Page 1

Operation Manual

GT-24, GT-30

Glasswashers

Rev. 04-29-10

GT-24-CW

GT-30-CCW

Glastender, Inc. · North Michigan Road · Saginaw, MI · 48604-9780

800.748.0423 · 989.752.4275 · Fax 989.752.4444 · www.glastender.com

© 2010 Glastender, Inc.

Page 2

Page 3

Index

Topic Page

Introduction ............................................................................................................... 2

What is a glasswasher? ............................................................................................. 2

Uncrating Instructions and Equipment Checklist ..................................................... 3

Main Section - Top View .......................................................................................... 4

Wiring Diagrams

Manufactured Before Jan. 2003 ...................................................................... 5

Manufactured After Jan. 2003 ......................................................................... 6

Utility Requirements and Connections ..................................................................7-8

Start-Up Instructions ..............................................................................................8-9

Peristaltic Pump Adjustments .............................................................................. 9-10

Useful Information About Water, Detergent, and Sanitizer ................................... 11

How to Operate the Glasswasher ........................................................................... 12

How the Glasswasher Operates .........................................................................12-14

Tips for Trouble-Free Operation ............................................................................. 14

Important Information About Chemicals ................................................................ 15

Diagnosing Poor Wash Results ............................................................................... 16

Cleaning Instructions .........................................................................................17-18

Troubleshooting Guide ......................................................................................19-21

Warranty .................................................................................................................. 22

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

1

Page 4

IntroductIon

This manual describes the operational features of the GT-24 and GT-30 model glasswashers with digital temperature gauges. Please review this information before attempting installation and operation.

Long-term, trouble-free operation will follow if good housekeeping and maintenance procedures are followed.

Thank you for selecting Glastender, Inc. products.

what Is a Glasswasher?

Glastender, Inc. manufactured the original automatic rotary glasswasher in 1969. Today, Glastender glasswashers have been installed around the world.

But what is a glasswasher? It is simply a piece of machinery that washes glassware, which eliminates the need

for human labor and the conventional three-compartment sink. The glasswasher is, in effect, a mechanized threecompartment sink. It “washes”, “rinses”, and “sanitizes” glassware.

note the sImplIcIty:

FunctIon desIGn

wash Hot water and a preset portion of detergent join in the Wash Tank. Operating temperature

is maintained between 130ºF (54ºC) and 150ºF (66ºC) by a stainless steel heater, and the

proper water level is maintained with a liquid level control. During operation, 5 gallons

per minute of hot soapy water are pumped in a forceful, but gentle, spray pattern across

the moving glassware. This entire wash compartment is isolated by curtains, and the

wash water is recirculated to conserve water and detergent. Actual hot water consumption

during operation is ¼ gallon per minute.

rInse and

anItIze

s

Please read on to learn more about this simple machine.

Cold water and a preset portion of sanitizer join in the sanitizing compartment called the

Rinse Tank. The proper water level is maintained with a liquid level control. During

operation, 2 gallons per minute of cold rinse water are pumped in a forceful, but gentle,

spray pattern across the moving glassware and down the drain. The unique pumped rinse

feature ensures a consistent, thorough rinse.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

2

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 5

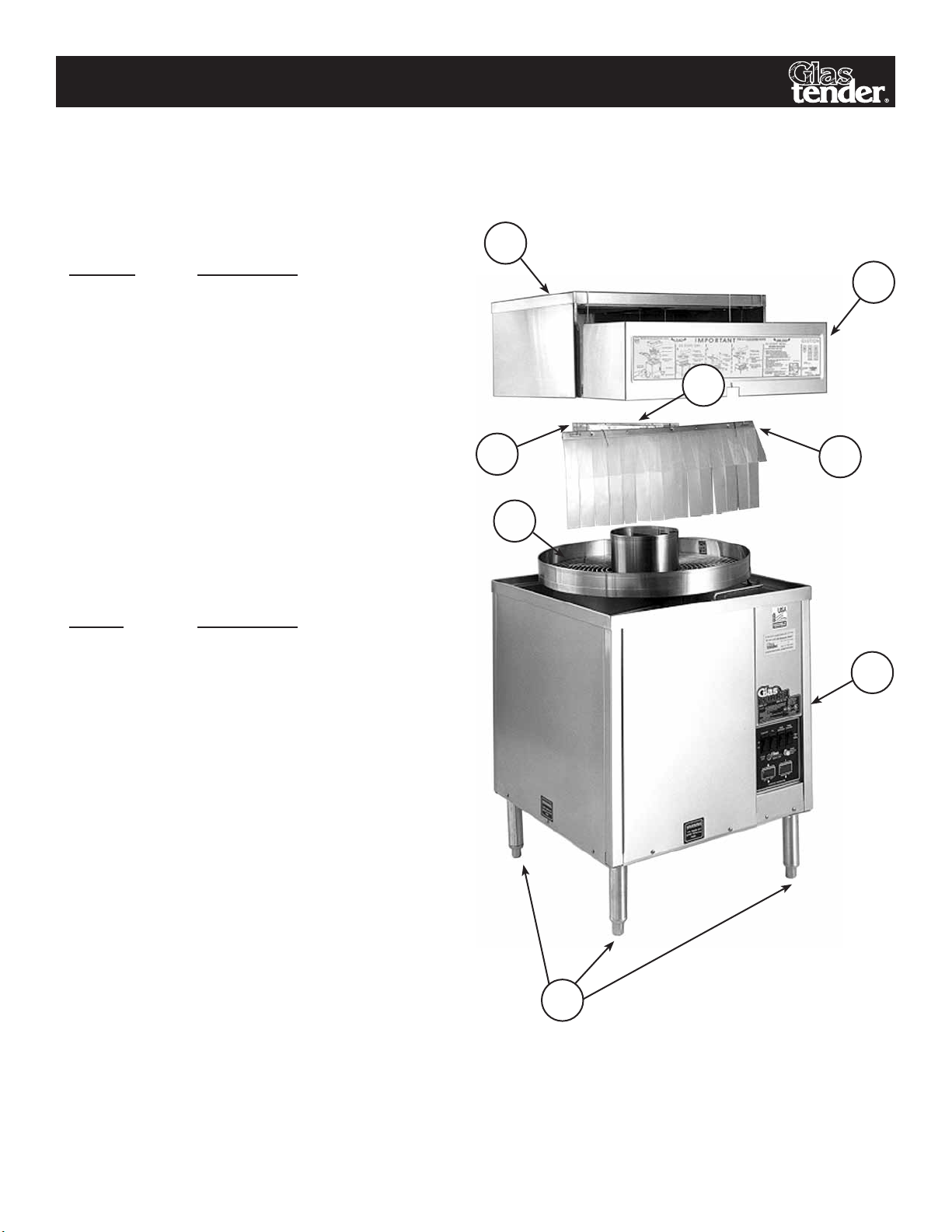

uncratInG InstructIons and equIpment checklIst

The glasswasher is shipped in one carton. Please refer to Figure 1 and locate the following items:

the Items are:

Item

number descrIptIon

1 Main Section

2 Stainless Steel legs (4)

3 Conveyor

4 Front Curtain

5 Wash Curtain

6 Rinse Curtain

7 Front Shield

8 Top Section

assembly procedures:

assembly

order descrIptIon

1 Bolt the legs to the base of

the Main Section.

