Glasco UV GUV-7, GUV-10, GUV-15, GUV-20 Operation & Maintenance Manual

March 2009

ULTRAVIOLET WATER DISINFECTION SYSTEM

OPERATION & MAINTENANCE MANUAL

GUV SERIES UV System

GUV-7, GUV-10, GUV-15, GUV-20

Use the attached chart to record lamp changes to the system:

Lamp Change Date

Lamp Change Date

INSTALL DATE:

March 2009

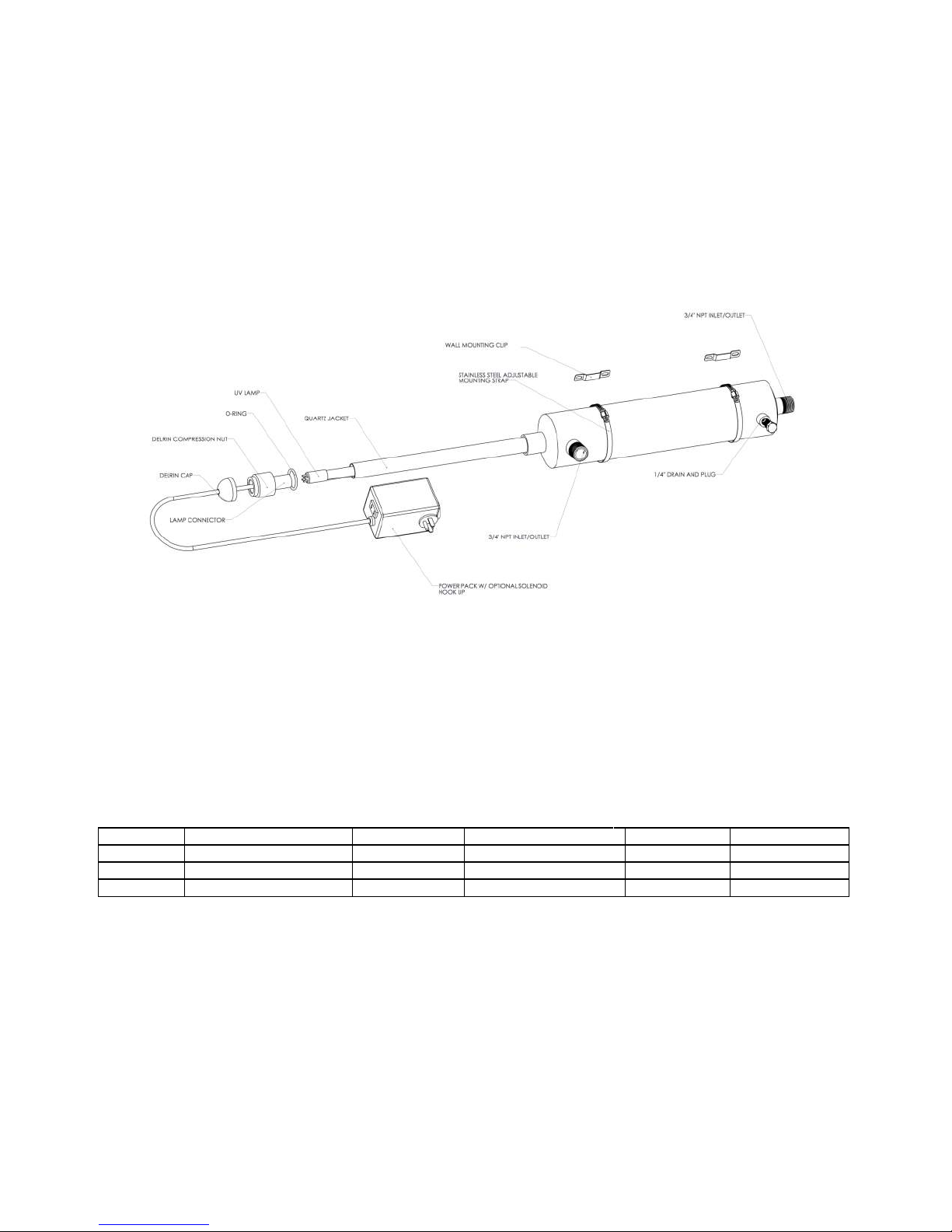

You should have received the following:

