Girolami TC 25, TC 35, TC DA 25, TC DA 35, TC Curvo 25 Instructions For Use And Maintenance Manual

...

Code TC Rev. 0 dated 01/04/2011

BOILER FIREPLACES

INSTRUCTIONS FOR USE AND MAINTENANCE

Series TC INSTRUCTIONS FOR USE AND MAINTENANCE

BOILER FIREPLACES

Codice TC Rev.0 del 01/04/2011

2

BOILER FIREPLACES

Codice TC Rev.0 del 01/04/2011

3

CONTENTS

1 INTRODUCTION

1.1 Intended use

1.2 Aim and contents of manual

1.3 Storing this manual

1.4 Updating this manual

1.5 Generalities

1.6 Main workplace safety standards to be respected

1.7 Legal warranty

1.8 Manufacturer responsibility

1.9 Characteristics of use

1.10 Technical support

1.11 Spare parts

1.12 Delivery of the fireplace

2 SAFETY INSTRUCTIONS

2.1 Installation instructions

2.2 User instructions

2.3 Maintenance instructions

3 CHARACTERISTICS AND DESCRIPTION OF THE MACHINE

3.1 Description

3.2 Data plate

3.3 Combustion

4 HANDLING AND TRANSPORT

5 PREPARATION FOR ON-SITE INSTALLATION

5.1 Safety precautions

5.2 Flues and chimneypots

5.3 Dry positioning

5.3.1 Safety recommendations

5.4 Height adjustment

5.5 Air vents

5.6 Connecting the flue

5.7 Connecting the water sensor

5.8 Counter-hood and inspection panel

5.8.1 Smoke valve adjustment

6. CONNECTING THE FIREPLACE TO THE SYSTEM

6.1. Key to fireplace inputs and outputs

6.1.1. Rules for proper layout of the flows inside the fireplace

6.2. INSTALLING THE FIREPLACE

6.2.1. Warning

6.2.2. Positioning the fireplace

6.2.3. Main characteristics of the system

6.2.4. Positioning the expansion vessel

6.2.5. Positioning the circulator

6.2.6. Connections for producing hot water

6.2.7. Electrical connections

6.3. CONNECTION TO A PRE-EXISTING CLOSED CIRCUIT SYSTEM

6.3.1. Warning

6.3.2. Connection

6.4. System diagrams

7. COMMISSIONING AND USING THE FIREPLACE

7.1. Routine maintenance by the user

7.1.1. First ignition

7.1.2. Fuel type

7.1.3. Combustion control

7.1.4. How to use the door

8. MAINTENANCE AND CLEANING

8.1. Safety Precautions

8.2. Glass cleaning

8.3. Cleaning the furnace and the ash pan

8.4. Cleaning the flue

9. SCRAPPING AND DISPOSAL INFORMATION

10. REQUEST TECHNICAL ASSISTANCE

BOILER FIREPLACES

Codice TC Rev.0 del 01/04/2011

4

GIROLAMI model TC heating equipment is built and tested in accordance with the safety stand-

ards set forth in European Directives 98/37/EC and EC 13229.

THIS MANUAL IS INTENDED FOR FIREPLACE OWNERS, INSTALLERS,

OPERATORS AND MAINTENANCE STAFF FOR TC SERIES FIREPLACES.

For clarifications regarding the contents, contact the manufacturer or the authorized Technical Support,

providing the paragraph number of the portion to be clarified.

Dear Customer

We would like to thank you for preferring and purchasing our product. We congratulate you on your choice.

To let you get the best out of your new MODEL TC TERMOCAMINO fireplace, we recommend following all

the information contained in this manual carefully.

1 INTRODUCTION

Do not operate the apparatus if you do not completely understand all of the information in this manual. If in

doubt, always request assistance from specialized GIROLAMI staff.

Girolami reserves the right to modify specifications and technical characteristics and/or functions of the machine at any time without advance notice.

1.1 INTENDED USE

GIROLAMI model TC equipment falls in the category of open circuit water heating devices and

are intended for use in closed areas such as houses and offices. With is entirely metal structure and furnace with vitroceramic door, the fireplace is suitable for heating houses through the

heating circuit normally used for that purpose. Maximum performance is obtained with the door

closed.

