Page 1

Operation Manual and Parts Directory

LC65, LC85, LC86, LC44, LC47

Draft Pro remote Glycol line chillers

Rev. 01-24-17

LC65

LC44

Glastender, Inc. · 5400 North Michigan Road · Saginaw, MI · 48604-9780

800.748.0423 · 989.752.4275 · Fax 989.752.4444 · www.glastender.com

© 2007 Glastender, Inc.

Page 2

Page 3

inDex

Topic Page

Line Chiller Specifications and Wiring Diagrams.......................................1-5

LC65 ....................................................................................................... 1

LC85 ....................................................................................................... 2

LC86 ....................................................................................................... 3

LC44 ....................................................................................................... 4

LC47 ....................................................................................................... 5

Inspection Upon Arrival .................................................................................6

Set-Up Remote Glycol Line Chiller ............................................................... 6

Electrical Hook-Up ......................................................................................... 6

Glycol Line Connection .................................................................................. 6

Glycol Filling .................................................................................................. 7

Unit Start-Up ................................................................................................... 7

Cold Control Adjustment ................................................................................ 8

System Start-Up .............................................................................................. 8

Trouble Shooting ............................................................................................9

Typical Installation Detail ............................................................................. 10

Parts Directory .........................................................................................11-20

LC65 ................................................................................................ 11-12

LC85 ................................................................................................13-14

LC86 ................................................................................................15-16

LC44 ................................................................................................17-18

LC47 ................................................................................................19-20

Remote Beer Line Chiller Accessories ......................................................... 21

Installation Notes .......................................................................................... 22

Warranty ........................................................................................................ 23

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 4

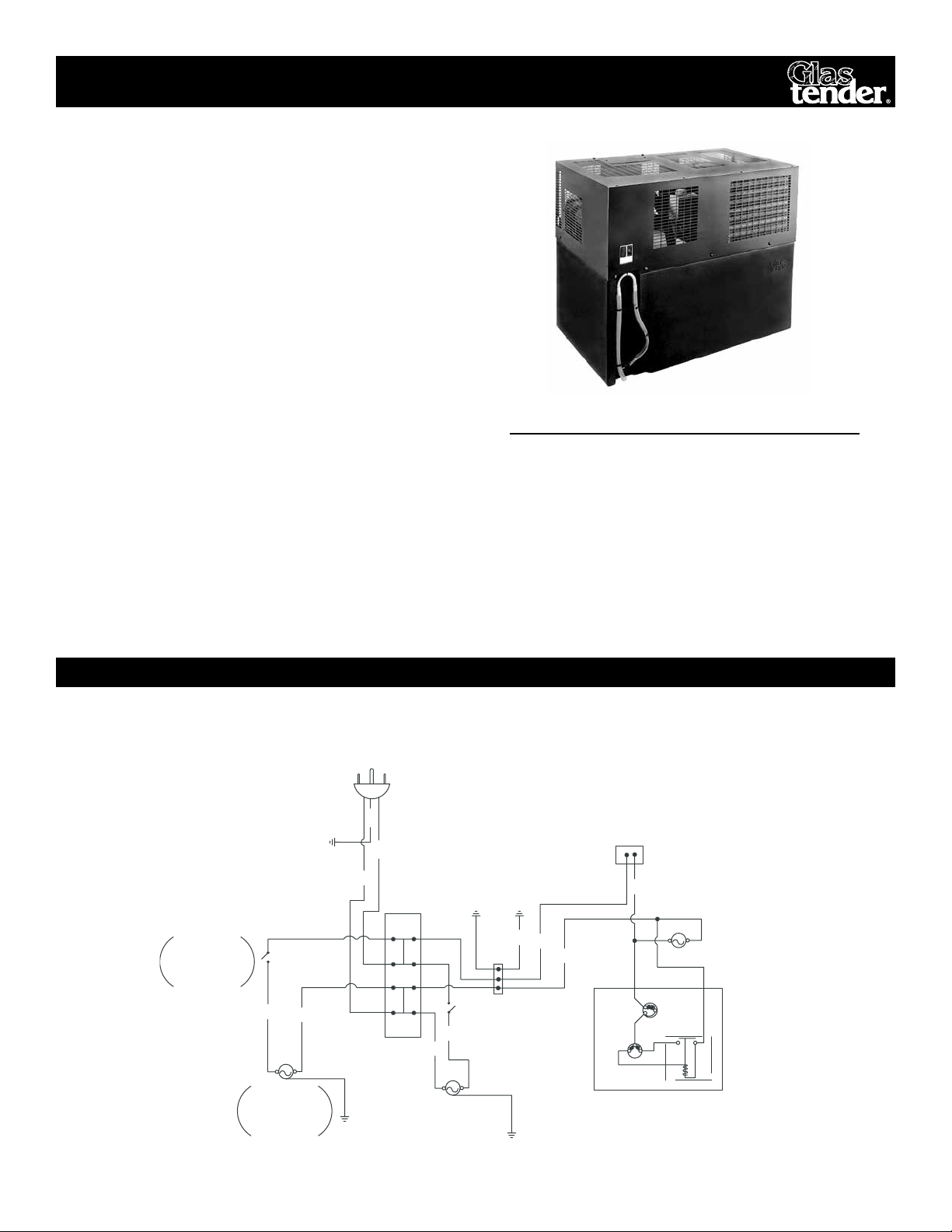

lc65 sPecifications

TEMPERATURE CONTROL

RED

RELAY START

Dimensions

• Height - 20.0” (49.5 cm)

