Page 1

BEER PANELS

INSTALLATION INSTRUCTIONS

Glastender, Inc. · North Michigan Road · Saginaw, MI · 48604-9780

800.748.0423 · 989.752.4275 · Fax 800.838.0888 / 989.752.4444 · www.glastender.com

BPIK, Beer Pump Panel

Page 2

BPIK-Y, Beer Pump Panel with Y Angle Bracket

Page 4

BIK, Beer Panel

Page 6

BPIK-E, Beer Pump Panel with Empty Keg Detector

Page 3

BPIK-EY, Beer Pump Panel with Empty Keg Detector

& Y Angle Bracket

Page 5

BIK-E, Beer Panel with Empty Keg Detector

Page 7

BIK-Y, Beer Panel with Y Angle Bracket

page 8

Rev. 04-06-06

Page 1 of 9

BIK-EY, Beer Panel with Empty Keg Detector &

Y Angle Bracket

Page 9

© 2006 Glastender, Inc.

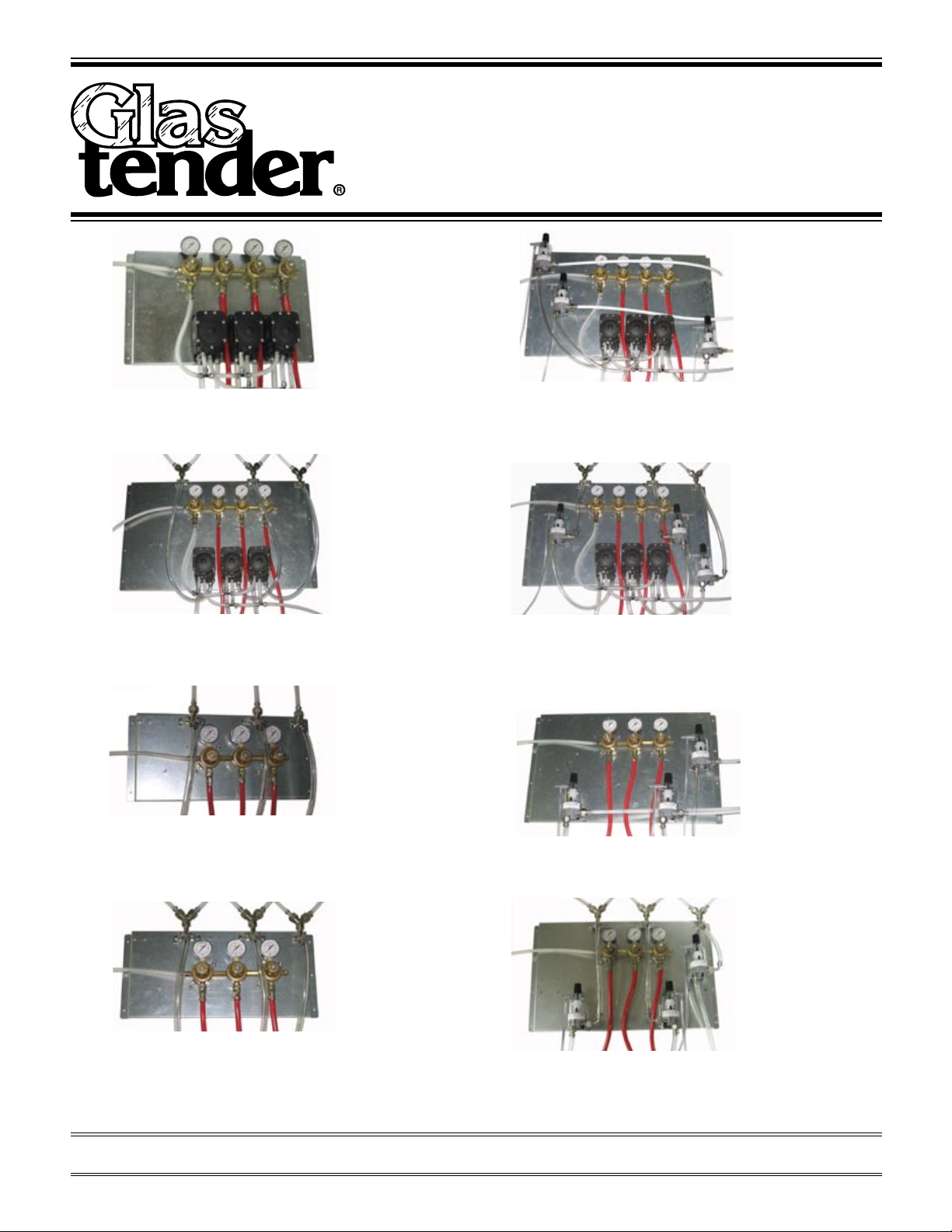

Page 2

BPIK

Beer Pump Panel

Installation Instructions

A

G

D

C

These instructions assume that the primary regulator

and CO2 line to the walk-in cooler are already

installed.

1. Position the regulator panels according to factory instructions.

2. Connect CO2 source line to one end (A) of regulator bank. If there is more than one panel, continue the line to the next

panel until all panels are connected.

3. Approximately 9 feet of clear vinyl beer line (B) is provided for the keg jumper line from each keg to its beer pump.

Trim clear line to size and attach one end to the input port of the beer pump and the other end to the keg tap. The beer

pump ports are shipped loose in a bag attached to the regulator.

4. Approximately 9-1/2 feet of red air line (C) is provided for the jumper line from each keg to its regulator (D). Trim red

air line to size and attach one end to the regulator and the other end to the keg tap.