8

7

6

5

3

4

1

2 Remove all packaging from

the Main Section.

3 Remove plastic protective

paper from all stainless steel

parts. This may require

removing side panels.

4 Place glasswasher in position

and level by adjusting the bot tom portion of the stainless legs.

5 Make plumbing and electrical

connections (see page 8).

note: Figure 1 shows a clockwise model with front switch panel.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

2

FIGure 1

3

Page 6

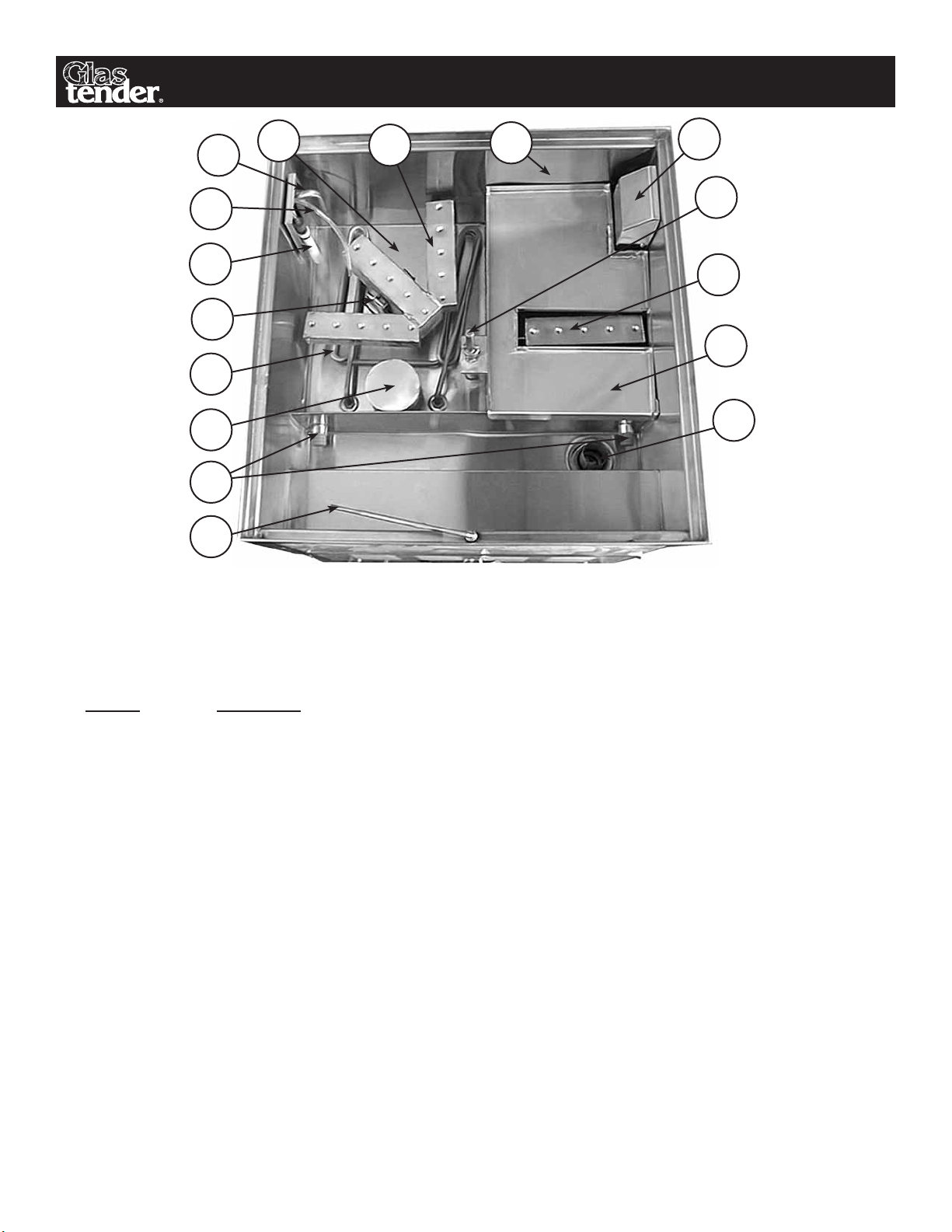

maIn sectIon - top VIew

8

9

10

11

7

6

12

13

14

5

15

4

3

16

2

FIGure 2

1

note: Figure 2 shows a model GT-24 with clockwise conveyor movement. Counterclockwise

conveyor movement models have identical parts in reverse positions.

Please familiarize yourself with the following parts:

Item

number descrIptIon

1 Glass Stop Arm

2 Drain Plug (2 required)

3 Pump Inlet Screen (2 required) - One pump inlet screen is in the rinse tank hidden from

view below the rinse tank guide.

4 Heater

5 Spray Box Cam Lock

6 Wash Tank Liquid Control and Low-Level Pick-Up Tube - The rinse tank liquid control

and low-level pick-up tube is hidden from view by the rinse tank pick-up tube cover.

7 Detergent Inlet Tube

8 Hot Water Inlet and Air Gap (in side wall) - Pick-up tube cover has been removed for

illustrative purposes.

9 Wash Tank

10 Wash Spray Box

11 Rinse Tank

12 Rinse Tank Pick-Up Tube Cover - The cold water inlet and sanitizer inlet tube are under-

neath the cover

13 Conveyor Drive Shaft

14 Rinse Spray Box

15 Rinse Tank Guide

16 Drain Tank with Drain Screen

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

4

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 7

wIrInG dIaGram unIts beFore Jan. 2003

-208V or 240V,4KW

-1/12 HP,2.7A

-1/12 HP,2.7A

o

LEGEND

W

B

W

24VDC Sanitizer Pump Motor

4

3

2

1

Sanitizer P.C. Board

24V

AC

B = Black

W

R

B

W/O

W/0

R(20 AWG)

B(20 AWG)

W/O(20 AWG)

W/O(20 AWG)

W

24VDC Detergent Pump Motor

W

B

4

3

2

1

Detergent P.C. Board

AC

24V

Bl = Blue

Br = Brown

R

B

W/Br

W/Br

W/Br(20 AWG)

W/Br(20 AWG)

P = Purple

G = Green

O = Orange

B(20 AWG)

R(20 AWG)

Y = Yellow

R = Red

W = White

W/B = White W/Black

W

R(12 AWG)

Heating Element

B(12 AWG)

W/R = White W/Red

W/G = White W/Green

W/O = White W/Orange

W/Bl = White W/Blue

W/Br = White W/Brown

W

Coil

Relay

120/208V or 120/240V, Single Phase

60Hz, 3 Wire, 20 Amp. All wires

are 16 Gauge unless marked

otherwise. Wire Temperature Rating

equals 105 C.