• Width - 18.0” (45.7 cm)

• Depth - 25.75” (50.2 cm)

Electrical

• 115V, 1 phase, 60 Hz, 10.8 full load amps

• 230V, 1 phase, 50 Hz, 5.8 full load amps

• Dedicated 15 amp circuit is required

• Includes a 8-foot grounded cord

Refrigeration

• 1/3 HP R134a lift-out high temperature condensing unit

Glycol Bath Capacity

• 7.5 U.S. gallons (28.4 l)

Maximum Distance to Taps

• 125 ft (22.9 m)

Circulating Pump

• 60 gph (227 lph)

Circulating Motor

• 1/3 HP (.25 kW)

Shipping Weight

• 92 lbs (41.8 kg)

Operating Weight

• 152 lbs (69.1 kg)

Shipping Cube

• 9.5 cu ft (.28 cu m)

Options

• 4” Adjustable legs (up to 5-1/2”)

LC65

StanDarD Features

• Modular lift-out refrigeration system for easy

in-field service

• High capacity refrigeration and recirculation for

high volume and remote long distance installations

• CFC-free R134a refrigerant

• Light-weight, roto-molded glycol bath with drain

• Polyurethane foamed-in-place insulation

NOTE: Clearance of 12” required around unit for

maintenance and air flow.

1

MAIN POWER

SUPPLY

230v/60hz

RECIRC MOTOR

RECIRC MOTOR

OPTIONAL

GREEN

lc65 WirinG DiaGram

BLACK

BLACK

RED

BLACK

RED

BLACK

GREEN

MM

RED

BLACK

GREEN

TERMINAL BLOCK

RED

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

BLACK

BLACK

CONDENSER FAN

M

OVERLOAD

COMMON

RED

RUN START

COMPRESSOR

Page 5

lc85 sPecifications

MAIN POWER

RELAY START

Dimensions

• Height - 22.25” (56.5 cm)

• Width - 26.75” (67.9 cm)

• Depth - 16.50” (41.9 cm)

Electrical

• 115V, 1 phase, 60 Hz, 10.8 full load amps

• 230V, 1 phase, 50 Hz, 5.8 full load amps

• Dedicated 15 amp circuit is required

• Includes a 8-foot grounded cord

Refrigeration

• 1/3 HP R134a lift-out high temperature condensing unit

Glycol Bath Capacity

• 14.80 U.S. gallons (56.0 l)

Maximum Distance to Taps

• 125 ft (38.1 m)

Circulating Pump

• 60 gph (227 lph)

Circulating Motor

• 1/3 HP (.25 kW)

Shipping Weight

• 107 lbs (48.5 kg)

Operating Weight

• 225 lbs (102 kg)

Shipping Cube

• 9.5 cu ft (.28 cu m)

Options

• 4” Adjustable legs (up to 5-1/2”)

LC85

StanDarD Features

• Modular lift-out refrigeration system for easy

in-field service

• High capacity refrigeration and recirculation for

high volume and remote long distance installations

• CFC-free R134a refrigerant

• Light-weight, roto-molded glycol bath with drain

• Polyurethane foamed-in-place insulation

NOTE: Clearance of 12” required around unit for

maximum air flow and 20” of overhead

clearance for servicing compressor.

OPTIONAL

RECIRC SWITCH

LC86 ONLY

BLACK

WHITE

M

OPTIONAL

RECIRC MOTOR

LC86 ONLY

lc85 WirinG DiaGram

SUPPLY

115v/60hz

GREEN

BLACK

WHITE

GREEN

BLACK

RECEPTICAL

RECIRC SWITCH

BLACK

TERMINAL BLOCK

WHITE

M

RECIRC MOTOR

TEMPERATURE CONTROL

WHITE

COMMON

RUN START

BLACK

M

CONDENSER FAN

OVERLOAD

COMPRESSOR

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

2

Page 6

lc86 sPecifications

MAIN POWER

RELAY START

Dimensions

• Height - 24.25” (61.6 cm)

• Width - 26.75” (67.9 cm)

• Depth - 16.50” (41.9 cm)

Electrical

• 115V, 1 phase, 60 Hz, 16.0 full load amps

• 230V, 1 phase, 50 Hz, 8.0 full load amps

• Dedicated 20 amp circuit is required

• Includes a 8-foot grounded cord

Refrigeration

• 1/2 HP R134a lift-out high temperature condensing unit

Glycol Bath Capacity

• 14.80 U.S. gallons (56.0 l)

