Page 1

WELDED STEEL LOCKER

W10722620A

IT'S TIME TO RETHINK THE GARAGE.™

ES TIEMPO DE VOLVER A PENSAR EN EL GARAGE.™

LE GARAGE REPENSÉ.™

Assembly Instructions

ARMARIO DE ACERO

SOLDADO

Instrucciones de ensamblaje

VESTIAIRE EN ACIER

SOUDÉ

Instructions de montage

TABLE OF CONTENTS/ÍNDICE/TABLE DES MATIÈRES

CABINET/LOCKER SAFETY ..................... 1

ASSEMBLY INSTRUCTIONS..................... 2

Tools and Parts........................................ 2

Locker Use Requirements .......................2

Unpack the Locker................................... 2

MOUNT LOCKER TO WALL...................... 3

Hollow Wall Assembly .............................3

Mounting Holes Align with Wall Stud ......4

Flush Mount to Wall ................................. 4

Non-Flush Mount to Wall......................... 4

Assemble Dual J Hook to Shelf............... 4

ASSEMBLE COMBINATION LOCK

AND HANDLE .............................................5

ACCESSORIES ...........................................6

WARRANTY ................................................7

SEGURIDAD DEL ARMARIO ..................... 8

INSTRUCCIONES DE ENSAMBLAJE ....... 8

Herramientas y piezas .............................. 8

Requisitos para el uso del armario........... 8

Desempaque el armario ...........................8

MONTAJE DEL ARMARIO

EN LA PARED.............................................. 9

Ensamblaje en pared hueca..................... 9

Montaje de los orificios alineados

con el montante de pared ...................... 10

Empotrado en pared............................... 10

No empotrado en pared ......................... 10

Ensamblaje del gancho

doble en J al estante .............................. 11

ENSAMBLAJE DE LA CERRADURA CON

COMBINACIÓN Y LA MANIJA..................11

ACCESORIOS.............................................12

GARANTÍA .................................................13

SÉCURITÉ DE L’ARMOIRE/

DU VESTIAIRE...........................................14

INSTRUCTIONS DE MONTAGE ..............14

Outillage et pièces..................................14

Conditions d’utilisation du vestiaire .......14

Déballage du vestiaire ............................14

MONTAGE DU VESTIAIRE AU MUR.......15

Montage sur cloison creuse...................15

Alignement des trous de montage

avec les poteaux de colombage ............16

Montage contre le mur ...........................16

Montage à distance du mur ...................17

Montage du double crochet

à l’étagère ...............................................17

MONTAGE DE LA SERRURE À

COMBINAISONS ET DE LA TIRETTE .....17

ACCESSOIRES..........................................18

GARANTIE .................................................19

Page 2

CABINET/LOCKER SAFETY

You can be killed or seriously injured if you don't immediately

You

can be killed or seriously injured if you don't

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

follow instructions.

instructions.

DANGER

WARNING

WARNING

Excessive Weight Hazard

Use two or more people to move, assemble or install

locker.

Failure to do so can result in back or other injury.

ASSEMBLY INSTRUCTIONS

Tools and Parts

Gather the required tools and parts before starting installation.

Unpack the Locker

Tools Needed

■ ³⁄₄" open-end wrench

■ ³⁄₈" socket wrench

■ Phillips screwdriver

■ Rubber hammer

Parts Supplied

■ Combination dial lock

Assembly

■ Combination lock (1)

■ Pull tab handle (1)

■ Cam (1)

■ Cam screw (1)

■ Jam nut (1 - separate)

■ Mounting Hardware

■ Hollow wall anchors (4)

■ #8 x 2" mounting screws (4)

■ #8 - ³⁄₄" fender washers (8)

■ Intended for use in a garage and home.

■ Maximum weight limit is 50 lbs (22 kg) for each shelf.

■ Maximum weight limit is 100 lbs (37.3 kg) for the locker.

Locker Use Requirements

■ Dual J Hook Assembly

■ #10 – 24 x ¹⁄₂"

pan-head screws (2)

■ #10 - 24 self-locking

nut (1)

■ Dual J hook

1. Remove and verify the contents. See “Parts Supplied” in “Tools

and Parts” for your model.

2. Dispose of/recycle all packaging materials.

NOTES:

■ The locker may be mounted directly to a wall stud using the #8 x

2" mounting screws.

■ The supplied hardware requires ³⁄₈" to ¹⁄₂" drywall/wall board for

mounting the locker.

NOTE: Mounting to a wall with a different thickness or a different

material may require new mounting hardware. Customer will be

responsible for consulting a professional for mounting

instructions other than specified in this manual.

■ Lockers can be mounted side-by-side; however, each locker

must be individually mounted to the wall according to the

installation instructions in this manual.

IMPORTANT: Lockers are not designed to be attached to each

other. This locker mounts directly to the wall using hardware

provided. As an option, lockers can be mounted to Gladiator

GearWall

kit. See the “Accessories” section for information on ordering.

