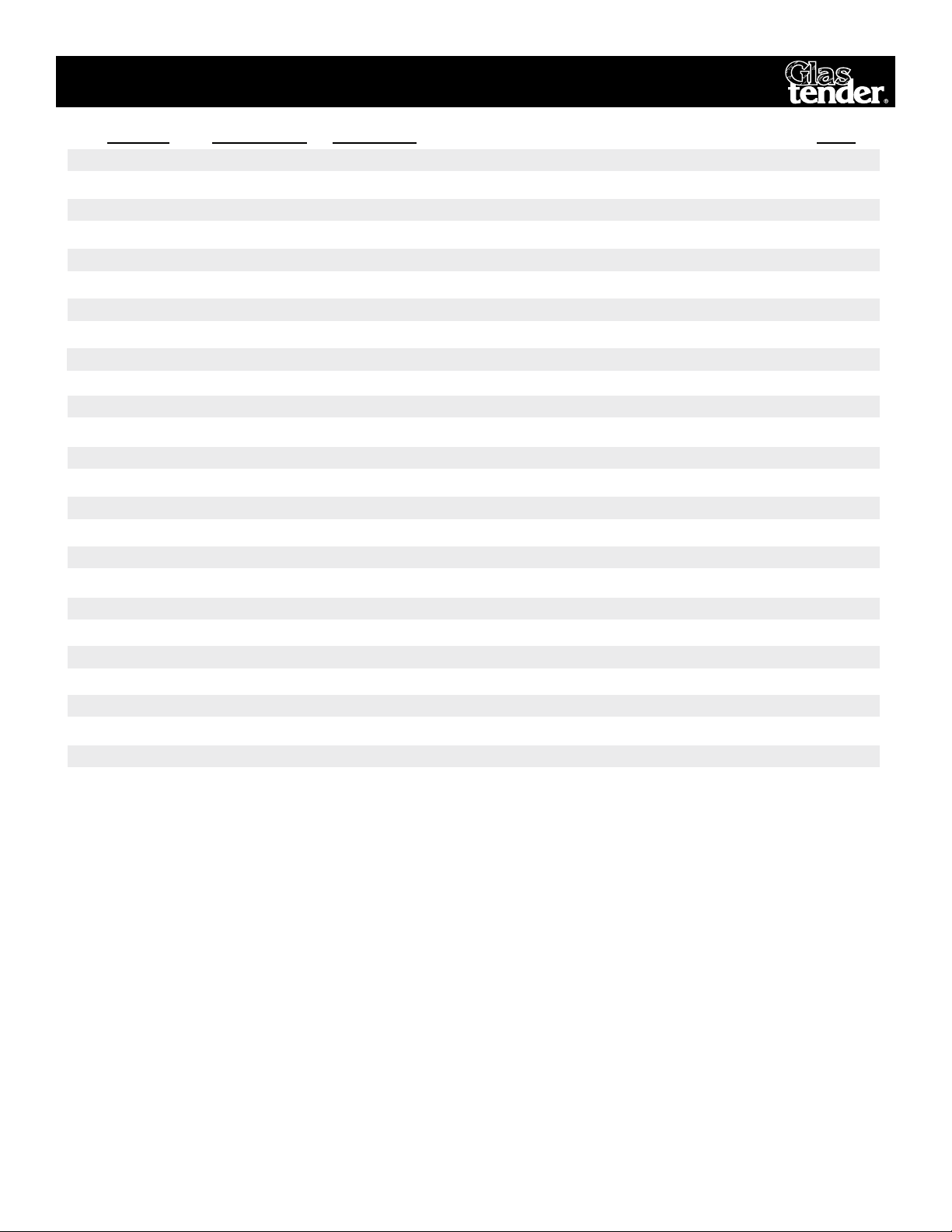

Dimensions

• Height - 22.25” (56.5 cm)

• Width - 26.75” (67.9 cm)

• Depth - 16.50” (41.9 cm)

Circuits

• Six (6) syrup, plus soda and water

Electrical

• 115V/60 Hz/16.0 Amps

• 230V/50 Hz/8.0 Amps

• 20 amp circuit required

• Includes a 6-foot grounded cord

Refrigeration

• 1/3 HP, R134a refrigerant

Water Bath

• Roto-molded polyethylene

Insulation

• Polyurethane foamed-in-place

NOTE: Clearance of 12”

required around unit for

maintenance and air flow.

Ice Bank

• 35 lbs (15.9 kg)

Maximum Draw Rate

• 6 oz drinks - 460 at 4 per min

• 12 oz drinks - 253 at 2 per minute

• Based on a 40ºF (4.4ºC) or below

dispensed drink, ambient and

incoming syrup and water at a tem perature of 75ºF (23ºC)

Recovery

• 3 six ounce drinks per minute

Pull Down

• 6.9 hours operational

Maximum Distance to Dispensers

• 150 ft (46 m)

Carbonator

• Integral cold carbonator

22.25”

16.50”

26.75”

Carbonator Pump

• 100 gph (378 lph)

Carbonator Motor

• 1/3 HP (.25 kW)

Circulating Pump

• 70 gph (265 lph)

Circulating Motor

• 1/3 HP (.25 kW)

Shipping Weight

• 143 lbs (65 kg)

Operating Weight

• 261 lbs (119 kg)

Shipping Cube

• 9.8 cu ft (.278 cu m)

Options

• 4” Adjustable legs (up to 5-1/2”)

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

7

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 11

FRONT SIDE REAR

sPeCifiCations

NOTE: Air flow & proper ventilation required for compressor

12” gap on sides for ventilation & to remove cover,

3” gap in rear for recirculation line hook-up, and 20”

gap on top for ventilation and servicing.