Maximum Distance to Taps

• 250 ft (53.4 m)

Circulating Pump

• 60 gph (227 lph)

Circulating Motor

• 1/3 HP (.25 kW)

Shipping Weight

• 125 lbs (56.7 kg)

Operating Weight

• 243 lbs (110 kg)

Shipping Cube

• 9.5 cu ft (.28 cu m)

Options

• Additional recirculating pump kit

• 4” Adjustable legs (up to 5-1/2”)

LC86

StanDarD Features

• Modular lift-out refrigeration system for easy

in- field service

• High capacity refrigeration and recirculation for

high volume and remote long distance installations

• CFC-free R134a refrigerant

• Light-weight, roto-molded glycol bath with drain

• Polyurethane foamed-in-place insulation

NOTE: Clearance of 12” required around unit for

maximum air flow and 20” of overhead

clearance for servicing compressor.

OPTIONAL

RECIRC SWITCH

LC86 ONLY

BLACK

WHITE

M

OPTIONAL

RECIRC MOTOR

LC86 ONLY

lc86 WirinG DiaGram

SUPPLY

115v/60hz

GREEN

BLACK

WHITE

GREEN

BLACK

RECEPTICAL

RECIRC SWITCH

BLACK

TERMINAL BLOCK

WHITE

M

RECIRC MOTOR

TEMPERATURE CONTROL

WHITE

COMMON

RUN START

BLACK

M

CONDENSER FAN

OVERLOAD

COMPRESSOR

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

3

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 7

lc44 sPecifications

TEMPERATURE CONTROL

WHITE

RELAY START

Dimensions

• Height - 30.56” (77.6 cm)

• Width - 20.125” (51.1 cm)

• Depth - 25.125” (63.8 cm)

Electrical

• 115V, 1 phase, 60 Hz, 16.0 full load amps

• 230V, 1 phase, 50 Hz, 8.0 full load amps

• Dedicated 20 amp circuit is required

• Includes a 8-foot grounded cord

Refrigeration

• 1/2 HP R134a lift-out high temperature con-

densing unit

Glycol Bath Capacity

• 16.25 U.S. gallons (61.78 l)

Maximum Distance to Taps

• 250 ft (53.4 m)

Circulating Pump

• 60 gph (227 lph)

Circulating Motor

• 1/3 HP (.25 kW)

Shipping Weight

• 125 lbs (56.82 kg)

Operating Weight

• 243 lbs (110.45 kg)

Shipping Cube

• 12.75 cu ft (.36 cu m)

Options

• Additional recirculating pump kit

• 4” Adjustable legs (up to 5-1/2”)

LC44

StanDarD Features

• Modular lift-out refrigeration system for easy

in- field service

• High capacity refrigeration and recirculation for

high volume and remote long distance installations

• CFC-free R134a refrigerant

• Light-weight, roto-molded glycol bath with drain

• Polyurethane foamed-in-place insulation

NOTE: Clearance of 12” required around unit for

maximum air flow and 20” of overhead

clearance for servicing compressor.

MAIN POWER

SUPPLY

115v/60hz

RECIRC MOTOR

RECIRC MOTOR

OPTIONAL

GREEN

lc44 WirinG DiaGram

BLACK

BLACK

RECEPTICAL

RECEPTICAL

OPTIONAL

POWER SWITCH

WHITE

WHITE

BLACK

BLACK

BLACK

TERMINAL BLOCK

TERMINAL BLOCK

WHITE

BLACK

WHITE

MM

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

BLACK

CONDENSER FAN

M

OVERLOAD

COMMON

WHITE

RUN START

COMPRESSOR

4

Page 8

lc47 sPecifications

TEMPERATURE CONTROL

RED

RELAY START

Dimensions

• Height - 34.56” (87.7 cm)

• Width - 20.125” (51.1 cm)

• Depth - 25.125” (63.8 cm)

Electrical

• 230V, 1 phase, 60 Hz, 12.4 full load amps

• Dedicated 20 amp circuit is required

• Includes a 8-foot grounded cord

Refrigeration

• 3/4 HP R134a lift-out medium temperature con-

densing unit

Glycol Bath Capacity

• 16.25 U.S. gallons (61.78 l)

Maximum Distance to Taps

• 400 ft (91.5 m)

Circulating Pump

• 60 gph (227 lph)

Circulating Motor

• 1/3 HP (.25 kW)

Shipping Weight

• 155 lbs (70.34 kg)

Operating Weight

• 273 lbs (123.87 kg)

Shipping Cube

• 12.75 cu ft (.36 cu m)

Options

• Additional recirculating pump kit

• 4” Adjustable legs (up to 5-1/2”)

LC47

StanDarD Features

• Modular lift-out refrigeration system for easy

in-field service

• High capacity refrigeration and recirculation for

high volume and remote long distance installations

• CFC-free R134a refrigerant

• Light-weight, roto-molded glycol bath with drain

• Polyurethane foamed-in-place insulation

NOTE: Clearance of 12” required around unit for

maximum air flow and 20” of overhead

clearance for servicing compressor.