The intended use stated above and the foreseen machine configurations are the only ones permitted by the

manufacturer: do not use the machine in any way not described in this manual.

DANGER: the intended use is valid only for equipment in full structural, mechanical and electrical working

order. The GIROLAMI fireplace is for internal use only.

1.2 PURPOSE AND CONTENTS OF THE MANUAL

PURPOSE

The purpose of this manual is to allow the user to take the necessary precautions and have all the human

and material means necessary for its correct, safe and lasting use. CONTENTS

This manual contains all the information necessary for installation, use and maintenance of the TER-

MOCAMINO TC, 25 and 35 fireplace.

Scrupulous compliance with this information guarantees a high level of product safety and performance.

1.3 STORING THIS MANUAL

The manual must be stored carefully and must always be available for consultation by the users, assembly

workers and maintenance staff. The Use and Maintenance Manual is an integral part of the machine.

DETERIORATION AND DISPOSAL

If necessary, another copy may be requested from the manufacturer by providing the serial number.

1.4 UPDATING THIS MANUAL

This manual reflects the state of the product at the time of purchase. If any improvements are made to the

machine, the manual may be modified and updated without advanced notice by Girolami Caminetti. Therefore, if a new copy of this manual is requested from Girolami Caminetti, providing the product serial number

is essential.

BOILER FIREPLACES

Codice TC Rev.0 del 01/04/2011

5

1.5 GENERAL INFORMATION

INFORMATION

In the event of data exchange with the fireplace Manufacturer, refer to the serial number located on the data

plate, the revision number located at the bottom of every page in this handbook or the identifying data indicated on the “TECHNICAL SPECIFICATIONS” at the end of this manual.

RESPONSIBILITY

Upon delivery of this manual, GIROLAMI disclaims any and all responsibility, both civil and penal, for accidents arising from partial or total failure to follow the safety, installation and use information contained in this

manual.

GIROLAMI further disclaims any and all responsibility for improper use of the machine, improper use by

the operator, for unauthorized modifications and/or repairs, for use of spare parts that are not original or not

specifically for these FIREPLACE models.

Extraordinary maintenance

Extraordinary maintenance operations must be performed by qualified personnel appointed to work on the

fireplace models referred to in this manual.

Responsibility for installation operations

Fireplace installation operations are not GIROLAMI’s responsibility. They are and remain the responsibility

of the installer, who is charged with carrying out checks of the flue, air intake and accuracy of the installation. All regulations provided for by local, national and European legislation in force in the country where the

machine is installed must be respected.

USE

Use of the machine is subject to the information in this manual as well as compliance with all safety regulations set forth in the legislation in force in the country where the machine is installed.

1.6 PRIMARY WORKPLACE SAFETY STANDARDS TO BE RESPECTED

A) Directive 73/23/EEC: “electrical equipment designed for use within certain voltage limits”.

B) Directive 89/336/EEC: “on the approximation of the laws of the Member States relating to Electromagnetic Compatibility”.

C) Directive 89/106/EEC: “on the approximation of laws, regulations and administrative provisions of the

Member States relating to construction products”.

D) Directive 85/374/EEC: “on the approximation of the laws, regulations and administrative provisions of the

Member States concerning liability for defective products”.

E) Standard UNI EN 13229: “Inset appliances including open fires fired by solid fuels - Requirements and test

methods”.

1.7 LEGAL WARRANTY

In order for the user to make use of the legal warranty, as per EEC Directive 1999/44/EC, the information in

this manual must be scrupulously respected, especially:

• Always operate within the limits of use of the fireplace;

• Always perform constant and diligent maintenance;

• Only authorize use by capable, responsible individuals adequately trained specifically on the use of

the furnace.

• All of the parts usually subjected to wear are not covered under warranty, such as glass sliding

blocks, seals and all parts that can be removed from the furnace.

• The warranty does not cover transport costs and damage during transport, tampering, damage due

to improper installation, improper maintenance and improper use, overheating, fuels not in compliance

with this manual’s specifications, atmospheric agents, natural disasters, electric shock, fire and hydraulic

or electric plants not in compliance with this manual’s specifications and the standards in force.

