Page 1

Operation Manual

A Family Company Manufacturing In The USA Since 1969

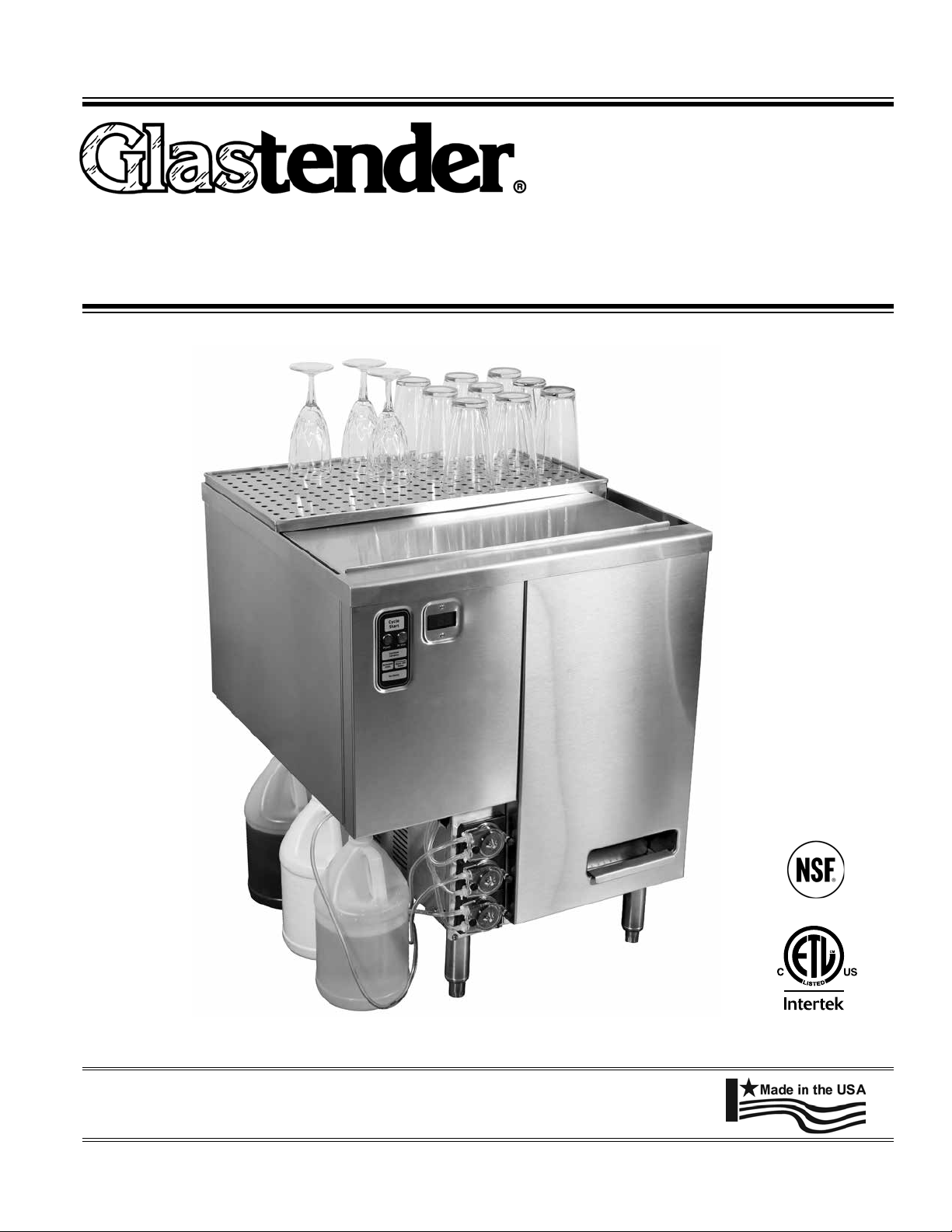

GW24 GlassWasher

Glastender, Inc. · 5400 North Michigan Road · Saginaw, MI · 48604-9780

800.748.0423 · 989.752.4275 · Fax 989.752.4444 · www.glastender.com

Rev 03-24-14

Conforms to ANSI/UL STD 921

Certied to CSA STD

C22.2 No. 168

© 2011 Glastender, Inc.

