Gis GCH250/1N, GCH250/1NF, GCH250/1HF, GCH250/1SF, GCH250/2N Instruction Manual

...

INSTRUCTION MANUAL

Electric chain hoist GCH 250/500 • GCH 1000 • GCH 1600/2000/2500

GIS CHAIN HOIST

SWISS QUALITY

GCH

GCHK

GCHS

GCHH

GCHR

07.11 Original document 9401.9000.1.doc

Table of contents

0 General information..................................................................4

0.1 General safety information .................................................................................. 4

0.1.1 Safety and hazard precautions............................................................................ 4

0.2 General safety specifications and procedures..................................................... 4

0.2.1 Warning paint / Marking / Danger signs .............................................................. 4

0.3 Special safety directions...................................................................................... 4

0.4 Notes on hazard protection ................................................................................. 5

0.4.1 Hazards caused by mechanical influences .........................................................5

0.4.2 Hazards caused by electrical energy / power supply .......................................... 5

0.4.3 Sound level (SPL)................................................................................................ 6

0.5 Technical status .................................................................................................. 6

0.5.1 Technical data ..................................................................................................... 6

0.5.2 Recurrent checks................................................................................................. 6

0.5.3 Warranty .............................................................................................................. 7

0.6 Operational parameters....................................................................................... 7

0.6.1 Directions for using the instruction manual ......................................................... 7

1 Description ................................................................................8

1.1 Operating conditions............................................................................................ 8

1.2 General description ............................................................................................. 9

1.3 Special models .................................................................................................. 10

2 Start-up ....................................................................................11

2.1 Transport and assembly.................................................................................... 11

2.2 Connection ........................................................................................................ 11

2.2.1 Electrical connection ......................................................................................... 11

2.2.2 Load chain.........................................................................................................12

2.2.3 Limit switch........................................................................................................14

2.2.4 Chain bucket...................................................................................................... 15

3 Service and maintenance.......................................................15

3.1 General regulations for service and maintenance work .................................... 15

3.2 Service and maintenance..................................................................................16

3.2.1 Maintenance overview....................................................................................... 16

3.2.2 Service overview ............................................................................................... 16

3.2.3 Brake system..................................................................................................... 16

3.2.4 Load chain.........................................................................................................17

3.2.5 Limit stop assembly........................................................................................... 17

3.2.6 Gearbox............................................................................................................. 17

3.2.7 Slip clutch .......................................................................................................... 17

3.2.8 Suspension parts............................................................................................... 18

3.3 Ordering spare parts.......................................................................................... 18

4 Measures for obtaining a safe period of operation.............18

4.1 Determining the actual utilization period S ........................................................ 18

4.2 General overhaul ............................................................................................... 18

5 Appendix .................................................................................19

5.1 Technical data ................................................................................................... 19

5.2 EC Declaration of conformity............................................................................. 21

5.3 EC Declaration of incorporation......................................................................... 22

GIS CHAIN HOIST SWISS QUALITY 2

Spare parts / Ordering spare parts

The correct order numbers for original spare parts can be obtained from the relevant

spare parts list. Please ensure that you have the following data on your chain hoist to

hand. This will enable the correct spare parts to be supplied without delay.

Electric chain hoist type : ..........................................................................................

Manufacture number : ..........................................................................................

Year of manufacture : ..........................................................................................

Load capacity : ..........................................................................................

Original spare parts for the electric chain hoist can be acquired from the following

addresses:

1. Manufacturer

GIS AG

Hebe- und Fördertechnik

Luzernerstrasse 50

CH-6247 Schötz

Tel. +41 (0)41 984 11 33

Fax +41 (0)41 984 11 44

tel@gis-ag.ch

www.gis-ag.ch

2. Agent

............................................................................................................................................

............................................................................................................................................

............................................................................................................................................

............................................................................................................................................

............................................................................................................................................

............................................................................................................................................