• Moreover, the warranty does not cover the costs for removal and subsequent re-installation of the

product if necessary, nor any type of reimbursement for the period of inefficiency of the fireplace.

• For warranty service on the product, the user is kindly requested to contact the reseller where the

machine was purchased, who will expedite the paperwork Girolami Caminetti requires in order to execute the request.

BOILER FIREPLACES

Codice TC Rev.0 del 01/04/2011

6

• Girolami Caminetti shall not, in any way, be responsible for any problems due to poor flue draught

since, even though they provide instructions on proper installation, these instructions are subject to exceptions that can be linked to factors that the company is unable to foresee (climate, geophysical and

geological conditions, etc.). For this purpose, we again request that you contact capable and experienced technicians who will take responsibility in the event of a malfunction.

• All interventions covered by the warranty and which can be executed directly at the end user’s prem-

ises shall be carried out solely and exclusively if the parts to be replaced are accessible. In the event that

the parts to be replaced/repaired are inaccessible, Girolami Caminetti. will not perform the intervention

and reserves the right to claim financial compensation for the costs linked to the service call, travel and

the technical labour hours that the company lost.

• Warranty conditions for accessories supplied by but not manufactured by Girolami Caminetti: for the

above mentioned parts, the terms and conditions of the warranty are contained in the instruction booklet for each individual part attached to the products. In the event of a malfunction, contact the reseller

where the machine was purchased, who will then communicate the issue.

Failure to follow the instructions in this manual will immediately void the warranty.

1.8 MANUFACTURER RESPONSIBILITY

The manufacturer disclaims any and all civil and penal indemnity, direct or indirect, due to:

Installation that is not complaint with current national regulations and safety directives;

Failure to follow the instructions in this manual;

Installation by unqualified and untrained personnel;

Use that is not compliant with safety directives;

Modifications and repairs to the machine that were not authorized by the manufacturer;

Use of non-original spare parts or spare parts not intended for this model of furnace;

Lack of maintenance;

Extraordinary events.

1.9 USER CHARACTERISTICS

The user of the fireplace must be a responsible adult who has the technical knowledge needed to carry

out regular maintenance on the fireplace components.

WARNING: some parts of the fireplace such as the glass, handle and door can become very hot. ALWAYS

KEEP CHILDREN AT A SAFE DISTANCE!

1.10 TECHNICAL SUPPORT

Girolami is able to resolve any technical problem related to use and maintenance during the entire life cycle

of the machine as long as the installation procedures are executed correctly. Failure to create inspection

compartments could make it physically impossible for Girolami personnel to execute such services. For

services under warranty and not under warranty to be carried out on the company’s premises, or in the

event of product replacement due to faulty manufacturing, Girolami Caminetti shall not be held in any way

responsible for expenses related to disassembly and reassembly of the covering, as it is not installed by

Girolami. Therefore we suggest carefully evaluating the creation of any and all coverings so that they can

be easily removed from the equipment if necessary.

Our headquarters is at your disposal for any and all advice related to coverings, and to schedule service

interventions if necessary.

1.11 SPARE PARTS

Only use original spare parts.

Do not wait until components are completely worn out from use to replace them.

Replacing a worn component before it breaks helps prevent accidents caused by sudden breakage of

components, which can cause serious injury to people and objects. Perform periodic maintenance inspections as indicated in the chapter “MAINTENANCE AND CLEANING”.

1.12 DELIVERY OF THE FIREPLACE

The fireplace is delivered packaged and attached to a wooden pallet to facilitate handling with a forklift and/

or other means.

WARNING: turning the machine upside-down can cause some of its parts to lock up. DO NOT

TURN IT UPSIDE-DOWN OR LAY ON ITS SIDE.

The following materials are attached inside the fireplace:

• The use, installation and maintenance booklet

• Door lock

• Thermal glove

BOILER FIREPLACES

Codice TC Rev.0 del 01/04/2011

7

2 SAFETY INSTRUCTIONS

2.1 INSTRUCTIONS FOR THE IN-

STALLER DANGER:

• Make sure that the furnace settings comply with local, national and European regulations;

• Comply with the instructions given in this manual;

• Check that the flue and air inlet are suitable for the type of installation;

• Do not execute electrical connections with temporary or non-insulated cables;

• Check that the earthing of the electrical system is efficient;

• Always use individual safety devices and other means of protection as required by law.

