Page 1

User’s Guide

EN

LT801577_D _UG DISPENSMAN.indd 1 09/11/2017 15:01:11

Page 2

2

| DISPENSMAN

®

TABLE OF CONTENTS

GENERAL PRODUCT DESCRIPTION | 3

Description | 3

Component Description| 5

Parts Checklist | 5

SAFETY & USER PRECAUTIONS | 6

General Safety Precautions | 6

Safety Considerations Before Initial Operation | 7

Operating Limitations | 7

Liquids Contact Material | 7

INSTALLATION | 8

Telescopic Tube | 8

Bottle Adapter | 8

OPERATION | 9

Volume adjustment | 9

Air Purging | 9

Dispensing | 10

Anti-Drop system | 10

MAINTENANCE | 11

Disassembly | 11

Assembly | 11

CLEANING AND STERILIZATION | 12

Cleaning | 12

Sterilization | 12

CALIBRATON | 13

TROUBLESHOOTING | 14

SPECIFICATIONS | 15

SPARE PARTS | 16

Spare Parts for Small Volumes (2.5, 5, and 10 mL) | 16

Spare Parts for Large Volumes (25 and 50 mL) | 16

APPENDIX | 17

WARRANTY | 18

TABLE OF CONTENTS

LT801577_D _UG DISPENSMAN.indd 2 09/11/2017 15:01:12

Page 3

GENERAL PRODUCT DESCRIPTION

3

DISPENSMAN

®

| USER’S GUIDE

Chapter 1

GENERAL PRODUCT DESCRIPTION

DISPENSMAN® is a sophisticated dispensing system that fulfills increasing

requirements for quality, precision, and reproducibility in laboratories. It

consists of high precision components and extremely robust materials. It has

a built-in recalibration mechanism that ensures reproducibility for the life of

the instrument.

DISPENSMAN is an exclusive instrument with 0% loss of reagent due to airpurging and draining within a closed circuit. The valve block can rotate 360°;

therefore, the label of the bottle is always visible for your added safety. The

dispenser has our unique 100% drip-free system for your safety at work: just

turn the nozzle switch to “Empty” (180°) to drain it and prevent uncontrolled

flow of liquid.

The dispenser is fully autoclavable at 121°C and can be completely

disassembled for cleaning. Each instrument is individually tested and

delivered with a certificate of performance.