Page 2

Index

Topic Page

Introduction .....................................................................................................1

What is a glasswasher? ................................................................................... 1

Utility Requirements and Connections ........................................................... 2

Uncrating and Assembly Instructions ............................................................. 2

GW24 Parts Identification .............................................................................. 3

Start-Up Instructions ....................................................................................4-5

Water Level/Temperature Adjustment Procedure ..................................4

Chemical Adjustment Procedure ............................................................ 5

Control Panel Operation .................................................................................6

Wash Cycle Description .................................................................................. 6

Wiring Diagram ..............................................................................................7

Cleaning Instructions ...................................................................................8-9

De-liming Procedure .......................................................................................9

Slide-Out Chemical Bottle Rack Installation ...............................................10

Useful Information About Water, Detergent and Sanitizer .......................... 11

Important Information about Chemicals .......................................................12

Tips for Trouble-Free Operation ................................................................... 12

Trouble Shooting Guide ................................................................................13

Warranty ........................................................................................................ 14

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 3

IntroductIon

This manual describes the operational features of the GW24 model glasswasher. Please

review this information before attempting installation and operation. Long term, troublefree operation will follow if good housekeeping and maintenance procedures are followed.

Thank you for selecting Glastender, Inc. products.

What Is a GlassWasher?

Glastender, Inc. invented the world’s first automatic rotary glasswasher in 1969. Today, Glastender glasswashers

have been installed around the world. But what is a glasswasher? It is simply a piece of machinery that washes

glassware, which eliminates the need for human labor and the conventional three-compartment sink. The glasswasher is, in effect, a mechanized three-compartment sink. It “washes”, “rinses”, and “sanitizes” glassware.

note the sImplIcIty:

FunctIon desIGn

Wash

rInse and

sanItIze

Please read on to learn more about this simple machine.

Hot water and a preset portion of detergent join in the tank. During operation, hot soapy water is

pumped in a forceful, but gentle, spray pattern across the moving glassware. When the wash cycle

is complete, all water is drained. While the drain is still open, clean water pre-rinses the holding

tank to prepare for the rinse and sanitize cycle.

Fresh water and a preset portion of sanitizer and rinse aid join in the tank. During operation, rinse

water is pumped in a forceful, but gentle, spray pattern across the moving glassware. At the end

of the cycle, all water is drained so the next load can begin with fresh, clean water.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

1

Page 4

utIlIty requIrements and connectIons

1. General plumbInG

(Hot and cold water

required)

2. hot Water Wash

3. cold Water rInse

2. draIn

3. electrIcal

4. deterGent

5. sanItIzer

a. Use 1/2" OD (or larger) copper to 3/8" FMPT adapter provided.

b. Minimum water pressure - 25 PSI.

c. Maximum water pressure - 100 PSI. Install water pressure regulator if line pressure is over

100 PSI. Water valve on unit has built-in strainer and flow control to provide consistent vol-

ume between 25 and 100 PSI.

d. Install separate water shut-off valve for each connection.

e. Unit has built-in air gaps - vacuum breakers NOT required.

a. Maximum temperature 150°F (66°C). Minimum supply temperature 130°F (54°C) to ensure

a minimum wash temperature of 120°F (49°C).

a. No minimum cold water inlet temperature. Control module automatically tempers rinse

based on temperature setting (see Start-Up Instructions page 5, Step 5).

a. 1-1/2" tailpiece provided on unit.

b. Use open type floor drain for maximum drainage.

a. 120V, single phase, 60Hz, 6-foot grounded cord included.

b. A dedicated 15 amp circuit is recommended.

c. Power requirements - 3.5 amps.

a. Extra heavy-duty non-foaming commercial liquid dish detergent required. Adjust to .30% con-

centration.

b. Consult The local chemical supplier to match detergent with local water conditions.

a. Liquid chlorine bleach (sodium hypochlorite - 5.25% solution) adjusted to 50 PPM.

6. rInse aId

7. notes

a. Liquid Rinse Aid adjusted for proper sheeting.

a. In all cases, consult local plumbing, electrical, and health codes for regulations which may

not be consistent with the above.

b. Utilityconnectionsaremadeupfromtheooratthebottomoftheunitapproximately6"high.

c. A side notch located on the left side of the unit provides space for three one-gallon chemical

containers within the 24" x 24" footprint.

uncratInG and assembly InstructIons

The glasswasher is shipped in one carton. Refer to the images on the opposite page to identify the following:

1. Main section

2. Drainboard insert

3. Drainboard pan

4. Sliding cover

5. Inner cover

assembly procedures:

1. Remove all packaging from the main section.

2. Remove plastic protective paper from all stainless steel parts.

3. Place glasswasher in position and level by adjusting the bottom portion of the stainless legs.

4. Make plumbing connections in accordance with utility requirements listed above.

5. Install chemical bottle rack accessory if ordered with unit. See page 10 for installation instructions.

6. Conveyor

7. Spray box

8. Spray box gasket

9. Tank screen

10. Drain stopper

11. Inlet screen

12. Scrap tray

13. Water inlets

14. Chemical inlets

2

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 5

GW24 part IdentIFIcatIon*

Digital temperature gauge

Control Panel

Chemical feed lines

Chemical pumps

toP view

2. Drainboard insert

3. Drainboard pan

5. Inner cover

4. Sliding cover

1. Main section

12. Scrap tray

6. Conveyor

7. Spray box

8. Spray box gasket

Drain hole for drainboard

pan drain tube

9. Tank screen

10. Drain stopper

Front Panel removed

Water inlet lines

Drainstopper cam

and linkage arm

Circuit Board

11. Inlet screen

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

13. Water inlets

14. Chemical inlets

* For a more comprehensive parts list,

reference the GW24 Parts Directory.

3

Page 6

start-up InstructIons

WARNING: The chemicals used in commercial glass washing are very harsh. Exposure to human skin can cause severe

burns. Chemical containers should be stored in a manner and/or location that prevents them from spilling or splashing. Chemical containers must be secured. Please consult your chemical vendor to ensure proper storage or call the

Glastender factory to purchase an accessory chemical storage drawer, part number 01001500.

1. Place chemical Feed Lines into the proper chemical containers.

Red - Detergent

Blue - Rinse Aid

Clear - Sanitizer

2. After utility connections described on page 2 are completed, plug in glasswasher.

3. Prime Chemical Pumps: Slide cover open to view chemical inlets.

Depress Prime switches to fill Feed Lines (see page 6 - Control Panel Operation).

Stop priming when chemicals come out of inlets.

NOTE: Always run a complete cycle or dump clean water in the tank after using the

prime switches. Undiluted chemicals will damage stainless steel.

4. Fill Level Adjustment: Cycle the glasswasher to check water fill level (water fill level

is preset at the factory but may require adjustments due to variations in water pressure/flow at installation location).

With the sliding cover open, initiate cycle by pressing Cycle Start (see page 6 - Control Panel Operation).

When fill is complete, verify that the water level is at the FILL mark (top of the drain screen handle - see photo

below).

If water level is correct, skip to Step 5.

If water level is above or below the fill mark, fill adjustment is required.

• Unplug glasswasher and remove front panel.

• Adjust the Fill adjustment knob on the circuit board. Turn knob clockwise to increase fill time or counterclockwise to decrease fill time.

• Leaving the sliding cover open will end the cycle and drain the tank after 30 seconds and cycle can be restarted to check water level again.

Once water level is correct, continue with Step 5.

Chemical inlets

Adjust circuit board knobs as neededFILL mark - top of drain screen handle

Circuit board slides

out for easy access

4

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 7

start-up InstructIons

5. Rinse Temperature Adjustment: With the sliding cover closed, initiate a cycle by pressing Cycle Start to check rinse

water temperature (Rin Temp knob is set fully open at the factory and may require adjustment at installation location).

Machine will perform wash cycle and proceed to rinse cycle. NOTE: Wash cycle water temperature must register

between 120°F (49°C) and 150°F (66°C). Adjust hot water supply source if necessary.

During rinse cycle (recirculating pump must be on to mix and stabilize temperature reading), observe digital temperature

read out. The sliding cover can also be opened, interrupting the rinse cycle to insert thermometer into the tank water.

NOTE: Minimum rinse temperature is 75°F (24°C) per FDA Ordinance and Code for Food Service Establishments,

Section 5-103(e)(2).

If the rinse water temperature is at desired temperature, skip to Step 6.

If the rinse water temperature is not correct, temperature adjustment is required.

• Unplug glasswasher and remove front panel.

• Adjust the Rin Temp knob counterclockwise to increase rinse temperature and clockwise to decrease the rinse

temperature. NOTE: The cold water inlet supply minimum temperature may exceed 75°F, resulting in the

inability to lower the water temperature further.

• Leaving the sliding cover open will end the cycle and drain the tank after 30 seconds and cycle can be restarted to check rinse temperature again.

Once rinse water temperature is correct, continue with Step 6.

6. Chemical Concentration Adustment: With the sliding cover closed, initiate a cycle by pressing Cycle Start to check

chemical settings.

The chemical strengths should be tested with a professional test kit by the chemical supplier. Water samples should be

taken during both the wash cycle and the rinse cycle.

Proper concentration levels:

Detergent - .30% concentration

Sanitizer - 50 PPM (sodium hypochlorite [bleach])

Rinse Aid - until proper sheeting is achieved

If chemical adjustment is correct, skip to Step 8.

