GKS Perfekt 320833 User Manual

OPERATING AND MAINTENANCE INSTRUCTIONS No. 09 / 2011FOR GKS-PERFEKT

TOE JACK MODEL V

GKS NA-OMI Jacks 2011 Cover Page

GKS Hydraulic Jacks, e.g. Type V10

OPERATING AND MAINTENANCE INSTRUCTIONS No. 09/2011 FOR GKS-PERFEKT

TOE JACK MODEL V

KEEP THE OPERATING INSTRUCTIONS ALWAYS CLOSE WITH YOU !

Please read these instructions carefully

before using the jack!

TEST CERTIFICATES

ANSI / ASME

SALES AND SERVICE

GKS-PERFEKT LIFTING AND MOVING SOLUTIONS

LLC

300 E. Auburn Avenue

Springfield, OH 45505

USA

phone: +1 (937) 324 - 8867

fax: +1 (937) 324 - 8171

e-mail: info@gksweb.com

website: www.gksweb.com

GKS NA-OMI Jacks 2011 Page 1/11

CONTENTS

Contents

I. General information/Technical data

II. What to do before operation

III. How to operate the jack correctly

IV. What to check during operation

V. Sources of operating errors

VI. Safety instructions

VII. Storage and maintenance

VIII. Troubleshooting

IX. Extras: Separate hydraulic pump and QUADRO

X. Other tips

XI. EC Declaration of Conformity/Specifications

CONTENTS

page

1

2

3

3/4

5

6

7

8

9

10

11

11

TOE JACK MODEL V

OPERATING AND MAINTENANCE INSTRUCTIONS No. 09/2011 FOR GKS-PERFEKT

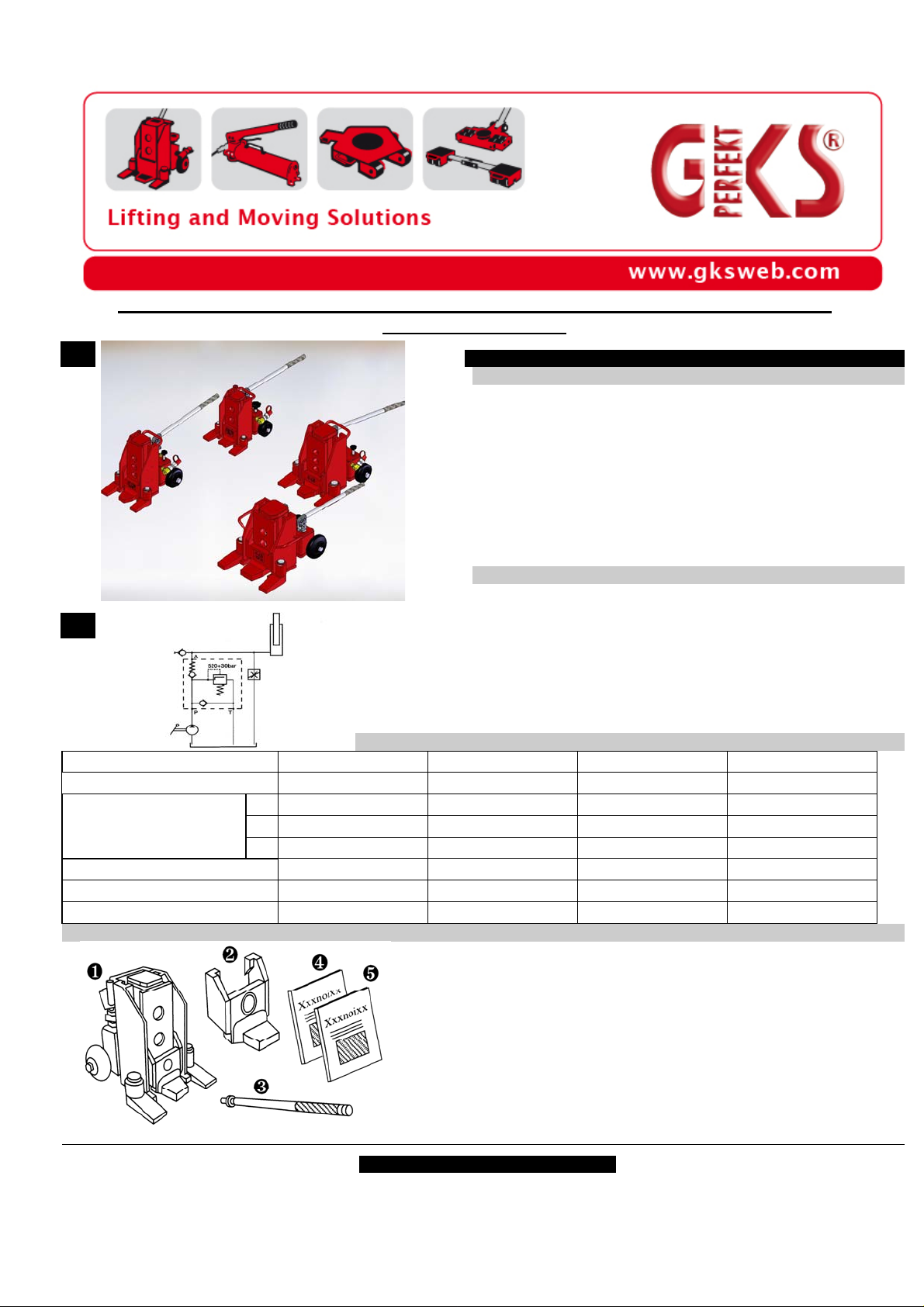

A

V10

B

V 5

V15

V20

