Page 1

GS100-ATEX

Hazardous Areas Infra-Red Beam

PULSE MODULATED ACTIVE INFRA-RED BEAM

FOR HAZARDOUS AREAS ZONE 1 OR ZONE 2

The GS100 IR beam set carries ATEX certication for use within the

petrochemical industry, or other similar industries where an explosion-proof,

ameproof, weather, or dust proof housing is required.

The electronic modules and associated housings have been designed &

assembled in accordance with ATEX DIRECTIVE 2014/34/EU.

Product Description Flameproof IR Transmitter & IR

Receiver Enclosure

II 2 G Ex d op is IIC T6 Gb -20 °C ≤ Ta ≤

+40 °C, IP66

II 2 D Ex tb op is IIIC T80°C Db IP66

Type EMH29

CERTIFICATION AND CONFORMITY

EN 60079-0:2012/A11:2013, EN 60079-1:2014, EN 60079-31:2014,

EN62368-1:2014

Suitable for:

European Classication

Group II Category 2 G Zone 1 & Zone 2 Hazardous areas

North American Classication

Class I, Division 1 & Class I, Division 2

European Classication

Group II Category 2 D Zone 21 & Zone 22 Hazardous areas

North American Classication

Class II, Division 1 & Class II, Division 2

In accordance with EC type examination certicate No. TRAC13ATEX0054X,

a review of EN 60079-0:2012/A11:2013, EN 60079-1:2014, EN 60079

31:2014 and Manufacturing Specication and Parts List-06109 EMH29-

06108.

GENERAL

The GS100 beam set is a detection device only, and is designed to be used

in association with alarm annunciation equipment, or other devices that

provide a means of monitoring the GS100 voltage free relay alarm output

(i.e. CCTV / NVR integrations, etc).

The beam set comprises of two parts, an infra-red beam transmitter, and

an infra-red beam receiver. Both modules are mounted within a ameproof

(EExd) enclosure c/w gasket, chromate primed and polyester coated white

nish.

A heat strengthened plate glass aperture is incorporated in which the

infra-red beam is projected (via TX optics) and monitored (via RX optics). An

interruption in the ‘aligned’ beams path, is designed to provide a change of

relay state at the receiver (N/C & N/O alarm relay O/P).

A heater element can optionally be provided in both the transmitter (TX) and

the receiver (RX), to help combat the build up of condensation.

It is however normal practice to t such a device to the RX housing only,

as an attempt to tamper with the TX device will automatically generate an

output at its associated receiver. i.e. if the TX optics are moved, supply

interrupted, or device is low in voltage, the low energy projected infra-red

beam, or no projected beam present, will be detected by its associated

receiver.

As the beam sets use an infra-red light source that is invisible to the human

naked eye, a beam alignment voltage output is provided for this process, via

a terminal (align. O/P), or test pin.

Additionally, an optical alignment module is provided, that may be used

(placed on) the TX and RX optical assemblies to aid initial alignment, prior to

nal alignment via the voltage O/P.

The voltage O/P is designed to be used with a standard voltmeter

(0 – 10VDC), or for easy single man alignment operation, via an optional

‘Mini-strobe’ beam alignment tool.

The GS100 incorporates both high security ‘Asynchronous’, and

‘Synchronous’ beam set synchronisation, allowing many sets of beams to

be installed on the same site, or indeed stacked above each other (greater

detection), without ‘cross interference’.

The use of the synchronisation facility when installing only one set, or

several sets in different locations of a site is recommended (although not

essential). Doing so will ensure that the receiver (RX) circuitry ignores other

infra-red light sources that may unknowingly be present and falling directly

on the RX optical axis (invisible to see).

Synchronisation monitoring is incorporated when the interconnections are

made, refer to technical specication.

It is recommended that the 12VDC supply have a oating output to accept

the negative earth, and that all cables should be screened throughout their

entirety.

This product is a component system and is intended for inclusion within

other equipment tted by professional installers only.

The unit must not be operated as stand alone equipment.

Where applicable, compliance with the EMC directive or Machinery Directive

is the responsibility of the installer.