Unplug glasswasher, remove front panel, and adjust chemicals on the circuit board as required.

Detergent: If the factory setting does not render the proper concentration, turn the Det adjustment knob clockwise

to increase or counterclockwise to decrease the dispense time. Repeat chemical testing procedure and adjust again if

necessary.

Sanitizer: If the factory setting does not render the proper concentration, turn the San adjustment knob clockwise

to increase or counterclockwise to decrease the dispense time. Repeat chemical testing procedure and adjust again if

necessary.

Rinse Aid: If the factory setting does not render the proper level of sheeting, turn the Rin Aid adjustment knob clockwise to increase or counterclockwise to decrease the dispense time. Run a test cycle to check wash results and adjust

again if necessary.

7. Replace panel and plug in glasswasher.

Repeat Step 6 to recheck chemical settings.

8. Your glasswasher is now ready for operation.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

5

Page 8

control panel - Wash cycle

Control Panel Operation

Wash cycle descrIptIon:

1. Load the conveyor with glassware. To aid in loading the conveyor,

rotate the conveyor 1/2 turn by pressing the Conveyor Advance

button on the control panel.

Cycle

Start

Power In Use

Conveyor

Advance

Detergent

Prime

Cycle Start - Push to start wash cycle

Power - Green light* indicates power to

unit when illuminated

In Use - Red light* indicates cycle in

progress when illuminated

Conveyor Advance - Push to rotate

conveyor 1/2 turn to aid in loading/

unloading glassware

Sanitizer/

Rinse Aid

Prime

De-liming

2. Close the sliding cover.

3. Cycle is initiated by pressing the Cycle Start button on the control

panel. Once in cycle, the red In Use light will illuminate.

4. Wash water fill is initiated and the drain will close when hot water

is sensed or 15 seconds into the cycle, whichever is sooner.

5. Detergent is automatically injected into the tank during fill. The

sliding cover can be opened during fill to visually verify detergent

is being injected into wash water.*

6. The wash cycle will automatically start once full. Opening the

sliding cover during the wash cycle will pause the cycle, turning off

the recirculating pump and conveyor. Closing the sliding cover will

continue the cycle.*

7. At the completion of the wash cycle, the wash water will drain.

8. The rinse water fill is initiated with the drain open to rinse detergent

from the tank. The drain then closes to allow the tank to fill.

9. Sanitizer and Rinse Aid are automatically injected into the tank

during fill. The sliding cover can be opened during fill to visually

verify chemicals are being injected into the rinse water.*

10. The rinse cycle automatically starts once the tank if full. Opening

the sliding cover during the rise cycle will pause the cycle, turning

off the recirculating pump and conveyor. Closing the sliding cover

will continue the cycle.*

11. At the completion of the rinse cycle, the rinse water will drain.

Detergent Prime - Push and hold to

prime detergent

Sanitizer / Rinse Aid Prime - Push and

hold to prime sanitizer and rinse aid

De-liming - Push to start de-liming cycle

* Alternating flashing of the red and green

light indicates the sliding cover interlock

switch has interrupted cycle or a chemical

detection switch (optional accessory) has

detected a chemical outage.

6

12. The red In Use light will turn off, indicating that the cycle is

complete.

13. Open the sliding cover.

14. Unload the glassware from the conveyor. Pressing the Conveyor

Advance button will rotate the conveyor 1/2 turn to aid in unloading

the conveyor.

* NOTE: If the sliding cover is open for more than 30 seconds, the

cycle will terminate and the tank will drain. Press Cycle Start to

initiate a new cycle.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 9

HOT

Neutral

c

Bl

Cycle Start

Bl

Br/W

C

Door Switch

Y

O

R

De-Lime

Det Prime

R

O

San / Rin Prime

Y

NC

NO

Br/W

C

Low Det.

Air Switch

Low Chemical Option

NC

C

NO

Low San.

