Page 1

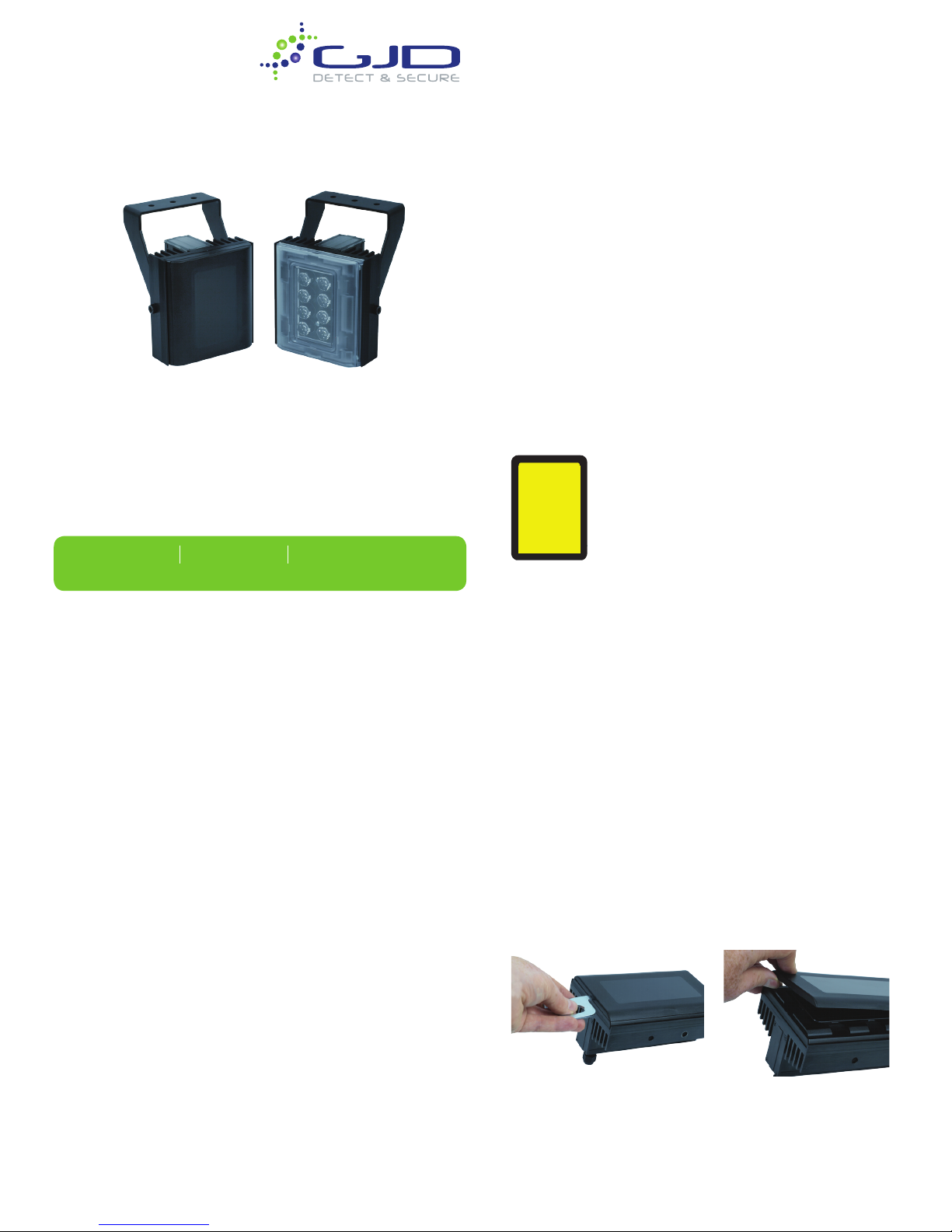

Clarius® PLUS IP

IR WL

• Dual Core LED™ Technology

• Interchangeable Lens Diffuser Technology

Description

A complete range in infra-red and white light illuminators for

CCTV, the visible and Invisible range feature state of the art

technology and installation friendly design.