Page 2

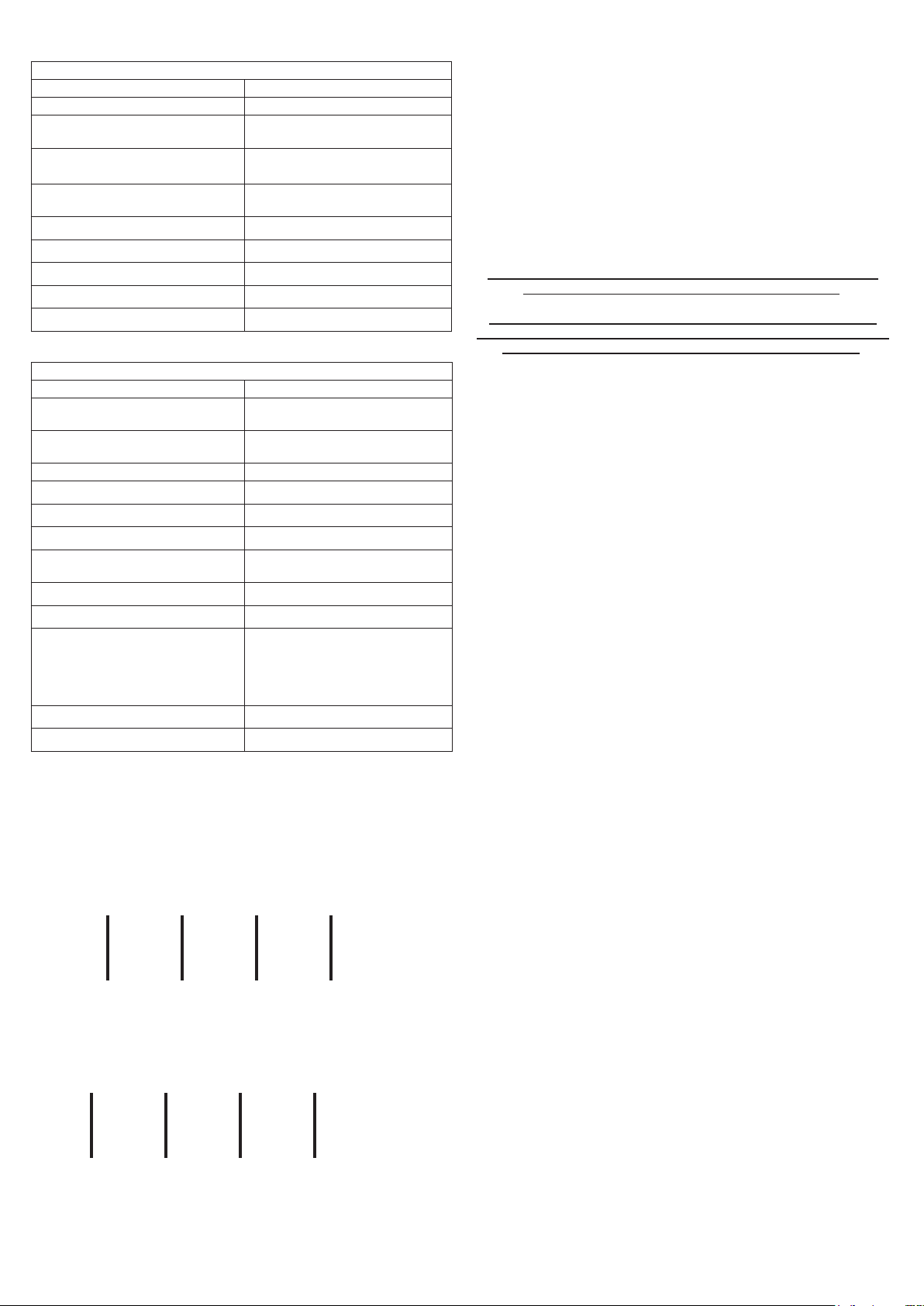

SPECIFICATIONS

ADDITIONAL FEATURES

TRANSMITTER

DETECTION TYPE Quad

PROTECTION DISTANCE 10m – 100m / with 75% attenuation

INPUT VOLTAGE Nominally 12Vd.c Min 10.5Vd.c

EFFECTIVE TRANSMITTED BEAM

ANGLE

TAMPER OUTPUT 1 x voltage free N/C contact: Max.