GIS CHAIN HOIST SWISS QUALITY 3

0 General information

0.1 General safety information

0.1.1 Safety and hazard precautions

0.2 General safety specifications

and procedures

0.2.1 Warning paint / Marking /

Danger signs

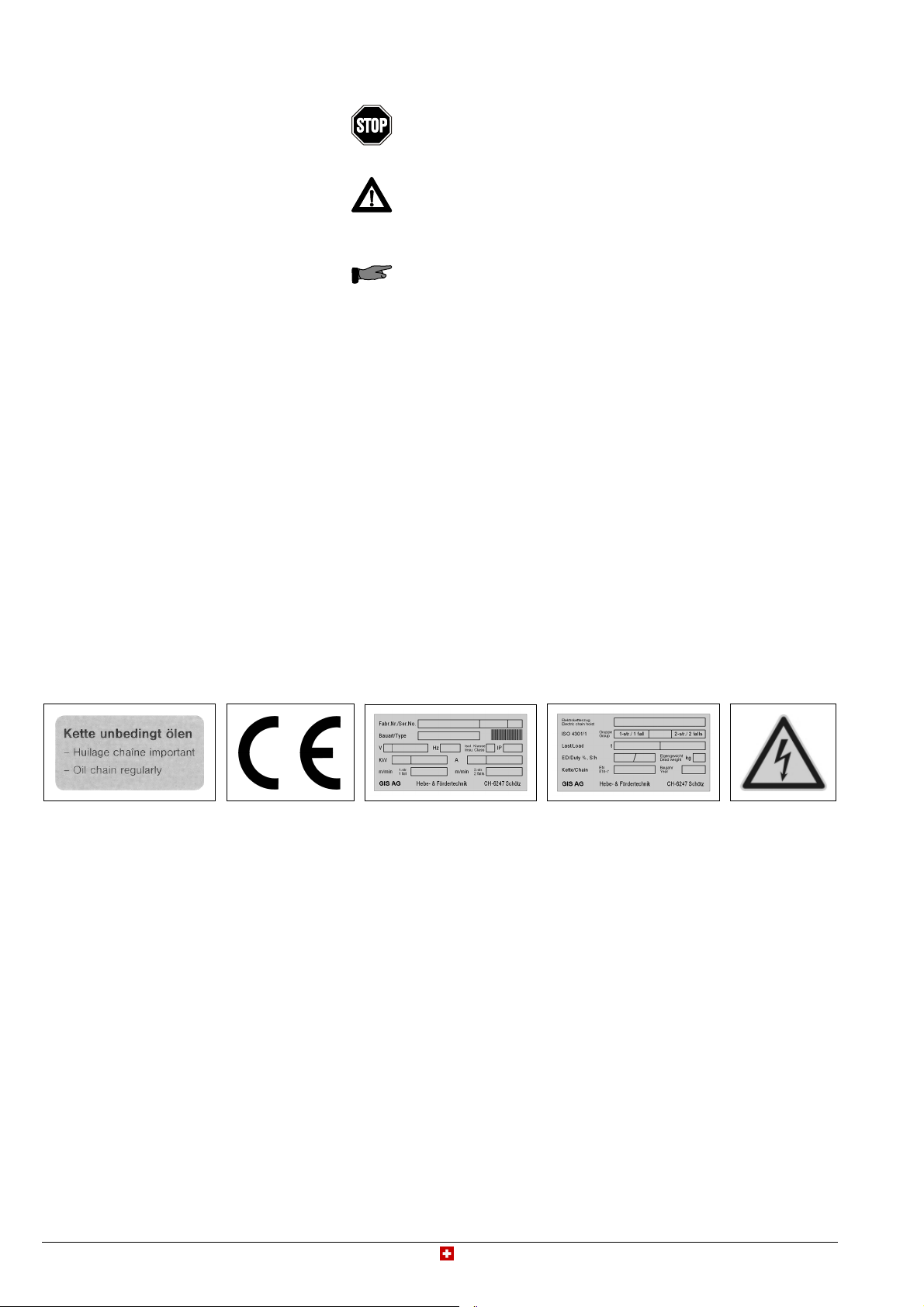

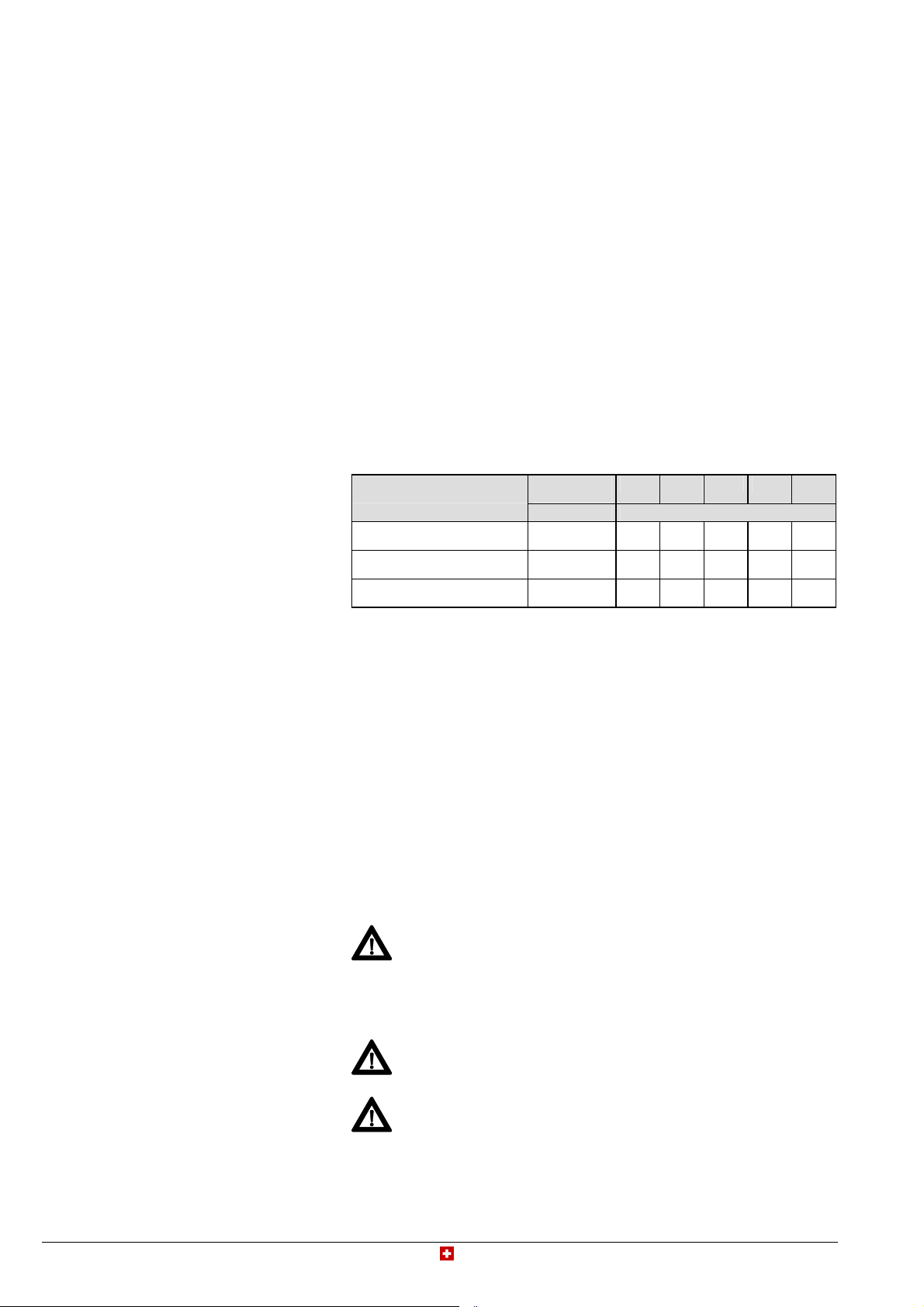

Figure 0-1 Figure 0-2 Figure 0-3 Figure 0-4 Figure 0-5

0.3 Special safety directions

The following symbols and terms are used in this instruction manual for safety and

hazard instructions:

DANGER !

Non-compliance, either in part or full, with operating instructions marked

with this symbol can result in serious personal injury or even death.

Danger notices must be strictly complied with.

CAUTION !