R(12 AWG)

R

B

Power Light

B(12 AWG)

ELECTRICAL RATINGS

Wash Recirculating Pump Motor

Rinse Recirculating Pump Motor

Heating Element

-85mA

-85mA

-63mA

-160mA

-1/140 HP,0.48A

-160mA

Detergent Pump Motor

Cold Water Solenoid

Hot Water Solenoid

Conveyor(Gear)Motor

Relay

Sanitizer Pump Motor

W

W

Conveyor

Motor

W

Recircu-

Rinse Water

W

Recircu-

Wash Water

W

lating

lating

Pump Pump

Sanitizer Prime Switch

W

G

Y Y

B B

G

C NC

Glass Stop Switch

On-Off

Conveyor Switch

P

B

R

W

(24 VAC Secondary)

Sanitizer Pump Transformer

W

Cold Water

Inlet Valve

G

Detergent Prime Switch

R

B

Bl

Br

NC

Wash

Bl

C

P

Fill Switch

Thermostat

NO

P

Pressure Switch

P

On-Off

W

Bl

P

W

Transformer

(24 VAC Secondary)

(24 VAC Secondary)

Detergent Pump Transformer

W

O O

NC

Rinse

C

Pressure Switch

P O

P

G

P

W

Hot Water

G

Br

Inlet Valve

P

R

Rinse

Wash

Temperature

Display

Display

Temperature

W/B(20 AWG)

W/B(20 AWG)

W/B(20 AWG)

"Check Chemical" Light on Switch Panel

W/B(20 AWG)

W/R

C

NC

NO

Detergent Empty Sensor

Pressure Switch

W/R(16 AWG)

R(20 AWG)

W/R(16 AWG)

C

NC

C

Sanitizer Empty Sensor

Pressure Switch

W/R(16 AWG)

B(12 AWG)

R(12 AWG)

P

W

W

Field Connection Box

Ground

W

B

R

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

5

Page 8

wIrInG dIaGram unIts aFter Jan. 2003

P

W

2

Sanitizer/Detergent

R+ B-

24VDC Detergent Pump Motor

24VDC Sanitizer Pump Motor

AC

24V

Sanitizer

Prime Switch

W

AC

24V

Detergent

Prime Switch

Dashed Lines = 240 VAC 50 HZ Models

W

Motor

Conveyor

W

W

Rinse

lating

Water

Pump

Recircu-

B

GG

Y Y

B

B B

- 10

R+ B-

8 +

O/W(20 AWG)

O/W(20 AWG)

Cold Water

W B

Br/W(20 AWG)

Br/W(20 AWG)

O

O

Inlet Valve

O

R+ B-

O/W

O/W

Br/W

Br/W

W W

1

Module

Speed Control

5 6 1413

SAN

Speed Control

Potentiometers

12 11

7 + - 9

W B

DET

O

W

W

Double Lines = 120 VAC 60 HZ Models

Pump

Wash Water

Recirculating

C NC

Y

G

P PP

W

On-Off

Conveyor Switch Glass Stop Switch

P

NC

Rinse

C

Pressure Switch

P

P

G

P

G

W

O

-85mA

-63mA

-85mA

-160mA

-208V or 240V,4KW

Br

Display

TemperatureTemperature

Y = Yellow

R = Red

Bl = Blue

W

G = Green

Br = Brown

R

B

P = Purple

O = Orange

Power Light

BL

"Check Chemical" Light

W = White

R/W = Red W/White

Br/W = Brown W/White

R

R(10 AWG)

B(10 AWG)

NC

R/W(16 AWG)

on Switch Panel

R/W(16 AWG)

LEGEND

B = Black

Rinse Wash

Display

O

Heating Element

Br

Br

Hot Water

Inlet Valve

Wash

P

W

R(10 AWG)

Coil

Relay

B(10 AWG)

Bl

Thermostat

Bl

Bl

NC

NO

C

Pressure Switch

P

P

On-Off

Fill Switch

o

ELECTRICAL RATINGS

O/W = Orange W/White

are 16 Gauge unless marked

otherwise. Wire Temperature Rating

120/208V or 120/240V, Single Phase

60Hz, 3 Wire, 20 Amp. All wires

R R

C

NC

NO

Sanitizer Empty Sensor

Detergent Empty Sensor

Pressure Switch

R(20 AWG)

equals 105 C.

C

C

Pressure Switch

R/W(16 AWG)

B(10 AWG)

R(10 AWG)

Heating Element

-160mA

-1/12 HP,2.7A

-1/12 HP,2.7A

-1/140 HP,0.48A

Conveyor(Gear)Motor

Cold Water Solenoid

Hot Water Solenoid

Sanitizer Pump Motor

Detergent Pump Motor

Rinse Recirculating Pump Motor

Wash Recirculating Pump Motor

Relay

Solid-Single Lines = 120/240 VAC 50/60 HZ Models

NOTE: Double lines specify

120 VAC 60 HZ wiring only,

dashed lines specify 240 VAC

50 HZ wiring only.

6

50/60 HZ

W O

Secondary

W

P

Box

Field

Connection

W

B

R

Primary

Ground

R

B

W

240 VAC

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

120 VAC

50/60HZ

For European Models

Optional Transformer

Page 9

utIlIty requIrements and connectIons

1. General Plumbing ................. a. Use 3/8" O.D. copper to 3/8" FMPT adapter provided.

(Hot water and cold .............. b. Minimum water pressure - 25 psi.

water required) ..................... c. Maximum water pressure - 100 psi. Install water pressure regulator if line

.............................................. pressure is over 100 psi. Water valve on unit has built-in line strainer and

.............................................. flow control to provide consistent volume between 25 psi and 100 psi.

.............................................. d. Install separate water shut-off valve for each connection.

.............................................. e. The unit has built-in air gaps. Vacuum breakers are NOT required.

2. Hot Water Only .................... a. Maximum temperature 150° F (66° C). Minimum temperature 130° F (54° C).

.............................................. b. Initial fill 3.00 gallons (GT-24) or 3.50 gallons (GT-30).

.............................................. c. Consumption - 1/4 gallon per minute during operation.

3. Cold Water Only ................... a. Minimum temperature is 75° F (24° C) per FDA Ordinance and Code for

Food Service Establishments, Section 5-103(e)(2). Install hot/cold water

mixing valve if necessary.

.............................................. b. Initial fill 2.25 gallons (GT-24) or 3.50 gallons (GT-30).

.............................................. c. Consumption - two gallons per minute during operation.

4. Drain ..................................... a. 1-1/2" tailpiece provided on unit.

.............................................. b. Use open type floor drain for maximum drainage.

.............................................. c. Two white plastic drain cocks extending below the bottom are for recircu-

lating pump drainage when required for pump replacement or winterizing.

The drain cocks are shipped in the closed position. No plumbing is required.

5. Electrical ............................... a. Specifications: 120/208-240V, single phase, 60 Hz., 3 wire (two hot and

one neutral), ground connection per local code (green wire), 20 amp for

240 volt or 30 amp for 208 volt (4 wires total). Unit will operate satisfac-

torily within 10% of rated voltage.

.............................................. b. A dedicated 20 Amp circuit is required [30 amp for 208V]

.............................................. c. A power relay in the unit separates the high and low voltages and directs

the respective power to the electrical components. The heater and power

light operate on 208 volts or 240 volts as specified. All other components

.............................................. operate on 120 volts.

6. Detergent .............................. a. An extra-heavy-duty, non-foaming, commercial liquid dishwashing deter-

gent is required. Adjust to .30% concentration.

.............................................. b. The local chemical supplier should be consulted to match detergents with

local water conditions.

7. Sanitizer ................................ a. Liquid chlorine bleach (sodium hypochlorite - 5.25% solution). Adjust to

50 PPM.

.............................................. b. Or low-sudsing iodine type sanitizer. Adjust to 12.5 PPM.

notes: .................................. A. In all cases, consult local plumbing, electrical, and health codes for regu-

lations which may not be consistent with the above.

