Page 1

402 Dilutor Dispenser

User’s Guide

Page 2

Page 3

402 Dilutor Dispenser

User’s Guide

LT801310/C - ©2003 Gilson SAS All rights reserved November 2003

Page 4

Page 5

Contents

Table of Contents 0

Safety

1 Introduction

Notational Conventions .................................................................. 1-2

Overview .......................................................................................... 1-3

Unpacking ...................................................................................... 1-5

Warranty ......................................................................................... 1-6

Customer Service .......................................................................... 1-7

2 Description

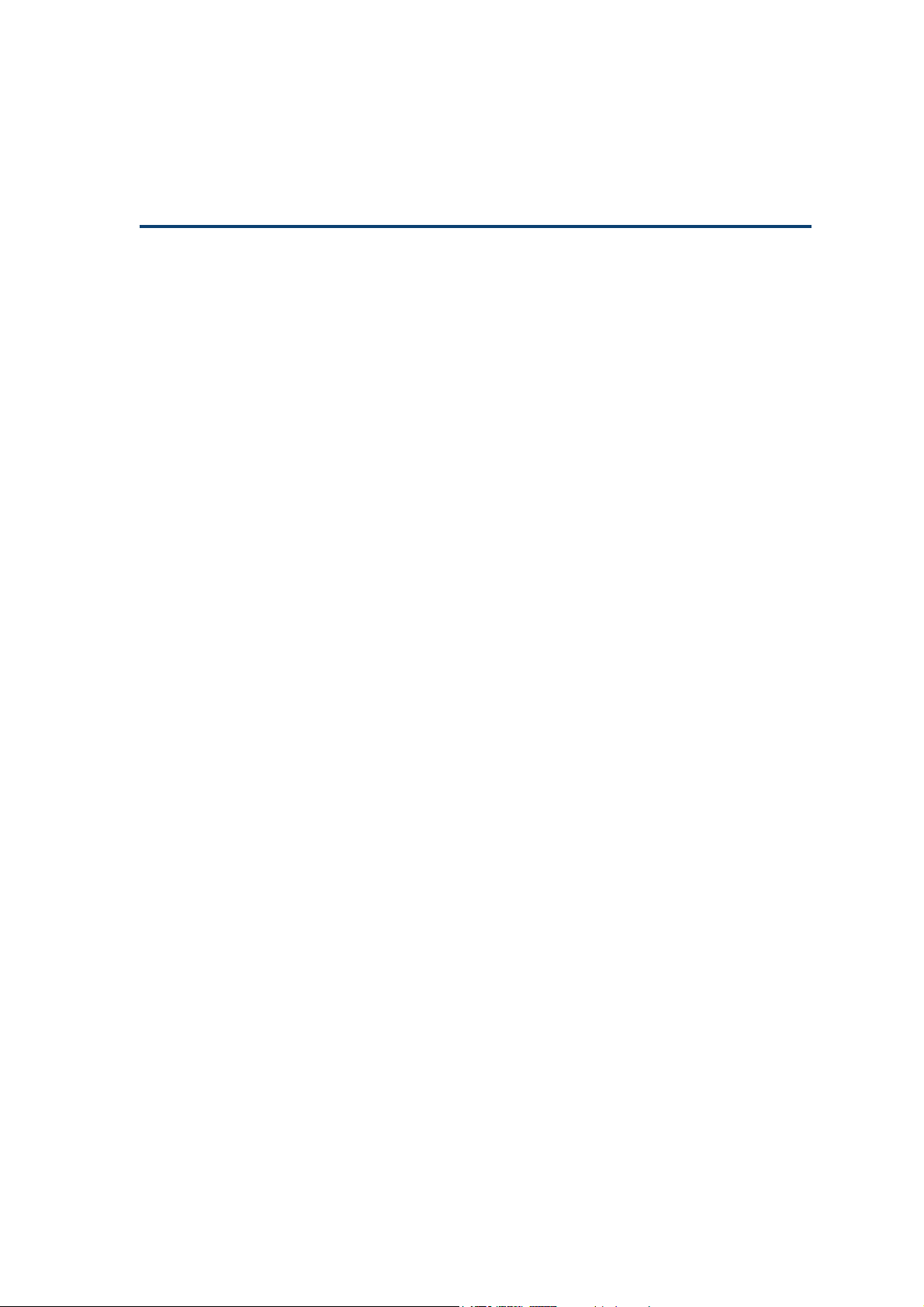

Single-Syringe Model ....................................................................... 2-2

Front Panel ................................................................................ 2-2

Rear Panel ................................................................................. 2-2

