Glasdon SIGNMASTER LED Instructions Manual

SIGNMASTER LED 24V INSTALLATION KIT INSTRUCTIONS

Ensure that personnel carrying out this conversion have the relevant qualifications/certificates and all work

!

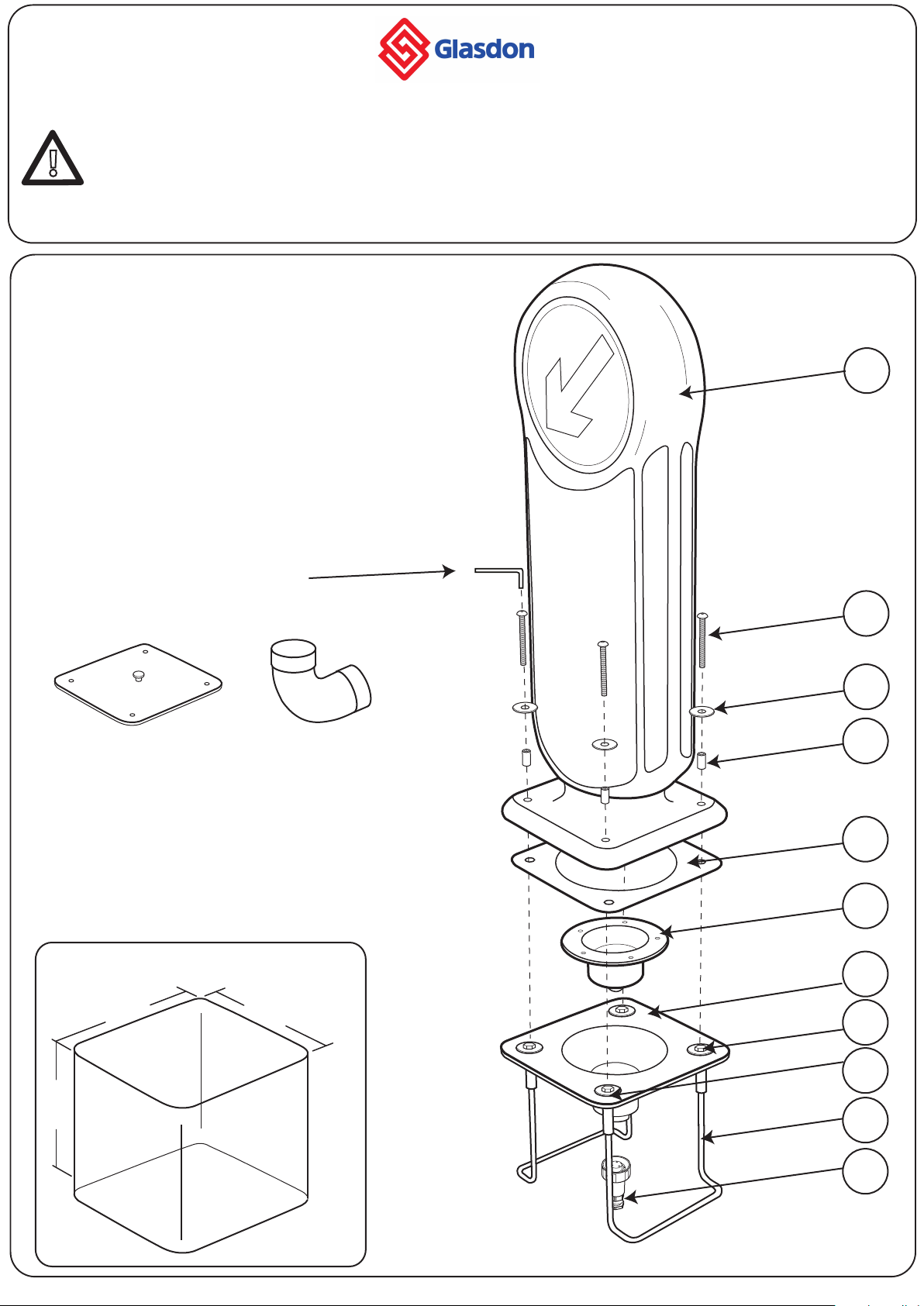

KIT CONTENTS

is carried out in accordance with BS6771:2008/I.E.E. Wiring Regulations 17th Edition.

Ensure that all relevant personnel read the points listed within this leaflet and that a copy is given to staff

involved with the installation and maintenance of this product.

Glasdon recommends that a full Health and Safety analysis is carried out prior to installation.

1- Signmaster Bollard x1

2- M10 x 100 Screw x4

3- M10 x Ø50 White Washer x4

4 - Spacer x1

5- Gasket x1

6- LED Housing x1

7- Concrete-In Plate x1

8- M10 x 70 Hex Head Bolt x4

9- M10 x Ø50 Silver Washer x4

10- Concrete-In Bars x2

11- IP68 Plug x1

1

Allen Key 6mm x1

Optional Extras

Installation Lid 100mm Angled Bend

EQUIPMENT REQUIRED

-Ø17mm Spanner/Socket

-Spade

-Spirit Level

-Support Block x2

-Concrete Mix (we suggest using a quick setting

concrete i.e. QC10 in areas prone to vandalism).