®

Panels and GearTrack® Channels using a standard bracket

®

2

Page 3

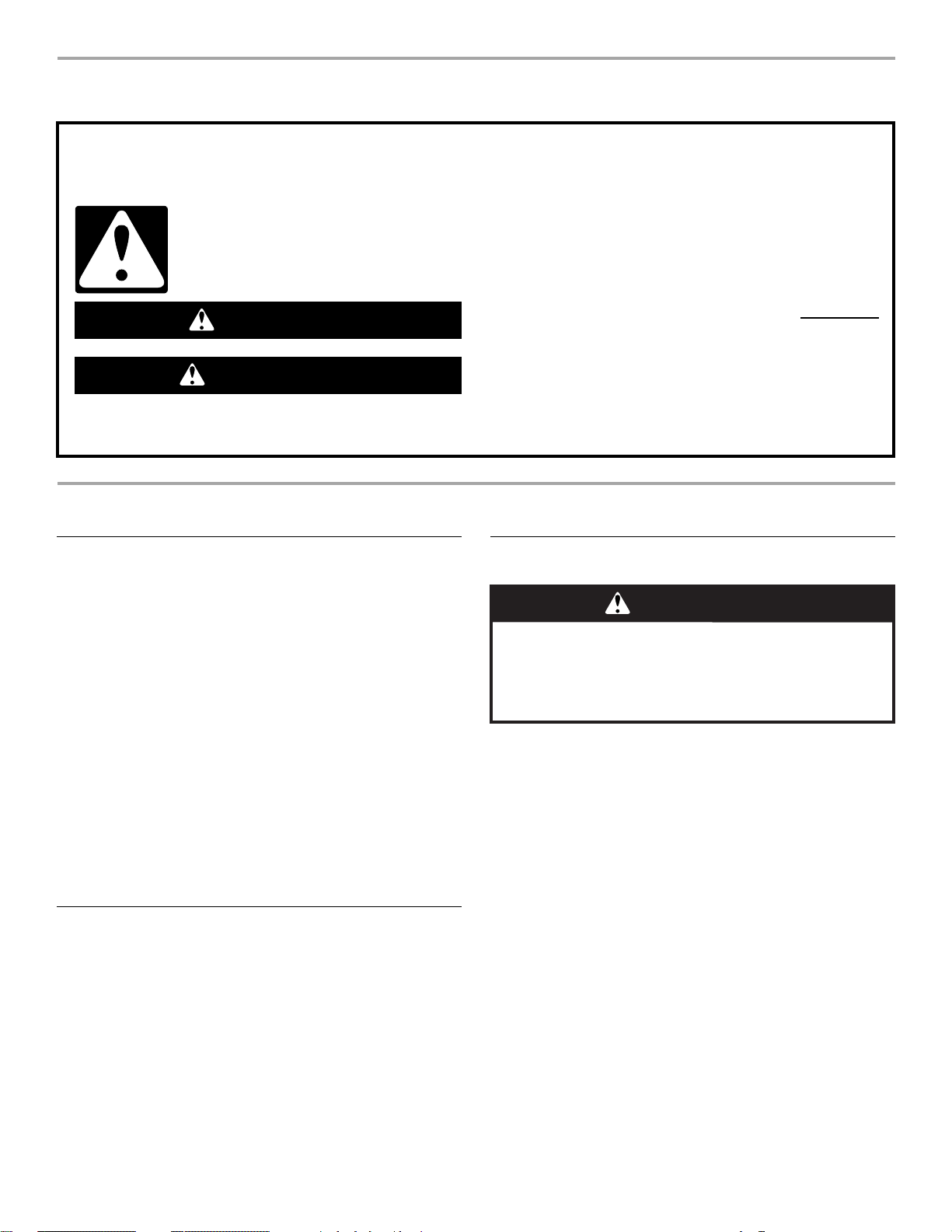

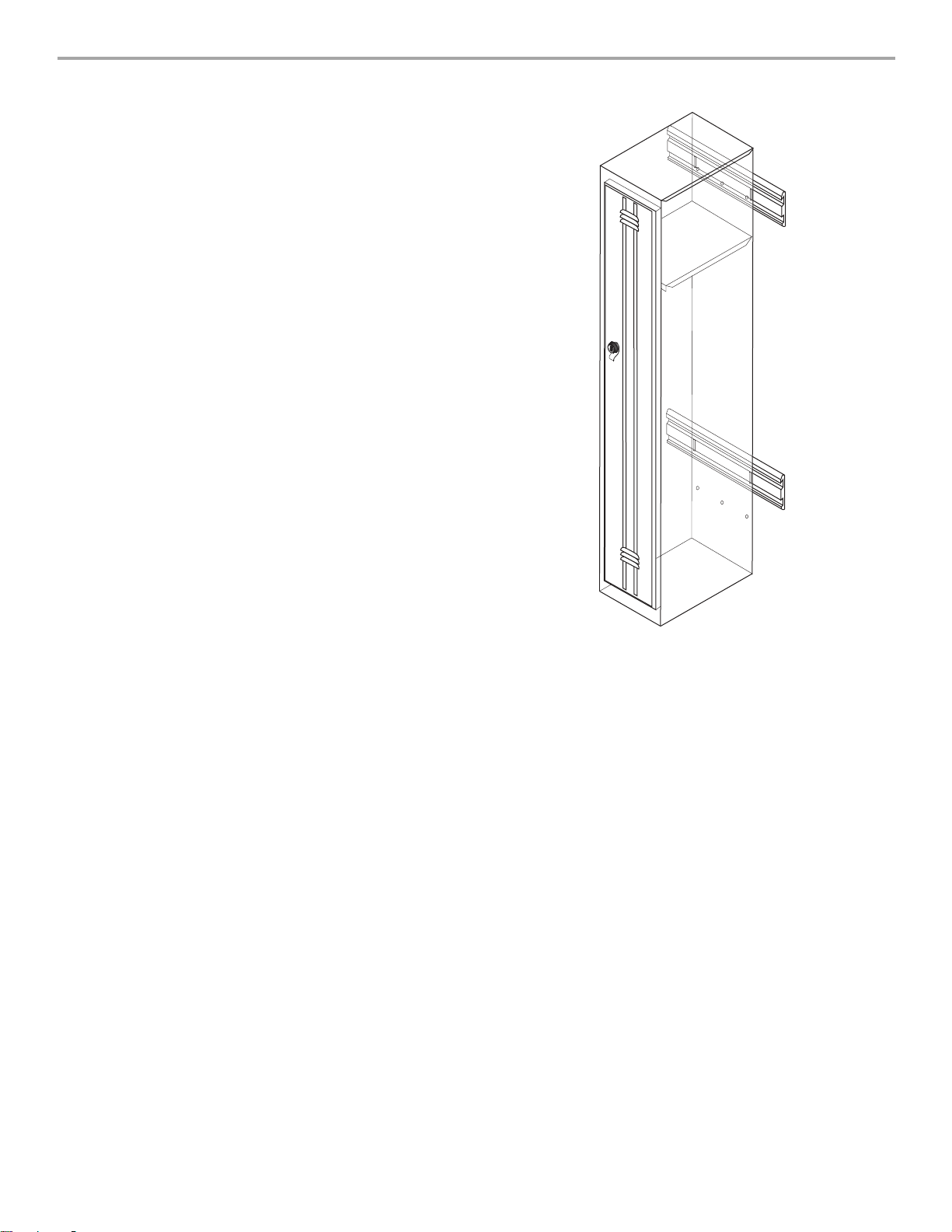

MOUNT LOCKER TO WALL

WARNING

Tip Over Hazard

Mount locker to wall, GEARTRACK® channels, or

GEARWALL

®

panels according to installation

instructions.

Failure to do so can result in death or serious injury.

A

B

A

D

C

B

A

1. Unpack and verify that all mounting hardware is included.

2. Identify locker wall location.

3. Using 2 or more people, position the locker against the wall at

the mounting location.

4. Using a pencil, mark the four mounting locations through the

back locker wall.

Wall Anchor Mounting Holes

5. NOTE: Use of all four mounting holes is required for proper

mounting of the locker.

Hollow Wall Assembly

1. Drill a ⁵⁄₁₆" pilot hole through the wall board at each marked

mounting location (4 holes).

2. Insert a wall anchor through each pilot hole, as shown.

Fold down (A) and insert into wall (B), as shown.

6. Move locker away from the wall.

7. Determine if any of the mounting holes align with a wall stud.

Stud location can be determined with a standard stud finder (not

provided). If mounting holes align with a stud, then assemble

according to section “Stud Alignment Assembly.” If mounting

holes do not align with studs, then assemble according to

section labeled “Hollow Wall Assembly.”

A. Wall anchor mounting holes

A. Folded anchor

B. Anchor inserted into wall

3. Using a rubber hammer, tap flush with the wall.

4. Insert the anchor pin (provided) into the wall anchor hole until it

stops. See the following illustration. Move the pin forward until

you hear a click which is the sound of the wall anchor fingers

opening on the other side of the wall.

A. Anchor pin

B. Hollow wall anchor fingers

5. If the locker is flush-mounted to the wall, proceed to the section

“Flush Mount to Wall.” If the locker is not flush mounted to the

wall (due to baseboard, etc.), go to the section “Non-Flush

Mount to Wall.”

