Page 1

Models

GARA904X/YGRA904X/GARB904X - 90" Heavy Duty Mega Rack

GARS774X/GARS774S/GARM774X - 77" Heavy Duty Rack

GARS604T/YGRS604T/GARS604TK - 60" Heavy Duty Rack

GARS484T/YGRS484T/GARS484TK - 48" Heavy Duty Rack

Compatible accessories

GASL182PHB - Rack Shelf Liner 2-Pack for 18" Deep Shelves

GASL242PHB - Rack Shelf Liner 2-Pack for 24" Deep Shelves

GAGP24WRHY - Heavy Duty Rack GearTrack® Pack

TABLE OF CONTENTS/TABLE DES MATIÈRES/ÍNDICE

HEAVY DUTY METAL RACK SHELVING

SAFETY ..................................................... 2

DIMENSIONS ........................................... 2

PARTS ....................................................... 3

HEAVY DUTY METAL RACK SHELVING

INSTALLATION INSTRUCTIONS ............. 5

Shelving Use Requirements ...................5

Unpack .................................................. 5

Assemble & Complete ........................... 5

WARRANTY .............................................. 8

SÉCURITÉ DE L’ÉTAGÈRE MÉTALLIQUE

POURCHARGES LOURDES ................... 9

DIMENSIONS ........................................... 9

PIÈCES ................................................... 10

INSTRUCTIONS D’INSTALLATION

DE L’ÉTAGÈRE MÉTALLIQUE

POURCHARGES LOURDES ................. 12

Spécications d’utilisation

de l’étagère .......................................... 12

Déballage ............................................. 12

Assemblage ......................................... 12

GARANTIE .............................................. 15

HEAVY DUTY METAL

RACK SHELVING

Assembly Instructions

ÉTAGÈRE MÉTALLIQUE

POUR CHARGES

LOURDES

Instructions d’assemblage

ESTANTERÍA DE METAL

DE ALTA RESISTENCIA

Instrucciones de ensamblaje

SEGURIDAD DE LA ESTANTERÍA

DEMETAL DEALTARESISTENCIA ...... 16

DIMENSIONES ....................................... 16

PIEZAS .................................................... 17

INSTRUCCIONES DE INSTALACIÓN

DELA ESTANTERÍA DE ACERO DE

ALTARESISTENCIA ............................... 19

Requisitos de uso de laestantería....... 19

Desempaque ........................................ 19

Ensamble y complete .......................... 19

GARANTÍA .............................................. 22

W11320048D

In U.S.A. call: 1-866-342-4089

Aux États-Unis, composer le : 1 866 342-4089

En los EE. UU., llame al: 1-866-342-4089

In Canada call: 1-800-807-6777

Au Canada, composer le : 1-800-807-6777

En Canadá, llame al: 1-800-807-6777

www.gladiatorgarageworks.com

www.gladiatorgarageworks.ca

Page 2

HEAVY DUTY METAL RACK SHELVING SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

This storage rack unit must be placed on a level surface.

NOTES:

■ Do not stand or climb on the unit.

■ Do not overload.

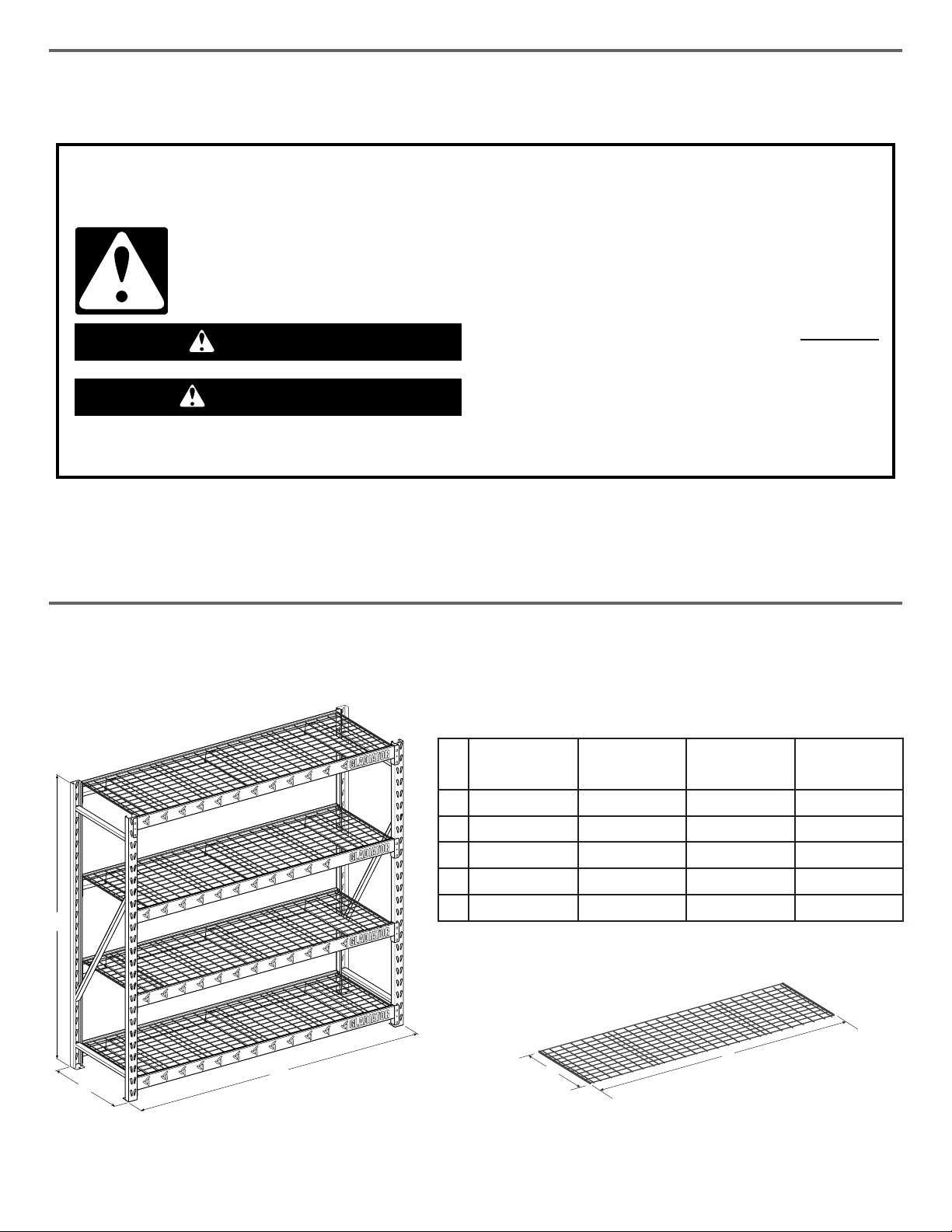

DIMENSIONS

A

■ Evenly distribute the weight on each shelf, and keep the

heaviest loads on the bottom shelf.

