PB32 - Revised 120810

The POWERBOR

©

range of machines are exclusively manufactured by

G&J Hall Ltd, Sheffield, England

INSTRUCTION MANUAL

POWERBOR PB32 & PB32 COMBI

ELECTRO-MAGNETIC HOLE CUTTING SYSTEM

WARNING !

Read and understand this manual

and all instructions before operating

the machine.

Failure to follow all instructions may

result in electrical shock, damage

to the machine or even personal

injury.

Machine shown PB32

without safety guard for

clarity.

2 PB32 - Revised 120810

MACHINE SPECIFICATION

PB32

Machine Height 300mm (slide in down position)

Machine Width 90mm (without handles)

Machine Depth 240mm

Stroke 165mm

Machine Weight 12.5Kg

Rated Motor Power 720W

Voltage 110V / 240V AC

Rated Current 6.0A / 3.0A

IP Rating IP20

Spindle Speed 550 min

-1

(no-load load speed will vary with cutter diameter)

No. of speeds Single

FWD/REV No

Power Cord Length 2.5M

Annular Cutter Capacity Ø32mm

Annular Cutter Depth 25mm (50mm with optional Arbor)

Twist Drill Capacity 13mm (18mm with reduced shank drill)

Tapping Capacity N/A see PB32 Combi

Countersink Yes

Chuck Type 3/4” Weldon Shank Arbor or 13mm Chuck

Spindle Fitting 1/2” x 20 UN

Magnet Dimensions 160mm x 85mm

Magnet Power 50W

Magnetic Adhesion 1000Kg (on 25mm plate)

Minimum Plate Thickness 10mm (minimum recommended)

Sound Level Exceeds 85dB(A) - Ear protection must be worn

Hand-arm Vibration Less than 2.5 m/s2

PB32 Combi

Specification as above except :FWD/REV Yes

Spindle Speed 25-550 min

-1

(no-load load speed will vary )

STANDARD ACCESSORIES

The PB32 & PB32 Combi are supplied with the following as standard :-

3/4” Weldon Shank Arbor (25mm cut depth)

13mm Drill Chuck and Chuck Key

Rugged Plastic Carrying Case

Safety Ratchet Strap

Safety Guard

250ml Bottle of Cutting Oil

Allen Key Set

Spanners for Arbor/Chuck Removal

3 PB32 - Revised 120810

PB32 BASIC DIMENSIONS

NOTES

4 PB32 - Revised 120810

INTENDED OF USE OF POWER TOOL

This power tool is intended to be used for drilling holes with annular cutters, twist drills,

counterbores, countersinks and step drills in an industrial environment.

The PB32 COMBI also has variable speed and FWD/REV for tapping threaded holes.

The machine is meant to be held onto a magnetisable surface using its electro-magnetic

base.

The power tool should be used in a weather protected environment and be used with the

accessories provided or Powerbor recommended accessories only.

The power tool can be used vertically, horizontally and upside down, provide the

magnetic adhesion and work environment allow.

PROHIBITED USE OF POWER TOOL

This power tool should never be used without a ground or protective earth connection.

This power tool should not be used in a potentially explosive environment.

This power tool should not be use in a wet environment where water could be drawn into

the power tools cooling and ventilation system.

This power tool should never be positioned on a workpiece between the electrode and

ground of an arc type welder. Damage to the machine will result as the welder will ground

through the power tools ground or earth cable.

This power tool should not be used where the voltage is abnormally lower than the rated

voltage, subject to voltage tolerances. Check the power tool rating plate, check the

voltage available.

Operating on a lower than rated voltage will result in the electro magnet being at reduced

power and the machine may become insecure whilst drilling.

5 PB32 - Revised 120810

GENERAL POWER TOOL SAFETY

WARNING: When using electrical power tools basic safety precautions should

always be followed to reduce the risk of fire, electrical shock or personal injury.

Please read the following carefully.

Working Environment.

Always keep the working area well lit and uncluttered. A poorly lit or untidy workspace

can lead to accidents.

Always ensure the work area is well lit and uncluttered.

Explosive Environments.

Power tools produce sparks that may ignite flammable substances such as gases,

flammable liquids or dust.

Also dust may enter the ventilation system of the power tool causing clogging and

overheating.

Do not operate this power tool in a potentially explosive environment.

Bystanders, Children in the Workplace.

Always ensure that any bystanders within the working environment are kept safe from

moving parts.

Do not operate this power tool in the presence of children.

Any distraction can cause a loss of control of the power tool which could result in

personal injury.

Operate the power tool in a safe environment.

Ensure any persons in close proximity are safe from moving parts.

Guards, Safety Equipment

Always use safety guards and any other safety equipment supplied with the power tool.

6 PB32 - Revised 120810

ELECTRICAL SAFETYAlways carry the power tool properly with the carrying handles

Earthing / Grounding.

This power tool requires a ground or earth connection.

The power tool must be plugged into an outlet properly installed and grounded or earthed

in accordance with all local codes and regulations.

Never remove or tamper with the ground or earth prong in any way.

Do not use adaptor plugs.

Always check with a qualified electrician if you are in doubt as to whether the power outlet

is properly grounded or earthed.

If the tool should electrically malfunction or breakdown, grounding or earthing will provide

a low resistance patch to carry harmful electricity away from the user.

Power Cord

Never carry the power tool by its power cord or electrical hose.

Keep power cords away from heat, oil and sharp edges.

Never pull the power cord to disconnect it from the receptacle.

Always carry the power tool properly with the carrying handles provided.

Periodically inspect the power cord for damage,

If any damage is found the power tool should not be used until the damage has been

repaired by a qualified electrician.

A damaged power cord will increase the risk of electric shock.

Using the Power Tool Outside

Do not expose the power tool to rain or wet conditions, water entering the power tool will

increase the risk of electric shock.

When operating the power tools outside, if required, an extension cord rated for outdoor

use should be used.

These extension cords are rated for outdoor use and reduce the risk of electric shock.

Electrical Enclosure

The electrical components on this power tool are housed within the main body casting,

this and the side panels of the main body create an electrical enclosure.

The panels should not be removed except by a suitable trained or qualified electrician.

