TODAY’S CLAY PIPE BUILT FOR TOMORROW

VITRIFIED CLAY PIPE

GLADDING MCBEAN

www.gladdingmcbean.com

3

Gladding, McBean is a specialty manufacturer of Vitrified Clay Pipe

products which are used by contractors and agencies throughout the world.

Our state-of-the-art manufacturing processes and technology produces a

ceramic product which has great strength, high density and water tight

jointing. Vitrified Clay Pipe is the most inert of all sanitary sewer pipe

materials. It does not have gradual reduction in strength over time as with

resin type products. Chemical resistance likewise does not deteriorate.

Vitrified Clay Pipe is the only pipe which offers both a design and service

life exceeding 100 years.

We have shown standard stock items herein. We typically manufacture

non-stock items and non-standard sizes by special order. Please contact our

staff for specific dimension information as all dimensions shown herein are

subject to change without notice.

Our mission is to provide the optimum level of value, service and quality

products to our customers. Our experienced and knowledgeable staff are

here to assist in the design and/or installation of your projects.

Introduction

4

Standard Bell & Spigot

Nominal

Pipe Size

4"

6"

8"

10"

12"

15"

18"

21"

24"

27"

30"

33"

36"

39"

42"

Standard Lengths

1', 2', 4'

1', 2', 5'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 5.5'

1', 2', 5.5'

MINIMUM 3-EDGE BEARING STRENGTH

SSPWC "Green Book"

Extra Strength

lb.f/ (kN/

linear ft. linear m)

2000 (29.2)

2000 (29.2)

2200 (32.1)

2400 (35.0)

2600 (37.9)

3100 (45.2)

3600 (52.5)

4200 (61.3)

4800 (70.2)

5200 (75.9)

5500 (80.3)

5800 (84.6)

6300 (91.9)

6600 (96.3)

7000 (102.2)

ASTM C-700

Extra Strength

lb.f/ (kN/

linear ft. linear m)

2000 (29.2)

2000 (29.2)

2200 (32.1)

2400 (35.0)

2600 (37.9)

2900 (42.3)

3300 (48.2)

3850 (56.2)

4400 (64.2)

4700 (68.6)

5000 (73.0)

5500 (80.3)

6000 (87.6)

6600 (96.3)

7000 (102.2)

SSPWC "Green Book"

High Strength

lb.f/ (kN/

linear ft. linear m)

2000 (29.2)

2200 (32.1)

2400 (35.0)

2600 (37.9)

2900 (41.7)

3400 (49.7)

4000 (57.8)

4600 (67.4)

5300 (77.2)

5700 (83.3)

6100 (88.3)

6400 (93.0)

6900 (101.1)

7300 (105.9)

7700 (112.4)

D1

4"

6"

8"

10"

12"

15"

18"

21"

24"

27"

30"

33"

36"

39"

42"

L

1', 2', 4'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 6'

1', 2', 5.5'

1', 2', 5.5'

Weight plf

11 lb

21 lb

30 lb

44 lb

54 lb

90 lb

141 lb

168 lb

230 lb

290 lb

333 lb

415 lb

445 lb

540 lb

603 lb

D2

5.3125"

7.87"

10.02"

12.47"

14.52"

18.30"

21.87"

25.78"

28.85"

32.77"

36.06"

39.52"

43.01"

46.42"

50.17"

T1

.6875"

7.87"

.98"

1.10"

1.26"

1.71"

2.03"

2.36"

2.47"

2.99"

3.13"

3.23"

3.68"

3.66"

4.06"

D3

6.5"

9.05"

11.49"

14.07"

15.96"

20.30"

23.90"

27.78"

30.78"

34.92"

38.26"

41.74"

45.77"

49.66"

53.18"

D4

7.625"

10.43"

13.09"

15.87"

18.51"

22.96"

24.47"

30.78"

34.06"

38.26"

42.18"

46.43"

49.93"

54.83"

58.50"

T2

.5"

0.67"

0.78"

0.92"

0.99"

1.28"

1.50"

1.60"

1.71"

1.76"

2.02"

2.27"

2.27"

2.49"

2.55"

D5

1.5"

2.33"

2.31"

2.61"

2.84"

2.81"

3.22"

3.73"

3.67"

3.97"

3.90"

4.14"

4.05"

4.10"

4.67"

NOTE: 1. The above dimensions are average measurements and do not reflect the actual tolerances.