C. ⁵⁄₁₆" pilot hole

D. ³⁄₈" or ¹⁄₂" drywall

3

Page 4

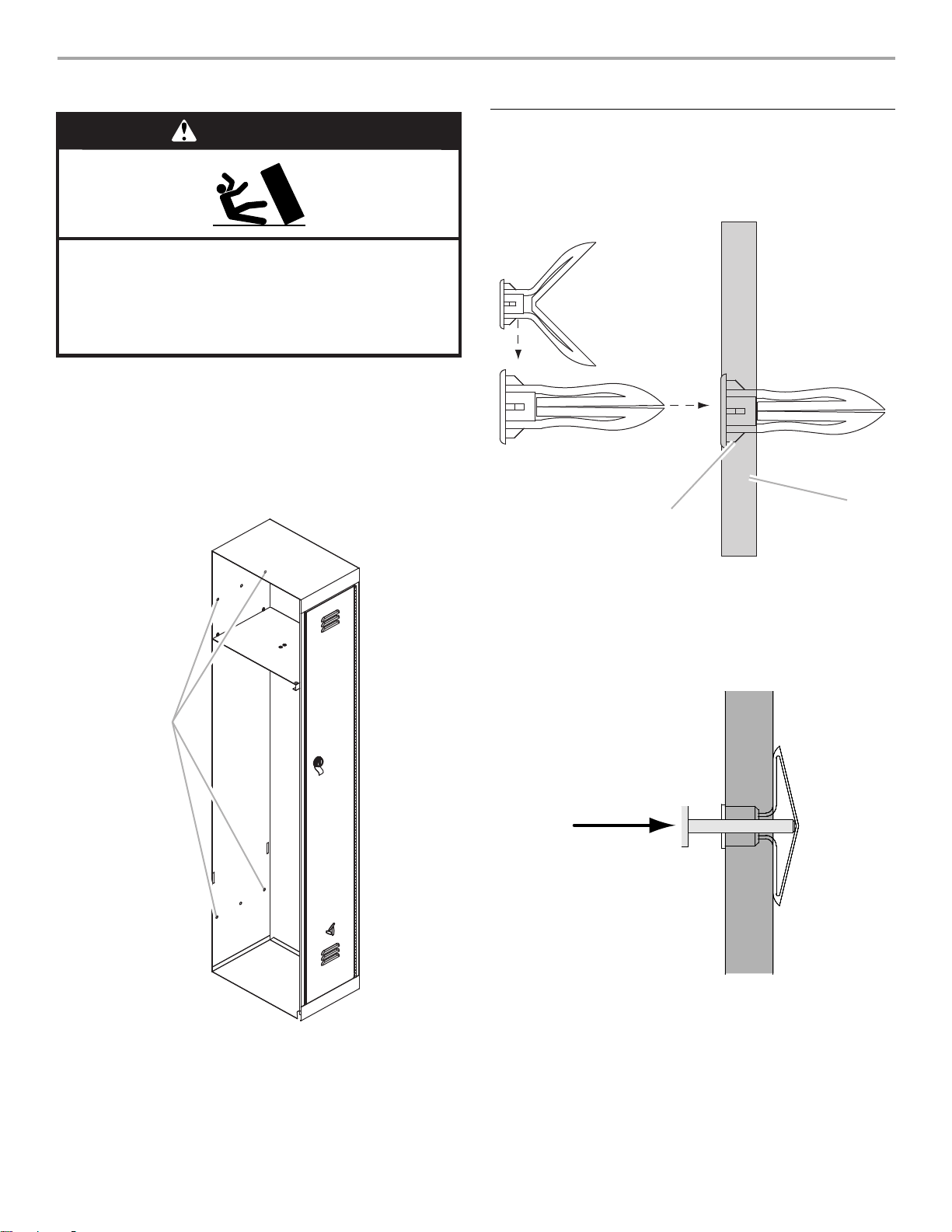

Mounting Holes Align with Wall Stud

B

C

A

D

A

B

C

A

B

C

E

D

F

A

C

B

B

A

1. Mark centerline of wall stud and locker mounting holes.

NOTE: Mounting holes that align with a wall stud do not need

wall anchors. The mounting screw and washer will mount directly

to the stud, as shown.

NOTE: When mounting screws on one side to a stud, the screws

on the opposite side will require a hollow wall anchor.

Wall Stud Alignment

Non-Flush Mount to Wall

1. Using two or more people, move the locker to the wall mounting

location and align the mounting holes in the back of the locker

with the wall anchors and/or stud centerlines. Leave

approximately a 1" (2.5 cm) gap between the wall and the back

of the locker to install the spacer and washer.

2. Slide a washer onto a #8 mounting screw and from the interior,

insert through the back of the locker.

3. On the exterior back of the locker, align a spacer and washer with

the end of the screw. Insert screw through the spacer/washer

and into the wall anchor. Tighten three or four turns.

NOTE: Do not tighten screw completely to allow for installation

of the remaining mounting screws/spacers.

4. Repeat steps 2 and 3, for the remaining mounting screw

locations.

5. Completely tighten each mounting screw until the locker is snug

against the wall.

A. Wall stud

B. Wall

2. If the locker can be flush-mounted to the wall, proceed to the

section “Flush Mount to Wall.” If the locker cannot be flush

mounted to the wall (due to baseboard, etc.), go to the section

“Non-Flush Mount to Wall.”

C. Back of cabinet

Flush Mount to Wall

1. Using two or more people, move the locker to the wall mounting

location and align the mounting holes in the back of the locker

with the wall anchors an/or stud center lines.

2. Slide a washer onto a #8 mounting screw, and then insert

through the back of the cabinet into the wall anchor and/or stud,

as shown.

A. Back of cabinet

B. Fender washer

C. Mounting screw

D. Spacer

E. Hollow wall anchor

F. W a ll

Assemble Dual J Hook to Shelf

1. Unpack and verify J hook components.

2. Insert J hook mounting screws into the mounting holes from the

top side of the shelf.

3. Align dual J hook mounting holes with mounting screws

protruding from the bottom of the upper shelf.

4. While holding the J hook in position, slide jam nut onto the

mounting screw and tighten.

5. Repeat with remaining J hook mounting screw.

A. Back of cabinet

B. Fender washer

3. Using a Phillips screwdriver, turn the screw until it is flush and

tight against the back of the locker.

NOTE: Do not overtighten mounting screws.

4. Repeat steps 2 and 3 for each remaining mounting holes.

4

C. Mounting screw

D. Hollow wall anchor

A.

#10 – 24 x ¹⁄₂" pan-head screws

B. #10 - 24 self-locking nuts

C. Dual J hook

Page 5

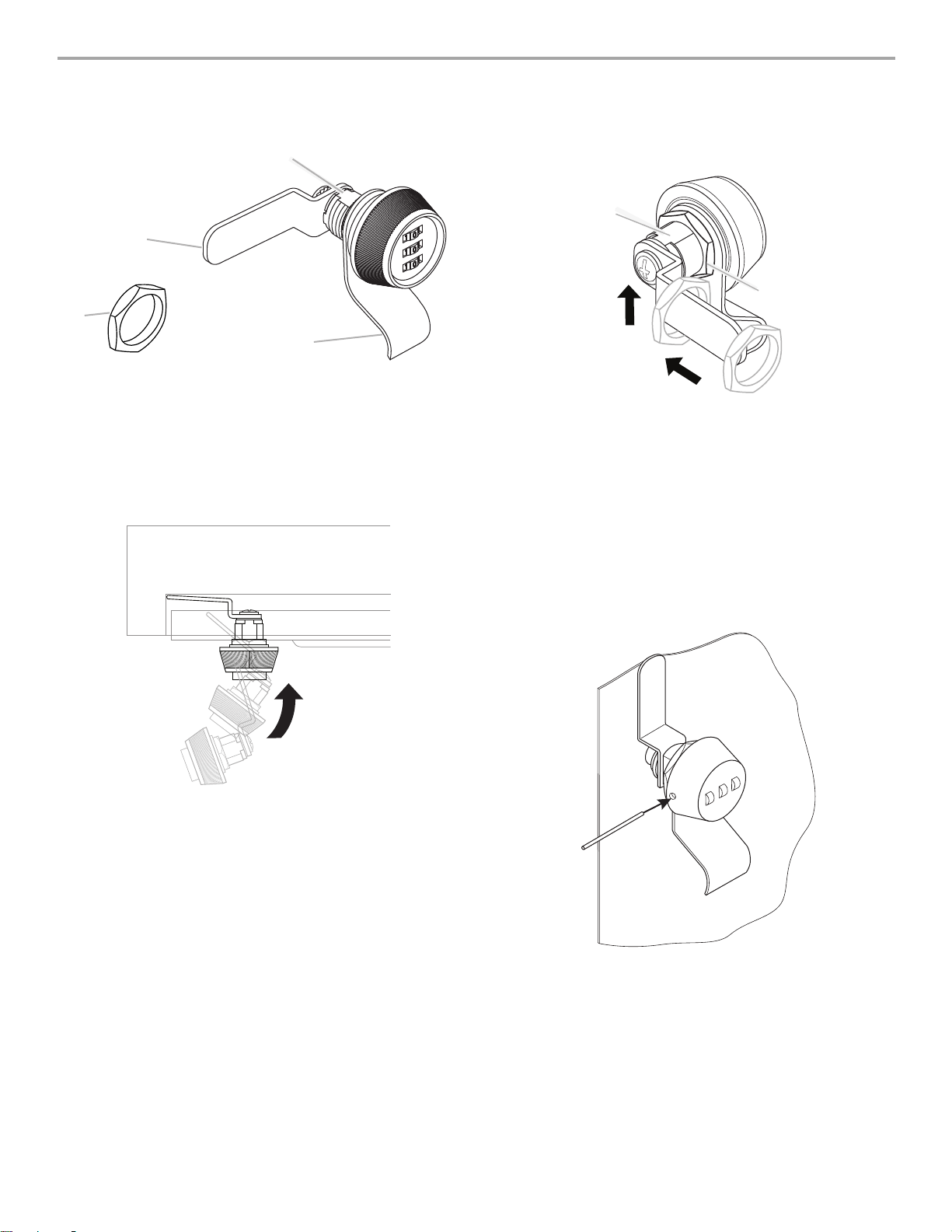

ASSEMBLE COMBINATION LOCK AND HANDLE

A

B

A

5. From the inside of the door, rotate the jam nut onto the cam and

thread and into the final assembly location. The jam nut should

A

B

C

D

be flush and snug against the back of the door.

