Givi Misure VISION 700 Instruction Manual

INSTRUCTION MANUAL

FOR DIGITAL READOUT

MICROCOMPUTER

Measuring and control systems

Via Assunta, 57 - 20054 - Nova Milanese (MILANO)

(+39 0362/366126 +39 0362/366876 *sales@givimisure.it www.givimisure.it

10/06/2008 M042.E GQ

•1¥72

DECLARATION OF CONFORMITY “CE”

4

FOREWORD

5

INSTALLATION

6

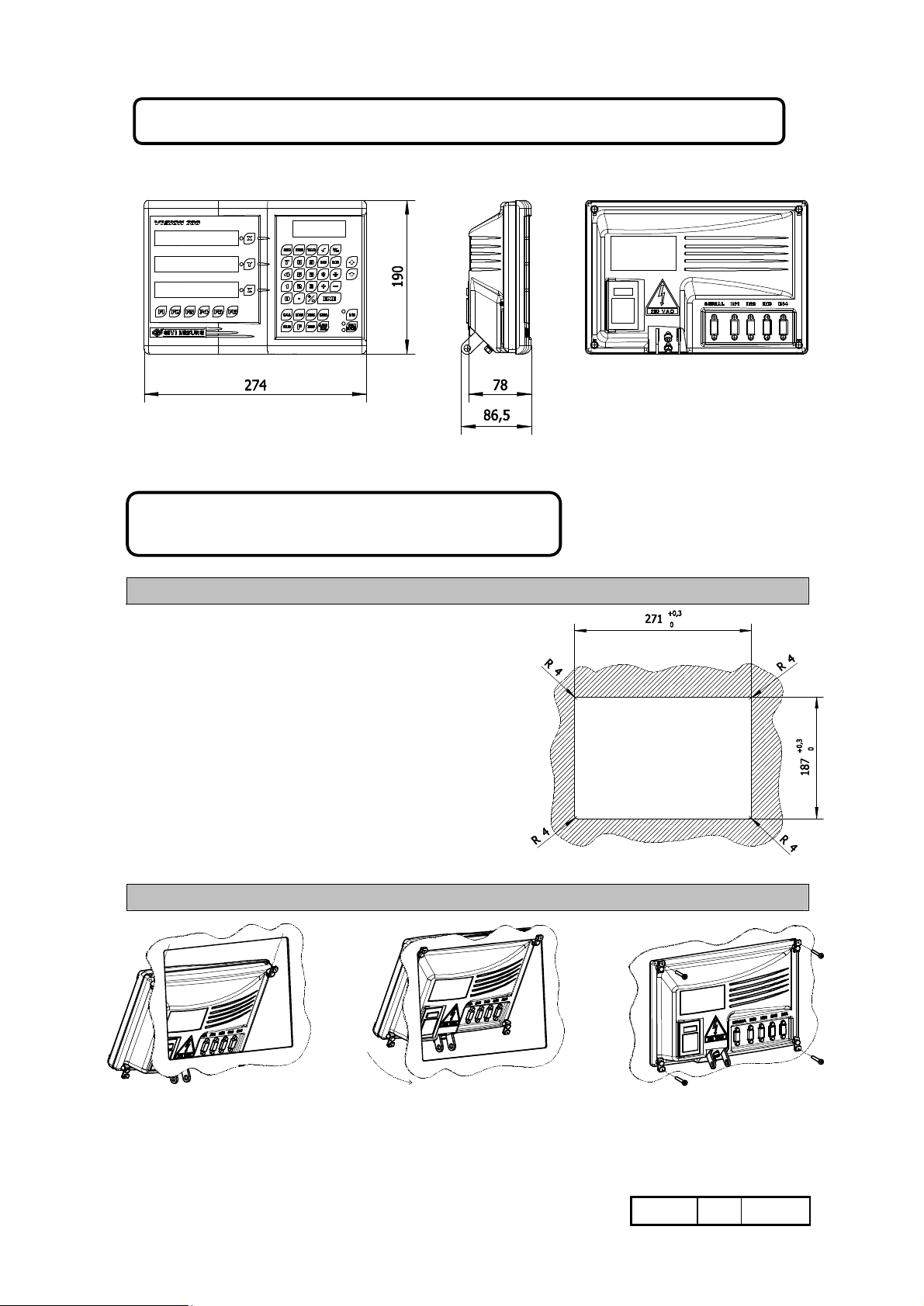

DIMENSIONAL SPECIFICATIONS (STANDARD VERSION)

7

DIMENSIONAL SPECI

FICATIONS (PANEL MOUNTABLE VERSION)

7

CONNECTION OF CONNECTORS

8

KEY

-

MESSAGES AND SIGNALLING

10

RETENTION OF DATA AND PROGRAMS

13

VISION 700 MICROCOMPUTER

TABLE OF CONTENTS

USE OF STANDARD FUNCTIONS

INVERSION OF COUNTING DIRECTION

SCALE ZERO REFERENCE (rEF)

SELF-TESTING

ABSOLUTE/INCREMENTAL COUNT

RESETTING/PRE-SETTING A DIMENSION

MMS/INCHES CONVERSION

WORKPIECE CENTER

STORED DATA CLEARING

SETTING PRINTING LINE SPACINGS

CONSTANT PITCH

SUM FOR TWO AXES

LINEAR CORRECTION

NON-LINEAR CORRECTION (10 POINTS)

SCALE FACTOR

RADIUS/DIAMETER CONVERSION

VARIABLE RESOLUTION

SEXAGESIMAL DEGREE READING

CHANGING OF ANGULAR READING MODE

CALCULATING THE TAPER

AUTOMATICALLY CALCULATING THE TAPER

CALCULATING THREADS

CALCULATING THE WEIGHTS OF MATERIALS

CALCULATING THE TIP SPEED

CALCULATING THE ANGULAR SPEED

AUTOMATICALLY QUOTA SENDING ENABLING

CIRCULAR FLANGE

SPECIAL CIRCULAR FLANGE

LCD

LCD

LCD

LCD

LCD

LCD

F 0 EXE

F 9 EXE

F 26 EXE

F 28 EXE

F 30 EXE

F 31 EXE

F 32 EXE

F 34 EXE

F 36 EXE

F 37 EXE

F 38 EXE

F 44 EXE

F 46 EXE

F 48 EXE

F 50 EXE

F 52 EXE

F 54 EXE

F 55 EXE

F 64 EXE

F 66 EXE

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

14

15

16

16

17

19

19

20

21

22

23

25

26

29

30

31

32

33

34

35

36

37

38

39

40

41

42

10/06/2008 M042.E GQ

•2¥72

AUXILIARY LCD DISPLAY

66

TECHNICAL SPECIFICATIONS

67

WARRANTY CONDITIONS

68

USE OF STANDARD FUNCTIONS

INCLINED CONSTANT PITCH

ZERO APPROACHING ALERT

PROGRAMMING THE MEMORY BLOCKS

CENTRE OF A CIRCUMFERENCE

SPECULAR IMAGE

SCALE VALUE SET

AXIS SPEED DISPLAYING

INCLINED CONSTANT PITCH

DISPLAYING RECALLED TOOL

DEVICE DIAGNOSTIC

DISPLAYING W AXIS

100 TOOL OFFSETS

100 ORIGINS OF THE AXES

RECALL OF SPECIAL FUNCTIONS (F1-F6)

SETTING THE TYPE OF SPINDLE ROTATION SPEED

SELECTING A LANGUAGE

CALCULATOR

RS-232 SERIAL OUTPUT

LCD

LCD

LCD

LCD

F 68 EXE

F 69 EXE

F 70 EXE

F 72 EXE

F 74 EXE

F 78 EXE

F 80 EXE

F 81 EXE

F 82 EXE

F 89 EXE

F Z

STO

F REF

F nn Fn

F 98718 EXE

F 98762 EXE

CAL.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

44

46

47

51

52

52

53

44

54

55

57

58

59

60

61

63

64

65

OPTIONS

MISCELLANEOUS

SPECIAL FUNCTIONS REQUIRED BY CUSTOMER

NOTES

10/06/2008 M042.E GQ

•

•

•

•

•

69

71

•3¥72

DECLARATION OF CONFORMITY

The Manufacturer: GIVI MISURE SRL

Address: VIA ASSUNTA, 57 - 20054 NOVA MILANESE (MI)

ITALY

Declares that the product: DIGITAL READOUT MOD.

