User’s Manual

Check before using Module NO: A-00-001

Contents

Check before use

Read me first ----------------------------

Introduction of G-scan ----------------------

Safety Warnings and Cautions before Use ------

G-scan Configuration

Specification ----------------------------------

Introduction of component ----------------------

Introduction of function -------------------------

Basic Use of G-scan

Power supplying ----------------------------

Power ON/OFF ----------------------------

Description for Main Component of H/W -----------

Description for Main Component of S/W Screen ------

Connecting the DLC cable ---------------------

Self Test Adapter connection ------------------

Configuration

Setup ------------------------------------

User Information

Version

Self Test

- 1 -

-----------------------------------

----------------------------------

-----------------------------

Module NO: A-00-001

Vehicle Communication Function

System Select --------------------

User’s Manual

Fault Code Searching

DTC Analysis

DATA Analysis

Actuation Test

----------------------

------------------

---------------------------

Vehicle S/W Management

ECU Upgrade

------------------------------

OBD-II Function (CARB OBD-II)

Flight Recording

--------------

------------

---------

-----------------

PC Communication

Software Installation --------------------------

Operating Program

--------------------------

Appendix

How to install Optional Items --------------------

O/S & Bootloader Update --------------------

G-scan and Peripherals Limited Warranty ----------

Disposal of Old Electrical and

Electronic Equipment

--------------------

- 2 -

User’s Manual

- 3 -

User’s Manual

Check before use Module NO: A-00-002

Read me first

Introduction

Thank you for purchasing G-scan. This manual describes the basic

information for using G-scan. Before using G-scan, please read this

manual to be familiar with important information.

Copyright

Global Information Technology Co., Ltd copyrights this Manual. All rights

reserved. No part of this manual may be reproduced in any form without

the prior written permission of Global Information Technology Co., Ltd.

No patent liability is assumed with respect to the use of the information

contained herein.

G-scan is registered trademark or trademark of Global Information

Technology Corporation in the United States and/or other countries.

ⓒ2007 Global Information Technology Co., Ltd. All Right Reserved.

Disclaimer

G-scan specifications and manual are subject to change without prior

notice. Global Information technology Co., Ltd. assumes no liability for

the products, which GIT do not produce.

- 4 -

User’s Manual

Introduction of G-scan

Check before use Module NO: A-00-003

Overview

Comparing with the conventional diagnosis equipment, the interface of

G-scan is configured to be easily operated. Anyone can easily use the

G-scan to maintain the vehicle with maximized service efficiency.

z Input using the Touch Screen

Without complicated button operation, you can select menu and

function on the screen directly. You can use diagnosis equipment

easily.

z 5.6″ Color TFT LCD

Adapting the 5.6″ large size Color TFT LCD, various data can be

shown on the same screen at the same time.

z TPMS (Option)

Embedding with TPMS module, it is possible to access to the TPMS

sensor installed in the vehicle with wireless communication.

z USB communication interface

Using the USB communication interface, it is possible to connect with

the diagnosis newly developed in future easily..

- 5 -

User’s Manual

Safety Warnings and Cautions

Check before use Module NO: A-00-003

Before Use

This section contains WARNINGS and CAUTIONS for safe usage of

G-scan Before use, the user should read the following information.

WARNING

This indicates incorrect handling may result in a

major accident involving death or serious injury.

z The G-scan should be secured in a safe location when operated in

the vehicle to avoid interference with other vehicle equipment.

z Only use the specified adapters and cables when connecting the G-

scan module. (7~35VDC).

z Ensure all cables are properly connected during operation. Do not

disconnect communication cable or power cables unless finished with

the equipment.

z Do not disassemble the G-scan module.

z When updating G-scan, connect the external power (AC/DC adaptor)

to supply stable power.

z Ensure that the module is installed in a safe and secure location to

avoid interference with other vehicle equipment.

z Use only genuine accessory parts supplied by GIT.

- 6 -

User’s Manual

Module NO: A-00-003

z Never connect the device to equipment rather than vehicles.

z Products are to be used within the right temperatures. (Refer to

Specifications)

z Products are to be stored within the right temperatures. (Refer to

Specifications)

z Use GIT products for their original purpose only.

z This product is designed for technicians with proficient skills therefore

all users must digest manuals fully before using the product.

z Users have their own responsibility for Product damages, fire hazards

and emitted gas caused by users with no full understanding of the

Cautions and other information stated in the manual.

z GIT products should never be tested or repaired by any one rather

those authorized service technicians by GIT.

z When exchanging rechargeable battery, comply with the method

described in this manual by reading before exchanging it.

z Use only rechargeable battery supplied from GIT.

z Do not disconnect the rechargeable battery at one’s discretion.

z Be careful that the rechargeable battery is not wet in water.

z Do not put the rechargeable battery near the fire.

z Do not impact to or prick the rechargeable battery with sharpen object.

z Don not put the rechargeable battery into the microwave oven or high

pressed vessel.

z Do not throw or apply with physical impact to the rechargeable battery.

- 7 -

Module NO: A-00-003

User’s Manual

z Be careful that the terminals of rechargeable battery are not shorted.

z If the rechargeable battery makes any abnormal condition such as

odor, heat, deformation or discolor, do not use it. If you are charging

or using the battery, stop the operation and remove the battery

immediately.

z Do not reverse the positive(+) and negative(-) terminals.

z Do not connect the battery directly to wall outlets or car cigarette-

lighter sockets.

z Do not put the battery into a fire or apply direct heat to it.

z Do not short-circuit the battery by connecting wires or other metal

objects to the positive(+) and negative(-) terminals.

z We GIT are not responsible for products other than products produced

by GIT.

CAUTION

This indicates incorrect handling may lead to

injury or damage to properties. Under certain

conditions more serious consequences may

result.

z Do not drop the G-scan.

z Do not place any objects (tools, manuals, etc.) on the G-scan.

z When connecting cables under the hood, secure the cables to avoid

damage caused by hot or moving parts.

z When connecting the DLC cable, check the locking device.

z Observe correct polarity when connecting the power supply cable.

z Properly store all components when not in use.

- 8 -

User’s Manual

z Do not use cables as carrying handles.

z Do not store products in places where

Extremely high or low temperature (Refer to feature of products)

Extremely high or low humidity (Refer to feature of products)

Inside a vehicle during summer season for a long time

z Exposed to direct rays

z Avoid a shock or vibrations or under heavy weight.

z Avoid a shock or vibrations during shifting.

z Keep products away and store from moisture.

z Keep products away from flammable substances or places where

fierce static electricity can occur.

z Products and accessories are not to be coated or painted with

chemical substances or acid that can corrode the equipment.

z Do not expose the equipment to X-ray or Microwave. This might cause

severe damage to the equipment.

z When inserting SD memory, check the direction.

z When supplying electric power to G-scan with 220/100V source, use

only the adapter supplied with this product.

z When using touch screen, use the specified stylus pen only. If you use

other sharp or keen object on the touch screen, it can be damaged

severely.

z Do not store the battery in the hot area. It may reduce the service time

of battery.

z If the G-scan with battery pack has to be stored for a long time(over 3

months), the environmental condition(Temperature: 23±5℃, Humidity:

- 9 -

User’s Manual

65±20%RH, Battery Level Indicator: 2 of 3 levels) should be observed.

z When your eyes contact battery liquid, do not rub your eyes, but clean

out them with fresh water. Contact doctor immediately.

z Do not expose the LCD to moisture or water.

z When LCD is broken, the liquid crystal material will be flown out. Do

not contact liquid crystal. If you contact it, clean it out immediately

with soap water.

z When LCD surface is contaminated, clean it using soft clothes with

alcohol.

z Do not contact volatile material except alcohol to LCD surface.

z Do not lay any heavy object down on LCD panel.

z After using for a long time, conduct zero calibration to the touch

screen.

