SPECIFICATION, INSTALLATION

& OPERATION MANUAL

(READ ALL INSTRUCTIONS BEFORE USE)

Electric Models:

ST30T / ST40T

SH20T / SH30T

SRE1410T / SRE1210T

Revision: A - 15/10/2020

Page Intentionally Left Blank

Page 1

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Introduction

Your New Giorik Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Australia and New Zealand Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warranty Period

Warranty Registration

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Warnings

Installation

Setting Up Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Handling

Unpacking

Disposal

Positioning

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Information

Installation

Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation

Specification

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

ST40T

ST30T

SH30T

ST20T

SRE1210T

SRE1410T

Operation

Operating Instructions - ST30T / ST40T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Operation - Manual Mode

Operation - Automatic Mode

Operation - Saving a Program

Operating Instructions - SH20T / SH30T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Operation

Operating Instructions - SRE1210T / SRE1410T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Operation

Cleaning and Maintenance

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Cleaning Schedule

Materials Required

General Information

Corrosion Protection

Surface Finish

Cleaning Schedule

Materials Required

Cleaning Procedure

Cleaning Procedure - External Surfaces

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Page 2

Introduction

Thank you for choosing this quality Giorik product.

To register your new product, Follow the below Link/QR code.

www.stoddart.com.au/warranty-information

All Stoddart manufactured and distributed products are covered by Stoddart’s standard Australia and New Zealand Product Warranty (minimum

12 month on-site parts and labour, terms and conditions apply). Further to this standard warranty, certain products have access to an extended

warranty. Full terms, conditions and exclusions can be found using the below Link/QR code.

Warranty & Registration

Your New Giorik Product

All Giorik products are designed and manufactured to meet the needs of food service professionals. By caring for and maintaining this new

Giorik product in accordance with these instructions, will provide many years of reliable service.

Stoddart is a wholly Australian owned company, which manufactures and/or distributes a comprehensive range of food service equipment for

kitchens, food preparation and presentation. Stoddart products are manufactured and/or engineered in Australia to provide excellent results

whilst offering value-for-money, ease-of-use and reliability.

Carefully read this instruction booklet, as it contains important advice for safe installation, operation and maintenance.

Keep this booklet on hand in a safe place for future reference by other operators or users.

Disclaimer

The manufacturer and distributor cannot be held responsible or liable for any injuries or damages of any kind occurred to

persons, units or others, due to abuse and misuse of this unit in regards to installation, removal, operation, servicing or

maintenance, or lack of conformity with the instructions indicated in this documentation.

All units made by the manufacturer are delivered assembled, where possible, and ready to install. Any installation, removal,

servicing, maintenance and access or removal of any parts, panels or safety barriers that is not permitted, does not comply

in accordance to this documentation, or not performed by a TRAINED AND AUTHORISED SPECIALIST will result in the

IMMEDIATE LOSS OF THE WARRANTY.

The manufacturer cannot be held responsible or liable for any unauthorised modifi cations or repairs. All modifi cations or

repairs must be approved by the manufacturer in writing before initiating. All modifi cations or repairs performed to this unit

must be performed at all times by a TRAINED AND AUTHORISED SPECIALIST.

Stoddart design, manufacture & distribute Food Service Equipment (appliances) exclusively for the commercial market.

This appliance is not designed nor intended for household or domestic use and must not be used for this purpose.

This product is intended for commercial use, and in line with Australian electrical safety standards the following warnings are provided:

• This product is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or instruction concerning the use of the product by a person

responsible for their safety. Children should be supervised to ensure that they do not play with the product

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualifi ed persons in order to avoid

a hazard

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

Page 3

www.stoddart.co.nz

Introduction

Warranty & Registration

Australia and New Zealand Warranty

Warranty Period

All Stoddart manufactured and distributed products are covered by Stoddart’s standard Australia and New Zealand Product Warranty (minimum

12 month on-site parts and labour, terms and conditions apply). Further to this standard warranty, certain products have access to an extended

warranty. Full terms, conditions and exclusions can be found using the below Link/QR code.

Warranty Registration

To register your new product, Follow the below Link/QR code.

www.stoddart.com.au/warranty-information

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Page 4

Introduction

General Precautions

When using any electrical unit, safety precautions must always be observed.