Model: VISION 700

conforms to the following EC regulations including the latest

modifications and to relative national legislation:

• LOW VOLTAGE Directive 2006/95/EC and

98/37/EC (Enclosure III)

• ELECTROMAGNETIC COMPATIBILITY Directive 2004/108/EC

and the following harmonised rules have been applied:

EN 61010-1 Safety requirements for electrical equipment for measurement, control,

and laboratory use

EN 60529 Degrees of Protection Provided by Enclosures (IP Code)

EN 61000-6-3 Electromagnetic compatibility (EMC) - Part 6.3: Generic standards

EN 55011 Radio-frequency disturbance (ISM)

EN 55022 Radio-frequency disturbance (ITE)

EN 61000-6-2 Immunity for industrial environments

EN 61000-4-2 Electrostatic discharges

EN 61000-4-3 Radio-frequency radiated fields

EN 61000-4-4 Electrical fast transients/burst

EN 61000-4-6 Conducted disturbances, induced by radio-frequency fields

YEAR OF AFFIXING OF

PIERLUIGI GUERRA

Chairman

LABELLING: 95

10/06/2008 M042.E GQ

MARKING Directive

•4¥72

Dis

European Council Directive (2002/96/EC)

By ensuring this product is

disposed of correctly, you will help protect the environment. For

more detailed information about the recycling of this product,

please contact your local authority, your household waste

service provider or the retailer where you purchased the

FOREWORD

GIVI MISURE would like to thank you for purchasing the programmable digital

readout

MICROCOMPUTER

and to confirm that you have made an excellent choice.

Thanks to a powerful micro-controller, this instrument is fully programmable via the

keypad. This means that VISION can be optimised with a number of specific functions for

any type of machine-tool.

posal of old electrical & electronic equipment (WEEE)

The use of the WEEE Symbol indicates that this product may not

be treated as household waste.

disposal

product.

10/06/2008 M042.E GQ

•5¥72

INSTALLATION

W A R N I N G !

Do not switch on the instrument unless the machine conforms 98/37/EC

regulations.

The installation of the instrument must be carried out by authorised skilled

staff who will follow the regulations stated by the Manufacturer.

EARTHING The instrument is connected to earth by means of the power supply

PROTECTION According to power supply:

connector. In order to avoid discharges it is advisable to use an

earthed socket. If the instrument is not connected or is improperly

connected to earth, all the accessible parts, including those which

may appear to be protected, may generate electrical discharges.

Under no circumstances is it possible to access the inside of the

instrument when it is powered from the mains power supply or by

other power-supply devices.

q 230 Vac - 50/60 Hz or 110 Vac 60 Hz by fuse located on the

rear panel (use only delayed-action fuses, φ 5 x 20 mm, 500

mA 250 V).

q 24 Vac 50/60 Hz by an automatic brake circuit (self-

restoring), in case of overcurrent, short circuit and so on.

PREVENTION In order to avoid the possibility of fires or explosions, this

instrument may not be used in the presence of inflammable gases,

solvents, explosives, etc.

REAR This may be removed exclusively by specialised personnel, and in

PANEL any case after disconnecting the instrument from the mains power

supply (it is not sufficient to place the switch in the OFF position).

INSTALLATION Install the measuring scales (or rotary encoders) in accordance

with the Manufacturer’s instructions. Connect the Axis connectors

to the corresponding inputs (X,Y and Z) on the instrument. Connect

the power supply cable and then switch on the instrument (key-type

switch on the rear).

IMPORTANT NOTE: The instrument is protected against incorrect

information caused by uncertain situations (due, for example, to sudden or

momentary mains voltage drops). In these cases, in order to inform the operator

that an accidental upset of this type has occurred, when the instrument is switched

on again, it prompts the operator to find the scale zero (rEF).

10/06/2008 M042.E GQ

•6¥72

DIMENSIONAL SPECIFICATIONS (STANDARD VERSION)

DIMENSIONAL SPECIFICATIONS

(PANEL MOUNTABLE VERSION)

HOW TO PREPARE THE PANEL

Panel thickness reference : 2 ÷ 5 mm.