2. The above weights are average weights and do not reflect the actual tolerances.

3. The above pipe lengths are standard stock lay lengths. We also regularly manufacture custom lengths.

D2

D1

T1

T2

D3D5D4

L

5

Standard Perforated Pipe

Standard

Lengths

1', 2', 4'

1', 2', 5'

1', 2', 6'

1', 2', 6'

1', 2', 6'

Approximate

Wei gh t

11 lb

21 lb

30 lb

44 lb

54 lb

MINIMUM 3-EDGE BEARING STRENGTH

ASTM C-700 Extra Strength

lb.f/linear ft. (kN/linear m)

2000 (29.2)

2000 (29.2)

2200 (32.1)

2400 (35.0)

2600 (37.9)

Nominal

Pipe Size

4"

6"

8"

10"

12"

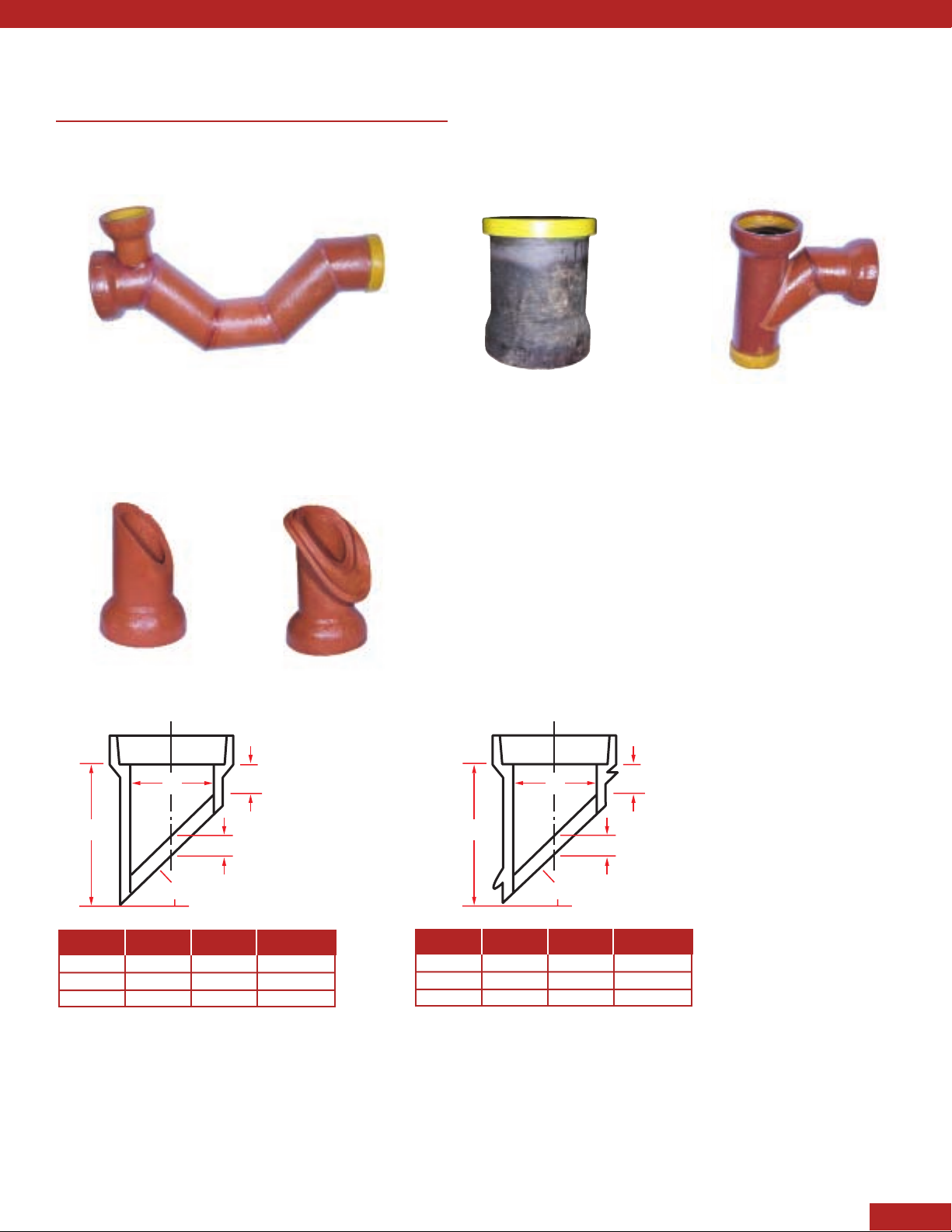

Available in 4" - 42". Mitered bends having a 1/16 bend (or 22-1/2°) are available in 6" - 42".

