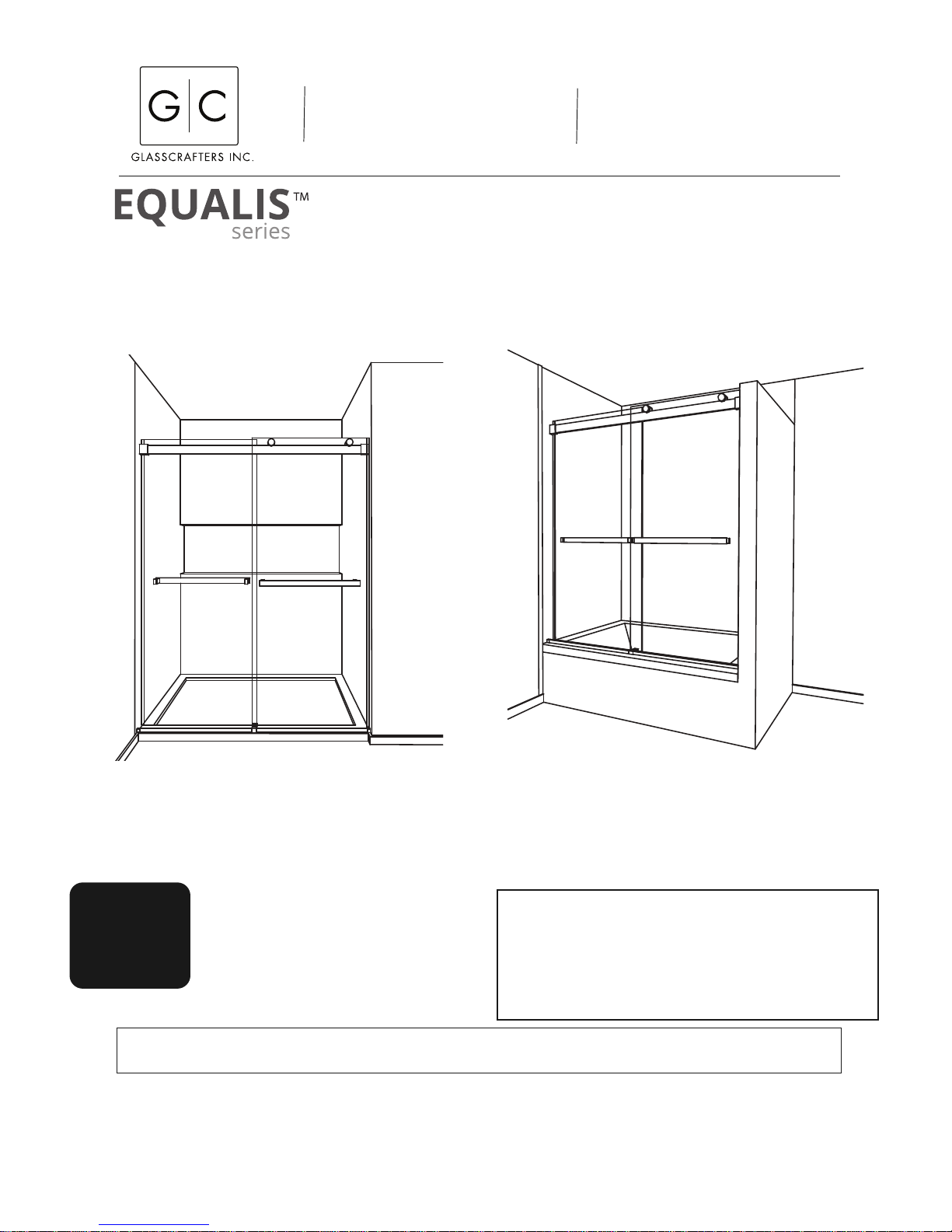

GlassCrafters Equalis series Installation Instructions Manual

Frameless By-Pass Shower/Tub Enclosure

Installation Instructions

The following instruction sheet is for the installation of the models:

SHOWER ENCLOSURES: DS-48T-38

45”- 48”w X 76”h , DS-54T-38 51”- 54’w X 76”h , DS-60T-38 57”- 60”w X 76”h , DS-66T-38 63”- 66”w X 76”h

TUB ENCLOSURES: DT-60T-38 57”- 60”w X 66”h , DT-66T-38 63“- 66”w X 66”h

All Units are available in three finishes:

Brushed Stainless Steel (BSS), Polished Stainless Steel (PSS), Polished Chrome Aluminum (CHA) or Iron Black (IBK)

Please use extreme care while unpacking and handling your GlassCrafters’ Shower or Tub Enclosure. If you need

replacement parts or have installation questions and to report any damage contact our GlassCrafters’ customer service

team at sales@glasscraftersinc.com or 888-683-1362, Monday thru Friday from 8:00 am to 5:00 pm (EST).

Installation shall be made according to manufacturers’ instructions and drawings .

GlassCrafters recommends the installation be performed by a trained installer.

Revised110/2018

WARNING: TO INSTALL ON CAST IRON, FIBERGLASS, ACRYLIC OR RESIN TUB OR SHOWER BASE

Check with the tub or shower base manufacturer to determine the tooling required.

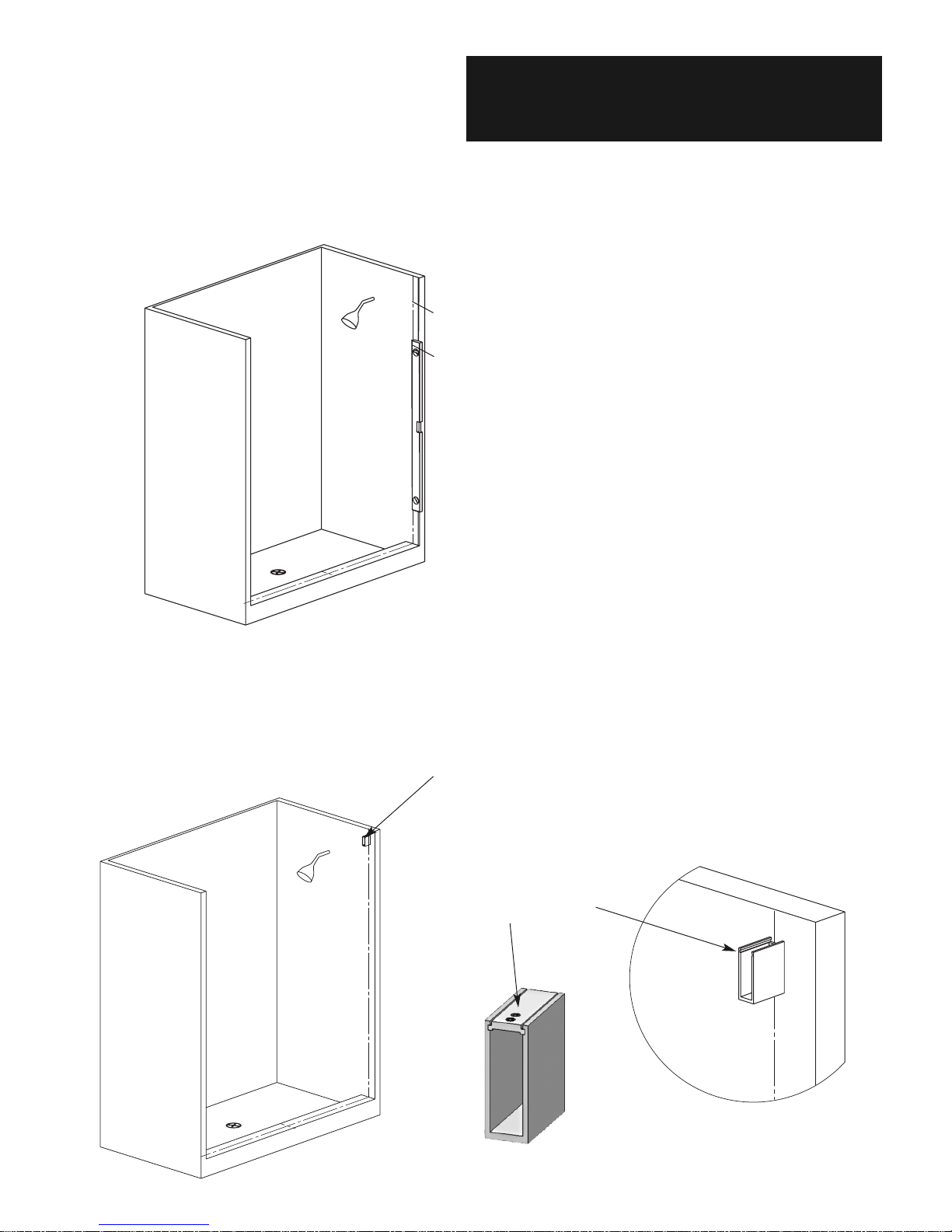

Shower Enclosure

Tub Enclosure

INSTALLING

THESE UNITS

REQUIRES

2 PERSONS

FOR BEST RESULTS

GlassCrafters recommends the installation be

performed by a trained installer.