HOW TO ASSEMBLE IT

10/06/2008 M042.E GQ

•7¥72

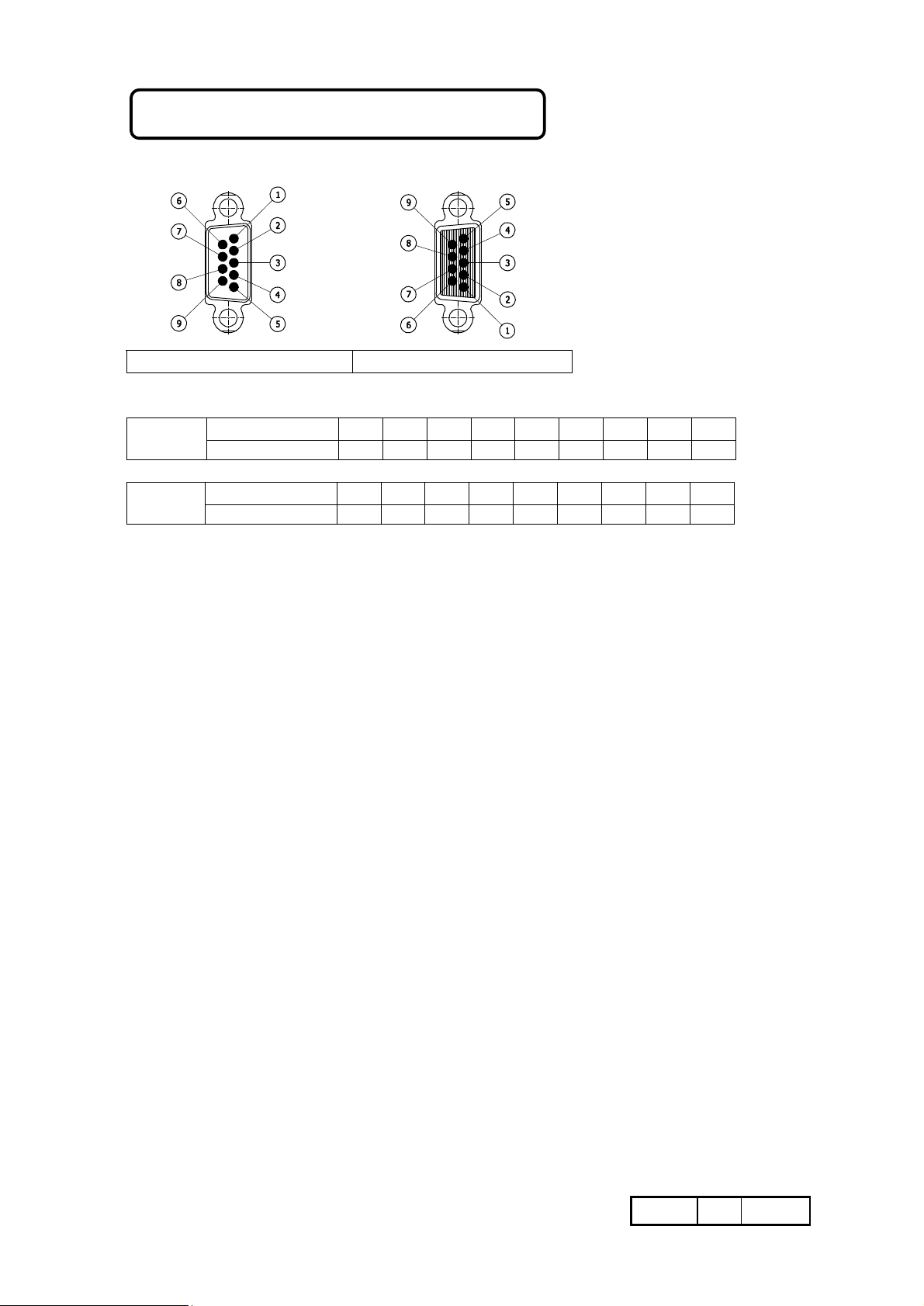

CONNECTION OF CONNECTORS

SERIAL IN1 / IN2 / IN3 / IN4

SERIAL

Reference number

Signal / RX TX / GND / / / /

1 2 3 4 5 6 7 8 9

IN1-IN4

Reference number

Signal B / Z A / / V+ GND SHD

1 2 3 4 5 6 7 8 9

10/06/2008 M042.E GQ

•8¥72

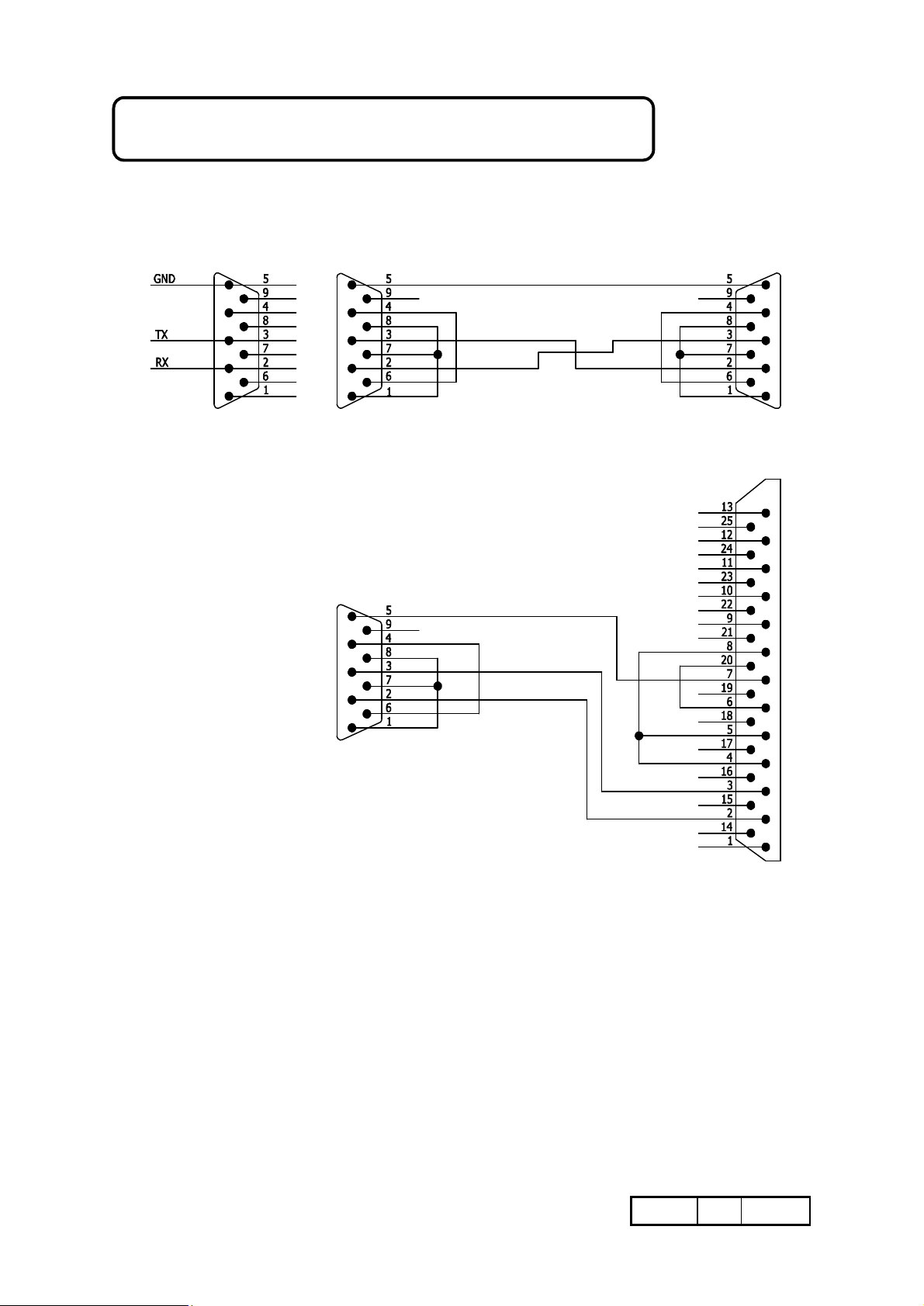

VISION – PC CONNECTIONS

VISION – SERIAL PRINTER CONNECTIONS

CONNECTOR

(RS-232) TO VISION CONNECTION CABLE

10/06/2008 M042.E GQ

•9¥72

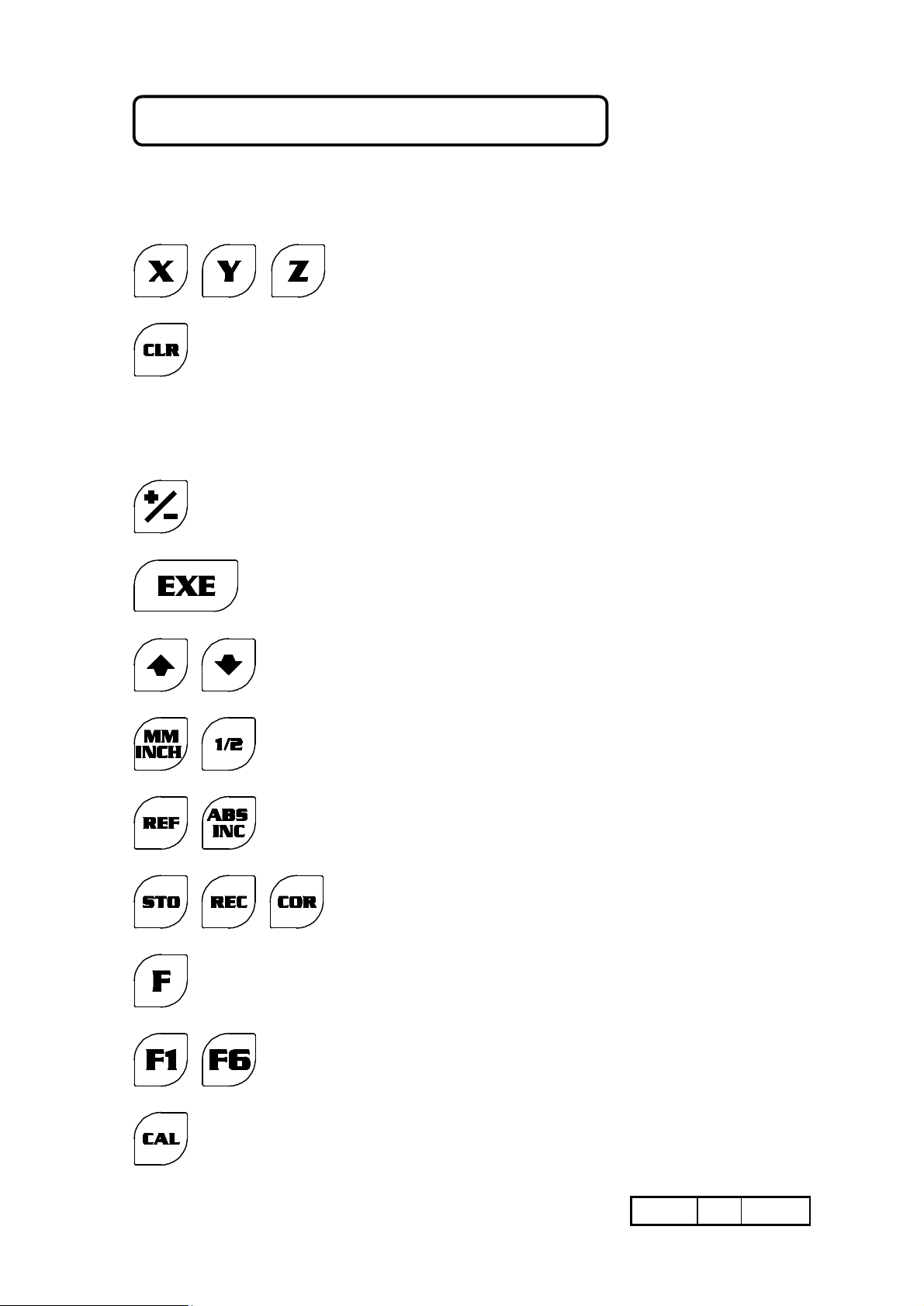

KEY - MESSAGES AND SIGNALLING

In the manual, the following graphic (or numerical) symbols are used to indicate :

1 3 3 . 0 5

X, Zo OR Z AXIS KEYS

KEY FOR RESETTING THE CORRESPONDING AXIS.