5. Attach the polyline (E) provided in the beer line set (conduit) to the output port of each pump.

6. The CO2 exhaust port of each pump has been pre-plumbed at the factory to create one CO2 exhaust port connection

(F). Use the CO2 line provided to exit the CO2 from the walk-in cooler. An extra tee is provided with each panel in case

you want to join the exhaust lines of adjacent panels. THE EXHAUST PORT OF EACH PUMP MUST BE VENTED

OUTSIDE THE WALK-IN.

7. The keg regulators (D) provide individual pressure to each keg. Set each keg regulator at the keg’s natural internal head

pressure, normally between 12 to 16 pounds. To get to the natural head pressure level for the keg, start with the regulator set around 10 pounds. Draw beer through the line. If bubbles appear in the clear keg jumper line, then the pressure

should be adjusted upward slightly. Repeat until the bubbles do not form in the line. Be careful not to set the pressure too

high or the beer will over-carbonate. NOTE: This step needs to be done in conjunction with step #8 until proper results

are achieved.

8. The beer pump regulator (G) controls the pressure going to the beer pumps on that panel. Each pump on the panel

receives the same level of pressure, which is intended for beer lines traveling to the same tower (i.e. same length of beer

line). Upon start-up, the beer pump regulator should be set at a pressure level that provides the proper ow rate. Start

around 10 pounds and work up from there to achieve a 2 ounces per second ow rate.

NOTE: If supplied, empty keg detectors (FOB stops) should be mounted after the beer pump.