.............................................. B. The utility connections are made up from the floor at the bottom of the unit

.............................................. approximately 7" to 8" high.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

7

Page 10

utIlIty requIrements and connectIons

3-3/4"

5-3/4"

1-1/4"

19-3/8"

2

6-1/2"

3-1/2"

24-1/8"

3

12-1/16"

12-1/16"

1

4

16"

2"

1 = HOT WATER

2 = COLD WATER

3 = DRAIN

4 = ELECTRICAL

1

2"

12-1/16"

CCW CW

FRONT FRONT

30-1/8"

2

4

3

15-1/16"

1-3/8"

CCW CW

FRONT FRONT

1

15-1/16"

20-3/8"

2-1/2"

GT-24

1 = HOT WATER

2 = COLD WATER

3 = DRAIN

4 = ELECTRICAL

GT-30

1

20-3/8"

2-1/2"

24-1/8"

30-1/8"

15-1/16"

12-1/16"

4

3

4

3

2

3-3/4"

16"

5-3/4"

1-1/4"

15-1/16"

2

3-1/2"

19-3/8"

6-1/2"

1-3/8"

start-up InstructIons

1. Place Top Section of glasswasher on the extreme rear of the Main Section (see Figure 1, page 3.).

Note: The Glass Stop Arm always identifies the front of the unit.

2. Remove front panel of Main Section (see Figure 1, page 3.).

3. Detergent and Sanitizer Feed Lines are stored in Main Section. Access is provided in the floor of the

front Main Section. Fully extend the Feed Lines to the Detergent and Sanitizer Containers which are

external of the unit. Shorten Feed Lines if necessary.

Note: Consult your chemical supplier for detergent and sanitizer products.

a. Use an extra-heavy-duty, non-foaming, commercial liquid dishwashing detergent.

b. Use liquid bleach (sodium hypochlorite - 5.25% solution) or low-sudsing iodine type sanitizer.

4. Remove Rinse Tank Guide.

5. Make sure the Fill Switch and Conveyor Switch are in the “off” position.

6. Open the hot water and cold water supply valves.

7. Turn electrical power “on.” Green Power Light will now be illuminated.

8. Turn Fill Switch to “on” position. The Wash Tank will fill with hot water and the Rinse Tank will fill

with cold water. The liquid level controls will automatically turn off the hot water and the cold water

when the tanks are full.

9. Depress Detergent and Sanitizer prime buttons until chemicals are observed dripping into the Wash and

Rinse Tank respectively.

Note: The prime button overrides the pre-set adjustment and dispenses at full speed.

10. Turn Fill Switch to “off” position.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

8

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 11

start-up InstructIons

11. Remove Drain Plugs allowing tanks to drain.

12. Adjust Detergent and Sanitizer Pumps. (See pages 9-10)

13. Replace Drain Plugs.

14. Turn Fill Switch to “on” position. The Wash and Rinse Tanks should now fill near the top of the

overflow walls. When the Wash Tank is full, the thermostatically controlled Heater will turn on and

off as necessary to maintain the water temperature at approximately 150° F.

NOTE: The Thermostat is preset at the factory.

15. Install Rinse Tank Guide (see Figure 2, page 4 - item 9).

16. Install Wash, Rinse, and Front Curtains (see Figure 1, page 3 - items 4, 5, and 6).

17. The unit is now ready to test detergent and sanitizer strength. Your chemical supplier will test the

concentration levels which are:

a. .30% for detergent, and

b. 50 PPM (parts per million) for chlorine bleach sanitizer, or

c. 12.5 PPM for iodine sanitizer.

Turn Conveyor Switch to “on” position for approximately 30 seconds to mix water and chemicals for

testing purposes. If further adjustment is necessary, refer to the next section on Peristaltic Pump Adjustment.

18. This glasswasher is equipped with an Empty Sensor for the Detergent and Sanitizer. Check the

operation by lifting the Detergent Feed Line from the Detergent container. This should turn on the visual

alarm. Place Detergent Feed Line back into Detergent container and repeat procedure for Sanitizer Feed Line.

19. Install Conveyor (see Figure 1, page 3 - item 3) and Front Shield (see Figure 1, page 3 - item 7). The Front

Shield clips to the Top Section.

20. Install front panel of Main Section (see Figure 1, page 3).

21. Your glasswasher is now ready for operation.

perIstaltIc pump adJustment

unIts manuFactured beFore January 2003 - dIscontInued cIrcuIt board type

1. Locate Peristaltic Pump in Glasswasher.

2

1

2. Locate Pump Control Circuit Board.

3. Each pump has its own adjustment dial.

One for Detergent and one for Sanitizer.

Turn dial clockwise for faster pump speed

or counter-clockwise for slower pump

speed.

3

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

9

Page 12

perIstaltIc pump adJustment

unIts manuFactured beFore January 2003 - cube relay tImer type

3

2

1

1. Locate Peristaltic Pump in Glasswasher.

2. Locate Pump Control Cube Relay Timers.

3. Each pump has its own adjustment dial.

One for Detergent and one for Sanitizer.

Turn dial clockwise for faster pump speed

or counter-clockwise for slower pump

speed.

unIts manuFactured aFter January 2003 - pump control module type

1. Locate Peristaltic Pump in Glasswasher.

2

1

2. Locate Pump Control Module.

3. Each pump has its own adjustment dial.

One for Detergent and one for Sanitizer.

Turn dial clockwise for faster pump speed

or counter-clockwise for slower pump

speed.

3

10

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 13

useFul InFormatIon about water, deterGent, and sanItIzer

water condItIons

Your water supply fits one of the following descriptions.

Greater detergent consumption is required with “hard” water.

GraIns parts

descrIptIon per Gallon per mIllIon

Soft Less than 1.0 Less than 17.1

Slightly Hard 1.0 to 3.5 17.1 to 60

Moderately Hard 3.5 to 7.0 60 to 120

Hard 7.0 to 10.5 120 to 180

Very Hard 10.5 and over 180 and over

deterGent tItratInG InstructIons

A Titrating Kit is required for proper chemical adjustment. If a kit is not available from your chemical supplier,

one can be purchased from Glastender, Inc. When using the kit supplied by Glastender, Inc, follow the

instructions below (instructions are also included in kit):

1. Fill test tube with five (5) ml of detergent solution from the Wash Tank.

2. Add five (5) drops of “Indicator” to solution. The solution will turn a pink (magenta) color.

3. Detergent concentration is determined by amount of “Titrate” required to make the solution turn clear.

• Add one (1) drop of “Titrate” at a time.

• After each drop is added, close the test tube top with finger and rock test tube back and forth three (3)

times to mix solution.

• The solution should turn clear between ten (10) and twelve (12) drops of “Titrate”. Less than ten

(10) drops indicates the detergent concentration is too low, more than twelve (12) drops indicates the

detergent concentration is too high. Proper detergent concentration is .30% by volume.

sanItIzer tItratInG InstructIons

Operate glasswasher to allow sanitizer levels to stabilize. With Conveyor removed and Conveyor Switch “On”,

dip Chlorine or Iodine test strip into Rinse Tank near Rinse Spray Box for one (1) second. Then immediately

compare the strip to the scale on the side of the test strip container tube. Adjust sanitizer (bleach) to 50 PPM,

and iodine type sanitizer to 12.5 PPM.