MINIMUM HOLE DIMENSIONS

430mm

430mm

2

3

4

5

6

7

8

450mm

Diagram A

9

10

11

Please note that diagrams are not to scale

1

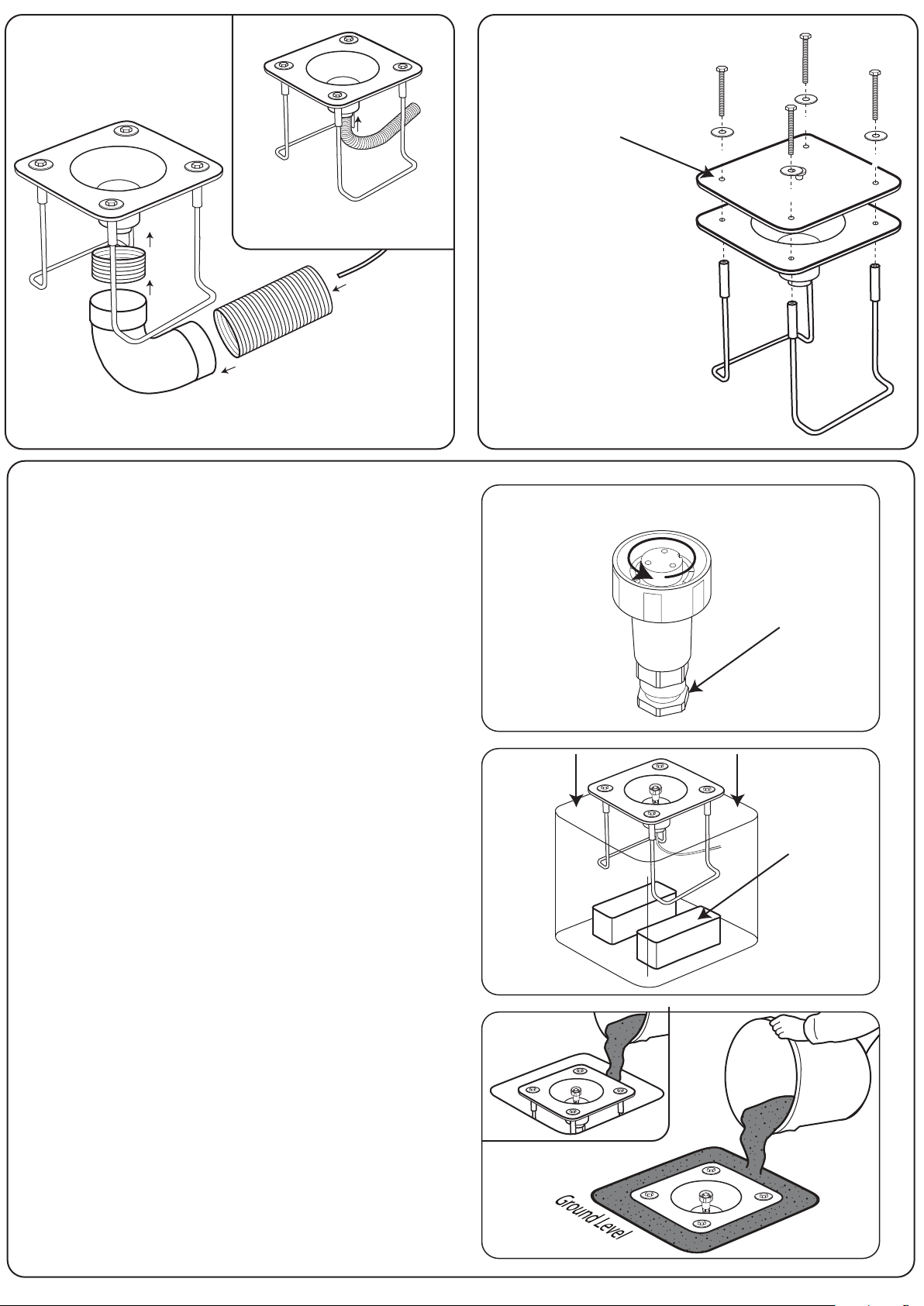

Installation using

Installation using Optional

Ducting and Optional

Angled Bend

If using 50mm ducting slot inside

Concrete-In Plate as shown.

In coming 24V

Electrical Supply

If using 100mm ducting, cut to size and snap t onto angled

bend (if applicable) as shown above.

Diagram B

Standard Installation Instructions

Dig a hole to the minimum dimensions (see Diagram A)

1

taking care to avoid buried services.

Installation Lid

Installation

Lid

If using an optional

Installation Lid remove

all four xings (Kit

Contents H & I),

position the

Installation Lid onto

the plate ensuring the

holes are aligned and

re attach the xings as

shown. Remove Lid

when concrete has set

and LED Housing is to

be pluged in.

Unscrew plug anticlockwise

Diagram E

If using ducting (50mm or 100mm), excavate trench to the

2

recommended depth to accept the incoming 24 Vac

supply.

Note: Alternatively 24V armoured cables may be layed by

slot cutting the road surface.

Remove approximately 60mm of the armouring to expose

3

the internal cable (maximum diameter 8.1mm).

Remove the Plug (Item 11) from the 24V LED Unit (Item 6)

4

by unscrewing then pulling from the unit.

Disassemble the plug (Item 11) by unscrewing the centre

5

ring and gland (see Diagram C) and remove centre to

expose cable terminals.

Insert cable through gland, connect cables to terminals and

6

re-assemble Plug ensuring the gland is tightened to

maintain ingress protection.

Assemble the ducting to the Concrete-In Plate (Item 7) as

7

shown in diagram B, and position in the previously

prepared hole.

Ensure the Concrete-In Plate is level using a spirit level. Also

8

ensure the plate is at ground level, support blocks or gravel

may be required to achieve this (see Diagram D).

Gland

Diagram C

Support Block

Diagram D

Ensure the Plate is in the correct orientation and feed the

9

cable/plug through the centre of the Concrete-In Plate.

If using an Installation Lid follow guidelines in Diagram E.

10

Pour concrete into hole ensuring the Concrete-In Bars (Item

11

10) are fully covered and the hole is completely lled (see

Diagram F). Allow to set.

Diagram F

2

Loading...

Loading...