7 PB32 - Revised 120810

PERSONAL SAFETYAlways carry the power tool properly with the carrying handles pro-

Attention

Always watch what you are doing and use common sense at all times when operating

power tools.

Do not use the power tool whilst tired, or under the influence of drugs, alcohol or

medication.

A moment of inattention when using a power tool may result in personal injury.

Clothing

Always dress appropriately, do not wear loose clothing or jewellery.

Contain long hair, keep your hair, clothing and gloves away from any moving parts.

Loose clothes, jewellery or long hair can be caught in moving parts.

Accidental Start-up

Be sure all switches are in their OFF positions before plugging in the machine.

When carrying or moving tools always keep your fingers away from the switches

Plugging in a power tool with the switches in the ON position could invite accidents.

Intentional Start-up

Before starting up the power tool always remove any adjusting keys or tools.

A wrench key left in a rotating part of the power tool may result in injury.

Over Reaching

Never over reach when using a power tool. Always ensure you have a proper stable

footing and balance at all times before operating the tool.

Proper footing and balance enables better control of the tool in case of unexpected

situations.

Personal Protective Equipment

Always wear eye protection.

Always wear ear protection.

Always wear non-skid safety shoes.

Where appropriate wear a hard hat and/or dust mask and gloves depending on the

working environment.

WORK IN A SAFE MANNER AT ALL TIMES

8 PB32 - Revised 120810

MAGNETIC DRILL SAFETYAlways carry the power tool properly with the carrying han-

Safety Strap

The electro-magnet base on this power tool can release if there is a interruption in power

supply or electrical malfunction.

The safety strap provided should be used at all times to prevent the power tool from

falling in the event of power failure or electrical malfunction, possibly causing injury.

The safety ratchet strap should be attached to the fixing points provided and checked for

security before commencing any drilling operation.

Magnetic Adhesion

The magnets strength depends on the thickness and condition of the work piece material.

Always ensure that the work piece has a minimum thickness of 12mm or 1/2” to ensure

there is adequate magnetic adhesion.

If the work piece is less than 12mm or 1/2” then a piece of steel plate 12mm or 1/2” in

thickness and larger than the magnet footprint must be inserted between the magnet and

work piece to supplement the magnetic adhesion.

The surface on which the magnet is placed should be clean, flat and clear from debris or

rust. The base of the magnet should be inspected to ensure it is also clean flat and clear

of debris.

Always check the magnet is securely adhered to the work piece before commencing any

drill operations.

Do not use other appliances on the same power receptacle, any variation in voltage

cause by other appliances could result in the magnet releasing. Always us the tool on its

own power receptacle.

This power tool can be used on a vertical surface or upside down provided there is

sufficient magnetic adhesion, extra care should be taken when drilling vertically or upside

down . When using the machine vertically or upside down it is possible hot and sharp

swarf or chips may fall. Always wear appropriate personal protective equipment

When Cutting

When using coolant of lubricants, ensure coolants and lubricants do not enter the drill

units ventilation/cooling openings.

When using annular cutters ensure that the slug ejected at the end of the cut will not

endanger anyone in the vicinity, if working at height some form of collection device for the

ejected slug may be necessary.

Care should be taken with the ejected slug, this will be both hot and sharp, gloves should

be worn when handling the slug.

9 PB32 - Revised 120810

TOOL USE AND CAREAlways carry the power tool properly with the carrying handles

Always ensure the work piece is secure and stable before attempting to work on it.

Do not force the tool, always use the correct type of cutting tool for your application and

use it at the rate it was designed to work at.

Do not use the power tool if the power switch does not turn it on or off, any tool which can

not be turned on or off with the switch is dangerous and must be repaired before use.

Always disconnect the plug from the power supply before making any adjustments,

changing accessories or storing the tool. This will prevent the risk of the starting the tool

accidentally.

Always store tools not in use out of reach of children and untrained persons. Tools are

dangerous in the hands of an untrained user.

Maintain all cutting tools with care, keep them sharp and clean, properly maintained tools

with sharp edges are less likely to bind and will be easier to control.

Do not operate the power tool with dull or damaged cutting tools, this may overload the

motor.

Check the power tools periodically for misalignment or binding of moving parts, also

broken parts or any other condition that may affect the tools operation. If damaged have

the tool serviced before using, Poorly maintained tools can cause accidents.

Use only Powerbor recommended accessories, accessories made for other power tools

may not be suitable and could become hazardous when used.

SERVICEAlways carry the power tool properly with the carrying handles provided.

Only trained repair personnel should perform tool service. Service or maintenance

performed by untrained personnel could result in a risk of injury.

When servicing the power tool, only use identical replacement parts, pay attention to the

power tools voltage rating and model number to ensure the correct replacement parts are

specified.

P O W E R B O R W A R R A N T Y S T A T E M E N T

Powerbor warrants its magnetic drills for one (1) year from the date of purchase against

defects due to faulty material or workmanship and will repair or replace (at its option)

without charge, any items returned. This warranty is void if the item has been damaged

by accident or unreasonable use, neglect, improper service or other causes not arising

out of defects in material workmanship. No other expressed warranty is given or

authorised. Powerbor disclaims any implied warranty of merchantability or fitness for any

period beyond the expressed warranty, and shall not be liable for incidental or

consequential damages. To obtain warranty service, return the item(s) to your nearest

factory authorised repair centre.

This warranty is on lieu of any other warranty, expressed or implied, including any

warranty of merchantability or fitness for a particular purpose.