Important note: Glasswashers are NOT water conditioners. Consult local water conditioning experts to

determine your specific water condition.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

11

Page 14

how to operate the Glasswasher

The automatic rotary conveyor glasswasher is designed to “wash, rinse, and sanitize” hundreds of glasses per hour. The

rotating conveyor automatically moves glassware through the three operations.

Since the machine is typically dis-assembled for cleaning at the end of each day, start each day by ensuring that the machine

was properly re-assembled after the previous day’s use. Once re-assembly is complete, press the fill switch to fill the wash

and rinse tanks with water. The machine is now ready for use.

Press the conveyor switch to put the conveyor in motion. The conveyor rotation determines the loading side of the glasswasher. A clockwise rotation loads on the left side, a counterclockwise rotation loads on the right side.

Remove all garnishes, straws, and ice from the soiled glass before loading the glasswasher. Turn the glass upside down and

load the conveyor. The glass will spend approximately 60 seconds in the wash section and approximately 60 seconds in the

rinse section. The conveyor movement automatically stops when the clean glass touches the “glass stop arm.” Removing

the glass starts the conveyor. Or, if extremely busy, the “glass stop arm” can be set aside with starting and stopping controlled by the “conveyor switch.”

At the end of each day, turn off the conveyor and fill switches. Remove the drain plugs to empty the water from the wash

and rinse tanks and follow the cleaning procedure outlined on pages 17 and 18 of this manual.

how the Glasswasher operates

An important part of owning a GT-24 or GT-30 glasswasher is becoming familiar with the machine’s components and

operation. This section of the Operation Manual covers machine operation and identifies some of the machine components. Many more of the machine components are identified on pages 2 through 4 of this manual.

When the fill switch is turned on at the start of each day, water inlet valves send water to each tank through the stainless

steel inlet tubes on the side of each tank. The wash and rinse tanks each have their own water inlet valve.

The water level in each tank is controlled by an air switch

and low-level sensor pick-up tube. When the fill button

is on, the water level rises and increases the air pressure

inside the pick-up tube, much like placing an empty glass

upside down into water traps air inside the glass. The

increased pressure triggers the air switch to turn off the

water inlet valve. When the machine is in operation

(spraying water), water is lost. A decrease in the water

level in a tank decreases the air pressure inside the pickup tube, which triggers the air switch to turn on the water

Switch Panel

Water Inlet Valve

inlet valve.

The same air switch and low-level pick-up tube assembly

that controls the water inlet valve for the wash side, also

controls the detergent pump (and the rinse side controls

the sanitizer pump). Whenever the machine is filling with

new water, it is also filling with new chemicals, which

makes sense, because you only need to add new chemicals if you are adding new water.

Stainless Water Inlet Tube and Low-Level

Sensor Pick-Up Tube (Cover Removed)

Air Switch

12

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 15

how the Glasswasher operates (contInued)

The chemical pumps have chemical feed lines

that are attached to a chemical low-level sensor

pick-up tube. One set of lines is labeled for

detergent and the other for sanitizer. Both set

of lines must be placed inside the appropriate

Chemical Feed Line

chemical container. The purpose of the chemical low-level sensor pick-up tube is to make the

low-level chemical light flash when the chemicals get low. There is an air pressure switch on

the other end of the chemical low-level pick-up

Detergent and Sanitizer Feed Lines with Chemical Low Level Sensor Pick-Up Tubes Attached

tube line and when the chemical level gets low the pressure on the switch decreases, turning the switch on, and causing the

low-level chemical light on the switch panel to blink. It is very important to clean the pick-up tube assembly from time to

time and to prevent the assembly from being cracked or damaged. Debris clogged in the pick-up tube or a crack or hole

in the pick-up tube assembly can cause a false low level chemical reading.

When the fill switch is on, turning on the conveyor switch puts the conveyor in motion.

Whenever the conveyor is in motion, water is spraying through the spray boxes in each

of the tanks. There is a water recirculating pump for each tank that sucks water from the

tank and forces it through the spray box and onto the glassware. It is important to have

the pump inlet screens in place to prevent foreign debris (broken glass, lemon seeds, etc.)

from being sucked in and damaging

Water Recirculating Pump

the water recirculating pump.

Pump Inlet Screens

Low-Level Sensor Pick-Up Tube

Glassware is placed on the rotating conveyor so it can pass through

the wash section and then the rinse and sanitize section. The GT-24

and GT-30 glasswashers have a glass stop arm (or flag) that stops the

conveyor when the glassware strikes it. This is intended to prevent the

machine from operating constantly and

Rinse Tank Guide

washing the same glassware repeatedly.

However, during busy times, the glass

stop arm can be manually moved to the

side so the conveyor will run constantly.

The GT-24 and GT-30 also have three curtains and a rinse tank guide. The front curtain is

to prevent water from splashing out the front of the machine. The wash and rinse curtains

run perpendicular to the front curtain and are intended to prevent the wash and rinse water

from mixing. The rinse tank guide is a stainless cover over the rinse tank (it has a hole over

the spray box) that guides the used rinse water to the drain compartment so the rinse water

is not used more than once. Wash water is re-used, but the constant splashing causes much

Glass Stop Arm

of the water to escape into the drain tank, so fresh water and chemicals are being regularly

added to both the wash and rinse tanks. Since the rinse water is not re-used, the rinse tank

uses more water than the wash tank when the machine is in operation.

At the end of each day of operation, turn off the conveyor and fill switches

and remove the drain plugs to empty the wash and rinse tanks. [NOTE:

Always be careful when removing the drain plugs, since the wash water

is hot.] Simple daily cleaning takes approximately five minutes. Follow

the cleaning procedures outlined on pages 17 and 18 of this manual and

perform the heavier cleaning procedures, such as de-liming, as necessary.

Spray Boxes

Inside view of wash and rinse tanks for clockwise GT-24

Drain Plugs

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

13

Page 16

how the Glasswasher operates (contInued)

what are the prIme swItches?

Chemical pumps have a speed control so they can be made to run faster or slower (see pages 9-10). Chemical vendors

adjust the amount of chemicals that get inserted into a tank of water by altering the speed of the chemical pump. The water

inlet valve only takes a certain amount of time to fill the tank. The chemical pumps only operate when the tank is filling,

so adjusting the speed of the pump will increase or decrease the amount of chemicals dispensed during the fill time.

Prime switches are used to empty excess air from the tubing and fill it with chemicals by overriding the speed control

and forcing the chemical pumps to operate at full speed. CAUTION: NEVER PRIME CHEMICAL PUMPS WITHOUT

WATER IN THE TANKS. UNDILUTED CHEMICALS CAN DAMAGE STAINLESS STEEL.

NOTICE: On models manufactured before January 2003, the prime switches and the pumps only work when the machine

is filling with water. The best way to use the prime switches is to remove the rubber drain plugs for each tank while the

fill button is on, which causes the machine to constantly fill with water. Since the plugs are out, the water level will never

rise high enough to turn off the liquid level air switches, thus the water inlet valves and the chemical pumps will operate

constantly. ALWAYS BE CAREFUL WHEN REMOVING THE DRAIN PLUGS, SINCE THE WASH WATER IS HOT.

tIps For trouble-Free operatIon

1. NEVER, NEVER wash ash trays in the glasswasher. Since ashes are smaller than the opening in the Pump Inlet

Screens, ashes could adhere to glasses. Also, with ashes recirculating in the wash water, the cleaning effectiveness of

the detergent is greatly reduced. The final result of washing ash trays is dirty glasses.