HEATER CURRENT 125mA

IR WAVELENGTH 880nm

DIMENSIONS 160 x 146 x 137mm

TEMPERATURE RANGE -20 °C +40 °C

WEATHER PROTECTION IP66

DETECTION TYPE Quad

INPUT VOLTAGE Nominally 12Vd.c Min 10.5Vd.c

ALARM OUTPUT 1 x voltage free change over

RESPONSE TIME > 20ms < 40ms

DWELL TIME 800ms

HORIZONTAL ADJUSTMENT +/- 15 degrees

VERTICAL ADJUSTMENT +/- 15 degrees

TAMPER OUTPUT 1 x voltage free N/C contact: Max.

HEATER CURRENT 125mA

DIMENSIONS 160 x 146 x 137mm

SYNCHRONISATION MODES Synchronous connection &

TEMPERATURE RANGE -20 °C +40 °C

WEATHER PROTECTION IP66

Note: Housing manufacturer installation & maintenance instructions can be

found within the housing and should be observed prior to xing.

TW-MM100 (Transmitter) USER NOTICE:

When unpacked or tted within housing, never leave the Transmitter optics

facing towards direct sunlight without being covered by the black lter

material.

12v DC

- +

1 2

TW-MM100 (Receiver) USER NOTICE:

When unpacked or tted within housing, never leave the Receiver optics

facing towards direct sunlight without being covered by the black lter

material.

12v DC

- +

1 2

Sync

I/P

Sync

3

O/P

3

O/P

Sig

4

Max. 15Vd.c (15mA)

6° approximately

rating 24V 1A 30VA

RECEIVER

Max. 15Vd.c (40mA)

contact: Max. rating 24V 1A 30VA

rating 24V 1A 30VA

Asynchronous connection in

both modes Synchronising Link

monitoring is incorporated as

standard

O/P

Sync

4

O/P

Align

5

I/P

Ext

5

RELAY OPs

N/O - C - N/C

6 7 8

Spare

6

The equipment utilises pulse modulation.

For high security and avoidance of cross talk between beam sets, the

system can be synchronised by means of an ‘asynchronous’ connection.

For lower security and avoidance of cross talk between beam sets, the

system can be synchronised by means of a ‘synchronous’ connection.

The GS100 circuitry incorporates ‘Sync. Line’ monitoring, providing a change

of relay state (alarm O/P) at the receiver (RX), if the synchronisation cable is

maliciously or accidentally cut, or short circuited.

The product is guaranteed against faulty workmanship for a period of 2 years

from date of despatch.

Our progressive design policy reserves us the right to modify our

products, data and specication, without prior notice.

The infra-red beam is designed as a detection device only and its

output used for connection to an alarm control / monitoring panel. As

such we will not accept responsibility for any theft / damage.

INSTALLATION GUIDANCE NOTES

Please additionally refer to any supporting instructions that may be provided

by the housing manufacturer and may be present within the TX or RX

housing.

Using the M6 mounting holes at the rear of both TX and RX housings, the

units should be mounted on a rigid, vibration free at surface. Depending

upon the structure being xed to, it may be necessary to employ some form

of mounting plate, as the housings must not in any instances be drilled.

The transmitter (TX) & receiver (RX) unit should be mounted so as to face

each other squarely, and at the same height, assuming that the ground is

level.

The optical heads of the TX & RX can be adjusted (+/- 15deg. approx.),

however the housing aperture restricts movement and should be used as

a means of overcoming unavoidable inaccuracies that may occur during

installation.

Further adjustment is catered for in the TX & RX mounting plates. Two

sets of mounting holes are provided (one set above the other), allowing the

electronics and associated optics positions within the housings to be shifted

in the vertical plane.

Where greater angles are required, then this should be dealt with using

suitable adjustable mounting plates.

Cable type, mechanical protection, and entry glands should be provided by

others and suitable for the type of installation.

When choosing the appropriate cable for the installation, consideration

needs to be paid to the TX & RX terminal cable size (refer to tech. spec.)

and in particular to the size of conductor used for the 12V DC supply voltage

over the length of the cable run (to avoid voltage drop).