• Only install the equipment with open circuit system with expansion vessel.

2.2 INSTRUCTIONS FOR THE USER

DANGER:

• Prepare the furnace installation location according to local, national and European regulations. As it

is a heating device, the fireplace has especially hot external surfaces.

• For this reason we recommend using extreme caution when the machine is in use.

• Do not touch or go near the glass door as you could get burnt;

• Do not touch the smoke discharge;

• Do not carry out any type of cleaning;

• Make sure that children are kept away;

• Comply with all of the warnings given in this manual;

• Comply with the instructions and warnings given on the plates on the fireplace;

• Only use fuels compliant with the information given in the chapter regarding fuel characteristics;

• Scrupulously follow the routine and extraordinary maintenance schedule;

• Do not use the burner without carrying out a daily inspection first, as dictated by the chapter “Mainte-

nance” in this manual;

• Do not use the fireplace if it is not functioning properly;

• Do not spray water to extinguish fire on the brazier;

• Do not lean on the open door;

• Do not use the fireplace as a support or anchor of any type whatsoever;

• Do not clean the fireplace until both the structure and ashes are completely cold;

• During operation, only use the sliding shutter to open.

• Use the protective glove to open the door in order to avoid touching hot metal parts with bare hands.

• NEVER OPEN THE SWINGING HINGED DOOR DURING USE (danger of poisoning).

• Perform all operations calmly and safely;

• In the event of a chimney fire, turn off the fireplace and call for emergency assistance.

2.3 INSTRUCTIONS FOR MAINTENANCE

ENGINEER DANGER:

• Comply with the instructions given in this manual;

• Always use individual safety devices and other means of protection;

• Before beginning any type of maintenance operation, make sure the fireplace is completely cold if it

has been recently used;

• Completely disconnect the power supply before servicing electrical and electronic parts and connec-

tors.

BOILER FIREPLACES

Codice TC Rev.0 del 01/04/2011

8

TERMOCAMINI AD ACQUA

CARATTERISTICHE E DESCRIZIONE DELLA MACCHINA

3.1 DESCRIZIONE

Con il termine Termocamino si definisce un caminetto costruito con una struttura completamente metallica

con focolare chiuso da un vetro-ceramico destinato al riscaldamento di uno o più ambienti.

Il vetro-ceramico è inserito in una portina apribile con scorrimento verticale a scomparsa verso l’alto nella

controcappa.

Il termocamino è munito di

cassetto ceneri griglia in ghisa e regolazione aria comburente.

3.2 TARGHETTA DI IDENTIFICAZIONE

E’ posta nella parte superiore del termocamino in corrispondenza della zona dove và effettuato il vano

d’ispezione per le carrucole dello sportello a saliscendi. Il numero di matricola, da indicare sempre, per qual-

siasi richiesta è posto in prossimità del raccordo per il vaso di espansione.

3.3 LA COMBUSTIONE

Molti sono i fattori che concorrono a rendere efficace la combustione in termini di prestazione termiche e

basse emissioni di sostanze inquinanti (CO- Monossido di Carbonio).

Alcuni fattori dipendono dall’apparecchiatura nella quale avviene la combustione altri invece dipendono da

caratteristiche ambientali, di installazione e dal grado di manutenzione ordinaria effettuato al prodotto e alla

canna fumaria.

Alcuni fattori importanti sono:

Aria comburente;

Qualità della legna (umidità e dimensioni);

Caratteristiche del sistema di evacuazione dei prodotti della combustione.

Nei paragrafi successivi sono riportate alcune indicazioni da rispettare per ottenere il massimo rendimento

dal prodotto acquistato.

Per ottenere un buon rendimento è necessario utilizzare combustibile di buona qualità, come il faggio e

quest’ultimo deve essere privo di umidità.