2. For best results, keep the Conveyor full of glassware. This keeps the water and detergent consumption to a minimum.

3. Water spotting can occur when glassware is placed on flat surfaces after washing, thus preventing air to assist the drying process. Make sure the proper shelf liner is used.

4. The maximum glass height is eleven (11) inches to fit through the Top Section of the glasswasher. Keep this in mind

when ordering beer pitchers and wine carafes.

5. Glasses which have been frequently washed by hand may have deposits of invisible “film”. Although initially appearing clean, these glasses may show unsightly signs of “dirt” after passing through the glasswasher. This unsightly

condition will exist until the film is removed with frequent passes through the glasswasher, or it may be necessary to

use a de-liming agent to clean glassware.

6. Do not place wet glasses into glass chillers or frosters. Allow glasses to dry and sanitizer odors to dissipate first.

7. Changing detergents may require readjustment of the Detergent Pump to maintain .30% detergent concentration. A

greater volume of low-strength detergent is required to maintain the proper level.

8. Only Glastender, Inc. replacement parts should be used. Components from other suppliers may result in machine

malfunctions.

Please consult your Glastender, Inc. service agent if service or technical assistance is required. The factory is also

available to answer any operational questions.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

14

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 17

Important InFormatIon about chemIcals

The GT-24 and GT-30 glasswashers have chemical pumps that automatically dispense chemicals into the machine. The

detergent and sanitizer chemicals are supplied by a chemical vendor. Since the type of chemicals and the condition of

water varies by region, the chemical pumps are not pre-set at the factory. The chemical pumps must be adjusted at start-up

to achieve the proper titration levels or the machine may not produce good wash results. Typically, the chemical vendor

is responsible for adjusting the chemical pumps.

Since detergent and sanitizer chemicals play an important role in the performance of a glasswasher, understanding how the

chemical pumps work and how to maintain them is very important. Reviewing the following information will help ensure

the proper operation of your glasswasher and its chemical pumps:

1. CAUTION: Never prime chemical pumps without water in the tanks. Undiluted chemicals can damage stainless steel.

NOTE: On models manufactured before Jan. 2003, the prime switches will only operate when the machine is filling

with water (See page 14 for more information).

2. The chemical feed line and the chemical empty sensor line must be attached and properly placed inside the appropriate chemical container. Damaged chemical lines will spill chemicals on the machine and floor and create poor wash

results. Damaged or dirty chemical low-level lines will cause a false low level reading.

3. Every glasswasher requires chemical pump adjustment and titrating by a chemical vendor. Poor wash results will

occur if the chemicals are not in proper concentration (see the operation manual for proper concentration levels).

4. Glasswasher chemicals are highly caustic and will cause severe burns when they contact human skin. These same

caustic chemicals will also corrode stainless steel and destroy machine components. A glasswasher should be checked

regularly for chemical leaks and any leaks should be corrected immediately.

5. All of the chemical tubing on a glasswasher should be inspected regularly and replaced at least once per year. The

highly caustic chemicals cause the chemical tubing to get brittle, and since leaking chemicals destroy glasswasher

components, it is good preventative maintenance to replace chemical tubing often. The various tubing includes the

lower tubing assembly or main chemical feed line, the pump squeeze tube (especially susceptible to damage), and the

upper tubing assembly from the pump to the glasswasher tank.

6. A GT-24 or GT-30 glasswasher can use either Iodine or Chlorine for sanitizer. Iodine is often used in hard water

conditions, because it has a sheeting action the helps to prevent water spots. You cannot switch between these two different chemicals for sanitizing without re-adjusting the chemical pumps, because they require different concentration

levels.

7. Chemical vendors that deliver chemicals to your establishment are typically responsible for adjusting the chemical

levels in your glasswasher. They are also helpful for assisting you with chemical tubing inspection and replacement.

Nothing removes your responsibility for proper maintenance, but the chemical vendor will help.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

15

Page 18

dIaGnosInG poor wash results

The best way to understand why you are getting poor results is to know what components belong in your machine and how

they are supposed to operate. If you are getting poor results from your GT-24 or GT-30 glasswasher, follow these simple

steps to help diagnose your problem.

Possible Cause

1. The machine is dirty and/or the spray box holes are

clogged. The machine may require de-liming, because

of excess water deposit build-up.

2. The machine is missing components, like the wash and

rinse curtains or the rinse tank guide, which can cause

the wash and rinse water to mix or the rinse water to

be re-used.

3. The chemical feed lines are in the wrong chemical

container.*

4. The chemical containers are empty, so that no chemicals are being dispensed into the glasswasher.*

5. The chemicals are in the wrong concentration. This is

usually evidenced by slimy or greasy feeling glasses,

even though all of the machine components are in

place and the chemical feed lines are in the proper

containers.*

Remedy

1. Clean and/or de-lime the machine.

2. Replace missing components.

3. Put the chemical feed lines in the proper container.*

4. Get a new jug of chemicals. Pump priming may be

required.*

5. Contact your chemical vendor to have the concentration levels checked.*

6. The chemical tubing is disconnected or damaged and

leaking somewhere instead of getting into the wash or

rinse tank.*

7. Water is not spraying through the wash or rinse spray

box.

* NOTE: Commercial dishwashing detergent and sanitizer are highly caustic and will burn human skin on contact.

Please exercise extreme caution when handling.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

16

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

6. Replace chemical tubing. Your chemical vendor may

help or contact your service company.*

7. The water recirculating pump is plugged or broke.

Have your service company inspect it.

Page 19

cleanInG InstructIons

The following cleaning instructions are recommended. Operating procedures of an establishment may alter the

time of cleaning and the personnel assigned to cleaning.

At the close of business, and after all glasses have been washed and unloaded, turn the Conveyor Switch and the

Fill Switch to the “off” position. No other attention is required until the next morning.

In the morning, the bartender should follow the recommended cleaning instructions. The bartender is responsible for the drink quality of the establishment. Since drink quality includes clean glassware, knowledge of the

glasswasher is important.

step-by-step InstructIons

1. Remove the Front Shield.

2. Position Glass Stop Arm past the Conveyor.

3. Removing the Front Curtain(s). (Note the two attachment tabs.)

4. Remove Conveyor.

5. Turn the Fill Switch to the “on” position to insure that the Wash and Rinse Tanks are full.

6. Turn the Conveyor Switch to the “on” position for as long as necessary to check the 15 nozzles in the Wash Spray

Box and the five (5) nozzles in the Final Rinse and Sanitize Spray Box for a uniform spray pattern.

7. Turn the Conveyor Switch and Fill Switch to the “off” position.

8. Remove Drain Plugs to drain tank.

9. Remove Rinse Tank Guide.

10. See which condition listed below best fits the unit. Then follow the suggested procedures.

condItIon descrIptIon comment procedure

LIGHT Moderate debris in tanks This unit is receiving proper Follow LIGHT

(straws, garnishes, etc.). user maintenance. All personnel procedures on

All spray nozzles are should be congratulated for doing next page.

functioning. a good job.