Our units have been designed for high performance. Therefore, the unit must be used exclusively for the purpose for which it has been designed.

• All units MUST be installed according to the procedures stated in the installation section of this manual

• In the case of new personnel, training is to be provided before operating the equipment

• DO NOT use this unit for any other purpose than its intended use

• DO NOT store explosive substances such as aerosol cans with a fl ammable propellant in or near this unit

• Keep fi ngers out of “pinch point” areas

• Unit is not waterproof DO NOT use jet sprays, hoses or pour water over/on the exterior of the unit

• Only use this unit with voltage specifi ed on the rating label

• DO NOT remove any cover panels that may be on the unit

• DO NOT use sharp objects to activate controls

• If any fault is detected, refer to troubleshooting

• The manufacturer declines any liability for damages to persons and/or things due to an improper/wrong and/or unreasonable use of the

machine

• Only specifi cally trained/qualifi ed Technicians (Stoddart, one of our service agents, or a similarly qualifi ed persons) should carry out any

and all repairs, maintenance and services

General Warnings

• DO NOT USE OR STORE FLAMMABLE MATERIALS IN OR NEAR THIS APPLIANCE

• DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION

• DO NOT MODIFY THIS APPLIANCE

• DO NOT PLACE ARTICLES ON OR AGAINST THIS APPLIANCE

The equipment complies with the essential requirements of the Low Voltage Directive 2006/95/EC.

It meets the provisions of the following electrical and Gas standards:

• AS/NZS 60335.1

• AS/NZS 60335.2.42

The equipment complies with the essential requirements of the Electromagnetic Compatibility Directive 2004/108/EC.

Page 5

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Installation

Setting Up Information

WARNING

Improper installation, adjustments, alterations, service or maintenance can cause property damage, injury or death.

Handling

• Use suitable means to move the unit;

- For smaller items use two people

- For large items a fork lift, pallet trolley or similar (the forks should reach completely beneath the pallet)

Unpacking

• Check the unit for damage before and after unpacking. If unit is damaged, contact the distributor and manufacturer

• Should any item have physical damage, report the details to the freight company and to the agent responsible for the dispatch within

seven (7) days of receipt. No claims will be accepted or processed after this period

• Remove all protective plastic film, ties and packers before installing and operating

• Clean off any remaining residue from the interior/exterior of the unit using a clean cloth dampened with warm soapy water

Disposal

• At the end of the appliance’s working life, make sure it is scrapped & components recycled properly

• Current environmental protection laws in the state/country of use must be observed

• Doors must be removed before disposal

• Power supply cable must be removed before disposal

• For further information on the recycling of this product, contact the local dealer/agent or the local body responsible for waste disposal

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Page 6

Positioning

IMPORTANT

DO NOT install unit under a bench.

Under Bench installation will void warranty

The room where the equipment will be positioned must:

• Be ventilated and not exposed to atmospheric agents;

• Have a smooth, level floor which can bear the weight of the appliance at full load.

• Have a temperature above +4°C;

• Have maximum humidity of 70%;

• Comply with the regulations in force in terms of safety in the workplace and the systems;

• Not contain potentially explosive materials or substances;

• Be dedicated to food preparation. In addition, a gas-fired appliance requires, by law, rooms with a surface area and ventilation that are

suitable for the power of the oven and that have a means of externally evacuating flue gases

• Please consult national and local standards to ensure that your unit is positioned in accordance with any existing requirements

• Do not allow cables or other items to rest/hang over the exhaust vents

• Salamander MUST NOT be installed above a heat source

• Allow an air gap between the unit and other objects or surfaces. A minimum gap of 100mm from all sides and 50mm from the back is

recommend for normal operational use (if the unit is near any heat sensitive material we suggest you allow additional space)