I ciocchi vanno posizionati in maniera che tra uno e l’altro l’aria circoli in maniera corretta come mostrato nella

foto di seguito. L’aria comburente deve essere leggermente aperta (circa 4mm) e lo sportello deve essere

chiuso.

CHARACTERISTICS AND DESCRIPTION OF THE

MACHINE

3.1 DESCRIPTION

The term fireplace heating system refers to a fireplace built with a completely metal structure and furnace

closed using vitroceramic and intended for heating one or more rooms.

The vitroceramic is inserted in a door that can be opened by sliding upwards and fitting under the counterhood.

The fireplace heating system has a

ash box grille in cast iron and air combustion regulation.

3.2 DATA PLATE

It is located on the upper part of the fireplace near the area where the inspection compartment is created for

the sliding door pulleys. The serial number, which must be given when making any type of request, is located

near the fitting for the expansion vessel.

3.3 COMBUSTION

Many factors contribute to effective combustion in terms of thermal performance and low emissions of pollutants (CO - Carbon Monoxide).

Some of these factors depend on the unit itself while others depend on

the environmental and installation conditions and the routine maintenance carried out on the product and on

the flue.

Some important factors are:

• Air for combustion;

• Quality of the wood (humidity and sizes);

• Features of the system for evacuating the combustion products.

Some instructions are given in the following paragraphs that should be complied with in order to achieve

maximum performance of the product purchased.

For best performance, use good quality fuel like beech and fuel that is free of humidity.

The logs should be positioned so that air circulates properly between them as shown in the photo below. The

combustion air must be slightly open (about 4mm) and the door must be closed.

BOILER FIREPLACES

Codice TC Rev.0 del 01/04/2011

9

3

245

200 °C 0.07

400 °C 0.10

600 °C 0.14

800 °C 0.17

4 HANDLING AND TRANSPORT

We recommend waiting until the fireplace is in the installation location before unpacking it.

The machine is delivered with all of its parts.

Be careful, as the machine tends to wobble and tilt.

Avoid brisk movements and tugs when lifting.

Make sure the lifting capacity of the forklift is greater than the machine to be lifted.

The forklift driver is wholly responsible for lifting the loads correctly.

DANGER: Do not let children play with the packaging materials (e.g., films and polystyrene).

Suffocation hazard!

5 PREPARATION FOR ON-SITE INSTALLATION

ASSEMBLY DIAGRAM

The location and environment where the fireplace is placed must meet certain minimum requirements.

• It must not be a bedroom or bathroom.

• It must not be a place where flammable or explosive materials are stored at any time in any way

whatsoever.

• It must be equipped with openings (windows) to clear the air in case of accidental smoke pollution.

• It must have an adequate cubic size to guarantee an air flow of 65 m³/h.

• It must be furnished with an opening for the combustion air intake created in order to avoid acciden-

tal obstruction.

• For proper installation the flue pipe between the stove and the chimney must be made airtight by

sealing all joints.

• If the fireplace is installed on a flue that was previously used with other fireplaces, it must be cleaned

thoroughly in order to avoid abnormal operation and prevent a fire due to the combustible materials that

deposit on the walls of the flue pipe.

• On all fireplaces, the outer sides of the furnace and hood must have panels of rock wool with a thick-

ness of 4 cm and a density of 245kg/m3 to thermally insulate the fireplace. The table of characteristics

that the material must have is shown below.