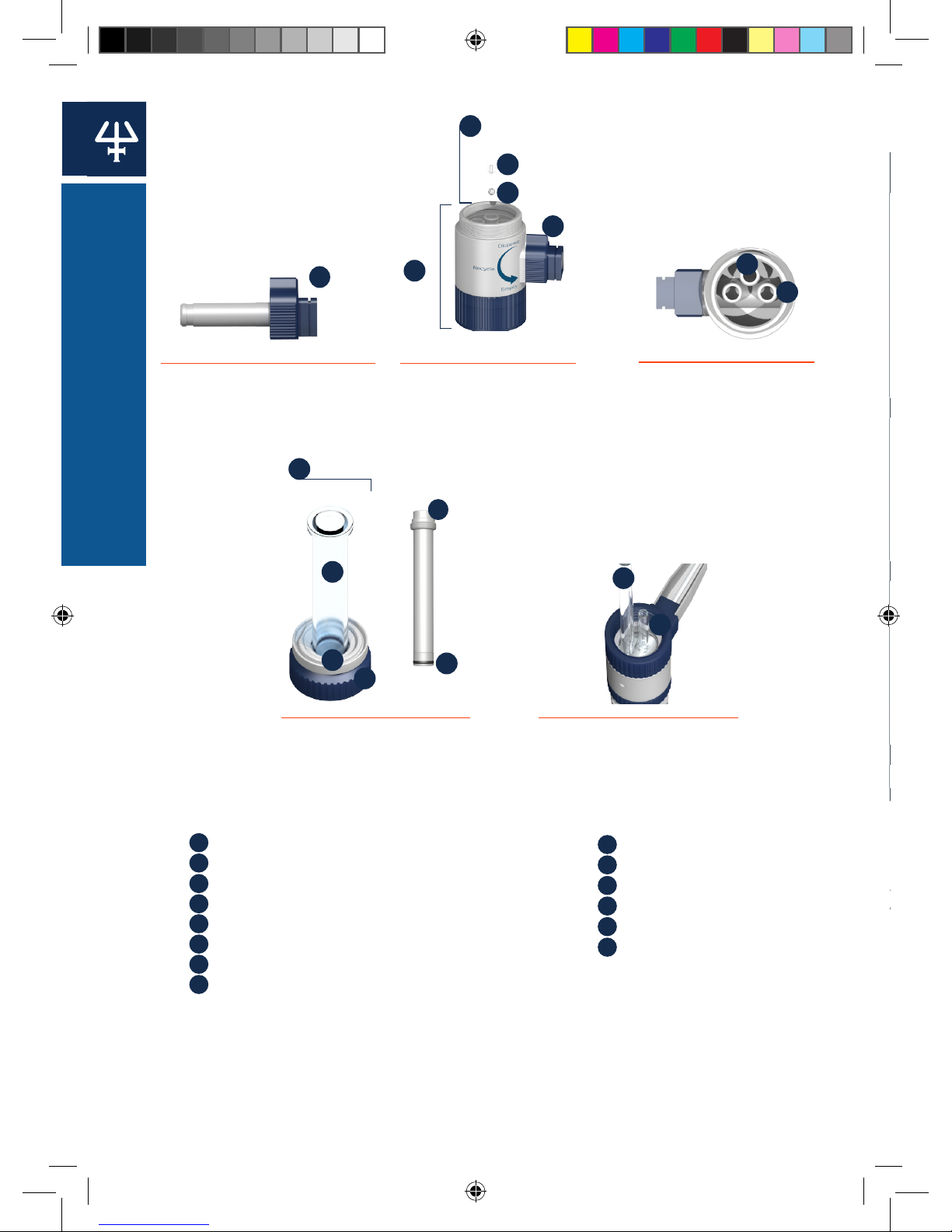

Description

1

2

3

4

5

6

8

7

9

20

10

11

Safety cap

Recalibration mechanism

Outer housing

Quick-lock knob

Adaptor ring

Cap nut

Nozzle switch

Protective sleeve

Discharge tube

Nozzle set

Bottle adaptor

Valve block

1

2

3

4

5

6

7

8

9

10

11

20

LT801577_D _UG DISPENSMAN.indd 3 09/11/2017 15:01:12

Page 4

GENERAL PRODUCT DESCRIPTION

4

GENERAL PRODUCT DESCRIPTION | DISPENSMAN

®

IMPORTANT: Edges on top!

Adaptor ring

Cap nut

Nozzle switch

Suction valve

Valve star

Valve ball

Ejection valve

O-ring

Piston

Cylinder set

Cylinder

Valve block

Telescopic tube

Reflux tube

19

5

6

15

20

7

22

21

12

5

6

7

20

21

22

12

7

16

14

13

17

18

19

18

17

16

15

14

13

12

Figure 1

Nozzle switch and its axle,

located inside the valve block

Figure 2

Valve block without nozzle

Figure 3

Valve block, top view

Figure 4

Aspiration system, located

under outer housing

Figure 5

Valve block, bottom view

Component Description

COMPONENT MATERIAL

Outer housing PP (polypropylene) with 20% talcum

Adaptor ring PP (polypropylene) with 20% talcum

Inside nozzle switch PTFE (polytetrafluoroethylene)

Protective sleeve PP (polypropylene)

Bottle adaptor PP (polypropylene)

Valve ball Ceramic

Piston PTFE (polytetrafluoroethylene) / PVDF (polyvinylidene fluoride)

Valve block PP (polypropylene) with 20% talcum

White component inside

telescopic tube PTFE (polytetrafluoroethylene)

Safety cap

Recalibration knob PP (polypropylene)

Sliding volume adjuster PA66 (polyamide) with 30% glass fiber

Cap nut PP (polypropylene)

Nozzle switch PP (polypropylene)

Discharge tube FEP (fluorinated ethylene propylene)

Inside valve block ETFE (ethylene tetrafluoroethylene)

Valve star ETFE (ethylene tetrafluoroethylene)

Cylinder Glass

Protective transparent

plastic for cylinder PTFE (polytetrafluoroethylene)

Telescopic tube FEP (fluorinated ethylene propylene)

Reflux tube FEP (fluorinated ethylene propylene)

O-ring FKM (fluorocarbon rubber)

Parts Checklist

After unpacking the DISPENSMAN, verify that the following items were included

and not damaged:

• 1 Gilson DISPENSMAN with an attached reflux tube

• 1 telescopic tube

• 1 protective sleeve with an attached discharge tube

• 1 calibration tool

• 4 adaptors with dierent diameters (mm):