A. Dial lock flats

B. Cam

1. Facing the front of the dial lock, with the cam facing to the left

and the pull tab handle pointing down, align the dial lock flats

with the flats on the door opening.

2. Angle the combination lock assembly, as shown.

3. Insert the tip of the cam at the angle shown.

4. Rotate the dial lock assembly into the final assembly location, as

shown.

C. Jam nut

D. Pull tab handle

A. Dial lock threaded body

B. Jam nut final assembly location

6. The lock combination is preset at the factory to 0-0-0

combination. The lock combination can be changed as follows:

■ Rotate the lock body clockwise 90 degrees to the open

position.

■ Locate the hole in the side of the lock body. The hole will

be located on the left-hand side (at the nine o’clock

position) of the lock body. In this position, the hole will

align with the lock combination reset button inside the

main lock body.

■ Insert a pin into the hole and depress the lock combination

reset button.

A. Pin

■ While holding the reset button in, turn each individual

combination dial to the desired new lock combination

number.

■ Release the reset button to set the new lock combination.

7. To lock, turn the combination dial away from the set combination

number.

NOTE: Maintain a record of your combination. Locks cannot be reset

without the current combination.

5

Page 6

ACCESSORIES

To order accessories, call 1-866-342-4089 and ask for the

accessory Part Number listed below, contact your authorized

Gladiator brand dealer, or visit www.gladiator/GW.com. In

Canada, call 1-800-807-6777.

GearTrack® Mounting Bracket

Order Part # GABK122PDS

Gear Track® Channels

Order Part # GAWC042PZY

6

Page 7

PRIMETIME™ LOCKER BY GLADIATOR® GARAGEWORKS

WELDED-STEEL LOCKER WARRANTY

LIFETIME LIMITED WARRANTY

For the life of the product, when the PrimeTime™ Locker is used and maintained according to the instructions attached to or furnished

with the product, Gladiator

materials or workmanship.

Gladiator® GarageWorks will not pay for:

1. Service calls to correct the installation of any Gladiator® GarageWorks products or to instruct you on how to use or install them.

2. Damage resulting from improper handling or shipping of products, or products damaged by accident, misuse, abuse, fire, flood,

improper installation, acts of God, neglect, corrosion, modification or mishandling.

3. Shipping or freight fees to deliver replacement products or to return defective products.

4. Repairs or replacement when your product is used in other than normal, single-family household use, such as a commercial

environment or handled in any way inconsistent with the installation instructions included with the product.

5. Cosmetic damage including scratches, dings, dents or cracks that do not affect the structural or functional capability of the

product.

6. Replacement parts or product for Gladiator

7. In Canada, travel or transportation expenses for customers who reside in remote areas.

8. Any labor costs during the limited warranty period.

9. Damage resulting from improper loading beyond the specified maximum weight capacity outlined in the assembly instructions

provided with the product, including overloading of hooks, baskets, shelves, cabinets, and other Gladiator

accessories used with the product.

10. Surfaces damaged due to chemical interaction resulting in corrosion of paint or metal.

11. Replacement keys or locking mechanism.

12. Loss of product contents due to theft, fire, flood, accident or acts of God.

®

GarageWorks will pay for replacement or repair of the defective product or parts to correct defects in

®

GarageWorks products operated outside the United States and Canada.

®

GarageWorks

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATION OF REMEDIES

IMPLIED WARRANTIES, INCLUDING TO THE EXTENT APPLICABLE WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, ARE EXCLUDED TO THE EXTENT LEGALLY PERMISSIBLE. ANY IMPLIED WARRANTIES THAT MAY BE

IMPOSED BY LAW ARE LIMITED TO ONE YEAR, OR THE SHORTEST PERIOD ALLOWED BY LAW. SOME STATES AND PROVINCES

DO NOT ALLOW LIMITATIONS OR EXCLUSIONS ON HOW LONG AN IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

LASTS, SO THE ABOVE LIMITATIONS OR EXCLUSIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL

RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE OR PROVINCE TO PROVINCE.

Outside the 50 United States and Canada, this warranty does not apply. Contact your authorized Gladiator® GarageWorks dealer to

determine if another warranty applies.

If you need service, call the Gladiator

®

GarageWorks Customer eXperience Center, 1-866-342-4089 (toll-free), from anywhere in the

U.S.A. In Canada, contact your Whirlpool Canada LP designated service company or call 1-800-807-6777.

®

In the United States, Gladiator

GarageWorks means Whirlpool Corporation, Benton Harbor, Michigan 49022. In Canada, Gladiator®

GarageWorks means Whirlpool Canada LP, Mississauga, ON L5N 3A7. 6/14

Keep this book and your sales slip together for future

reference. You must provide proof of purchase or installation

date for in-warranty service.

Write down the following information about your PrimeTime™

Locker to better help you obtain assistance or service if you ever

need it. You will need to know your complete model number and

serial number. You can find this information on the model and

serial label located on the back of the product.

Dealer name _________________________________________________

Address _____________________________________________________

Phone number _______________________________________________

Model number _______________________________________________

Serial number ________________________________________________

Purchase date _______________________________________________

7

Page 8

SEGURIDAD DEL ARMARIO

Si no sigue las instrucciones de inmediato, usted puede

morir o sufrir una lesión grave.

Si no sigue las instrucciones, usted puede morir o sufrir

una lesión grave.

Todos los mensajes de seguridad le dirán el peligro potencial, le dirán cómo reducir las posibilidades de sufrir una lesión y lo que

puede suceder si no se siguen las instrucciones.

Su seguridad y la seguridad de los demás es muy importante.

Hemos incluido muchos mensajes importantes de seguridad en este manual y en su electrodoméstico. Lea y obedezca siempre

todos los mensajes de seguridad.

ADVERTENCIA

PELIGRO

Este es el símbolo de advertencia de seguridad.

Este símbolo le llama la atención sobre peligros potenciales que pueden ocasionar la muerte o una lesión a

usted y a los demás.

Todos los mensajes de seguridad irán a continuación del símbolo de advertencia de seguridad y de la palabra

“PELIGRO” o “ADVERTENCIA”. Estas palabras significan:

ADVERTENCIA

Peligro de Peso Excesivo

Use dos o más personas para mover, ensamblar o

instalar

el casillero.

No seguir esta instrucción puede ocasionar una

lesión en la espalda u otro tipo de lesiones.

INSTRUCCIONES DE ENSAMBLAJE

Herramientas y piezas

Reúna las herramientas y piezas necesarias antes de comenzar la

instalación.

Desempaque el armario

Herramientas necesarias

■ Llave de boca de ³⁄₄"

■ Llave de cubo de ³⁄₈"

■ Destornillador Phillips

■ Martillo de goma

Piezas suministradas

■ Ensemblaje de la cerradura con

combinación

■ Cerradura con combinación (1)

■ Manija con lengüeta

para jalar (1)

■ Leva (1)

■ Tornillo de la leva (1)

■ Tuerca fiadora (1 - separada)

■ Piezas de montaje

■ Anclajes para pared hueca (4)

■ Tornillos de montaje Nro. 8 x

■ Arandelas anchas Nro. 8 de ³⁄₄"

2" (50,8 mm) (4)

(19,05 mm) (8)

Requisitos para el uso del armario

■ Diseñado para usarse en garajes y hogares.

■ El límite de peso máximo es de 50 libras (22,7 kg) para cada

■ El límite de peso máximo es de 100 libras (45,4 kg) para el

estante.

armario.

8

■ Ensamblaje del gancho

doble en J

■ Tornillos de cono de

cabeza achatada Nro.

10 - 24 x ¹⁄₂"

(12,7 mm) (2)

■ Contratuerca Nro.

10 - 24 (1)

■ Gancho doble en J

1. Desempaque y verifique el contenido. Vea “Piezas

suministradas” en “Herramientas y piezas” correspondiente a su

modelo.

2. Deshágase de todos los materiales de empaque o recíclelos.

NOTAS:

■ El armario puede montarse directamente en un montante de

pared utilizando los tornillos de montaje Nro. 8 de 2" (50,8 mm).