B

E

F

F-750-356 Rev. A

Glastender, Inc. 5400 North Michigan Road Saginaw, MI. 48604-9780

800.748.0423 989.752.4275 Fax: 989.752.4444 www.glastender.com

04-06-06

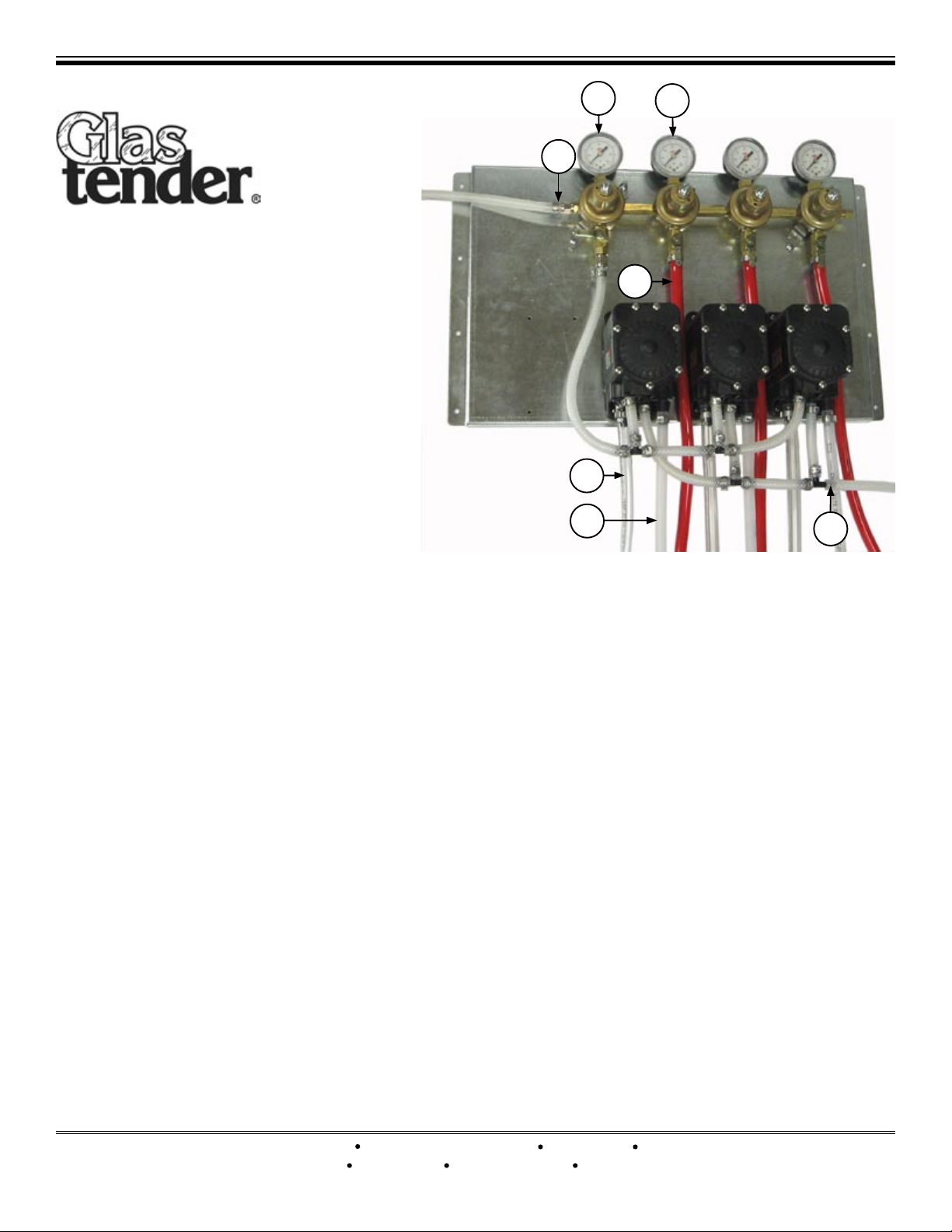

Page 3

E

H

G

A

J

D

BPIK-E

Beer Pump Panel

F

C

Installation Instructions

These instructions assume that the primary

regulator and CO2 line to the walk-in cooler are

already installed.

1. Position the regulator panels according to factory instructions.

2. Connect CO2 source line to one end (A) of regulator bank. If there is more than one panel, continue the line to the

next panel until all panels are connected

3. Approximately 9 feet of clear vinyl beer line (B) is provided for the keg jumper line from each keg to its beer pump.

Trim clear line to size and attach one end to the input port of the beer pump and the other end to the keg tap. The beer

pump ports are shipped loose in a bag attached to the regulator.

4. Approximately 9-1/2 feet of red air line (C) is provided for the jumper line from each keg to its regulator (D). Trim red

air line to size and attach one end to the regulator and the other end to the keg tap.

5. Attach an Empty Keg Detector (E) to each of the black EKD mounting brackets by sliding them in place. The EKD can

be mounted to ow left or right. The standard set up is to ow left. The EKDs may need to be repositioned if right ow

is required. The panel has pre-punched holes to allow repositioning of the EKDs if necessary.

6. Attach the appropriately numbered, pre-made jumper line (F) from the output port of each pump to the bottom input port

of its EKD. Use a black washer on the EKD end.

7. Attach the polyline (G) from the beer line set (conduit) to the side output port of each EKD.

8. Approximately 6 feet of exhaust line (H) is provided for the exhaust port of each EKD. Trim the exhaust line to length

and attach to each EKD exhaust port so the exhaust can be drained to a bucket. No clamp is required.