Mitered 1/8 or 45° BendMitered 1/4 or 90° Bend

Bends

D

6"

8"

10"

12"

15"

18"

21"

24"

37"

30"

33"

36"

39"

42"

A

6-1/4"

7-5/8"

8-5/8"

9-3/4"

12-3/4"

14"

16"

18"

20-1/2"

22"

23-7/8"

25-5/8"

28"

29-3/4"

B

8-1/2"

8"

9"

9-3/4"

11-5/8"

14"

16"

18"

20-1/2"

22"

23-7/8"

25-5/8"

28"

29-3/4"

C

3-1/4

3-5/8"

3-5/8"

3-7/8"

5"

5"

5-1/2"

6"

6-1/2"

7"

7-1/2"

8"

8-1/2"

9"

E

4"

4"

4"

4"

4"

5"

5-1/2"

6"

6-1/2"

7"

7-1/2"

8"

8-1/2"

9"

F

7-7/8"

10"

12-1/2"

14-1/2"

18-1/4"

21-7/8"

25-1/2"

29"

33-3/4"

36"

39-1/2"

42-5/8"

47"

50-1/4"

G

7-1/2"

8"

11-1/2"

12-5/8"

19-1/8"

23"

26-5/8"

30"

34-1/2"

36-3/4"

40-1/4"

43-1/4"

47-1/2"

50-1/2"

H

9-1/4"

9-1/4"

10-1/4"

11-3/4"

17-1/8"

19-1/2"

22-1/8"

24-1/2"

28"

30-1/4"

32-5/8"

35"

37-1/2"

40-1/2"

I

8"

8"

8-5/8"

9-3/4"

12-3/4"

14"

16"

18"

20-1/2"

22"

23-7/8"

25-5/8"

28"

29-3/4"

J

8"

9-1/4"

10-1/4"

11-3/4"

17"

19-1/2"

22-1/8"

24-3/4"

28"

30-1/4"

32-5/8"

35"

37-1/2"

40-1/2"

K

12"

14-1/4"

16-1/4"

19-1/4"

26-1/8"

30-1/2"

34-7/8"

39-1/4"

44-7/8"

48-1/4"

52-3/8"

56-3/8"

61"

63-1/4"

A

H

J

K

G

I

D

E

A

B

1/8 BEND

C

D

F

E

6

Wye Reverse Wye

Available in 4" - 42". Branches are made approximately 45° to the barrel. Standard wyes 4" - 21" shown below.

Wyes

D1&D2

4"

6"

6"

8"

8"

8"

10"

10"

10"

10"

12"

12"

12"

12"

12"

15"

15"

15"

15"

15"

18"

18"

18"

18"

18"

21"

21"

21"

21"

21"

D3

4"

4"

6"

4"

6"

8"

4"

6"

8"

10"

4"

6"

8"

10"

12"

6"

8"

10"

12"

15"

6"

8"

10"

12"

15"

6"

8"

10"

12"

15"

A

11"

12-5/16"

14-5/16"

13-3/8"

15-3/8"

16-7/8"

14-3/8"

16-3/8"

18-3/8"

20-3/8"

15-3/4"

17-5/8"

19-5/8"

21-5/8"

23-1/8"

19-5/8"

21-5/8"

22-1/8"

25-1/8"

26-5/8"

21-7/8"

23-7/8"

25-7/8"

26-7/8"

29-7/8"

23-7/8"

25-7/8"

27-7/8"

29-7/8"

30-7/8"

B

9-11/16"

11-1/2"

12-9/16"

13"

14"

15-1/8"

14-9/16"

15-5/8"

16-3/4"

18-3/8"

16-1/4"

17-1/4"

19"

20"

21-3/8"

19-7/8"

21"

22-5/8"

24"

25-7/8"