5

MAIN POWER

SUPPLY

230v/60hz

RECIRC MOTOR

RECIRC MOTOR

OPTIONAL

GREEN

MM

lc47 WirinG DiaGram

BLACK

BLACK

RED

BLACK

RED

BLACK

GREEN

RED

BLACK

GREEN

TERMINAL BLOCK

TERMINAL BLOCK

RED

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

BLACK

BLACK

CONDENSER FAN

M

OVERLOAD

COMMON

RED

RUN START

COMPRESSOR

Page 9

insPection anD set-uP

1. insPection uPon arrival:

Immediately upon arrival, a visual inspection of the carton should be made to determine if there is

evidence of damage in shipment. Following uncrating, make an inspection for any signs of external

damage.

2. set-uP of remote Glycol line chiller:

Once the survey of the location has been completed to determine the positioning of the remote glycol

line chiller and the connecting draft beer dispensing stations (refer to the specification sheet to be

certain that the trunk line will be within the recommended distance), make the necessary provisions

to locate the unit and provide for the electrical services.

The ideal set-up is to mount the glycol line chiller on a proper machine stand that is easily accessible

for routine maintenance and service.

In less-than-ideal circumstances, it may be necessary to locate the unit on top of the walk-in cooler or

on the floor.

NOTE: Do not locate the glycol chiller in the walk-in cooler, as the cold ambient temperature

will reduce the cooling performance of the unit.

Ensure that the unit receives adequate ventilation, by avoiding obstructions to the air

intake and exhaust grillwork on the unit.

If the unit is located on the floor:

• Ensure the cabinet is sealed to the floor with NSF listed silicon RTV sealant applied around the

entire bottom edge of the cabinet.

• Optional 4” legs and base plate may be installed to the bottom of the cabinet.

3. electrical hook-uP:

Models LC65 and LC85 are supplied with a 15 Amp grounded cord and plug that connects at the rear

of the unit. Models LC86, LC44, and LC47 are supplied with a 20 Amp grounded cord and plug that

connects at the rear of the unit. A corresponding 15 Amp or 20 Amp grounded receptacle, depending

on the line chiller model used, must be installed within reach of the factory installed cord and plug.

4. Glycol line connection:

Install the insulated trunk line between the walk-in cooler, the glycol chiller and the dispensing

station(s).

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

6

Page 10

Glycol fillinG anD unit start-uP

5. Glycol fillinG:

The LC65 glycol bath capacity is 7.5 gallons (US). The LC85 and the LC86 glycol bath capacity is

14.8 gallons (US). The LC44 and LC47 glycol bath capacity is 16.25 gallons (US).

Glycol supplied by Glastender, Inc. may be diluted to a ratio of (1) part glycol to (2) parts water for

freeze protection down to 0ºF (-18ºC) or a ratio of (1) part glycol and (3) parts water for freeze protection down to 10ºF (-12ºC). These mix ratios are recommended, since the refrigeration system is not

capable of lowering the temperature of the glycol bath below 15ºF (-9.4ºC)

For glycol not supplied by Glastender, Inc. please consult the glycol manufacturer’s recommended mix-

ing ratio for the desired operating temperature.

NOTE: Do not place full strength glycol (undiluted) in the bath, as it will reduce the efficiency

of the refrigeration system and may result in damage to the recirculation pump due to

increased viscosity of cold glycol.

NOTE: Select and use only a propylene glycol product that meets FDA (Food and Drug

Administration) regulations as a food grade product. Any substitution of food grade

glycol with automotive anti-freeze or other products will expose people to hazardous

chemicals.

Fill the bath with glycol mixture by placing funnel in the fill hole (remove black plug in refrigeration

deck platform). Pour in the glycol mixture until the level in the bath reaches the top, and the liquid

begins to flow slightly from the overflow tube at the front of the unit.

6. unit start-uP:

• Plug in unit to fifteen (15) or twenty (20) amp protected circuit (Refer to Step 3, Electrical Hook Up).

• Models LC65 and LC44 have a power switch that allows the condensing unit and recirculating pump

to operate when is the on position.

• Once models LC85 and LC86 are plugged in, the condensing unit will operate. There is a separate

power switch to operate recirculating pump.

• Once the LC47 is plugged in, both the condensing unit and the recirculating pump will operate.

• Check all glycol circuit line connections for leaks.