Classification temperature °C 1000

Density kg / m

3

245

Return to reference temperature, 12 hours % 1.3 / 1000 °C

Cold compression resistance MPa 1.4

Flexion resistance MPa 0.5

Thermal expansion coefficient m / mK 5.4 x 10

Specific heat Kj / kgK 1.03

Thermal conductivity at average temperature W / kgK

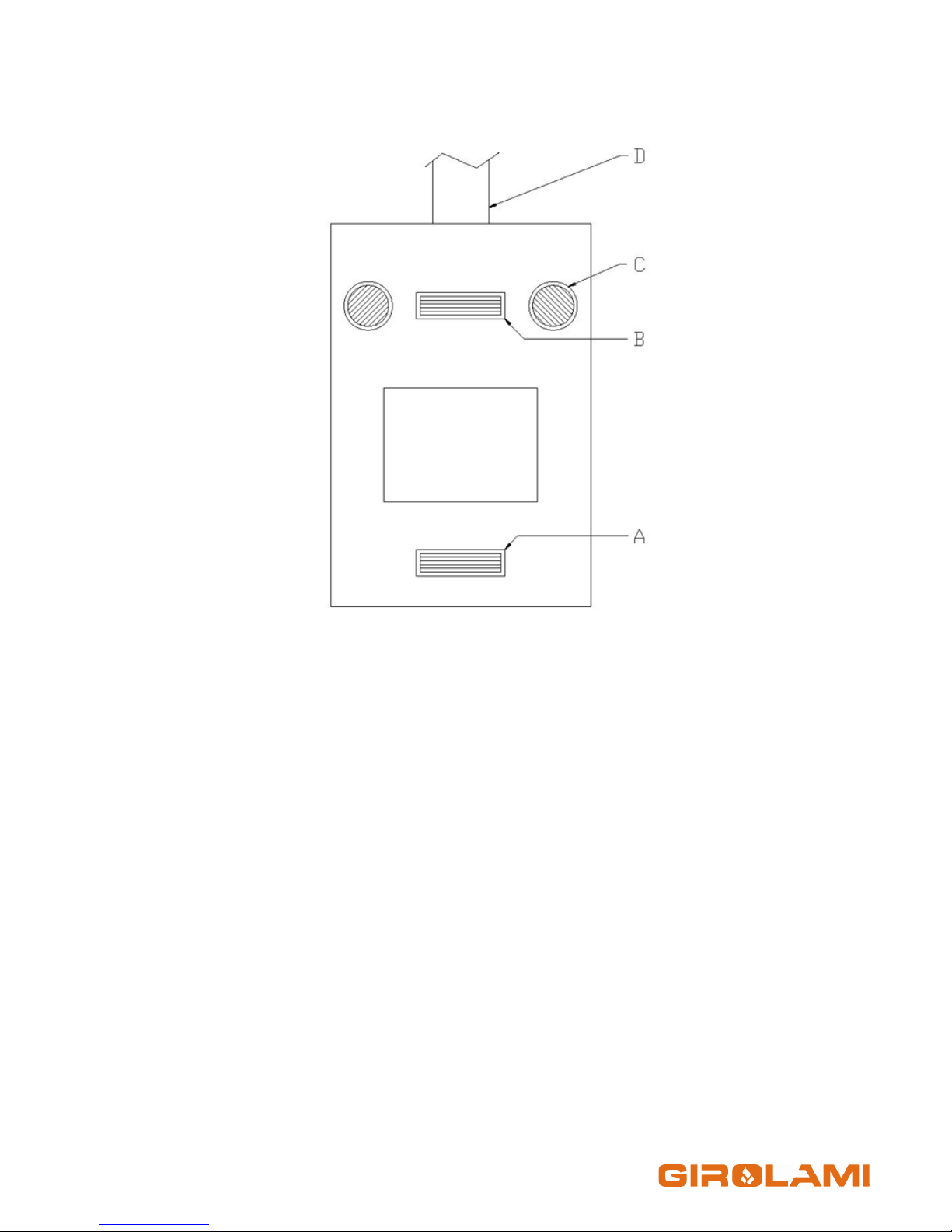

• For routine and extraordinary maintenance, inspection panels must be prepared in the upper front as

indicated by letter C in Fig. 1 (where the aluminium pulleys are). These panels must be at least 40 x 80

cm. There also must be side panels for maintenance of the conductors. See letter D in Figure 1.

• UNI standards require the installation of a heat recovery grille as close as possible to the ceiling.