REPLACEMENT PARTS LIST

MODEL

Lamp #

Quartz #

Ballast #

Orings

Compression

Fittings

GUV-7

#1 L-501414

#1 Q-532017

#1 P-78PIBP

#1 M-75214O

#1 M-001RCN

GUV-10

#1 L-524414

#1 Q-532017

#1 E-40HOIB

#1 M-75214O

#1 M-001RCN

GUV-15

#1 L-050433

#1 Q-521035

#1 E-361GUB

#1 M-75214O

#1 M-001RCN

GUV-20

#1 L-024433

#1 Q-521035

#1 E-33120B

#1 M-75214O

#1 M-001RCN

1. Your Disinfection Unit – Pre-Installation

Your Ultraviolet (UV) water disinfection system has been tested at Glasco’s manufacturing facility. The unit has been

hydrostatically pressure-tested to 100 psi. In some cases, a small amount of water may remain in the vessel. In order to

insure that the unit works at optimum performance, please follow the instructions outlined in this manual.

August 2009

1.1. Warning

UV light is harmful to your eyes and skin. Do not look directly into the light. Always unplug (disconnect power) your

unit before installing or removing a lamp. Your unit may have a green LED light that indicates that the lamp is

operating and the unit has an audible alarm that will sound in the event of lamp failure. If the LED goes out, contact

your dealer for service. If your unit has an audible alarm and it goes off, contact your dealer.

Since the unit is run by electricity, please remember to disconnect all power before servicing the equipment. Failure to

do so may result in serious injury or death.

When handling lamps and quartz, use gloves to prevent them from becoming dirty. If they do, wipe them with alcohol.

1.2. Your Water Supply

Glasco recommends that trained professionals test and maintain your water supply. In addition to testing the water to

see if UV is appropriate, we recommend pre-filtering systems (softeners, carbon or reverse osmosis) to help remove

tastes, odors, minerals and cysts.

1.3. UV Effectiveness

Your disinfection unit needs to be maintained. Change your lamp on a yearly basis and insure that the quartz sleeve is

cleaned on a regular basis.

Failure to do periodic maintenance will impact your unit’s effectiveness.

1.4. Flow Rate

Your unit has been designed to accommodate a certain flow rate. In order to work effectively, you may need to install a

flow control device. This device attaches to the inlet and controls the water that enters the system. Note: your system

may have come with a flow controller.

Failure to use a flow control (available at most plumbing supply stores) may reduce the effectiveness of your

disinfection unit.

1.5. Inspection

Insure that lamps and quartz have not been broken. We recommend that you use gloves when handling lamps and

quartz sleeves to prevent them from becoming dirty. Dirt and skin oils will impact the UV output.

A warranty sheet has been included. Please fill out the warranty and send back to manufacturer or dealer. This

warrantees the chamber for 7 years and electrical components for 1-year.

1.6. Electrical Requirements

The electronics have been designed to work with standard power supplies. Since the unit is susceptible to power

fluctuations, we recommend that the system be kept off any lines where there are surges. This includes pumps or

motors. If there are fluctuations, please use a surge suppressor. Systems will come with plugs, which require no “hard

wiring”. Please look at the outside of the electrical “box” for Voltage, Cycle and AMP draw.

1.7. Location of Unit

UV disinfection works best when it is installed closest to point of use. When installing, remember that you will need to

be able to remove lamps and quartz as part of a maintenance schedule. Allow yourself enough room to accomplish

these tasks. Unit can be mounted vertically or horizontally. Inlet and outlet can face up or down.

Loading...

Loading...