OR CLEAR THE OPERATION

DIGIT TO BE ENTERED VIA THE NUMERICAL KEYPAD.

KEY FOR ALGEBRAIC SIGNS. USED IN SOME CASES TO

“CHANGE THE PROMPT”.

TO CONFIRM THE SELECTION

KEY USED TO “CHANGE THE PROMPT” DURING

OPERATION OF SELECTION DATA.

SPECIAL FUNCTION KEY. THE INTERNAL INDICATION

SHOWS THE FUNCTION .

SPECIAL FUNCTION KEY. THE INTERNAL INDICATION

SHOWS THE FUNCTION .

STORE / RECALL AND SHOW MEMORY PROGRAMS.

FUNCION CODE KEY (USE BY NUMERIC CODE).

PROGRAM KEY TO RECALL FUNCTIONS.

TO RECALL CALCULATOR FUNCTION.

10/06/2008 M042.E GQ

•10¥72

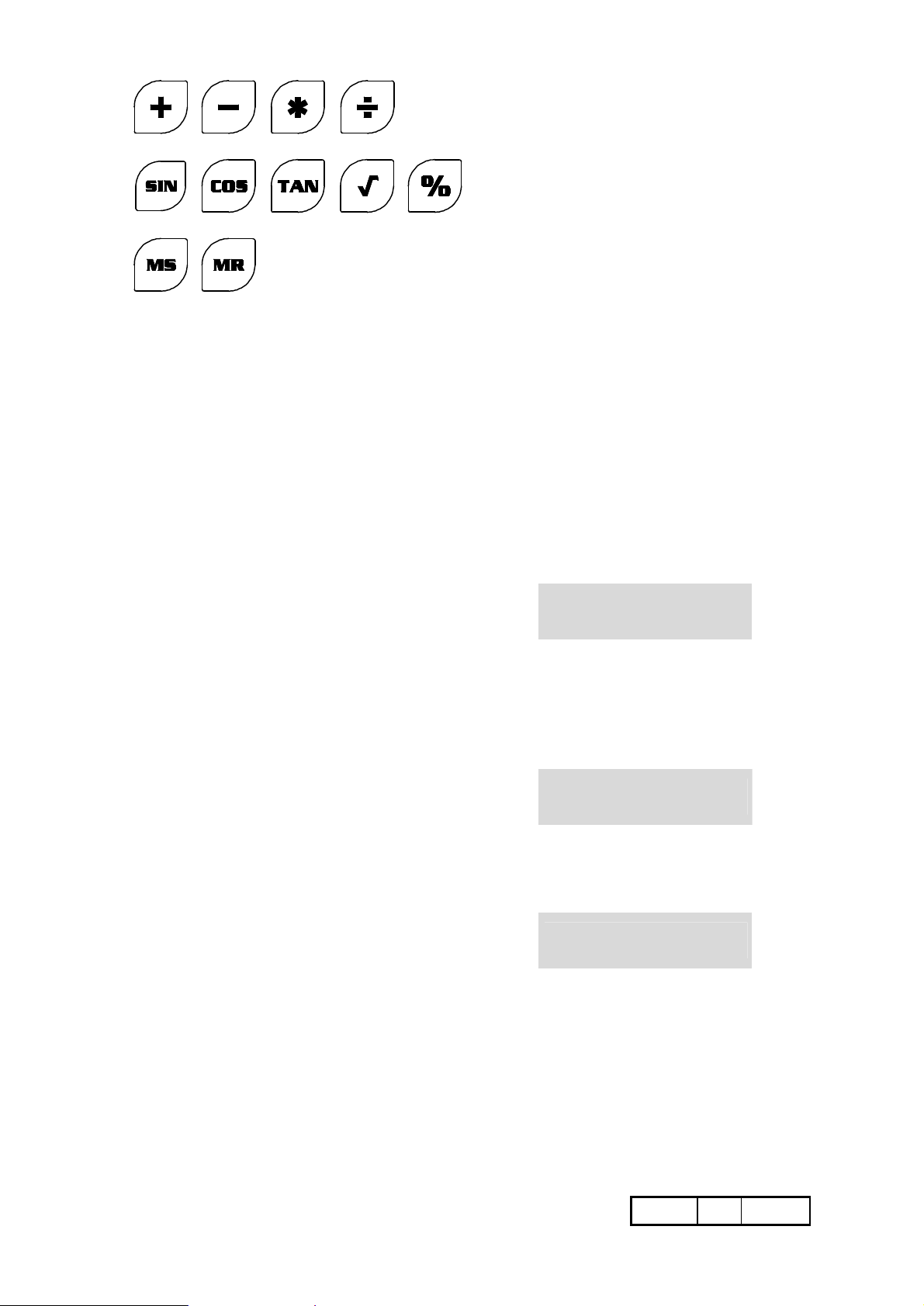

FUNCTION KEYS (CALCULATOR)

To exit from this type of situation, see

FUNCTION KEYS (CALCULATOR)

MEMORY KEYS (CALCULATOR)

® FLASHING AXIS LED ˜ STEADY AXIS LED

The instrument provides a series of acoustic and visual signals to indicate the succession of

the settings. Every time a key is pressed, a “short” sound of a buzzer is heard, while

messages consisting of wordings or numbers appear on the display depending on the type

of setting made (see manual). Finally, the Axis LED underlines the activation of the axes

or that they have been set to perform (or to have performed) a given function. If the LED

flashes, the function is in progress, while if it is steadily lit (or if it extinguishes), the

function has been completed and performed.

In the event of incorrect entries, an acoustic alarm consisting of a “long” buzzer signal will

occur, accompanied by a visual alarm consisting of the following message:

E r r o r

This appears momentarily on the display in order to inform the operator that he has

pressed a key which is not compatible with the operation being carried out.

In the event of “overflow” errors, which occurs if measurements having a number of

digits greater than the counting capacity of the instrument are entered, the error is

indicated on the display as follows :

page 17

Some bad condition uses are shown by a numerical message

For example :