• For small volumes (2.5, 5, 10 mL): A25, A28, S40, A32/45

• For large volumes (25, 50 mL): A25, A28, S40, A45/32

• 1 certificate of performance

• 1 user’s guide

LT801577_D _UG DISPENSMAN.indd 4 09/11/2017 15:01:13

Page 5

GENERAL PRODUCT DESCRIPTION

5

DISPENSMAN

®

| USER’S GUIDE

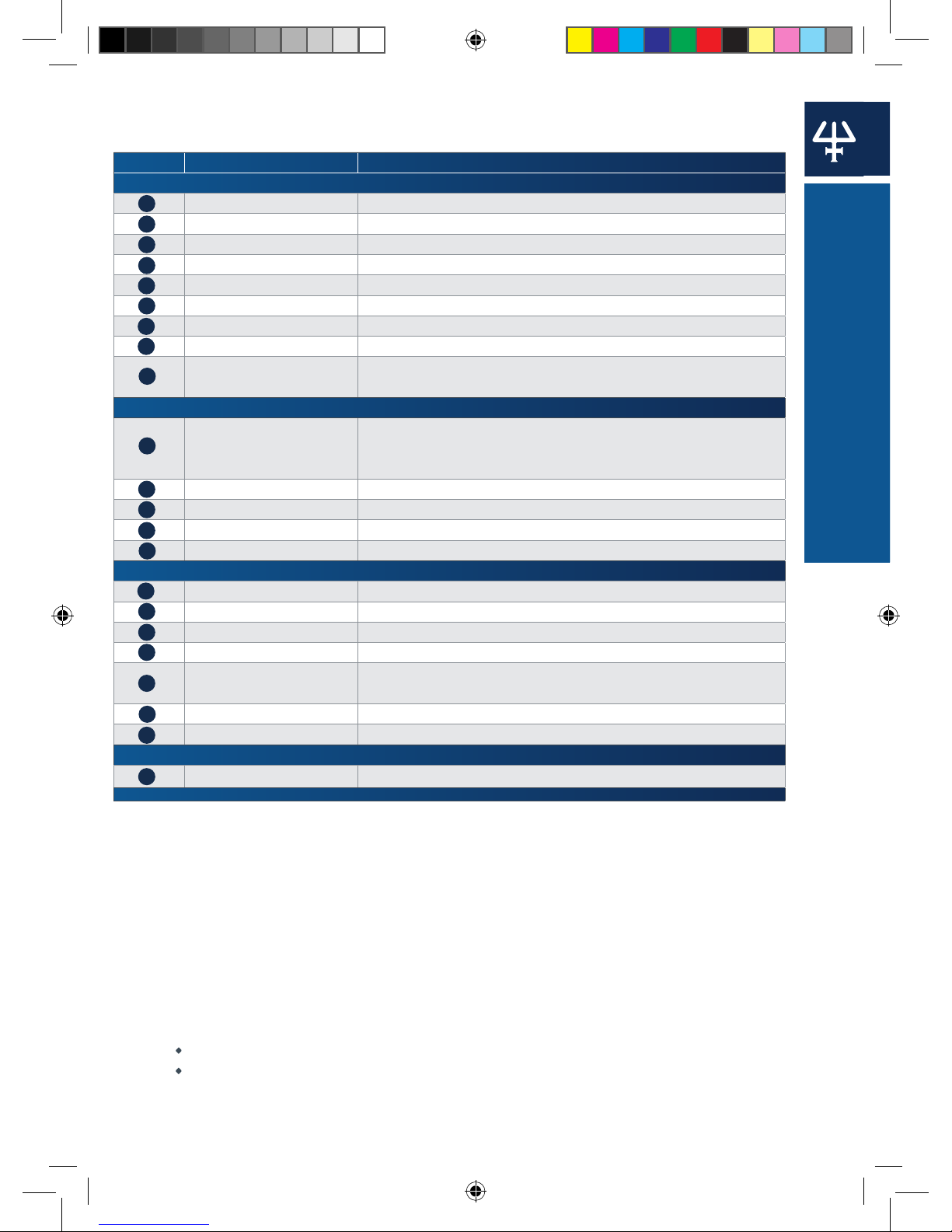

Component Description

COMPONENT MATERIAL

White components

Outer housing PP (polypropylene) with 20% talcum

Adaptor ring PP (polypropylene) with 20% talcum

Inside nozzle switch PTFE (polytetrafluoroethylene)

Protective sleeve PP (polypropylene)

Bottle adaptor PP (polypropylene)

Valve ball Ceramic

Piston PTFE (polytetrafluoroethylene) / PVDF (polyvinylidene fluoride)

Valve block PP (polypropylene) with 20% talcum

White component inside

telescopic tube PTFE (polytetrafluoroethylene)

Blue components

Safety cap

Small volumes (2.5, 5, 10mL): PP (polypropylene)

with 20% talcum

Large volumes (25, 50mL): PP (polypropylene) with glass fiber

Recalibration knob PP (polypropylene)

Sliding volume adjuster PA66 (polyamide) with 30% glass fiber

Cap nut PP (polypropylene)

Nozzle switch PP (polypropylene)

Clear components

Discharge tube FEP (fluorinated ethylene propylene)

Inside valve block ETFE (ethylene tetrafluoroethylene)

Valve star ETFE (ethylene tetrafluoroethylene)

Cylinder Glass

Protective transparent

plastic for cylinder PTFE (polytetrafluoroethylene)

Telescopic tube FEP (fluorinated ethylene propylene)

Reflux tube FEP (fluorinated ethylene propylene)

Dark components

O-ring FKM (fluorocarbon rubber)

3

1

20

17

14

8

7

5

12

9

7

6

4

2

21

19

19

13

22

16

11

21

Parts Checklist

After unpacking the DISPENSMAN, verify that the following items were included

and not damaged:

• 1 Gilson DISPENSMAN with an attached reflux tube

• 1 telescopic tube

• 1 protective sleeve with an attached discharge tube

• 1 calibration tool

• 4 adaptors with dierent diameters (mm):

• For small volumes (2.5, 5, 10 mL): A25, A28, S40, A32/45

• For large volumes (25, 50 mL): A25, A28, S40, A45/32

• 1 certificate of performance

• 1 user’s guide

LT801577_D _UG DISPENSMAN.indd 5 09/11/2017 15:01:13

Page 6

SAFETY & USER PRECAUTIONS

6

SAFETY & USER PRECAUTIONS | DISPENSMAN

®

Chapter 2

SAFETY & USER PRECAUTIONS

General Safety Precautions

In order to put the instrument into operation as quickly as possible and free from

defects, it is necessary that you read this manual carefully before using this

instrument.

Highest safety precautions should be used when dispensing corrosive,

poisonous, radioactive, or hazardous chemicals.

• Observe the general safety regulations for handling chemicals (e.g.,

protective clothing, protective goggles).

• Use DISPENSMAN only with regard to the chemical resistance of materials

and for the purpose for which is intended (see the chemical compatibility

list, pages 17 and 18).

• Always check the instrument for leak tightness and a firm position of the

plug and socket connection before you use it.

• Never use force. Breakage of any part will lead to hazardous exposure for the

user as well as for other persons.

• Clean the instrument every week and if you want to use DISPENSMAN for

another chemical solution or if you do not use it for a longer time.

• The temperature of the dispenser and reagent should not exceed 40°C (104°F).

• The user is responsible for checking that the instrument is suitable for his

application.

• The proper and secure function is only guaranteed by using the supplied

discharge tube 9. Do not use any other discharge tube.

• Never use damaged or deformed tubes. If the valve is damaged, the

discharge tube might drop.

• The discharge tube should never face the user and a collection vessel should

be placed underneath.

• Check all fittings for tightness approximately one hour after assembly or

disassembly as temperature variations may cause material expansion, which

can cause leakages.

• If you are unsure about dispensing a specific chemical solution, refer to the

chemical compatibility list in pages 17 and 18 or contact your local Gilson

representative.

Safety Considerations Before Initial Operation

• Check instrument for damage caused in transit.