- 10 -

User’s Manual

- 11 -

User’s Manual

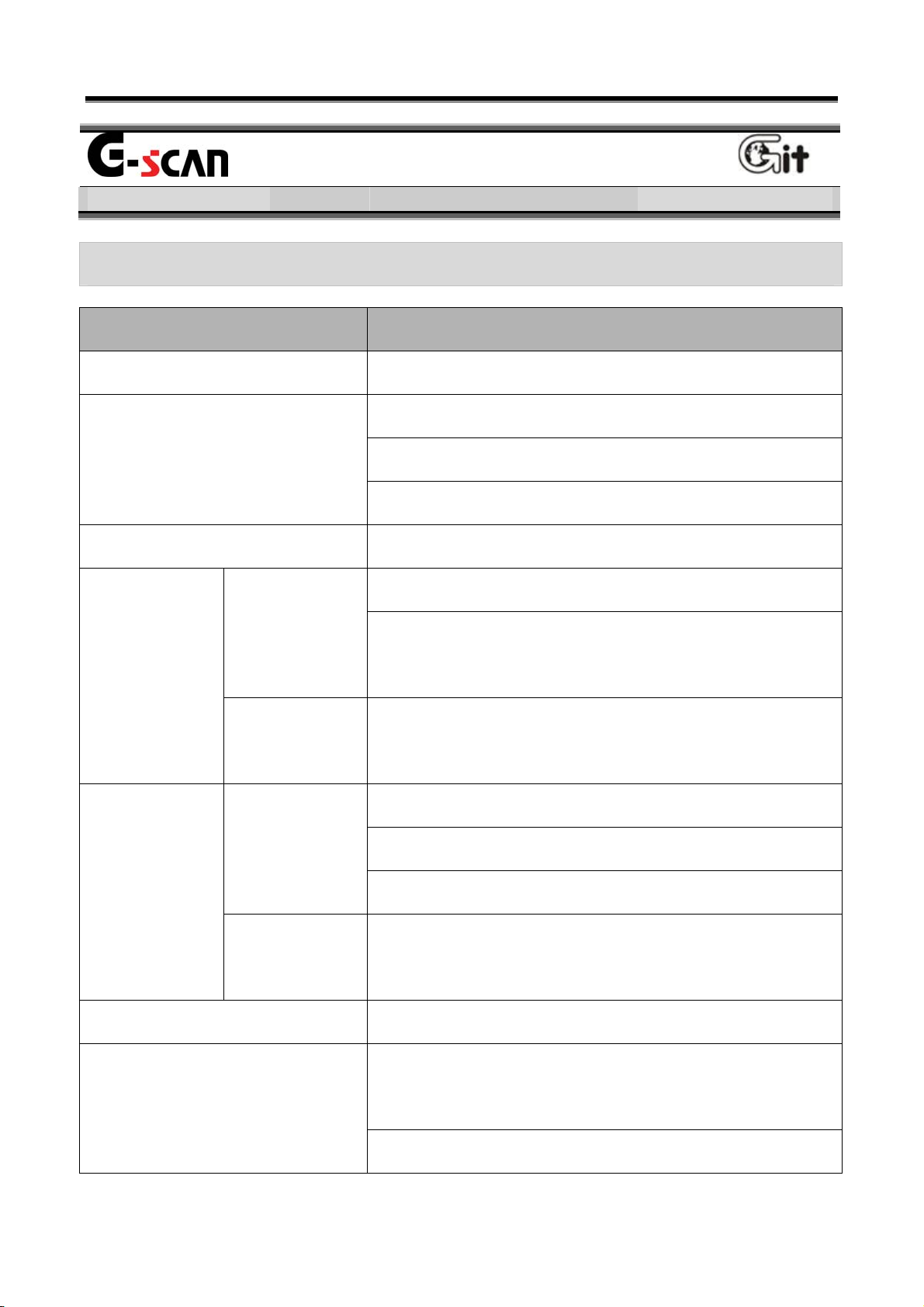

G-scan Components Module NO: A-01-001

Specification

Main Specification

Item Specifications

Micro Controller ARM9 (S3C2440A) @400MHz

NOR Flash Memory 16MB

Memory

External Memory 1GB (up to 4GB)

NAND Flash 64MB

SDRAM Memory 32MB×2

0℃~45℃(32℉~113℉) : Battery Charging

Temperature

Relative

Humidity

Operating

Storage

Operating

Storage

LCD 5.6″ TFT Analog LCD (480 × 234 pixel)

0℃~50℃(32℉~113℉) : Battery Discharging or

without Battery

-10℃~70℃(14℉~158℉)

(Refer to cautions of manual)

Noncondensing @ 0℃~10℃(32℉~50℉)

90%RH @ 10℃~30℃(50℉~86℉)

70%RH @ 30℃~50℃(86℉~122℉)

Noncondensing @ -10℃

(Refer to cautions of manual)

Power ON/OFF Key, Enter Key, ESC Key,

~70℃(14℉~158℉)

Input Devices

- 12 -

Arrow 4 Keys, Functional 6 Keys

Touch Screen 5.6 ″

User’s Manual

External Lamps 2 Color LED × 3 (Power, DLC, Option)

Sound Buzzer 1 Tone

Battery (*Option) Li-Ion Polymer 2100mAh 1cell

Operating Voltage 7~35VDC

Housing PC + ABS & Rubber Shroud

Dimension 194×129×59 mm

Weight about 900g(Body weight including Battery, TPMS

G-scan TPMS

Item Specifications

TPMS radio frequency

Module NO: A-01-001

Pack)

Transmission: 125Khz Reception: 315Mhz or

433Mhz

TRW (ASK, FSK)

TPMS Protocol

LEAR (FSK)

Siemens (FSK)

PC SPEC.

Item Specifications

External input/output device USB Host, USB Slave (USB 1.1)

G-scan (Vehicle Communication Interface)

Item Specifications

CAN ISO – 11898, ISO - 11519

K-Line/L-Line ISO-9141, ISO-9141-CARB, KWP-2000

- 13 -

Commercial Veh SAE-J1708, RS-232C

Data/Control Line Melco Pull-Down UART

Module NO: A-01-001

Added interface

Item Specifications

1. VSS Vehicle Speed Simulation

2.Voltage Output 5~20 VDC

User’s Manual

- 14 -

User’s Manual

FCC ID: TMGG1PZFMN001

NOTE: This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

CAUTION: Changes or modifications not expressly approved by the

party responsible for compliance could void the user's authority to

operate the equipment.

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including

interference that may cause undesired operation.

- 15 -

User’s Manual

Introduction of Components

G-scan Components Module NO: A-01-002

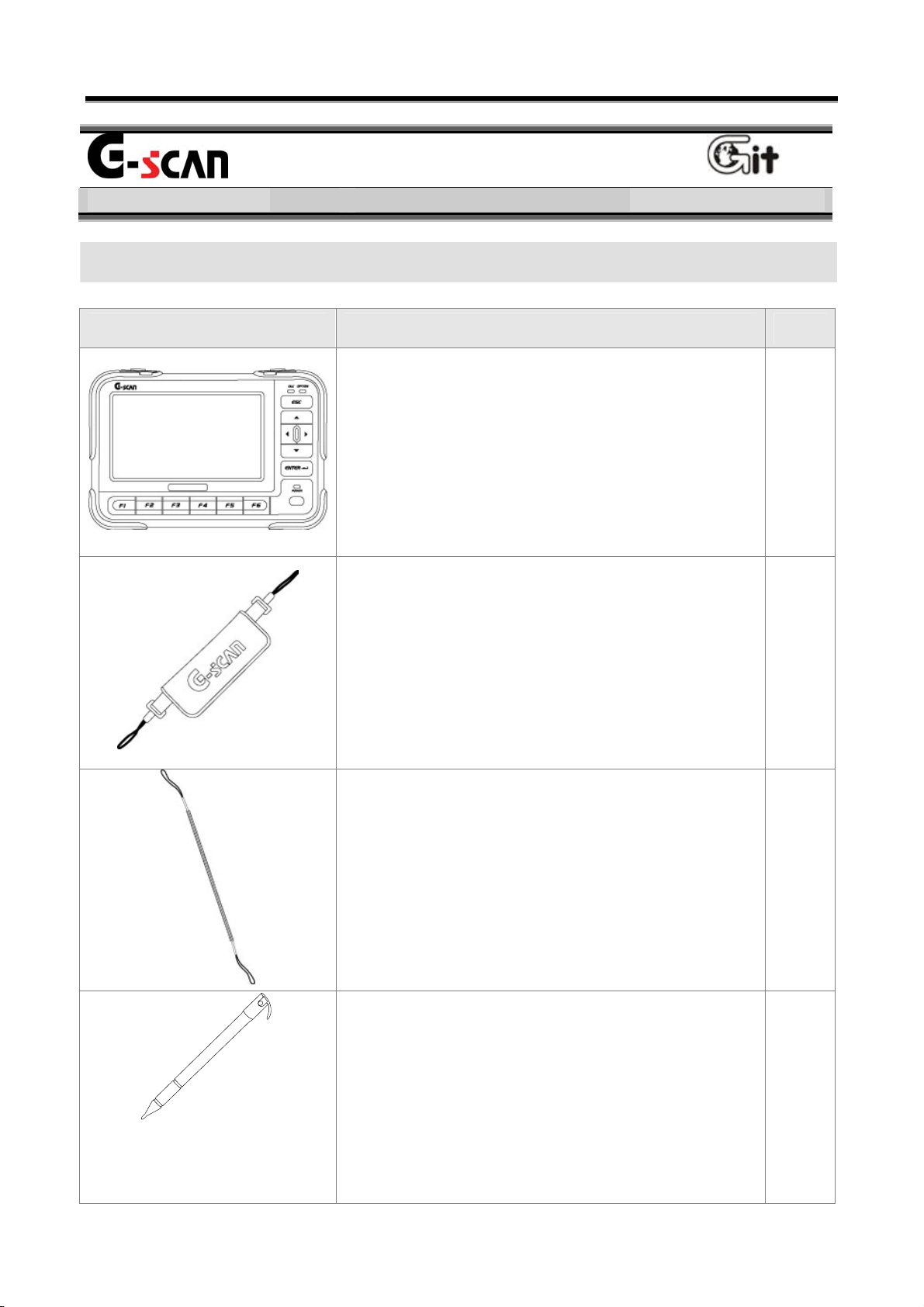

G-scan Hardware Components

Part Description Qty.

Part Name: G-scan module

P/No:G1PZFMN001

G-scan module comprises of the main module

for vehicle communication and the option pack

(Battery pack, TPMS pack).

P/Name: Hand Strap

P/No: G1PDDMN002

1

This is the hand strap for preventing damages

by falling during using the G-scan.

P/Name: String - Stylus

P/No: G1PDDMN003

A spring type string for preventing the stylus

pen from being lost.

P/Name: Stylus Pen

P/No: G1PDDMK020

The specific tool for operating touch screen of

1

1

G-scan. When using the touch screen, use

- 16 -

this stylus pen only.

1

User’s Manual

Part Description Qty.

P/Name: CABLE-DLC

P/No: G1PDDCA001

DLC main cable for communication between

G-scan module and (16 pin) OBD-II diagnosis

connector on vehicle.

P/Name: User’s Manual

P/No: N/A

The book describing the basic information for

1

using the G-scan.

P/Name: CD (S/W)

P/No: N/A

CD includes the PC utility program.

The PC utility supports the G-scan update and

the G-scan system recovery.

P/Name: Adapter[16pin-20pin(R)]

1

1

P/No: GHDM-244000

DLC Adapter cable [16pin to 20pin(R)] for

Main DLC cable (P/No: G1PDDCA001) and

20-pin diagnosis connector on vehicle.

20pin (R) connector is GRAY in color.

- 17 -

1

User’s Manual

Part Description Qty.

P/Name: CABLE - CIGAR

P/No: G1PDDCA002

It is used for supplying external power to the

G-scan using cigarette lighter terminal.

P/Name: CABLE - BATTERY

P/No: GSTA-37210A

The cable for connecting the Cable – Cigar

(P/No: G1PDDCA002) to the battery terminals.

P/Name: CABLE-mini USB(DOWNLOAD)

P/No: G1PDDCA003

1

1

Cable for communication between G-scan and

PC(Laptop)

1

P/Name: ADAPTER(Self Test Jig)

P/No: GHDM-24D000

This self-test adapter is used for selfdiagnosis functions that are described in a

separate chapter. Do not use this adapter

except for its specified purposes. For more

information about self-diagnosis, see chapter

(Module: A-02-006) Self-test adapter.

1

- 18 -

User’s Manual

Part Description Qty.