GARA904XIG

YGRA904X

GARB904XIG

A 90" (229 cm) 72" (183 cm) 72" (183 cm) 72" (183 cm)

B 24" (61 cm) 24" (61 cm) 18" (46 cm) 18" (46 cm)

C 90" (229 cm) 77" (196 cm) 60" (152 cm) 48" (122 cm)

D 22" (56 cm) 22" (56 cm) 16" (41 cm) 16" (41 cm)

E 84½" (215 cm) 72" (183 cm) 55" (139 cm) 43" (108 cm)

GARS774XEG

GARS774SZG

GARM774XHG

GARS604TEG

YGRS604TGG

GARS604TKW

GARS484TEG

YGRS484TGG

GARS484TKW

E

C

B

2

D

Page 3

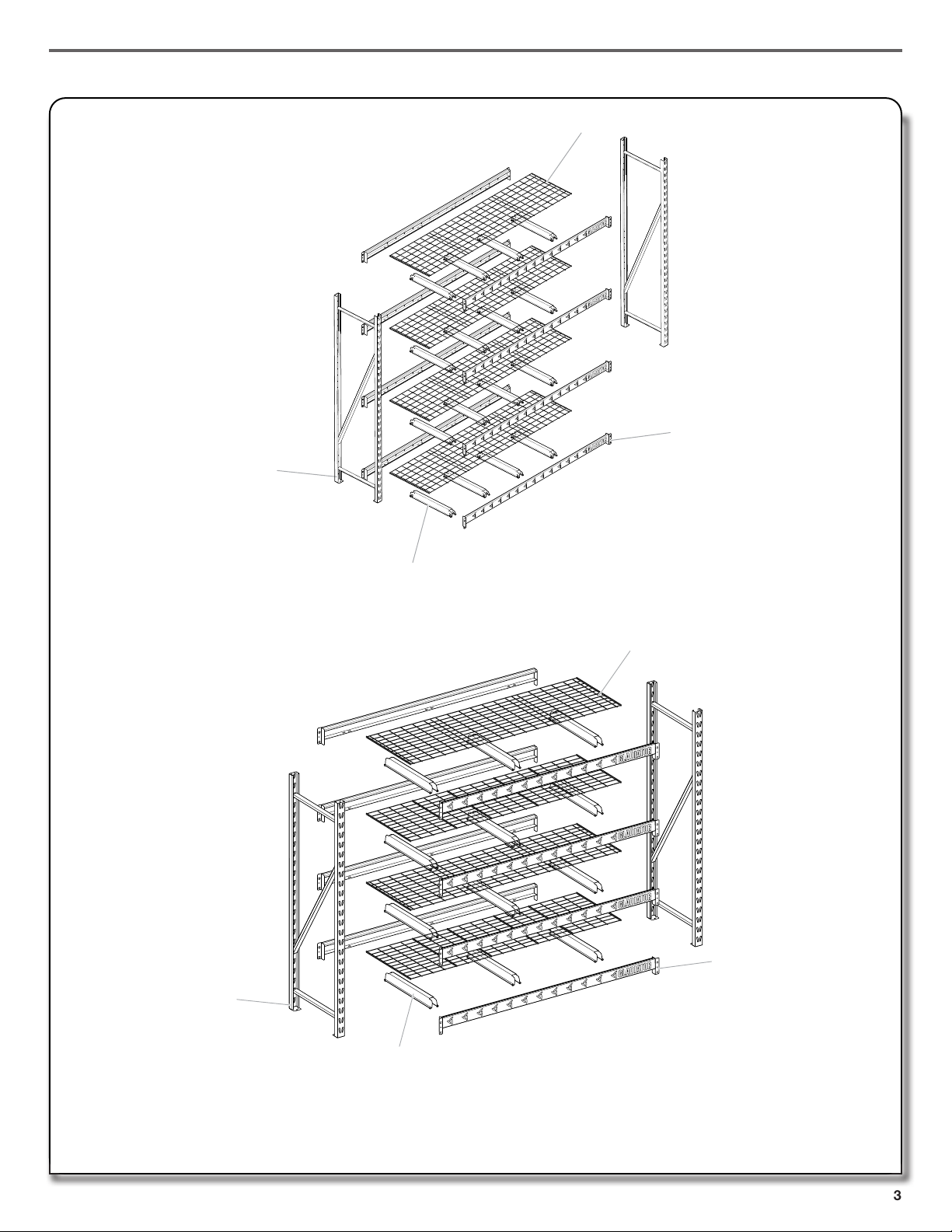

P4

PARTS

P1

P2

P4

P3

90" (229 cm) Wide Rack Shelving

P1

P2

P3

77" (196 cm) Wide Rack Shelving

P1—Wire shelves (4)

P2—Support beams (8)-4 in front, 4 in back

P3—Tie channel supports (quantity varies by size)

P4—Welded-end frame assemblies (2)

