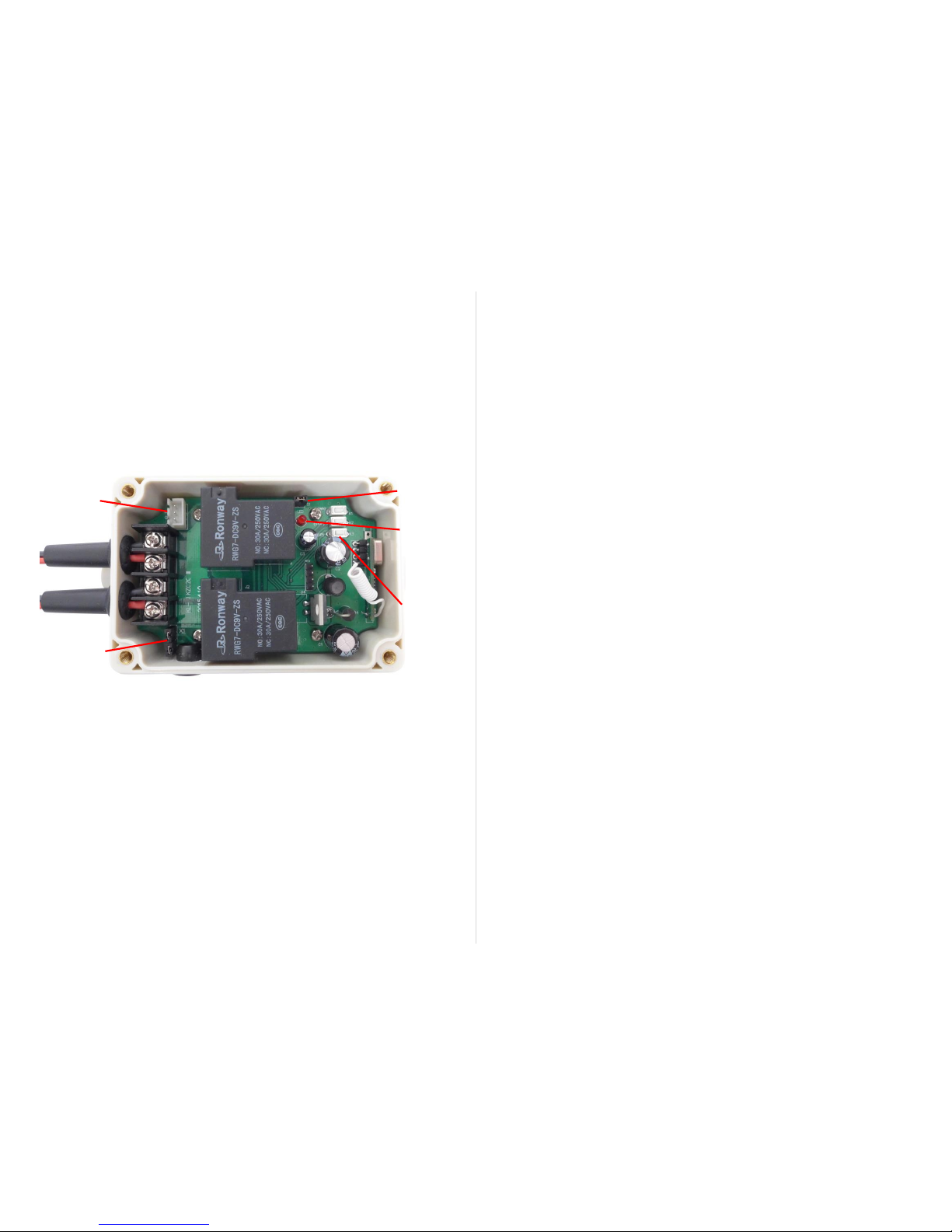

1. Each GLA-CU-X2 unit is supplied with two small ‘keyfob’ transmitters (the

items labelled #2 in the below image) and a rectangular receiver unit (item

labelled #1). The remote transmitter is able to send encrypted instructions to the

receiver which then decodes them and switches a connected actuator or DC

motor in either one direction, the opposite direction, or off.

To get started you should connect the two input leads (those with a white tag

marked ‘INPUT’) to a DC (direct current) supply between 12V and 36V (absolute

limits 9V to 40V). Ensure that the red lead is connected to the positive (+) of the

supply and that the black lead is connected to negative (-). Each unit is supplied

with the included keyfob remote(s) memorised, meaning that if you press the up

and down buttons after having applied power to the receiver you should hear a

‘clicking’ noise as the internal relay switches are activated. If this is the case you

may skip to section 3 of this guide, otherwise use the ‘learning’ procedure

detailed in section 2.

GLA-CU-X2

Actuator & DC Motor Remote Control Unit

Set-up Guide

01/2016

5. If the working range of the remote transmitter falls and/or the LED on the

remote dims noticeably when a button is pressed, it’s likely the remote battery

is running low. To access and replace the battery (a single cell of type A27,

12V) remove the plastic back cover of the transmitter (via three screws), as

shown below. Ensure the new battery is oriented correctly.