Air Switch

NC

NO

Low Rinse

Air Switch

Br/W

C

NC

NO

GW24 WIrInG dIaGram

San

pump

12345 6

Br/W

Control Box

MC3003463FS

R/W

pump

O/W

Rinse

pump

Bl/W

7 8

12

910

34

5 6

Det

R

O

Coveyor

Advance

P

Bl

P

24Vac

Transformer

Y +

Y -

21

43

W/R

65

87

109

Bl

P

Br

1

65432

ROY

B/W

BARE

R/W

R

B

Temp Sensor

MC4003491TS

1

2

Conveyor

3

Soft Start

4

5

B

Conveyor

Moptor

O

6

HOT

120 Va

W

Neutral

Hot Water

Solenoid

Cold Water

Solenoid

Drain

Recirc Pump

MC3003463K2HS

2

Bl

P

Br

P

C

C

NO NONC NC

Br

Br

Y

Power Box

34561

R/W

R

Bl/W

Green

Light

W

B

Red

Light

B

120 Vac

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

7

Page 10

cleanInG InstructIons

Regular maintenance of your Glastender glasswasher will extend its useful life and lower the service costs. The

following parts are removable for daily cleaning:

1. Drainboard insert

2. Drainboard pan

3. Sliding cover

4. Inner cover

5. Conveyor

6. Spray box

7. Spray box gasket

8. Tank screen

The daily cleaning procedures consist of the following steps:

1. Remove drainboard insert, drainboard pan, sliding cover, and inner cover.

Wipe down each part as necessary.

Drainboard insert

Drainboard pan

2. Remove the conveyor wheel. Any large debris found inside the machine, like

broken glass, lemon seeds, stir sticks, and so on, should be removed.

9. Pump inlet screen

10. Drain stopper

11. Scrap tray

Sliding cover

Inner cover

Conveyor

Spray box

Spray box gasket (located under

spray box - not shown)

3. Remove and scrub clean the spray box, spray box gasket,

and tank screen. Remove and wipe down the drain stopper. Remove any debris from the lower wash tank. Make

sure nothing is clogging the pump inlet screen. The pump

inlet screen can be removed for cleaning if necessary.

Drain stopper

Tank Screen

Pump inlet screen

8

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 11

cleanInG InstructIons

4. Remove the scrap tray and empty out any debris that may have passed through

the tank screen.

5. Use a damp cloth to wipe down the entire wash

tank. For more stubborn stains, use a nylon brush

or a Scotch-Brite Stainless Steel Cleaner® pad.

Never use steel wool to clean stainless steel. Steel

wool will cause the stainless steel to rust.

Wash tank

6. Re-assemble the glasswasher.

7. CheckDetergent,Sanitizer,andRinseAidcontainers.Rellorreplaceifempty.

8. Visually inspect the Chemical Inlets by opening the sliding cover during the

washandrinsecyclell.Youshouldnoticedetergentintermittentlydrippinginto

thetankduringthewashllandSanitizerandRinseAidintermittentlydripping

intothetankduringtherinsell.NOTE:Afterverifyingthechemicalshavebeen

dispensed, close the sliding cover to allow the glasswasher to resume cycle. If the

sliding cover is left open for more than 30 seconds, the water will be drained and

the cycle will terminate. In the event the cycle does terminate, push the Cycle

Start button to initiate a new cycle.

Scrap tray

Detergent, Sanitizer, and

Rinse Aid Containers

9. Your glasswasher is now ready for operation

Chemical inlets

de-lImInG procedure

When the interior is coated with a white chalky substance, perform the following de-liming procedure. De-liming should be executed after daily cleaning has been completed.

1. With the conveyor empty, press the De-Liming button. The red In Use light will illuminate.

2. The GW24 holds 1.25 gallons of water - measure out the appropriate amount of de-liming solution.

WARNING! Most de-liming chemicals are hazardous. Follow chemical manufacturers instructions

very carefully!

3. Duringwaterll,openslidingcoverandpourde-limingchemicalsintotank.Closeslidingcover.

4. The de-liming cycle consists of a 5 minute wash and two rinse cycles.

5. The red In Use light will turn off after the de-liming cycle is complete.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

9

Page 12

slIde-out chemIcal bottle rack InstallatIon

A slide-out chemical bottle rack

accessory is available for easyaccess storage of chemical bottles.

Specify part number 01001500.

The chemical bottle rack accessory consists of two parts

- a stationary bottom tray and a slide-out chemical bottle

holder.

Stationary

bottom tray

Slide-out chemical

bottle holder

To install the chemical bottle rack onto the GW24:

1. Remove the screw located

at the front of the stationary bottom tray and set

aside. Pivot the hinge fully

to open the securing clasp.

2. Position the back rear semi-circular cutout of the tray

around the back left leg of the GW24. Slide the front

securing clasp around the front left leg of the GW24.

3. Close the securing clasp around the front leg and

reinstall the screw.

4. Place the slide-out chemical bottle holder into the

stationary bottom tray.

5. The front cover of the chemical tray can be adjusted

verticallytone-tunethetbeneaththeGW24skin.

To adjust, loosen the 3 attachment screws on the

inside of the front cover. Move the cover up/down.

Once the cover is at the desired height, retighten the

attachment screws.

