Glasco UV GUV-C7, GUV-C10, GUV-C15, GUV-C20, GUV-C7-Plus Operation & Maintenance Manual

...

ULTRAVIOLET WATER DISINFECTION SYSTEM

OPERATION & MAINTENANCE MANUAL

RESIDENTIAL AND COMMERCIAL

GUV C “The Classic” and GUV C “PLUS”

GUV-C7 (7 GPM), GUV-C10 (10 GPM), GUV-15C (15 GPM), GUV-C20 (20 GPM)

GUV-C7-PLUS, GUV-C10-PLUS, GUV-15C-PLUS, GUV-C20-PLUS

GUV C “CLASSIC” (audible lamp out) GUV-C PLUS (alarms + countdown timer)

Use the chart to record lamp changes to the system:

SYSTEM INSTALLATION DATE:

Lamp should be changed 1 x year (8,760 hours)

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Lamp Change Date:

Manufactured in the United States by Glasco UV, LLC.

November 2017

2

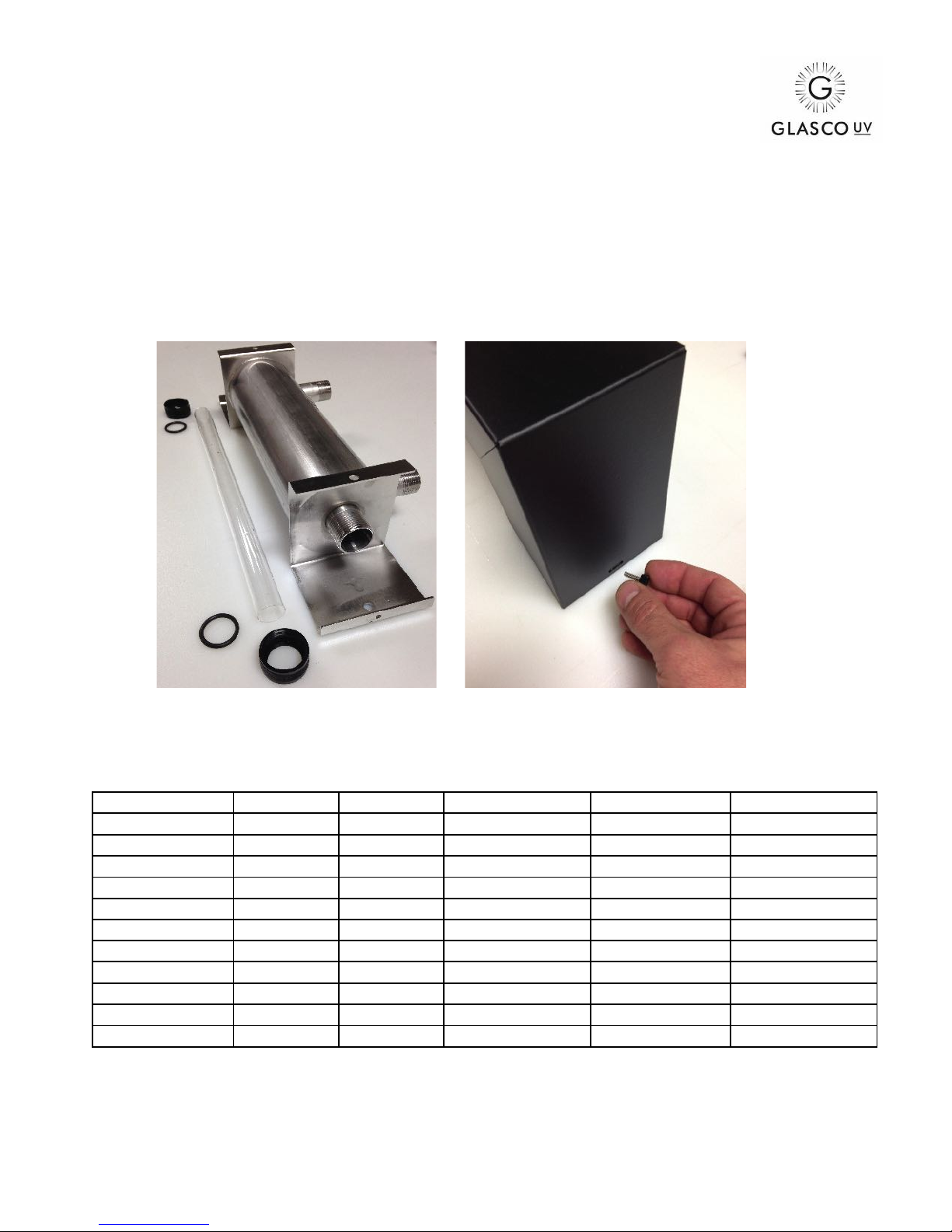

You will have received the following:

1. Disinfection chamber for GUV-C7/10/15/20

2. Removable cover (2 thumb screws hold cover on)

3. Ballast Power System (BPS) with lamp harness (removable on Plus Series)

4. Quartz sleeve

5. O-rings

6. Compression nuts

7. UV lamp

REPLACEMENT PARTS LIST

Model

Lamp #

Quartz #

Ballast #

O-rings

Compression

Fittings

GUV-C7

L-501414

Q-511014

E-06105B

#2 M-75214O

#2 M-A015CN

GUV-C10

L-524414

Q-511014

E-06110B

#2 M-75214O

#2 M-A015CN

GUV-C15

L-572433

Q-502032

E-06105B

#2 M-75214O

#2 M-A015CN

GUV-C20

L-024433

Q-502032

E-06110B

#2 M-75214O

#2 M-A015CN

GUV-C7-Plus

L-501414

Q-511014

P-07100P

#2 M-75214O

#2 M-A015CN

GUV-C10-Plus

L-524414

Q-511014

P-10100P

#2 M-75214O

#2 M-A015CN

GUV-C15-Plus

L-572433

Q-502032

P-15100P

#2 M-75214O

#2 M-A015CN

GUV-C20-Plus

L-024433

Q-502032

P-20100P

#2 M-75214O

#2 M-A015CN

GUV-C7-SC-+

L-501414

Q-511014

P-07100P-SC

#2 M-75214O

#2 M-A015CN

GUV-C10-SC-+

L-524414

Q-511014

P-10100P-SC

#2 M-75214O

#2 M-A015CN

GUV-C15-SC-+

L-572433

Q-502032

P-15100P-SC

#2 M-75214O

#2 M-A015CN

GUV-C20-SC-+

L-024433

Q-502032

P-20100P-SC

#2 M-75214O

#2 M-A015CN

November 2017

3

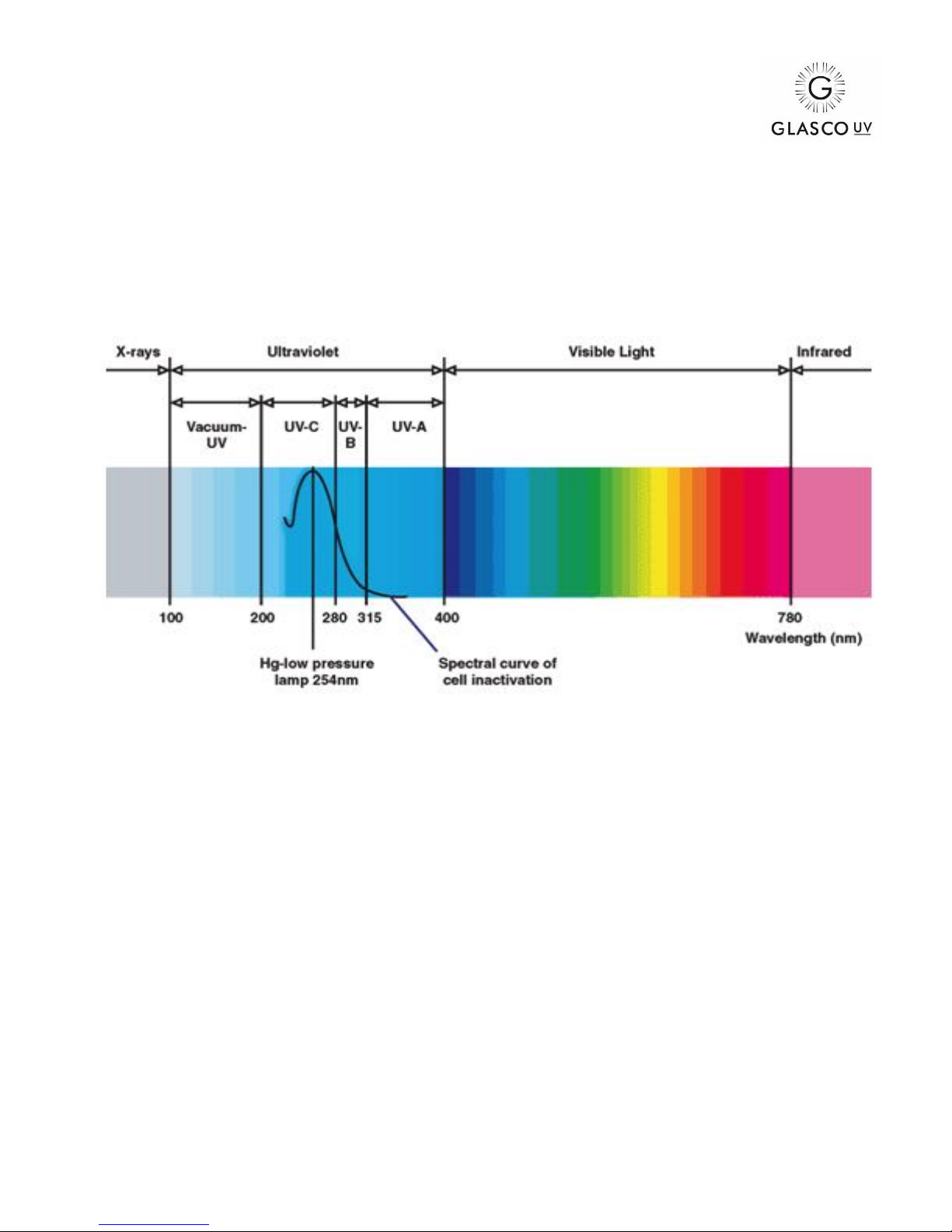

1. About Ultraviolet (UV) Disinfection

The technology uses UV light to target and disable disease-causing microorganisms (pathogens). This includes

such waterborne diseases as: E-coli, hepatitis, cholera, dysentery, typhoid fever as well as many others.

Over 100 years ago, scientists discovered that if you exposed pathogens to UV light, their reproduction was

limited. The UV light source that they used, resided in the UVC range of the light spectrum. Specifically, they