Top, front, & sides are one piece and are

removable for servicing the compressor.

On/Off

Switch

26.75" 16.50"

ISOMETRIC

Air Intake

remove cover

Screws to

towards you

Cover-Pull

to remove

Removable

22.25"

12.125"

1.625"

Exhaust

10.125"

Air Intake

14.375"

Removable

Cover

Compressor Area

(Under cover)

TOP

Exhaust

Exhaust

Exhaust

allow 20" clearance above unit to service compressor

note: compressor failure due to restriction

or blockage of air flow will void warranty.

Electrical

Cord & Plug

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

8

Page 12

tyPiCaL instaLLation diagRaMs

Typical Installation - Using bag-in-box syrup system

Typical Installation - Using product tank syrup system

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

9

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 13

GREEN

115v/60hz 20 amp RECEPTICAL REQUIRED

RELAY STARTER

WiRing diagRaM

CARBONATOR

SWITCH

CARBONATOR

TANK

SWITCH

BLACK

M

CARBONATOR

MOTOR

BLACK

WHITE

WHITE

RECIRC SWITCH

BLACK

TERMINAL BLOCK

WHITE

M

RECIRC MOTOR

AGITATOR MOTOR

GREEN

RECEPTICAL

BLACK

M

BLACK

WHITE

M

CONDENSER FAN

OVERLOAD

COMMON

RUN START

COMPRESSOR

TEMPERATURE CONTROL

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

10

Page 14

LC84 CoMPRessoR and ReLated PaRts

2

6

9

12

10

11

7

4

8

13

3

1

5

15

16

20

14

17

18

11

21

19

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Page 15

LC84 CoMPRessoR and ReLated PaRts

PaRt no. oLd PaRt no. desCRiPtion PRiCe

1. 09000416 GT-037436 Refrigeration Deck Assembly Complete $985.00

2. 09000299 GT-032805 Condenser Fan Blade 10.50

3. 06001439 GT-035014 1/3 HP Compressor R-134A 405.00

4. 09000291 GT-032598 Evaporator coil, LC83, 84 & 85, Copper 110.00

5. 06001313 GT-031400 Condensing unit power cord 20.00

6. 09000340 GT-035119 Recirculating pump 350.00

7. 09000257 GT-006552 Complete basket assembly 508.00

8. 09000482 GT-006554 Soda circuit only, tubing coil 139.00

9. 06001595 Insulation, pump, white, set of 2 pieces 9.00

10. 09000261 GT-031404 104” exterior power cord 20.00

11. 09000412 GT-037112 Carbonator tank, 115V 415.00

12. 09000479 GT-034114 Relay, compressor 20.00

09000480 GT-031211 Compressor overload 11.50

09000481 GT-032210 Compressor start capacitor 10.00

13. 09000338 GT-035116 Agitator motor, stainless steel shaft 170.00

14. 09000336 GT-035109 Condenser fan motor 85.00

09000463 GT-041306 Accumulator, cap tube assembly 40.00

15. 09000327 GT-034517 Soda Water pump 350.00

16. 09000328 GT-034518 Water pump 190.00

17. 09000304 GT-033208 Ice bank control 100.00

18. 09000410 GT-037110 Main cabinet tank 130.00

19. 09000395 GT-036135 Complete cover, black vinyl clad 78.00

20. 09000293 GT-032615 Condenser coil 125.00

21. 06001412 GT-033421 Rocker switch 4.00

06001409 GT-033304 Snap-in receptacle 5.00

09000436 GT-036497 Plug, black plastic, 1 3/4” hole .50

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

12

Page 16

APPLICABLE TO ALL PRODUCTS SOLD WITHIN THE UNITED STATES AND CANADA

LABOR: Glastender, Inc. warrants all products to be free of defects in

material and workmanship. In established areas, a start-up is included

with glasswasher models GT-24 and GT-30. A 1-year labor warranty

applies to all glasswashers. BDS model bottle disintegration systems

and self-contained refrigeration models, except beer line chillers,

include a 1-year labor warranty, for the duration of one year from date of

installation or up to 18 months from date of factory shipment, whichever

occurs sooner. For warranty labor claims beyond 15 months from the

date of factory shipment, proof of date of installation or occupancy must

be provided. Authorization for labor must be obtained from Glastender

within the warranty period and prior to the service being performed.

Labor warranty applies to the United States and Canada only.

