Page 1

DUAL TECH

GJD360 Triple Technology External Detector

PACKAGE CONTENTS

Package Contains:

• 1 x Dual Tech

• 1 x Drilling template for xing holes

• 1 x Allen Key

• 3 x 31.75mm wall plugs

• 3 x 31.75mm screws

• 2 x Spare Sliding Curtains

• 2 x Tamper Feet

• 1 x Installation manual

INTRODUCTION

The Dual Tech is an outdoor motion detector and alarm trigger

that uses two independent passive infra-red detectors plus a

microwave sensor module. All three sensors must trigger to

cause the detector to signal an alarm. Utilising triple detection

technology, the Dual Tech delivers precise, reliable presence

detection.

QUICK INSTALLATION

1. Mount and connect the detector following the instructions

given later in this sheet.

2. Apply supply voltage to the unit. The detection LED (blue)

ashes three times.

3. Wait approximately 2 to 3 minutes to allow the detector to

settle.

4. Press the programming button once to activate walk test

mode. The detection LED is now enabled for ve minutes.

Note: The front cover must be tted when walk testing.

The default settings are:

• Range: 30 meters

• Pulse count: 1 (always set to 1 during walk rest)

• Detection LED: off (always enabled during Walk Test)

MOUNTING THE UNIT

During installation, protect the electronics against water, as

trapped moisture can affect or damage the unit.

1. Drill the wall to accept the two xing screws, the cable entry,

and the tamper cup (if used). See Figures 1 and 2. A hole drilling template is provided.

Note: We recommend using the tamper cup on uneven wall

surfaces.

2. Remove the cover assembly by loosening the locking screw

using the allen key provided. The cover hinges from the top

and lifts out of the location slot. See Figure 3.

3. Feed standard eight-core alarm cable into the cable entry.

Bare the wires and connect 6 wires to the terminal block and

optionally connect 2 to the tamper board. See Figures 2, 4, 5,

6 & 7.

4. Screw the unit to the wall ensuring that the tamper pin is

correctly located and that the tamper microswitch is closed.

See Figure 7. To aid installation, two spare tamper feet are

provided. One is 1mm longer and the other is 2mm longer

than the tamper foot originally tted. The tamper foot is a

push t and can be removed by carefully pulling it from the

pin. See Figure 2.

5. When the detector is aligned, connected, and programmed to

suit the installation, replace the front cover and lock as

shown. See Figure 8.

MULTIBEAM ALIGNMENT & MASKING

The multifunction lens tted to Dual Tech produces seven

long range beams and seven medium to short range curtain

PIR beams. The PIR circuitry detects changes in heat and

movement in the beam pattern; therefore items such as trees,

shrubs, ponds, boiler ues, and animals should be considered

when positioning the detector.

Note: The PIR sensor is more sensitive to movement across

the beams, and less sensitive to movement directly towards or

away from the beams.

The detector module is tted with two sliding shutters to reduce

the detection angle.

The curtains are tted to the pan and tilt module as shown

in Figure 9 (shown with primary and additional curtain sliders

tted). Each section of the detector lens gives a coverage

pattern of approximately 10 degrees.

An additional set of curtain sliders is provided should the beam

pattern need to be narrowed even further, e.g. if the minimum

detection angle of 10 degrees is required.

When coverage exceeds the desired detection area, adjust the

module as required and mask off any beams, either vertically or

horizontally, to avoid unwanted detection.

Use portions of the self-adhesive silver mask applied to the

rear, smooth side of the lens as shown in Figures 10 & 11.

Always replace the lens the correct way up to ensure exact

beam pattern coverage (top of the lens is marked TOP).

When mounted at heights above 3 metres there could be a

signicant reduction in the range of detection and the target

will have to move a greater distance within the eld of view

before an alarm is generated.