• Once the pump has operated for a few minutes and the glycol circuit lines are fully flooded, the bath

will need to be topped-off with additional glycol mixture.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

7

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 11

colD control aDjustment anD system start-uP

7. Cold Control Adjustment:

Scale

Adjusting Knob

Cold Control

8. system start-uP:

It is a good practice to operate the glycol recirculation system for sixty (60) minutes before run-

ning beer through to the remote dispensing station(s). This enables the glycol circuit to be checked

for leaks. Also, recirculating cold glycol through the lines enables the temperature inside the trunk

line to stabilize before beer is introduced.

• Once the refrigeration unit and the glycol recirculating pump have operated for sixty (60)

minutes or more, the beer product can be connected and drawn through the trunk line

• Check the system for leaks.

• Thoroughly insulate all line joints in the trunk line and dispensing station(s).

NOTE: Be certain to close off the trunk line end with insulating tape at the point where

the glycol recirculating lines enter, otherwise condensation will occur on exposed

lines.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

8

Page 12

trouble shootinG

9. trouble shootinG:

Complaints of warm beer...

• Check the temperature of walk-in beer cooler.

• Check the glycol bath temperature.

• Check that recirculating pump is operating.

Refrigeration Compressor Will Not Run...

• Check that the unit is getting electrical power.

• Check that cold control is working.

• Check that all wiring connections are secure.

Refrigeration Compressor Runs But Stops...

• Check for dirt build-up on condenser coil surface.

• Check that there is no obstruction of air flow into the cabinet.

• Ensure that enough voltage is supplied to the unit.

Refrigeration Compressor Runs But Not Cooling...

• Check for refrigerant leaks.

Noisy or Hot Recirculating Pump...

• Ensure that glycol bath is not frozen.

• Ensure that the glycol solution has been properly diluted.

• Check motor and pump coupling for wear.

Recirculation Pump Not Working...

• Ensure that pump and motor coupling has not worn free.

• Check power supply to the motor.

• Replace worn pump.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

9

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 13

CHASEWAY

tyPical installation Detail

OF BEER TOWER

SIDE ELEVATION

RESTRICTION LINES ON

TOWER ARE CONNECTED

TO THE BEER LINE SET

(DO NOT CHANGE LENGTH

WITHOUT CONSULTING

THE FACTORY)

ON BAR TOP

2

CO2

4

(STEP DOWN PRESSURE

TO BELOW 60 POUNDS)

PRIMARY REGULATOR

RUNS TO WALK-IN COOLER

TANK MOUNT REGULATOR

MAIN CO2 LINE FROM

INSULATED LINE CONTAINING

IN AND OUT GLYCOL LINES

SET ARE CONNECTED TO

BEER LINES FROM LINE

1

THE BEER PUMPS

KEG KEG KEG

PREVENT ICE BUILD-UP.)

CLEAR JUMPER LINES

TO THE BEER PUMP

CONNECT THE KEG

THRU CHASE, SO GLYCOL

(MUST INSULATE LINES

CAN CIRCULATE BACK

TO THE LINE CHILLER.