Jacks designated Type V are designed for vertical lifting of machines

and loads.

Max. operating pressure: 7542 psi (+ 435 psi) [520 + 30 bar]

When the pump lever is manually operated, oil is routed from the tank

into the lifting cylinder which then moves vertically to the top of the

slides, and thereby lifts the load resting on the lifting toe (see diagram).

Upon reaching the maximum operating pressure of 7542 psi (+435 psi)

an integral safety valve opens to prevent lifting of loads heavier than

the specified lifting capacity. Opening the discharging screw allows oil

to flow back into the tank, the lifting piston returns to its lowest position

and the load is lowered

Jack type V5 V10 V15 V20

Total lifting cap. in lbs (t) 11,000 (5) 22,000 (10) 33,000 (15) 44,000 (20)

Dimensions in inch (mm)

W 8 ½ (210) 9 ½ (240) 11 (278) 12 ½ (320)

H 10 (255) 12 (310) 12 (310) 12 ½ (325)

Oil capacity in gall. (l) 1/16 (0.25) 1/8 (0.6) 1/4 (1.0) 1/3 (1.3)

Weight approx. in lbs ( kg) 46 (21) 70 (32) 116 (53) 159 (72)

Article-no. 10181 10182 10183 10184

L 10 ½ (260) 12 ½ (320) 14 (353) 18 (455)

SCHEDULE OF PARTS SUPPLIED

1. Jack assembly complete

2. Adjustable lifting toe

3. Pump handle

4. Operating instructions and maintenance manual

5. Inspection certificate

I. GENERAL INFORMATION

APPLICATION

MODE OF OPERATION (Pic B)

.