100mm

50mm

APPLIANCE

100mm

Front

Page 7

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Installation

Electrical Connection

Information

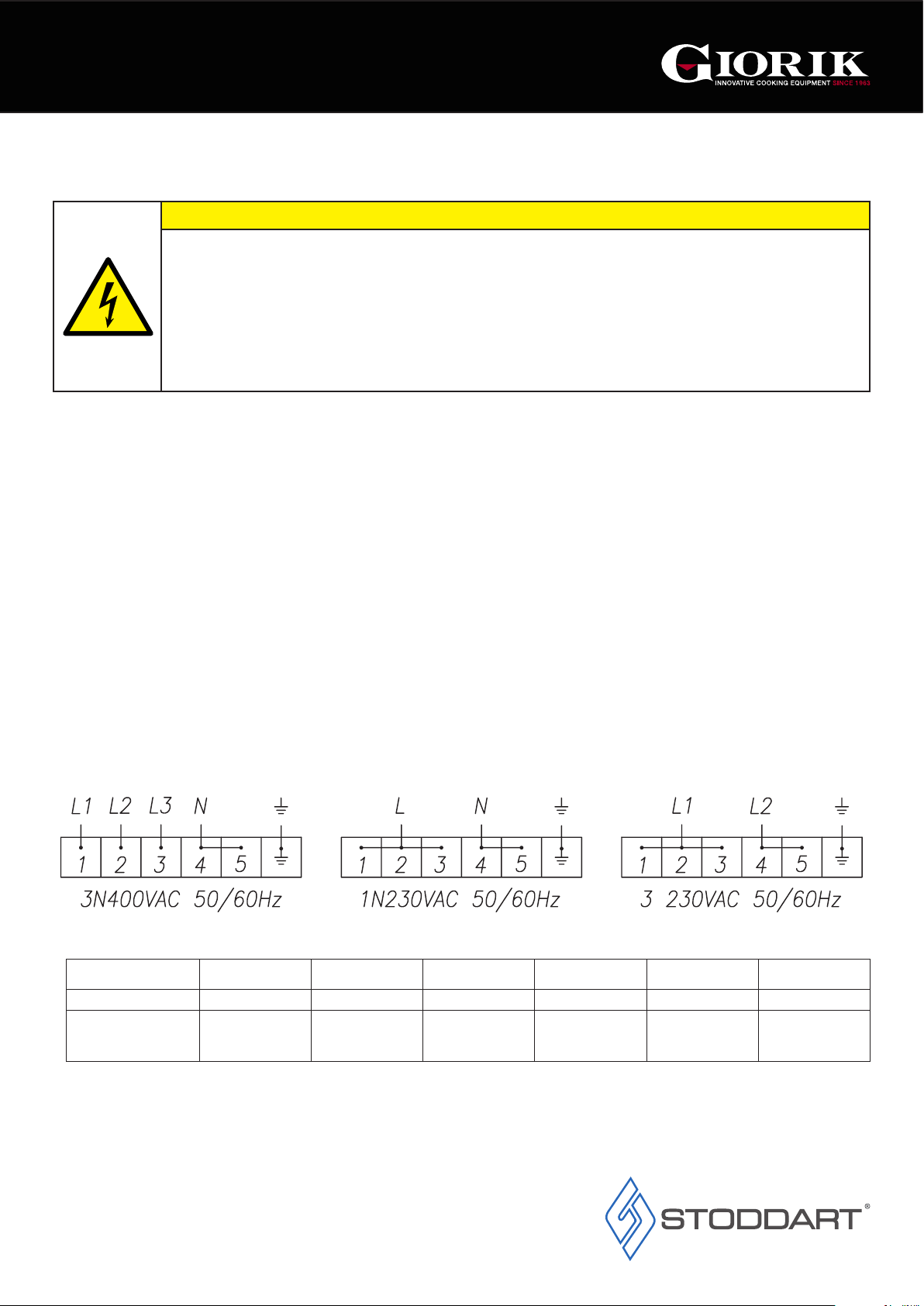

WARNING

This unit must be installed in accordance with AS/NZS 60335.1

Some procedures in this manual require the power to the equipment to be turned off and isolated.

Turn the power OFF at the power point and unplug the power supply lead by the plug body. If the

power point is not readily accessible turn the equipment off at the isolation switch or the circuit

breaker in the switchboard. Attach a yellow “CAUTION-DO NOT OPERATE” tag. This must be

performed where relevant unless the procedures specify otherwise.

FAILURE TO DO SO MAY RESULT IN ELECTRIC SHOCK.

