Glastender GT-18+3 Installation Manual

Operation Manual

A Family Company Manufacturing In The USA Since 1969

GT-18 SerieS GlaSSwaSherS

GT-18, GT-18+1, GT-18+1L, GT-18+1R, GT-18+2, GT-18+2-IC and GT-18+3

(manufactured after August 2006)

GT-18 Glasswasher Operation & Maintenance Video - http://www.glastender.com/videos/

The GT-18 is a simple and effective glasswasher that, if properly maintained, will provide years of reliable service.

This video provides a visual illustration of proper care and cleaning of the glasswasher.

GT-18

Glastender, Inc. · 5400 North Michigan Road · Saginaw, MI · 48604-9780

800.748.0423 · 989.752.4275 · Fax 989.752.4444 · www.glastender.com

Rev. 04-19-17

GT-18+2

© 2010 Glastender, Inc.

index

Topic Page

Introduction .....................................................................................................1

What is a glasswasher? ................................................................................... 1

Utility Requirements and Connections ........................................................... 2

Main Section - Front View .............................................................................2

Uncrating and Start-Up Instructions ............................................................... 3

Operation .........................................................................................................4

Thermostat Control ................................................................................4

Low Water Pressure ................................................................................ 4

Exploded View of GT-18 Series Glasswashers ..............................................5

Wiring Diagrams .........................................................................................6-8

Useful Information About Water, Detergent and Sanitizer ............................ 9

Important Information about Chemicals .......................................................10

Tips for Trouble-Free Operation ................................................................... 11

Cleaning Instructions .................................................................................... 12

Trouble Shooting Guide ................................................................................13

Warranty ........................................................................................................14

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

inTroducTion

This manual describes the operational features of the GT-18, GT-18+1, GT-18+1L, GT-18+1R, GT-18+2,

GT-18+2-IC and GT-18+3 model glasswashers. Please review this information before attempting installation and operation. Long term, trouble-free operation will follow if good housekeeping and maintenance

procedures are followed.

For a video illustration of care and cleaning of the GT-18 visit http://www.glastender.com/videos/.

Thank you for selecting Glastender, Inc. products.

whaT iS a GlaSSwaSher?

Glastender, Inc. has been manufacturing automatic glasswashers since 1969. Today, Glastender glasswashers

have been installed around the world. But what is a glasswasher? It is simply a piece of machinery that washes

glassware, which eliminates the need for human labor and the conventional three-compartment sink. The glasswasher is, in effect, a mechanized three-compartment sink. It “washes”, “rinses”, and “sanitizes” glassware.

noTe The SimpliciTy:

FuncTion deSiGn

waSh 120ºF (48.9ºC) water and a preset portion of detergent join in the tank. During operation, 5 gal-

lons per minute of hot soapy water are pumped in a forceful, but gentle, spray pattern across the

moving glassware. When the wash cycle is complete, all water is drained. While the drain is still

open, clean water pre-rinses the holding tank to prepare for the rinse and sanitize cycle.

rinSe and

aniTize

S

Please read on to learn more about this simple machine.

120ºF (48.9ºC) water and a preset portion of sanitizer and rinse aid join in the tank. During operation, 5 gallons per minute of rinse water are pumped in a forceful, but gentle, spray pattern across

the moving glassware. At the end of the cycle, all water is drained so the next load can begin with

fresh, clean water.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

1

uTiliTy requiremenTS and connecTionS

1. General

Plumbing

2. Drain

3. Electrical

4. Detergent

5. Sanitizer

a. 1/2” OD (or larger) copper to 3/8” FMPT adapter provided

b. Minimum water pressure is 25 PSI

c. Maximum water pressure is 100 PSI. Install water pressure regulator if line pressure is

over 100 PSI. Water valve on unit has built-in strainer and flow control to provide consis-

tent volume between 25 and 100 PSI

d. Install separate water shut-off valve

e. Unit has built-in air gap - vacuum breaker is not required

f. Maximum temperature is 150ºF (66ºC)

g. Minimum temperature is 120ºF (49ºC)

h. Consumption is 2-1/2 gallons per cycle

a. 1-1/2” tailpiece

b. Use open type floor drain for maximum drainage

a. 120V, single phase, 60Hz, 6-foot grounded cord included

b. Dedicated 15 amp circuit recommended

c. Power requirements - 3.5 amps

a. Extra heavy duty, non-foaming, commercial liquid dishwashing detergent is required - .30%

concentration

b. Consult local chemical supplier to match detergent with local water conditions

a. Liquid chlorine bleach (sodium hypochlorite - 5.25% solution) adjusted to 50 ppm

6. Rinse Aid

7. Installation

Considerations

a. Liquid Rinse Aid adjusted for proper sheeting

a. 1” clearance required to remove top

b. Front side service is essential

c. Detergent, Sanitizer, and Rinse Aid containers are stored externally - six-foot lengths of

tubing are provided. Storage for three one-gallon containers is required within ve feet