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE

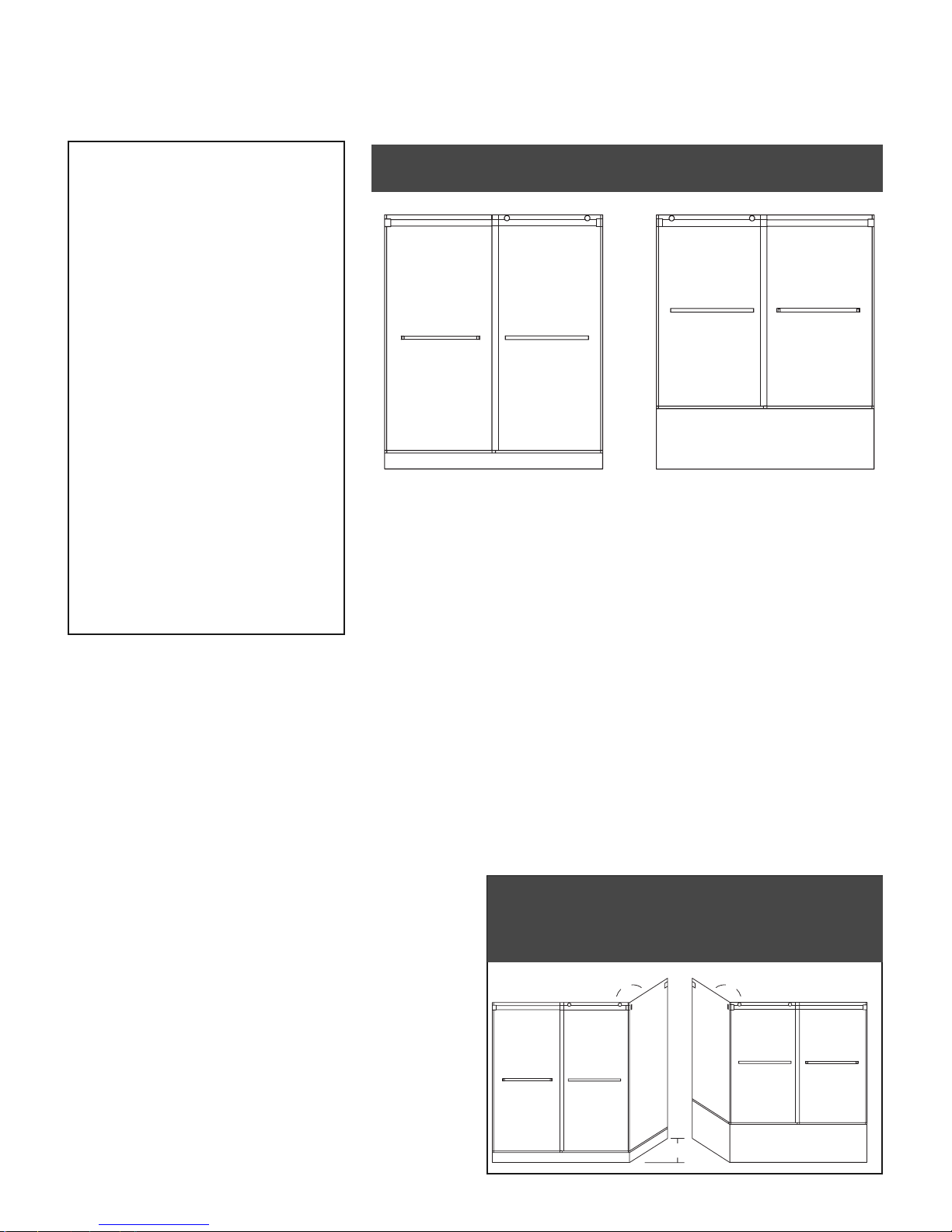

EQUALIS Series Frameless By-Pass

Shower/Tub enclosures are also

available with a Return Panel.

Separate Installation Instructions for the

Return Panel are supplied in the Return Package.

GLASSCRAFTERS, INC

193 Veterans Blvd., Carlstadt, NJ 07072

1+(888) 683-1362 -- (Fax) 201-525-1117

sales@glasscraftersinc.com

Tools Required - For installation of

Your Shower Enclosure

Safety glasses

Measuring tape

Pencil

H

ack saw or chop saw

(for stainless steel)