Where it is decided to use optional heater elements to combat condensation

build up on the glass apertures (external exposed locations), then it is good

practice to use a separate pair of conductors for the supply voltage to the

heater terminal connections.

The TX & RX units should be connected in accordance with the wiring

diagrams provided, with connection made to the heaters and tamper

switches where tted.

A separate terminal block is provided on the underside of each heater

module, and requires a 12V DC supply voltage for element operation

(refer to tech. spec. for current of each heater). For ease of installation,

the termination block is removable (pull downward off of board connection

mounting pins). Note: cable connections are to the outer two terminals only,

the centre one not being used.

Page 3

A separate terminal block is provided via a ‘ying lead’ from the tamper

switch (housing lid removal detection device). As provided, the connections

to the changeover switch is of a solder made to the tags, suitable for the

security industry i.e. when the lid is secured a closed circuit is present at

the terminal block, going open circuit when the lid is removed. Should this

operation require to be reversed, then an alternative solder tag is provided

on the switch.

Note: the tamper switch operation should be tested prior to nal

commissioning, and the switch adjusted as necessary to ensure false alarm

free operation. Adjustment can be made by applying gentle pressure to the

arm of the switch just above the switch contact point, and bending slightly

outwards as may be necessary.

To obtain the benets of beam synchronisation as described previously, the

facility will only be in full operation when a hard-wired cable connection is

made between each beam set TX and its associated RX unit.

If the TX and RX of each set are powered from the same 12V DC power

supply, then only a single core cable / conductor is required between

terminal 3 (Sync. O/P) of the Transmitter (TX) and terminal 3 (Sync. I/P) of

its associated Receiver (RX).

Where the TX & RX units are powered via separate power supply units, it

is necessary to common the negative supply line of the PSU’s, or install

an additional core cable / conductor between the TX terminal 1 and its

associated RX terminal 1 (negative supply of TX & RX units).

FINAL ALIGNMENT

This process aligns the beam path between the TX & RX for optimum

performance in all weather conditions.

It is simplied by the use of the mini strobe alignment tool (optional).

However, where not available the use of a standard voltmeter with 0 –

10VDC range is adequate in most instances.

Unlike the single man operation with the mini strobe, unless a drum of twocore cable is available to temporarily run above ground between the TX &

RX units, nal alignment will require a two-man operation.

Where a voltmeter and a drum of cable is available, the alignment voltage

information that is only available at the receiver (RX) unit, can now be

observed by the voltmeter at the transmitter unit, via connection to the temp.

run cable, that in turn is to be connected to the RX voltage alignment O/P. In

this manner the process can be carried out by a single man operation.

For alignment using the ‘Mini Strobe’ refer to accompanying instructions.

Set the voltmeter, to 10V DC range and connect negative probe to terminal

1 on the receiver (RX) unit (negative supply). Connect the positive probe to

terminal 5 on the receiver (RX) unit (Align O/P).

In addition to these terminals, alignment information is mimicked via the test

pins to the right of the termination block, and identied by ‘ALIGN + / 0v’.

If on a single beam set installation the synchronisation system is not desired,

then no interconnect between the TX and RX should be made, other than

possibly the 12VDC supply (TX & RX Term. 1 - & 2 +).

Note: In an unsynchronised system, the beam sets will operate even with

the TX and RX units powered from separate 12V DC power supply units

(PSU’s), and the 230 / 110 V input to the PSU’s powered via different mains

phases.

The ‘synchronous’ type synchronisation system is not covered within the

instructions. It is to be used under guidance from our tech. dept, who will

be pleased to discuss the connection requirements if in our view we deem

it applicable for the type of installation. Terminals applicable are:- TX term.

4 & 5 and RX term. 4. These terminals should not be used for any other

connections.

OPTICAL SIGHTING MODULE

The Optical Alignment module is designed to be placed upon the top of both

the transmitter (TX) & receiver (RX) GS100 ‘Optical Head’ to aid the process

of ‘initial alignment’.

optical sighting module (SAA1-16) optical head of TX/RX Unit

If initial alignment has been carried out, the alarm LED (far right of RX

termination block) may be extinguished, and / or an alignment O/P voltage

may be present on the alignment O/P terminals. Even at this point, the beam

sets should be aligned for optimum performance.