P/Name: Carrying Case

P/No: G1PDDHA001

The case preserving G-scan body and

components. For preventing from being

damaged and lost, G-scan should be stored in

this case after using.

P/Name: AC/DC Adapter

P/No: GHDM-260001

Adapter for supplying power to the G-scan

main module from AC power

1

1

P/Name: AC Power Cable

P/No: GHDM-273000

Cable for AC/DC adapter

The socket plug for AC power cable can be

different depends on each area. Please

purchase the right plug if it doesn’t match with

your country’s electrics specification.

P/Name: Adapter(16-12)

P/No: GHDM-245000

This adapter is connected between Main DLC

cable(P/No: G1PDDCA001) on the G-scan

module and 12pin diagnosis connecter on

1

1

some specific vehicles.

- 19 -

User’s Manual

Part Description Qty.

P/Name: (10-8-2)

P/No: GHDM-247000

DLC adapter cable for reprogramming and

setting Remote Keyless Entry(RKE). 3 different

(Optional Item)

(Optional Item)

connectors each(10, 8 and 2pins) compose

the other side of this 16pins diagnosis

connector. This adapter is used with the main

DLC cable(P/No: G1PDDCA001) , while

connected to the G-scan module.

P/Name: G-scan TPMS Pack

P/No:

TPMS module and rechargeable battery are

embedded.

P/Name: G-scan Battery Pack

P/No:

Rechargeable battery is embedded.

1

1

z Please check above items at opening this product.

z The optional items are for purchasing additionally.

1

- 20 -

User’s Manual

Module NO: A-01-003

G-scan Components Module NO: A-01-003

Introduction of function

z Possible to communicate with all vehicles of HMC/KIA

z 5.6″ TFT LCD

z Possible to search the DTC of all control module installed in vehicle at

the same time

z ECU upgrade

z Diagnose the vehicle with CARB OBD-II

z Record the travel data

z Support supplementary functions for diagnosis

z Actuator enforced drive test

z Comparison analysis through dual mode

z Support data relating to DTC

z Convenience and Long endurance

z Easy to operate using touch screen

z Expandable function using USB interface

z TPMS module diagnosis

z Embedded rechargeable battery (Option)

z Support supplementary function relating to TPMS (Option)

- 21 -

User’s Manual

- 22 -

User’s Manual

Basic Use of G-scan Module NO: A-02-001

Power Supplying

1. Supply external power

There are 4 methods for supplying external DC power to the G-scan.

z With DLC cable

z From the cigarette lighter terminal in cabin

z From the battery of vehicle

z From the AC/DC adapter

2. Power supplying from embedded rechargeable battery (Option)

z When using wireless communication (LF/RF) of TPMS

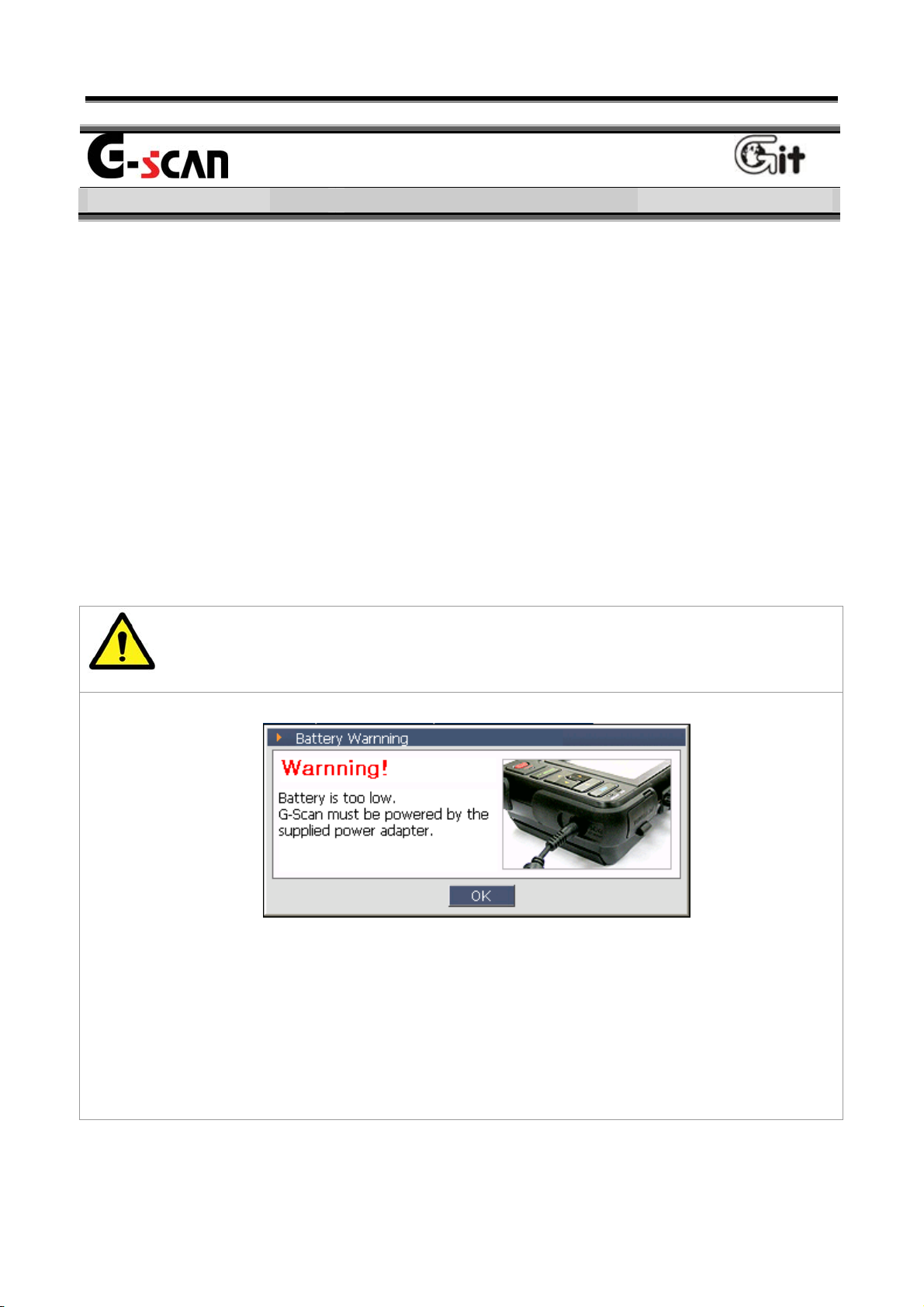

Caution

<Figure 1: Low Voltage Warning for Rechargeable Battery>

z The <Figure 1> is the message warning the low battery. If you see

this message, supply the external power immediately.

z Otherwise, the G-scan will be turn OFF automatically.

- 23 -

Module NO: A-02-001

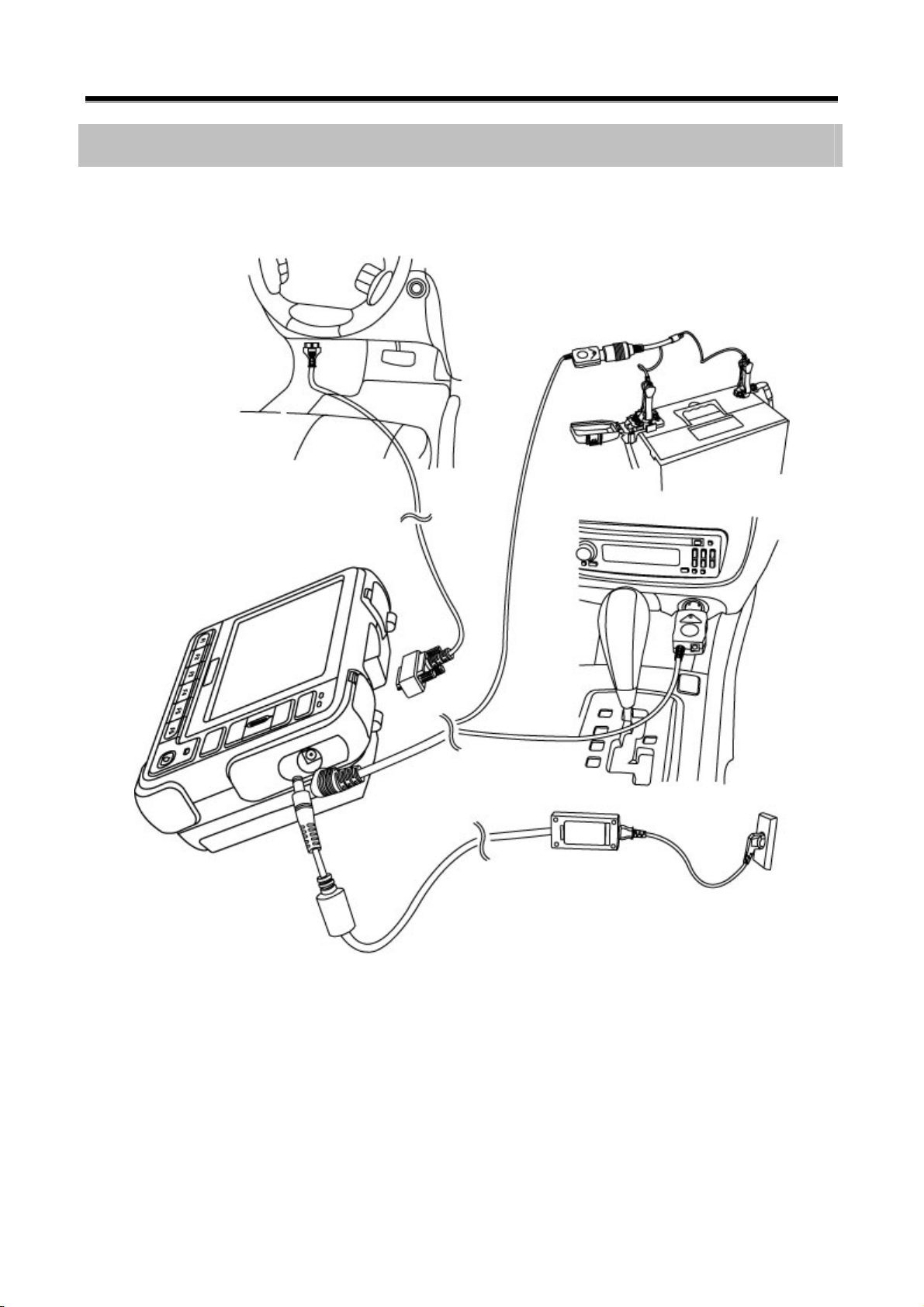

How to connect the external power

User’s Manual

<Figure 2: Connect the External DC power to G-scan>

- 24 -

User’s Manual

Module NO: A-02-001

Description of Power Supplying Method

Power supplying with the DLC cable

The vehicle of which diagnosis connector terminal is the 20-Pin

connector or which is satisfying the OBD-II communication regulation

can be supplied the electric power from the DLC cable without any

additional power line.