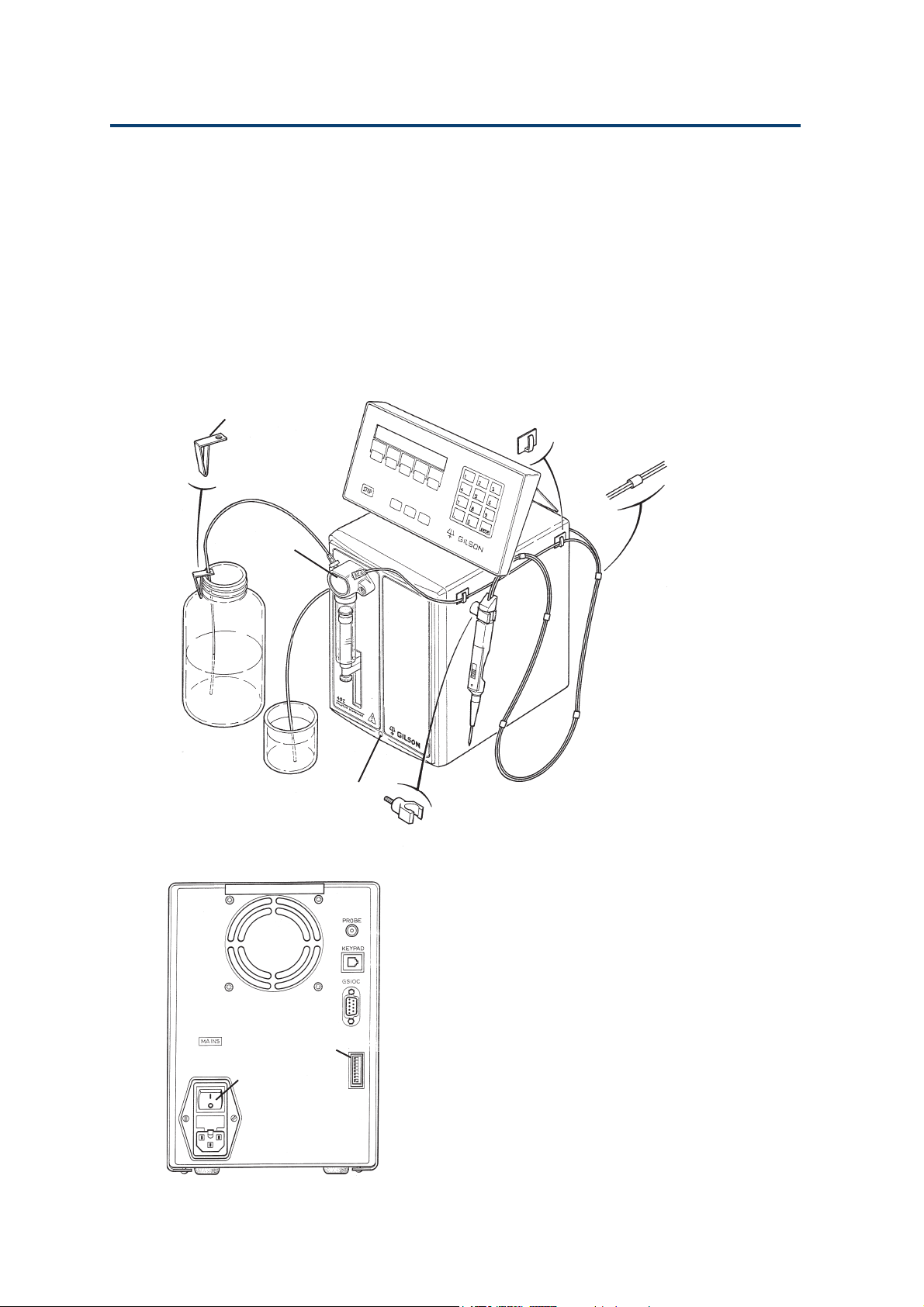

Dual-Syringe Model ...................................................................... 2-3

Front Panel ................................................................................ 2-3

Rear Panel ................................................................................. 2-3

Keypad and Probe ......................................................................... 2-4

Keypad ...................................................................................... 2-4

Probe .......................................................................................... 2-4

Hydraulic Components ............................................................... 2-5

Valve .......................................................................................... 2-5

Tee-junction .............................................................................. 2-5

Syringes ..................................................................................... 2-5

3 Installation

Assembling the Probe ...................................................................... 3-2

For Standard Use ........................................................................ 3-2

Adapter Kit for Disposable Tips ................................................ 3-2

Connecting the Tubing .................................................................... 3-4

Single-Syringe Model ................................................................. 3-4

Dual-Syringe Model ................................................................ 3-5

Electrical Connections.................................................................. 3-7

Sector Block ............................................................................... 3-7

Voltage Selector........................................................................ 3-7

Installing the Fuses ................................................................. 3-7

Connecting the Power Cord .................................................. 3-8

Connecting the Keypad.......................................................... 3-8

Connecting the Probe .............................................................. 3-8

Syringes........................................................................................... 3-9

Assembling a Syringe ............................................................. 3-9

Fitting a Syringe ....................................................................... 3-9

Table of Contents-1

Page 6

Upgrading to Dual-Syringe Model ........................................... 3-10

Removing the Cover .............................................................3-11

Connecting the Flat Cable.................................................... 3-11

Inserting the Module ............................................................ 3-11

4 Operation - Standard Use