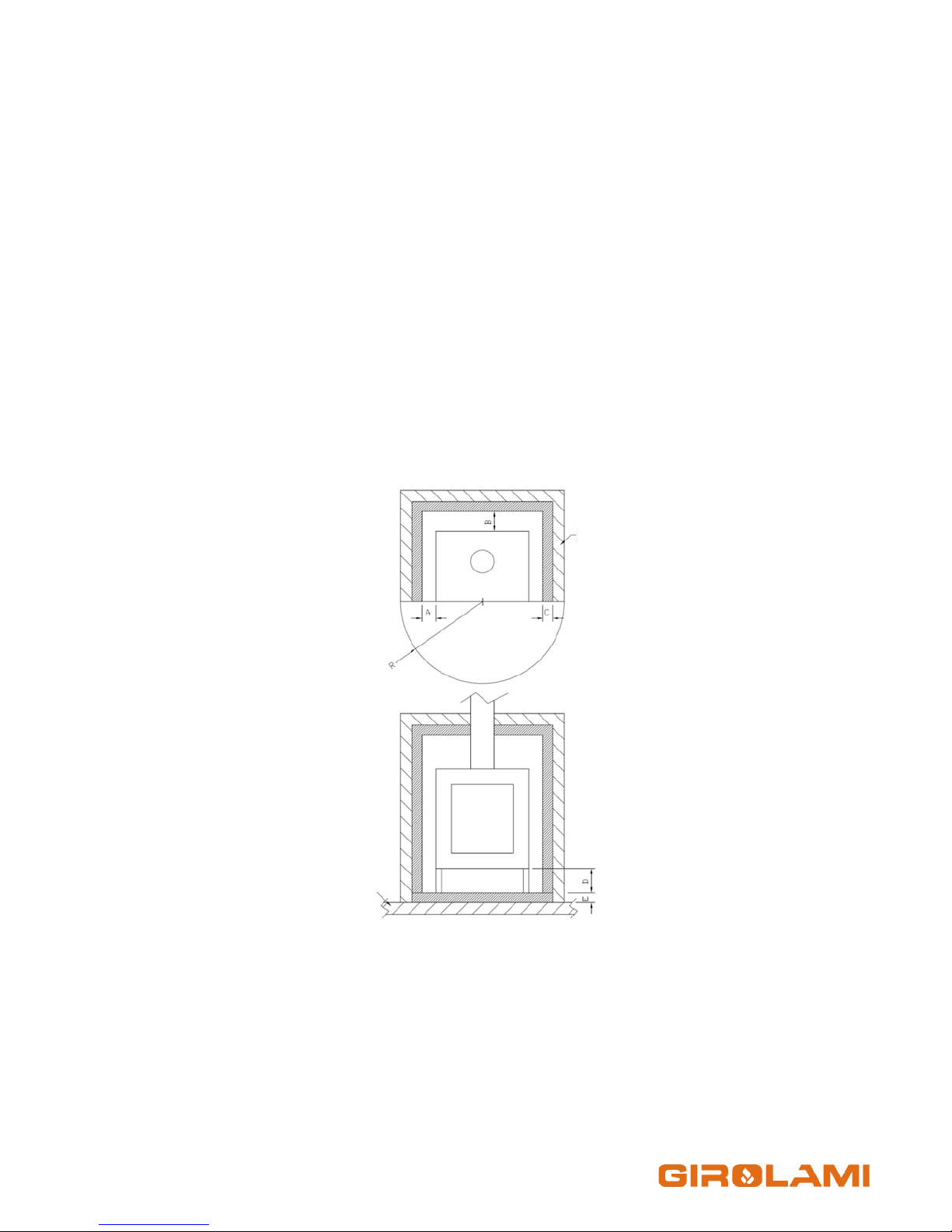

FIG. 1: installation with inert material linings

A) Convective air output

B) Convective air input

C) Front inspection compartment

D) Side inspection compartment

E) smoke pipe

F) ceramic fibre or rock wool lining

without external aluminium

G) Counter-hood and fireproof supporting structure

H) circulator positioned so that it can be inspected

200° C 0.07

400° C 0.10

600° C 0.14

800° C 0.17

BOILER FIREPLACES

Codice TC Rev.0 del 01/04/2011

10

TERMOCAMINI AD ACQUA

5.1. PRECAUZIONI PER LA SICUREZZA

La responsabilità delle opere eseguite nello spazio d’ubicazione della macchina è, e rimane, a cari-

co dell’utilizzatore; a quest’ultimo è demandata anche l’esecuzione delle verifiche relative alle soluzioni

d’installazione proposte.

L’utilizzatore deve ottemperare a tutti i regolamenti di sicurezza locali, nazionale ed europei.