Miter Box or Square

Level

Electric Drill

Center Punch

Rubber Mallet

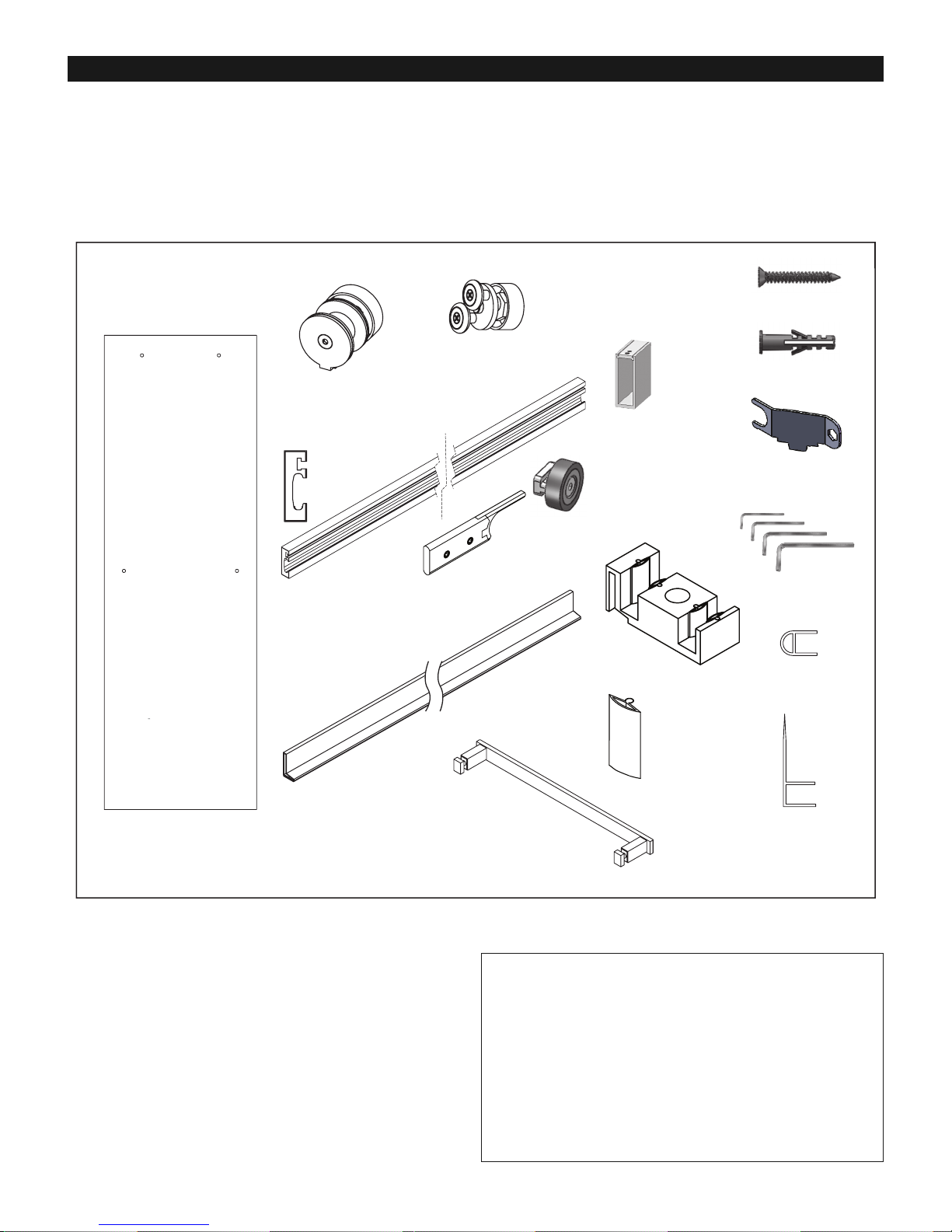

1. Header Wall Brackets 2

2. Header 1

3. Inside Roller Door Stop 2

4. Outside Roller Door Stop 2

5. Glass Door 2

6. Inside Door Roller Assembly 2

7. Outside Door Roller Assembly 2

8. Flat Head Screws, #8 x 1 1/4” 7

9. Plastic Wall Anchors 7

10. Center Guide 1

11. Roller Adjustment Wrench 2

12. Curb Dam 1

13. Center Guide Leaf 4

14. Hex Key Set (4) 1

15. Towel Bar Assembly 2

16. “A” Vinyl /Bumper 2

17. Clear “H” Vinyl 1

Parts Description

ITEM NO. DESCRIPTION QTY.

D

rill bit, 5/16” masonry

(for installation on ceramic

tiles or marble)

Power screwdriver

#2 phillips screwdriver

Caulking gun

Cutting Pliers

Suction Glass Lifters

(rated for more than 100 lbs)

WARNING: TO INSTALL ON CAST IRON,

FIBERGLASS, ACRYLIC OR RESIN TUB

OR SHOWER BASE

Check with the tub or shower base

manufacturer to

determine the tooling required.

ASSEMBLY AND INSTALLATION INSTRUCTIONS:

GlassCrafters recommends the installation be performed by

a trained installer.

• Read the manual and become familiar with the steps

involved in installation.

• This product requires Two Persons for safe installation.

• Always wear safety glasses during this installation.

• The proper dimensions for this installation were submitted

at the time of order. The two doors may overlap to

accommodate minor smaller opening. One end of the Header

many be cut with a Hacksaw for stainless steel, but it must fit

completely in the Header Wall Brackets for a safe installation.

• When installing any mechanical parts through the

pre-drilled holes in the glass door and panel be sure to use

the gaskets and bushings supplied between any metal

element and the glass. Do no overtighten any fittings.

• If the installation is over ceramic tiles the wall Jamb must lay

flat on these tiles for the entire height of the unit.

• Silicone Sealant is used to seal some parts during

installation.

2

CAUTION: Risk of injury or product damage. Do not attempt to cut tempered glass.

IMPORTANT! Children should be supervised at all times while in Tub/Shower Enclosure.

IMPORTANT! Never use Door Handle to support yourself. This is for towels or wash cloths only.

PLEASE STOP THE INSTALLATION AND CONFIRM WITH FACTORY IF THE ACTUAL NUMBER OR TYPE OF PARTS IS DIFFERENT.