Non-compliance, either in part or full, with operating instructions marked

with this symbol can result in major damage to machinery, property or

material.

Cautionary notices must be strictly adhered to.

NOTE

Following the instructions marked by this symbol will lead to more effective

and straightforward operation.

"Note" directions make work easier.

The instruction manual for the electric chain hoist must always be available within the

operating area of the hoist. The instructions mentioned in this manual must be strictly

adhered to.

Furthermore, supplementary to the instruction manual, the statutory regulations

governing general accident prevention and environmental protection are to be enforced.

Operating and service personnel must have read and understood the operating

instructions, in particular the safety instructions, before commencing work. Protective

equipment must be made available for operating and service personnel and worn at all

times.

The operator or his representative is responsible for supervising operating personnel

and ensuring they are aware of the hazards and safety implications of working with the

electric hoist.

Lubricate chain....................figure 0-1

CE symbol...........................figure 0-2

Model plate .........................figure 0-3

Data plate............................figure 0-4

Voltage................................ figure 0-5

Transport and assembly:

Electric chain hoists, single parts and large components should be carefully affixed

to suitable and technically acceptable hoisting apparatus / load lifting members

Connection:

Connection work is only to be performed by personnel specifically designated and

trained for the job

Start-up / operation:

Before initial start-up, as well as daily start-up, carry out a visual check and carry out

the predefined user-checks routine

Only operate the electric chain hoist if the protective and safety equipment provided

is ready and working

Damage to the electric chain hoist and changes in its operational characteristics

must be reported immediately to the person responsible

After use, or when in a non-operational mode, the chain hoist should be secured

against unauthorised and unintentional use

Refrain from hazardous procedures

See also operational parameters (chapter 0.6)

GIS CHAIN HOIST SWISS QUALITY 4

0.4 Notes on hazard protection

0.4.1 Hazards caused by mechanical

influences

0.4.2 Hazards caused by electrical

energy / power supply

Cleaning / service / repair / maintenance / refitting:

Use the working platforms and ladders provided for assembly work above body

height

Do not use machine parts for this purpose

Check electrical cables for damage or wear

Ensure any oils or other agents used are discharged, collected and disposed of

safely and in an environmentally sound manner

Reassemble and check safety apparatus that has been disassembled for servicing

or repairing the hoist once service and repair work has been completed

Adhere to predefined testing and service intervals specified in the instruction

manual

Follow the directions in the instruction manual regarding exchanging parts

Operating personnel should be informed before commencing special or refitting

work

Secure the repair working area

Prevent the electric chain hoist from being inadvertently switched on during service

or repair work

Erect warning signs

Disconnect the power cable and ensure it cannot be inadvertently switched on again

Retighten screw connections that have been loosened for repair or service work

Replace parts that are not reusable, such as O-rings, gaskets, self locking nuts,

split-pins and washers

Shut down / storage:

Clean and preserve (lubricate/grease) the chain hoist before long periods of

inactivity or storage

Hazardous areas must be clearly marked by warning signs and cordoned off. It must be

ensured that warnings regarding hazardous areas are given due attention.

Hazards can stem from:

incorrect application

not following safety directions properly

not carrying out test and service work thoroughly

Physical injury:

Unconsciousness and injury through:

crushing, shearing, cutting and twisting

drawing in, ramming, piercing and rubbing

slipping, stumbling and falling

Causes:

crush, shear and twist area

parts rupturing or bursting

Safety options:

keep floor, equipment and machinery clean

eliminate leakages

observe the required safety distance

Work on electrical apparatus or machinery may only be performed by qualified

electricians or persons under the supervision and guidance of qualified electricians,

in accordance with predefined electrotechnical regulations.

Physical injury:

Death from electrical shock, injury and burns through:

contact

faulty insulation

faulty servicing or repair work

short circuit

DANGER !

DANGER !