• The telescopic tube

• Do not use the outer housing

need to carry the instrument, hold it by the base of the instrument.

• Attach discharge tube

damage.

• When screwing on/o the bottle do not hold the instrument at its outer

housing 3, but at the screw base.

• Do not pump before the instrument has been assembled completely and a

collecting vessel has been placed underneath.

Operating Limitations

Do not use for:

• PTFE swelling solvents

• Hydrofluoric acid

• Chemical solutions that react with platinum-iridium alloys

Liquids used with DISPENSMAN must not exceed the following limits:

Liquid Contact Materials

The components having direct contact with the reagent are made of chemical

resistant materials: platinum spring, ceramic valve balls, PTFE piston, and borosilicate

glass 3.3 cylinder.

OPERATION LIMIT MAXIMUM

Vapor pressure 600 mbar

Viscosity 500 mm

Density 2.2 g/cm

Temperature

LT801577_D _UG DISPENSMAN.indd 6 09/11/2017 15:01:13

Page 7

SAFETY & USER PRECAUTIONS

7

DISPENSMAN

®

| USER’S GUIDE

Safety Considerations Before Initial Operation

• Check instrument for damage caused in transit.

• The telescopic tube 21 should reach the bottom of the bottle.

• Do not use the outer housing 3 for carrying the assembled dispenser. If you

need to carry the instrument, hold it by the base of the instrument.

• Attach discharge tube 9 and clip on protective sleeve 8 carefully to avoid

damage.

• When screwing on/o the bottle do not hold the instrument at its outer

housing 3, but at the screw base.

• Do not pump before the instrument has been assembled completely and a

collecting vessel has been placed underneath.

Operating Limitations

Do not use for:

• PTFE swelling solvents

• Hydrofluoric acid

• Chemical solutions that react with platinum-iridium alloys

Liquids used with DISPENSMAN must not exceed the following limits:

Liquid Contact Materials

The components having direct contact with the reagent are made of chemical

resistant materials: platinum spring, ceramic valve balls, PTFE piston, and borosilicate

glass 3.3 cylinder.

OPERATION LIMIT MAXIMUM

Vapor pressure 600 mbar

Viscosity 500 mm2/s

Density 2.2 g/cm

3

Temperature

<+15°C and >+40°C

<+59°F and >+104°F

LT801577_D _UG DISPENSMAN.indd 7 09/11/2017 15:01:13

Page 8

INSTALLATION

8

INSTA L L AT I O N | DISPENSMAN

®

Chapter 3

INSTALLATION

Telescopic Tube

Press gently the telescopic tube 21 into the smaller hole of the bottom part of

the valve block. Check for the proper length of the telescopic tube (it should

reach the bottom of the bottle).

The reflux tube 22is already attached to the bigger hole.

Bottle Adaptor

Choose the right adaptor according to your bottle.

Screw the chosen adaptor on to the extremity of the bottle and screw

DISPENSMAN into the adaptor.

Check the stability of the instrument on the bottle before operating.

21

22

Figure 6

Valve block, bottom view

LT801577_D _UG DISPENSMAN.indd 8 09/11/2017 15:01:13

Page 9

OPERATION

9

DISPENSMAN

®

| USER’S GUIDE

Chapter 4

OPERATION

Legend of arrows in pictures:

ARROW SIGNIFICATION

User action on the instrument

Liquid movement into the instrument

Recycle

(90°)

4

Volume Adjustment

The quick-volume adjustment is performed with the

quick-lock knob 4. Push the quick-lock knob, slide

it down to the desired volume, and then release.

Air Purging

Turn the nozzle switch 7 to “Recycle” (90°). Set a

small volume and dispense until the cylinder 19 is

free from air. Air-purging is performed in a closed

circuit for zero loss of reagent.

Turn the discharge tube back to “Dispense” (0°).

Adjust to the desired volume. Dispense liquid

precisely and carefully until the end of discharge

tube 9 is fully filled. Without any air in the entire

instrument, this step will guarantee that the

dispensed volume is precise (zero point). Then, fill

the cylinder up to the selected volume.

The DISPENSMAN is now ready to dispense the

desired volume.

7

9

LT801577_D _UG DISPENSMAN.indd 9 09/11/2017 15:01:13

Page 10

OPERATION

10

OPERATION | DISPENSMAN

®

Dispensing

To avoid personal injury from

chemicals, wear eye protection

and protective clothing and use

appropriate safety equipment.

Follow safety and operation

instructions in this manual.

Raise the outer housing until it reaches a hard

stop at the set volume. The set volume will be

dispensed into the collecting vessel by pressing

down the outer housing to the lowest point. The

movements should be smooth and constant to

achieve an accurate dispense volume.

Noise while aspirating or dispensing is acceptable

as it is because of the high quality suction valve

with valve ball.

Anti-Drop System

Turn the nozzle switch 7 to “Empty” (180°). The

liquid from the discharge tube will now rinse back

into the bottle. Any further dispensing of liquid is

not possible in this position.

Turn the nozzle switch 7 to “Recycle” (90°) to

seal the dispenser.

Dispense

(0°)

Empty

(180°)

3

3

7

CAUTION

LT801577_D _UG DISPENSMAN.indd 10 09/11/2017 15:01:14

Page 11

MAINTENANCE

11

DISPENSMAN

®

| USER’S GUIDE

Chapter 5

MAINTENANCE

To avoid valve clogging, clean the dispenser if it has not been used for a while (refer to

Chapter 6 CLEANING & STERILIZATION, page 12).

Release clogged valves with a thin object (wire, paper clip, etc.) by pushing the

upper side of the ejection valve 15 and / or the bottom side of the suction valve

12

(refer to Figure 3, page 4). Make sure that you rinse the valves residue-free,

since clogged valves may lead to leakage of the instrument.