INSIDE WALK-IN TO

RED CO2

AIR LINE

TO KEG

TO NEXT PANEL

AS NECESSARY

TWO GLYCOL LINES GO

COOLER

BEER PUMP

BEER LINES GOING

CHILLER

POWER

WALK-IN

LINE

3

7

BEER PUMP REGULATOR

CONTROLS CO2 PRESSURE

TO BEER PUMPS

5

SECONDARY

REGULATORS CONTROL

CO2 PRESSURE TO KEGS

FROM BEER PUMPS

CO2 EXHAUST LINE

KEG TAP

6

AS NECESSARY

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

CO2 LINE GOING TO

NEXT BEER PUMP PANEL

8

10

Page 14

lc65 comPressor anD relateD Parts

11

19

10

2

6

1

3

7

16

4

17

5

8

9

18

14

12

15

11

13

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 15

lc65 comPressor anD relateD Parts

Part no. olD Part no. DescriPtion Price

1. 06001439 GT-035014 1/3 HP 134A Tecumseh compressor $435.00

2. 09000336 GT-035109 Condenser fan motor 85.00

09000483 GT-031537 Bracket, condenser fan motor mounting 4.00

3. 09000299 GT-032805 Fan blade, condenser, 3 blade 10.50

4. 09000463 GT-041306 Filter dryer, suction line accumulator,

and cap tube assembly

5. 09000293 GT-032615 Condenser coil 125.00

6. 09000296 GT-032626 Evaporator 110.00

7. 09000340 GT-035119 Recirculating pump motor 350.00

8. 09000331 GT-034536 Pump, glycol, 60 gph, brass 225.00

9. 00000006 GT-031115 Clamp, recirculating pump 3.00

10. 06001595 Insulation, pump, white (set of two pieces) 9.00

11. 09000413 GT-037117 Main cabinet tank 115.00

12. 09000402 GT-036172 Cover, LC65 114.00

13. 09000420 GT-037443 Complete refrigeration deck 960.00

14. 09000436 GT-038497 Plug, black, 1 3/4

15. 06001412 GT-033421 Rocker switch 5.00

16. 06001409 GT-033304 Snap in receptacle 5.00

17. 09000303 GT-033207 Thermostat 160.00

18. 09000429 GT-038474 Knob, thermostat 4.00

09000261 GT-031404 Exterior power cord, 104

19. 06001313 GT-031400 Condensing unit power cord 20.00

˝ hole .50

˝ 20.00

40.00

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

12

Page 16

lc85 comPressor anD relateD Parts

9

18

11

19

7

15

2

1

3

16

17

4

5

6

13

12

8

13

10

14

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 17

lc85 comPressor anD relateD Parts

Part no. olD Part no. DescriPtion Price

1. 06001439 GT-035014 1/3 HP 134A Tecumseh compressor $435.00

2. 09000336 GT-035109 Condenser fan motor 85.00

3. 09000483 GT-031537 Bracket, condenser fan motor mounting 4.00

4. 09000299 GT-032805 Fan blade, condenser, 3 blade 10.50

5. 09000463 GT-041306 Filter dryer, suction line accumulator, 40.00

and cap tube assembly

6. 09000293 GT-032615 Condenser coil 125.00

7. 09000291 GT-032598 Evaporator coil, LC 83, 84 & 85 Copper 110.00

8. 09000340 GT-035119 Recirculating pump motor 350.00

9. 09000331 GT-034536 Pump, glycol, 60 gph, brass 225.00

00000006 GT-031115 Clamp, recirculating pump 3.00

10. 06001595 Insulation, pump, white (set of two pieces) 9.00

11. 09000410 GT-037110 Main cabinet tank 130.00

12. 09000399 GT-036158 Cover, LC85 160.00

09000417 GT-037437 Complete refrigeration deck 900.00

13. 09000436 GT-038497 Plug, black, 1 3/4

14. 06001412 GT-033421 Rocker switch 5.00

15. 06001409 GT-033304 Snap in receptacle 5.00

16. 09000303 GT-033207 Thermostat 160.00

17. 09000429 GT-038474 Knob, thermostat 4.00

18. 09000261 GT-031404 Exterior power cord, 104

19. 06001313 GT-031400 Condensing Unit Power Cord 20.00

˝ hole .50

˝ 20.00

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

14

Page 18

lc86 comPressor anD relateD Parts

9

17

10

8

4

7

2

3

1

5

11

15

18

6

14

12

16

15

13

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 19

lc86 comPressor anD relateD Parts

Part no. olD Part no. DescriPtion Price

1. 09000334 GT-035015 1/2 HP R134A Tecumseh compressor $720.00

2. 09000336 GT-035109 Condenser fan motor, 9w, 115v 85.00

3. 09000483 GT-031537 Bracket, condenser fan motor mounting 4.00

4. 09000299 GT-032805 Fan blade, condenser 10.50

5. 09000462 GT-041305 Filter dryer, suction line accumulator, 41.00

and cap tube assembly

6. 09000293 GT-032615 Condenser coil 125.00

7. 09000290 GT-032597 Evaporator coil, copper, LC 86 220.00

8. 09000340 GT-035119 Recirculating pump motor, 1/3 hp, 115v 350.00

9. 09000331 GT-034536 Pump, glycol, 60 gph, brass 225.00

00000006 GT-031115 Clamp, recirculating pump 3.00

10. 06001595 Insulation, pump, white (set of two pieces) 9.00

11. 09000410 GT-037110 Main cabinet tank 130.00

12. 09000400 GT-036159 Cover, complete LC-86 176.00

09000421 GT-037445 Complete refrigeration deck 1350.00

13. 09000436 GT-036497 Plug, black, 1 3/4

06001412 GT-033421 Rocker switch 5.00

14. 06001409 GT-033304 Snap in receptacle 5.00

15. 09000303 GT-033207 Thermostat 160.00

16. 09000429 GT-038474 Knob, thermostat 4.00

17. 09000261 GT-031404 Exterior power cord, 104” 20.00

18. 06001313 GT-031400 Condensing Unit Power Cord 20.00

˝ hole .50

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

16

Page 20

12

lc44 comPressor anD relateD Parts

19

7

11

8

17

9

3

2

16

4

14

13

15

10

6

18

17

1

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

5

Page 21

lc44 comPressor anD relateD Parts

Part no. olD Part no. DescriPtion Price

1. 09000334 GT-035015 1/2 HP R134A Tecumseh compressor $720.00

2. 09000336 GT-035109 Condenser fan motor, 9w, 115v 85.00