PARTS: Within one year from date of installation or 18 months from

date of factory shipment, whichever occurs sooner, Glastender, Inc.

will replace any part or assembly found defective under normal use and

service. Field replacement parts include a warranty of 90 days from date

of installation.

FOUR YEAR ADDITIONAL COMPRESSOR WARRANTY:

Glastender will warrant to the original user the compressor for all selfcontained refrigeration models for an additional four years following the

regular one-year warranty period. This plan applies to the compressor

only.

A warranty claim form MUST accompany all returned defective parts or

assemblies. This form MUST be completed in full. Failure to do so may

result in delay or denial of credit. Any defective part or assembly must

be returned to Glastender, Inc., Saginaw, Michigan, with all transportation and delivery charges prepaid. Warranty repairs or replacements

will be shipped FOB factory in Saginaw, Michigan. Reimbursement for

applicable freight charges covers ground service only.

Glastender provides in-warranty repairs during a service company’s

regular working days and hours. There is no provision for payment

of a premium rate during “overtime” hours. When warranty service is

requested during other than normal working hours, the end user will be

charged the premium portion of the overtime rate.

The warranty covers substantiated travel expenses for up to 2 hours /

100 miles round trip and a maximum of $150. Any additional costs due

to installations that require extra work, time, or travel to gain access

for service are the sole responsibility of the equipment purchaser. Any

exceptions to these travel and access limitations must be pre-approved

by a factory representative.

The warranty does not cover equipment subjected to accidents, freight

damage, alterations from the original design, improper power and/or

plumbing hookups, improper chemical use, general misuse, or lack

of routine required maintenance as determined by Glastender, Inc.

Installation, normal control adjustments, general maintenance, correcting an installation error, or service calls that reveal the unit is functioning normally will not be reimbursed under warranty.

Condenser coils on self-contained refrigeration products must be

cleaned regularly. Failure to provide adequate air flow to a refrigeration

unit will void the warranty.

Glastender shall not be liable for loss of use, revenue, or profit, or for

any other indirect, incidental, special, or consequential damage including, but not limited to, product spoilage or loss.

This warranty is conditioned upon Glastender receiving notice of any

defect subject to this warranty within sixty (60) days of its discovery

by the end user or dealer. All products are warranted only for the initial

place of installation. Removal of a product automatically terminates

this warranty.

SECOND YEAR EXTENDED PARTS & LABOR WARRANTY:

Glastender’s one-year parts and labor warranty on self-contained refrigeration units, excluding beer line chillers, can be extended to two years

with the purchase of a two year parts and labor warranty. Specify part

number EWR2 ($150 net price) when ordering.

EXPORT WARRANTY - One year parts only.

EXCLUSION OF WARRANTIES

EXCEPT AS PROVIDED ABOVE, GLASTENDER MAKES

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE

OR NON-INFRINGEMENT.

LIMITATION OF REMEDIES AND DAMAGES

If Buyer makes a valid and timely claim as outlined above, Glastender’s

liability and Buyer’s remedies under this agreement will be limited solely

to labor charges authorized and/or replacement or credit, at Glastender’s

option, with respect to Products returned at Buyer’s expense within thirty (30) days after warranty repair. GLASTENDER’S LIABILITY WILL

IN NO EVENT BE GREATER IN AMOUNT THAN THE PURCHASE

PRICE OF THE RETURNED PRODUCTS. GLASTENDER

WILL NOT BE LIABLE UNDER ANY CIRCUMSTANCE FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING,

BUT NOT LIMITED TO, LABOR COSTS EXCEPT AS COVERED

UNDER OUR WARRANTY, LOST PROFITS OR THE LOSS OF

PERISHABLE PRODUCTS RESULTING FROM THE USE OF OR

INABILITY TO USE OUR PRODUCTS OR FROM OUR PRODUCTS’

INCORPORATION INTO OR BECOMING A COMPONENT OF

ANY OTHER PRODUCT. NEITHER PARTY WILL HAVE ANY

NEGLIGENCE OR OTHER TORT LIABILITY TO THE OTHER, OR

TO ANY THIRD PARTY, ARISING FROM ANY BREACH OF THIS

AGREEMENT.

GOVERNING LAW - JURISDICTION

The terms and conditions of an order are to be governed and construed

according to the laws of the State of Michigan, without regard to conflict

of laws principles. Buyer hereby consents to the jurisdiction and venue

of the courts located in Saginaw County, Michigan.

No representative, distributor, dealer, or any other person is authorized

to modify this warranty. This warranty replaces all other written or

verbal warranties.

NOTE: Glastender, Inc.’s policy of constant quality improvement

means that prices, specifications, and policies are subject to change

without notice. Questions regarding this warranty should be directed to

Glastender’s Customer Service Representative.

03-21-14

IMPORTANT!!

Attention Refrigeration Service Companies

Please review the important warranty information on this page. If you

believe a service call should be covered by the factory, please call

the factory for authorization between 8AM and 5PM EST, Monday

through Friday.

13

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 800.838.0888 / 989.752.4444 • www.glastender.com

Loading...

Loading...