3

Page 4

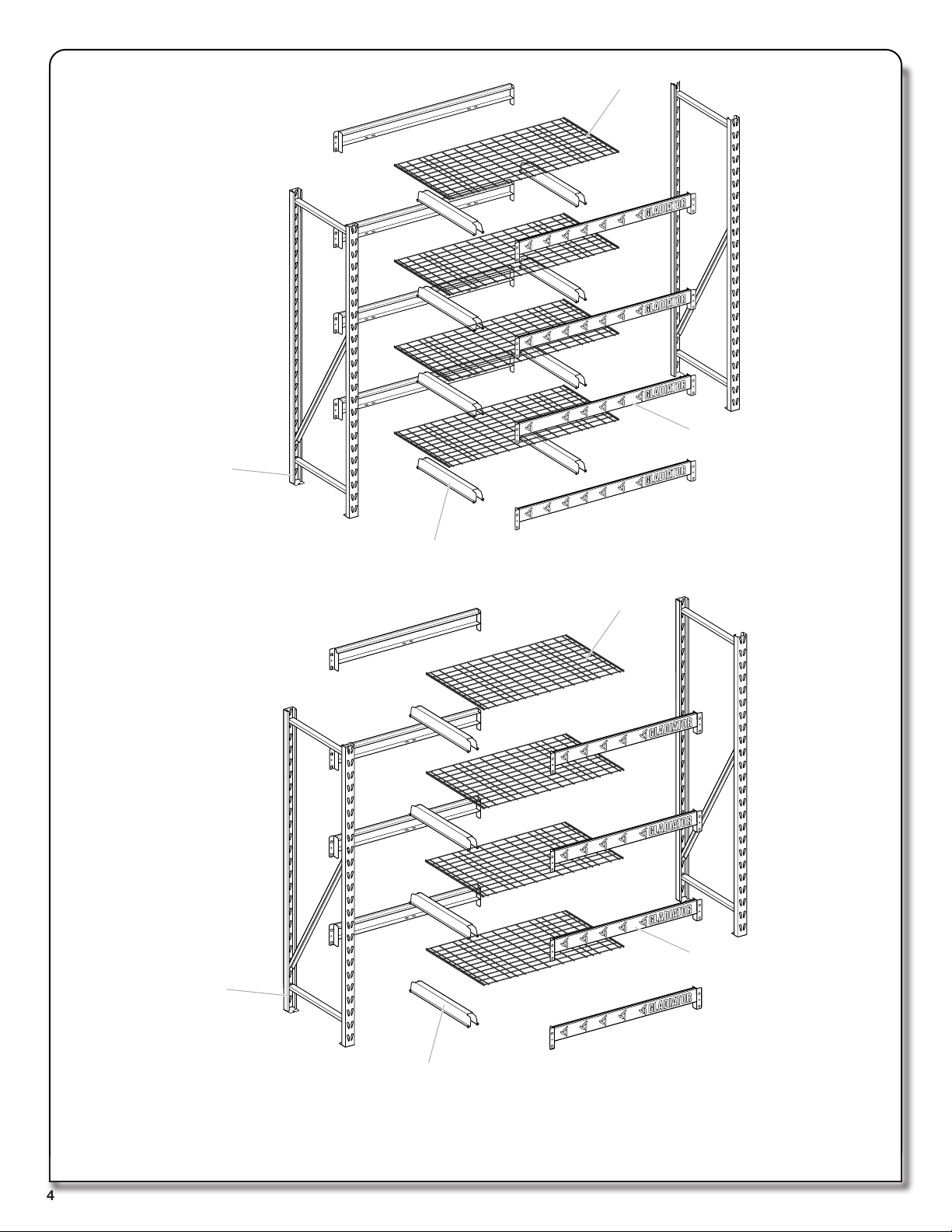

P4

P1

P2

P4

P3

60" (152 cm) Wide Rack Shelving

P1

P2

P3

48" (122 cm) Wide Rack Shelving

P1—Wire shelves (4)

P2—Support beams (8)—4 in front, 4 in back

P3—Tie channel supports (quantity varies by size)

P4—Welded-end frame assemblies (2)

4

Page 5

HEAVY DUTY METAL RACK SHELVING

INSTALLATION INSTRUCTIONS

Shelving Use Requirements

All rack shelf sizes: maximum weight limit is 2,000 lbs (907 kg)

for each shelf, not to exceed 8,000 lbs (3,628 kg) for the entire

shelving unit.