27A 12V Battery

Transmitter with the

rear cover removed

(accessed via three

cross-head screws)

Troubleshooting

If the input supply voltage drops below 9V then the receiver will cease to

function. Ensure that the power supply (or battery) used can handle the

load current and is adequately charged otherwise such a voltage drop

may occur.

If the receiver stops responding to the transmitter it may be out of range or

the transmitter battery may be low, try bringing the transmitter closer to

the receiver and if that doesn’t help try replacing the transmitter battery via

removing its back cover (see section 5). Be aware that the effective

operation range will be reduced significantly by large metal objects

between the transmitter and receiver (as these shield against radio

waves)

Ensure that the input and output leads do not get tugged hard, if this

happens the screw terminals that they are connected to on the control

board may become loose.

For any product issues or questions not covered in this guide please contact us

either by email at support@gimsonrobotics.com

or via the website at www.gimsonrobotics.co.uk/contact.html

#2 Transmitters

#1 Receiver

2. The receiver unit is able to selectively memorise which remote transmitters

to respond to; in this way one remote may control one or multiple receivers, or

one receiver may be controlled by one or multiple remotes (each receiver is

able to memorise up to seven separate remotes). Multiple (>20) remote and

receiver pairs may also be used independently in the same area provided that

they are ‘learned’ separately from one-another.

The procedure for ‘learning’ a remote is as follows:

1. Remove the plastic lid from the receiver casing (by removing four cross-head

screws). You should then be able to see three small white push-buttons on the

board labelled UP (K3), STOP (K2) and DOWN (K1), as shown below:

2. Connect the unit INPUT lead to a DC power source between 12-36V, do not have

the OUTPUT connected to a device at this point (and do not allow the ends of the

OUTPUT leads to touch one-another). Be sure not to expose the board to any

metal objects (such as loose screws) while the cover is removed.

3. Check that when you (briefly) press a white push-button the red LED on the board

lights up, if it does then the receiver should be on. Have the remote you wish the

unit to memorise to-hand and then simultaneously press the ‘UP’ button on the

receiver board and the up button on your remote, then release the receiver button

and the LED on the board should start flashing.

4. Repeat step three with the white button labelled STOP and the stop button on the

remote to calibrate this button.

5. Repeat step three with the button DOWN and the down-arrow remote button.

6. The board should now have learned the remote and the next time you press an up

or down button (with the board powered) a relay should 'click' meaning the

controller is switching the output current.

If you wish to reverse the remote operation (so that the travel of the controlled

device is reversed for a given command) then follow the learning steps above

but in the opposite order (UP to remote down button, DOWN to up button).

Learning

Buttons

UP (K3)

STOP (K2)

DOWN (K1)

LED

To erase the memory of previously learnt remotes press and hold any white

button on the board for a long time (around 10 seconds), the red LED should turn

on initially and then after a long pause turn off which signifies that the memory is

now clear, you can then release the button.

3. Using the receiver with a DC motor or actuator is simple, just connect the two

output leads (labelled ‘OUTPUT’) to the two leads of the device to be operated,

then when a DC source is connected to the ‘INPUT’ you should be ready to go.

Pressing the up button on the remote should cause the device to travel in one

direction and pressing the down button should reverse the direction of the output

current and the reverse the motor or actuator travel.

Control modes: Two operating modes may be selected, either Latching (a single

press of a remote leads to a constantly-on output, only turning off when a different

button is pressed) or Momentary (the output will only stay on for as long as a

remote button is held, and the ‘stop’ button becomes redundant). Latching is the

default operating mode, to change to momentary remove the black jumper cap

from position S1 on the receiver board (and keep the jumper safe in case you wish

to change modes back again later).

Wired switch input: A SPDT rocker-switch or two push-buttons may be used to

operate the receiver via the white connector labelled ‘UP, GND, DOWN’. If 'UP'

and 'GND' are connected to one-another then the receiver will change the output to

'UP', if 'DOWN' and 'GND' are connected then the output will change to the

opposite direction. Any wired inputs supplied to the board here will override

instructions given by remote transmitters to the receiver. A lead with three-way

(white plastic) connector is included, to match the connector on the board.

Automatic-off Timer: (applies to units supplied from Feb 2016) The receiver has

an optional timer function (enabled by default), which automatically switches off the

output in latching mode if no new control instruction has been received within 120

seconds. This feature can help to save energy by minimising the time that a relay

is being powered (whereas otherwise the relay would continue to operate until a

‘stop’ button were pressed). To disable the timer remove the black plastic jumper

from the position marked ‘120S’ on the PCB (by the wired-switch input connector).

4. The receiver features inputs for limit switches (if you are using a device with

built-in limit switches or one that does not need them you may disregard this

section). There are four contacts on the board, in two pairs labelled X1 and X2

(bottom-left of diagram in section 2.), these are supplied with two black jumpers

bridging each contact pair but if these jumpers are removed you may put

Normally-Closed switches in their place to serve as limit switches. Each time a

switch were pressed (and went open-circuit) the receiver would prevent the

output from switching in a one direction. In this way you can mount switches on

the device you are controlling that will automatically stop movement when an end

position (as determined by a limit switch trigger position) is reached.

Wired Switch

Inputs

(UP, GND,

DOWN)

Limit Switch

Inputs (X1, X2)

Mode

Selection

Jumper (S1)

Loading...

Loading...