Essential Steps .................................................................................. 4-2

Standard Parts.......................................................................... 4-2

Connect the Keypad ................................................................ 4-2

Fit the Fuses and Connect the Power ................................... 4-2

Assemble and Connect the Probe ......................................... 4-2

Connect the Tubing ................................................................. 4-2

Switch-on .................................................................................. 4-3

Configuration (Conf) .............................................................. 4-4

Fit the Syringe(s) ...................................................................... 4-7

Creating a Method (Edit) ....................................................... 4-7

Prime the 402 (Man) .............................................................. 4-10

Running a Method (Run) ..................................................... 4-11

5 Operation - Advanced Use

Correct Use of the 402 ................................................................... 5-2

Single-Syringe Model .............................................................. 5-2

Dual-Syringe Model ................................................................ 5-2

Software .......................................................................................... 5-5

Entering the Configuration (Conf)........................................ 5-6

Creating a Method (Edit) ....................................................... 5-9

Saving a Method.................................................................... 5-10

File Manipulations (File) ...................................................... 5-10

Direct Manipulations (Man) ............................................... 5-12

Tasks - Detailed Descriptions .............................................. 5-15

Additional Information ............................................................. 5-31

Flow Rates............................................................................... 5-31

Syringe Correction Function................................................ 5-33

Use of Disposable Tips .........................................................5-33

6 Maintenance

Table of Contents-2

Cleaning ......................................................................................... 6-2

Cleaning the Exterior .............................................................. 6-2

Cleaning the Valve.................................................................. 6-2

Cleaning the Tee Junction ...................................................... 6-3

Cleaning the Syringe Assembly ............................................ 6-4

Autoclaving.................................................................................... 6-5