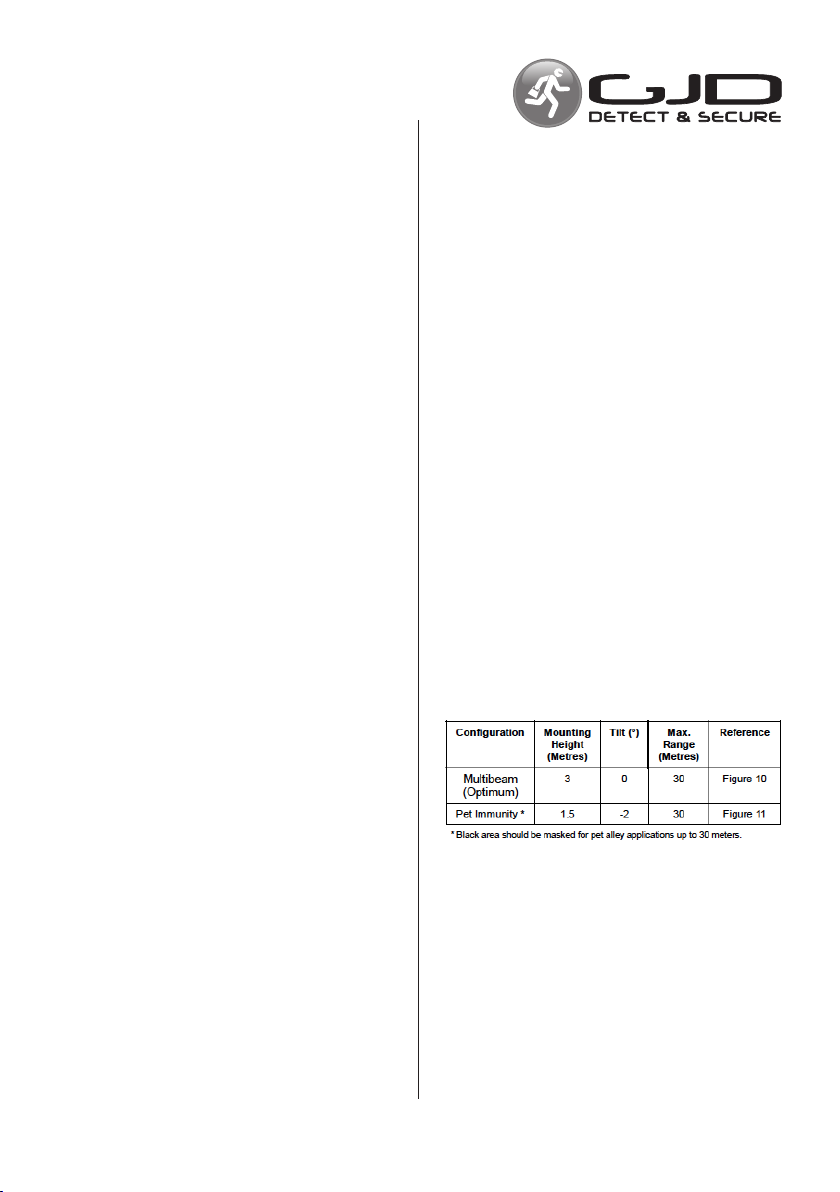

Masking Congurations For Maximum Range

Figure 12 shows the pattern for the maximum range in the

optimum position (see Figure 10). Masking the top section

of the lens reduces the range to 20m.

Figure 13 shows the pattern for the minimum range (10m). In

this case masking the top section of the lens reduces the range

to 6 meters.

Figures 14 and 15 illustrates alignment recommendations for

when the detector is mounted close to a wall.

-1-

Page 2

The alignment shown in Figure 14 is not recommended. If

the detector module is orientated at an angle of 90° to the

perimeter, the mounting wall may cut off short and medium

range beams. The long range beam will still detect an intruder,

however the wall can cause false alarms when heated by

sunlight.

Figure 15 shows the recommended alignment. The detector

module is orientated at a 55° angle to the perimeter. As a result,

short and medium range beams are parallel to the perimeter,

but the detection range along the perimeter is reduced to 25

metres.