GIS CHAIN HOIST SWISS QUALITY 5

0.4.3 Sound level (SPL)

0.5 Technical status

0.5.1 Technical data

0.5.2 Recurrent checks

Causes:

contact with, touching or standing too close to uninsulated power and voltage supply

terminals

use of uninsulated tools

exposed electricity supply terminals following insulation failure

inadequate safety checks following repair work

incorrect fusing

Safety options:

isolate machinery and equipment designated for repair or service work before

commencing such work

first check isolated parts for voltage

regularly check electrical fittings

replace loose or damaged cables immediately

always replace blown fuses with fuses of the correct value

avoid contact with or touching live terminals

only use insulated tools

Tests on the chain hoist sound level are performed at a range of 1, 2, 4, 8 and 16

metres from the centre of the chain hoist motor to the measuring device.

Measurement of SPL according to DIN 45 635.

The SPL was measured:

a) during operation of electric chain hoists on factory site

b) during open-air operation

Table 0-1 Sound level

Types Measuring

Measurement dBA

GCH 250/500 a)

GCH 1000 a)

GCH 1600/2000/2500 a)

distance

b)

b)

b)

1 m 2 m 4 m 8 m 16 m

75

72

69

66

75

72

72

75

75

69

69

66

72

69

63

66

60

69

63

57

63

54

66

57

63

51

60

48

63

51

The present document was written in 2010. It corresponds to directive 2006/42/EC of

the European Parliament and of the Council of 17 May 2006.

0.5.1.1 Models GCH..............................table 0-2, page 19

0.5.1.2 Models GCHK............................table 0-3, page 19

0.5.1.3 Models GCHS............................table 0-4, page 20

0.5.1.4 Models GCHHK.........................table 0-5, page 20

0.5.1.5 Models GCHHTD.......................table 0-6, page 20

0.5.1.6 Models GCHR ...........................table 0-7, page 20

Each device/ unit operator should adequately note all checks, maintenance and

inspections performed in the log book, and have these confirmed by the competent

person in charge.

Incorrect or missing entries will lead to forfeiture of the manufacturer's warranty.

CAUTION !

Equipment and cranes should be periodically tested by an expert. Basically,

visual and functional checks should be performed to determine the

condition of components as regards damage, wear, corrosion or other

modifications. In addition, safety equipment is assessed for completeness

and efficiency. It may be necessary to dismantle the equipment under

inspection to correctly assess expendable parts.

CAUTION !

Suspension apparatus must be inspected over its entire length, including

covered or hidden parts.

CAUTION !

All periodical inspections should be arranged by the operator.

GIS CHAIN HOIST SWISS QUALITY 6

0.5.3 Warranty

0.6 Operational parameters

0.6.1 Directions for using the

instruction manual

the warranty is void if the installation, operation, testing or maintenance is not

carried out according to these instructions

troubleshooting and repair under warranty may only be carried out by qualified

persons and only after consultation and agreement with the manufacturer / supplier.

Any modifications to the product or the use of non-original replacement parts will

void the warranty

Electric chain hoists of the series GCH are hoists of differing load capacities. They can

be installed as stationary or mobile units. Electric chain hoists are manufactured in

accordance with the latest technical developments and recognised safety standards,

and are tested for safe operation by the manufacturer.

Electric chain hoists are approved by various international institutes such as BG and

others.

Electric chain hoists of the above series may only be used when in an acceptable

technical condition, in accordance with their operating parameters, by trained personnel

in a safe and responsible manner.

The operational parameters of the electric chain hoist also encompass compliance with

the pre-defined operating, service and maintenance requirements laid down by the

manufacturer.

The operational parameters do not include:

exceeding the defined load capacity

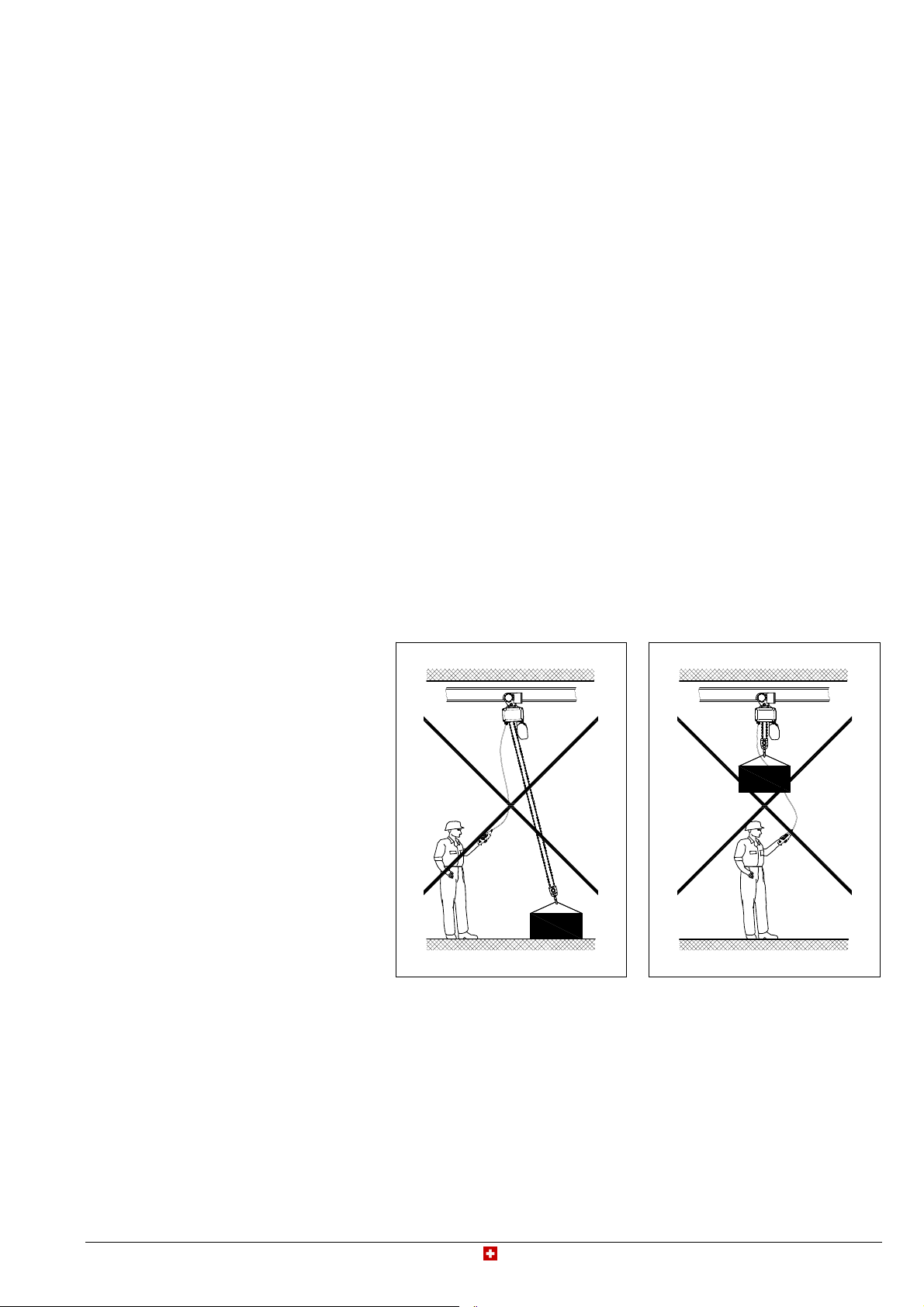

pulling the load diagonally (see figure 0-5)

heaving, pulling or dragging the load

transporting persons

transporting loads when personnel are underneath

standing under suspended loads (see figure 0-6)

transporting excessive loads

pulling on the control cable

failing to observe the load hook constantly

running the chain over edges

failing to observe the load constantly

allowing the load to fall due to a slack chain

use at temperatures below -15° C or above +50° C

use in an explosive environment

See also chapter 0.3.

Figure 0-5 Figure 0-6

Inching operations, ground mooring and driving against the limit switches should be

avoided. The manufacturer accepts no responsibility for damage to equipment and third

parties ensuing from such action.

This instruction manual includes the following chapters:

0 General information 4 Measures for obtaining a safe

1 Description period of operation

2 Start-up 5 Appendix

3 Service and maintenance

GIS CHAIN HOIST SWISS QUALITY 7

Loading...

Loading...