Autoclaving the Tubing ......................................................... 6-5

Changing the Syringe Piston Assembly.................................... 6-6

Replacing the Piston ............................................................... 6-6

Page 7

7 Troubleshooting

Appendices

Changing the Piston Syringes and Piston Noses .................... 6-7

Changing the 100 and 250 µL Piston Noses ...................... 6-7

Changing the 500 µL Piston Noses ......................................6-9

Changing the 1 mL Piston Noses ....................................... 6-10

Changing the 25 mL Piston Noses ..................................... 6-11

Changing the 5 mL and 10 mL Piston Noses................... 6-11

Mechanical Problems ................................................................... 7-2

Hydraulic Problems ...................................................................... 7-3

Electrical Problems ........................................................................ 7-4

A - Parts and Accessories Lists ....................................... Appendix A-1

402 Single Syringe ............................................... Appendix A-2

402 Dual Syringe with Tee Junction Config. ...Appendix A-3

Additional Accessories....................................... Appendix A-4

Spare Parts ............................................................ Appendix A-5

B - Chemical Compatibility ..................................... Appendix B-2

Materials in Contact with Liquids ................... Appendix B-2

Compatibility ....................................................... Appendix B-2

C - Technical Data ..................................................... Appendix C-1

Hydraulics ............................................................Appendix C-2

Mechanics............................................................. Appendix C-5

Environmental .....................................................Appendix C-6

D - Error Messages ................................................... Appendix D-2

Index

Table of Contents-3

Page 8

Page 9

Safety 0

Safety

Read this section carefully before installing and operating the instrument.

For safe and correct use of the instrument, it is essential that both operating and

service personnel follow generally accepted safety procedures as well as the safety

instructions given in this document, the 402 Dilutor-Dispenser User’s Guide.

The instrument described in this document is a syringe operated pump for transferring liquids. It should only be used in the laboratory or similar indoor environment for

analytical purposes, by qualified personnel. If an instrument is used in a manner not

specified by Gilson, the protection provided by the instrument may be impaired.

Voltages present inside the instrument are potentially dangerous. If there is a problem

with the instrument, the power cable should be removed until qualified service personnel

have repaired it. This is to prevent anyone from inadvertently using the instrument,

thus causing possible harm to themselves, or damage to the instrument itself.

The leakage current of this instrument is within the limits allowed by international

safety standards for laboratory equipment. An efficient ground connection is imperative for the physical protection of the user.

Power supply cord reference 7080316106 is for use in France and Germany. Power

supply cord reference 7080316105 is for use in USA and Canada. For other countries

contact your local Gilson distributor. You must only use the type of fuse described in

this document: 1.0 Amp type “T” slow blow.

Adequate protection including clothing and ventilation must be provided if dangerous

liquids are used in the analytical work. In case of incidental spillage, carefully wipe with a

dry cloth, taking into account the nature of the spilled liquid and the necessary safety

precautions.

Cleaning, dismantling, maintenance, and repair should only be performed by personnel

trained in such work, and who are aware of the possible dangers involved.

Safety-1

Page 10

Safety

!

1

Individual components:

parts of the valve, the Tee

junction, and the syringes

(except for the 25 mL syringe)

may be autoclaved after

dismounting (121°C, 0.1 MPa,

20 min).

Symbol Explanation

Alternating current

~

PROTECTIVE CONDUCTOR

TERMINAL

On (Supply switch)

I

Off (Supply switch)

O

This instrument1 must not be sterilized, using an

autoclave, or any other mechanical device. When

you need to clean an instrument, use one of the

three following methods:

1 - a clean dry cloth,

2 - a cloth dampened with water,

3 - a cloth dampened with soapy water.

If a cloth dampened with soapy water is used to clean

the instrument, only domestic soap may be used.

No other form of detergent or chemical may be

used.