Disassembly

Follow the general safety precautions (refer to Chapter 2

SAFETY & USER PRECAUTIONS, page 6).

1. Rinse the dispenser with distilled water or alcohol (Refer to Chapter 6

CLEANING & STERILIZATION, page 12).

2. Remove the telescopic tube 21 and the reflux tube22.

3. Remove the protective sleeve 8 and then the discharge tube 9.

4. Loosen the fix screw 2 and pull out the piston 17.

5. Pull o the adaptor ring 5 from outer housing 3.

6. Press down the quick-lock knob 4 and pull it out of the slot.

7. Remove the outer housing 3 .

8. Loosen the cap nut 6.

9. Pull the cylinder set 18 out of the valve block 20, be aware that the valve

star 13 and the valve ball 14 might fall out.

10. Take the valve star 13 and the valve ball 14 out of the valve block 20.

11. Pull the nozzle switch 7 out of the valve block 20.

Assembly

1. Push the nozzle switch 7 into the valve block 20.

2. Place the valve ball 14 and the valve star 13 into the suction valve. Check

that the edges of the valve star 13 point upwards.

3. Attach the cylinder set 18 to the valve block 20. Check that the notches of

the cylinder set are placed exactly over the spikes of the valve block.

4. Tighten the glass cylinder 19 with the cap nut 6. Check that all parts fit tightly.

5. Slide the outer housing 3 onto the cylinder 19.

6. Place the instrument horizontally and mount the quick-lock knob 4 into the

slot of the outer housing 3.

7. Clip the adaptor ring 5 to the outer housing 3.

8. Push the piston 17 into the cylinder 19 until it stops.

9. Attach the fix screw 2 to the outer housing 3.

10. Attach the discharge tube 9 to the nozzle switch 7.

11. Slide the protective sleeve 8 over the attached discharge tube 9 + 7.

12. Push the reflux tube 22 and the telescopic tube 21 into the valve block 20.

13. Screw the assembled instrument on the reagent bottle.

CAUTION

LT801577_D _UG DISPENSMAN.indd 11 09/11/2017 15:01:14

Page 12

CLEANING & STERILIZATION

12

CLEANING & STERILIZATION | DISPENSMAN

®

Chapter 6

CLEANING & STERILIZATION

Cleaning

Cleaning is necessary if you want to use the dispenser for another chemical

solution or if has not been used for a long time. During cleaning, please follow the

safety instructions (refer to Chapter 2 SAFETY & USER PRECAUTIONS, page 6).

Before cleaning, remove all liquid from the dispenser without any loss of reagent

by following these steps:

1. Turn the nozzle switch to “Empty” (180°) and let the remaining reagent from

the discharge tube flow back into the reagent bottle.

2. Unscrew the dispenser from the bottle.

3. Drain the telescopic tube 21 by slightly tapping inside the reagent bottle.

4. Turn the nozzle switch from ”Empty” (180°) to “Recycle” (90°) and remove all

remaining liquid from the cylinder back into the reagent bottle.

For cleaning, follow these steps:

1. Attach the telescopic tube and then screw the dispenser on a bottle with

distilled water or alcohol.

2. Turn the nozzle switch to “Dispense” (0°).

3. Dispense multiple times until the instrument is clean.

If necessary, disassemble the dispenser (Chapter 5 MAINTENANCE, on page 11) and

clean all components.

The dispenser should be cleaned daily if used with following chemicals:

• Solutions that tend to crystallize (e.g., salts)

• Inorganic oxidizing solutions (e.g., biuret reagent)

Sterilization

After removal of the reflux tube 22 and the telescopic tube 21, the dispenser can

be steam-sterilized (121°C, 1 bar, 20 minutes) according to EN ISO 17665. Place the

instrument on a cloth and avoid any contact with hot, metal surfaces.

The discharge tube 9 has to be attached to the protective sleeve 8.

In order to prevent loss of adjustment due to heat expansion of the dierent

materials, the quick-lock knob 4 has to be set to a minimum of 2/10 of its

maximum volume. Before you use the dispenser, let it reach room temperature

(about 2 hours cooling time). After autoclaving, check all screw fittings for

tightness and the calibration of the instrument. Recalibrate the dispenser, if

necessary (refer to Chapter 7 CALIBRATION, page 13). After autoclaving, perform

a visual check of the instrument for any changes and verify all screw fittings.

In case of deformation, please return the instrument with a description of the

autoclave protocols that were used.

DISPENSMAN is calibrated according to EN ISO 8655-5:2002 and

EN ISO 8655-6:2002. After assembling the instrument, calibrate it per the

instructions below:

1. Remove the safety cap

visible (Figure 7).

2. Attach the calibration tool or standard hex key to the safety bolt (Figure 8).

3. Use the calibration tool or hex key to pull out the safety bolt.

4. Attach the calibration tool with the thicker side to the site of the safety bolt

(Figure 9).

5. To recalibrate a volume set too low, rotate the calibration tool clockwise. To

recalibrate a volume set too high, rotate the calibration tool counter-clockwise.

6. Attach the safety bolt to the piston (Figure 8).

7. Check the volume. If the measured volume exceeds the tolerance limits, then

calibrate the instrument again. If the calibration was successful, attach the

safety cap (Figure 10).