TECHNICAL DATA

GKS NA-OMI Jacks 2011 Page 2/11

I. GENERAL INFORMATION

OPERATING AND MAINTENANCE INSTRUCTIONS No. 09/2011 FOR GKS-PERFEKT

D

TOE JACK MODEL V

II. WHAT TO DO BEFORE OPERATION ?

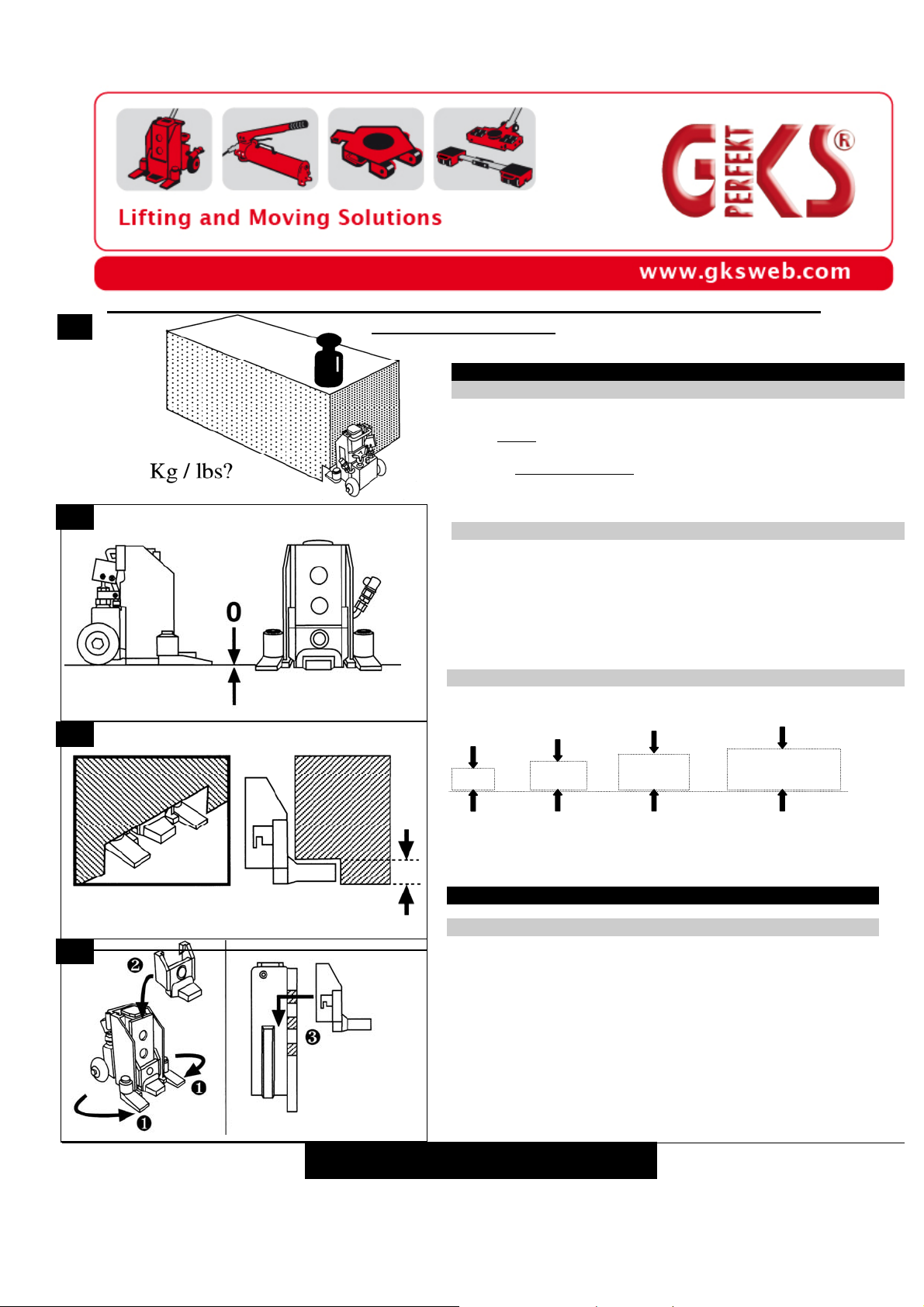

WEIGHT/CENTER OF GRAVITY OF THE LOAD (Pic D)

Check the following before operation:

the weight of the machine or load, to choose the jack suited best for

the lifting operation

locate the center of gravity of the machine or load, to find the most

suitable point of lifting

E

FLOOR AND GROUND CONDITIONS (Pic E)

Ensure, that

the jack is standing firm on a leveled floor and that

the bottom of the housing has complete contact with the floor

TOE HEIGHT FOR JACKS (Pic F)

F

5,91 in. 7,87 in 9,84 inches 15,75 inches

V5 V10 V15 V20

III. HOW TO OPERATE THE JACK CORRECTLY ?

G

To operate correctly, you must

1.

place the swivel feet in the direction of the load, then

pilot the lifting toe from above over the slider and

2.

hook into the suitable hole of the front plate

3.

(depends on clearance height needed)

continuation on page 4

(Pic G)

GKS NA-OMI Jacks 2011 Page 3/11

II. WHAT TO DO BEFORE OPERATION ?

III. HOW TO OPERATE THE JACK CORRECTLY ?

Loading...

Loading...