10

Back

Adjust the

front cover

up or down

Front

Attachment

screws

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 13

useFul InFormatIon about Water, deterGent, & sanItIzer

Water condItIons

Your water supply fits one of the following descriptions.

Greater detergent consumption is required with “hard” water.

GraIns parts

descrIptIon per Gallon per mIllIon

Soft Less than 1.0 Less than 17.1

Slightly Hard 1.0 to 3.5 17.1 to 60

Moderately Hard 3.5 to 7.0 60 to 120

Hard 7.0 to 10.5 120 to 180

Very Hard 10.5 and over 180 and over

deterGent tItratInG InstructIons

An Alkalinity Test Kit, as recommended by your chemical supplier, is required for proper chemical adjustment.

Follow kit instructions to test.

sanItIzer tItratInG InstructIons

After the water has agitated during the rinse cycle, open the sliding cover and dip a Chlorine test strip into the

tank for one (1) second. Immediately compare the strip to the scale on the side of the test strip container tube.

Adjust sanitizer (bleach) to 50 PPM, and iodine type sanitizer to 12.5 PPM. NOTE: Leaving the sliding cover

open more than 30 seconds will end the cycle and drain the tank.

Important note: Glasswashers are NOT water conditioners. Consult local water conditioning experts to

determine your specific water condition.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

11

Page 14

Important InFormatIon about chemIcals

The GW24 glasswasher has chemical pumps that automatically dispense chemicals into the machine. The detergent and sanitizer chemicals are supplied by a chemical vendor. Since the type of chemicals and the condition of water varies by region, the chemical pumps

are not pre-set at the factory. The chemical pumps must be adjusted at start-up to achieve the proper titration levels or the machine

may not produce good wash results. Typically, the chemical vendor is responsible for adjusting the chemical pumps.

Since detergent and sanitizer chemicals play an important role in the performance of a glasswasher, understanding how the chemical

pumps work and how to maintain them is very important. Reviewing the following information will help ensure the proper operation

of your glasswasher and its chemical pumps:

1. CAUTION: Always cycle the machine after using the prime switches to rinse out the wash/rinse tank. Undiluted chemicals will

damage stainless steel.

2. The chemical feed lines must be properly placed inside the appropriate chemical container. Damaged chemical lines will spill

chemicals on the machine and floor and create poor wash results.

3. Every glasswasher requires chemical pump adjustment and titrating by a chemical vendor. Poor wash results will occur if the

chemicals are not in proper concentration (see page 5, Step 6, for proper concentration levels).

4. Glasswasher chemicals are highly caustic and will cause severe burns when they contact human skin. These same caustic chemicals will also corrode stainless steel and destroy machine components. A glasswasher should be checked regularly for chemical

leaks. Any leaks should be corrected immediately.

5. All of the chemical tubing on a glasswasher should be inspected regularly and replaced at least once per year. The highly caustic

chemicals cause the chemical tubing to get brittle, and since leaking chemicals destroy glasswasher components, it is good preventative maintenance to replace chemical tubing often. The various tubing includes the lower tubing assembly or main chemical feed

line, the pump squeeze tube (especially susceptible to damage), and the upper tubing assembly from the pump to the glasswasher

tank.

6. Chemical vendors that deliver chemicals to your establishment are typically responsible for adjusting the chemical levels in

your glasswasher. They are also helpful for assisting you with chemical tubing inspection and replacement. Nothing removes

your responsibility for proper maintenance, but the chemical vendor will help.

tIps For trouble-Free operatIon

1. NEVER, NEVER wash ash trays in the glasswasher. Since ashes are smaller than the opening in the Pump Inlet Screens, ashes can

adhere to glasses. Also, with ashes recirculating in the wash water, the cleaning effectiveness of the detergent is greatly reduced.

The final result of washing ash trays is dirty glasses.

2. For best results, run glasswasher full of glassware. This keeps the water and detergent consumption to a minimum and helps prevent glassware from tipping over.

3. Water spotting can occur when glassware is placed on a flat surface after washing, thus preventing air to assist the drying process. Make

sure the proper shelf liner or drying surface is used.

4. Clearance below the top cover of the glasswasher allows for a maximum glass height of ten (10) inches. Keep this in mind when

ordering beer pitchers and wine carafes.

5. Glasses which have been frequently washed by hand may have deposits of invisible “film”. Although initially appearing clean, these

glasses may show unsightly signs of “dirt” after passing through the glasswasher. This unsightly condition will exist until the film is

removed with frequent passes through the glasswasher, or it may be necessary to use a de-liming agent to clean glassware.