Note:

The DLC connector, in general, is located at the lower part of the

driver’s front panel. This location may be different somewhat, please

check the correct location before connecting.

From the cigarette lighter in the cabin

Using the cigarette lighter power cable purchased as a basic item with

the G-scan, the electric power can be supplied.

Note:

When using the cigar cable, the power will be cut during ignition of the

engine. Therefore, for the G-scan without rechargeable battery, the

power will be OFF. If your G-scan does not have rechargeable battery

and you diagnose vehicle relating to the ignition of engine, use other

power supplying method.

- 25 -

Module NO: A-02-001

User’s Manual

From the vehicle battery

When power is supplied form the vehicle battery, the electric

power can be supplied without interruption.

Cautions at connecting the vehicle battery

Do not contact the battery power line to the driving part in the

engine room.

Connect correct power lines to the battery terminals.

From the AC/DC adapter

Using the AC/DC adapter purchased as a basic item with the G-

scan, the electric power can be supplied to the G-scan.

When updating the G-scan, use the AC/DC adapter for supplying

stable power to the G-scan.

Warning

Use only the AC/DC adapter supplied by GIT for the G-scan. GIT

has not responsibility for the damage by different kinds of AC/DC

adapter.

Caution

At communicating with vehicle (for all vehicle diagnosis function

with DLC cable), the vehicle battery should be connected always.

For updating the G-scan, connect the AC/DC adapter for supplying

the stable power.

- 26 -

User’s Manual

Basic Use of G-scan Module NO: A-02-002

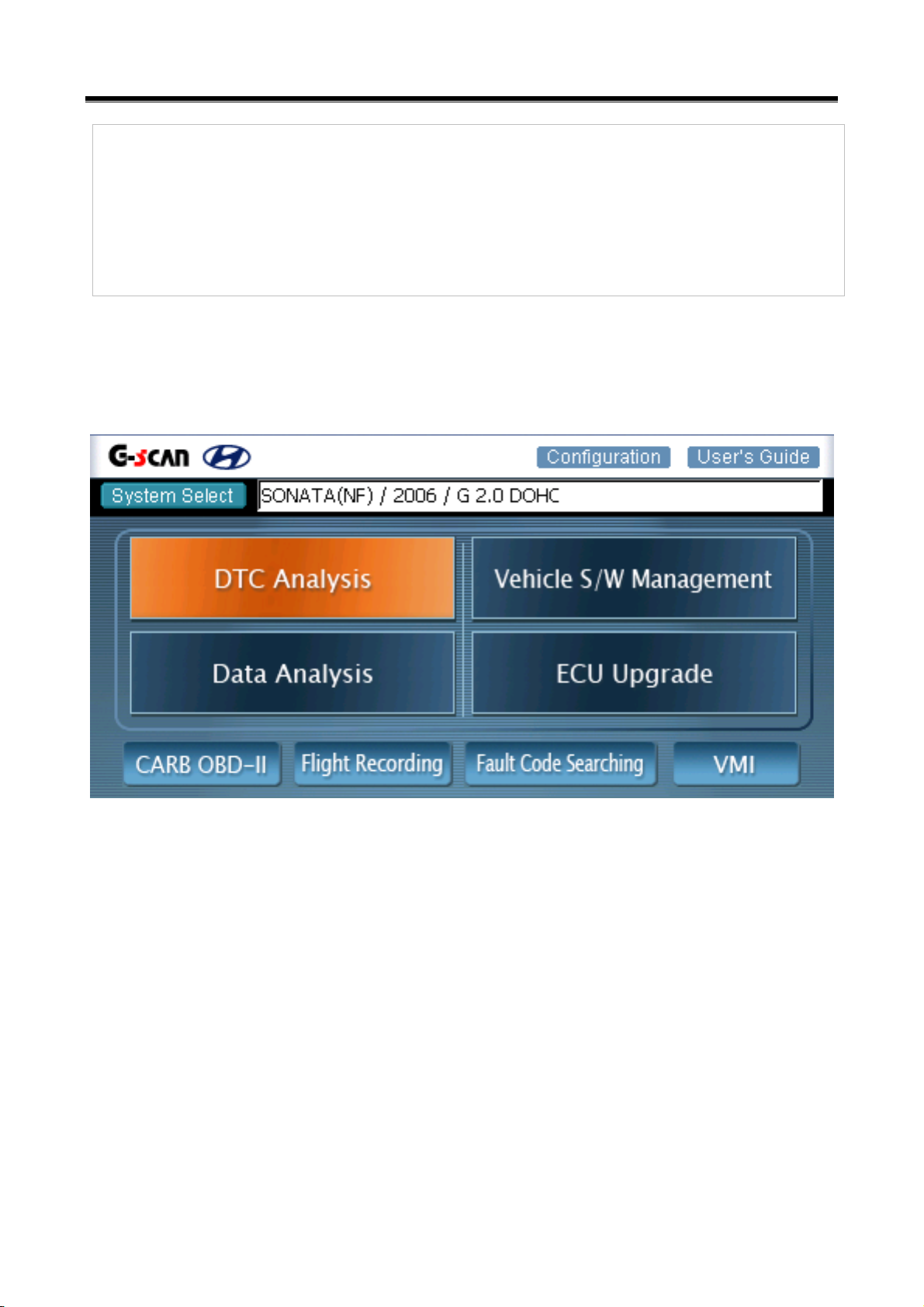

Power ON/OFF

<Figure 1: Location of the Power S/W>

Power ON/OFF Method

Power ON

1) Check the power supplying condition of G-scan.

Notice:

For the details of power connection to the G-scan, refer to “Power

Supplying” of the “Basic use of G-scan”.

2) Press the “Power Switch” shown in <Figure 1> until the DLC LED and

OPTION LED located at upper right of the G-scan are turn from amber

to green. (It requires about 0.5 seconds..)

- 27 -

Module NO: A-02-002

User’s Manual

Notice

For the lightening color of POWER LED, refer to the “Description for

Main Component of H/W” of the “Basic Use of G-scan” (Module: A-

02-003).

After booting the G-scan normally, the main screen of G-scan will be

shown as <Figure 2>.

<Figure 2: Main Screen of G-scan>

Power OFF

z Press the power switch for 2.5 seconds, the G-scan will be turn off.