LT801577_D _UG DISPENSMAN.indd 12 09/11/2017 15:01:14

Page 13

CALIBRATION

13

DISPENSMAN

®

| USER’S GUIDE

Chapter 7

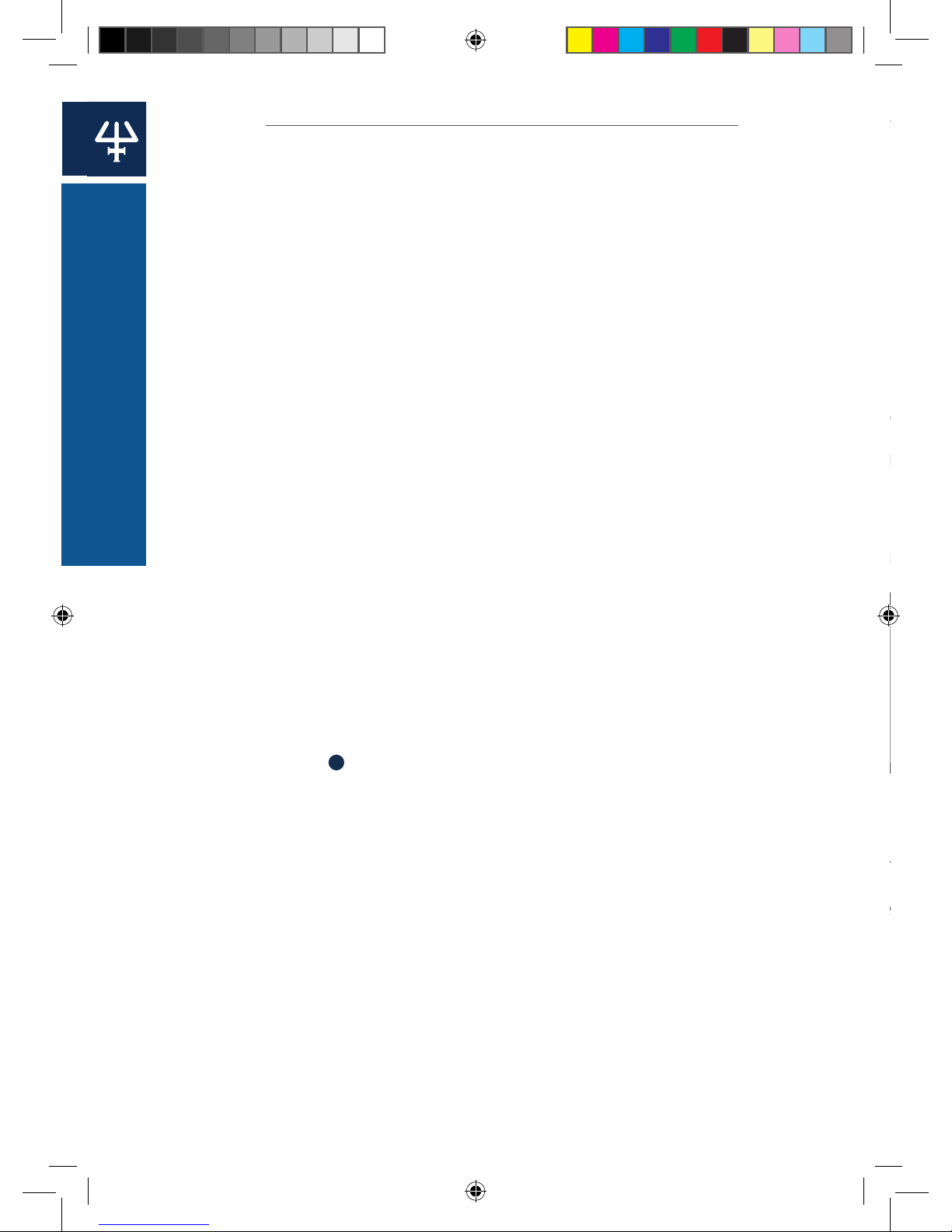

CALIBRATION

DISPENSMAN is calibrated according to EN ISO 8655-5:2002 and

EN ISO 8655-6:2002. After assembling the instrument, calibrate it per the

instructions below:

1. Remove the safety cap 1. The built-in recalibration mechanism is now

visible (Figure 7).

2. Attach the calibration tool or standard hex key to the safety bolt (Figure 8).

3. Use the calibration tool or hex key to pull out the safety bolt.

4. Attach the calibration tool with the thicker side to the site of the safety bolt

(Figure 9).

5. To recalibrate a volume set too low, rotate the calibration tool clockwise. To

recalibrate a volume set too high, rotate the calibration tool counter-clockwise.

6. Attach the safety bolt to the piston (Figure 8).

7. Check the volume. If the measured volume exceeds the tolerance limits, then

calibrate the instrument again. If the calibration was successful, attach the

safety cap (Figure 10).

Calibration tool

Safety cap

Safety bolt

Fix screw

Piston

Figure 7

Built-in recalibration

mechanism

Figure 8

Use of calibration tool

Figure 9

Thin side of safety bolt

Figure 10

Put back the safety cap

Figure 11

Calibration system, from the top of DISPENSMAN to inside, under outer housing

LT801577_D _UG DISPENSMAN.indd 13 09/11/2017 15:01:15

Page 14

TROUBLESHOOTING

14

TROUBLESHOOTING | DISPENSMAN

®

Chapter 8

TROUBLESHOOTING

Valve Sticks

With the dispensing unit screwed on, ensure that the valves are surrounded by

liquid and that the valve system is easy to move by rinsing it with distilled water

and/or laboratory cleaning agent. As a last step, rinse with alcohol.

Piston Dicult to Move

Check whether crystals have formed, and if so, carry out intensive cleaning of the

piston and the cylinder (refer to Chapter 5 MAINTENANCE, page 11).

No Liquid Dispensed

• Check that the nozzle switch is set to “Dispense” (0°).

• Check the suction valve and then clean it, if necessary.