_ _ _ _ _ _ _ _

E r r o r 20

10/06/2008 M042.E GQ

•11¥72

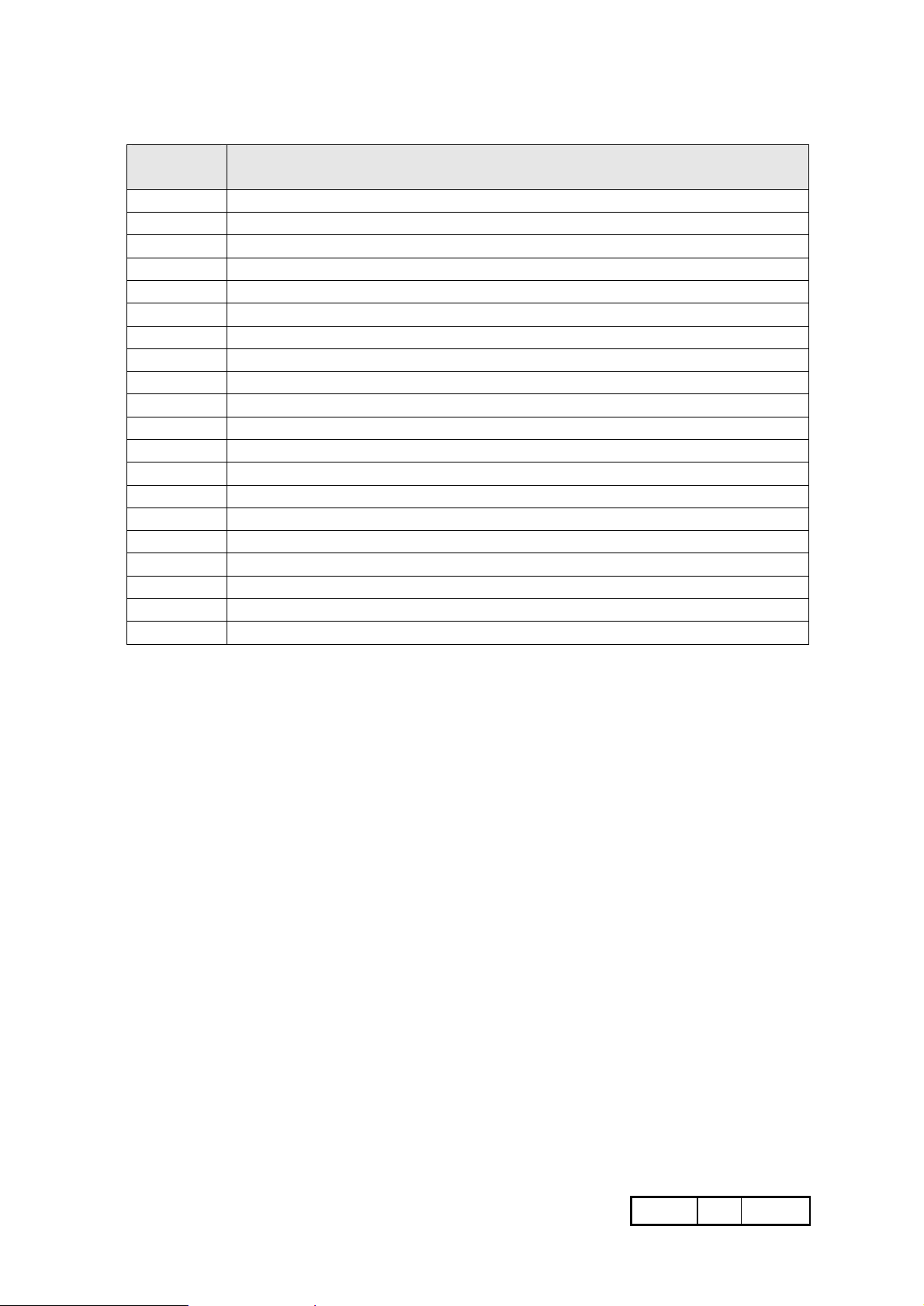

Message list error:

Error ref.

N.

10

11

12

20

21

22

23

28

80

81

90

E0

Start researching reference positions (rEF)

Axis set up not in “Linear” reading mode

Axis set up not in “Angular” reading mode

Function not allowed

Key button not programmed

Program not allowed

Memory end

Algebraic sum entered

LCD display required

Sum of two axes required

Internal fault (service required)

Wrong configuration (service required)

Description

10/06/2008 M042.E GQ

•12¥72

RETENTION OF DATA AND PROGRAMS

Program setting of VISION is carried out beforehand by the Manufacturer, who is aware

of the access codes and of the procedures (configuration). The user can then enter the

settings required for using it. All the information is permanently stored, and can only be

changed voluntarily, by re-entering it. The instrument is also able to “remember” the last

piece of data acquired, when the power supply is switched off.

In addition to the information referred to above, the following will

also be retained:

A) The selected unit of measurement (MM/INCH).

B) Confirmed function settings, with the exception of the scale

factor and variable resolution.

C) The last Axis counting position, and any messages (not of the

transient type) indicating abnormal situations, such as :

_ _ _ _ _ _ _ _

To clear all the “operational” settings entered (resetting of counters, origins of the Axes,

tool offsets, etc.) see function “F0”

IMPORTANT Either the instrument is in the ABS or the INC mode, it is unable to

consider any shifting of the Carriages (due to inertia, manual

repositioning or thermal expansion) when there is no power supply. If

this occurs, the measurements indicated on the display will no longer

be reliable, since they will be unable to show the new position of the

Carriages but only the one before the instrument switched off.

In order to avoid errors, which may be even considerable, the operator

must consider the opportunity of relating the ABS/INC counting mode

to the scale zero reference (rEF). He will link to rEF all those functions

which he intends to use and which require this condition, as specified in

the descriptions related to the single functions (it is recommended that

these descriptions are carefully read).

10/06/2008 M042.E GQ

•13¥72

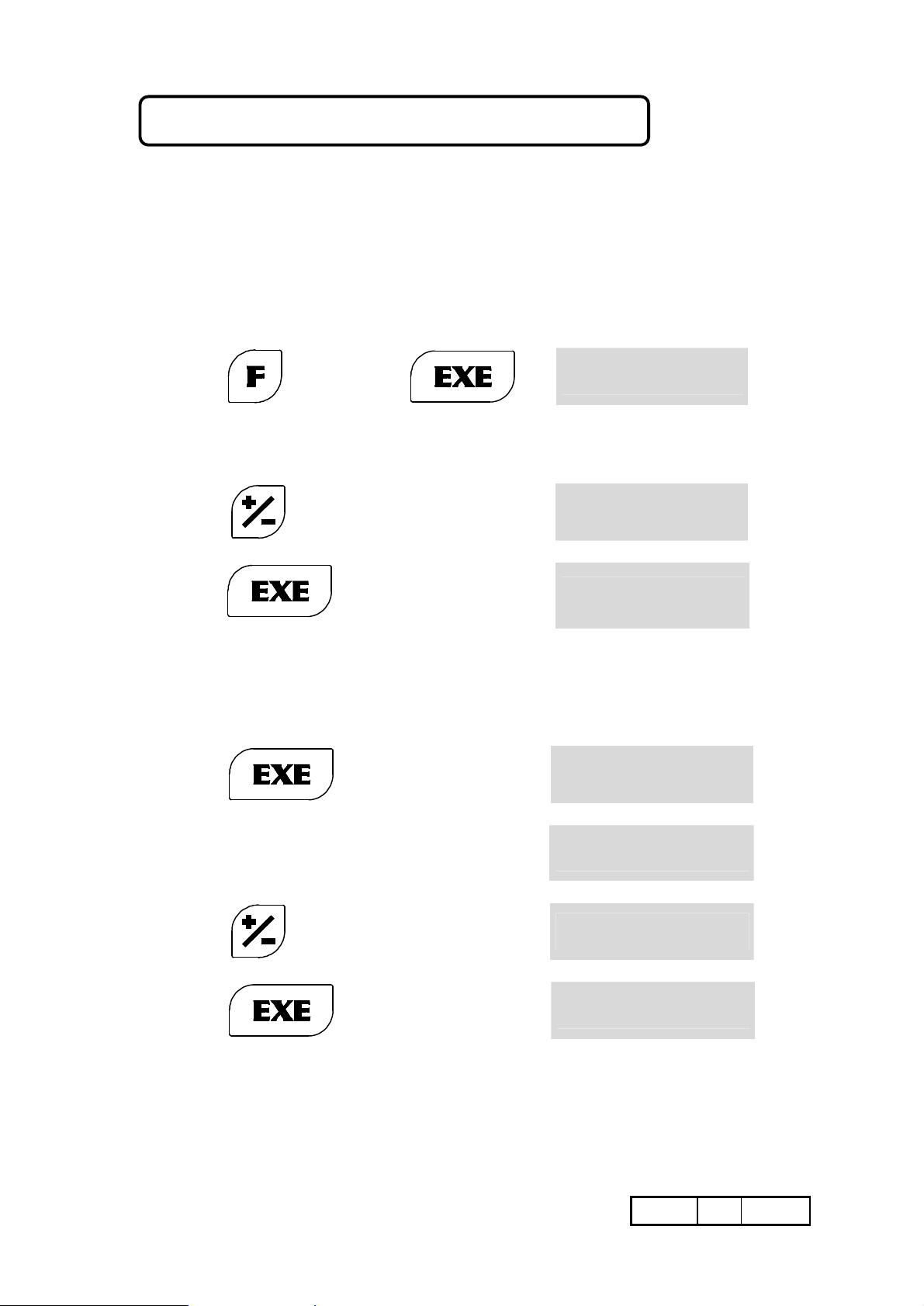

the selection is confirmed

and the X axis has been

while for the Z Axis, which has

INVERSION OF COUNTING DIRECTION

Switch on the instrument and wait for the end of the self-test cycle.