- 28 -

User’s Manual

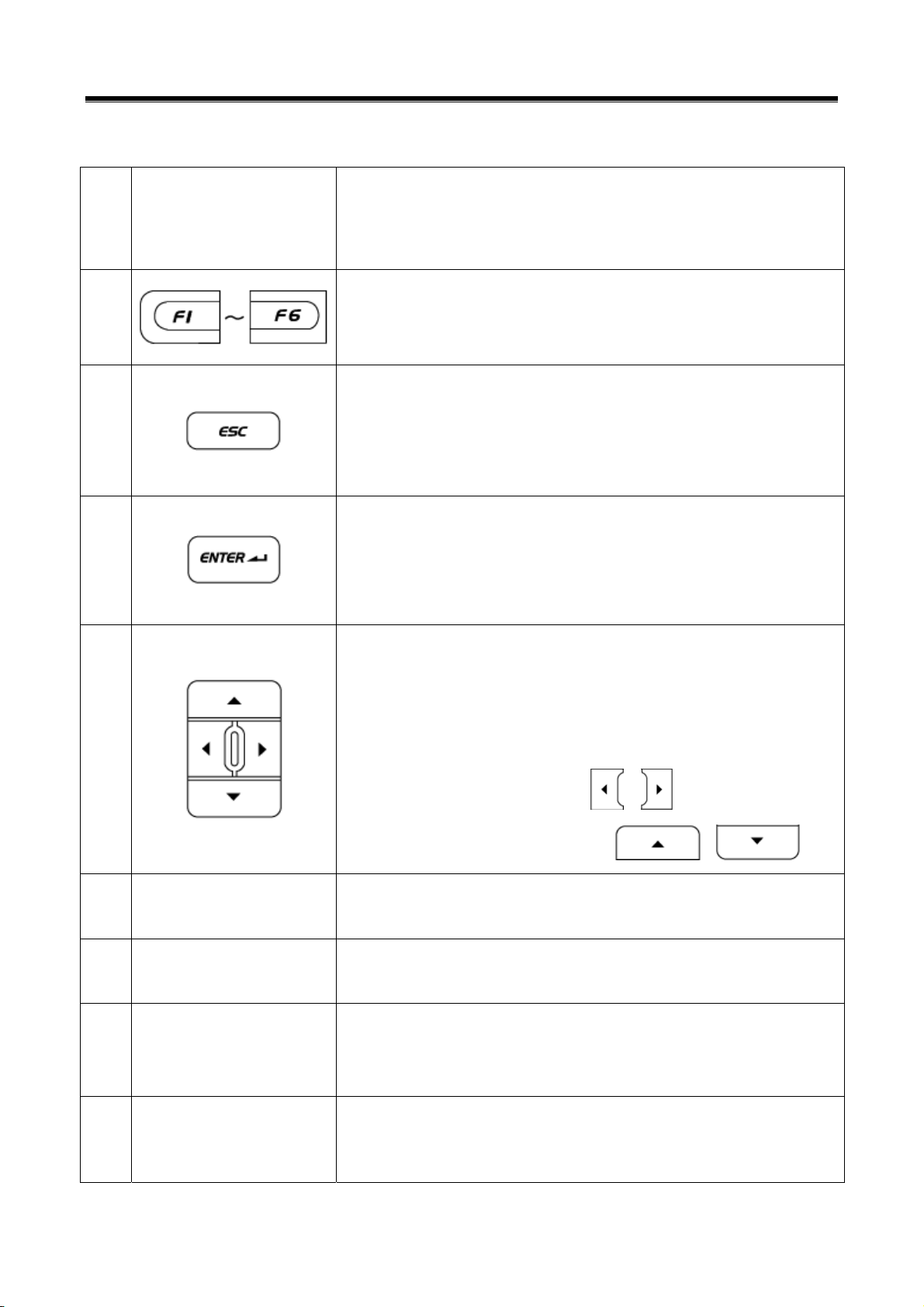

Description for Main

Component of H/W

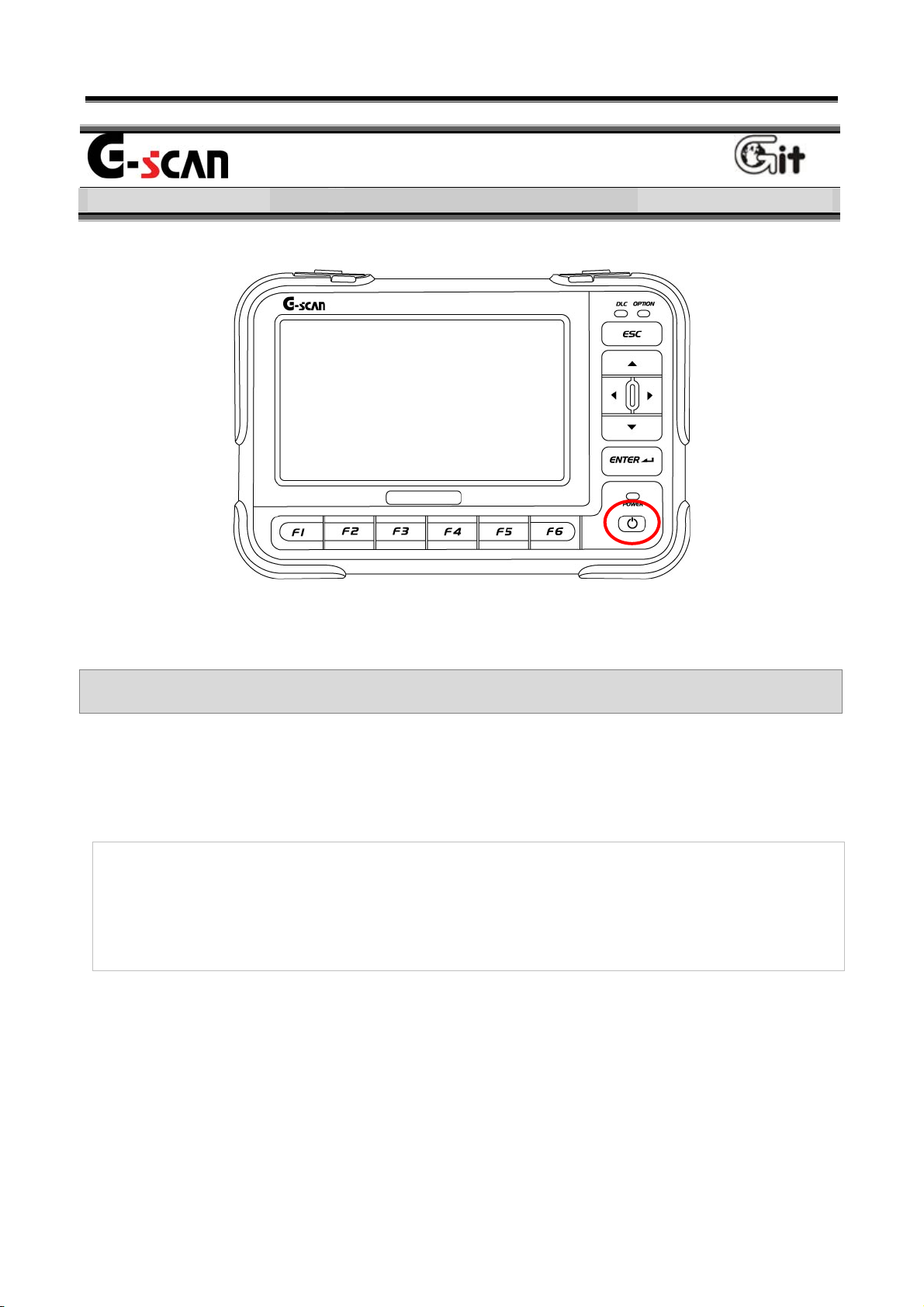

Basic Use of G-scan Module NO: A-02-003

Even the G-scan is developed as its function can be operated through

the touch screen, for more fluent operation of G-scan, please be familiar

with the functions and positions of the buttons, terminals and LEDs

installed at the G-scan hardware.

Touch Screen and Input Button

<Figure 1: Front view of G-scan>

- 29 -

Module NO: A-02-003

1. Description for Front side of Body

Use the specific stylus pen at selecting functions

①

Touch Screen

and items on the touch screen

H/W buttons for operating functions represented in the

User’s Manual

②

③

④

⑤

screen function button at bottom of screen.

Exit from the screen currently executed.

Move the previous screen at selecting model.

Close the pop-up window.

Execute the item or function selected on the current

screen

Move to the next screen at selecting model.

Move the cursor to the wanted item or function on the

current screen.

At diagnosing in dual mode, you can select the

⑥

⑦

⑧

⑨

- 30 -

Power ON/OFF the power of G-scan.

POWER LED LED showing the power condition.

DLC LED

OPTION LED

diagnosing window with

the diagnosing window with

LED showing the communication condition with the

control module installed in the vehicle.

LED showing the communication condition with

supplementary option item connected to G-scan.

, and the items in

, .

User’s Manual

Module NO: A-02-003

Note:

As the CALIBRATION of the touch screen may be changed by the

temperature variation or passing of the time, reset the CALIBRATION of

the touch screen at the “Setup” in the Configuration.

Notice

For the details relating to the power ON/OFF, refer to the “Power

ON/OFF” in the “Basic Use of G-scan” <Module NO: A-02-002>.

z POWER LED Lighting Condition

Charging Charged

With DC power LED (Red) ON LED (Green) ON

Battery Pack

Installation

Without DC

LED OFF LED OFF

power

Tips

If the battery pack is not installed, when the external power is connected,

the Power LED lights the Green up.

Notice:

For the details of the power supplying, refer to the “Power Supplying” in

the “Basic Use of G-scan” <Module NO: A-02-001>.

- 31 -

z DLC LED Lighting Condition

LED operating condition

Communicate with Control

Module

Communication with Control

module is OFF

z OPTION LED Lighting Condition

TPMS Pack (LF) wireless

transmission

User’s Manual

LED (Green) Flicker

LED OFF

LED (Red) ON

TPMS Pack (RF) wireless reception LED (Green) ON

Communication by USB port (Host)

LED (Green) Flicker

of the G-scan body

Others LED OFF

- 32 -

User’s Manual

2. Description for the Communication Terminals

<Figure 2: G-scan COM port>

Terminal for connecting to DLC cable to

DLC

communicate with vehicle.

OPTION

PC COMM

The USB Host port prepared for expanding

the function by connecting to additional

equipments in future.

The COM port for using the vehicle COM

PASS-THRU

functions from the PC.

The COM port for maintaining the G-scan and

DOWNLOAD

expanding the functions in future.

- 33 -

3. SD Memory Slot & Reset Button

<Figure 3 SD Memory Slot and Reset Button>

User’s Manual

SD Memory

Slot

RESET Button

Slot for inserting the SD card restoring the various

data for driving the G-scan.

When program has errors by the O/S or other

problems, press the Reset button to turn OFF the

G-scan in force. After pressing the Reset button,

press the Power Switch to reboot the G-scan.

- 34 -

User’s Manual

Description for the Main

Component of the S/W Screen

Basic Use of G-scan Module NO: A-02-004

Unlike the conventional diagnosis equipments, the screen of the Gscan is equipped with the touch screen. The images output on the Gscan screen are not simple pictures but the functional buttons for

operating the diagnosis equipment.

This chapter describes the functions and marks commonly applied to

the Main Screen of the G-scan and other diagnosing screen. Please be

familiar with these descriptions to operate G-scan freely.

Components of the Initial Screen

①

②

③

④

⑤

⑫

⑥

⑦

⑧ ⑨ ⑩ ⑪

<Figure 1: Components of the Main Screen>

- 35 -

Description for the Components of the Initial Screen

Configuration and Help

ConFigure or proceed to the “Setup”, “User

①

Information”, “Software version” or “Self-diagnosis”

User’s Manual

②

Model Selection

③

Diagnosis Menu

④

⑤

⑥

Support the Help for using this product.

Select the model and system for diagnosing.

* The selected system is shown in the window right

side of the “System Select” button.

Show the fault code on the screen by

communication with the selected vehicle system.

Show the additional fault codes by further

communication.

Check the data of input/output devise of ECU

installed at the current vehicle by the communication

with the selected vehicle system.

Support supplementary vehicle S/W function except

the diagnosing functions (DTC, Current Data,

Actuation Test).

⑦

⑧

⑨

⑩

⑪

- 36 -

Support the ECU upgrade.

Diagnose the vehicle applied with OBD-II COM

program.

Recording the travel data, analyze the data.

Search the fault codes of vehicle systems setup in

system selection multiply at the same time without

re-selection of system.

At connecting GDS VMI (expanded install item), the

multi-meter, oscilloscope, simulation test functions

are possible.

User’s Manual

Diagnosis Screen Components

<Figure 2: Diagnosis Screen>

Showing the Diagnosing Model and Hot Key

z The diagnosing item currently undergoing and the model for

diagnosing are shown. For the right icons, refer to the following table.

z Description for the Common Icons in Diagnosing Window

Closing the window currently undergoing, return to the initial main

screen.

Capture the screen currently undergoing and save it.

The captured screen will be saved at the “Storage Card₩GscanImage₩Model” folder of SD memory inserted into G-scam.

Show the data of the system currently communicating in detail.

Change the system for diagnosing except the vehicle model.

Change to the dual mode from the overall screen.

Change to the overall screen from the dual mode.

- 37 -

User’s Manual

Diagnosing Window

According to the diagnosis mode of the G-scan, it shows the data and

the results of the diagnosis.

<Figure 3: Data Output Window>

Screen Function Button

<Figure 4: Screen Function Button>

At the diagnosis item currently undergoing, the functions of the function

button

are shown. the function can be operated by

selecting it using the stylus pen.