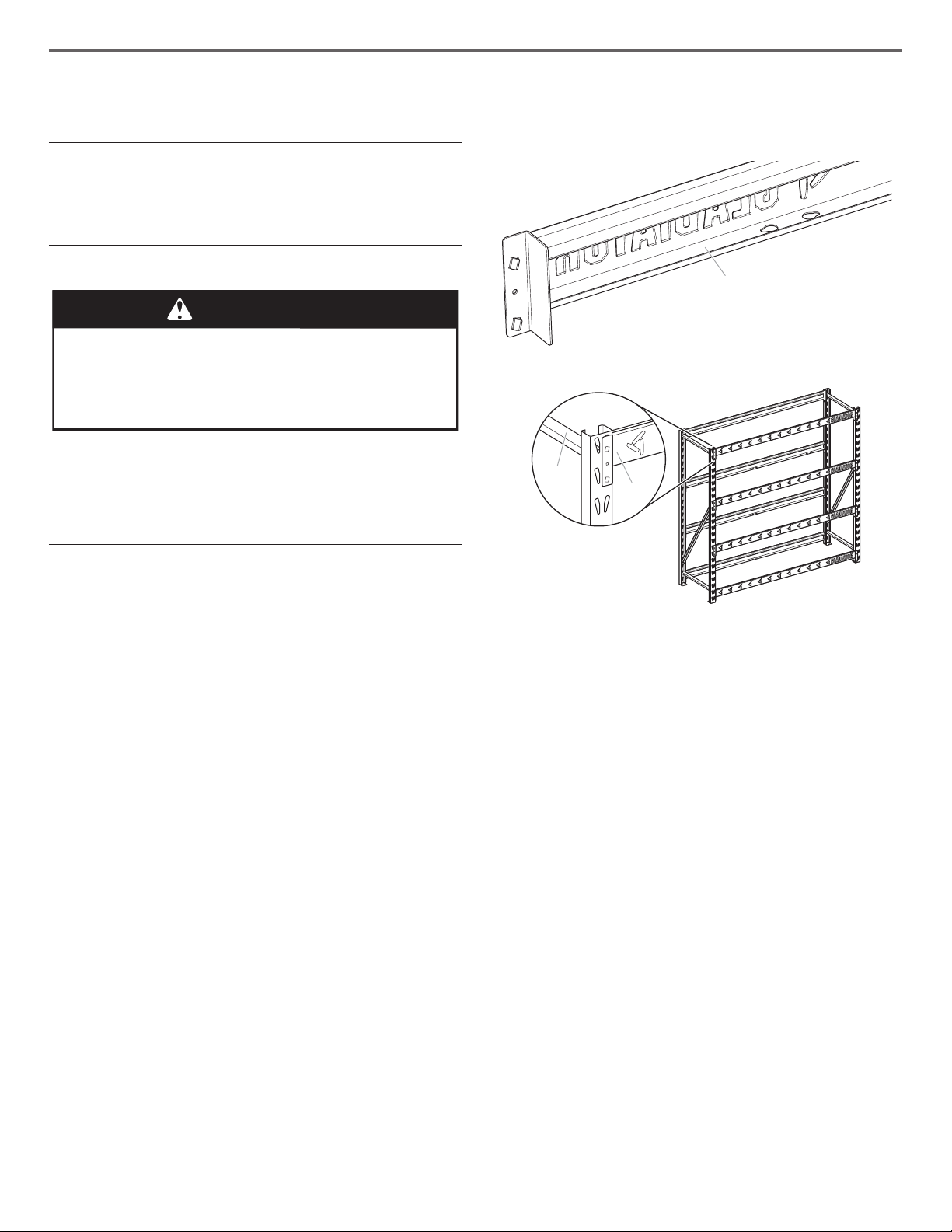

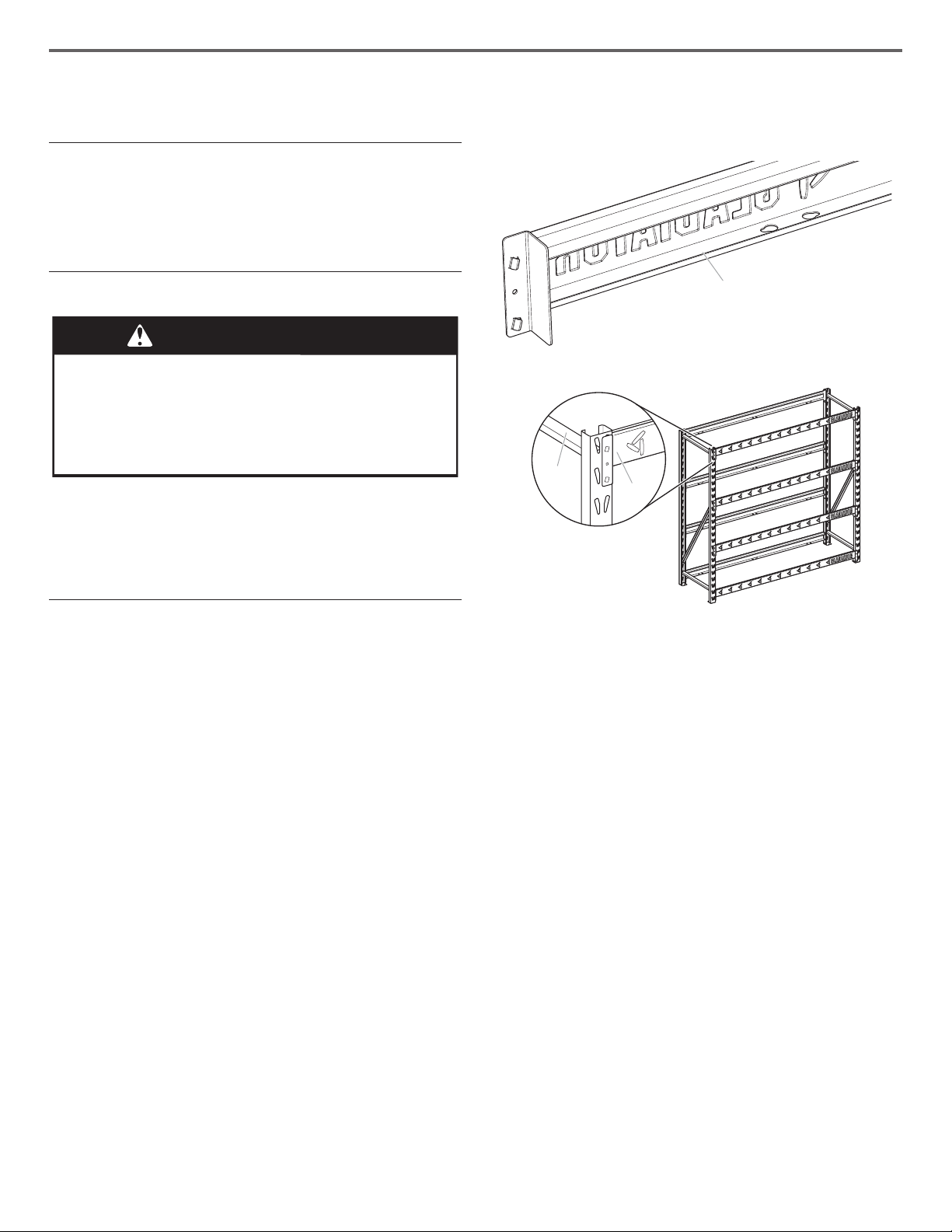

Support Beam Orientation

Unpack

WARNING

Excessive Weight Hazard

Use two or more people to move and assemble

shelving.

Failure to do so can result in back or other injury.

NOTE: Use two people to assemble shelving and to move it.

1. Remove and verify the contents. See the “Parts” section to

sort out all of the parts.

2. Dispose of/recycle all packaging materials.

Assemble & Complete

■ No tools or hardware required.

IMPORTANT:

■ Use two people to assemble shelving and to move it.

■ Determine shelf spacing before assembly.

NOTE: It is recommended to space the shelves equally from

top to bottom of the shelving unit and build it from the bottom

up. See the “End Frames/Support Beams” illustration.

■ Prior to assembly, refer to the sticker located on the bottom

of one of the welded-end frame assemblies (P4) and record

model and serial numbers on the included warranty page.

There are many benets of registering the product. Find out

more and register the product online at

www.gladiatorgarageworks.com.

In Canada, contact your Whirlpool Canada LP designated

service company or call 1-800-807-6777.

P2

P2 - Support beams

End Frames/Support Beams

P4

P2

P2 - Support beams (8)-4 in front, 4 in back

P4 - Welded-end frame assemblies (2)

NOTES:

■ It is recommended to put the rst shelf in slots 1 and 2 from

the bottom, the second shelf in slots 8 and 9 from the bottom,

the third shelf in slots 9 and 10 from the top, and the fourth

shelf in slots 1 and 2 from the top. Keep two of the shelves on

the bottom half of the shelving rack.

■ The tie channel supports (P3) provide load support and

structural integrity.

■ All tie channel supports (P3) must be assembled as shown in

the “Tie Channel Support Assembly” illustration.