The displays remain on and show the zero search (rEF). Press CLR to enable the Axes for

counting. Move the Carriages by hand and decide which Axes need to be reversed (the

direction in which they advance depends on the mode of application of the rulers, and is

therefore random).

EXAMPLE X AXIS = TO BE REVERSED

Y AXIS = CORRECT

Z AXIS = TO BE REVERSED

PROGRAMMING THE AXES :

Key

The LED of the X Axis will then start to flash. The position of the dash (-) is purely

indicative.

press

press

Once the operation has been completed, the instrument automatically goes on to consider

the next Axis (the LED of the Y Axis will start to flash).

Since, based on the example, this does not have to be reversed :

press

98722

(because it has to be reversed)

reversed.

to be reversed:

1 d i r -

1 - d i r

1 - d i r

2 d i r -

3 d i r -

®X

®X

X

Y

®Z

press

press

On pressing EXE to confirm the last entry, the programming mode will be exited (all the

displays indicate dimensions). In the event of a wrong setting, press the CLR key and start

from the beginning again.

10/06/2008 M042.E GQ

(because it has to be reversed)

3 - d i r

X X X. X X

®Z

Z

•14¥72

SCALE ZERO REFERENCE (rEF)

The ruler zero reference (rEF) can be considered a precision micro-contact, generally

located at the midpoint of the travel. Its position in relation to the geometrical trim of the

machine is invariable in time, and can only “move” if the scale is disassembled (for

servicing, maintenance or replacement), and re-assembled differently. In this case the

operator will have to set the references again. When using scales with reference marks at

coded distance, the research of rEF is completed after a travel of appr. 20 mm on the

travel direction. Note: for a correct rearrangement of rEF position, on scales with

reference marks at coded distance, it is important to properly set the counting way,

according to the installation instruction. The zero rEF can be searched either in

automatic mode, every time the instrument is switched on, or in manual mode:

A) Automatically, every time there is a momentary or long-lasting interruption of

the mains power supply, either voluntary or otherwise, in order to avoid presenting

the operator with incorrect numerical values (LAST POSITION), the instrument

displays a prompt to the operator suggesting a new scale zero (rEF) search. This is

the case, for example, in the event of a sudden power failure occurring while the

Carriage is moving (since it would continue to move due to inertia), or movements

due to thermal expansion (due, perhaps, to a temperature drop at night), or

involuntary or accidental shifting (while cleaning the machine, for example). In this

way, the operator is warned that there is a probable “risk situation”. He may decide

to carry out a scale zero (rEF) search by passing the Carriages over the

corresponding points, or else to cancel the scale zero by pressing CLR (this should

be done in any case if the rulers do not have the ruler zero reference. In this case it

is advisable to check the precision of the positions reached).

B) Every time the operator thinks that it is necessary, he can check the positions

reached by the Carriages by setting the scale zero (rEF) search manually on the

Axes concerned (or on all the Axes).

For example enter:

X and/or

Key

The LEDs of the activated Axes flash and indicate that the instrument is ready

for the scale zero (rEF) operation.

and/or

and/or

r E F

®Yand/or

Z

NOTES: Every time an Axis completes the ruler zero (rEF) search, it is automatically excluded

from this function so that it will not interfere with the other operating conditions. In any

case, the instrument will not accept any settings until all the Axes have terminated the

ruler zero (rEF) search, and will display an error message if any keys except CRL are

pressed. The operator may then decide to proceed as follows:

A) to complete the zero search for all the Axes activated;

B) to carry it out for the Axis concerned and cancel it for the remaining Axes;

C) to cancel the search right away for all the Axes because it is considered superfluous.

10/06/2008 M042.E GQ

•15¥72

SELF-TESTING

A general test of the instrument is carried out every time it is switched on, and the validity

of the data stored in the memory is checked. If this is found to be reliable, while the

function is being performed the following wording will appear on the display for a few

seconds:

t E S t

®X

n o E r r o r

®X

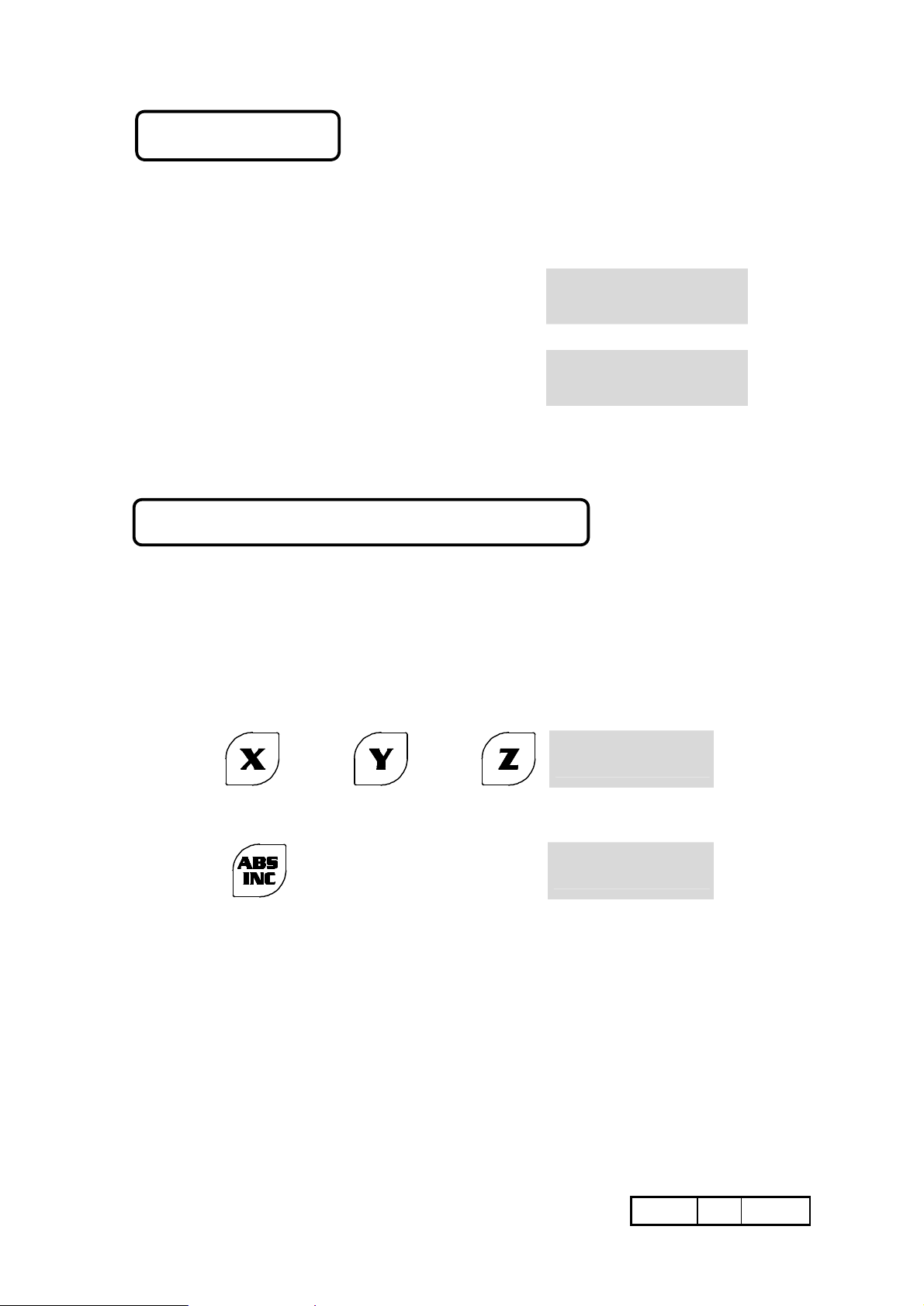

ABSOLUTE/INCREMENTAL COUNT

The LED of each Axis always signals the following:

• AXIS LED ON = AXIS IN ABSOLUTE COUNT (ABS) MODE

• AXIS LED OFF = AXIS IN INCREMENTAL COUNT (INC) MODE

• AXIS LED WILL FLASH = FUNCTION BEING PERFORMED

It is possible to switch either a single Axis or all the Axes from one counting mode to the

other as follows :

X and/or

key

The LEDs of the activated Axes will flash

press

The LED will light up (or extinguishes) and signal that the Axis is in ABS (or INC) mode.