22-11/16"

23-13/16"

25-7/16"

26-13/16"

28-11/16"

25-1/16"

26-3/16"

27-13/16"

29-3/16"

31-1/16"

Barrel

Diameter

24"

24"

24"

24"

24"

27"

27"

27"

27"

27"

30"

30"

30"

30"

30"

33"

33"

33"

33"

33"

36"

36"

36"

36"

36"

39"

39"

39"

39"

39"

Spur

Diameter

6"

8"

10"

12"

15"

6"

8"

10"

12"

15"

6"

8"

10"

12"

15"

6"

8"

10"

12"

15"

6"

8"

10"

12"

15"

6"

8"

10"

12"

15"

A

25-5/8"

27-5/8"

29-1/8"

31-1/8"

32-1/8"

28-1/8"

30-1/8"

31-5/8"

33-5/8"

34-5/8"

30-1/8"

32-1/8"

34-1/8"

35-5/8"

36-1/8"

32-1/2"

34"

36"

37-1/2"

37-1/2"

34-1/2"

36-1/2"

38-1/2"

39"

39"

36-3/8"

38-3/8"

40-3/8"

41-3/8"

41-3/8"

B

27-5/8"

28-3/4"

30-3/8"

31-3/4"

33-5/8"

30-1/8"

31-1/4"

32-7/8"

34-1/4"

36-1/8"

32-7/16"

33-1/2"

35-1/4"

36-1/2"

38-7/16"

34-7/8"

36"

37-5/8"

39"

40-7/8"

37-3/16"

38-5/16"

39-15/16"

41-5/16"

43-3/8"

40"

41-1/8"

42-3/4"

44-1/8"

46"

D

2

A

D

D

3

B

1

7

Available in 4" - 42". Branches are made approximately 90° to the barrel. Standard tees 4" - 21" shown below.

Te e

Double Tee

Tees

D1&D2

4"

6"

6"

8"

8"

8"

10"

10"

10"

10"

12"

12"

12"

12"

12"

15"

15"

15"

15"

15"

18"

18"

18"

18"

18"

21"

21"

21"

21"

21"

D3

4"

4"

6"

4"

6"

8"

4"

6"

8"

10"

4"

6"

8"

10"

12"

6"

8"

10"

12"

15"

6"

8"

10"

12"

15"

6"

8"

10"

12"

15"

A

6"

6-1/16"

7-1/16"

6-3/8"

7-3/8"

8-3/8"

6-3/8"

7-7/8"

8-7/8"

9-7/8"

6-5/8"

8-1/8"

9-1/8"

10-1/8"

11-1/8"

8-1/8"

9-1/8"

10-1/8"

11-5/8"

13-1/8"

8-3/8"

9-3/8"

10-3/8"

11-7/8"

12-7/8"

8-3/8"

9-3/8"

10-7/8"

11-7/8"

13-3/8"

B

6-1/16"

7-5/16"

7-1/8"

8-3/8"

8-3/16"

8-1/4"

9-1/2"

9-5/16"

9-3/8"

9-7/8"

10-5/8"

10-7/16"

10-1/2"

11"

11-1/4"

12-5/16"

12-3/8"

12-7/8"

13-1/8"

13-1/8"

14-5/16"

14-3/8"

14-7/8"

15-1/8"

15-1/8"

16"

16-1/16"

16-9/16"

16-13/16"

16-13/16"

D1&D2

24"

24"

24"

24"

24"

27"

27"

27"

27"

27"

30"

30"

30"

30"

30"

33"

33"

33"

33"

33"

36"

36"

36"

36"

36"

39"

39"

39"

39"

39"

D3

6"

8"

10"

12"

15"

6"

8"

10"

12"

15"

6"

8"

10"

12"

15"

6"

8"

10"

12"

15"

6"

8"

10"

12"

15"

6"

8"

10"

12"

15"

A

8-5/8"

9-5/8"

11-1/8"

12-1/8"

14-1/8"

9-1/8"

10-5/8"

11-5/8"

12-5/8"

14-1/8"

9-5/8"

10-5/8"

11-5/8"

13-1/8"

14-5/8"

10"

11"

12"

13"

15"

10-1/2"

11-1/2"

12-1/2"

13-1/2"

15-1/2"

10-7/8"

11-7/8"