Tips:

The property of the screen function button will be changed according to

the diagnosis mode (or the activated window at the dual mode).

- 38 -

User’s Manual

Basic Use of G-scan Module NO: A-02-005

Connecting the DLC cable

For the communication between the control module installed at the

vehicle and the G-scan, the DLC cable should be connected.

According to the kinds of connector used in the communication, there

are different in connection of power supplying line and the adaptor

connection.

<Figure 1: Connecting the DLC cable>

- 39 -

User’s Manual

Vehicle with the OBD-II Standard Connector

Only with the DLC COM cable without additional power line, it is possible

to communicate with control module and to supply power.

Tips

In general, the DLC connector is located at the lower part of the driver’s

front panel. According to the kinds of vehicle, it may be different.

Therefore, before connecting, please check the correct position at first.

Vehicle without the OBD-II Standard Connector

Connecting the power

For the vehicle without the OBD-II standard connector, connect the

power line additionally for operating the G-scan

Connecting the vehicle diagnosis

For the communication with the control module installed at the vehicle,

additional adapter is required. After connecting the adapter to the 16

pin of the DLC cable, connect it to the COM connector terminal of the

vehicle.

Notice:

For the power supplying, refer to “Power Supplying”<A-02-001> in the

“Basic Use of G-scan”.

th

- 40 -

User’s Manual

Caution

When disconnecting the main DLC cable, press the locking clip. Do not

pull the wire or distort it. It may cause the damages of the cable or

connector.

- 41 -

User’s Manual

Caution

At connecting the main DLC connector to the G-scan, tighten the 3

clamping screws to the body of G-scan firmly.

At carrying the G-scan, do not hold the DLC cable. Hold the module

body or hand strap.

- 42 -

User’s Manual

Basic Use of G-scan Module NO: A-02-006

Self Test Adapter

The self-test functions are used to check the Main DLC cable (P/No:

G1PDDCA001) and specific related circuits. Not all G-scan circuits are

checked with the self-test functions.

Purpose and Scope of Self Test (Semi-Test)

Basic operation of the self-test function is the loop-back theory.

Loop-back theory is verification between sent data from the G-scan

module and returned data, which passed through the pins of all the

outside connectors during the self-test.

Some communication circuits such as high speed CAN, low speed CAN

and SAE-J1708, cannot be checked with loop-back tests.

There are 2 self-test steps included in the Self Test function on the

Configuration menu.

z Step A: Performs test functions by automatically changing circuit

Configurations at the inner end of DLC connector of the G-scan

module.

- 43 -

User’s Manual

z Step B: Performs test functions on the Main DLC cable using the self-

test adapter which will short all the terminals (except power and

ground functions) at the end of Main DLC cable.

This self-test function cannot determine open or short circuits in other

adapter cables except Cable-DLC (P/No: G1PDDCA001).

- 44 -

–

User’s Manual

-

Connecting the Self-Test Adapter (GHDM – 24D000)

Before performing the self-test function, connect the Main DLC cable

(P/No: G1PDDCA001) between G-scan module and Self-test adapter

(P/No: GHDM – 24D000). Then, connect the other side of Self-test

Adapter to the OBD-∥ Connector on the vehicle as shown in [Figure1].

Figure 1. Installation of the Self-test adapter

After installing the adapter, follow the instructions as indicated on the

Self-Test screen located on the Configuration menu.

- 45 -

User’s Manual

Configuration

- 46 -

User’s Manual

Configuration Module NO: A-03-001

Setup

Selecting at the main screen, “Setup” screen will be

shown. In this item, the brightness of touch screen can be adjusted for

the user’s favor, the language can be selected and the operation of key

pad and calibration of the touch screen can be controlled.

Introduction of the Setup Main Screen

<Figure 1: Setup Screen>

The descriptions for the screen function button in “Setup” are as follows.

Item for setup the brightness of LCD screen.

Item for setup the language.

Checking the operations of the 12 function buttons.

Calibrating of the touch screen.

Set the diagnosis Data unit and the Buzzer ON/OFF.

Move to the next Tab.

- 47 -

User’s Manual

Operating Order and References

Screen Brightness Adjustment

1) Select the “Back Light” item to change the gray scale of ambient color.

Select the function button

Select the

at the bottom of screen on the touch screen.

.

Select the “Back Light(F1)” on the touch screen.

<Figure 2: Back Light Adjustment>

2) Adjust the brightness using stylus pen or pressing the on the

key pad.

3) It can be adjusted with 5 levels. Screen will be brighter as it is adjusted

to (+).

4) Item movement after adjusting screen

Using stylus pen, move to the item directly on the screen

Selecting the

, move to the menu and use the direction

arrow keys to move to wanted item.

- 48 -

User’s Manual

Language Selection

1) Selecting the “Language” item, the gray scale of around is changed.

Select the function button .

Select the

at the bottom of the touch screen.

Select the 의 “Language(F2)” on the touch screen.

<Figure 3: Move to Language Selection>

2) Using the stylus pen, press the right mark of language window or ,

and press the

. Then language list will be shown.

<Figure 4: Language Selection>

- 49 -

3) Change item after selecting language

Using stylus pen, select item want to move on the touch screen.

User’s Manual

Select

arrow keys

or to move to menu, change item using

- 50 -

User’s Manual

Keypad Test

1) Selecting “Keypad Test” item, around color is changed as shown in

<Figure 5>.

Select the function button .

Select

at the bottom of the touch screen.

Select the “Keypad Test(F3)” on the touch screen directly.

<Figure 5: Keypad Test>

2) Pressing the function button F1~F6, arrow keys, ENTER, ESC key, the

color of position representing mark of button will be changed to

orange color. You can easily check the button condition.

3) Change Item after completing Keypad Test

Select item want to move on the touch screen using stylus pen.

Select

+ at the same time, move to menu. Using

arrow keys, move to the wanted item.

- 51 -

User’s Manual

Calibration of Touch Screen

Selecting the “Touch Screen Calibration(F4)” item, following screen will

be shown.

Select the function button

Select the

at the bottom of the touch screen.

.

Select the “Touch Screen Calibration(F4)” directly on the touch

screen.

<Figure 6: Calibration of Touch Screen>

1) Select the center of (+) mark on the touch screen as shown in the

above figure with the stylus pen.

* Totally 5 points are shown on the screen. Select all center points of the

5 marks.

- 52 -

User’s Manual

2) After selecting 5 centers of (+) marks, message is shown in <Figure 7>.

: Save the new calibration and move to menu.

: Cancel the new calibration and move to menu.

<Figure 7: Completion of the Touch Screen Calibration >

- 53 -

Setup for Unit and Buzzer ON/OFF

User’s Manual

1) Selecting

or ‘F5’, following setup window will be shown.

<Figure 8: Unit & Buzz setup>

2) Setup the Unit and Buzz operation in the setup window.

Using stylus pen, setup on the touch screen.

Setup using the function button

Change to the wanted item among the

①

setup items

②

Select the item to setup

Unit: select wanted unit in the list.

③

Buzz: select ON or OFF

Unit: after selecting unit, move to

setup list.

④

Buzz: after setup ON/OFF, move to

setup list.

Repeating ①~④, setup the unit

- 54 -

User’s Manual

3) After completing all setup, select at the bottom of setup

window.

Notice:

The unit selected at this Tab is applied to the unit of data represented in

the diagnosis function.

- 55 -

User’s Manual

Exit from“Setup”

After completing “Setup” item, move to other Tab.

Select to move to “User Info”.

Using stylus pen, select the “Tab” on the upper portion of the touch

screen directly to move.

Move to the main screen

Select to move to the main screen.

Select

at the right upper portion of the screen to move to the

main screen.

Selecting ‘Move to main screen’, following message will be shown.

<Figure 9: Save Message>

Save the setups and exit to the main screen.

Cancel the setups and exit to the main screen.

“Back Light”, “Touch SCR”, “Unit” among the “Setup” items will be

save with the final setups regardless of this message shown at moving

to main screen.

- 56 -

User’s Manual

Configuration Module NO: A-03-002

User Information

This is the item for inputting customer’s personal information.

To change items in the below level of ‘User Info’ item, use the touch

screen and the function button. To input personal information, us the

touch screen only.

How to input the User Information

How to change to“User Info” item

Selecting the “User Info” on the touch screen using the stylus pen,

following screen will be shown.

Select the

“User Info”.

, buttons in the “Setup” to move to

How to change between “User Info” lists

Select the items on the touch screen using the stylus pen.

Using arrow keys (Up, Down) of the function button, move to the

list want to input and press the arrow key (right) to select it.

<Figure 1: User Info Screen>

- 57 -

User’s Manual

Input the personal information

It is impossible to input the information using the Function &

Supplementary Function buttons. Use the stylus pen on the touch screen

to input personal information.

How to input

1) Using stylus pen, at the “User Info” screen, select the input window or

using the direction button

and select the

, then following keyboard will be shown.

, select the User Info list

2) Using the stylus pen, press the keyboard on the touch screen to input

the personal information.

3) After input the user information, select

or select other input

window using the stylus pen.

<Figure 2: Screen Keyboard>

- 58 -

User’s Manual

Exit from “User Info”

After setup the “User Info” item, move to other Tab

Select the

to move to “Version”.

Select the “Tab” at the upper side of the touch screen using the stylus

pen to move.

Move to main screen

Select

Select

at the upper right side of the touch screen to move to the

to move to the main screen.

main screen.

Selecting the ‘to main screen’, the following message will be shown.

<Figure 3: Save Message>

Save the setups and move to main screen.

Cancel the setups and move to main screen.

- 59 -

User’s Manual

Configuration Module NO: A-03-004

Self Test

It is the function for checking if the circuits relating to the

communication of G-scan and the DLC cable have defects or not. If the

equipment has problems relating to the communication function,

conduct test following to the instruction of the screen.

Description of Self Test Screen

<Figure 1: Description of Self Test Screen>

Item for checking the defects of circuits relating to the

communication of G-scan.

Item for checking the defects of the DLC cable.

Start the Self Diagnosis Test.

- 60 -

User’s Manual

Self Diagnosis Test

How to change to the “Self Test” item

z Selecting the “Self Test” on the touch screen using the stylus pen, the

following screen will be shown.

z Press the 에서

, button at “Version” to move to the

“Self Test”.