discovered that light in the 254 nanometer (nm) range was the most effective wavelength. Today, specialized UV

lamps are used for a variety of disinfection applications.

When water pathogens are exposed to UV light, their cells become damaged and this damage inhibits

reproduction. The UV light, produced by a special UV lamp, damages the cell’s DNA and RNA and once

damaged, they are unable to replicate. This physical process renders them harmless.

The amount of damage is a result of the intensity of the lamp’s UVC output multiplied by the time the water is

exposed to the light. The applied dosage is expressed as milliwatt seconds per square centimeter (mW.s/cm2) or

millijoules per square centimeter (mJ/cm2). Dosages of 30,000 uW.s/cm2 (30 mJ cm2) to 40,000 uW.s.cm2 (40

mJ cm2) are common for drinking water

Using UV for disinfection is a practical and acceptable technology, but do not confuse disinfection with

sterilization. Sterilization means the complete and total inactivation of microorganisms.

When water enters the vessel, it is exposed to UV light. The UV lamp used for germicidal disinfection produces a

portion of its light in the 254-nm wavelength. At this wavelength, UV light destroys bacteria, protozoa, viruses,

molds, algae and other microbes.

The actual lamps are housed in quartz sleeves. Both lamps and sleeves are very fragile and are manufactured

from a special material that allows UV light to emanate. These sleeves not only help maintain maximum

operating temperature, but also prevent the lamps from coming in contact with the water.