■ Las piezas suministradas requieren un panel de pared/yeso de

³⁄₈" (9,53 mm) a ¹⁄₂" (12,7 mm) para montar el armario.

NOTA: El montaje en paredes de grosores diferentes o

materiales diferentes puede requerir el uso de nuevas piezas de

montaje. El cliente será responsable de consultar a un

profesional respecto de las instrucciones de montaje que no

sean las especificadas en este manual.

■ Los armarios pueden montarse uno al lado del otro; sin embargo,

cada armario debe montarse en la pared en forma individual,

según las instrucciones de instalación de este manual.

IMPORTANTE: Los armarios no están diseñados para fijarse unos a

otros. Este armario se monta directamente en la pared utilizando las

piezas suministradas. Como opción, los armarios pueden montarse

en paneles Gladiator

juego de soporte estándar. Vea la sección “Accesorios” para obtener

información sobre pedidos.

®

GearWall® y canales GearTrack® usando un

Page 9

MONTAJE DEL ARMARIO EN LA PARED

ADVERTENCIA

Peligro de vuelco

Monte el casillero sobre la pared, canales

GEARTRACK

®

o paneles GEARWALL®, según las

instrucciones de instalación.

No seguir estas instrucciones puede ocasionar la

muerte o heridas graves.

A

B

A

D

C

1. Desempaque y verifique que todas las piezas de montaje estén

incluidas.

2. Identifique la ubicación del armario en la pared.

3. Con la ayuda de 2 o más personas, posicione el armario contra

la pared en la ubicación de montaje.

4. Con un lápiz, marque las cuatro ubicaciones de montaje a través

de la pared posterior del armario.

Orificios de montaje de anclajes para pared

5. NOTA: Para un montaje correcto del armario, es necesario usar

los cuatro orificios de montaje.

7. Determine si algún orificio de montaje está alineado con un

montante de pared. La ubicación del montante puede

determinarse con un detector de montantes estándar (no

suministrado). Si los orificios de montaje están alineados con un

montante, ensamble de acuerdo con la sección “Ensamblaje con

alineación de montante”. Si los orificios de montaje no están

alineados con los montantes, ensamble de acuerdo con la

sección titulada “Ensamblaje en pared hueca”.

Ensamblaje en pared hueca

1. Taladre un orificio piloto de ⁵⁄₁₆" (7,94 mm) a través del panel de

pared en cada ubicación de montaje marcada (4 orificios).

2. Inserte un anclaje para pared a través de cada orificio piloto,

como se muestra en la figura.

Pliegue hacia abajo (A) e inserte en la pared (B), como se

muestra en la figura.

A. Orificios de montaje de anclajes para pared

6. Retire el armario de la pared.

A. Anclaje plegado

B. Anclaje insertado en la pared

3. Con un martillo de goma, golpee hasta que quede al ras de la

pared.

C. Orificio piloto de ⁵⁄₁₆"

(7,94 mm)

D. Pared de yeso de

(9,52 mm) o ¹⁄₂"(12,7 mm)

³⁄₈"

9

Page 10

4. Inserte el pasador de anclaje (suministrado) en el orificio de

B

A

B

C

A

A

B

C

anclaje para pared hasta que se detenga. Vea la siguiente

ilustración. Mueva el pasador hacia adelante hasta que oiga un

chasquido, que es el sonido de las uñas de anclaje de pared

cuando se abren del otro lado de la pared.

A. Pasador de anclaje

B. Uñas de anclaje en la

pared hueca

5. Si el armario será empotrado en una pared, pase a la sección

“Empotrado en pared”. Si el armario no será empotrado en una

pared (debido al zócalo, etc.), pase a la sección “No empotrado

en pared”.

Montaje de los orificios alineados con el

montante de pared

1. Marque la línea central del montante de pared y los orificios de

montaje del armario.

NOTA: El montaje con orificios alineados a un montante de

pared no necesita de anclajes de pared. El tornillo y la arandela

de montaje se montarán directamente en el montante, como se

muestra en la figura.

NOTA: Cuando se montan tornillos a un montante en un lado, los

tornillos del lado opuesto requieren un anclaje de pared hueca.

Alineación con el montante de pared

Empotrado en pared

1. Con la ayuda de dos o más personas, mueva el armario hacia la

ubicación del montaje en pared y alinee los orificios de montaje

en la parte posterior del armario con los anclajes para pared y/o

líneas centrales del montante.

2. Coloque una arandela en un tornillo de montaje Nro. 8 y luego

insértelo a través de la parte posterior del armario en el anclaje

de pared y/o montante, como se muestra en la figura.

D

A. Parte posterior del armario

B. Arandela ancha

3. Con un destornillador Phillips, gire el tornillo hasta que quede

apretado y nivelado contra la parte posterior del armario.

NOTA: No apriete demasiado los tornillos de montaje.

4. Repita los pasos 2 y 3 para cada orificio de montaje restante.

C. Tornillo de montaje

D. Anclaje de pared

hueca

No empotrado en pared

1. Con la ayuda de dos o más personas, mueva el armario hacia la

ubicación del montaje en pared y alinee los orificios de montaje

en la parte posterior del armario con los anclajes para pared y/o

líneas centrales del montante. Deje un espacio de

aproximadamente 1" (2,5 cm) entre la pared y la parte posterior

del armario para colocar el espaciador y la arandela.

2. Coloque una arandela en el tornillo de montaje Nro. 8 y, desde el

interior, insértelo a través de la parte posterior del armario.

3. En el exterior de la parte posterior del armario, alinee un

espaciador y una arandela con el extremo del tornillo. Inserte el

tornillo a través del espaciador/la arandela y dentro del anclaje

para pared. Apriételo dándole tres o cuatro vueltas.

NOTA: No ajuste el tornillo por completo para permitir instalar el

resto de los tornillos/espaciadores de montaje.

4. Repita los pasos 2 y 3 para las ubicaciones restantes de tornillos

de montaje.

A. Montante de pared

B. Pared

C. Parte posterior del

armario

2. Si el armario puede empotrarse en una pared, pase a la sección

“Empotrado en pared”. Si el armario no puede empotrarse en

una pared (debido al zócalo, etc.), pase a la sección “No

empotrado en pared”.

10

Page 11

5. Apriete por completo cada uno de los tornillos de montaje hasta

A

B

C

E

D

F

A

C

B

B

A

A

B

D

C

que el armario quede firme contra la pared.

Ensamblaje del gancho doble en J

al estante

1. Desempaque y verifique los componentes del gancho en J.

2. Inserte los tornillos de montaje del gancho en J en los orificios de

montaje en el lado superior del estante.

3. Alinee los orificios de montaje del gancho doble en J con los

tornillos de montaje que sobresalen de la parte inferior del

estante superior.

4. Mientras sostiene el gancho en J en posición, deslice la tuerca

fiadora en el tornillo de montaje y apriétela.

5. Repita con el otro tornillo de montaje del gancho en J.

A. Parte posterior del armario

B. Arandela ancha

C. Tornillo de montaje

D.Espaciador

E. Anclaje de pared hueca

F. P a re d

A. Tornillos de cono de cabeza achatada

Nro. 10 – 24 x ¹⁄₂" (12,7 mm)

B. Contratuercas Nro. 10 - 24

C. Gancho doble en J

ENSAMBLAJE DE LA CERRADURA CON COMBINACIÓN

Y LA MANIJA

3. Inserte la punta de la leva en el ángulo que se muestra.

4. Gire el ensamblaje de la cerradura con combinación dentro de la

ubicación del ensamblaje final, como se muestra en la figura.

A. Patas planas de la cerradura con combinación

B. Leva

C. Tuerca fiadora

D. Manija con lengüeta para jalar

1. Mirando hacia el frente de la cerradura con combinación, con la

leva mirando hacia la izquierda y la manija con lengüeta para

jalar apuntando hacia abajo, alinee las patas planas de la

cerradura con combinación, con las patas planas de la abertura

de la puerta.

2. Ponga el ensamblaje de la cerradura de combinación en ángulo,

como se muestra en la figura.

11

Page 12

5. Desde el interior de la puerta, gire la tuerca fiadora sobre la leva y

A

B

A

la rosca y dentro de la ubicación final de ensamblaje. La tuerca

fiadora debe quedar al ras y firme contra la parte posterior de la

puerta.