9. The CO2 exhaust port of each pump has been pre-plumbed at the factory to create one CO2 exhaust port connection (I). Use the CO2 line provided to exit the CO2 from the walk-in cooler. An extra tee is provided with each panel

in case you want to join the exhaust lines of adjacent panels. THE EXHAUST PORT OF EACH PUMP MUST BE

VENTED OUTSIDE THE WALK-IN.

10. The keg regulators (D) provide individual pressure to each keg. Set each keg regulator at the keg’s natural internal

head pressure, normally between 12 to 16 pounds. To get to the natural head pressure level for the keg, start with the

regulator set around 10 pounds. Draw beer through the line. If bubbles appear in the clear keg jumper line, then the

pressure should be adjusted upward slightly. Repeat until the bubbles do not form in the line. Be careful not to set the

pressure too high or the beer will over-carbonate. NOTE: This step needs to be done in conjunction with step #8 until

proper results are achieved.

11. The beer pump regulator (J) controls the pressure going to the beer pumps on that panel. Each pump on the panel

receives the same level of pressure, which is intended for beer lines traveling to the same tower (i.e. same length of beer

line). Upon start-up, the beer pump regulator should be set at a pressure level that provides the proper ow rate. Start

around 10 pounds and work up from there to achieve a 2 ounces per second ow rate.

B

I

F-750-357 Rev. A

Glastender, Inc. 5400 North Michigan Road Saginaw, MI. 48604-9780

800.748.0423 989.752.4275 Fax: 989.752.4444 www.glastender.com

04-06-06

Page 4

BPIK-Y

G

E

A

I

D

Beer Pump Panel

Installation Instructions

These instructions assume that the primary regulator

and CO2 line to the walk-in cooler are already

installed.

1. Position the regulator panels according to factory instructions.

2. Connect CO2 source line to one end (A) of regulator bank. If there is more than one panel, continue the line to the

next panel until all panels are connected

3. Approximately 9 feet of clear vinyl beer line (B) is provided for the keg jumper line from each keg to its beer pump.

Trim clear line to size and attach one end to the input port of the beer pump and the other end to the keg tap. The beer

pump ports are shipped loose in a bag attached to the regulator.

4. Approximately 9-1/2 feet of red air line (C) is provided for the jumper line from each keg to its regulator (D). Trim red

air line to size and attach one end to the regulator and the other end to the keg tap.

5. Attached to each Y angle bracket (E) is a clear jumper line (F). Attach the pump port end of the clear jumper line to the

appropriate pump output port.

F

B

C

H

6. Attach the polyline (G) from the beer line set (conduit) to the top output ports of each Y angle bracket.

7. The CO2 exhaust port of each pump has been pre-plumbed at the factory to create one CO2 exhaust port connection

(H). Use the CO2 line provided to exit the CO2 from the walk-in cooler. An extra tee is provided with each panel

in case you want to join the exhaust lines of adjacent panels. THE EXHAUST PORT OF EACH PUMP MUST BE

VENTED OUTSIDE THE WALK-IN.

8. The keg regulators (D) provide individual pressure to each keg. Set each keg regulator at the keg’s natural internal

head pressure, normally between 12 to 16 pounds. To get to the natural head pressure level for the keg, start with the

regulator set around 10 pounds. Draw beer through the line. If bubbles appear in the clear keg jumper line, then the

pressure should be adjusted upward slightly. Repeat until the bubbles do not form in the line. Be careful not to set the

pressure too high or the beer will over-carbonate. NOTE: This step needs to be done in conjunction with step #8 until

proper results are achieved.

9. The beer pump regulator (I) controls the pressure going to the beer pumps on that panel. Each pump on the panel

receives the same level of pressure, which is intended for beer lines traveling to the same tower (i.e. same length of beer

line). Upon start-up, the beer pump regulator should be set at a pressure level that provides the proper ow rate. Start

around 10 pounds and work up from there to achieve a 2 ounces per second ow rate.

Glastender, Inc. 5400 North Michigan Road Saginaw, MI. 48604-9780

F-750-358 Rev. A

800.748.0423 989.752.4275 Fax: 989.752.4444 www.glastender.com

04-06-06

Page 5

I

L

F

D

A

BPIK-EY

B

H

C

K

Beer Pump Panel

Installation Instructions

These instructions assume that the primary

regulator and CO2 line to the walk-in cooler are

already installed.

E

J

G

1. Position the regulator panels according to

factory instructions.