5

Page 6

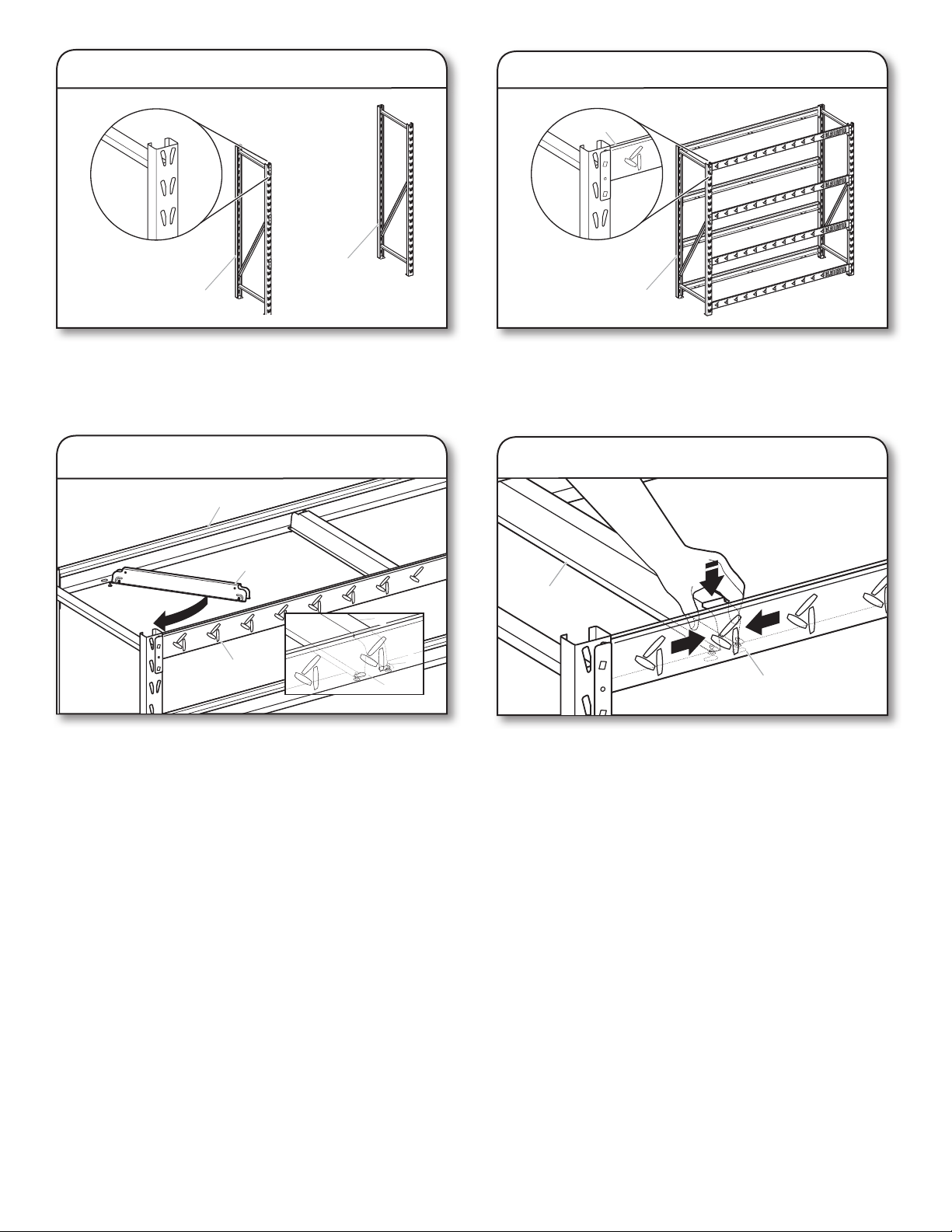

1. Assemble end frame

2. Align support beams

P2

P4

P4

Position the two welded-end frames (P4) vertical with the

foot end of each frame at ground level and prole slots facing

forward.

3. Assemble tie channel supports

P2

P3

A

P2

Rotate the tie channel support (P3) into the front and back

support beam (P2), aligning the tie channel rivet heads with

the matching large diameter hole of the support beam keyhole.

This shelving unit is equipped with one, two, or three tie

channel supports (P3) for each shelf, depending on the size of

the shelf unit.

NOTE: The tie channel supports (P3) provide load support

and structural integrity. All tie channel supports (P3) must be

assembled as shown.

B

C

P4

At the desired shelf location, align both of the support beam (P2)

end tabs with the inside triangular frame slots on the welded

frame (P4).

4. Insert rivet into keyhole

P3

P2

To insert the rivet head on the other side of the tie channel

support (P3), apply pressure to both sides of the tie channel

support (P3), squeezing the sides toward each other. Insert the

rivet head into the matching larger hole of the support beam

keyhole on the front and back support beam (P2). Release

pressure.

6

Page 7

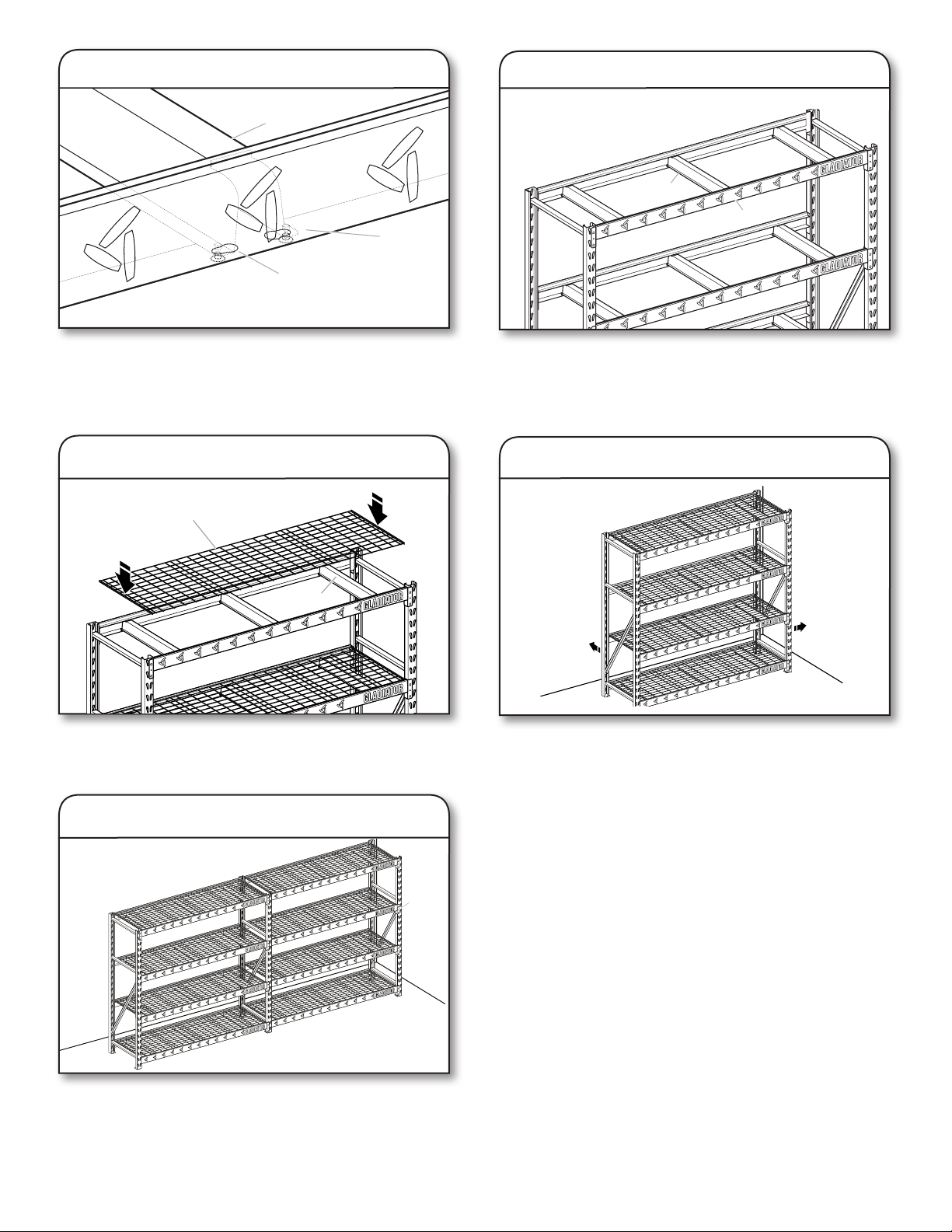

5. Check the rivets

P3

P2

Smaller

hole

6. Check all beams and tie channels

P3

P2

Check that the rivets are held behind the smaller hole of the

support beam keyholes. Repeat steps 4 and 5 for each tie

channel support.

7. Add wire shelves

P1

P3

Place the wire shelf (P1) on top of the tie channel supports (P3)

for each shelf. Make sure that the long rods of wire shelves are

at the bottom.

Verify that all support beams (P2) and tie channel supports

(P3) are properly assembled and rmly seated into the top and

bottom post slots.

8. Move shelving

Use two or more people to move the rack shelving to its nal

location.