90°

B

90°

T

HIS MANUAL IS FOR INSTALLATION OF THE EQUALIS SERIES™

FRAMELESS -BYPASS FOR SHOWER STALL OR TUB ENCLOSURES

THE EQUALIS SERIES™ FRAMELESS -BYPASS IS ALSO

AVAILABLE WITH RETURN

FOR BOTH SHOWER STALL OR TUB ENCLOSURES.

THE RETURN CONFIGURATION HAS A

SEPARATE MANUAL FOR THE RETURN.

T

UBSTALL

IMPORTANT: Determine if your Tub/Shower Stall

Enclosure ledge is Level and Walls are plumb.

If they are out of Level/Plumb, by more than 3/8”,

STOP! and call Customer Service.

The Phone number is 1-888-683-1362 .

If they are Level/Plumb, or out of Plumb for less than

3/8” proceed with installation.

SPECIAL NOTE:

2 3/4” MINIMUM CURB WIDTH REQUIRED.

When ordering replacement parts,please specify the

Model Number, Item Number & Part Description.

Save these Installation Instructions For

Future Reference.

Write your Dealer information down on Notes Section.

Ask your Dealer for JOB LOG NUMBER (Lxxxxxx-xxx)

referencing to your shower enclosure.

Parts

3

U

npacking: • A box Cutter should not be use to open any box.

• Please remove all staples from the box prior to unpacking metal and glass.

• Stand Panels upright on a cushioned base, such as a piece of carpet or towel.

•

Never place glass directly on hard surfaces.

• Any assembly that requires the panel to lay flat must be on a cushion surface.

IMPORTANT: Read all instructions carefully and become familiar with all parts before installation.

1

Header

Bracket

2

Header

3

Inside Door

Stop

4

Outside Door

Stop

6

Inside Door

Roller

8

Flathead Screw

9

Anchor

7

Outside Door

Roller

16

”A” Vinyl

15

Towel Bar

14

Hex Key Set

13

Center Guide

Leaf

12

Curb Dam

(From Inside)

11

Roller Adjustment

Wrench

10

Center Guide

(From Inside)

17

”H” Vinyl

(Splash Guard)

5 Glass Doors

Header

(Section view)

VERY IMPORTANT -- If your installation includes a

RETURN PANEL consult the instructions and part list

for the Return Panel and follow those steps.