<Figure 2: Move to the Self Test>

z Using the stylus pen, select it on the touch screen or press the

direction buttons

, then , can be

selected.

- 61 -

User’s Manual

STEP-A Test

The purpose of STEP-A test is for diagnosing the specific

communication circuit of the G-scan. During proceeding with this test,

the power is supplied by the DLC cable and the Self Test adapter. For

the details of Self Test adapter, refer to the ‘Connecting the Self Test

adapter’ in the ‘Basic Use of G-scan’.

<Figure 3: Self Test A Screen>

Method for proceeding with the test is as follows.

1) Connect the DLC cable to the G-scan and connect the Self Test

adapter to the other end of DLC cable. Connect the adapter to the

OBD-II connector of the vehicle.

2) Turn the power of G-scan ON and change to the ‘Self Test’ item of

configuration.

- 62 -

User’s Manual

3) After selecting the , select the or ‘F1’ to

proceeding to the test.

<Figure 4: Self Test A Proceeding 1>

4) Check the ‘Test Result’ shown on the test result window.

<Figure 4: Self Test A Result>

Good: Proceed with the test of 16-pin DLC cable; begin the “STEP-

B” test.

Failure: G-scan main module may be inoperative. Contact the

authorized service provider

- 63 -

User’s Manual

STEP-B Test

The STEP-B test is the function for checking if the DLC main cable

line is broken or shorted with the condition in which the communication

module of G-scan is normal state. During proceeding to this test, the

power is supplied by the DLC cable and the Self Test adapter. For the

details of Self Test adapter, refer to the ‘Connecting Self Test adapter’ in

the ‘Basic Use of G-scan.’

<Figure 5: Self Test B Screen>

The method for proceeding to test is as follows.

1) Connect the DLC cable to the G-scan and connect the other end to

the Self Test adapter. Connect the adapter to the OBD-II connector of

the vehicle.

2) Turn the G-scan power on to move to the ‘Self Test’ item of the

configuration.

- 64 -

User’s Manual

3) Select the and then select the or ‘F1’. The

test will be proceeding.

<Figure 6: Self Test B Proceeding>

4) Check the test result in the test window.

<Figure 7: Self Test B Result>

- 65 -

Module: A-02-006 (p.10)

User’s Manual

The test result messages are explained below:

Good: You may still need to test cable integrity by wiggling to test for

intermittent connections.

** If the test results indicate “Good” and the vehicle communication

continues to fail after the self-test adaptor is removed, verify that the

communication problem is not vehicle related; contact the authorized

service provider if necessary.

Failure: When the test result in self-diagnosis STEP-A are good but the

result of STEP-B is failure, then there is a high possibility that the 16-pin

Main DLC cable (P/No: G1PDDCA001) is inoperative. Contact the

authorized service provider.

- 66 -

User’s Manual

Exit from the “Self Test”

After setup the “Self Test” item, move to other Tab.

z Select the

to move to the “Setup”.

z Using stylus pen, select the “Tab” at the upper side of the touch

screen to move there.

Move to main screen

z Select the

z Select the

at the upper right side of the touch screen to move

to move to the main screen.

to the main screen.

Selecting ‘Move to main screen’, the following message will be shown.

<Figure 8: Save Message>

Save the setups and move to main screen.

Cancel the setups and move to main screen.

- 67 -

User’s Manual

- 68 -

User’s Manual

Vehicle COM Function Module NO: A-04-001

System Select

For diagnosing the vehicle using the G-scan, select the vehicle model

and system wanted to be diagnosed by user at first.

The system selection can select the multiple systems saved in the Gscan at the same time and diagnose the system problems.

Introduction of Model Selection Screen

For the convenience of user, it is divided into the Model, Year, Engine,

System and Option. According to the order of selected windows, the

system selected by user can be shown in the “Selected” window at right

side.

<Figure 1: Model Selection Screen>

Save the diagnosing system selected by user. Change to the

initial main screen or the diagnosis item screen selected by user.

Cancel the selection of system selection of current window and

return to the main screen.

Release the all system items currently selected.

Set to system SPEC setup in the latest version.

Delete the list on which the cursor is located in the list of the

“Selected” zone.

- 69 -

User’s Manual

System Selection using the H/W Button

Select the on the main screen, then the screen as

shown in below figure will be shown.

How to select System

1) Model Selection

Changing to the system selection screen, the cursor will be located at

the upper portion of the Model Selecting Zone as follows.

1

2

,

Set the cursor on the model to be diagnosed.

Select the model to be diagnosed. Move to

,

“Year” zone.

<Figure 2: Change to Model Selection Screen>

- 70 -

User’s Manual

2) Year Selection

1

2

Set the cursor on the year of model to be

,

diagnosed.

Select the year of model to be diagnosed. Move

,

to “Engine” zone.

<Figure 3: Year Selection>

3) Engine Selection

1

2

,

,

Set the cursor on the engine of model to be

diagnosed.

Select the engine of model to be diagnosed.

Move to “System” zone.

<Figure 4: Engine Selection>

- 71 -

4) System Selection

User’s Manual

1

,

diagnosed.

After selecting the system of model to be

diagnosed, conduct followings according to the

condition.

Set the cursor on the system of model to be

2

,

When there is one system option:

The system is registered in the “Selected” zone.

When there are two or more system options:

Move to the “Option” zone.

<Figure 5: System Selection>

- 72 -

User’s Manual

5) Option Selection

1

2

,

,

Set the cursor on the system option of model to

be diagnosed.

The system option of model to be diagnosed is

registered in the “Selected” zone.

<Figure 6: Option Selection>

6) Multiple System Selection

When the number of the System to be diagnosed is multiple, press the

or with cursor locating at “Selected” zone to move to

the “System” zone and repeat from 4) to select again.

Notice:

During selecting system, when it moves to upper zone than “System”

zone (“Model”, “Year”, “Engine” zones), all previously selected

system selection will be released.

- 73 -

7) Main Diagnosis System Selection

User’s Manual

Using

wanted system and select the

in the “Selected” zone, locate the cursor on the

. Then the ; mark will be

shown at the front of the system name as following figure.

Main Diagnosis System:

The vehicle communication function except the “Fault Code Searching”

can communicate with the control module marked with

selection. Please be advised that the other control modules without

; at vehicle

;

mark can communicate in the “Fault Code Searching”.

<Figure 7: Main Diagnosis System Selection>

8) Completion of System Selection

After selecting all system to be diagnosed, press the

or

button to complete the system selection.

9) Delete the selected System

For deleting the system registered in the “Selected” zone, select the

system to be deleted in the “Selected” zone and then press the

or button.

- 74 -

User’s Manual

System Selection using touch screen

z The system selection order and cautions using the touch screen are

the same with them using the H/W button described above. Using the

stylus pen, select wanted items on the touch screen.

z When the wanted items are not shown in each zone, move the scroll

bar up and down to find the items.

z To delete the registered system in the “Selected” zone, select the

system in the “Selected” zone again and then press the

or

button.

Note:

The system selection setup finally by user is not deleted even the

power is OFF. When the

is selected, the previous setup

will be applied again.

.

Multiple System Selection

The multiple of control modules registered in the “Selected” will shows

all fault codes saved in the control modules to be diagnosed in one

screen by just one function selection using the .

Select all control modules which may have problems in the vehicle.

However, it is not supported to the vehicle applied with special protocol

type communication method.

- 75 -

User’s Manual

Vehicle COM Function Module NO: A-04-002

Fault Code Searching

It, the error diagnose mode, can search the all fault codes occurred at

the multiple system selected at the ‘System Selection’, diagnose the

problems at the system having fault code and move to the ‘Service Data’

directly.

Introduction for Fault Code Auto Searching Screen

<Figure 1: Fault Code Search Screen>

Change to the Error Diagnosis Mode of system

selected at the “Fault Code Search” window.

Change to the Service Data Mode of system selected

at the “Fault Code Search” window.

Search the fault code of the selected system again.

Close the current window and change to the main

screen.

- 76 -

User’s Manual

Operating Sequence and Reference

Fault Code Searching

Executing the

in the main screen after completing

system selection, the fault code occurred at all system selected at the

system selection are searched and shown on the screen as the

following figure.

<Figure 2: Fault Code Search>

DTC Analysis, Current Data Analysis

1) Using the stylus pen or

buttons, select the

searched fault code item.

2) Select the diagnosis mode.

Move to DTC Analysis of system

having fault code selected at step 1).

Select

or

Move to Data Analysis of system

having fault code selected at step 1).

- 77 -

Select

or

User’s Manual

z When

is selected

You can delete the fault code and check the data for the related DTC.

<Figure 3: When ‘GOTO DTC’ is selected>

z When

is selected

You can check the input/output status of related control module.

<Figure 4: When ‘GOTO DATA’ is selected>

- 78 -

User’s Manual

Vehicle COM Function Module NO: A-04-003

DTC Analysis

The "Fault Code Searching" searches the fault code of the system

selected by user and presents exact information of the fault code and

can delete the fault code after troubleshooting the faults.

There are 3 methods for using the fault code searching.

z On the main screen, select the

.

→ Move to the DTC Analysis of main diagnosis system set at the

system selection.

z On the “Fault Code Searching”, select the

.

→ Move to the DTC Analysis of the control module in which DTC

selected at the “Fault Code Searching” is include.

z Select the DTC among the menu output after selecting the

at the “Data Analysis”

→ The “DTC Analysis” and “Data Analysis” of the control module

which communicated at the “Data Analysis” are output at the same

time in dual mode.

- 79 -

Introduction of Fault Code Searching Screen

<Figure 1: DTC Analysis Screen>

User’s Manual

General Description of fault code are shown.

As the Freeze Frame function, the input/output data of the control

module relating to the saved fault code when the fault code is

occurred.

* According to the specification of control module, function

supporting is different.

Delete all fault codes saved at the control module

Delete the fault code selectively among the fault codes shown by

the fault searching.

* According to the specification of control module, function

supporting is different.

Show the “Fault Detail Information”.

* According to the specification of control module, function

supporting is different.

Change to the dual mode and use other supplementary

information function.