The counting system is managed by the instrument, which has a dual internal counter

(ABS/INC) for each Axis. The information relating to the movement of the Axis updates

both counters at the same time. The information entered by the operator, on the other

hand, only affects the counter of the selected counting system. It goes without saying that

if the ABS counter is reset at a given point of the travel (ORIGIN) and the

INCREMENTAL counting mode is used (this is handier and more versatile to use), the

operator can then carry out all the resetting, pre-selections, functions and so on required

by the machining process, since he can return to the ABS count at any time to find out the

“absolute” positions of the Carriages at that time and thus find the ORIGINS which had

been set.

10/06/2008 M042.E GQ

and/or

and/or

1 2 3. 4 5

1 2 3. 4 5

®Yand/or

Z

˜X

•16¥72

without the decimal

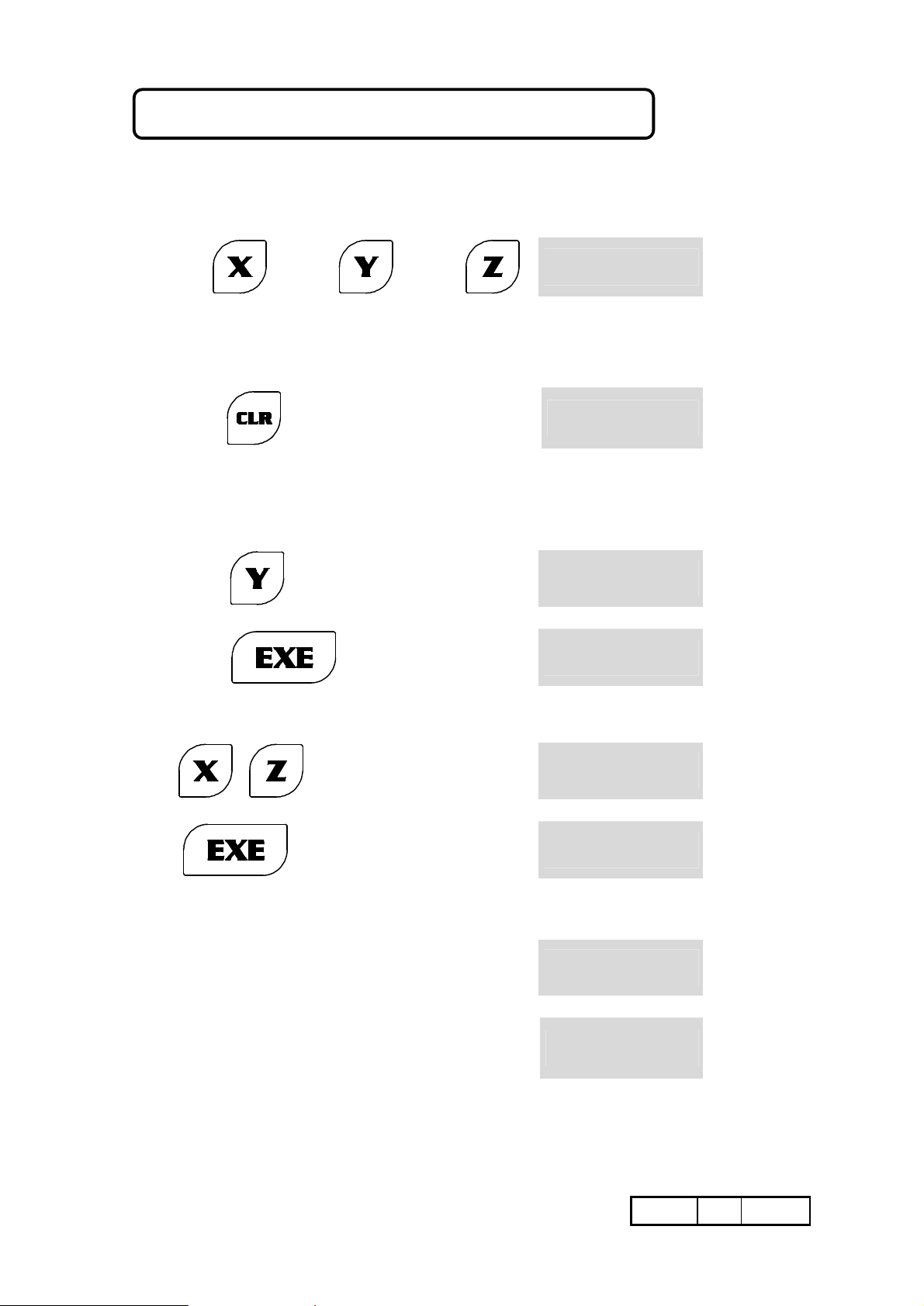

RESETTING/PRE-SETTING A DIMENSION

Regardless of the selected counting mode, ABS or INC, resetting of a datum is obtained

by proceeding as follows :

Key

The LEDs of the activated Axes will flash.

press

To enter a (pre-set) datum, for example 113.03, on the Y Axis:

Key

press

and/or

and the datum will be reset

and/or

113.03

1 2 3. 4 5

0. 0 0

1 2 3. 4 5

1 1 3. 0 3

X and/or

®Yand/or

Z

X and/or

Yand/or

Z

®Y

Y

If the same datum has to be entered for more than one Axis, for example

100.05 for both Axes X and Z, proceed as follows:

Key

press

ON EACH DISPLAY THE DATA CAN BE ENTERED:

a)

zero references which

are not significant:

b) with a number of

relevant decimal

digits:

100.05

and the datum will be reset

1250

1133.04

1 0 0. 0 5

1 0 0. 0 5

1 2 5 0. 0 0

1 1 3 3. 0 4

®X and Z

X and Z

10/06/2008 M042.E GQ

•17¥72

In any case, the data entered is rounded off:

- downwards:

- upwards:

c) With a total number of digits not exceeding the counting capacity of

the instrument (7 digits with a sign and the decimal point) that

means:

-999999.9 with decimal resolution

-99999.99 with a resolution of hundredths

-9999.999 with a resolution of thousandths

Attempts to enter a higher number of digits will take to an “overflow” error.

Let us suppose that the datum 123456.78 has to be entered for the Y Axis.

We will proceed as follows:

Key

from 13.051 to 13.054

from 13.055 to 13.059

123456.78

1 3. 0 5

1 3. 0 6

E r r o r

X

If we attempted to enter it in any case by pressing :

It is possible to quit this situation correctly as follows:

Key

or by resetting the Axis:

Key

d) With the negative algebraic sign entered during or on completion of the

ACOUSTIC ALARM

the datum would not be

accepted

(“overflow” error)

1 2 3 4 5 6. 7

_ _ _ _ _ _ _ _

XXXXX.XX

(correct datum)

datum entry (is understood the positive sign has been entered and in any

case it is never shown on the axis display).

XXXXX. XX

0. 0 0

®Y

Y

Y

Y

10/06/2008 M042.E GQ

•18¥72

MMS/INCHES CONVERSION

Every time the following key is pressed the unit of measurement is switched from

MM to INCHES or vice versa. Switching takes place instantaneously for all the Axes

being counted. The selected unit of measurement is shown by the position of the LED lit

on the keypad, and also by the position of the decimal points for the Axes being counted.

If activation of the conversion is not compatible with the operational conditions of the

instrument, pressing this key will cause an error message to be displayed.