3. 09000300 GT-032806 Fan blade, condenser fan motor 15.00

4. 09000483 GT-031537 Bracket, condenser fan motor mounting 4.00

5. 09000462 GT-041305 Suction line accumulator and cap tube assembly 41.00

6. 09000292 GT-032614 Condenser coil 170.00

7. 09000289 GT-032595 Evaporator coil, copper LC 44, 45 200.00

8. 09000340 GT-035119 Recirculating pump motor, 1/3hp, 115v 350.00

9. 09000331 GT-034536 Pump, glycol, 60 gph, brass 225.00

10. 00000006 GT-031115 Clamp, recirculating pump 3.00

11. 06001595 Insulation, pump, white (set of two pieces) 9.00

12. 09000396 GT-036138 Cover, Complete, LC44 143.00

13. 09000436 GT-036497 Plug, black, 1 3/4

14. 06001412 GT-033421 Rocker switch, 20 amp, recirc. pump 5.00

15. 09000303 GT-033207 Thermostat, LC 160.00

16. 09000429 GT-038474 Knob, thermostat 4.00

17. 09000261 GT-031404 Exterior power cord, 104

18. 06001313 GT-031400 Condensing Unit Power Cord 20.00

19. 09000411 GT-037111 Main Cabinet Tank 280.00

09000362 GT-037439 Complete Refrigeration Deck 1650.00

˝ hole .50

˝ 20.00

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

18

Page 22

lc47 comPressor anD relateD Parts

13

12

8

9

10

20

14

2

1

3

17

4

18

11

19

7

19

15

5

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

6

16

Page 23

lc47 comPressor anD relateD Parts

Part no. olD Part no. DescriPtion Price

1. 09000335 GT-035020 3/4 HP R134A Tecumseh compressor $930.00

2. 09000337 GT-035113 Condenser fan motor 98.00

3. 09000299 GT-032805 Fan blade, condenser, 3 blade 10.50

4. 09000485 GT-031538 Bracket, condenser fan motor mounting 9.00

5. 09000285 GT-032504 Filter dryer 32.00

6. 09000286 GT-032505 Suction line accumulator, and cap tube assembly 126.00

7. 09000294 GT-032620 Condenser coil, 3/4 hp LC 221.95

8. 09000486 GT-032629 Evaporator Coil, LC47 200.00

9. 09000342 GT-035123 Recirculating pump motor 396.80

10. 09000331 GT-034536 Pump, glycol, 60 gph, brass 225.00

11. 00000006 GT-031115 Clamp, recirculating pump 3.00

12. 06001595 Insulation, pump, white (set of two pieces) 9.00

13. 09000411 GT-037111 Main cabinet tank, plastic, 4 series box 280.00

14. 09000487 GT-036175 Cover, LC47 165.00

15. 09000418 GT-037440 Complete refrigeration deck 1800.00

16. 09000436 GT-038497 Plug, black, 1 3/4

17. 06001412 GT-033421 Rocker switch 5.00

18. 09000303 GT-033207 Thermostat 160.00

19. 09000429 GT-038474 Knob, thermostat 4.00

20. 09000262 GT-031405 Exterior power cord, 104

˝ hole .50

˝ 27.00

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

20

Page 24

remote beer line chiller accessories

Line ChiLLer Leg sets

LCLS-6

Line ChiLLer stands

moDels lcs-s anD lcs-G

A line chiller stand is 26-1/2″ wide by 39″ high by 24″ deep and comes with adjustable

feet for leveling. The bottom shelf is at the 8″ high level. The top shelf has holes that cor-

respond to the line chiller leg set mounting holes, so the line chiller can be bolted to the

shelf. One size stand is used for all line chiller models.

LCS-G

moDels lsls-6 anD lcls-4

All Glastender line chillers may be placed on 4″ legs that are adjustable up to 5-1/2″.

The leg set includes a 16 gauge galvanized steel frame plate that is sized to match the

particular unit.

Line ChiLLer WaLL raCks

LCR-G

21

moDels lcr-s anD lcr-G

A line chiller wall rack is a shelf that is mounted to a structural wall. The shelf has

holes that correspond to the line chiller leg set mounting holes, so the line chiller can

be bolted to the shelf. One size rack is used for all line chiller models.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 25

installation notes

Installation Notes

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

_________________________________________________________________________________________

Original System Installer

Company: _____________________________________________

Address: _____________________________________________

_____________________________________________

City, State, Zip: _____________________________________________

Phone Number: _____________________________________________

Fax Number: _____________________________________________

Contact: _____________________________________________

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

22

Page 26

Warranty statement

APPLICABLE TO ALL PRODUCTS SOLD WITHIN THE UNITED STATES AND CANADA

Glastender, Inc. warrants all products to be free of defects in material and workmanship. One-year labor and parts warranty applies to

all glasswashers, self-contained refrigeration models, and BDS model

bottle disintegration units. In established areas, a start up is included

with GT-24 and GT-30 model glasswashers. Warranty is effective for

one year from the date of installation or up to 18 months from date of

factory shipment, whichever occurs sooner. Glastender, Inc. will replace

any part or assembly found defective under normal use and service.

For warranty labor claims beyond 15 months from the date of factory

shipment, proof of date of installation or occupancy must be provided.

Authorization for labor must be obtained from Glastender within the

warranty period and prior to the service being performed.

Labor warranty applies to the United States and Canada only.