2. Connect CO2 source line to one end (A) of

regulator bank. If there is more than one panel, continue the line to the next panel until all panels are connected

3. Approximately 9 feet of clear vinyl beer line (B) is provided for the keg jumper line from each keg to its beer pump.

Trim clear line to size and attach one end to the input port of the beer pump and the other end to the keg tap. The beer

pump ports are shipped loose in a bag attached to the regulator.

4. Approximately 9-1/2 feet of red air line (C) is provided for the jumper line from each keg to its regulator (D). Trim red

air line to size and attach one end to the regulator and the other end to the keg tap.

5. Attach an Empty Keg Detector (E) to each of the black EKD mounting brackets by sliding them in place. The EKD

can be mounted to ow left or right. Position them so that the EKD output port points in the appropriate direction to

ow to the corresponding Y angle bracket (F).

6. Attach the appropriately numbered, pre-made jumper line (G) from the output port of each pump to the bottom input

port of its EKD. Use a black washer on the EKD end.

7. Attached to each Y angle bracket (F) is a clear jumper line (H). Attach the free end of the clear jumper line to the

appropriate EKD side output port, using a black washer.

8. Attach the polyline (I) from the beer line set (conduit) to the top output ports of each Y angle bracket.

9. Approximately 6 feet of exhaust line (J) is provided for the exhaust port of each EKD. Trim the exhaust line to length

and attach to each EKD exhaust port so the exhaust can be drained to a bucket. No clamp is required.

10. The CO2 exhaust port of each pump has been pre-plumbed at the factory to create one CO2 exhaust port connection

(K). Use the CO2 line provided to exit the CO2 from the walk-in cooler. An extra tee is provided with each panel

in case you want to join the exhaust lines of adjacent panels. THE EXHAUST PORT OF EACH PUMP MUST BE

VENTED OUTSIDE THE WALK-IN.

11. The keg regulators (D) provide individual pressure to each keg. Set each keg regulator at the keg’s natural internal

head pressure, normally between 12 to 16 pounds. To get to the natural head pressure level for the keg, start with the

regulator set around 10 pounds. Draw beer through the line. If bubbles appear in the clear keg jumper line, then the

pressure should be adjusted upward slightly. Repeat until the bubbles do not form in the line. Be careful not to set the

pressure too high or the beer will over-carbonate. NOTE: This step needs to be done in conjunction with step #8 until

proper results are achieved.

12. The beer pump regulator (L) controls the pressure going to the beer pumps on that panel. Each pump on the panel

receives the same level of pressure, which is intended for beer lines traveling to the same tower (i.e. same length of

beer line). Upon start-up, the beer pump regulator should be set at a pressure level that provides the proper ow rate.

Start around 10 pounds and work up from there to achieve a 2 ounces per second ow rate.