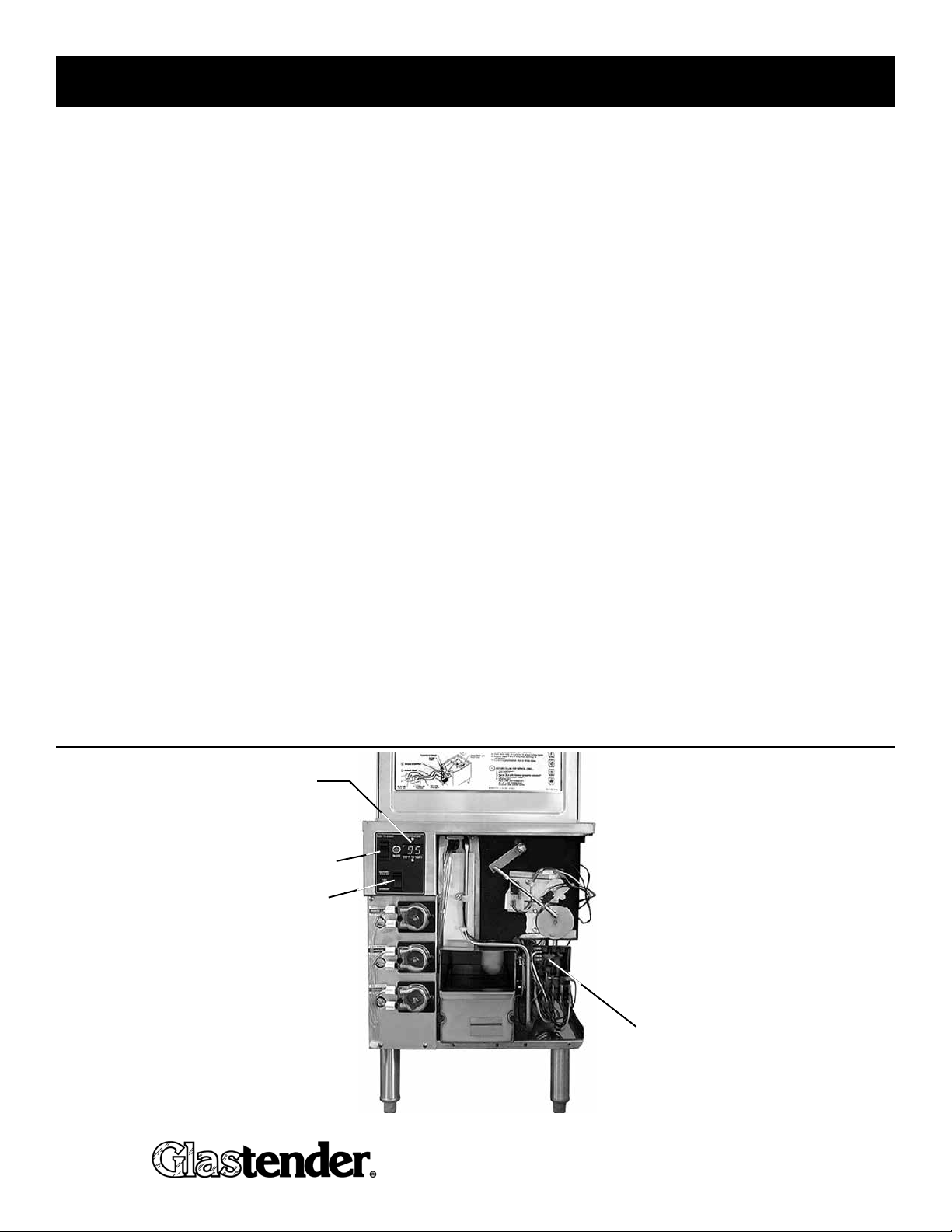

main SecTion FronT View

Digital

Temperature

Gauge

Start Switch

Chemical Pump

Prime Switch

Electronic

Control Timer

GT-18 Glasswasher with front panel removed

2

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

uncraTinG and STarT-up inSTrucTionS

The glasswasher is shipped in two cartons. After uncrating, follow this procedure:

1. Set in place and install top.

2. Place chemical Feed Lines into the proper chemical containers.

a. Red is detergent.

b. Blue is rinse aid.

c. Clear is sanitizer.

WARNING: The chemicals used in commercial glasswashing are very harsh. Exposure to human skin can

cause severe burns. Chemical containers should be stored in a manner and/or location that prevents them from spilling or splashing. Chemical containers must be secured. Please consult your

chemical vendor to ensure proper storage or call the Glastender factory to purchase a clip-on

chemical rail, part number 01000710.

3. After utility connections described above are completed, plug in glasswasher.

4. Depress Prime switches to fill Feed Lines. NOTE: Always cycle the machine after using the prime switches. Undiluted chemicals will damage stainless steel.

5. Cycle the glasswasher and check chemical settings.

6. If chemical adjustment is required, unplug glasswasher, remove front panel, and adjust chemicals as required

using the Electronic Control Timer. See chemical adjustment procedure below.