Single Phase Units:

• A terminal block for on-site connection, by a licensed electrician located inside the service compartment of the unit, indicated as:

- 1Ø + N + E

• Supplied and fi tted with an appropriately rated plug and lead

Three Phase Units:

• A terminal block for on-site connection, by a licensed electrician located inside the service compartment of the unit, indicated as:

- 3Ø + N + E

On-site Connection:

• The electrical supply must comply with the rating plate data

• Ensure that the machine is connected to a suitably rated power source

• Disconnection must be incorporated in the fi xed wiring in accordance with the wiring rules

• To connect the power, the unit has a terminal block supplied inside the service compartment

Notes:

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualifi ed persons in order to avoid a

hazard. Please contact Stoddart for parts and we will advise how to do this in order to avoid any electrical hazard

• The power cable should be dry and/or isolated from moisture or water

ST30T ST40T SH20T SH30T SRE1410T SRE1210T

Weight 69 80.5 43 69 38 64

Power (kW)

4.5kW

415V 3Ø + N + E

230V 1Ø + N + E

6.0kW

415V 3Ø + N + E

230V 1Ø + N + E

3.0kW

230V 1Ø + N + E

15A Plug and Lead

4.5kW

415V 3Ø + N + E

230V 1Ø + N + E

2.2kW

230V 1Ø + N + E

10A Plug and Lead

3.9kW

230V 1Ø + N + E

20A Plug and Lead

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Page 8

Installation

Wall Mounting

IMPORTANT

DO NOT install unit above any heat source

Installation

1. Place the bracket on the wall at desired height from the worktop. Ensure the bracket is level, mark the screw hole locations and/or

outline around the bracket. Drill holes and attach the bracket to the wall using sufficient load bearing fasteners

2. Place the unit bracket slots over the bracket

3. Adjust the wall spacer bolts so that the unit sits level

1. 2. 3.