WARRANTY

10 PB32 - Revised 120810

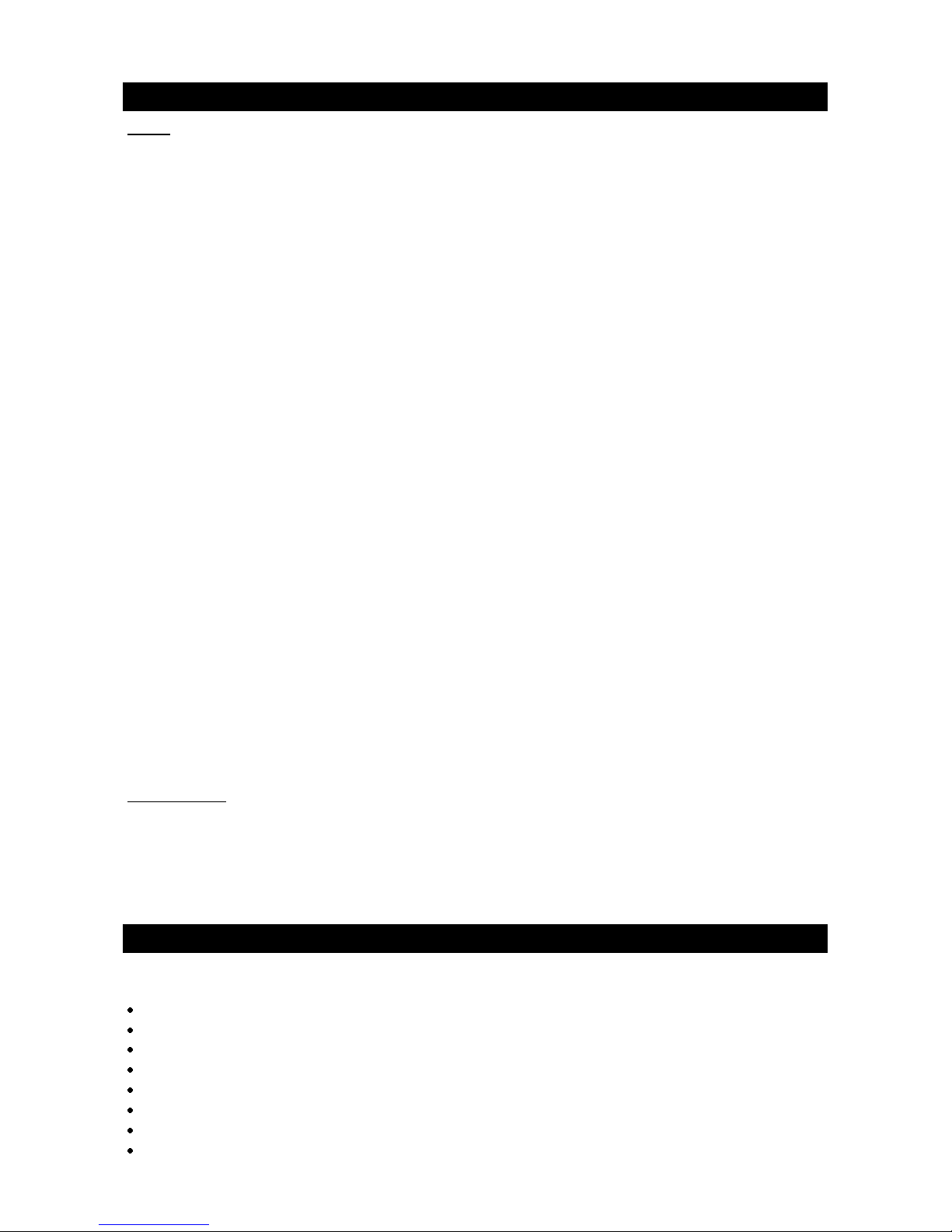

USING THE SAFETY STRAP carry

A ratchet type safety strap is provided.

The power tool has 2 x „D‟ loop rings to allow

the hooks on the safety strap to be attached

securely.

Always ensure the strap is correctly fitted and

the machine is secure BEFORE starting the

motor unit.

The safety strap is used to reduce the risk of

injury in the case of a power supply or

electrical malfunction.

The strap will hold the power tool if the

electro-magnet looses its magnetic adhesion.

If the strap becomes damaged or lost, it must

be replaced BEFORE using the power tool.

DO NOT use the safety strap as an

alternative clamping method, the

electro-magnet should have good magnetic

adhesion at all times whilst using this power

tool.

