Page 1

Cocktail Station

Assembly Instructions

CS-42

CS-72-CCW

Server Side

CS-72-CCW

Bartender Side

F-750-045 Rev A 01/24/07

Page 2

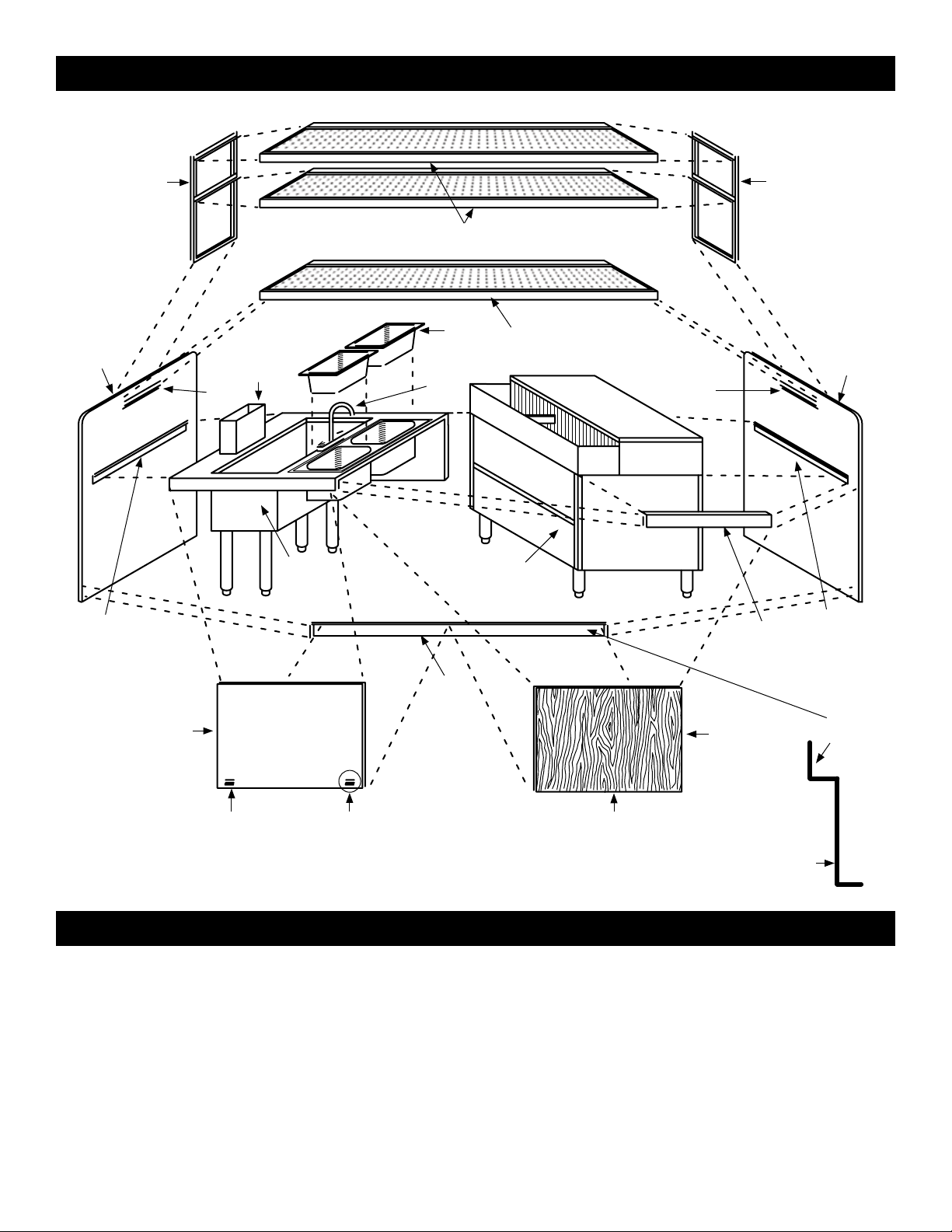

Assembly Illustration

*

D

K

N

O

H

A

Q

M

R

G

B

P

E

N

C

L

I

Back side shown with pre-mounted clips

View is of Cocktail Station Server Side

Cocktail Station Components

A Sink, ice, and tubing chase section

B GT-30 Rotary Glasswasher

C

End Panel

D End Panel

E Trim Rail for Glasswasher

F Kick Rail

G Tray Shelf

H Tubing Chase

I Front Panel - Back side showing

F

F Cross Section

J

Front side shown

Place this side

facing out

J Front Panel - Front side showing

K End Panel Clip

L End Panel Clip

M Overshelves

N Overshelf Bracket

O Tray Shelf Clip

P Tray Shelf Clip

Q Faucet

R Wet Waste Strainers

Page 3

Cocktail Station Assembly Instructions

Install 4 legs on A Sink, ice and tubing chase section and 4 legs on B GT-30 Rotary

1.