Glastender, Inc. 5400 North Michigan Road Saginaw, MI. 48604-9780

800.748.0423 989.752.4275 Fax: 989.752.4444 www.glastender.com

04-06-06F-750-359 Rev. A

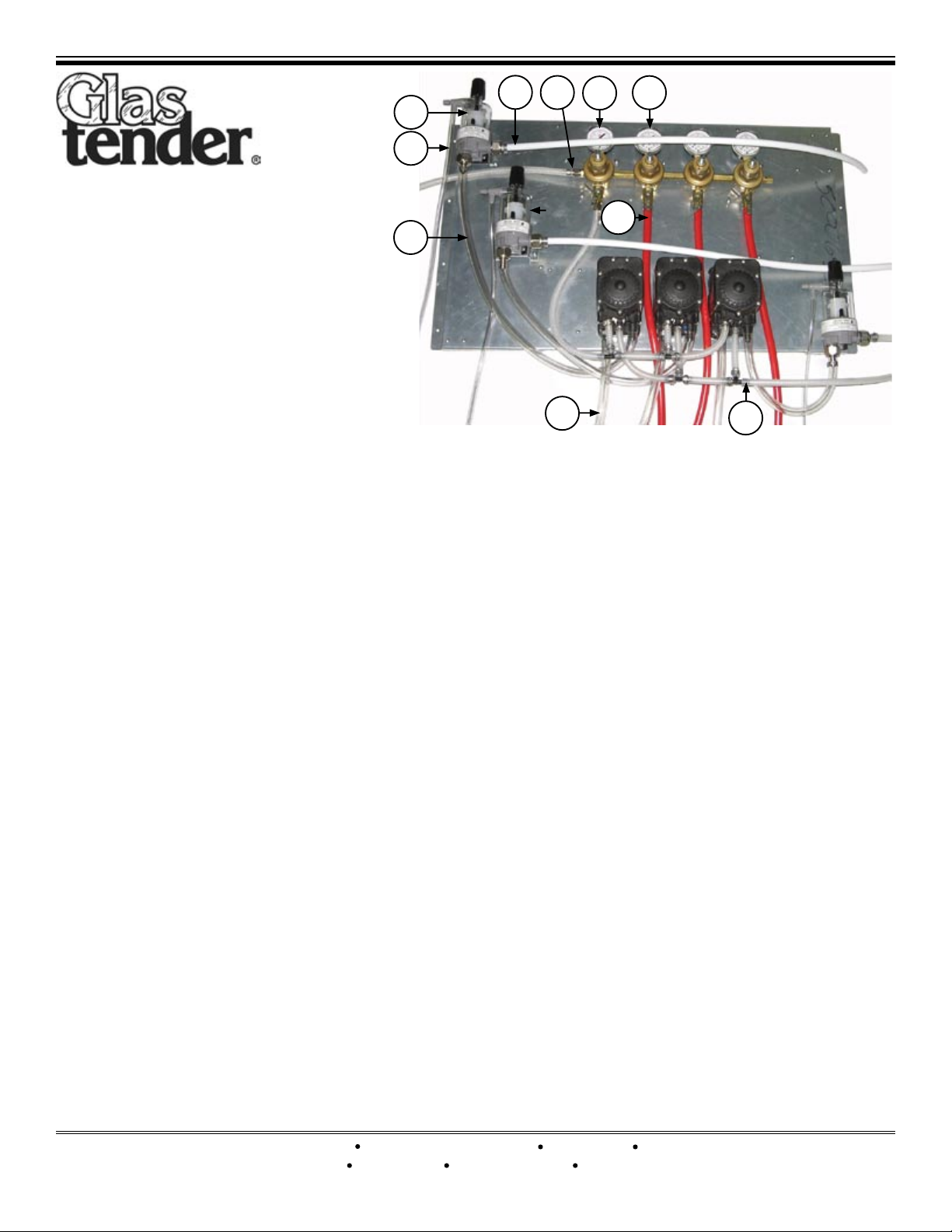

Page 6

BIK

Beer Panel Installation Instructions

F

C

E

A

B

D

These instructions assume that the primary regulator and CO2 line to the walk-in cooler are already installed.

1. Position the regulator panels according to factory instructions.

2. Connect CO2 source line to one end of regulator bank (A). If there is more than one panel, continue the line

to the next panel until all panels are connected.

3. Approximately 9 feet of clear vinyl beer line (B) is provided for the keg jumper line from each keg to its angle

bracket (C). Trim clear line to size and attach one end to bottom of angle bracket and the other end to the keg

tap.

4. Approximately 9 feet of red air line (D) is provided for the jumper line from each keg to its regulator (E). Trim

red air line to size and attach one end to the regulator and the other end to the keg tap.

5. Attach the polyline (F) provided in the beer line set (conduit) to the top of each angle bracket (C).

6. The keg regulators (E) provide individual pressure to each keg. Upon start up, the ideal gauge pressure will

depend on the type of gas involved as well as the length of the line runs. The goal is to achieve a ow rate of

2 ounces per second.

Glastender, Inc. 5400 North Michigan Road Saginaw, MI. 48604-9780

F-750-360 Rev. A

800.748.0423 989.752.4275 Fax: 989.752.4444 www.glastender.com

04-06-06

Page 7

BIK-E

Beer Panel Installation Instructions

E

A

D

B

G

F

C

These instructions assume that the primary regulator and CO2 line to the walk-in cooler are already installed.

1. Position the regulator panels according to factory instructions.

2. Connect CO2 source line to one end of regulator bank (A). If there is more than one panel, continue the line

to the next panel until all panels are connected

3. Attach an Empty Keg Detector (B) to each of the black EKD mounting brackets by sliding them in place. The

EKD can be mounted to ow left or right.