These electronic and hazard symbols

appear on the 402 Dilutor Dispenser:

Caution, risk of electric shock

Caution (refer to User’s Guide)

Safety-2

Page 11

Introduction 1

The following chapter describes the instrument, the service and warranty conditions.

1-1

Page 12

Introduction 1

Notational Conventions

The conventions in this User’s Guide are as follows.

Used in the stand-alone mode, this instrument is

referred to as ‘402 Dilutor-Dispenser’ or simply 402.

Specific keys to press on the Gilson Keypad are

represented in bold capitals, for example: ‘key in

the value and press ENTER’; where ENTER is a

Notational Conventions

key on the keypad.

For a soft-key that must be pressed, the function of

that key is represented in bold, for example: ‘Press

Prime to prime the pump’.

The Gilson Keypad displays on-screen messages as

normal typeface inside a frame.

1-2

Page 13

Introduction 1

Overview

The 402 Dilutor-Dispenser, is used to transfer liquids

between vials according to user defined protocols

(Methods). You program the 402 Dilutor-Dispenser

via the keypad, which includes an LCD screen, for

communication purposes.

You may store a total of 99 linkable Methods using

the keypad. Each Method consists of one or more of

the following tasks: Dilute, Dispense, Mix, Pipette,

and Rinse. In addition three functions for direct

manipulation are available: Priming, Titration,

Volume Measurement.

Gilson’s 402 Dilutor-Dispenser is available in two

configurations: Single-syringe, or Dual-syringe.

The 402 Dilutor-Dispenser is very versatile; it may

be fitted with seven sizes of syringe. The standard

402 Dilutor-Dispenser is equipped with a handheld probe for aspirating and dispensing liquids.

Optionally, the probe may be fitted with disposable

tips (Gilson Diamond® Tips, D200 and D1000).

Overview

This versatility means that your 402 Dilutor-Dispenser

may be used for a wide variety of applications

including the chemical field where the ability to

handle large volumes or high dilution ratios may be

appreciated, and the biological field where small

volumes and protection against cross-contamination

are important (see Autoclavability, page 6-5).

It can even be used with corrosive liquids (see

Chemical Compatibility, Appendix B).

Refer to Appendix A for lists of the standard

equipment, additional accessories and spare parts.

The 402 DD is supplied with a tubing kit for connecting to a solvent reservoir. Syringes are not

included in the standard equipment; you should

order syringe(s) appropriate to your Method (volume,

systematic error and flow rate requirements; refer to

Appendix C). Also, a Tee junction kit (not including the syringe) is available for upgrading a Singlesyringe Dilutor-Dispenser to the Dual-syringe version.

1-3

Page 14

Introduction 1

Good Laboratory Practice (GLP) is facilitated by the

following:

Overview

씮 codes to protect the program files against unau-

thorized modification,

씮 counters for the number of syringe and valve

operating-cycles,

씮 checking protocol for the hydraulic specifica-

tions (IQ/OQ procedures),

씮 correction of the syringe-piston stroke to com-

pensate for environmental factors (temperature,

viscosity, etc.).

1-4

Page 15

Introduction 1

Unpacking

Your 402 Dilutor-Dispenser is shipped in a box

together with its various accessories. The original

box and packing material should be kept in case

the equipment has to be returned to your Gilson

distributor.

You should check off the parts received in the box

against the parts list (refer to Appendix A), at the

time that you receive the shipment, even if the 402

is not to be used immediately. Your Gilson distributor should be notified immediately of any inconsistencies between the contents of the box and the

parts list, or if any of the parts appear to have been

damaged in transit.

Unpacking

1-5

Page 16

Introduction 1

Warranty

Warranty

If the 402 Dilutor-Dispenser does not appear to

function correctly, first verify the electrical connections are correct and that the instrument is

switched ON. Contact your Gilson distributor for

technical advice or possibly a service visit. Any

service required will be given within the warranty

conditions assured by your Gilson distributor.