‘D’LOOP

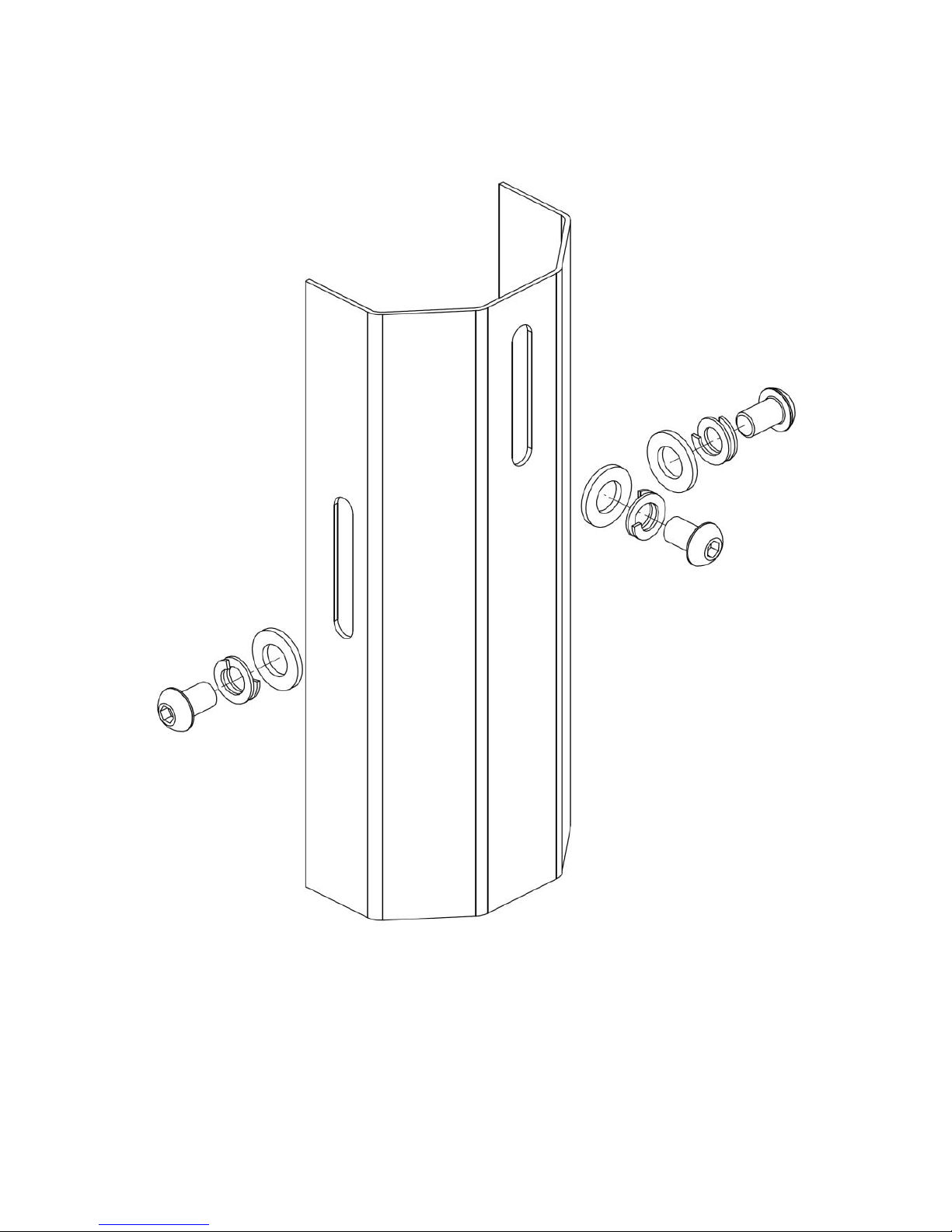

USING THE SAFETY GUARD

FIXING

SCREWS

SAFTEY

GUARD

RATCHET

STRAP

A safety guard is supplied with this power

tool, it should be attached BEFORE using the

power tool.

The guard is attached at 3 points, by button

head screws to the motor. The nylon washer

should be closest to the guard with the spring

washer between the nylon washer and the

screw head.

The screws should be tightened just enough

to allow the spring washers to hold the guard

up.

The guard has approximately 50mm of travel

which is adequate standard length cutters.

The guard should be adjusted so it is able to

slide with light pressure.

11 PB32 - Revised 120810

MOUNTING CUTTERS INTO THE ARBOR

The holder for the cutting tool is known as the

arbor. The arbor is designed to accept

Powerbor 3/4” Weldon shank annular cutters.

The Powerbor annular cutters normally have

two flats disposed at 90°to each other.

To mount the cutter.

First ensure the ejector pin is in place.

Align the two flats with the two fixing screws.

Push the cutter up into the arbor until it stops.

Tighten the two fixing screws onto the cutter

flats with the hex keys supplied.

FITTING THE DRILL CHUCK SUPPLIED

To replace the arbor (A) with the drill chuck

supplied first remove the arbor.

To do this, using the spanners supplied, place

one spanner on the flats of the drill output

shaft.

Turn clockwise (as viewed from above) until

the spanner meets the dovetail slide.

Place the the second spanner on the flats of

the arbor, apply pressure, again clockwise as

viewed from above.

If possible the magnet can be used to hold

the machine whilst removing the arbor.

If the arbor is tight the spanner on the arbor

flats can be tapped with a soft mallet.

Once the arbor is unscrewed the arbor

support bracket (B) needs to be removed.

This is accomplished by removing the two

hexagon socket head cap screws.

To fit the drill chuck simply screw it into place

on the spindle nose.

A special left handed screw is provided to

hold the chuck if the spindle rotation is

reversed (PB32 Combi only)

Replacement of the arbor is a reversal of the

procedure above.

TO REMOVE ARBOR

A

B

12 PB32 - Revised 120810

REVERSING OF THE HANDLES

The three handles (C) which raise and lower the drill unit

are attached to the pinion shaft (D).

These handles and the pinion shaft itself can be turned

around so the handles can be used on each side of the

machine. This is useful if access is limited on one side of

the machine because of the machines location.

The handles are normally mounted on the same side as the

controls, if they need to be reversed the following procedure

should be used.

First, the drill unit and its slide should either be supported or

put into its lowest position to prevent the risk of it falling

when the pinion is disengaged.

The hexagon head cap screw in the end of the pinion shaft

end cap (E) should be unscrewed.

The pinion shaft end cap can then be removed, the pinion

shaft and handle assembly can be withdrawn.

The pinion shaft and handle assembly can then be mounted

on the opposite side of the machine, taking care to ensure

the pinion gear teeth engage with the rack teeth.

The pinion shaft end cap and its hexagon head cap screw

should then be replaced and re-tightened.

C

D

E

MAGNET CONTROL PB32

The magnet is controlled by the magnet switch (F) located

at the bottom of the control panel.

„O‟ indicates magnet OFF „I‟ indicates magnet ON.

Ensure the magnet switch is OFF before connecting the

power supply.

Ensure the magnet is clean and free from debris and that

the machine is on a flat clean ferrous surface of the

required minimum thickness (10mm).

To switch the magnet ON, press the switch to the „I‟

position, the switch will illuminate to indicate there is a

power supply to the machine.

The security of the magnet should always be physically

checked BEFORE starting the drill unit.

The magnet is protected by a 2A fuse (G).

F

G

13 PB32 - Revised 120810

MOTOR CONTROL PB32

H

The drill unit or “motor” of the PB32 is controlled by a twin

push button switch at the top of the control panel.

The green button is ON the red button is OFF.

The green button is flush with the surrounding bezel.

The red button is raised above the surrounding bezel.

This is to prevent inadvertent operation of the drill unit.

The motor will not operate unless the magnet is switched

ON first.

BEFORE staring the motor the security of the magnet

should be physically checked, if any movement is possible

this should be rectified BEFORE using the drill.

If motor control has an under-voltage relay, if the power is

interrupted the motor will stop and will not restart when the

power is resumed until the motor control is operated again.

The PB32 is a single speed drill unit with a nominal no-load speed of 550 rev/min.

The PB32 Combi is variable speed, but for the purposes of using annular cutters on mild

steel, the speed should be st to its maximum.