ACCESORIOS

Para pedir accesorios, llame al 1-866-342-4089 y solicite el

número de pieza apropiado que se detalla a continuación,

póngase en contacto con su distribuidor autorizado de

Gladiator o visite www.gladiator/GW.com. En Canadá, llame al

1-800-807-6777.

A. Cuerpo roscado de la

cerradura con combinación,

B. Ubicación final del ensamblaje

de la tuerca fiadora

6. La combinación de la cerradura está prefijada de fábrica en

0-0-0. La combinación de la cerradura puede cambiarse de la

siguiente manera:

■ Gire el cuerpo de la cerradura 90 grados en el sentido de

las agujas del reloj para la posición abierta.

■ Ubique el orificio en el lado del cuerpo de la cerradura. El

orificio estará ubicado en el lado izquierdo (en la posición

de las nueve en punto) del cuerpo de la cerradura. En

esta posición, el orificio se alineará con el botón de

reajuste de la combinación de la cerradura dentro del

cuerpo principal de la cerradura.

■ Inserte un pasador dentro del orificio y oprima el botón de

reajuste de la combinación de la cerradura.

Soporte de montaje GearTrack

Pida la pieza número GABK122PDS

Canales GearTrack

Pida la pieza número GAWC042PZY

®

®

A.Pasador

■ Mientras sostiene el botón de reajuste, gire cada

cuadrante de combinación individual hacia el nuevo

número de combinación de la cerradura deseado.

■ Suelte el botón de reajuste para fijar la nueva

combinación de la cerradura.

7. Para bloquear, gire el cuadrante de combinación sacándolo del

número de la combinación fijada.

NOTA: Guarde un registro de su combinación. Las cerraduras no

pueden volver a fijarse sin la combinación actual.

12

Page 13

ARMARIO DE PRIMETIME™ DE GLADIATOR® GARAGEWORKS

GARANTÍA DEL ARMARIO DE ACERO SOLDADO

GARANTÍA LIMITADA DE POR VIDA

Durante la vida útil del producto, siempre y cuando se le dé al armario PrimeTime™ un uso y mantenimiento de conformidad con las

instrucciones adjuntas o provistas con el producto, Gladiator

piezas defectuosos para corregir defectos en los materiales o en la mano de obra.

Gladiator® GarageWorks no pagará por:

1. Visitas de servicio técnico para corregir la instalación de cualquier producto de Gladiator® GarageWorks o para enseñarle a usarlo o

instalarlo.

2. Daños causados por mal manejo o envío de productos, productos dañados por accidente, uso indebido, abuso, incendio,

inundación, instalación incorrecta, actos fortuitos, negligencia, corrosión, modificación o maltrato.

3. Costo de envío o flete para entregar productos de repuesto o para devolver productos defectuosos.

4. Reparaciones o reemplazo cuando su producto ha sido empleado para fines ajenos al uso doméstico normal de una familia tal

como uso en un lugar comercial o se haya tratado de alguna manera en contra de las instrucciones de instalación incluidas con el

producto.

5. Daños estéticos incluyendo rayaduras, golpes, abolladuras o rajaduras que no afecten la capacidad estructural o de

funcionamiento del producto.

6. Piezas o productos de repuesto para los productos Gladiator

Canadá.

7. En Canadá, gastos de viaje o de transporte para clientes que residen en áreas remotas.

8. Cualquier gasto de mano de obra durante el período de la garantía limitada.

9. Daños causados por la carga indebida que exceda el peso máximo especificado que se detalla en las instrucciones de ensamblaje

provistas con el producto, incluyendo la sobrecarga de ganchos, canastas, estantes, armarios y otros accesorios de Gladiator

GarageWorks usados con este producto.

10. Superficies dañadas debido a la interacción química dando como resultado la corrosión de pintura o metal.

11. Mecanismo de bloqueo o llaves de reemplazo.

12. Pérdida del contenido del producto debido a robo, incendio, inundación, accidente o actos fortuitos.

®

GarageWorks pagará por el reemplazo o la reparación del producto o las

®

GarageWorks que se empleen fuera de los Estados Unidos y

®

EXCLUSIÓN DE GARANTÍAS IMPLÍCITAS; LIMITACIÓN DE RECURSOS

LAS GARANTÍAS IMPLÍCITAS, INCLUYENDO EN LA MEDIDA QUE CORRESPONDA LAS GARANTÍAS DE COMERCIABILIDAD O DE

CAPACIDAD PARA UN PROPÓSITO PARTICULAR, QUEDAN EXCLUIDAS EN LA MEDIDA EN QUE SEA LEGALMENTE PERMISIBLE.

TODA GARANTÍA IMPLÍCITA QUE SEA IMPUESTA POR LEY SERÁ LIMITADA A UN AÑO O AL PERÍODO MÁS CORTO PERMITIDO

POR LEY. ALGUNOS ESTADOS Y PROVINCIAS NO PERMITEN LAS LIMITACIONES O EXCLUSIONES ACERCA DE CUÁNTO DEBE

DURAR UNA GARANTÍA IMPLÍCITA DE COMERCIABILIDAD O CAPACIDAD, DE MODO QUE LAS LIMITACIONES O EXCLUSIONES

ARRIBA MENCIONADAS PUEDEN NO APLICARSE EN SU CASO. ESTA GARANTÍA LE OTORGA DERECHOS LEGALES

ESPECÍFICOS Y ES POSIBLE QUE USTED TENGA TAMBIÉN OTROS DERECHOS QUE PUEDEN VARIAR DE UN ESTADO A OTRO O

DE UNA PROVINCIA A OTRA.

Esta garantía no tiene vigor fuera de los cincuenta estados de los Estados Unidos y Canadá. Póngase en contacto con el distribuidor

autorizado de Gladiator

Si necesita servicio técnico, llame al Centro para la eXperiencia del cliente de Gladiator

®

GarageWorks para determinar si corresponde otra garantía.

®

GarageWorks, 1-866-342-4089 (gratuito),

desde cualquier lugar de los EE.UU. En Canadá, póngase en contacto con su compañía de servicio designada de Whirlpool Canada LP

o llame al 1-800-807-6777.

®

En los Estados Unidos, Gladiator

Gladiator

®

GarageWorks significa Whirlpool Canada LP, Mississauga, ON L5N 3A7. 6/14

Guarde este libro y su comprobante de compra juntos para

referencia futura. Usted deberá proporcionar el comprobante

de la compra o la fecha de instalación para obtener servicio

bajo la garantía.

Anote la siguiente información acerca de su armario PrimeTime™

para facilitar la obtención de asistencia o servicio técnico si

llegara a necesitarlo. Deberá tener a mano el número completo

del modelo y la serie. Usted puede encontrar esta información en

la etiqueta con el número de modelo y serie que está ubicada en

la parte posterior del producto.

GarageWorks significa Whirlpool Corporation, Benton Harbor, Michigan 49022. En Canadá,

Nombre del distribuidor _______________________________________

Dirección ____________________________________________________

Número de teléfono___________________________________________

Número de modelo ___________________________________________

Número de serie______________________________________________

Fecha de compra

13

Page 14

SÉCURITÉ DE L’ARMOIRE/DU VESTIAIRE

Risque possible de décès ou de blessure grave si vous ne

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

AVERTISSEMENT

DANGER

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

AVERTISSEMENT

Risque du poids excessif

Utiliser deux ou plus de personnes pour déplacer,

assembler, ou installer

le casier.

Le non-respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

INSTRUCTIONS DE MONTAGE

Outillage et pièces

Rassembler les outils et pièces nécessaires avant d’entreprendre

l’installation.

Déballage du vestiaire

Outils nécessaires

■ Clé plate de ³⁄₄"

■ Clé à douille de ³⁄₈"

■ Tournevis Phillips

■ Maillet en caoutchouc

Pièces fournies

■ Serrure à

combinaison

■ 1 serrure à combinaison

■ 1 tirette d’ouverture de la porte

■ 1 loquet

■ 1 vis pour loquet

■ 1 écrou de blocage

■ Visserie

■ 4 chevilles pour cloison creuse

■ 4 vis de montage #8 x 2"

■ 8 rondelles larges de ³⁄₄"

Conditions d’utilisation du vestiaire

■ Le produit est prévu pour être utilisé dans un garage et à

■ La charge maximale est de 50 lbs (22 kg) pour chaque étagère.