1-6

Page 17

Introduction 1

Customer Service

Gilson and its worldwide network of authorized

distributors provide you with four types of assistance: sales, technical, applications and service.

Customer Service personnel are able to serve you more

efficiently if you provide the following information:

• The serial number and model number of the

equipment involved.

• The installation procedure you used.

• A concise list of the symptoms.

• A list of operating procedures and conditions you

were using when the problem arose.

• A list of other devices connected to the system (if

any) and a system diagram showing the connections.

Customer Service

• A list of other electrical connections in the room.

1-7

Page 18

Introduction 1

1-8

Page 19

Description 2

The following chapter describes the mechanics and hydraulics of the Dilutor-Dispenser.

Two models of 402 Dilutor-Dispenser are available: Single-syringe and Dual-syringe.

Each model comes with a keypad, a probe, and accessories. You order and fit the

syringe(s), from those described on page 2-6, most suited to your application.

Your 402 is delivered with the appropriate modules fitted. If later, you decide to

convert a Single-syringe model into a Dual-syringe model, you must order and fit a

Tee-junction module to the right-hand side of your dilutor; the left-hand always

contains a Valve module.

2-1

Page 20

Description 2

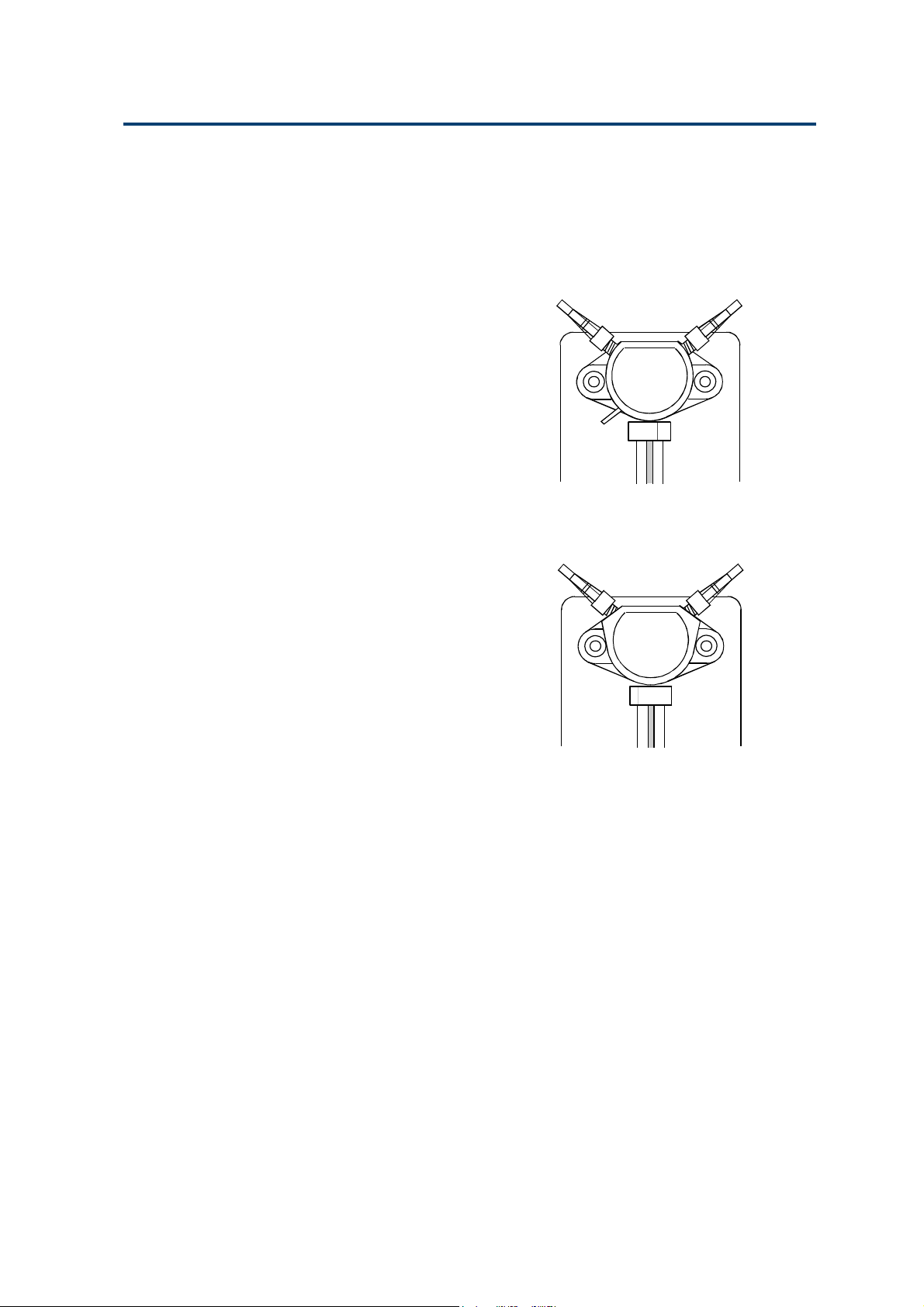

Single-syringe Model

The Single-syringe model has a Valve module at the

left, and a blanking plate at the right.

The Valve module includes one motor to operate

the syringe and another motor to switch the valve.

It is a liquid transfer station that can be used to

Single-syringe Model

deliver up to 25 mL in one stroke, and down to 1 µL

(typical value), with high accuracy.

Bottle Clip for Tubing

Valve Module

ON/OFF indicator

Tubing Clip (Self-adhesive)

Cable Support

Clamp for Probe

2-2

Microswitches

ON/OFF Switch

Front Panel

The front panel holds the hydraulic components

and is fitted with an ON/OFF indicator.

Rear Panel

The rear panel holds a socket for connecting the