9. Congure shelving

P4

Two or more racks of the same height and depth can be

connected by sharing the same welded-end frame (P4)

between them.

NOTE: Ensure there are at least two shelves per rack between

each set of welded-end frames (P4).

7

Page 8

WARRANTY

For warranty information:

In the U.S.A. call 1-866-342-4089 or visit our website at

www.GladiatorGW.com

In Canada call 1-800-807-6777 or visit our website at

www.gladiatorgarageworks.ca

8

Page 9

SÉCURITÉ DES ÉTAGÈRES MÉTALLIQUES

POURCHARGES LOURDES

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

Risque possible de décès ou de blessure grave si vous ne

DANGER

AVERTISSEMENT

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

Cette étagère de rangement doit être placée sur une surface plane.

REMARQUES:

■ Ne pas se tenir debout ou grimper sur l’étagère.

■ Ne pas charger excessivement.

DIMENSIONS

A 90po (229 cm) 72po (183 cm) 72po (183 cm) 72po (183 cm)

B 24po (61 cm) 24po (61 cm) 18po (46 cm) 18po (46 cm)

C 90po (229 cm) 77po (196 cm) 60po (152 cm) 48po (122 cm)

D 22po (56 cm) 22po (56 cm) 16po (41 cm) 16po (41 cm)

E 84 ½po (215cm) 72po (183 cm) 55po (139 cm) 43po (108 cm)

A

■ Répartir uniformément le poids sur chaque tablette, et ranger

les charges les plus lourdes sur la tablette du bas.

GARA904XIG

YGRA904X

GARB904XIG

GARS774XEG

GARS774SZG

GARM774XHG

GARS604TEG

YGRS604TGG

GARS604TKW

GARS484TEG

YGRS484TGG

GARS484TKW

E

C

B

D

9

Page 10

P4

PIÈCES

P1

P2

P4

P3

Étagère de 90po (229cm) de large

P1

P2

10

P3

Étagère de 77po (196cm) de large

P1—Tablettes métalliques (4)

P2—Poutres de support (8)—4 à l’avant, 4 à l’arrière

P3—Traverses en U (la quantité varie selon la taille)

P4—Cadres de montage dotés d’embouts soudés (2)

Page 11

P4

P1

P2

P4

P3

Étagère de 60po (152cm) de large

P1

P2

P3

Étagère de 48po (122cm) de large

P1—Tablettes métalliques (4)

P2—Poutres de support (8)—4 à l’avant, 4 à l’arrière

P3—Traverses en U (la quantité varie selon la taille)

P4—Cadres de montage dotés d’embouts soudés (2)

11

Page 12

INSTRUCTIONS D’INSTALLATION DE L’ÉTAGÈRE

MÉTALLIQUE POUR CHARGES LOURDES

Spécications d’utilisation

desétagères

Toutes les tailles d’étagères: La charge maximale de chaque

tablette est de 2000lb (907kg) et de 8000lb (3628kg) pour

l’étagère en entier.

Orientation des poutres de support

Déballage

AVERTISSEMENT

Risque du poids excessif

Utiliser deux ou plus de personnes pour déplacer et

assembler les étagères.

Le non-respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

REMARQUE: Il faut deux personnes pour assembler l’étagère et

la déplacer.

1. Retirer le contenu; vérier la présence de tous les composants.

Consulter la section “Pièces” pour trier toutes les pièces.

2. Éliminer/recycler tous les matériaux d’emballage.

Assemblage

■ L’assemblage ne requiert ni outil ni équipement.

IMPORTANT:

■ Il faut deux personnes pour assembler l’étagère et la déplacer.

■ Décider de l’emplacement de l’étagère avant de l’assembler.

REMARQUE: Il est recommandé de placer les tablettes à

une distance égale les unes des autres, du haut vers le bas,

etd’assembler l’étagère du bas vers le haut. Consulter la

gure “Bouts du cadre/Poutres de support”.

■ Avant l’assemblage, consulter l’autocollant situé sur la partie

inférieure de l’un des cadres de montage dotés d’embouts

soudés (P4) et noter les numéros de modèle et de série

sur la page de garantie incluse. Il y a plusieurs avantages

àenregistrer le produit. Pour obtenir plus de renseignements

et enregistrer le produit en ligne, consulter le

www.gladiatorgarageworks.com.

Au Canada, contactez votre compagnie de dépannage

désignée par Whirlpool Canada LP ou composez le

1-800-807-6777.

P2

P2 - Poutres de support

Bouts du cadre/Poutres de support

P4

P2

P2 - Poutres de support (8)—4 à l’avant, 4 à l’arrière

P4 - Cadres de montage dotés d’embouts soudés (2)

REMARQUES:

■ Il est recommandé de mettre la première tablette dans les

fentes 1 et 2 et la deuxième tablette dans les fentes 8 et 9 en

partant du bas; la troisième tablette dans les fentes 9 et 10 et

la quatrième tablette dans les fentes 1 et 2 en partant du haut.

Placer deux tablettes dans la moitié inférieure de l’étagère.

■ Les traverses en U (P3) fournissent le support de charge et

l’intégrité structurelle.

■ Toutes les traverses en U (P3) doivent être assemblées comme

illustré dans la gure “Assemblage des traverses en U”.

12

Page 13

1. Assemblage du cadre

2. Alignement des poutres de support

P2

P4

P4

Positionner les deux cadres dotés d’embouts soudés (P4) à la

verticale, de sorte que la base de chaque cadre est au niveau

du sol et les fentes sont orientées vers l’avant.

3. Assemblage des traverses en U

P2

P3

A

P2

Faire pivoter la traverse en U (P3) dans la poutre de support

à l’avant et à l’arrière (P2), en alignant les têtes de rivet de la

traverse en U avec le trou de grand diamètre correspondant de

la poutre de support. Cette étagère est équipée de une, deux

ou trois traverses en U (P3) pour chaque tablette, selon la taille

de l’étagère.

REMARQUE: Les traverses en U (P3) fournissent le support de

charge et l’intégrité structurelle. Toutes les traverses en U (P3)

doivent être assemblées comme illustré.

B

C

P4

À l’emplacement souhaité, aligner les deux onglets d’extrémité

de la poutre de support (P2) avec les fentes triangulaires internes

des cadres sur les cadres à embouts soudés (P4).

4. Insérer le rivet dans le trou

P3

P2

Pour insérer la tête du rivet de l’autre côté de la traverse en

U (P3), exercer une pression sur les deux côtés de la traverse

en U (P3), en comprimant les côtés l’un vers l’autre. Insérer la

tête du rivet dans le grand trou correspondant à l’avant et à

l’arrière de la poutre de support (P2). Relâcher la pression.

13

Page 14

5. Vérier les rivets

P3

P2

Petit

trou

6. Vérier toutes les poutres et

traverses en U

P3

P2

Vérier si les rivets sont posés derrière le plus petit des trous

de la poutre de support. Répéter les étapes 4 et 5 pour

chaque traverse en U.