• Energy efcient, low voltage operation for quick and easy

installation

• Dual Core LED™ technology with advanced electronic

control circuitry deliver improved thermal management,

long life and low cost of ownership.

• CleanLITE® Self cleaning lens coating technology

• Semi covert, covert and visible white light versions.

• Built in photo cell

• Easy integration with day/night cameras with relay contacts

indicating if the built in photo cell has activated the

illuminator

• Remote telemetry input

• Easy access to power and photo cell adjust

• Pressure equalisation vent prevents thermal expansion and

pressure cycling

• Interchangeable lens diffuser technology

Specification

Electronics High efciency surface mount high

power LEDs with advanced current

limited integral control circuitry

Beam Angles 10°, 20°, 30°, 60°, 80° & 95°

Lens/Beam Pattern The illuminator should be matched to

the scene and the camera lens focal

length

Wavelength 850nm,940nm and visible white light

Expected Life 10 years

Consumption Clarius IM / Clarius VM 25W

Input Voltage PoE+ (IEEE802.3at)

Operating Temp -50° to 50° (-58° to 122°F)

Environmental IP66. Suitable for indoor and outdoor use

Construction Robust high quality aluminium

extrusion

Front Window Polycarbonate high transmittance

protection (vandal-proof) with

CleanLITE® technology

Dimensions Clarius IM / Clarius VM 114 x 110 x 78mm

Weight Clarius IM / Clarius VM 1.05kg (2.3lbs)

Power Cable 1m. With IP68 connector

Mount Black power coated stainless steel wall

mount. Adjustable via M6 Allen Key

(included)

Installation

Note:

• Only to be installed outside of arms reach

• Installation should be done by skilled personnel or under supervision

of such personnel

• The illuminator is PoE+.

• Only to be installed in restricted Access Areas

• Terminal block not included. Installation may require advice from a

qualied person

Optimum results are achieved by setting up at night and viewing the

results on a monitor.

1. Attach the illuminator mount to pan/tilt unit, wall or camera housing.

Using stainless steel xings suitable for the relevant application.

2. Connect the lamp to a suitable (SELV) power supply.

3. Commission the mains supply, camera and monitoring equipment.

4. Select the diffuser angle sheet required from the Clarius box

(if required). To insert the required diffuser sheet, insert the tool

included in the slot at the bottom of the cover and prise upwards

slowly. Repeat at opposite end and carefully remove cover. Finally

rmly clip the lens cover back into place.

5. Adjust the pan angle of the illuminator to match the camera eld of

view.

6. Adjust the vertical alignment by loosening the side bolts (one on

each side of the main body) to maximise the results.

7. Tilt the lamp downwards until the rear part if the required eld of

view is saturated with light, as viewed on the monitor.

8. SLOWLY and GRADUALLY tilt the lamp upwards until the for part of

the required eld of view is illuminated correctly on the monitor.

Unit 2 Birch Business Park, Whittle Lane, Heywood, Lancashire, OL10 2SX

www.gjd.co.uk info@gjd.co.uk +44 (0) 1706 363 998

Clarius

®

LED Illuminators

Infrared & White Light LED Illuminators

RISK

GROUP 2

CAUTION

IR emitted

from this

product

Page 2

Clarius IP

Illuminators are powered by Power over the Ethernet (PoE) via a network cable

connector to a PoE IEEE802at compliant switch.

The power consumption of the illuminators comply with PoE IEEE802at.

These illuminators are not supplied with a power cord. Instead, they are supplied

with a 1m long network cable. At the end of the network cable is a female RJ45

Cat5e compliant connector with an IP68 rated cover.

The IP68 rated cover is supplied with the illuminator. Follow the instructions supplied

with the connector on how to attached if to the male Cat5e network cable.

ENSURE THAT THE IP68 RATED COVER IS CORRECTLY FITTED AND ATTACHED TO THE

NETWORK CABLE. IF THIS IS NOT FITTED CORRECTLY MOISTURE CAN GET INTO THE

CONNECTOR AND MAY CAUSE THE UNIT TO MALFUNCTION. THIS WOULD VOID THE

WARRANTY ON THE PRODUCT.