Under load the drill unit will regulate its speed depending on the load applied.

ie: a small cutter will run faster than a larger cutter (if the same feed rate is applied)

The PB32 has the optimum power / torque / spindle speed for HSS annular cutters in the

range Ø12mm to Ø 32mm, cutting EN10025 S235J steel or its equivalent.

CUTTING SPEEDS—HSS CUTTERS

Cutting Speeds (Imperial)

Aluminium 2.37”

Brass 1.75”

Mild Steel 1.00”

High Tensile 0.37”

0.37” 0.75” 1.25” 1.62” 2.0” 2.37” 2.75” 3.12”

Cutter Diameter (inches)

Material

Surface Speed

(Inches/min)

Cutting Speeds (Metric)

Aluminium 60

Brass 45

Mild Steel 24

High Tensile 9

Material

Surface

Speed

(M/min)

PLEASE NOTE: These figures are quoted for guidance, actual performance will be

dictated by material type, thickness, hardness, application and cutter condition

Cutting Speeds—suggested speed rates for varying cutter diameters / materials

14 PB32 - Revised 120810

MAGNET CONTROL PB32 COMBI

The PB32 Combi Magnet Control switch (I) is positioned at

the top of the PB32 Combi control panel.

„O‟ indicates magnet OFF „I‟ indicates magnet ON.

Ensure the magnet switch is OFF and the FWD/REV

switch is in the OFF position before connecting the power

supply.

Ensure the magnet is clean and free from debris and that

the machine is on a flat clean ferrous surface of the

required minimum thickness (10mm).

To switch the magnet ON, press the switch to the „I‟

position.

The security of the magnet should always be physically

checked BEFORE starting the drill unit.

I

J

K

K

OFF

FWD

REV

MOTOR CONTROL PB32 COMBI FWD/REV

The PB32 Combi drill unit or “motor” is controlled by a three position rotary switch (K) at

the bottom of the PB32 Combi control panel.

The motor or FWD / OFF / REV switch should be in the OFF position before connecting

the power supply to the machine.

The magnet switch should be in the ON position and the security of the magnet should

always be physically checked BEFORE the spindle is started.

To start the spindle in its normal rotation the three position selector switch should be in

the FWD position.

To start the spindle in the opposite rotation the three position selector switch should be in

the REV position.

The FWD / OFF / REV switch should NEVER be switched from FWD to REV or REV to

FWD without waiting until the motor has stopped rotating. Failure to follow this instruction

will result in damage to either the motor or switchgear.

The motor speed control on the PB32 Combi is intended mainly for tapping operations.

For normal use with an annular cutter the speed should be set to maximum to allow

maximum power.

The motor speed control knob (K) allows speed to be reduced by turning counter

clockwise and increased by turning clockwise.

Reducing the speed significantly will reduce the power/torque available.

MOTOR SPEED CONTROL PB32 COMBI

15 PB32 - Revised 120810

USING THE DRILL WITH ANNULAR CUTTERS

Insert the correct pilot pin for the cutter into the pilot pin hole through the shank of the

cutter.

Mount the cutter in the tool holder (arbor) of the machine as described in previous

chapters, ensuring the cutter is secure and correctly fitted.

Position the machine on the work piece ensuring the magnet is on a flat clean ferrous

surface and the work piece is not below the minimum recommended thickness.

Use the pilot pin to align the centre of the cutter to the desired hole position.

Switch on the magnet and physically check the machine is securely adhered to the work

piece.

Once in position, attach the safety strap, if the magnetic adhesion fails for some reason

the safety strap will reduce movement of the machine.

Apply cutting fluid through the small holes in the arbor, the arbor has a small reservoir for

coolant which is fed down through the central pin hole to the cutter. The use of cutting

fluid will enhance the quality of the cut and prolong the life of the cutter.

Lower the safety guard provided.

Switch on the drill motor, feed the cutter down by using the three handles provided.

Proceed with caution, apply pressure gradually until the cutter has formed a groove of

approx 3mm (1/8”). Once a groove is established the pressure can be increased.

DO NOT apply excessive pressure, if excessive pressure is required it is a sign the cutter

may be worn, continuing to use a worn or blunt cutter will result in damage to the drill

motor.

If the drill motor slows significantly under load ease off the downward pressure.

On deep holes it may be necessary to withdraw the cutter to remove swarf and to apply

more cutting fluid.

A cutter in good condition will need only moderate feed pressure and will produce

continuous chips or swarf. Broken chips or swarf indicate a cutter or material problem, so

care should be taken.

If excessive swarf builds up during the cut it may be necessary to withdraw the cutter to

remove the swarf, care should be taken as the swarf will be both hot and sharp.

As the cutter begins to break through the feed pressure should be reduced slightly.

When the cutter breaks through a slug of material at the centre of the cut will be ejected.

This will be both hot and sharp. Care should be taken when handling the slug.

Care should be taken that the ejection slug is safe and can not injure anyone in the

vicinity, the slug should be prevented from falling where possible.

16 PB32 - Revised 120810

TAPPING — PB32 COMBI ONLY

The PB32 Combi, in addition to drilling with annular cutters, is designed to allow the

tapping of screw threads.

The tapping capacity of the PB32 Combi is M6 to M12.

This machine has variable speed and both forward and reverse spindle rotation.

Magnetic based drills are normally used for cutting through holes with annular cutters,

the tapping facility of this drill is for tapping through holes.

If tapping of blind holes is required then an automatic reversing tapping chuck should be

used for best results.

The images below show the available Powerbor taps and holders, these have Powerbor

weldon shanks and fit directly into the 3/4” Weldon shank arbor of the machine.

COMBI DRILL/TAP - M6 - M10

(M12 With Annular Drill)

2-IN-1 DRILL TAP - M12

To tap a hole first set up the machine as for drilling with annular cutters in previous

chapters. Ensure the machine is secure before commencing any drilling operation.

Combi Drill/Tap

Drill the hole to the recommended tapping size for the thread to be cut.

Without disengaging the magnet replace the drill with the tap.

Set the spindle speed to the required tapping speed, apply tapping or cutting compound.

Start the drill spindle in the forward direction and feed the tap into the hole until it begins

to cut. Once cutting the tap will feed itself through, only gentle pressure on the feed

handles should be necessary.