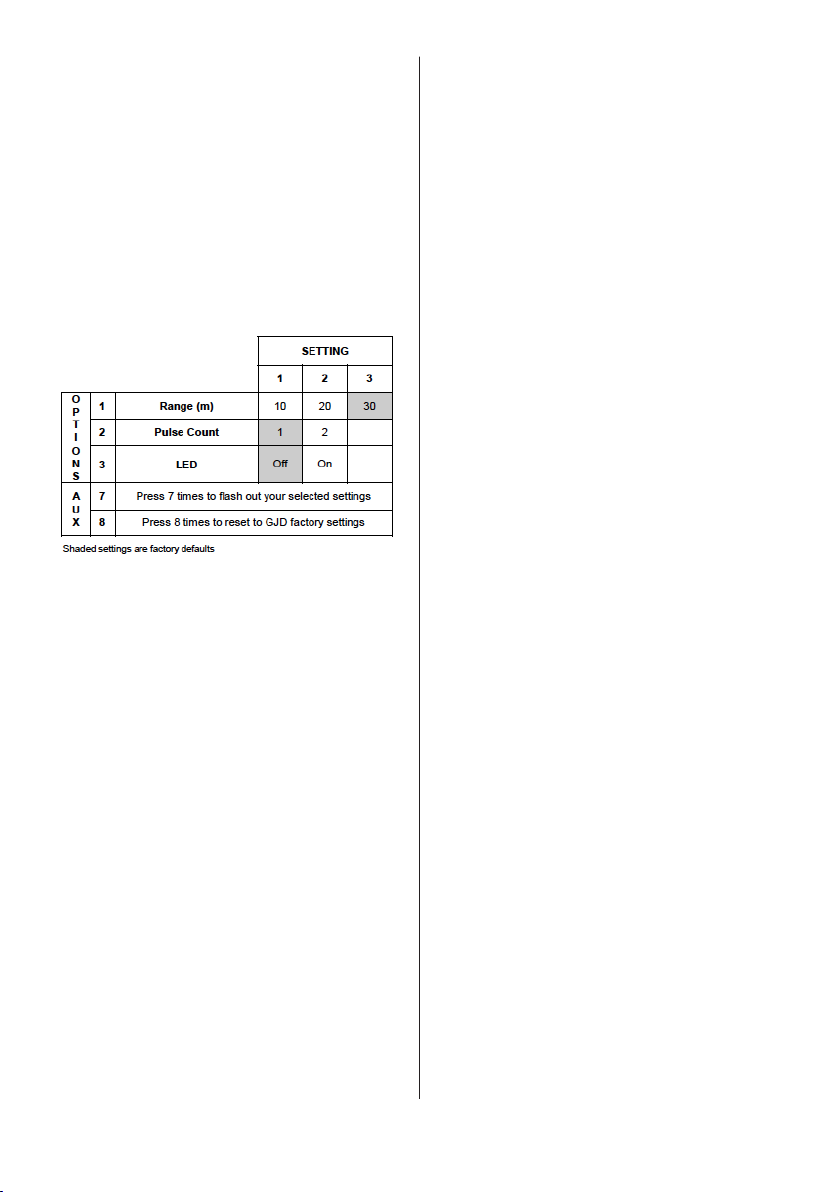

PROGRAMMING

The user can individually programme a number of congurable

settings, as illustrated in the programming chart.

Programming Chart

To change any of the Dual Tech settings:

1. Press the programme button, as shown in gure 16,

for the number of the Option to be changed, i.e. once for

range, twice for pulse count and three times for LED.

2. Wait until the blue LED indicator goes off (typically four

seconds).

3. The indicator will then ash out the existing settings.

4. To change the settings for that option, press the

programme button the number of times for the required

new setting.

5. The indicator blinks twice and the changes are stored in

the Dual Tech’s non volatile memory

Example: To change the LED setting from OFF to ON:

1. Press the programme button twice.

2. Wait until the blue LED indicator goes off (typically four

seconds).

3. The indicator will then ash once, indicating the current LED

setting is OFF.

4. Press the programme button twice to change the setting to

ON.

5. The indicator blinks twice and the changes are stored in the

Dual Tech’s non volatile memory.

PROGRAMMING OPTIONS DEFINITIONS

Pulse Count

This is the number of times the unit has to detect on both of its

sensors before signalling an output.

LED

LED Off – LED disabled.

LED On – LED signals a detection.

WALK TEST

In walk test mode, the detection LED option is set to ON, and

the pulse count option is set to 1. The detection LED lights each

time the Dual Tech detects your presence.

To enter the walk test mode, press the programming button

once. The detection LED lights and pulse count 1 is

automatically selected. The unit can then be aligned.

The test mode ends automatically ve minutes after last

detection. Alternatively, press the program button three times,

or remove and then reapply power to cancel the walk test

mode.

Note: When you conduct a walk test, make sure that the

front cover is in place. Do not conduct walk tests with the

cover removed.

The range of the detector increases without the protective

front cover. Therefore the front cover must be tted to establish

the correct beam pattern. Use programming chart to adjust the

range as necessary. Pan and tilt the lens module over the eld

of view to obtain the correct coverage area.

ACCESSORIES

GJD is able to supply the following accessories to aid

installation:

GJD304 Conduit cable entry adaptor ring

GJD305 Pole mount clamp

GJD380 D-Tect Walk Tester

-2-

Page 3

SPECIFICATIONS

Microwave

Frequency

Detection Area Programmable between 8 & 30

Coverage 10-70 degrees detection angle,

Adjustment 180 degree pan + 90 degree tilt.

Fresnel Lens 28 zones for each Pyro pair, which

Customised

Optics

Outputs Silent solid state magnetically

No. 1 N / OPEN

No. 2 N / CLOSED

Power Input 9 to 15 VDC.

Current 9mA (12V nominal).

Pulse Count 1 - 3.

Temp.

Compensation

Control Digital microprocessor – non volatile

Walk Test Output test mode with LED indication

metres.

30m x

30m coverage max.

can

be masked with curtain sliders and

special masking tape (supplied).

Double silicon shielded quad

element

eliminates 50,000 Lux of white light.

immune.

Volt free relay signal contact 24VAC/

DC

@ 50mA with an integral 25Ω

Alarm time 5 seconds

Volt free relay signal contact

24VAC/DC @ 50mA with an integral

25Ω

Alarm time 5 seconds

Digital sensitivity adjustment.

memory

Operating Temp. -20 to +55 Centigrade

Housing High impact zinc alloy.

Protection Rating IP 65

Dimensions 145 x 120 x 115 mm

Weight 750 grams NET, 880 grams GROSS

Mounting Height Variable - optimum height 3 metres.

Cable < 200m Using all ve outputs (including

Cable < 500m Using all ve outputs (including

CE Mark

Conformal coated electronics for

increased stability

tamper) – 12 core 7/0.2mm

tamper) – 12 core 16/0.2mm

-3-

Page 4

1

2

3

5

7

4

6

8

-4-

Page 5

9

10

11

13

15

12

14

16

-5-

Page 6

Page 7

ENGINEER NOTES

Technical: 01706 363990

Sales: 01706 363998

Fax: 01706 363991

Email: info@gjd.co.uk

Unit 2, Birch Business Park, Whittle,Lane,Heywood,OL10 2SX

Loading...

Loading...