4

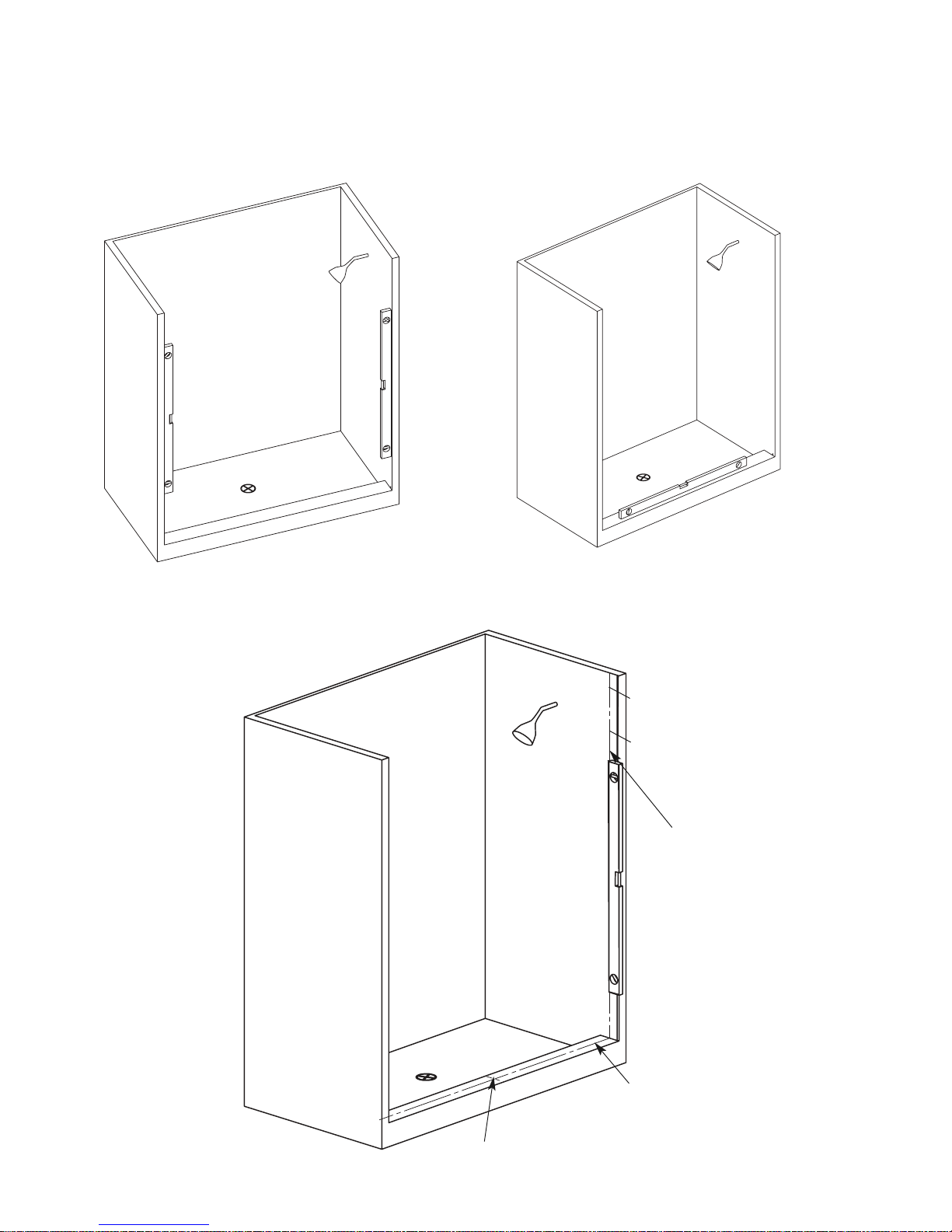

STEP 1B. Determine the Level and centerline

o

f the Curb. (Work from high side first.)

Determine the level of the curb and mark the “high” side

(A maximum of 3/8” out of level is acceptable.)

Draw a pencil line side to side on the center line of the

Curb. Draw a line front to back on the exact center of

t

he curb.

STEP 1. Determine the Plumb Condition of the

o

pening: Use a level to determined that the enclosure

is plumb on both sides. If any side is out of plumb more

that 3/8” it will make the adjustment of the Glass Doors

complicated.

D

etail 1A

Detail 1B

Detail 1C — Extend the centerline from the high side of the curb on the wall

Determine the high side

Find the Midpoint of the Curb and mark

a pencil line from front to back

Find the Centerline of the curb

and mark a pencil line from left

to right.

With a plumb line or a level

extend the center line to the

height of the header (either

66” or 76”)

76” high unit

66 high unit

5

D

etail 2B

Detail 3A

Detail 3B

Use a level to determine that the dotted line

on the template is perfectly vertical and

matched with the marked centerline on the

curb.

Mark the correct height for the top of the

bracket.

STEP 2. Using the penciled centerline on the wall use

a

level to recheck the exact vertical position. Mark the

top height for the bracket at 66” or 76” as per your

unit. Place the bracket in position on the centerline

and mark holes for the wall bracket.

76” high unit

66 high unit

NOTE: Loosen the set screws

and the bracket top slides out

for installation

After drilling the holes for the Header Bracket,

add silicone to each hole and put the anchors in

place.

FOR MODELS USING A RETURN PANEL:

Stop here and read the installation manual for the

R

ETURN PANEL. The Return panel and supporting

elements must be installed before proceeding.

STEP 3. Drill and install the install the Header Wall

Bracket Use the Flathead Screws and and anchors as

supplied.

Loading...

Loading...