Once the tap has threaded through the plate the drill should be stopped immediately.

The drill spindle should then be switched to reverse and the tap can be fed back out of

the hole.

17 PB32 - Revised 120810

TAPPING — PB32 COMBI ONLY (Cont.)

2 - IN - 1 Drill Tap

When using a 2 - IN - 1 Drill Tap, this type of tap is restricted to plate thicknesses of the

diameter of the tapping size. ie: M12 = 12mm plate. This is due to the length of the plain

portion of the shank after the threaded portion.

If the plate to be drilled is thicker than the diameter of the thread to be cut, the Combi

type drill and tap should be used.

Position the drill and ensure the security of the magnet on the work piece.

Set the spindle speed to the required speed, drill the hole with the drill portion of the

cutter, it may be necessary to slow the speed (depending on size) before tapping.

Always use tapping compound or cutting paste for best results and prolonged cutter life.

Allow the tap the feed through with little or no feed pressure, once the threaded section of

the tap is through the drill will stop feeding and just rotate.

Stop the spindle, switch to reverse, help the tap to begin feed up with very light upward

pressure on the feed handles.

Once the tap is out of the hole the machine can be removed.

IMPORTANT when tapping NEVER switch the machine from forward to reverse without

allowing the motor to stop first. Switching directly from foward to reverse can damage the

motor and switchgear.

TAPPING SPEEDS rev/min

Tap Size Mild Steel Alloy Steel

M6 480 320

M8 360 240

M10 290 190

M12 240 160

The tapping speeds shown above are for guidance only, condition of the cutter and

specific material conditions will dictate actual speeds required.

OPTIONAL COOLANT SYSTEM

The arbor supplied with PB32 and PB32 Combi has an internal reservoir for coolant built

in.

If additional coolant capacity is required, an external coolant system which feeds through

the arbor is available.

This system must be specified at time of purchase, as the external coolant system can

not be retro fitted to existing machines.

18 PB32 - Revised 120810

MAINTENANCE

To keep this machine in a safe working condition regular certain maintenance is

required.

1. The gib strip on the dovetail slide must be adjusted to eliminate any free play.

2. The dovetail slides will need to be lubricated will oil periodically.

3. The magnetic base should be inspected for damage on its magnetic surface or for

any damage to the resin, any damage should be repaired before using the drill.

4. A monthly inspection of the carbon brushes is recommended, excessive wear could

lead to motor damage or malfunction.

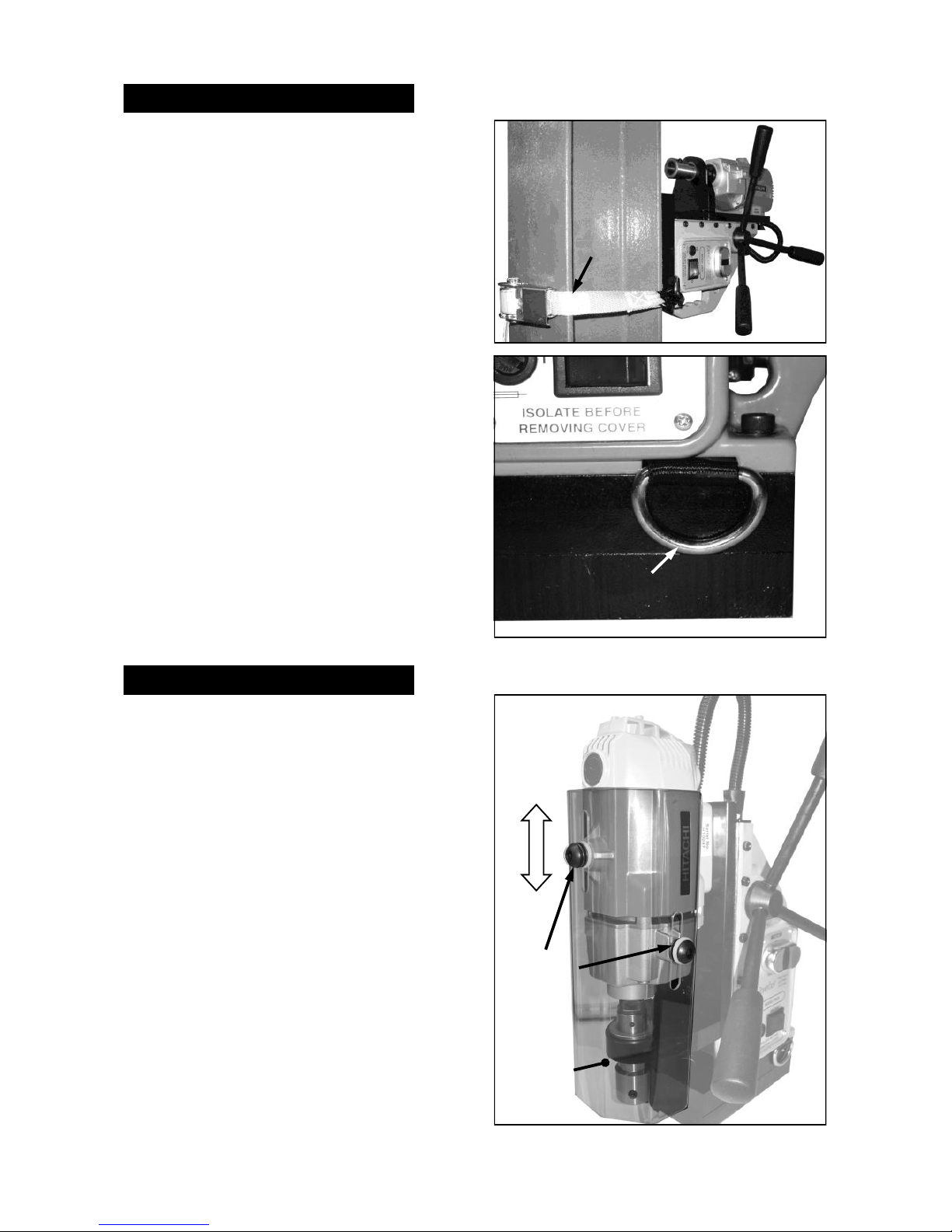

REPLACING CARBON BRUSHES

The carbon brushes (M) can be removed by

simply unscrewing the brush cap (L).