MEDIUM Light film in Wash Tank. This condition shows you were Follow MEDIUM

Considerable debris in the were busy last night, or proper procedures on the

tanks (straws, garnishes, maintenance has been neglected. next page.

and/ or broken glass, etc.).

Possible plugged spray

nozzle(s).

HEAVY Light to heavy white chalky Unit has been neglected. Install Follow HEAVY

substance (herein after referred proper maintenance procedures procedures on

to as “lime”) completely covers immediately. Caution: If the the next page.

the Wash Tank and components, unit operates in this condition,

especially the Heater. Excessive Heater and Recirculating Pump

debris in the tanks (straws, failures may result.

garnishes, broken glass, etc.).

Plugged spray nozzles.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

17

Page 20

cleanInG InstructIons

lIGht cleanInG procedures:

a. With tanks drained, remove all debris.

b. Remove both Pump Inlet Screens.

c. With damp cloth, wipe the interior of both tanks.

d. Rinse the interior with clean water.

e. Rinse the Pump Inlet Screens with clean water.

f. Proceed to Step 11 below.

medIum cleanInG procedures:

a. With tanks drained, remove Wash Spray Box, Spray Box Gasket, and Pump Inlet Screens.

b. Remove all debris.

c. Thoroughly scrub and rinse all components removed from unit.

d. With a Scotch-brite pad, normally purchased in a grocery store, thoroughly scrub the interior of the unit.

The Top Section can be removed for ease of cleaning. Do NOT use steel wool.

e. Rinse the interior with clean water.

f. Proceed to Step 11 below.

HEAVY

cleanInG procedures:

a. Reinstall Tank Plugs and Screens.

b. Turn Fill Switch to “on” position to fill Wash and Rinse Tanks.

c. Pour one cup of de-liming agent into the Wash Tank and one cup of de-liming agent into the Rinse Tank.

d. Reinstall Conveyor, Front Curtain(s), and Front Shield.

e. Allow the unit to reach operating temperature.

f. Turn Conveyor Switch to the “on” position.

g. Allow the unit to operate for 15 to 20 minutes.

h. Turn Conveyor Switch to the “off ” position.

i. Remove Front Shield, Front Curtain(s), and Conveyor.

j. Remove Tank Drain Plugs.

k. If lime has not been completely removed, repeat steps “a” through “j” above.

l. With all the lime removed, proceed to Medium Cleaning Procedures above. Follow steps “a” through “f ”.

11. Reinstall all components removed for cleaning except Conveyor, Front Curtain(s), and Front Shield.

See Figure 2, page 4.

12. Check Detergent and Sanitizer Containers. Refill or replace if empty.

13. Turn Fill Switch to the “on” position.

14. Visually inspect Detergent and Sanitizer Inlets while tanks are filling. Detergent and sanitizer should

be intermittently dripping.

15. Replace Conveyor, Front Curtain(s), and Front Shield.

16. Allow the unit to reach operating temperature.

17. Your glasswasher is now ready for operation.

18

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 21

troubleshootInG GuIde

trouble or sItuatIon cause remedy

A. Unit does not run 1. No power 1. Check power source.

(Power light “off.”)

2. Fill switch “off.” 2. Turn fill switch to “on” position.

3. Conveyor switch “off.” 3. Turn conveyor switch to “on”

position.

4. Glass stop switch in 4a. Glass holding glass stop arm in

Conveyor stop position. conveyor stop position.

4b. Front shield restricting glass

stop arm movement.

5. Defective fill switch. 5. Check if wash and/or rinse tanks

fill. If not, replace fill switch.

6. Defective conveyor switch 6. These switches are wired in

or glass stop switch. series. Test and replace

defective switch.

7. Wire connections poor, 7. Re-crimp and/or replace wire

loose, or broken. connection.

B. Conveyor runs but wash 1. Bad liquid level switch. 1. Check switch continuity.

and/or rinse tank(s) not Replace if necessary.

filling and detergent and/or 2. Liquid level out of adjustment. 2. Adjust liquid level pickup tube.

sanitizer pump is not operating 3. Water “off.” 3. Turn water “on.”

C. Conveyor runs but wash 1. Bad water valve. 1. Test valve, replace if necessary.

and/or rinse tank(s) 2. Loose pulley(s). 2. Tighten set screw(s). Note: The drive

not filling, and detergent motor pulley has an internal sleeve.

and/or sanitizer pump Set screw could be tightening against

is operating sleeve instead of motor drive shaft.

D. Conveyor moves 1. Loose belt. 1. Tighten belt by first loosening

intermittently the four motor mount towards

front and retighten bolts.

Caution: Excessive belt tension

could cause drive motor failure.

E. Water recirculating, 1. Obstruction in wash or 1. Remove obstruction.

conveyor not moving rinse area.

2. Conveyor not engaged 2. Rotate conveyor until it engages.

with conveyor drive shaft.

3. Defective drive motor. 3. Replace drive motor.

4. Defective of loose belt. 4. Replace or tighten belt.

F. Hot glasses at end 1. Rinse tank guide not 1. Replace rinse tank guide.

of cycle in place.

2. Plugged drain. 2. Clean drain.

3. Hot water supply connected 3. Replumb with cold water.

to cold water inlet.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

19

Page 22

troubleshootInG GuIde

trouble or sItuatIon cause remedy

G. Wash and/or rinse water 1. Completely plugged pump 1. Clean pump inlet screen.

not recirculating inlet screen.

2. Defective recirculating pump. 2. Replace recirculating pump.

H. Water leaking from 1. Defective pump seal. 1. Replace pump seal.

recirculating pump

housing - water on floor

I. Glasses slimy or soapy 1. Sanitizer feed line in 1. Clean line and place in proper

at end of cycle detergent container. container.

2. Rinse water not recirculating. 2. See G above.

J. Water spraying from 1. Partially plugged spray 1. Clean spray box nozzle(s). Refer

front of unit box nozzle(s). to cleaning instructions, pg. 17-18.

2. Front curtain not in place. 2. Install front curtain.

3. Worn front curtain. 3. Replace front curtain.

K. Recirculating wash and/ 1. Spray box not latched 1. Latch spray box properly.

or rinse pressure low properly.

2. Partially plugged pump 2. Clean pump inlet screen.Refer to

inlet screen. cleaning instructions, pg. 17-18.

3. Missing or worn spray 3. Replace gasket(s).

box gasket.

L. Low operating temperature 1. Thermostat set too low. 1. Increase temperature by turn ing screw clockwise.

2. Cold water supply con- 2. Replumb to hot water.

nected to hot water inlet.

3. Heater coated with lime. 3. De-lime wash tank. Caution:

Excessive lime build-up can

cause heater failure.

4. Defective heater. 4. Replace heater.*

5. Defective relay. 5. Replace relay.

6. Low power supply. 6. Check voltage and heater.

208V and 20V are available.

*NOTE: An Ohm meter can be used to verify if the heater is defective. Proper readings are: 208V = 9.5 to 11.5 240V = 13.1 to 15.0

M. Hot water runs contin- 1. Liquid level out of adjustment. 1. Remove obstruction or readjust.

uously, and detergent 2. Defective liquid level switch. 2. Test switch and replace if

pump is functioning necessary.