7. Ajouter les tablettes métalliques

P1

P3

Placer la tablette métallique (P1) au dessus des traverses en

U (P3) de chaque tablette. S’assurer que les longues tiges des

tablettes métalliques sont en bas.

9. Conguration des étagères

Vérier que toutes les poutres de support (P2) et traverses en

U (P3) sont bien assemblées et enfoncées dans les fentes des

montants supérieurs et inférieurs.

8. Déplacer l’étagère

À l’aide d’au moins deux personnes, déplacer l’étagère à son

emplacement nal.

P4

Au moins deux étagères de la même taille et de la même

profondeur peuvent être reliées en partageant le même

cadrede montage à embout soudé (P4) entre elles.

REMARQUE: Vérier qu’il existe au moins deux tablettes

par étagère entre chaque ensemble de cadres de montage

àembouts soudés (P4).

14

Page 15

GARANTIE

Pour des informations sur la garantie :

Aux États-Unis, composer le 1-866-342-4089 ou visiter notre site Web à l’adresse

www.GladiatorGW.com

Au Canada, composer le 1-800-807-6777 ou visiter notre site Web à l'adresse

www.gladiatorgarageworks.ca

15

Page 16

SEGURIDAD DE LA ESTANTERÍA DE METAL

DEALTARESISTENCIA

Su seguridad y la seguridad de los demás es muy importante.

Hemos incluido muchos mensajes importantes de seguridad en este manual y en su electrodoméstico. Lea y obedezca siempre

todos los mensajes de seguridad.

Este es el símbolo de alerta de seguridad.

Este símbolo le llama la atención sobre peligros potenciales que pueden ocasionar la muerte o una lesión a

usted y a los demás.

Todos los mensajes de seguridad irán a continuación del símbolo de advertencia de seguridad y de la palabra

“PELIGRO” o “ADVERTENCIA”. Estas palabras significan:

PELIGRO

ADVERTENCIA

Todos los mensajes de seguridad le dirán el peligro potencial, le dirán cómo reducir las posibilidades de sufrir una lesión y lo que

puede suceder si no se siguen las instrucciones.

Esta unidad de estantería de almacenamiento debe colocarse en

una supercie nivelada.

NOTAS:

■ No se pare ni suba en la unidad.

Si no sigue las instrucciones de inmediato, usted puede

morir o sufrir una lesión grave.

Si no sigue las instrucciones, usted puede morir o sufrir

una lesión grave.

■ No la sobrecargue.

■ Distribuya uniformemente el peso en cada estantería y

mantenga las cargas más pesadas en la estantería más baja.

DIMENSIONES

GARA904XIG

YGRA904X

GARB904XIG

A 90" (229cm) 72" (183cm) 72" (183cm) 72" (183cm)

B 24" (61cm) 24" (61cm) 18" (46cm) 18" (46cm)

C 90" (229cm) 77" (196cm) 60" (152cm) 48" (122cm)

D 22" (56cm) 22" (56cm) 16" (41cm) 16" (41cm)

E 84½" (215cm) 72" (183cm) 55" (139cm) 43" (108cm)

A

GARS774XEG

GARS774SZG

GARM774XHG

GARS604TEG

YGRS604TGG

GARS604TKW

GARS484TEG

YGRS484TGG

GARS484TKW

16

E

C

B

D

Page 17

P4

PIEZAS

P1

P2

P4

P3

Estantería ancha de 90" (229cm)

P1

P2

P3

Estantería ancha de 77" (196cm)

P1: Estantes de alambre (4)

P2: Vigas de soporte (8); 4 al frente, 4 atrás

P3: Fijaciones por canal de enlace (la cantidad varía

según el tamaño)

P4: Ensamblajes de marco soldado (2)

17

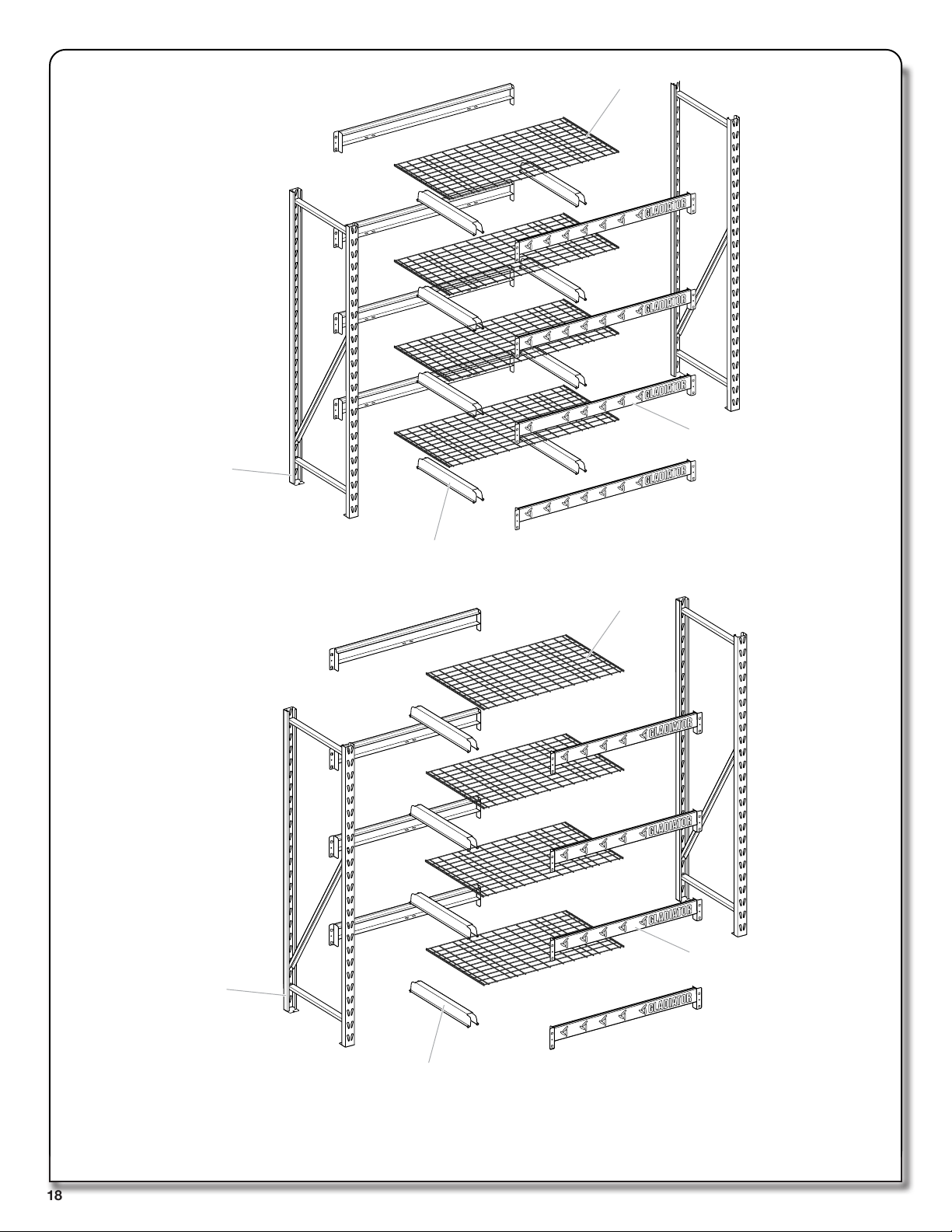

Page 18

P4

P1

P2

P4

P3

Estantería ancha de 60" (152cm)