Page 9

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Specification

Technical Specifications

ST40T

Specifications

Model ST40T

W x D x H (mm) 735 x 581 x 519

Weight 80.5kg

Capacity 1/1GN

Cooking Plate Size (mm) 725 x 358

Power 6.0 kW

415V 3Ø + N + E

230V 1Ø + N + E

519

513

534

581

358

190-90

141

735

725

34

667

735

735

34

34 423 43

ST30T

Specifications

Model ST30T

W x D x H (mm) 570 x 581 x 519

Weight 69kg

Capacity 1/1GN

Cooking Plate Size (mm) 560 x 358

Power 6.0 kW

415V 3Ø + N + E

230V 1Ø + N + E

519

23

519

21

52

513

534

581

358

190-90

141

570

560

34

502 34

570

36 421 43

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

519

21

23

52

Page 10

544

SH30T

Specification

Specifications

Model SH30T

W x D x H (mm) 570 x 581 x 519

Weight 69kg

Capacity 1/1GN

Cooking Plate Size (mm) 560 x 365

Power 4.5 kW

415V 3Ø + N + E

230V 1Ø + N + E

421

513

581

534

358

190-90

141

43

570

519

560

34

23

52

502

570

34

36

519

21

ST20T

Specifications

Model ST30T

W x D x H (mm) 570 x 581 x 519

Weight 69kg

Capacity 1/1GN

Cooking Plate Size (mm) 560 x 358

Power 6.0 kW

415V 3Ø + N + E

230V 1Ø + N + E

400

518

35

23

30

400

330

400

390

35

50

518

21

459

355

496

300

190-90

140

50

Page 11

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Specification

SRE1210T

Specifications

Model SRE1210T

W x D x H (mm) 650 x 475 x 570

Weight 64kg

Capacity 1/1GN

Cooking Plate Size (mm) 650 x 350

Power 3.9 kW

230V 1Ø + N + E

20A Plug & Lead Fitted

475

450

650

100

570

350

SRE1410T

Specifications

Model SRE1410T

W x D x H (mm) 450 x 475 x 470

Weight 38kg

Capacity 2/3GN

Cooking Plate Size (mm) 450 x 350

Power 2.2 kW

230V 1Ø + N + E

10A Plug & Lead Fitted

475

125

450

450

100

470

350

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

125

Page 12

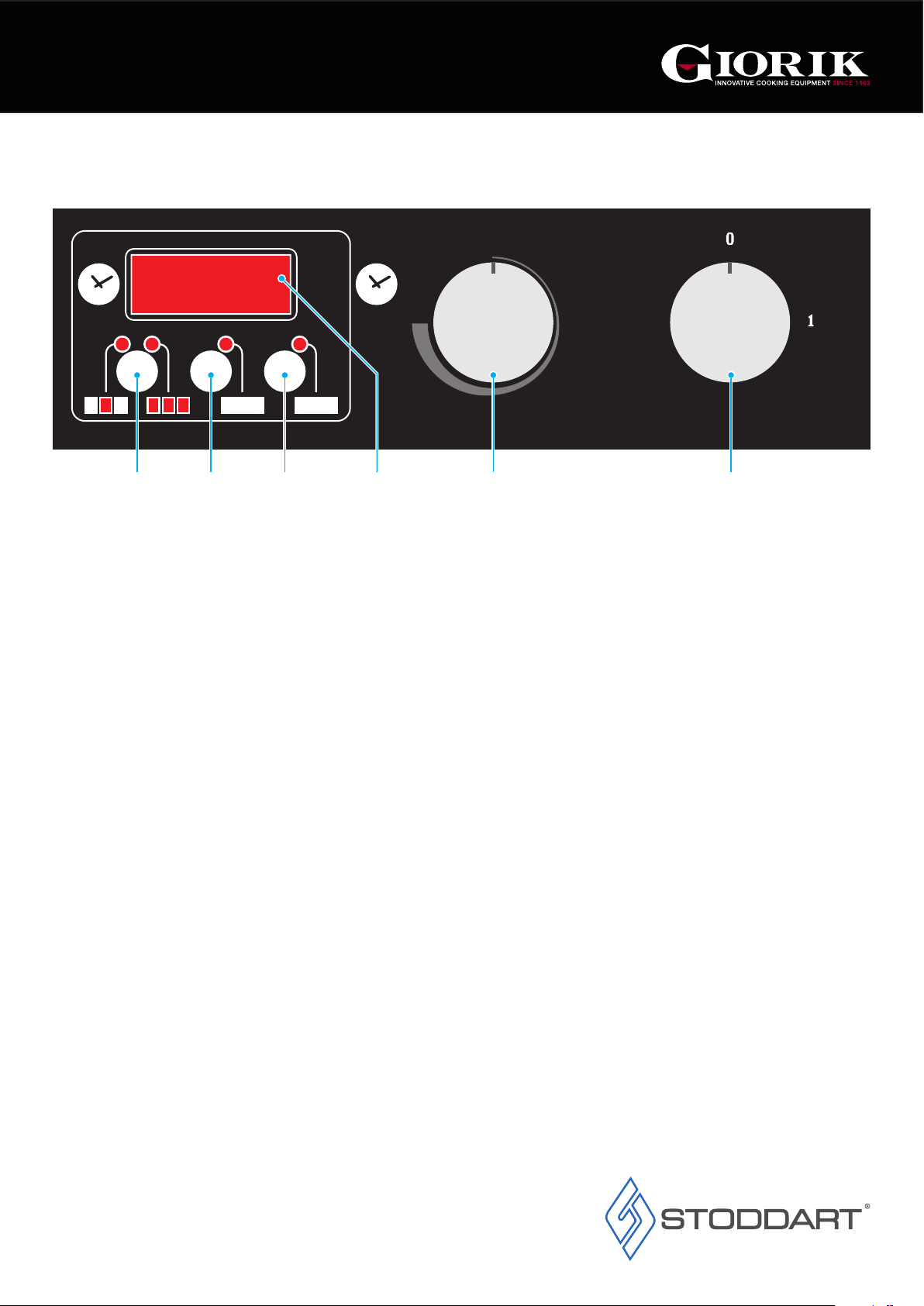

Operating Instructions - ST30T / ST40T

Control Panel

6 5 4 3 2 1

1. ON / OFF:

Turn the unit ON/OFF

2. START / STOP:

Start or stop cooking and hold modes

3. MODE SELECT:

Select either cook or hold modes for manual cooking. When using a program the operator can switch between cook / hold

4. ADJUSTMENT:

Increase or decrease the cook time and/or heat intensity of the hold mode

5. PRESET:

Three programs can be saved

6. ELEMENTS:

Set the cooking cycle with all resistances or just the central resistances

Operation

Operation - Manual Mode

• Switch on the salamander by pressing the ON/OFF button

• Press the MODE SELECT button to select the type of mode (cooking or hold – the corresponding LED above the display will come on)