12-7/8"

13-7/8"

15-7/8"

B

17-13/16"

17-7/8"

18-3/8"

18-5/8"

18-5/8"

19-9/16"

19-5/8"

20-1/8"

20-3/8"

20-3/8"

21-3/16"

21-1/4"

21-3/4"

22"

22"

22-15/16"

23"

23-1/2"

23-3/4"

23-3/4"

24-9/16"

24-5/8"

25-1/8"

25-3/8"

25-3/8"

26-9/16"

26-5/8"

27-1/8"

27-3/8"

27-3/8"

D

2

D

A

D

3

B

8

Available in 4" - 42". Branches are made approximately 45 degrees to the barrel. Dimensions for 4" - 8" are

shown below.

Double Wyes

D1

4"

6"

6"

8"

D2

4"

6"

6"

8"

D3

4"

4"

6"

6"

A

11"

12-5/16"

14-5/16"

15-3/8"

B

9-11/16"

11-1/2"

12-1/2"

14"

NOTE: Dimensions A and B are approximate.

Double Wye

D

4"

Rc

17"

L

10"

D

4"

Rc

10-1/4"L13-1/2"

D

4"

Rc

9-1/2"

L

26"

Available in 4" only.

Sweep 1/16 or 22°Sweep 1/4 or 90° Sweep 1/8 or 45° Bend

Sweeps

D

2

A

D

3

B

D

1

L

D

Rc

L

D

Rc

Rc

D

L

9

Available in 4" - 42". Dimensions for 4" - 8" shown below.

Increasers

4" x 6", 6" x 8", 8" x 10" IncreaserIncreaser

Available in 4" - 42". Dimensions for 4" - 8" shown below.

Reducer

Reducers

D1

4"

6"

8"

D2

6"

8"

10"

A

7"

7"

7"

B

12"

15"

18"

D1

4"

6"

8"

D2

6"

8"

10"

A

6-1/8"

17-1/2"

17-3/8"

B

8"

19-3/4"

20"

Used to join plain-end rubber coupling pipe to the

bell end of SPEED-SEAL.

Transitional Stubs

Used to join 4" plain-end rubber coupling pipe to the

bell end 6" SPEED-SEAL.

Transitional Increaser Stubs

D

2

B

D

1

A

A

D

1

D

2

B

10

Poly cap stoppers are not recommended in areas subject

to ground water.

Polycap Stopper

(4" thru 8")

Clay Stopper

(8" thru 24")

Stoppers

Tee Saddles

Square Base Tee Saddle

(Available in 4" & 6" only)

Collar Tee SaddlePlain Tee Saddle

Drop Manhole Double TeeDrop Manhole Tee Drop Manhole 1/4 Bend

Specialty Items

11

Handhole Trap

Specialty Items

D

4"

6"

8"

A

1-1/2"

2"

2-1/2"

B

1-1/2"

1-1/2"

1-1/2"

C

6-1/2"

9"

12"

D

4"

6"

8"

A

2-1/2"

3"

3-1/2"

B

1-1/2"

1-1/2"

1-1/2"

C

6-1/2"

9"

12"

Plain Wye Saddle

Collar Wye Saddle

Wye-Tee Combination

Alternate Pipe VCP Connections

A

B

B

A

C

D

C

45º

D

45º

12

Specifications

The Vitrified Clay Pipe products manufactured by Gladding, McBean are designed to exceed all applicable

requirements of both the ASTM Standards and the “GREENBOOK" Standard Specifications for Public

Works Construction.

Below is a table depicting a synopsis of specifications applicable to Vitrified Clay Pipe products. Please contact

our staff to request additional information or to obtain a copy of any standard.

SYNOPSIS OF SPECIFICATIONS APPLICABLE

TO VITRIFIED CLAY PIPE PRODUCTS

"Green Book"

SSPWC

Section 207-8

Section 208-2.3

Section 207-8.5

Item

1. Specification for strength.

2. Specification for compression joints.

3. Specification for perforated pipe.

4. Standard test methods.

5. Standard installation practice.

ASTM

C700

C425

C700

C301

C12

AASHTO

M65

M65

Used for the joining of regular or field-cut plain-end vitrified clay pipe to same.

Sewer Repair Coupling

Available with outside stainless steel shear

ring sizes 4" - 42".