N. Hot water runs contin- 1. Hot water inlet valve 1. Clean or replace hot water

uously, but detergent not seating properly. inlet valve.

pump turns on and off

20

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

Page 23

troubleshootInG GuIde

trouble or sItuatIon cause remedy

O. Cold water runs contin- 1. Liquid level out of adjustment. 1. Remove obstruction or readjust.

uously, and sanitizer 2. Defective liquid level switch. 2. Test switch and replace if

pump is functioning necessary.

P. Cold water runs contin- 1. Cold water inlet valve 1. Clean or replace cold water

uously, but sanitizer not seating properly. inlet valve.

pump turns on and off

Q. Heater glowing 1. Wash tank water valve 1. Replace valve.

not opening.

2. Liquid level switch stuck 2. Replace switch.

in closed position.

R. Detergent and/or 1. Detergent and/or sanitizer 1. Refill or replace container(s).

sanitizer not feeding container(s) are empty.

properly 2. Feed lines will not fill. 2. Replace defective parts.

Notes: The detergent or sanitizer

product advances in the line on

ea ch str o ke of the pump . The

product should hold position

between strokes. If the product

falls back toward the supply

container, one or more of the fol lowing conditions may exist:

a. Debris in pump,

b. Split feed line, or

c. Bad pump tube.

Replace parts as necessary.

S. Poor washing results 1. Clogged spray nozzles and 1. Clean unit. See cleaning

dirty wash tank. instructions, pg. 17-18.

2. Detergent container empty. 2. Fill container.

3. Poor water conditions. 3. Have filter or softener installed.

4. Chemicals not adjusted 4. Call chemical technician.

properly.

5. Curtains not installed properly. 5. Install curtains properly.

T. Glasses are “sudsy” 1. Iodine-type sanitizer used. 1a. Re-adjust iodine solution.

1b. Replace with chlorine bleach

(sodium hypochlorite - 5.25%

solution).

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

21

Page 24

warranty statement

APPLICABLE TO ALL PRODUCTS SOLD WITHIN THE UNITED STATES AND CANADA

LABOR: Glastender, Inc. warrants all products to be free of defects

in material and workmanship. In established areas, a start-up and a

90-day labor warranty are included with glasswasher models GT-24

and GT-30. The GT-18 series glasswashers include a 90-day labor

warranty. Self-contained refrigeration models, except beer line chillers, include a 1-year labor warranty, for the duration of one year from

date of installation or up to 18 months from date of factory shipment,

whichever occurs sooner. For warranty labor claims beyond 15 months

from the date of factory shipment, proof of date of installation or occupancy must be provided. Authorization for labor must be obtained from

Glastender within the warranty period and prior to the service being performed. Labor warranty applies to the United States and Canada only.

PARTS: Within one year from date of installation or 18 months from

date of factory shipment, whichever occurs sooner, Glastender, Inc.

will replace any part or assembly found defective under normal use and

service. Field replacement parts include a warranty of 90 days from date

of installation.

FOUR YEAR ADDITIONAL COMPRESSOR WARRANTY: Glastender

will warrant to the original user the compressor for all self-contained

refrigeration models for an additional four years following the regular

one-year warranty period. This plan applies to the compressor only.

A warranty claim form MUST accompany all returned defective

parts or assemblies. This form MUST be completed in full. Failure

to do so may result in delay or denial of credit. Any defective part or

assembly must be returned to Glastender, Inc., Saginaw, Michigan,

with all transportation and delivery charges prepaid. Warranty repairs

or replacements will be shipped FOB factory in Saginaw, Michigan.

Reimbursement for applicable freight charges covers ground service only.

Glastender provides in-warranty repairs during a service company’s

regular working days and hours. There is no provision for payment

of a premium rate during “overtime” hours. When warranty service is

requested during other than normal working hours, the end user will be

charged the premium portion of the overtime rate.

The warranty does not cover equipment subjected to accidents, freight

damage, alterations from the original design, improper power and/or

plumbing hookups, improper chemical use, general misuse, or lack

of routine required maintenance as determined by Glastender, Inc.

Installation, normal control adjustments, general maintenance, correcting an installation error, or service calls that reveal the unit is functioning normally will not be reimbursed under warranty.

Condenser coils on self-contained refrigeration products must be

cleaned regularly. Failure to provide adequate air flow to a refrigeration

unit will void the warranty.

SECOND YEAR EXTENDED PARTS & LABOR WARRANTY:

Glastender’s one-year parts and labor warranty on self-contained refrigeration units, excluding beer line chillers, can be extended to two years

with the purchase of a two year parts and labor warranty. Specify part

number EWR2 ($150 net price) when ordering.

EXPORT WARRANTY - One year parts only.

EXCLUSION OF WARRANTIES

EXCEPT AS PROVIDED ABOVE, GLASTENDER MAKES

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE

OR NON-INFRINGEMENT.

LIMI TATION OF REMED IES AND DAM AGES

If Buyer makes a valid and timely claim as outlined above, Glastender’s

liability and Buyer’s remedies under this agreement will be limited solely

to labor charges authorized and/or replacement or credit, at Glastender’s

option, with respect to Products returned at Buyer’s expense within thirty (30) days after warranty repair. GLASTENDER’S LIABILITY WILL

IN NO EVENT BE GREATER IN AMOUNT THAN THE PURCHASE

PRICE OF THE RETURNED PRODUCTS. GLASTENDER

WILL NOT BE LIABLE UNDER ANY CIRCUMSTANCE FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, INCLUDING,

BUT NOT LIMITED TO, LABOR COSTS EXCEPT AS COVERED

UNDER OUR WARRANTY, LOST PROFITS OR THE LOSS OF

PERISHABLE PRODUCTS RESULTING FROM THE USE OF OR

INABILITY TO USE OUR PRODUCTS OR FROM OUR PRODUCTS’

INCORPORATION INTO OR BECOMING A COMPONENT OF

ANY OTHER PRODUCT. NEITHER PARTY WILL HAVE ANY

NEGLIGENCE OR OTHER TORT LIABILITY TO THE OTHER, OR

TO ANY THIRD PARTY, ARISING FROM ANY BREACH OF THIS

AGREEMENT.

GOVERNING LAW - JURISDICTION

The terms and conditions of an order are to be governed and construed

according to the laws of the State of Michigan, without regard to conflict

of laws principles. Buyer hereby consents to the jurisdiction and venue

of the courts located in Saginaw County, Michigan.

No representative, distributor, dealer, or any other person is authorized

to modify this warranty. This warranty replaces all other written or

verbal warranties.

NOTE: Glastender, Inc.’s policy of constant quality improvement

means that prices, specifications, and policies are subject to change

without notice. Questions regarding this warranty should be directed to

Glastender’s Customer Service Representative.

Glastender shall not be liable for loss of use, revenue, or profit, or for any other indirect, incidental, special, or consequential

damage including, but not limited to, product spoilage or loss.

This warranty is conditioned upon Glastender receiving notice of any

defect subject to this warranty within sixty (60) days of its discovery

by the end user or dealer. All products are warranted only for the initial

place of installation. Removal of a product automatically terminates this

warranty.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

22

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

03/03/10

IMPORTANT!!

Attention Refrigeration Service Companies

Please review the important warranty information on this page. If you

believe a service call should be covered by the factory, please call

the factory for authorization between 8AM and 5PM EST, Monday

through Friday.

Loading...

Loading...