PERICOLO: l’apparecchio dovrà essere installato su pavimenti con adeguata capacità portante.

Nel caso in cui il pavimento non sia di capacità portante sufficiente, si consiglia di utilizzare una piastra di

distribuzione del carico di dimensioni adeguate.

Non istallare mai la macchina su pavimenti in legno se non adeguatamente protetto.

Le operazioni di montaggio e smontaggio del caminetto sono riservate ai soli tecnici specializzati

Nel caso in cui intervengano altri tecnici si raccomanda di accertarsi delle loro reali capacità.

L’installatore, prima di avviare le fasi di montaggio o di smontaggio della macchina, deve ottemperare alle

precauzioni di sicurezza previste per legge ed in particolare a:

A) non operare in condizioni avverse;

B) deve operare in perfette condizioni psicofisiche e deve verificare che i dispositivi antinfortunistici individuali

e personali , siano integri e perfettamente funzionanti;

C) deve indossare i guanti antinfortunistici;

D) deve indossare scarpe antinfortunistiche;

E) deve accertarsi che l’aria interessata alle fasi di montaggio e smontaggio sia libera da ostacoli.

DISTANZE DI SICUREZZA DA MATERIALE INFIAMMABILE

5.1. SAFETY PRECAUTIONS

The user is responsible for operations performed at the machine location. The user is also responsible for

checks related to the proposed installation solutions.

The user must comply with all local, national and European safety regulations.

DANGER: the device must be installed on a floor surface with adequate load-bearing capacity.

If the floor surface does not have sufficient load-bearing capacity, we recommend using an adequately sized

load distribution plate.

Never install the machine on wooden flooring if it is not adequately protected.

The fireplace assembly and disassembly operations must only be carried out by skilled technicians. If other technicians are called in, we recommend making sure they are truly qualified.

Before assembling or disassembling the machine, the installer must comply with the safety precautions

required by law, especially:

A) Do not operate under adverse conditions;

B) Operate only in perfect metal and physical health, and make sure that all individual accident-prevention

devices are sound and in perfect working order;

C) Wear safety gloves;

D) Wear safety shoes;

E) Make sure the assembly and disassembly area is free from obstacles.

SAFETY DISTANCES FROM FLAMMABLE MATERIAL

Distances from flammable material:

- Air space from flammable side wall: a = 100 mm

- Air space from flammable rear wall: b = 100 mm

- Thickness of front/rear insulating material: c = 80 mm

- Air space from flammable floor: d = 200 mm

- Thickness of floor insulating material: e = 0 mm

- Minimum front air space from flammable material: R = 100 cm

FLAMMABLE WALL

FLAMMABLE FLOOR

BOILER FIREPLACES

Codice TC Rev.0 del 01/04/2011

11

Convective air minimum input/output sections:

- Minimum convective air input section: A

ver. 25 = 300 cm²

ver. 35 = 400 cm²

- Minimum convective air input section: B

ver. 25 = 500 cm²

ver. 35 = 600 cm²

- Inner fireplace test diameter: D = Ø 200 mm

5.2 FLUES AND CHIMNEYPOTS

Girolami Caminetti guarantees that its fireplaces meet the technical characteristics indicated in the attached

documentation and in current technical standards.

Our Company has been operating in the market for many years and our fireplaces offer the best guarantees

for excellent operation and long life.

However, it must be remembered that efficient fireplace operation is closely linked to the flue, chimneypot

and fittings between the fireplace and the flue. The latter is neither provided nor installed by our company

and for optimal fireplace performance, we strongly advise hiring expert installers with absolute, proven technical ability.

These issues, which directly concern the chimney draught, are in fact outside of the scope of our company.

We provide the perfectly operating product but cannot assume responsibility for the flue draught. As the

supply, we in fact cannot know where and how the fireplace is installed for optimal performance.

To ensure regular fireplace operation, some fundamental rules regarding the FLUE must be followed, ref.

UNI 10683/98.

• The characteristics of the FLUE must be compliant with the Technical Specifications (minimum

draught 11 Pa/01 bar for ver. 25 and 12 Pa/01mbar for ver. 35).

Loading...

Loading...