Remote refrigeration models and beer line chillers include a one-year

parts warranty only. There is no labor warranty on these products.

Field replacement parts not covered under the original warranty include

a 90-day part warranty from the date of installation.

FOUR YEAR ADDITIONAL COMPRESSOR WARRANTY:

Glastender will warrant to the original user the compressor for all selfcontained refrigeration models for an additional four years following the

regular one-year warranty period. This plan applies to the compressor

only.

A completed warranty claim form MUST accompany all returned defective parts or assemblies. Upon request, a defective part or assembly must

be returned to Glastender, Inc., Saginaw, Michigan, with all transportation and delivery charges prepaid. Warranty repairs or replacements

will be shipped FOB factory in Saginaw, Michigan. Reimbursement for

applicable freight charges covers ground service only.

Glastender provides in-warranty repairs during a service company’s

regular working days and hours. There is no provision for payment

of a premium rate during “overtime” hours. When warranty service is

requested during other than normal working hours, the end user will be

charged the premium portion of the overtime rate.

The warranty covers substantiated travel expenses for up to 2 hours /

100 miles round trip up to a maximum of $150. Any additional costs

due to installations that require extra work, time, or travel to gain access

for service are the sole responsibility of the equipment purchaser. Any

exceptions to these travel and access limitations must be pre-approved

by a factory representative.

The warranty does not cover equipment subjected to accidents, freight

damage, alterations from the original design, improper power and/or

plumbing hookups, improper chemical use, general misuse, or lack

of routine required maintenance as determined by Glastender, Inc.

Installation, normal control adjustments, general maintenance, correcting an installation error, or service calls that reveal the unit is functioning normally will not be reimbursed under warranty.

Condenser coils on self-contained refrigeration products must be

cleaned regularly. Failure to provide adequate air flow to a refrigeration

unit will void the warranty.

Glastender shall not be liable for loss of use, revenue, or profit, or for

any other indirect, incidental, special, or consequential damage including, but not limited to, product spoilage or loss.

This warranty is conditioned upon Glastender receiving notice of any

defect subject to this warranty within sixty (60) days of its discovery

by the end user or dealer. All products are warranted only for the initial

place of installation. Removal of a product automatically terminates

this warranty.

SECOND YEAR EXTENDED PARTS & LABOR WARRANTY:

Glastender’s one-year parts and labor warranty on self-contained refrigeration units, excluding beer line chillers, can be extended to two years

with the purchase of a two year parts and labor warranty. Specify part

number EWR2 ($150 net price) when ordering.

EXPORT WARRANTY - One year parts only.

EXCLUSION OF WARRANTIES

EXCEPT AS PROVIDED ABOVE, GLASTENDER MAKES

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE

OR NON-INFRINGEMENT.

LIMITATION OF REMEDIES AND DAMAGES

If Buyer makes a valid and timely claim as outlined above, Glastender’s

liability and Buyer’s remedies under this agreement will be limited solely

to labor charges authorized and/or replacement or credit, at Glastender’s

option, with respect to Products returned at Buyer’s expense within thirty (30) days after warranty repair. GLASTENDER’S LIABILITY WILL

IN NO EVENT BE GREATER IN AMOUNT THAN THE PURCHASE

PRICE OF THE RETURNED PRODUCTS. GLASTENDER

WILL NOT BE LIABLE UNDER ANY CIRCUMSTANCE FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING,

BUT NOT LIMITED TO, LABOR COSTS EXCEPT AS COVERED

UNDER OUR WARRANTY, LOST PROFITS OR THE LOSS OF

PERISHABLE PRODUCTS RESULTING FROM THE USE OF OR

INABILITY TO USE OUR PRODUCTS OR FROM OUR PRODUCTS’

INCORPORATION INTO OR BECOMING A COMPONENT OF

ANY OTHER PRODUCT. NEITHER PARTY WILL HAVE ANY

NEGLIGENCE OR OTHER TORT LIABILITY TO THE OTHER, OR

TO ANY THIRD PARTY, ARISING FROM ANY BREACH OF THIS

AGREEMENT.

GOVERNING LAW - JURISDICTION

The terms and conditions of an order are to be governed and construed

according to the laws of the State of Michigan, without regard to conflict

of laws principles. Buyer hereby consents to the jurisdiction and venue

of the courts located in Saginaw County, Michigan.

No representative, distributor, dealer, or any other person is authorized

to modify this warranty. This warranty replaces all other written or

verbal warranties.

NOTE: Glastender, Inc.’s policy of constant quality improvement

means that prices, specifications, and policies are subject to change

without notice. Questions regarding this warranty should be directed to

Glastender’s Warranty Administrator.

01-12-16

IMPORTANT!!

Attention Service Companies

Please review the important warranty information on this page. If you

believe a service call should be covered by the factory, please call

the factory for authorization between 8AM and 5PM EST, Monday

through Friday.

23

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Loading...

Loading...