The brush has a spring and metal cap

attached, simply withdraw the brush to

inspect or replace it.

When replacing the brush, slide it into the

brush holder, make sure the metal cap of

the brush seats in the recess on the brush

cap, then screw the brush cap home.

Always use genuine replacement parts.

The brushes on this drill unit have an auto

stop feature, when the brush reaches its

wear limit to motor will stop until the brushes

are replaced

L

M

ACCESSORIES

18Y170—PB32

CHUCK ADAPTOR

This allows the drill

chuck to be quickly

placed into the arbor

of the machine.

18YPIPE—PIPE CLAMP

This allows the drill to be mounted

on a pipe or cylindrical object, the

magnet attaches to the “saddle” so

the material of the workpiece does

not need to be magnetic.

19 PB32 - Revised 120810

PB32 WIRING DIAGRAMS

20 PB32 - Revised 120810

PB32 COMBI WIRING DIAGRAMS

21 PB32 - Revised 120810

PB32 STAND - PARTS DIAGRAM

ITEM Part No. Description

1 18Y138 MAIN BODY CASTING

2 18Y134 ELECTRO-MAGNET BASE

3 18X312 BRASS GUIDES (PAIR)

4 18Y140 MACHINE RACK

5 18X304 DOVETAIL SLIDE

6 18Y141 ARBOR SUPPORT BRACKET

7 18Y130 ARBOR ASSEMBLY (1/2" X 20 UN)

8 18X321 ARBOR SPRING

9 18X323 ARBOR PISTON

10 18X206 INTERNAL CIRCLIP

11 18X309 SPINDLE BUSH

12 18Y143 SAFETY GUARD

13 18X311 RETAINING BRACKET

14 18X524 PINION END CAP

15 18X502 PINION BUSH

16 18Y144 PINION SHAFT

17 18X314 HANDLE (12mm)

18 18X520 KNOB (12mm)

17+18 18Y145 HANDLE/KNOB COMPLETE

ITEM Part No. Description

19 18Y519 CABLE GLAND (CORD GRIP)

19a 18X519/A CONDUIT GLAND

20 18Y180 CONDUIT LEAD

21 18Y181 MAINS CABLE 110V (2P+E)

22 18X503 MAINS CABLE 230V (UK)

23 18X316/A SIDE PANEL

24 18X515 RECTIFIER UNIT

25 18X315/A CONTROL PANEL

26 18Y182 START/STOP SWITCH

27 18X513 POWER RELAY 110V

28 18X514 POWER RELAY 230V

30 18X510 MAGNET SWITCH (110V & 230V)