4. Approximately 9 feet of clear vinyl beer line (C) is provided for the keg jumper line from each keg to its

EKD. Trim clear line to size and attach one end to bottom input port of the EKD and the other end to the keg

tap.

5. Approximately 9 feet of red air line (D) is provided for the jumper line from each keg to its regulator (E).

Trim red air line to size and attach one end to the regulator and the other end to the keg tap.

6. Attach the polyline (F) from the beer line set (conduit) to the side output port of each EKD.

7. Approximately 6 feet of exhaust line (G) is provided for the exhaust port of each EKD. Trim the exhaust

line to length and attach to each EKD exhaust port so the exhaust can be drained to a bucket. No clamp is

required.

8. The keg regulators (E) provide individual pressure to each keg. Upon start up, the ideal gauge pressure will

depend on the type of gas involved as well as the length of the line runs. The goal is to achieve a ow rate of

2 ounces per second.

Glastender, Inc. 5400 North Michigan Road Saginaw, MI. 48604-9780

F-750-361 Rev. A

800.748.0423 989.752.4275 Fax: 989.752.4444 www.glastender.com

04-06-06

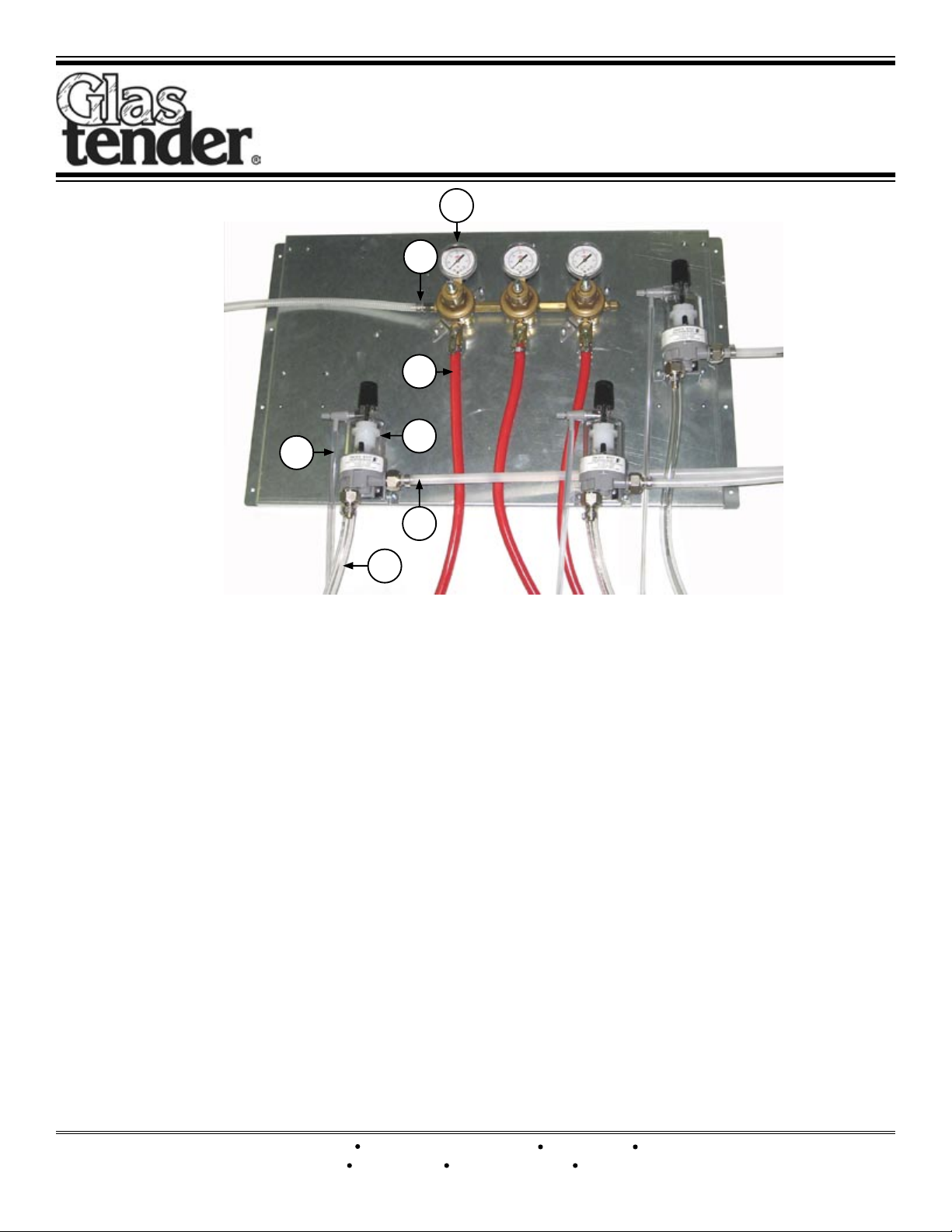

Page 8

F

BIK-Y

Beer Panel Installation Instructions

C

E

A

B

D

These instructions assume that the primary regulator and CO2 line to the walk-in cooler are already installed.

1. Position the regulator panels according to factory instructions.

2. Connect CO2 source line to one end of regulator bank (A). If there is more than one panel, continue the line

to the next panel until all panels are connected

3. Approximately 9 feet of clear vinyl beer line (B) is provided for the keg jumper line from each keg to its Y

angle bracket (C). Trim clear line to size and attach one end to bottom of Y angle bracket and the other end to

the keg tap.

4. Approximately 9 feet of red air line (D) is provided for the jumper line from each keg to its regulator (E). Trim

red air line to size and attach one end to the regulator and the other end to the keg tap.

5. Attach the polyline (F) provided in the beer line set (conduit) to the two top output ports of each Y angle

bracket (C).

6. The keg regulators (E) provide individual pressure to each keg. Upon start up, the ideal gauge pressure will depend on the type of gas involved as well as the length of the line runs. Since each keg is being split to dispense

out of two different faucets, the line runs between those two faucets must be balanced. The goal is to achieve

a ow rate of 2 ounces per second. If you do not have an even ow rate out of each of the two faucets and are