Glasswasher using 1/4-20 leg bolts provided.

Attach E Trim Rail for Glasswasher to A Sink, ice and tubing chase section, using 8-32S/S hex

2.

nut and afxed 8-32x1/2 phillips pan head machine screw into the end of trim rail.

Clip A Sink, ice, and tubing chase section to front edge and E Trim Rail to the side of B GT-30

3.

Rotary Glasswasher.

Utilizing pre-installed L End Panel Clip, attach C End Panel to back edge of B GT-30 Rotary

4.

Glasswasher.

Utilizing pre-installed K End Panel Clip, attach Clip D End Panel to edge of A Sink, ice, and

5.

tubing chase section.

Attach end of E Trim Rail to C End Panel using afxed screws into C End Panel.

6.

Attach ends of F Kick Rail to pre-mounted screws on C End Panel and D End Panel with

7.

screws provided. NOTE: Reference F Cross Section illustration for correct placement.

Insert top edge of I Front Panel with front side facing out under A Sink, ice, and tubing chase

8.

section until I pre-mounted clips are able to be placed over the top of F Kick Rail. Lower I

Front Panel until clips engage with F Kick Rail. Insert top edge of J Front Panel with front side

facing out under E Trim Rail until J pre-mounted clips are able to be placed over the top or F

Kick Rail. Lower J Front Panel until clips engage with F Kick Rail.

Mount H Tubing Chase with included screws into pre-punched holes of A Sink, ice, and tubing

9.

chase section.

Attach ends of G Tray Shelf to O and P pre-mounted Tray Shelf Clips located on D and C End

10.

Panels. Screws to mount are afxed in each end of G Tray Shelf.

Use afxed screws to attach N Overshelf Bracket to the top edges of C and D End Panels.

11.

Use afxed screws to attach M Overshelves to N Overshelf Bracket.

12.

Install Q Faucet with provided hardware.

13.

Place R Wet Waste Strainers in sinks of A Sink, ice, and tubing chase section.

14.

CS-72-CCW

NOTES:

For CW rotation glasswasher, reverse location of A

1.

and B.

Use adjustable feet in legs to level station and glass-

2.

washer to each other.

The illustration included in this instruction diagrams the

*

assembly of the CS-72 Cocktail Station with CCW Rotation

Glasswasher and double overshelves accessory. Assembly

of additional Cocktail Station models is synonymous with

slight variations.

Page 4

Promote Team Work, Increase Efciency

Glastender manufactures a large variety of pass-thru cocktail stations. Many of the typical features are

detailed in the example below. Reference our product directory for additional information.

Optional

Sneeze Guard

Overshelves (Optional)

• Single (shown)

and double available

Draining Tray Shelf

with perforated inserts

Laminated (shown)

or stainless front

and end panels

Automatic Glasswasher

• Available with some models

CS-72-CCW with optional SOS/SS-72 single overshelf and SG-30 sneeze guard

Why does a Cocktail Station have finish panels?

A Cocktail Station actually passes through the bar and is seen

from the customer side. Front and end finish panels are provided

to match the surrounding decor. The end panels are also necessary

to hold up the tray shelf and optional overshelves. Laminated panels are available in any standard manufacturer laminate color.

Please specify the manufacturer, color, and catalog number

when ordering. The finish panels may also be converted to

stainless steel (see cocktail station accessories for conversion

model numbers).

Why are Cocktail Stations offered without panels?

Glastender offers Cocktail Stations without finish panels because

some customers prefer to make their own and we want to offer

them that flexibility. However, the finish panels are required, so

if they are not provided by Glastender, they must be provided by

someone else. The Glastender Specification Guide has drawings

that show the details necessary to fabricate the finish panels.

Tubing Chase

Pass-thru Ice Bin

• Available with

some models

Wet Waste Sinks

with Faucet

and Strainers

Blender Shelf

Double Speed Rail

What is an orientation or rotation specification?

All Cocktail Stations have an orientation or rotation that determines the work flow. The orientation is dictated by the position of

the glasswasher within the station. Even though assembly style

Cocktail Stations do not have a glasswasher, their orientation

is based on the complete Cocktail Stations from which they

are derived. The orientation and work flow are determined as

follows:

Counterclockwise: The glasswasher is positioned to the bar-

tender’s

Clockwise: The glasswasher is positioned to the bartender’s

right. The work flow is left to right.

left. The work flow is right to left.

5400 NORTH MICHIGAN ROAD • SAGINAW, MICHIGAN 48604 • USA

800.748.0423 • 989.752.4275 • FAX 989.752.4444 • www.glastender.com

Loading...

Loading...