6. Do not place wet glasses into glass chillers or frosters. Allow glasses to dry and sanitizer odors to dissipate first.

7. Changing detergents may require readjustment of the Detergent Pump to maintain .30% detergent concentration. A greater volume of

low strength detergent is required to maintain the proper level.

8. Only Glastender, Inc. replacement parts should be used. Components from other suppliers may result in machine malfunctions.

Please consult your Glastender, Inc. service agent if service or technical assistance is required. The factory is also available to

answer any operational questions.

12

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 15

trouble shootInG GuIde

trouble or sItuatIon cause remedy

A. Unit does not run

B. Unit experiences a delay (up to 15 sec-

onds) before beginning a cycle

C. Conveyor runs but holding tank not

filling

D. Conveyor moves intermittently

E. Water recirculating, conveyor not

moving

F. Water not recirculating

G. Water leaking from recirculating

pump housing - water on floor

H. Glasses slimy or soapy at end of cycle

I. Recirculating water pressure low

J. Detergent, sanitizer, and/or rinse aid

not feeding properly

K. Poor washing results

1. Sliding cover open 1. Close sliding cover

2. Out of chemicals 2. Replace and prime empty chemicals

3. No power (Power light “off”) 3. Check power source

4. Defective switch panel 4. Replace switch panel

5. Wire connections poor, loose, or broken 5. Re-crimp and/or replace wire connection

1. Incoming water does not reach minimum

operating temperature

1. Water “off” 1. Turn water “on”

2. Bad water valve 2. Test valve, replace if necessary

1. Glassware or debris blocking rotation of

conveyor

2. Wor n drive coupling 2. Replace drive coupling

1. Obstruction in tank area 1. Remove obstruction

2. Conveyor not engaged with conveyor

drive shaft

3. Worn drive coupling 3. Replace drive coupling

4. Defective drive motor 4. Replace drive motor

1. Completely plugged pump inlet screen 1. Clean pump inlet screen

2. Defective recirculating pump 2. Replace recirculating pump

1. Defective pump seal 1. Replace pump

2. Pump housing cracked 2. Replace pump

1. Sanitizer feed line in detergent container 1. Clean line and place in proper container

2. Improper Rinse Aid setting 2. Adjust chemical setting

1. Spray box not latched properly 1. Latch spray box properly

2. Partially plugged pump inlet screen 2. Clean pump inlet screen

3. Missing or worn spray box gasket 3. Replace gasket

1. Chemical container is empty 1. Refill or replace container(s)

2. Feed lines will not fill 2. Replace defective parts. Notes: The deter-

1. Clogged spray nozzles and dirty holding

tank

2. Detergent container empty 2. Fill container

3. Poor water conditions 3. Have filter or softener installed

4. Chemicals not adjusted properly 4. Call chemical technician

5. No hot water 5. Check temperature of water source

1. Check temperature of water source

1. Clear obstruction

2. Rotate conveyor until it engages

Refer to page 8 cleaning instructions

gent, sanitizer, or rinse aid product advances in the line on each stroke of the pump.

The product should hold position between

strokes. If the product falls back toward the

supply container, one or more of the following conditions may exist:

a. Debris in pump

b. Split feed line

c. Bad pump tube

Replace parts as necessary

1. Clean unit -see page 8 cleaning instructions

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

13

Page 16

Warranty statement

APPLICABLE TO ALL PRODUCTS SOLD WITHIN THE UNITED STATES AND CANADA

LABOR: Glastender, Inc. warrants all products to be free of defects in

material and workmanship. In established areas, a start-up is included

with glasswasher models GT-24 and GT-30. A 1-year labor warranty

applies to all glasswashers. BDS model bottle disintegration systems

and self-contained refrigeration models, except beer line chillers,

include a 1-year labor warranty, for the duration of one year from date of

installation or up to 18 months from date of factory shipment, whichever

occurs sooner. For warranty labor claims beyond 15 months from the

date of factory shipment, proof of date of installation or occupancy must

be provided. Authorization for labor must be obtained from Glastender

within the warranty period and prior to the service being performed.

Labor warranty applies to the United States and Canada only.

PARTS: Within one year from date of installation or 18 months from

date of factory shipment, whichever occurs sooner, Glastender, Inc.

will replace any part or assembly found defective under normal use and

service. Field replacement parts include a warranty of 90 days from date

of installation.

FOUR YEAR ADDITIONAL COMPRESSOR WARRANTY:

Glastender will warrant to the original user the compressor for all selfcontained refrigeration models for an additional four years following the

regular one-year warranty period. This plan applies to the compressor

only.