■ La charge maximale est de 100 lbs (37,3 kg) pour le vestiaire.

domicile.

■ Double crochet

■ 2 vis à tête bombée

#10 – 24 x ¹⁄₂"

■ 1 écrou autobloquant

#10 - 24

■ Double crochet

1. Retirer le contenu; vérifier la présence de toutes les pièces. Voir

la section “Pièces fournies” de la partie “Outillage et pièces” de

votre modèle.

2. Éliminer/recycler tous les matériaux d’emballage.

REMARQUES :

■ Il est possible de monter le vestiaire directement sur un poteau

de colombage au moyen des vis de montage de #8 x 2".

■ La visserie fournie est prévue pour monter le vestiaire sur une

cloison sèche/plaque de plâtre de ³⁄₈" to ¹⁄₂" d’épaisseur.

REMARQUE : Le montage sur une cloison d’une autre épaisseur

ou d’un autre matériau peut nécessiter une visserie différente. Il

incombe au client de prendre conseil auprès d’un professionnel

pour les consignes de montage dans les situations autres que

celles spécifiées dans ce manuel.

■ Les vestiaires peuvent être montés côte à côte; cependant,

chacun doit être monté individuellement au mur en fonction des

instructions d’installation de ce manuel.

IMPORTANT : Les vestiaires ne sont pas prévus pour être fixés les

uns aux autres. Ce vestiaire se monte directement au mur au moyen

de la visserie fournie. En option, il est possible de monter les

vestiaires sur des panneaux Gladiator

GearTrack

“Accessoires” pour les informations de commande.

®

avec des supports standard. Voir la section

®

GearWall® et des profilés

14

Page 15

MONTAGE DU VESTIAIRE AU MUR

ADVERTISSEMENT

Risque de basculement

Fixer au mur le casier, les profilés GEARTRACK® ou les

panneaux GEARWALL

®

en suivant les instructions

d'installation.

Le non-respect de ces instructions peut causer un

décès ou une blessure grave.

A

B

A

D

C

B

A

1. Retirer l’emballage et vérifier que toute la visserie est incluse.

2. Déterminer l’emplacement de montage du vestiaire.

3. À deux personnes au moins, placer les vestiaires contre le mur à

sa position de montage.

4. Repérer avec un crayon les quatre orifices de montage à travers

la paroi arrière du vestiaire.

Orifices de montage des ancrages muraux

5. REMARQUE : Pour un montage correct du vestiaire, il est

impératif d’utiliser les quatre orifices de montage.

Montage sur cloison creuse

1. Percer un avant-trou de ⁵⁄₁₆" dans la plaque de plâtre sur chaque

position de montage repérée (4 trous).

2. Introduire une cheville murale dans chaque avant-trou comme

illustré.

La plier (A) et l’enfoncer dans le mur (B) comme illustré.

6. Éloigner les vestiaires du mur.

7. Déterminer si l’un des offices de montage et aligner avec un

poteau de colombage. Leur position peut être déterminée avec

un détecteur approprié standard (non fourni). Si les trous de

montage sont alignés avec un poteau, effectuer le montage

conformément à la section “Montage en alignement avec un

poteau”. Si les trous de montage ne sont pas alignés avec un

poteau, effectuer le montage conformément à la section

“Montage sur cloison creuse”.

A. Orifices de montage des ancrages muraux

A. Cheville pliée

B. Cheville enfoncée dans le

mur

3. À l’aide d’un maillet en caoutchouc, l’enfoncer jusqu’à ce qu’elle

affleure la paroi.

4. Enfoncer la broche d’ancrage (fournie) dans l’orifice d’ancrage

jusqu’à la butée. Voir l’illustration ci-dessous. Enfoncer la broche

jusqu’à entendre un clic, qui correspond au contact des doigts

d’ancrage mural qui s’ouvrent sur l’autre face de la paroi.

A. Broche d’ancrage

B. Doigt d’ancrage pour

paroi creuse

5. Si le vestiaire est monté contre la paroi, passer à la section

“Montage contre la paroi”. Si le vestiaire n’est pas monté contre

la paroi (en raison d’une plinthe, etc.), passer à la section

“Montage à distance du mur”.

C. Avant-trou de ⁵⁄₁₆"

D. Cloison sèche de

³⁄₈" ou ¹⁄₂"

15

Page 16

Alignement des trous de montage avec les

B

C

A

A

B

C

poteaux de colombage

1. Repérer l’axe du poteau de colombage et les orifices de

montage du vestiaire.

REMARQUE : Les orifices de montage alignés avec un poteau

de colombage n’ont pas besoin d’ancrages muraux. La vis de

montage et sa rondelle se montent directement dans le poteau

comme illustré.

REMARQUE : Lorsque les vis de montage sont fixées d’un côté

à un poteau de colombage, les vis de l’autre côté nécessitent

une cheville pour paroi creuse.

Alignement avec un poteau de colombage

Montage contre le mur

1. À deux personnes au moins, déplacer le vestiaire jusqu’à sa

position de montage au mur et aligner les orifices de montage à

l’arrière du vestiaire avec les chevilles murales et/ou l’axe du

poteau de colombage.

2. Placer une rondelle sur une vis de montage de #8, puis l’enfoncer

dans la cheville ou le poteau de colombage en traversant la paroi

arrière du vestiaire comme illustré.

D

APoteau de colombage

B. Cloison

2. Si le vestiaire peut être monté contre la paroi, passer à la section

“Montage contre la paroi”. Si le vestiaire n’est pas monté contre

la paroi (en raison d’une plinthe, etc.), passer à la section

“Montage à distance du mur”.

C. Paroi arrière du vestiaire

D. Paroi arrière du vestiaire

B. Rondelle large

3. Au moyen d’un tournevis Phillips, visser jusqu’à ce que la vis

affleure la paroi arrière du vestiaire.

REMARQUE : Ne pas serrer excessivement les vis.

4. Répéter les étapes 2 et 3 pour chaque orifice de montage.

C. Vis de montage

D. Cheville pour cloison creuse

16

Page 17

Montage à distance du mur

A

B

C

E

D

F

A

C

B

B

A

A

B

D

C

1. À deux personnes au moins, déplacer le vestiaire jusqu’à sa

position de montage au mur et aligner les orifices de montage à

l’arrière du vestiaire avec les chevilles murales et/ou l’axe du

poteau de colombage. Laisser un espace d’environ 1" (2,5 cm)

entre le mur et la paroi arrière du vestiaire pour installer la cale

d’écartement et la rondelle.

2. Placer une rondelle sur une vis de montage de #8 et, depuis

l’intérieur, la passer à travers la paroi arrière.

3. Sur la paroi arrière extérieure du vestiaire, aligner une cale

d’écartement et sa rondelle avec l’extrémité de la vis. Passer la

vis à travers la cale d’écartement et sa rondelle dans la cheville

pour cloison creuse. Serrer de trois ou quatre tours.

REMARQUE : Ne pas serrer complètement la vis pour permettre

l’installation des autres vis et cales d’écartement.

4. Répéter les étapes 2 et 3 pour les autres vis de montage.

5. Serrer complètement chaque vis de montage pour fixer

solidement le vestiaire à la paroi.

Montage du double crochet à l’étagère

1. Déballer et vérifier les pièces du double crochet.

2. Depuis le dessus de l’étagère, passer les vis du double crochet

dans les orifices de montage.

3. Aligner les orifices de montage du double crochet avec les vis

sortant du dessous de l’étagère supérieure.

4. En maintenant le double crochet en place, glisser l’écrou

autobloquant sur la vis de montage et le serrer.

5. Répéter la procédure avec l’autre vis.

A. Vis à tête bombée #10 – 24 x ¹⁄₂"

B. Écrous autobloquants #10 - 24

C. Double crochet

D. Paroi arrière du vestiaire

B. Rondelle large

C. Vis de montage

D. Cale d’écartement

E. Chevilles pour cloison creuse

F. M u r

MONTAGE DE LA SERRURE À COMBINAISONS ET DE LA TIRETTE

4. Faire pivoter la serrure à combinaison jusqu’à sa position finale

comme illustré.