With the meter connected, both the TX & RX optical heads must be adjusted

in both ‘pan’ & ‘tilt’ directions of movement, to achieve maximum alignment

voltage.

The actual alignment voltage achieved will depend on the distance

between the TX and RX unit, and as to whether the beam sets have been

synchronised via an interconnection cable.

For non- synchronised systems the maximum alignment voltage achievable

is generally 5 - 6V DC, whilst with a synchronised system, the voltage is

approximately halved to 2.5 – 3.0V DC max.

The beam sets are best aligned methodically, starting with trying to achieve

some alignment voltage whilst adjusting the receiver optics rstly in the pan

mode, and then in the tilt mode.

Repeat this procedure with the transmitter (TX) optics, until optimum

voltage O/P is achieved, and then back to the RX optics to see if any further

improvement can be made.

It is critical that alignment of the optical heads are carried out at each end

of the detection zone, i.e. both TX & RX optical heads are adjusted, and not

just the RX optical heads where the alignment voltage is made available.

The most critical optical head is that of the transmitter, as unless the

projected cone of energy is adjusted to fall on the receiver optics, no

adjustment at the receiver optics will produce an alignment O/P (receiver will

never pick up its associated transmitter signal).

sighting window (LEFT) sighting window (RIGHT)

FINAL TEST

An optional 70% or 90% attenuation lter is available, and can be inserted

in the beam path, in font of both the TX and RX optics. The lter will have

the effect of attenuating the beams signal strength by 70/90%, simulating the

effect of adverse weather conditions.

With the introduction of the lter into the correctly aligned beam set, the

receiver (RX) should not provide an alarm O/P. If an alarm is generated then

the alignment procedure should be repeated.

Page 4

Checking that a clear line of sight can be obtained, between the TX & RX

units and that the beam path is not ‘bouncing off’ any adjacent/reective

surfaces.

Once the optimum alignment voltage has been achieved, the operation of

the units should be tested at intervals along the detection zone length.

As the beam path is interrupted / blocked, the associated RX should trip to

an alarm condition (relay change state), and the alarm LED should indicate

accordingly.

BASIC TROUBLE SHOOTING

At certain points along the beam path, the beam can be blocked/interrupted

without generating an alarm condition.

Check for a bounced beam path from an adjacent object / reective surfaces

and realign.

Receiver is in an alarm condition and ‘Alarm LED’ is permanently ‘ON’

although alignment voltage is good.

Check position of receiver (RX) switch ‘S1’. For a synchronised system the

switch should be ‘ON’, for an unsynchronised system the switch should be

‘OFF’.

Check synchronisation cable /connections (if applicable).

No alignment voltage can be obtained at the receiver (RX), LED is ‘ON’

Check that the transmitter is switched ‘on’ via switch ‘S1’ to right of TX

terminal block.

Check supply voltage at TX and RX terminal 1 & 2 are within tolerances of

spec.

Check alignment operation and if still no alignment voltage, remove TX and

introduce in front of RX to test beam set operation (a battery may be used to

temp. power the TX).

Check operational distance is within specication and that glass aperture in

housing is clean.

Page 5

GS100 TX & RX Assembly (Out of housing)

optical alignment module

optical head assembly module

mounting plate

alignment adjustment ‘tilt’ axis

alignment adjustment

heater element (optional)

TX & RX PCB termination block

GS100 Transmitter (TX) PCB Termination Block

0 0 0 0

optional heater termination block

tamper switch/bracket (optional)

housing mounting holes (2 x positions)

tamper termination block

TX & RX switch / LED (refer to

termination layout below)

0V Test Pin

terminal block

GS100 Receiver (RX) PCB Termination Block

terminal block

sync.ON/OFF switch ‘S1’

1 2 3 4 5 6TX

0

12V DC O/P O/P I/P -----

- + Sync Sync Ext Spare

1 2 3 4 5 6

1 2 3 4 5 6 7 8RX

0

12V DC I/P O/P O/P RELAY O/P’s

- + Sync Sig Align N/O - C - N/C

1 2 3 4 5 6 7 8

PCB screening can

IR ON/OFF switch ‘S1’

PCB screening can

alarm LED

align. test pins

Loading...

Loading...