P1

P2

18

Estantería ancha de 48" (122cm)

P1: Estantes de alambre (4)

P2: Vigas de soporte (8); 4 al frente, 4 atrás

P3

P3: Fijaciones por canal de enlace (la cantidad varía

según el tamaño)

P4: Ensamblajes de marco soldado (2)

Page 19

INSTRUCCIONES DE INSTALACIÓN DE LA ESTANTERÍA

DE METAL DE ALTA RESISTENCIA

Orientación de las vigas de soporte

Requisitos de uso de

laestantería

Estanterías de todos los tamaños: El límite de peso máximo es

de 2000lb (907kg) para cada estante; no exceda las 8000lb

(3628kg) para la estantería completa.

Desempaque

ADVERTENCIA

Peligro de Peso Excesivo

Use dos o más personas para mover y ensamblar

la estantería.

No seguir esta instrucción puede ocasionar una

lesión en la espalda u otro tipo de lesiones.

NOTA: Se necesitan dos personas para ensamblar la estantería y

para moverla.

1. Desempaque y verique el contenido. Consulte la sección

“Piezas” para familiarizarse con las piezas.

2. Deseche o recicle todo el material de embalaje.

Ensamble y complete

■ No se requieren herramientas ni equipamiento.

IMPORTANTE:

■ Se necesitan dos personas para ensamblar la estantería y

para moverla.

■ Determine el espacio disponible antes de ensamblar.

NOTA: Se recomienda dejar un espacio equivalente entre los

estantes desde la parte superior a la inferior de la estantería y

construir desde abajo hacia arriba. Vea la ilustración “Marcos

externos/vigas de soporte”.

■ Antes del ensamblaje, consulte la etiqueta adhesiva ubicada

en la parte inferior de uno de los ensamblajes de marco

soldado (P4) y anote los números de modelo y serie en la

página de garantía incluida. Registrar el producto ofrece

muchos benecios. Obtenga más información y registre

elproducto en línea en

www.gladiatorgarageworks.com.

En Canadá, póngase en contacto con su compañía de

servicio designada de Whirlpool Canada LP o llame al

1-800-807-6777.

P2

P2 - Vigas de soporte

Marcos externos/vigas de soporte

P4

P2

P2 - Vigas de soporte (8); 4 al frente, 4 atrás

P4 - Ensamblajes de marco soldado (2)

NOTAS:

■ Se recomienda poner el primer estante en las ranuras 1 y

2 desde la parte inferior, el segundo en las ranuras 8 y 9

desdela parte inferior, el tercero en las ranuras 9 y 10 desde

la parte superior, y el cuarto en las ranuras 1 y 2 desde la

parte superior. Mantenga dos estantes en la mitad inferior de

la estantería.

■ Las jaciones por canal de enlace (P3) ofrecen soporte de

carga e integridad estructural.

■ Todas las jaciones por canal de enlace (P3) deben

ensamblarse como se muestra en la ilustración

“Ensamblajede jación por canal de enlace”.

19

Page 20

1. Ensamble el marco extremo

P4

2. Alinee las vigas de soporte

P2

P4

Ubique los dos marcos ensamblajes de marco soldado(P4) de

forma vertical con el pie de cada marco a nivel de suelo y las

ranuras de los perles mirando hacia adelante.

3. Ensamble las jaciones por canal

deenlace

P2

P3

A

P2

Gire la jación por canal de enlace (P3) en la viga de soporte

frontal y trasera (P2), alineando los cabezales de los remaches

con el oricio de diámetro amplio correspondiente de la entalla

de la viga de soporte. Esta estantería está equipada con uno,

dos o tres jaciones por canal de enlace (P3) por estante,

según el tamaño de la estantería.

NOTA: Las jaciones por canal de enlace (P3) ofrecen soporte

de carga e integridad estructural. Todas las jaciones por canal

(P3) deben ensamblarse como se muestra.

B

C

P4

En la ubicación deseada para la estantería, alinee las pestañas

de la viga de soporte (P2) con las ranuras del marco triangular

interno en el marco soldado (P4).

4. Inserte el remache en la ranura con

forma de bocallave

P3

P2

Para insertar el cabezal del remache en el otro lado de la

jación por canal (P3), aplique presión en ambos lados de

las jaciones por canal (P3), apretando los lados el uno hacia

el otro. Inserte el cabezal del remache en el oricio grande

correspondiente del entalle de la viga de soporte en la viga

desoporte frontal y trasera (P2). Libere la presión.

20

Page 21

5. Revise los remaches

P3

6. Revise todas las vigas y los canales

de enlace

P3

Agujero

pequeño

P2

Revise que los remaches estén jados detrás del oricio

pequeño de los entalles de las vigas de soporte. Repita los

pasos 4 y 5 para cada jación por canal.

7. Agregue los estantes de alambre

P1

P3

P2

Verique que todas las vigas de soporte (P2) y las jaciones

por canal de enlace (P3) estén ensambladas adecuadamente

y descansen rmemente en las ranuras superior e inferior

delposte.

8. Mover las estanterías

Ubique el estante de alambre (P1) sobre las jaciones por canal

de enlace (P3) para cada estante. Asegúrese que las varillas

largas de los estantes de alambre estén en la parte inferior.

9. Armado de las estanterías

P4

Se pueden unir dos o más canastas de la misma altura y

profundidad compartiendo el mismo ensamblaje de marco

soldado (P4) entre ellas.

NOTA: Asegúrese de que haya al menos dos estantes por

canasta entre cada juego de ensamblaje de marco soldado (P4).

Entre dos o más personas, mueva la estantería a su ubicación

denitiva.

21

Page 22

GARANTÍA

Para obtener información sobre la garantía:

En EE. UU., llame al 1-866-342-4089 o visite nuestro sitio web en

www.GladiatorGW.com

En Canadá, llame al 1-800-807-6777 o visite nuestro sitio web en

www.gladiatorgarageworks.ca

22

Page 23

NOTES

23

Page 24

W11320048D

®

/™ ©2020 Gladiator. All rights reserved. Used under license in Canada.

Tous droits réservés. Utilisé sous licence au Canada.

Todos los derechos reservados. Usado en Canadá bajo licencia.

Printed in U.S.A.

06/20

Imprimé aux É.-U.

Impreso en EE. UU.

Loading...

Loading...