• Check the nozzle switch. If it is not clean and operational, clean unit by

immersing nozzle set in cleaning fluid.

• Check the discharge tube. If it is not clean and operational, disassemble it,

and then flush it with cleaning fluid.

No Liquid Aspirated

• Check the fit of the telescopic tube into the suction valve. It should be firmly

pressed into the smaller hole of the bottom part of the valve block (please

refer to figure 6, page 8).

• Check the volume setting.

• Check the suction valve and then clean it, if necessary.

Air Bubbles in Aspirated Liquid

• Check whether all air has been removed from the instrument, (See Chapter 4

OPERATION, page 9).

• Check that the reservoir is not empty.

• Check the telescopic tube, if necessary slide it to shorten it or replace it in its

socket.

• Ensure slow, steady aspiration of reagent.

• Check the suction valve and then clean it, if necessary.

Incorrect Volume Dispensed

Calibrate the instrument (See Chapter 7 CALIBRATION, page 13).

LT801577_D _UG DISPENSMAN.indd 14 09/11/2017 15:01:15

Page 15

TROUBLESHOOTING

15

DISPENSMAN

®

| USER’S GUIDE

If any problem persists, please return DISPENSMAN back to your local Gilson

service center.

Return for Repair

Please clean the instrument carefully, as described in Chapter 6

CLEANING & STERILIZATION, page 12. Never send in instruments

filled with reagents. Returned instruments can only be

checked and repaired if they have been carefully cleaned and

decontaminated by the customer.

Forced opening of the instrument invalidates any warranty claim. Enclose with

the returned instrument a description of the trouble that has occurred and

specify which reagents were used.

Chapter 9

SPECIFICATIONS

DISPENSMAN is a high quality dispenser that oers excellent accuracy and

precision; it is fully compliant with ISO 8655.

Each dispenser is inspected and validated by qualified technicians. Gilson

declares that its manufactured dispensers comply with the requirements of the

ISO 8655 standard, by type testing. The adjustment is carried out under strictly

defined and monitored conditions.

MODEL

PART

NUMBER

VOLUME RANGE

SCALING

(mL)

MAXIMUM PERMISSIBLE ERRORS

GILSON ISO 8655-5

SYSTEMATIC

ERROR (mL)

RANDOM

ERROR (mL)

SYSTEMATIC

ERROR (mL)

RANDOM

ERROR (mL)

DISPENSMAN 2.5 mL F110101 0.25 – 2.5 mL 0.05 ±0.012 ≤ 0.002 ±0.030 ≤ 0.010

DISPENSMAN 5.0 mL F110102 0.5 – 5 mL 0.10 ±0.030 ≤ 0.005 ±0.030 ≤ 0.010

DISPENSMAN 10 mL F110103 1 – 10 mL 0.20 ±0.060 ≤ 0.010 ±0.060 ≤ 0.020

DISPENSMAN 25 mL F110104 2.5 – 25 mL 0.50 ±0.150 ≤ 0.025 ±0.150 ≤ 0.050

DISPENSMAN 50 mL F110105 5 – 50 mL 1.00 ±0.300 ≤ 0.050 ±0.300 ≤ 0.100

Noise During Aspiration and Dispensing

Noise while aspirating or dispensing is acceptable as it is because of the high quality

suction valve with valve ball.

SPECIFICATIONS

NOTICE

LT801577_D _UG DISPENSMAN.indd 15 09/11/2017 15:01:15

Page 16

SPARE PARTS

16

SPARE PARTS | DISPENSMAN

®

DESCRIPTION PART NUMBER

Calibration tool F107122

Protective sleeve for discharge tube, 2.5 mL, 5 mL, and 10 mL F107145

9

Discharge tube, 2.5 mL F107124

9

Discharge tube, 5 and 10 mL F107125

22

Reflux tube, 40mm, l.Ø:3mm, A.Ø: 4 mm F107127

21

Telescopic tube, 125 – 240 mm F107133

21

Telescopic tube, 250 – 480 mm F107135

21

Telescopic tube, 70 – 140 mm F107136

21

Telescopic tube, 195 – 350 mm F107137

11

Thread adapters made of PP invert GL A45/A32 F107139

11

Thread adapters made of PP GL A32/A45 F107140

11

Thread adapters made of PP GL A32/S40 F107141

11

Thread adapters made of PP GL A32/A38 F107142

11

Thread adapters made of PP GL A32/A28 F107143

11

Thread adapters made of PP GL A32/A25 F107144

8

Chapter 10

SPARE PARTS

Spare Parts for Small Volumes (2.5, 5, and 10 mL)

Spare Parts for Large Volumes (25 and 50 mL)