Power and Control Cable Connections

Remote Switching

The Illuminator may be activated remotely by a volt-free contact latched across

the telemetry wires (see Diagram above).

Photocell following contact

Volt-free relay contact-normally open (day) to normally closed (night). See

Diagram above.

Recommended PSU

Switch or injector compliant Any IEEE802.3at

Power supply should be approved to relevant EN Safety standards.

Power Supply should be used with devices to protect against short

circuits and overload.

External circuits used for interfacing with the illuminator (Camera Day/

Night switching and Telemetry) should be reinforced/double insulated

from mains.

Certifications

This product complies with the European Directive 2014/30/EU Electromagnetic

Compatibility and 2014/35/EU Low Voltage Directive by meeting the following

standards:

CE-EMC EN55032 (IT Immunity)

EN55024 (IT Emmision)

EN 61547 (Lighting-Immunity)

EN 55015 (Lighting-Emission)

EN 62493 (Lighting -EMF)

EN 50130-4 (Alarm-EMC)

CE-LVD EN 60598-1 (Luminaires-General)

EN 60598-2-1 (Luminaires)

Safety EN 62471 Risk group 2 (LED safety)

Environmental IEC/EN 60529 IP66

EN50130-5 (Alarm-environmental)

USA cULus, UL 1598

FCC, Class B

AUS RCM (AS/NZS CISPR 22 Class B)

WEEE: Waste Electrical & Electronic Equipment European

directive 202/96/EC

RoHS: Restriction of Hazardous Substances European

directive 202/95/EC

This symbol on the product means that the electrical and/or electronic equipment

to which it relates should be disposed of at the end of life separately from domestic

household waste.

There are separate collection systems for recycling in the EU. For more information

please contact the Local Authority or supplier of the product.

Photocell

The photocell is designed to automatically switch the lamps on at dusk and turn

off at dawn. A high degree of hysteresis is incorporated to void on/off switching in

marginal conditions. The unit is factory set at approximately 30 Lux On and 70 Lux

Off, but can be adjusted.

Trouble Shooting

Ensure all tests are undertaken by a qualied, trained engineer and ensure safe

working practices are followed at all times.

Step 1: Basics

• Check power connection

• Ensure PoE+ spectrum switch/injector

• Check the photocell is working - cover photocell ,light should turn on

• Ensure power supply is suitably rated to product - check the specications

Step 2: Set up Camera, lens and Illumination

• Check alignment of lamp

• Check camera lens- fully open at night and set correctly

• Check model number to performance specication to ensure required

distance is achievable

Step 3: Call for further assistance

If the lamp is still not delivering the required performance, please contact Technical

Support for further assistance

Note down:

• Model number and serial number of illuminator

• Camera make and model

• Lens make and model

mount

Reset

Shows LED

Pressure relief

valve

IM Ethernet cable with

IP68 connector

Safety Warning

• When the lamp is running, it is hot to touch. before touching switch off the illuminator

and allow to cool for a minimum of 10 minutes.

• The illuminator should be positioned so that prolonged starring into the illuminator at a

distance closed than 1m is not expected.

• The light source of this illuminator is not replaceable, when the light source reaches its

end of life the whole illuminator should be replaced.

• If the exible power cord of the illuminator is damaged it should be exclusively

replaced by an authorised service agent.

• This equipment is not suitable for us in locations where children are likely to be present.

OUTPUT +

OUTPUT -

TELEMETRY +

TELEMETRY -

Factory Default Settings

When using the system for the rst time, or if a factory reset has been made, the

following settings are used.

Product IP number: 192.168.0.10

Subnet mask: 255.255.255.0

Default router: 192.168.0.1

Login

1. Open a web browser.

2. In the address eld, type in the selected unit IP-address.

3. The user interface login page is shown.

4. Create your username and password.

Loading...

Loading...