• Set time and intensity and then press START or place the tray/plate against plate detection device to start the cooking cycle

• When the cooking cycle finishes, an audible sound will be emitted

• Press the START/STOP button or remove the tray/plate (the plate detection device switches unit off), this turn the HOLD mode off

Operation - Automatic Mode

• Switch on the salamander by pressing the ON/OFF button

• Select the desired program by pressing the P1 or P2 or P3 button

• Press START or place the tray/plate against the plate detection device

Operation - Saving a Program

• Switch on the unit on by pressing the ON/OFF button

• Hold down the desired program button (P1 or P2 or P3) until the display starts to flash

• Set the cooking or hold mode by pressing the MODE SELECT button. Set the time using the + and - buttons

• If “cooking mode” has been selected, a “hold mode” can also be set at the end of the cooking cycle by pressing the MODE SELECT

button immediately after setting the time and then setting the heat intensity from 1 to 8

• Save the program by pressing the program button (P1 or P2 or P3).

Note: If the program button is pressed without setting a hold mode first, the cooking mode only will be saved

Page 13

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Operation

Operating Instructions - SH20T / SH30T

Control Panel

STOPSTART

1 2 3 4 5 6

1. Heating elements selection. If light (2) is on, the central resistances cycle on and off at regular intervals during the cooking cycle

2. START button

3. STOP button (It can also be used to stop the buzzer)

4. Set time display

5. Timer Dial (15 sec to 20 min)

6. Power Dial:

0= OFF

1 = ON

Operation

• Turn the power dial (6) to position 1

• Set the cooking time by rotating the timer dial (5). The set time will be shown on display (4).

• Select the heating elements by pressing button (1)

• Press button (2) to start the cooking cycle

• At the end of the cooking cycle the salamander automatically switches off and an audible sound is emitted. Press button (3) to turn off

the buzzer

• To turn the alarm off during a cooking cycle press button (3) after starting the cooking cycle