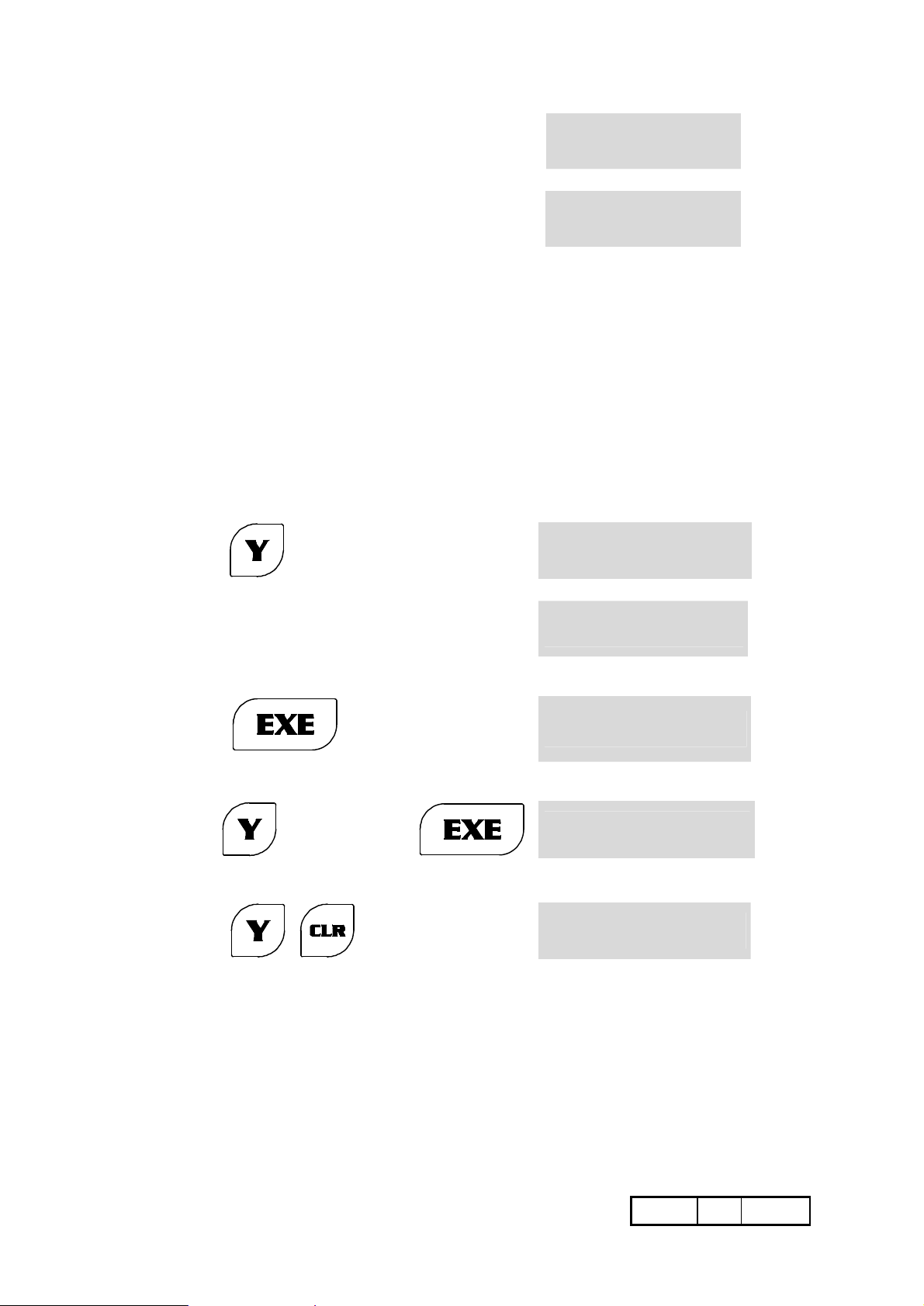

WORKPIECE CENTRE

This function makes it easy to identify the centre between two points A and B of a

workpiece being machined (distance between centres of holes, geometrical figures, sides

of the workpiece, etc.). To perform the function, for example on the Y Axis, proceed as

follows:

A) Go to the first position, A, by moving the Carriage along the Zo Axis.

Let us suppose that in this position the display of the Y Axis indicates

the dimension 30.00 (which it is not necessary to reset):

B) Key

Both the LED of the Y Axis and the LED of the ½ symbol will flash on the keypad.

The auxiliary display will show the wording “WORKPIECE CENTRE”.

C) Now go to the second position, B. Let us suppose that in this position the display of

the Y Axis shows the dimension 52.22

D) Key

The flashing LEDs will extinguish and a dimension will appear on the display of the

Zo Axis. This dimension is exactly half (rounded off, if necessary) of the path followed

by the Carriage between the two positions A and B. It will be sufficient to move the

Carriage as far as dimension “0.00” for it to be located exactly on the required

midpoint.

or

3 0. 0 0

1 1. 1 1

®Y

Y

NOTE: This function can only be carried out when the Axis concerned is set for

INCREMENTAL counting. Otherwise it is not completed by the calculation, as

this would interfere with the ABSOLUTE count settings.

10/06/2008 M042.E GQ

•19¥72

0

F 0 STORED DATA CLEARING

This function can be used to cancel the data entered by the operator, either globally or

selectively. The instrument has placed them in 11 different storage areas.

Key

and, if required

The indications concerning the types of data stored in the memory areas will be displayed,

together with the number corresponding to each area. If the keys indicated are pressed on

the keypad of the instrument:

All the data stored is cancelled.

1:

The data concerning linear corrections

2:

and scale factor corrections is cancelled

and these are reset to a value of 1 (that

10:

11:

Rotation speed is deleted

8:

Inclined constant pitch is deleted

9:

Circular flange is deleted.

Special circular flange is deleted

is to say, no correction).

Both the absolute and the incremental

3:

dimensions and references are cancelled.

The offsets are cancelled.

4:

The origins are cancelled

5:

The weight of materials is cancelled.

6:

The constant pitch is cancelled.

7:

Every time one of the numbers indicated above is pressed, the function will be carried out,

while for the functions without a code it is necessary to enter EXE.

10/06/2008 M042.E GQ

•20¥72

9

F 9 SETTING PRINTING LINE SPACINGS

When printing the labels (see SERIAL OUTPUT RS232), it is possible to set some

spacings among the printing lines (max .19), for the correct position on the labels.

To set the number of spacings, select function F 9.

Key

P r t. 0

X

press

press

Printer example (4 spacings) :

-------------- 1 spacing -------------->

-------------- 2 spacing -------------->

-------------- 3 spacing -------------->

-------------- 4 spacing -------------->

To increase the number (0-19)

To confirm the setting

P r t. 1

5 7. 0 8 6 5

= DIGITAL READOUT =

AXIS X : 57 . 0865

AXIS Y : 10 . 8480

AXIS Z : - 7 . 0985

UNIT : INCH

= DIGITAL READOUT =

AXIS X : 57 . 0865

AXIS Y : 10 . 8480

AXIS Z : - 7 . 0985

UNIT : INCH

X

X

10/06/2008 M042.E GQ

•21¥72

F 26 CONSTANT PITCH

This function is used to process workpieces having a constant machining pitch. Let us

suppose, for example, that six holes having a pitch of 13.75 mm have to be drilled:

Key

The instrument signals the operator to move the Carriages until the Origin of the 1st hole is

reached.

Key

Key

The instrument goes on to consider the other Axes. Enter the values or continue to press

EXE until you return to the initial X Axis (the LED on the X-Axis display flashes). Make

the first hole (the X-Axis display must indicate the dimension Zero. If this is not so, move

the Carriages to Zero).

Key

Follow the Zero with the Carriage and make the second hole Proceed as described until

the workpiece has been completed. If it is not necessary to repeat the same operation on

other

workpieces, press CLR. If it is, press REF. The display will indicate the total value of the

last

position reached, that is to say:

13.75 x n° 5 pitches = 68.75 (return to Zero with the Carriage, enter X and start

again)

When working it is possible to reverse the pitch direction for each axis:

13.75

26

and enter the value of the

pitch

The X display show the value

and the X Axis

display will be

reset

O r i G.

S t E P

0. 0 0

- 1 3. 7 5

®X

®X

X

®X

press

It must be remembered that:

A) The counting direction must be the same as the direction of displacement (if

necessary, use +/- to reverse it while entering the pitch, that is to say: 13.75 +/-

EXE).

B) Carrying out holes in succession does not lead to errors of the “cumulative” type,

even if the positions have not been reached with great accuracy by the operator.

C) It is not possible to perform any other functions during this operation.

10/06/2008 M042.E GQ

ex. inversion of X axis direction

- CONSTANT PITCH -

PITCH X: 1 ß

•22¥72

Loading...

Loading...