not certain of how to balance the system, consult the factory.

Glastender, Inc. 5400 North Michigan Road Saginaw, MI. 48604-9780

F-750-362 Rev. A

800.748.0423 989.752.4275 Fax: 989.752.4444 www.glastender.com

04-06-06

Page 9

BIK-EY

Beer Panel Installation Instructions

H

C

G

A

D

F

B

I

E

These instructions assume that the primary regulator and CO2 line to the walk-in cooler are already installed.

1. Position the regulator panels according to factory instructions.

2. Connect CO2 source line to one end of regulator bank (A). If there is more than one panel, continue the line to the

next panel until all panels are connected

3. Attach an Empty Keg Detector (B) to each of the black EKD mounting brackets by sliding them in place. The EKD can

be mounted to ow left or right. Position them so that the EKD output port points in the appropriate direction to ow to

the corresponding Y angle bracket (C).

4. A jumper line (D) ships attached to the bottom of each Y angle bracket (C). Connect the free end if the jumper line to

the side output port on the appropriate EKD. Use a black washer on the EKD end.

5. Approximately 9 feet of clear vinyl beer line (E) is provided for the keg jumper line from each keg to its EKD. Trim

clear line to size and attach one end to the bottom input port of the EKD and the other end to the keg tap.

6. Approximately 9 feet of red air line (F) is provided for the jumper line from each keg to its regulator (G). Trim red air

line to size and attach one end to the regulator and the other end to the keg tap.

7. Attach the polyline (H) from the beer line set (conduit) to the top output ports of each Y angle bracket.

8. Approximately 6 feet if exhaust line (I) is provided for the exhaust port of each EKD. Trim the exhaust line to length

and attach to each EKD exhaust port so the exhaust can be drained to a bucket. No clamp is required.

9. The keg regulators (G) provide individual pressure to each keg. Upon start up, the ideal gauge pressure will depend on

the type of gas involved as well as the length of the line runs. Since each keg is being split to dispense out of two different faucets, the line runs between those two faucets must be balanced. The goal is to achieve a ow rate of 2 ounces per

second. If you do not have even ow rate out of each of the two faucets and are not certain of how to balance the system,

consult the factory.

F-750-363 Rev. A

Glastender, Inc. 5400 North Michigan Road Saginaw, MI. 48604-9780

800.748.0423 989.752.4275 Fax: 989.752.4444 www.glastender.com

04-06-06

Loading...

Loading...