A. Méplats du mécanisme à combinaison

B. Loquet

C. Écrou de blocage

D. Tirette d’ouverture de la porte

1. En faisant face à l’avant du mécanisme à combinaison, loquet à

gauche et tirette vers le bas, aligner les méplats du mécanisme à

combinaisons avec ceux de l’orifice dans la porte.

2. Incliner la serrure à combinaisons comme illustré.

3. Insérer l’extrémité du loquet selon l’angle illustré.

17

Page 18

5. Depuis l’intérieur de la porte, passer l’écrou de blocage autour

A

B

A

du loquet et le visser à sa position finale. L’écrou de blocage doit

affleurer sans jeu à la paroi arrière de la porte.

ACCESSOIRES

Pour commander des accessoires, composer le 1-866-342-4089

et spécifier l’une des références d’accessoires ci-dessous,

contacter un revendeur Gladiator agréé ou visiter

www.gladiator/GW.com. Au Canada, composer le

1-800-807-6777.

A. Partie filetée de la serrure à combinaison

B. Position finale de l’écrou de blocage

6. La serrure possède la combinaison 0-0-0 en sortie d’usine. Pour

changer la combinaison de la serrure, procédez comme suit :

■ Faire pivoter le corps de la serrure dans le sens horaire de

90° en position ouverte.

■ Localiser l’orifice sur le côté du corps de la serrure. Il est

situé à gauche (en position neuf heures) du corps de la

serrure. Dans cette position, l’orifice est aligné avec le

bouton de réinitialisation de la combinaison à l’intérieur

du corps principal de la serrure.

■ Introduire une tige dans l’orifice et appuyer sur le bouton de

réinitialisation de la combinaison.

Support de montage GearTrack

®

Commander la pièce n° GABK122PDS

Profilés Gear Track

®

Commander la pièce n° GAWC042PZY

A. Tige

■ Tout en maintenant le bouton de réinitialisation enfoncé à

l’aide de la tige, tourner chaque rouleau de la

combinaison pour obtenir la nouvelle combinaison de

serrure souhaitée.

■ Relâcher le bouton de réinitialisation pour définir la

nouvelle combinaison de la serrure.

7. Pour verrouiller la porte, tourner les rouleaux.

REMARQUE : Il est impératif de se souvenir de sa combinaison. Il

n’est pas possible de réinitialiser la combinaison de la serrure sans

connaître la combinaison actuelle.

18

Page 19

VESTIAIRE PRIMETIME™ DE GLADIATOR® GARAGEWORKS

GARANTIE DU VESTIAIRE EN ACIER SOUDÉ

GARANTIE LIMITÉE À VIE

Pendant toute la vie du produit, lorsque le vestiaire PrimeTime™ est utilisé et entretenu conformément aux instructions fournies avec le

produit, Gladiator

de matière ou de fabrication.

Gladiator® GarageWorks ne paiera pas pour :

1. Interventions de dépannage pour rectifier l’installation d’un produit Gladiator® GarageWorks ou pour expliquer comment l’utiliser ou

l’installer.

2. Les dommages causés par une manipulation ou une expédition des produits incorrecte, ou les produits endommagés par accident,

mésusage, abus, incendie, inondation, installation incorrecte, catastrophes naturelles, négligence, corrosion, modification ou

mauvaise manipulation.

3. Les frais d’expédition ou de transport pour livrer des produits de rechange ou retourner des produits défectueux.

4. Les réparations ou remplacements lorsque le produit est utilisé autrement que pour une utilisation normale, unifamiliale, comme

dans un environnement commercial ou manipulé d’une façon non conforme aux instructions d’installation fournies avec le produit.

5. Les défauts d’apparence – éraflures, traces de choc ou fissures – n’affectant pas la fonction ou la résistance structurale du produit.

6. Les pièces ou le remplacement d’un produit Gladiator

7. Au Canada, les frais de déplacement ou de transport pour les clients qui habitent dans des régions éloignées.

8. Tous les frais de main-d’œuvre encourus au cours de la période de garantie limitée.

9. Les dommages causés par une charge incorrecte dépassant le poids maximum spécifié dans les instructions de montage fournies

avec le produit, y compris la surcharge de crochets, paniers, étagères, placards et autres accessoires Gladiator

utilisés avec le produit.

10. Les surfaces endommagées par une interaction chimique causée par la corrosion de la peinture ou du métal.

11. Les clés ou le mécanisme de verrouillage.

12. La perte du contenu du produit due à un vol, un incendie, une inondation, un accident ou une catastrophe naturelle.

®

GarageWorks paiera le remplacement ou la réparation du produit ou des pièces défectueux pour corriger les vices

®

GarageWorks non commercialisé aux États-Unis ou au Canada.

®

GarageWorks

CLAUSE D’EXONÉRATION DE RESPONSABILITÉ AU TITRE DES GARANTIES IMPLICITES; LIMITATION DES RECOURS

LES GARANTIES IMPLICITES, Y COMPRIS DANS LA MESURE APPLICABLE LES GARANTIES DE QUALITÉ MARCHANDE OU

D’APTITUDE À UN USAGE PARTICULIER, SONT EXCLUES DANS LA MESURE AUTORISÉE PAR LA LOI. TOUTE GARANTIE

IMPLICITE POUVANT ÊTRE IMPOSÉE PAR LA LOI EST LIMITÉE À UN AN, OU À LA PLUS COURTE PÉRIODE AUTORISÉE PAR LA

LOI. CERTAINES JURIDICTIONS NE PERMETTENT PAS LA LIMITATION DE LA DURÉE DE VALIDITÉ DES GARANTIES IMPLICITES DE

QUALITÉ MARCHANDE OU D’APTITUDE À UN USAGE PARTICULIER; PAR CONSÉQUENT LES LIMITATIONS OU EXCLUSIONS

STIPULÉES DANS LES PRÉSENTES PEUVENT NE PAS VOUS ÊTRE APPLICABLES. CETTE GARANTIE VOUS CONFÈRE DES

DROITS JURIDIQUES SPÉCIFIQUES ET VOUS POUVEZ ÉGALEMENT JOUIR D’AUTRES DROITS QUI PEUVENT VARIER D’UNE

JURIDICTION À UNE AUTRE.

À l’extérieur du Canada et des 50 États des États-Unis, cette garantie ne s’applique pas. Contacter votre concessionnaire Gladiator®

GarageWorks agréé pour déterminer si une autre garantie s’applique.

Si vous avez besoin d’un dépannage, appelez le Centre pour l’eXpérience de la clientèle de Gladiator

®

GarageWorks au

1-866-342-4089 (appel gratuit), de n’importe où aux États-Unis. Au Canada, contactez votre entreprise de dépannage désignée par

Whirlpool Canada LP ou composez le 1-800-807-6777.

®

Aux États-Unis, Gladiator

GarageWorks correspond à Whirlpool Corporation, Benton Harbor, Michigan 49022. Au Canada, Gladiator®

GarageWorks correspond à Whirlpool Canada LP, Mississauga, ON L5N 3A7. 6/14

Conserver ce manuel et le reçu de vente au même endroit

pour référence ultérieure. Pour un entretien ou une

réparation sous garantie, un document attestant de la date

d’achat ou d’installation doit être fourni.

Inscrivez les renseignements suivants au sujet de votre vestiaire

PrimeTime™ pour accélérer les procédures d’assistance ou

d’intervention en cas de besoin. Il faut connaître le numéro de

modèle et le numéro de série au complet. Vous trouverez ces

renseignements sur la plaque signalétique située à l’arrière du

produit.

Nom du revendeur____________________________________________

Adresse _____________________________________________________

Numéro de téléphone _________________________________________

Numéro de modèle ___________________________________________

Numéro de série______________________________________________

Date d’achat _________________________________________________

19

Page 20

W10722620A

®

/™ ©2014 Gladiator. Used under license in Canada. All rights reserved.

Usada en Canadá bajo licencia. Todos los derechos reservados.

Utilisée sous licence au Canada. Tous droits réservés.

10/14

Printed in U.S.A.

Impreso en EE,UU

Imprimé au E.-U.

Loading...

Loading...