DESCRIPTION PART NUMBER

Calibration tool F107123

Protective sleeve for discharge tube, 25 and 50 mL F107146

9

Discharge tube, 25 and 50 mL F107126

22

Reflux tube, 40mm, l.Ø:6mm, A.Ø: 7 mm F107128

21

Telescopic tube, 170 – 330 mm F107134

21

Telescopic tube, 250 – 480 mm F107138

11

Thread adapters made of PP invert GL A45/A32 F107139

11

Thread adapters made of PP GL A32/A45 F107140

11

Thread adapters made of PP GL A32/S40 F107141

11

Thread adapters made of PP GL A32/A38 F107142

11

Thread adapters made of PP GL A32/A28 F107143

11

Thread adapters made of PP GL A32/A25 F107144

Acetaldehyde Butyric acid Glycol

Acetic acid 100% Calcium carbonate Glycolic acid 50%

Acetic acid 96% Calcium chloride Hexanoic acid

Acetone Calcium hydroxide Hexanol

Acetonitrile Calcium hypochlorite Hydriodic acid 57%

Acetylacetone Chloro naphthalene Hydrochloric acid 20%

Acrylic acid Chloroacetaldehyde 45% Isoamyl alcohol

Acrylonitrile Chloroacetic acid Isobutanol

Adipic acid Chloroacetone Isopropanol

Allyl alcohol Chlorobenzene Isopropyl ether

Aluminium chloride Chlorobutane Lactid acid

Amino acids Chromic acid 50% Methoxybenzene

Ammonia 20% Chromosulfuric acid Methyl alcohol

Ammonium chloride Copper sulfate Methyl benzoate

Ammonium fluoride Cumene Methyl butyl ether

Ammonium sulfate Cyclohexanone Methyl ethyl ketone

n-Amyl acetate Decane Methyl formate

Amyl alcohol 1-Decanol Methyl propyl ketone

Aniline Dibenzyl ether Mineral oil

Barium chloride Dichlorobenzene Monochloroacetic acid

Benzaldehyde Diethanolamine Nitric acid 30%

Benzol Diethylamine Nitrobenzene

Benzoyl chloride 1.2 Diethylbenzene Oleic acid

Benzyl alcohol Diethylene glycol Oxalic acid

Benzylamine Dimethyl sulfoxide Perchloric acid

Benzylchloride Dimethylaniline Phenol

Boric acid 10% Dimethylformamide Phenylethanol

Bromobenzene Diphenyl ether Phenilhydrazine

Bromonaphthalene Ethanolamine Phosphoric acid 85%

Butanediol Ethyl acetate

1-Butanol Ethyl alcohol Piperidine

n-Butyl acetate Formaldehyde 40% Potassium chloride

Butyl methyl ether Formamide Potassium dichromate

Butylamine Glycerol Potassium hydroxide

8

LT801577_D _UG DISPENSMAN.indd 16 09/11/2017 15:01:15

Page 17

APPENDIX

17

DISPENSMAN

®

| USER’S GUIDE

Chapter 11

APPENDIX

Chemical Compatibility

Acetaldehyde Butyric acid Glycol

Acetic acid 100% Calcium carbonate Glycolic acid 50%

Acetic acid 96% Calcium chloride Hexanoic acid

Acetone Calcium hydroxide Hexanol

Acetonitrile Calcium hypochlorite Hydriodic acid 57%

Acetylacetone Chloro naphthalene Hydrochloric acid 20%

Acrylic acid Chloroacetaldehyde 45% Isoamyl alcohol

Acrylonitrile Chloroacetic acid Isobutanol

Adipic acid Chloroacetone Isopropanol

Allyl alcohol Chlorobenzene Isopropyl ether

Aluminium chloride Chlorobutane Lactid acid

Amino acids Chromic acid 50% Methoxybenzene

Ammonia 20% Chromosulfuric acid Methyl alcohol

Ammonium chloride Copper sulfate Methyl benzoate

Ammonium fluoride Cumene Methyl butyl ether

Ammonium sulfate Cyclohexanone Methyl ethyl ketone

n-Amyl acetate Decane Methyl formate

Amyl alcohol 1-Decanol Methyl propyl ketone

Aniline Dibenzyl ether Mineral oil

Barium chloride Dichlorobenzene Monochloroacetic acid

Benzaldehyde Diethanolamine Nitric acid 30%

Benzol Diethylamine Nitrobenzene

Benzoyl chloride 1.2 Diethylbenzene Oleic acid

Benzyl alcohol Diethylene glycol Oxalic acid

Benzylamine Dimethyl sulfoxide Perchloric acid

Benzylchloride Dimethylaniline Phenol

Boric acid 10% Dimethylformamide Phenylethanol

Bromobenzene Diphenyl ether Phenilhydrazine

Bromonaphthalene Ethanolamine Phosphoric acid 85%

Butanediol Ethyl acetate

Phosphoric acid 85% + Sulfuric

acid 98%, 1:1

1-Butanol Ethyl alcohol Piperidine

n-Butyl acetate Formaldehyde 40% Potassium chloride

Butyl methyl ether Formamide Potassium dichromate

Butylamine Glycerol Potassium hydroxide

LT801577_D _UG DISPENSMAN.indd 17 09/11/2017 15:01:15

Page 18

WARRANTY

18

WARRANTY | DISPENSMAN

®

Chapter 12

WARRANTY

Gilson warrants the dispenser against defects in material under normal use and

service for 1 year from the date of purchase. This warranty is valid only if the

dispenser is used in the manner described in this manual and for the purpose

for which it is designed. Gilson is not responsible for consequential damages

resulting from the misuse of this instrument.

Potassium permanganate Sodium acetate Tetramethylammoniumhydroxide

Propionic acid Sodium chloride Triethanolamine

Propylene glycol Sodium dichromate Triethylene glycol

Pyridine Sodium fluoride Urea

Pyruvic acid Sodium hydroxide 30% Zinc chloride 10%

Salicylaldehyde Sodium hypochlorite Zinc sulfate 10%

Silver acetate Sulfuric acid 98%

LT801577_D _UG DISPENSMAN.indd 18 09/11/2017 15:01:15

Page 19

NOTES

19

DISPENSMAN

®

| USER’S GUIDE

NOTES

LT801577_D _UG DISPENSMAN.indd 19 09/11/2017 15:01:15

Page 20

www.gilson.com/contactus

LT80157 7/ D | ©11/2017 Gilson, Inc. All rights reserved.

Specifications subject to change without notification — errors excepted.

Reproduction, adaptation, or translation without prior written permission is

prohibited, except as allowed under copyright laws.

LT801577_D _UG DISPENSMAN.indd 20 09/11/2017 15:01:15

Loading...

Loading...