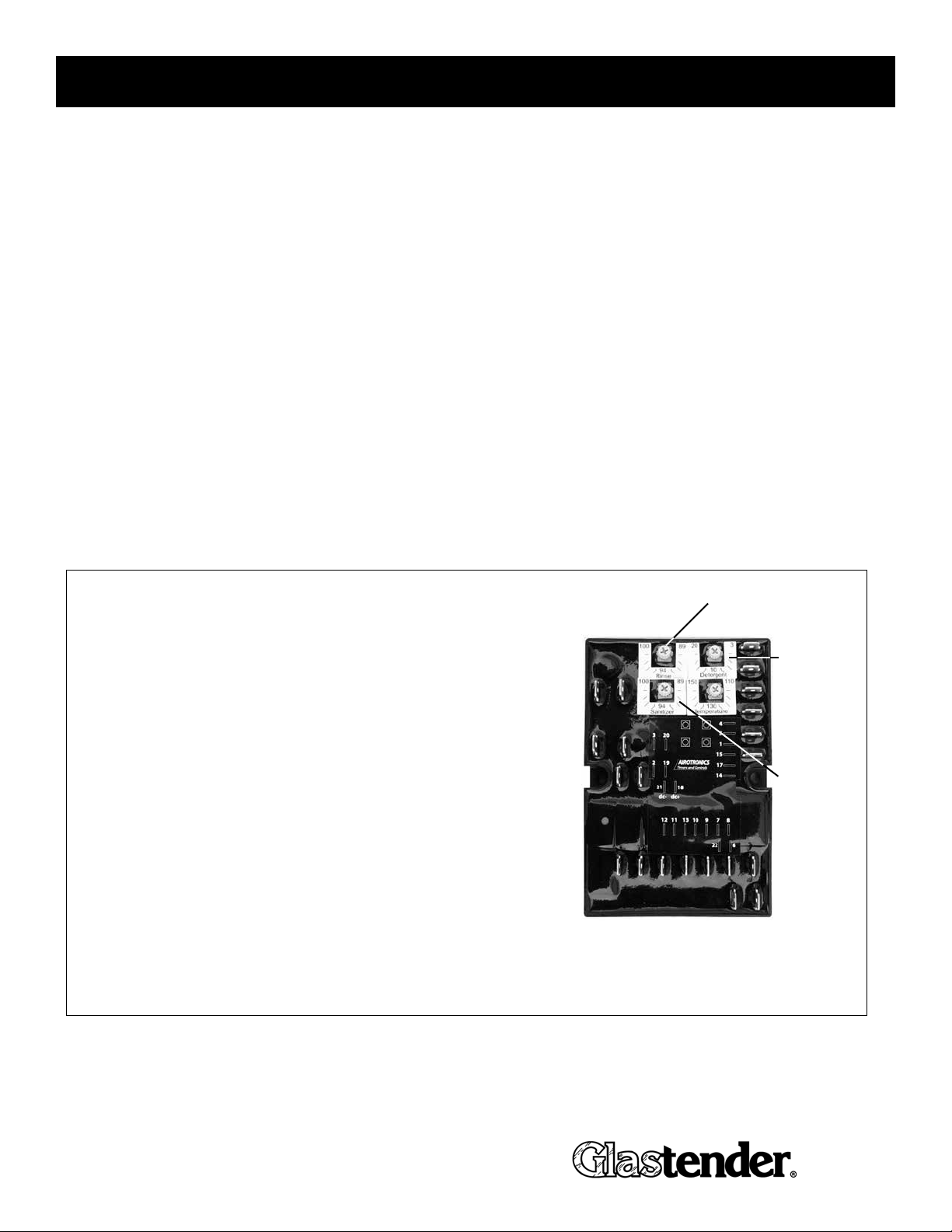

chemical adjuSTmenT procedure

The chemical strengths should be tested with a professional test kit by

the chemical supplier. Water samples should be taken during the wash

cycle and the rinse cycle.

Detergent - .30% concentration

Sanitizer - 50 PPM (sodium hypochlorite [bleach])

Rinse Aid - until proper sheeting is achieved

Detergent: If the factory setting does not render the proper concentration,

turn the detergent adjustment knob clockwise to increase or

counterclockwise to decrease the dispense time. Repeat chemical testing procedure and adjust again if necessary.

Sanitizer: If the factory setting does not render the proper concentration,

turn the sanitizer adjustment knob clockwise to increase or

counterclockwise to decrease the dispense time. Repeat chemical testing procedure and adjust again if necessary.

Rinse Aid: If the factory setting does not render the proper level of sheet-

ing, turn the rinse aid adjustment knob clockwise to increase

or counterclockwise to decrease the dispense time. Run a test

cycle to check wash results and adjust again if necessary.

Rinse Aid

Detergent

Sanitizer

Electronic Control Timer

7. Replace panel and plug in glasswasher. Cycle the glasswasher and check chemical settings. Repeat step 6

if necessary.

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

3

Loading...

Loading...