• By pressing button (2) again, the cooking cycle will run again

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Page 14

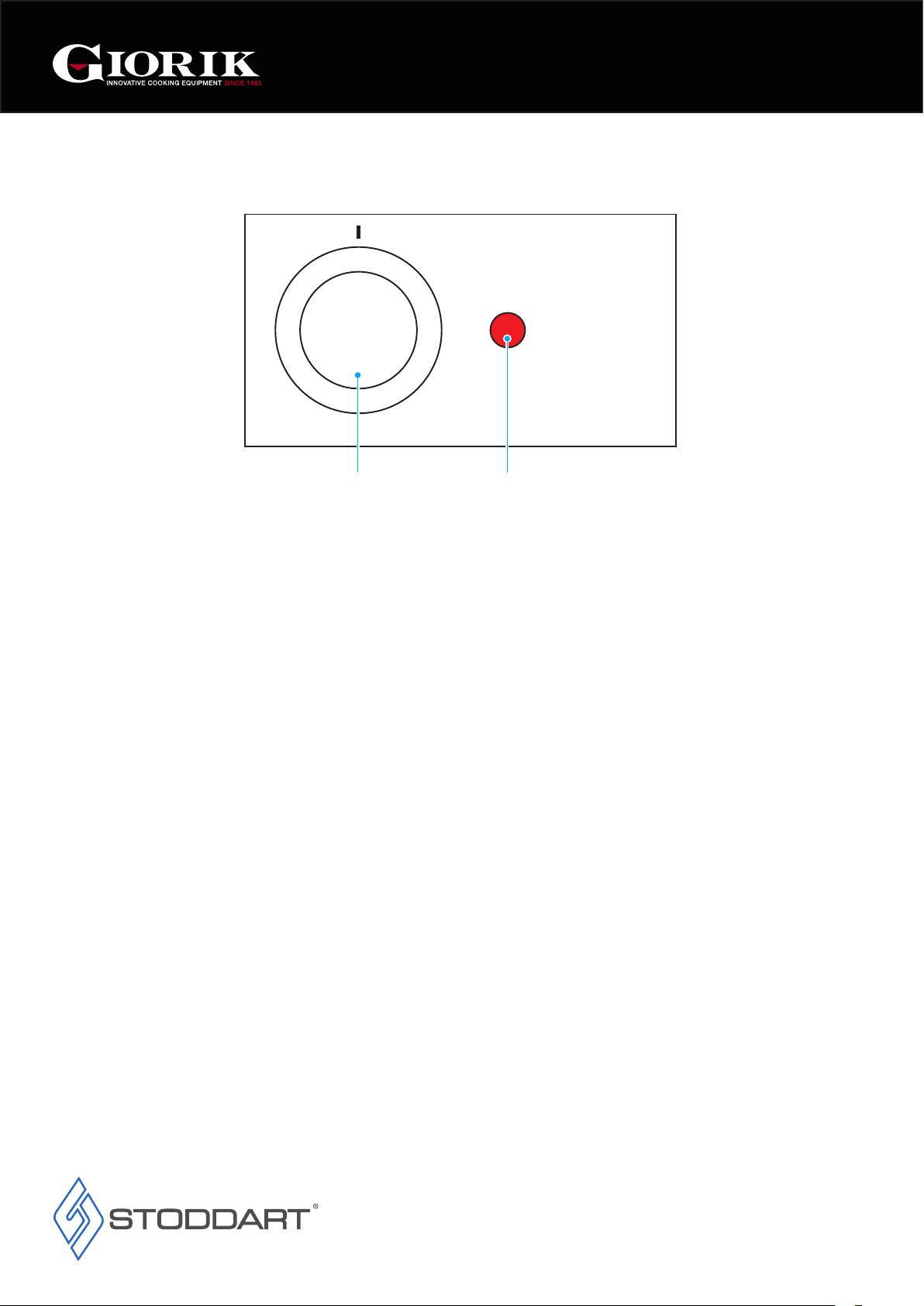

Operating Instructions - SRE1210T / SRE1410T

Control Panel

0

1

6

Operation

2

3

1. Power / Heat Dial. When the dial is in position 0 the unit is off

2. Indicator light

Operation

• Turn the power/heat dial (1) to required level 1-6

• Indicator light will turn on

4

1 2

5

Page 15

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Cleaning and Maintenance

Cleaning

Cleaning Schedule

• Daily cleaning is required for the oven, to help maintain and prolong the efficiency of the oven

• The oven should be cleaned at the end of each work day

• DO NOT USE: Wire brushes, steel wool/sponges, scrapers or other abrasive materials

• Wait for the oven chamber to cool down before cleaning. Must be under 100°C

Materials Required

• Stainless Steel Cleaner

• Non Abrasive Cleaning pad

• Clean Sanitised Cloth

General Information

• Cleaning is recommended for health and safety purposes and to prolong the life of the unit

• DO NOT use abrasive pads or cleaners on the stainless steel or any other metal parts of the unit

• DO NOT use industrial chemical cleaners, caustic based cleaners or bleaches and bleaching agents, as many will damage the metals

and plastics used on this unit

• DO NOT remove any screws and/or panels for cleaning (unless directed)

• This unit is NOT waterproof, DO NOT hose, DO NOT pour water directly onto the unit, DO NOT immerse in water

• Warm soapy water

• Appropriate PPE (Personal Protective Equipment)

Corrosion Protection

• Stainless steel exhibits good resistance to corrosion however, if not properly maintained stainless steel can rust and/or corrode

• Any sign of mild rust and/or corrosion should be thoroughly cleaned with warm soapy water and dried as soon as possible

• NEVER use abrasive pads or cleaners for cleaning

• All metal surfaces should be checked while cleaning for damage, scuffs or scrapes as these can lead to rust and further damage to the

product

• Mild rust and/or corrosion can be treated with a commercial cleaning agent that contains citric/oxalic/nitric/phosphoric acid.

DO NOT use cleaning agents with chlorides or other harsh chemicals as this can cause corrosion.

After treatment, wash with warm (not hot) soapy water and dry thoroughly

• Thoroughly wipe the surfaces dry after cleaning. DO NOT let water pool on the unit. Check crevices and folds for pooling

• When using, ensure all liquids and moisture is cleaned up straight away.

Food liquids such as juices from vegetables and fruits should not be left on preparation surfaces

• DO NOT leave items on the stainless steel such as cutting boards, rubber mats and bottles

Surface Finish

• To protect the polish, stainless steel should be dried by wiping a dry soft cloth in the same direction as grained polished fi nish

• For NON-food contact surfaces, a light oil can be wiped on the surfaces with a cloth to enhance the stainless steel surface.