November 2017

4

2. Your Disinfection Unit – Pre-Installation

Your American manufactured Ultraviolet (UV) water disinfection system has been tested at Glasco’s

manufacturing facility. The unit is constructed of high quality stainless steel that has been electropolished. The

unit has been hydrostatically pressure-tested to 100 psi (system designed for typical house pressure of 40 psi).

In some cases, a small amount of water may still remain in the vessel from this test. In order to ensure that the

unit works at optimum performance, please follow the instructions outlined in this manual.

The following signs indicate important information:

INFORMATION. Signifies helpful

information.

CAUTION. Indicates a potentially

dangerous situation. Failure to adhere to this warning

may lead to serious injury and or death.

ELECTRIC SHOCK. Indicates risk of

electrical shock, which may cause serious injury and or

death.

EYE PROTECTION. Indicates that eye

protection must be worn to protect from UV light and

debris.

HAND PROTECTION. Indicates that

gloves must be worn to protect the lamps from skin oils

and protect operators from UV light and hazards from

broken lamps or quartz.

2.1. Warnings

UV light is harmful to your eyes and skin. Do not look directly into the light. Always unplug (disconnect

power) your unit before installing or removing a lamp. Your unit may have a green LED light that

indicates that the lamp is operating and or have an audible alarm that will sound in the event of lamp

failure. If the LED goes out, contact your dealer for service. If your unit has an audible alarm and it goes

off, contact your dealer.

Since the unit is run by electricity, please remember to disconnect all power before servicing the

equipment. Failure to do so may result in serious injury or death.

When handling lamps and quartz, use gloves to prevent them from becoming dirty. If they do, wipe them

with alcohol. Oils will block the proper transmission of UV light.

November 2017

5

2.2. Your Water Supply

Since the use of UV generally indicates problems with waterborne pathogens (disease causing

microorganisms), Glasco recommends that you regularly have your water supply tested by water

professionals. In addition to testing the water to see if UV is appropriate, we recommend pre-filtering

systems (softeners, carbon or reverse osmosis) to help remove tastes, odors, minerals and cysts.

This list is the maximum recommended concentration levels to ensure optimum UV performance:

Turbidity: 5 NTU

Color: None

Iron: 0.3 PPm

Suspended Solids: 10 mg/l

Manganese: 0.05 mg/l

pH: 6.5 – 9.5

Hardness: 7 grains

Tannins: < 0.1 ppm (0.1 mg/L)

UV transmission: >75%

2.3. UV Lamp and Effectiveness

Your disinfection unit needs to be maintained. Change lamp on a yearly basis and ensure that the quartz

sleeve is cleaned on a regular basis. Failure to do periodic maintenance will impact your unit’s

effectiveness.

Just because the lamp is “ON” does not mean that it is actually producing the required UV light.

Please change your lamp yearly. Lamps may burn with a blue color for years without producing UV.

Lamps need to be recycled because they contain mercury. Many town recycling centers have the ability

to collect fluorescent lamps. Further information can be found at www.lamprecycle.org .

2.4. Flow Rate

UV disinfection systems are selected based on a specific flow rate. Small homes may use a 7 or 10-gpm

unit, while larger homes may use a 15 or 20-gpm unit. In order to work effectively, you may need to

install a flow control device.

Some installations find that the device limits water pressure and therefore do not use. In many

cases, home pressure will not exceed UV unit’s designed flow rate.

This device attaches to the inlet and controls the water that enters the system. Note: your system may

have come with a flow controller. It will look like a brass washer with a rubber fitting (needs to put into the

inlet side). Failure to use a flow control (available at most plumbing supply stores) may reduce the

effectiveness of your disinfection unit.

2.5. Inspection

Ensure that lamps and quartz have not been broken. Use gloves when handling lamps and quartz

sleeves to prevent them from becoming dirty. Dirt and skin oils will impact the UV output.

Warranty information has been attached. Please fill it out and send back to manufacturer or dealer. This

warrantees the chamber for 7-years and electrical components for 1-year.

Loading...

Loading...