31 18X511 FUSE HOLDER

32 18X512 2A FUSE

33 18X224 M5 X 18 CONE POINT SCREW

34 18X205 M8 X 8 GRUB SCREW

35 18X330 PLASTIC CASE

36 18Y170 CHUCK ADAPTOR

37 18Y136 ELECTRICAL PANEL ASSEMBLY

28

22

22 PB32 - Revised 120810

ITEM Part No. Description

25 18X315/F PB32 COMBI SWITCH PANEL

28 18Y183 MOTOR DIRECTION SWITCH

29 18X801 SPEED CONTROL MODULE

30 18X806 TRIAC

31 18X802 SPEED CONTROL KNOB

32 18X511 FUSE HOLDER

33 18X512 2A FUSE

35 18X510 MAGNET SWITCH

36 - HANDLE

23 PB32 - Revised 120810

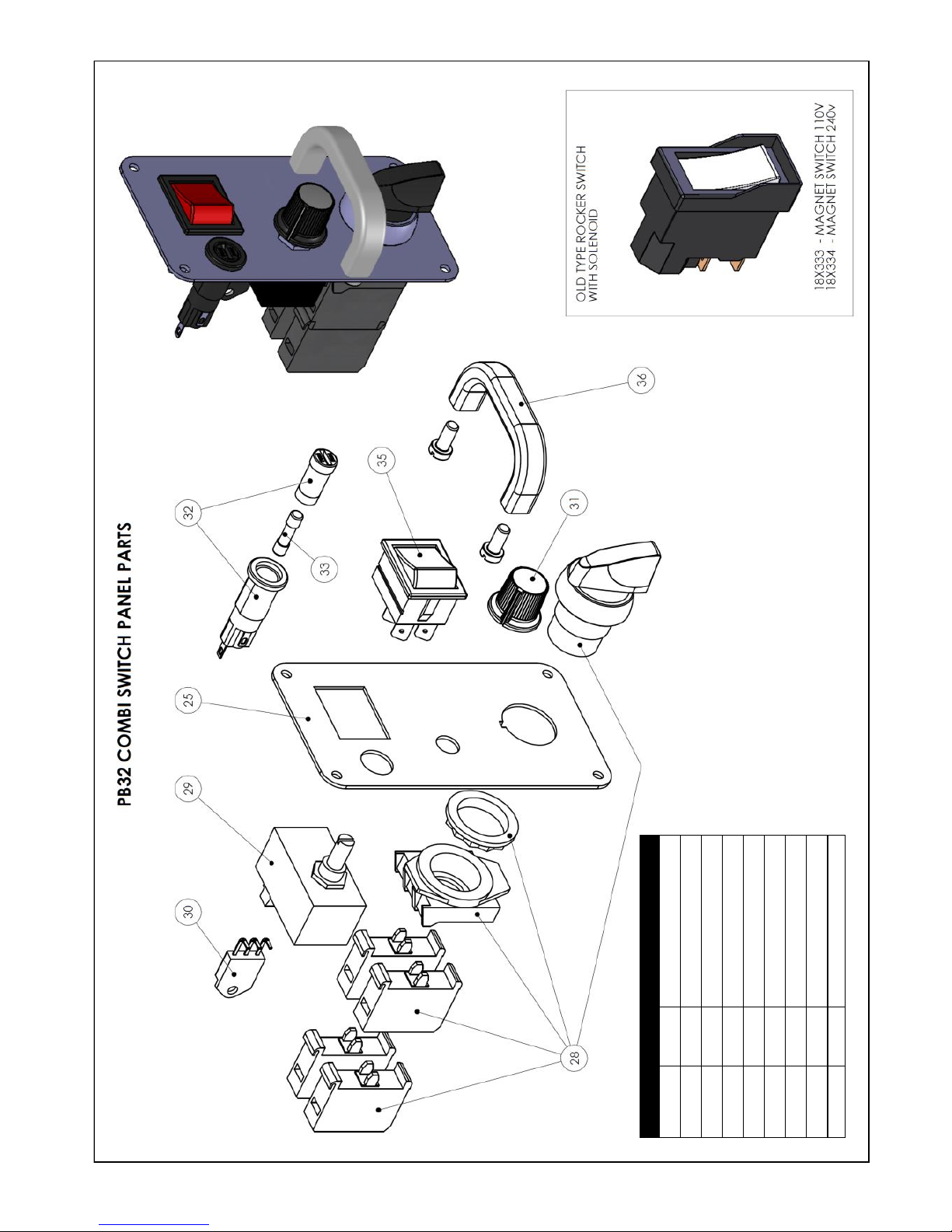

PB32 MOTOR - PARTS DIAGRAM

24 PB32 - Revised 120810

PB32 MOTOR - PARTS LIST

Item Part Number Description

Item Part Number Description

1

18ZA01 CHUCK WRENCH - HITACHI 930-515

30

18ZA30 BRUSH CAP - HITACHI 961-781

2b

18ZA02B DRILL CHUCK (13 VLR)(SUPPLY WITH 18ZA01) - HITACHI 950-275

31

18ZA31 SET CARBON BRUSHES - HITACHI 999-073

3b

18ZA03B SPINDLE D13 - HITACHI 981-667

33

18ZA33 BRUSH HOLDER - HITACHI 981-586

4

18ZA04 RETAINING RING (10) - HITACHI 939-556

34a

18ZA34A HEX SOCKET SET SCREW - HITACHI 985-114

5

18ZA05 BALL BEARING - HITACHI 620-2VV

36

18ZA36 D-TYPE HANDLE - HITACHI 982-794Z

6

18ZA06 RETAINING RING (10) - HITACHI 939-544

37

18ZA37 M10 SPECIAL BOLT - HITACHI 983-796Z

7

18ZA07 TAPPING SCREW - HITACHI 957-725

38

18ZA38 TAPPING SCREW - HITACHI 937-807

8

18ZA08 M5 SPRING WASHER (10) - HITACHI 949-454

39

18ZA39 M5 WASHER (10) - HITACHI 949-424

9

18ZA09 GEAR COVER - HITACHI 981-650

40

18ZA40 HANDLE (B) - HITACHI 984-361

10

18ZA10 FINAL GEAR - HITACHI 983-448

41

18ZA31 SET CARBON BRUSHES - HITACHI 999-073

11

18ZA11 BALL BEARING - HITACHI 627-VVM

42

18ZA42 SWITCH (2P PILLAR) - HITACHI 971-667Z

12

18ZA12 SECOND PINION - HITACHI 981-652Z

43

18ZA43 TUBE (D) - HITACHI 981-373

13

18ZA13 M8 WASHER (10) - HITACHI 949-426

44

18ZA44 PILLAR TERMINAL - HITACHI 982-804Z

14

18ZA14 BALL BEARING - HITACHI 608-VVM

45

18ZA45 PILLER TERMINAL (B) - HITACHI 982-805Z

15

18ZA15 INNER COVER ASSEMBLY - HITACHI 982-791

46

18ZA46 REVERSING SWITCH ASSEMBLY - HITACHI 982-802Z

16

18ZA16 WASHER - HITACHI 984-357

47

18ZA47 HANDLE (A) - HITACHI 984-360

17

18ZA16 WASHER - HITACHI 984-357

48

18ZA48 TAPPING SCREW (W/W) D4 X 20 - HITACHI 982-095

18

18ZA18J ARMATURE - 110V - HITACHI 981-657J

49

18ZA49 SUPPORT (B) - HITACHI 930-153

-

18ZA18 ARMATURE - 240V - HITACHI 981-657

51

18ZA51 TAPPING SCREW - HITACHI 930-446

19

18ZA19 FAN GUIDE - HITACHI 981-562

52

18ZA52 TUBE (D) - HITACHI 981-373

21

18ZA21 TAPPING SCREW - HITACHI 931-875

53

18ZA53 TERMINAL 50061 (10) - HITACHI 959-146

22

18ZA22 TAPPING SCREW - HITACHI 981-561

54

18ZA54 CORD CLIP - HITACHI 960-266

23

18ZA23J FIELD COIL - 110V - HITACHI 982-797J

55

18ZA55 HITACHI LABEL - HITACHI 957-561

-

18ZA23 FIELD COIL - 240V - HITACHI 982-797

56

18ZA56 CORD ARMOUR (D8.8) - HITACHI 953-327

24

18ZA24 WASHER (C) - HITACHI 984-367

57

18ZA57 CORD - HITACHI 500-231Z

25

18ZA25 BEARING LOCK - HITACHI 946-362

58

18ZA58 SPECIAL SCREW - HITACHI 981-122

26

18ZA26 BRUSH TERMINAL - HITACHI N/A

27

18ZA27 BRUSH TERMINAL - HITACHI 982-801Z

18X305 COMPLETE HITACHI D13 MOTOR UNIT - 110V

28a

18ZA28A HOUSING ASSEMBLY - HITACHI 982-790Z

18X306 COMPLETE HITACHI D13 MOTOR UNIT - 240V

29

18ZA29 SIDE HANDLE FOR M10 - HITACHI 981-205

25 PB32 - Revised 120810

ITEM Part No. Description

7 18Y130 ARBOR BODY (1/2" X 20 UN)

8 18X321 ARBOR SPRING

9 18X323 ARBOR PISTON

10 18X206 3/4" INTERNAL CIRCLIP

34 18X205 M8 x 8 SOCKET SCREW

PB32 ARBOR

26 PB32 - Revised 120810

PB32 SAFETY GUARD

Loading...

Loading...