Wipe in the direction of the grain

• Some commercial stainless steel cleaners can leave residue or fi lm on the metal; this may trap fi ne particles of food on the surface,

thus deeming the surfaces not food safe

IMPORTANT

Threaded fasteners can loosen in service.

Regular inspection and adjustment

should be carried out as required

This unit is NOT waterproof, do NOT

hose. DO NOT pour water directly onto

the unit. DO NOT immerse in water

WARNING

IMPORTANT

Some commercial stainless steel

cleaners leave residue or fi lm on the

metal that may entrap fi ne particles of

food, deeming the surface not

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

FOOD SAFE

WARNING

Wait until the unit has cooled to a safe

temperature before undertaking any

cleaning or maintenance. Contact with

hot surfaces can cause burns and

serious injury

Page 16

Cleaning and Maintenance

Cleaning Schedule

• Daily cleaning is required for toaster grillers, and external surfaces. This will help to maintain and prolong the efficiency of your unit

• The grill plate should be kept clean at all times, free from carbon and burnt materials

• The unit should be cleaned at the end of each work day

Materials Required

• Stainless Cleaner

• Non Abrasive Cleaning pad

• Clean Sanitised Cloth

• Paper Towel

• Container of warm water

• Nylon Brush

• Appropriate PPE (Personal Protective Equipment)

Cleaning Procedure

1. Isolate the unit from the power supply

2. Using a good quality nylon brush remove crumbs and small food items

3. Wipe clean using a cloth dampened (not wet) with clean warm water until all soil has been removed

4. Using a clean sanitised cloth, thoroughly wipe the stainless steel and metal parts dry. Do NOT let water pool on the unit. Check crevices

and folds

Cleaning Procedure - External Surfaces

1. Isolate the unit from the power supply

2. Wearing Personal Protective Equipment (PPE), apply Stainless Cleaner with the Cleaner pad to the external surfaces

3. Scrub any baked on soil with the cleaner pad in the same direction as grained polish

4. Wipe clean using a cloth dampened with clean warm water until all Stainless Cleaner and soil has been removed

5. Using a clean sanitised cloth, thoroughly wipe the stainless steel and metal parts dry. Do NOT let water pool on the unit. Check crevices

and folds

Page 17

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Cleaning and Maintenance

Troubleshooting

• If any faults/issues occur with the unit, follow the below troubleshooting procedures

• If the troubleshooting procedures do not correct the problem, contact the Stoddart Service Department

WARNING

Technician tasks are only to be completed by qualied service

people. Check faults before calling service technician.

Task Type - (O) = Operator

(T) = Technician Task

Problem Possible Causes Task Possible Corrective Action

Unit won’t turn on Unit is not plugged into a suitable power point O Plug unit in

Power switch is in the “Off” position O Change the power switch to the “ON” position

Power Point is faulty T Arrange a qualified Technician to repair the power point

Unit is overheating Airflow blockage O

Fan not working T Replace fan

Unit is not heating Elements not working T Replace Elements as required

Temp switch / Computer board not working T Replace switch / Computer board (whichever is applicable)

Product is burning Temperature set too high O Adjust temperature settings as required

Product is undercooked Temperature is set too low O Adjust temperature settings as required

Clear dirt / dust from fan guard and/ or clear all air vents around

the unit of any obstructions

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Page 18

Australia

Service / Spare Parts

Tel: 1300 307 289

Email: service@stoddart.com.au

Email: spares@stoddart.com.au

www.stoddart.com.au

Australian Business Number: 16009690251

New Zealand

Service / Spare Parts

Tel: 0800 935 714

Email: service@stoddart.co.nz

Email: spares@stoddart.co.nz

www.stoddart.co.nz

New Zealand Business Number: 6837694

Sales

Tel: 1300 79 1954

Email: sales@stoddart.com.au

Sales

Tel: 0800 79 1954

Email: sales@stoddart.co.nz

International

Service / Spare Parts

Tel: +617 3440 7600

Email: service@stoddart.com.au

Email: spares@stoddart.com.au

www.stoddart.com.au

Sales

Tel: +617 3440 7600

Email: sales@stoddart.com.au

Loading...

Loading...