Note:

z

When all items are not shown in one screen due to a lot of fault codes, move the

scroll bar at right side using the stylus pen or the arrow keys to

find item you want.

z If you want to back to main screen, press the or at the right upper

side in <Figure 1>.

- 80 -

User’s Manual

Fault Searching Sequence and Reference

See Tips

1) To see the detail information about the fault code occurred by the

diagnosis result, select the relating fault code item.

Select the or buttons, a description window will

2)

be shown as in <Figure 2>.

<Figure 2: Show Tips>

3) If you want to close the ‘General Description’ select the ,

or .

- 81 -

User’s Manual

See Freeze Frame

1) Select the fault code item of the Freeze Frame you want to see.

Freeze Frame: Data of sensor related to the fault code saved by the

control module when fault code is occurred.

2) Select or button on the fault searching screen,

you can see the Freeze Frame as shown in <Figure 3>.

<Figure 3: See the Freeze Frame>

3) If you want to close the Freeze Frame screen, select the of “DTC

Analysis” at the upper side of <Figure 2>.

Notice:

According to the control module, it is supported to some kinds of model.

- 82 -

User’s Manual

Delete the Fault Code

1) Select the

or button on the fault searching

screen.

<Figure 4: Delete Fault Code>

2) As shown in <Figure 4>, the message window for deleting the fault

code is shown overlapping the diagnosis window.

- When

is selected:

All fault codes are deleted and the message like the <Figure 5> will

be shown.

<Figure 5: Fault Code Delete Message>

- When

is selected:

The Fault Code delete will be canceled.

- 83 -

User’s Manual

Fault Code Selection Delete

1) Select the fault code to be deleted on the Fault Searching Screen.

2) Select the or button.

3) The message for checking the fault code delete will be shown.

- When

is selected:

The fault code selected in step 1) is deleted and message is shown.

- When is selected:

The fault code delete is cancelled.

See the Fault Code Detail Information

1) Select the fault code on the Fault Code Searching screen.

2) Select the

or button.

<Figure 5: Detail Fault Information>

3) As shown in <Figure 5>, the “Fault Code Detail Information” window

will be shown. You can check the detail information about the

selected fault code.

- 84 -

User’s Manual

DTC Analysis Dual Diagnosis Mode

See the DTC Analysis and Data Analysis at the same time

1) On the <Figure 1> DTC Analysis screen, select the

or

, the Function Menu is shown as in <Figure 6>.

<Figure 6: DTC Analysis “Function Menu”>

2) On the showing menu, select the Current Data, it changes to the Dual

mode as shown in <Figure 7>.

Using stylus pen, select on the touch screen directly.

After moving cursor using H/W buttons , press the

button

<Figure 7: DTC Analysis & Data Analysis Dual Diagnosis Mode>

- 85 -

See DTC Analysis and Actuation Test at the same time

User’s Manual

1) On the <Figure 1> DTC Analysis screen, select

or ,

The Function Menu will be shown as in <Figure 6>.

2) Select the Current Data on the showing menu, then it changes to the

Dual mode as shown in <Figure 8>.

Select it using stylus pen on the touch screen.

After moving the cursor using H/W buttons

the

button.

, press

<Figure 8: DTC Analysis & Actuation Test Dual Diagnosis Mode>

- 86 -

User’s Manual

Check the ECU Information

1) On the <Figure 1> DTC Analysis screen, select

or ,

then the Function Menu is shown as in <Figure 6>.

Selecting the ECU Info in the showing menu, the screen changes to the

ECU Information as shown in <Figure 9>.

Using the stylus pen, select on the touch screen directly.

After moving cursor using the H/W buttons

the

button.

, press

<Figure 9: ECU Information>

2) Press the button at the bottom of the “ECU Information”

to close the window.

- 87 -

Change to the Vehicle S/W Management

User’s Manual

1) On the <Figure 1> DTC Analysis screen, select the

or

, then the Function Menu is shown as <Figure 6>.

2) Select the Vehicle S/W Management in the showing menu, the screen

changes to the Vehicle S/W Management as <Figure 9>.

Using the stylus pen, select on the touch screen directly.

After moving cursor using the H/W buttons

the

button.

, press

<Figure 10: Vehicle S/W Management>

- 88 -

User’s Manual

Vehicle COM Function Module NO: A-04-004

It is the diagnosis item for checking the data input/output status of the

control mode to be diagnosed through the service data.

There are 3 methods for using the service data.

z Select the

→ Move to the “Data Analysis” of main diagnosis system set in the

System Selection.

z Select the

→ Move to the “Data Analysis” of the control module having DTC

selected in the “Fault Code Searching”.

Data Analysis

on the main screen

at the “Fault Code Searching”

z Select the

Data among the showing menu

→ The “DTC Analysis” and “Data Analysis” of the control module

communicated in the “DTC Analysis” are output in dual mode at the

same time.

in the “DTC Analysis” and select the Current

- 89 -

Introduction of Service Data screen

<Figure 1: Data Analysis Screen>

User’s Manual

Fix the selected item at the top of the screen.

Split the service data screen into left and right sides

and show the 26 data at maximum.

Show the fixed item in line graph.

Change to dual mode and use other functions.

Reference

z If the wanted item is not shown, move the scroll bar with the stylus

pen or use the direction buttons

to find it.

z If you want to return to initial screen, press the or at

the right upper side of screen

- 90 -

User’s Manual

Operating Sequence and References

Fix the Data Item

z How to fix the Data item

1) Select the item want to fix.

2) Select the

or at the bottom of the screen or

double click the item using the stylus pen on the touch screen,

then the selected item will be fixed at the top of the screen as

shown in <Figure 2>.

<Figure 2: Fix the Data Item>

z Release the fixed Data item

1) Select the fixed item again.

2) Select the

or at the bottom of the screen or

double click the item to be released using the stylus pen on the

touch screen.

Tips

* The number of Fix is 4 at most in single mode and 2 at most in dual

mode.

- 91 -

Full

z See with Full screen

User’s Manual

On the service data screen, select

or , then the

screen will be divided as shown in <Figure 3> and 26 data items are

shown.

<Figure 3: See in Full>

z Return to Normal screen

On Full screen mode, press

or .

Note:

On the screen in Full mode, FIX and Graph functions are not

available.

Find the item now shown on the screen using the arrow button or

moving the scroll bar with the stylus pen.

If all of item names are not shown, select the item using the

stylus pen, then all item name can be shown by moving it to right

side.

- 92 -

User’s Manual

Graph

1) Fix the item want to see in graph.

2) Select

or , then the selected item will be

shown in graph mode as in <Figure 4>.

<Figure 4: Graph Mode>

Initialize the Max and Min values output on graph.

Modify the item list on the graph.

* Add/Delete the graph list using

<Figure 5: Item List>

① In the graph mode, select

, then Item List is shown

as in <Figure 5>.

- 93 -

User’s Manual

(The item having “*” mark among the Item List means the item

shown in graph mode currently.)

② Select the item want to be deleted among the list shown in graph

mode currently using the arrow buttons

and

key or using the stylus pen on the touch screen.

③ Select the item want to be shown in graph mode among the list

not shown in graph mode using the arrow buttons

and key, or using the stylus pen on the touch

screen.

3) If you want to return to the service data, press the or

.

Note:

* The number of service data possible to applied to Graph mode is 4 at

most in single mode, and 2 at most in dual mode.

- 94 -

User’s Manual

Data Analysis Dual Diagnosis Mode

See the Data Analysis and the DTC Analysis at the same time

1) On the <Figure 1> DTC Analysis screen select

or

, the Function Menu will be shown as in <Figure 6>.

<Figure 6: DTC Analysis “Function Menu”>

2) On the showing menu, select the Current Data to change the screen

to the Dual mode as shown in <Figure 7>.

Using the stylus pen, select on the touch screen

Moving the cursor with H/W buttons , , press

the

key.

<Figure 7: Data Analysis & DTC Analysis Dual Diagnosis Mode>

- 95 -

User’s Manual

See the DTC Analysis and the Actuation Test at the same time

1) On the <Figure 1> DTC Analysis screen, select

or

, the Function Menu will be shown as in <Figure 6>.

2) On the showing menu, select the Current Data, the screen will be

changed to the Dual mode as shown in <Figure 8>.

Using the stylus pen, select on the touch screen directly.

Moving the cursor with H/W buttons , , press

the

key.

<Figure 8: Data Analysis & Actuation Test Dual Diagnosis Mode>

- 96 -

User’s Manual

Check the ECU Information

3) On the <Figure 1> Data Analysis screen, select

or

, the Function Menu will be shown as in <Figure 6>.

4) On the showing menu, select the ECU Info, then the ECU Information

popup window as in <Figure 9> is shown.

Using the stylus pen, select on the touch screen directly.

Moving the cursor with H/W buttons

, , press the

key.

<Figure 9: ECU Information>

5) Press the button at the bottom of the “ECU Information”

to close the window.

- 97 -

Change to Vehicle S/W Management

User’s Manual

3) On the <Figure 1> Data Analysis screen, select

, the Function Menu will be shown as in <Figure 6>.

On the showing menu, select the ECU Info, then the screen will be

changed to the Vehicle S/W Management as in <Figure 9> is shown.

Using the stylus pen, select on the touch screen directly.

Moving the cursor with H/W buttons

, , press the

key.

or

<Figure 10: Vehicle S/W Management>

- 98 -

User’s Manual

Vehicle COM Function Module NO: A-04-005

Actuation Test

Through the "Actuation Test", it is possible to check if the control

module and unit to be tested are defected or not.

There are two methods for using “Actuation Test”.

z At the “DTC Analysis”, select the "Actuation Test" of the menu

included in

.

Æ “DTC Analysis” and "Actuation Test" are output in dual mode.

z At the “Data Analysis”, select the "Actuation Test" of the menu

included in

.

Æ “DTC Analysis” and "Actuation Test" are output in dual mode.

- 99 -

Description of Actuation Test screen

<Figure 1: Actuation Test& Data Analysis>

User’s Manual

<Figure 2: Actuation Test overall screen>

Change to the "Actuation Test" overall screen:

Select the

indicated by the arrow in <Figure 1>, then screen will be

changed to the overall screen.

Change to the Dual Mode Previous on Overall screen:

Select the

at the upper right side of <Figure 2>, then the screen will

be change to the dual mode previous on overall screen.

- 100 -

Loading...

Loading...