A warranty claim form MUST accompany all returned defective parts or

assemblies. This form MUST be completed in full. Failure to do so may

result in delay or denial of credit. Any defective part or assembly must

be returned to Glastender, Inc., Saginaw, Michigan, with all transportation and delivery charges prepaid. Warranty repairs or replacements

will be shipped FOB factory in Saginaw, Michigan. Reimbursement for

applicable freight charges covers ground service only.

Glastender provides in-warranty repairs during a service company’s

regular working days and hours. There is no provision for payment

of a premium rate during “overtime” hours. When warranty service is

requested during other than normal working hours, the end user will be

charged the premium portion of the overtime rate.

The warranty covers substantiated travel expenses for up to 2 hours /

100 miles round trip and a maximum of $150. Any additional costs due

to installations that require extra work, time, or travel to gain access

for service are the sole responsibility of the equipment purchaser. Any

exceptions to these travel and access limitations must be pre-approved

by a factory representative.

The warranty does not cover equipment subjected to accidents, freight

damage, alterations from the original design, improper power and/or

plumbing hookups, improper chemical use, general misuse, or lack

of routine required maintenance as determined by Glastender, Inc.

Installation, normal control adjustments, general maintenance, correcting an installation error, or service calls that reveal the unit is functioning normally will not be reimbursed under warranty.

Condenser coils on self-contained refrigeration products must be

cleaned regularly. Failure to provide adequate air flow to a refrigeration

unit will void the warranty.

Glastender shall not be liable for loss of use, revenue, or profit, or for

any other indirect, incidental, special, or consequential damage including, but not limited to, product spoilage or loss.

This warranty is conditioned upon Glastender receiving notice of any

defect subject to this warranty within sixty (60) days of its discovery

by the end user or dealer. All products are warranted only for the initial

place of installation. Removal of a product automatically terminates

this warranty.

SECOND YEAR EXTENDED PARTS & LABOR WARRANTY:

Glastender’s one-year parts and labor warranty on self-contained refrigeration units, excluding beer line chillers, can be extended to two years

with the purchase of a two year parts and labor warranty. Specify part

number EWR2 ($150 net price) when ordering.

EXPORT WARRANTY - One year parts only.

EXCLUSION OF WARRANTIES

EXCEPT AS PROVIDED ABOVE, GLASTENDER MAKES

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE

OR NON-INFRINGEMENT.

LIMITATION OF REMEDIES AND DAMAGES

If Buyer makes a valid and timely claim as outlined above, Glastender’s

liability and Buyer’s remedies under this agreement will be limited solely

to labor charges authorized and/or replacement or credit, at Glastender’s

option, with respect to Products returned at Buyer’s expense within thirty (30) days after warranty repair. GLASTENDER’S LIABILITY WILL

IN NO EVENT BE GREATER IN AMOUNT THAN THE PURCHASE

PRICE OF THE RETURNED PRODUCTS. GLASTENDER

WILL NOT BE LIABLE UNDER ANY CIRCUMSTANCE FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING,

BUT NOT LIMITED TO, LABOR COSTS EXCEPT AS COVERED

UNDER OUR WARRANTY, LOST PROFITS OR THE LOSS OF

PERISHABLE PRODUCTS RESULTING FROM THE USE OF OR

INABILITY TO USE OUR PRODUCTS OR FROM OUR PRODUCTS’

INCORPORATION INTO OR BECOMING A COMPONENT OF

ANY OTHER PRODUCT. NEITHER PARTY WILL HAVE ANY

NEGLIGENCE OR OTHER TORT LIABILITY TO THE OTHER, OR

TO ANY THIRD PARTY, ARISING FROM ANY BREACH OF THIS

AGREEMENT.

GOVERNING LAW - JURISDICTION

The terms and conditions of an order are to be governed and construed

according to the laws of the State of Michigan, without regard to conflict

of laws principles. Buyer hereby consents to the jurisdiction and venue

of the courts located in Saginaw County, Michigan.

No representative, distributor, dealer, or any other person is authorized

to modify this warranty. This warranty replaces all other written or

verbal warranties.

NOTE: Glastender, Inc.’s policy of constant quality improvement

means that prices, specifications, and policies are subject to change

without notice. Questions regarding this warranty should be directed to

Glastender’s Customer Service Representative.

03-21-14

IMPORTANT!!

Attention Refrigeration Service Companies

Please review the important warranty information on this page. If you

believe a service call should be covered by the factory, please call

the factory for authorization between 8AM and 5PM EST, Monday

through Friday.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

14

Loading...

Loading...