Rubber Coupling

Available in sizes 4" - 12".

Banded Rubber Couplings

Torque Wrench

Non-adjustable torque wrench factory set to

60 inch pounds. Accommodates both 5/16

and 3/8 inch fasteners.

Used in combination with banded rubber couplings for transitions. From Plain-end vitrified clay pipe

to ductile iron pipe, cast iron pipe (CI), PVC pipe (PL) or ABS. Available in sizes 4" - 12".

Transitional Bushings For Rubber Couplings

13

When it is necessary to use curvilinear alignment due to terrain or to avoid existing

structures, the following design and installation criteria may be safely employed:

R =

360 degrees

Ø degrees

X

L

2 π

Ø = Allow deflection angle per joint

L = Length of pipe

R = Minimum Radius of curvature

The design and installation of curved sewer pipelines is common. Bends and curves to accommodate both grade

and alignment changes are commonly accomplished by the deflection of straight pipe or by the use of mitered

bends, beveling the joints or any combination thereof.

We manufacture mitered bends in sizes 4" to 42" to accommodate any change in angle designed by the engineer.

The deflection of standard straight pipe generally provides the required change in grade or alignment. Utilizing

shorter pipe lengths decreases the allowable radius. We are providing the following to assist you in such designs.

Curved Sewer Installations

NOMINAL

PIPE SIZE

MAX. DEFL. AT

EACH JOINT

APPROX. MAX.

DEFL./FT. OF PIPE

MINIMUM RADIUS OF CURVATURE - FEET

6' PIPE LENGTH 5-1/2' PIPE

LENGTH

5' PIPE LENGTH

4" - 12"

15" - 24"

27" - 36"

39" - 42"

4-1/2' PIPE

LENGTH

4' PIPE LENGTH 3' PIPE LENGTH 2' PIPE LENGTH

2.39°

1.79°

1.21°

0.92°

NOTE: When Ø is maximum R will be minimum.

1/2"

3/8"

1/4"

3/16"

144'

192'

288'

N/A

132'

176'

264'

352'

120'

160'

240'

320'

108'

144'

213'

280'

96'

128'

189'

249'

72'

96'

142'

187'

48'

64'

95'

125'

14

Our SPEED-SEAL joints are manufactured from a proprietary design and protected by a registered

trademark. SPEED-SEAL is composed of a two part polyurethane mixture, factory applied to the ends of

our pipe. The spigot part of the joint has a smooth surface, whereas the bell portion has a raised ridge.

Our joints are designed not to leak as required by ASTM C 425. We regularly check our joints by an

internal hydrostatic test of 10 psig.

We provide a vegetable lubricant to be used when inserting the spigot into the bell. When lubricated

and pushed together, the ridge portion of the bell and the spigot casting deform assuring you of a leakproof

design by giving a predicted, residual compression around the full circumference of the seal.

Our polyurethane formulation is impervious to detergents, acids, alkalis and gasses normally present in

sanitary sewer lines.

Pipe Joints

We provide a vegetable based soap lubricant for use during the assembly of our SPEED-SEAL joints. The

lubricant should be applied full strength to each joint surface immediately prior to assembly, following the

removal of all dirt and debris.

SPEED-SEAL Lubricant

Gladding McBean, in addition to being a

manufacturer of Vitrified Clay Pipe, provides

professional support to the engineering community

and is a resource for technical information during

both the design and construction of your project.

We will assist agencies with the identification and

resolution of construction issues and/or provide

information to the contractor to assist in the proper

installation of our products.

Engineering Services

Please contact our Engineering Services Department

to arrange a tour of our manufacturing plant located

in Lincoln, California.

Plant Tours

Gladding McBean primarily utilizes Material

Transport for the on-time delivery of our products

throughout the western United States.

Delivery of Pipe

Northern California

601 7th Street

Lincoln, CA 95648

Phone: (916) 645-3341

Fax: (916) 645-9538

Southern California

4301 Firestone Blvd.

South Gate, CA 90280

Phone: (323) 568-1860

Fax: (323) 564-7874

3725 Temescal Canyon Rd.

Corona, CA 92883

Phone: (951) 277-4466

Fax: (951) 277-2491

www.gladdingmcbean.com

G043 2,500 CP 8/24/06

Loading...

Loading...