keypad, a connector for the probe, the ON/OFF

switch, and voltage selector/fuse holder. There is

also a Gilson Serial Input Output Channel (GSIOC)

connector, which is a communications channel to

link the 402 Dilutor-Dispenser with other equipment,

if required. There is also a bank of microswitches

for use in setting up the communications channel.

Page 21

Description 2

Dual-syringe Model

The Dual-syringe model is fitted with a Valve

module at the left and a Tee-junction module at the

right. The modules are linked by plastic tubing.

Dual-syringe Model

Bottle Clip for Tubing

Valve Module

ON/OFF indicator

Front Panel

Tubing Clip (Self-adhesive)

Cable Support

Clamp for Probe

The front panel holds the hydraulic components

and is fitted with an ON/OFF indicator.

The Valve module includes one motor to operate the

syringe and another motor to switch the valve. The

Tee-junction module has only one motor, to operate

the syringe.

The Dual-syringe model may be fitted with syringes

of different volumes. The left syringe is the large

volume syringe and is used to deliver a large volume

of liquid in a minimum time. The right syringe can

be used to transfer smaller volumes with high

reproducibility and accuracy (refer to Appendix C

for Technical Data). The benefits of this configuration

are a large dilution ratio with the best reproducibility and fast transfer times.

Rear Panel

This is the same for both models.

2-3

Page 22

Description 2

Keypad and Probe

Keypad

The keypad includes an LCD display (two 24character lines), membrane touch-keys, and a

connecting cord.

Keypad and Probe

Numeric keys: the keypad has the numbers 0 to 9, a

decimal point key, and the Enter key.

Five Soft-keys: the function of each key depends on

the screen that is displayed (e.g. Next,

Prev, Chge...).

STOP key: Press this key to stop the current ac-

tion (Method or direct manipulation).

HELP key: Press this key to access help messages

relating to the current screen.

ESC key: Press this to quit a menu or return

to the first menu of the software

branch.

CLEAR key: Press this key to cancel a value and

return to the previous value before

validating it.

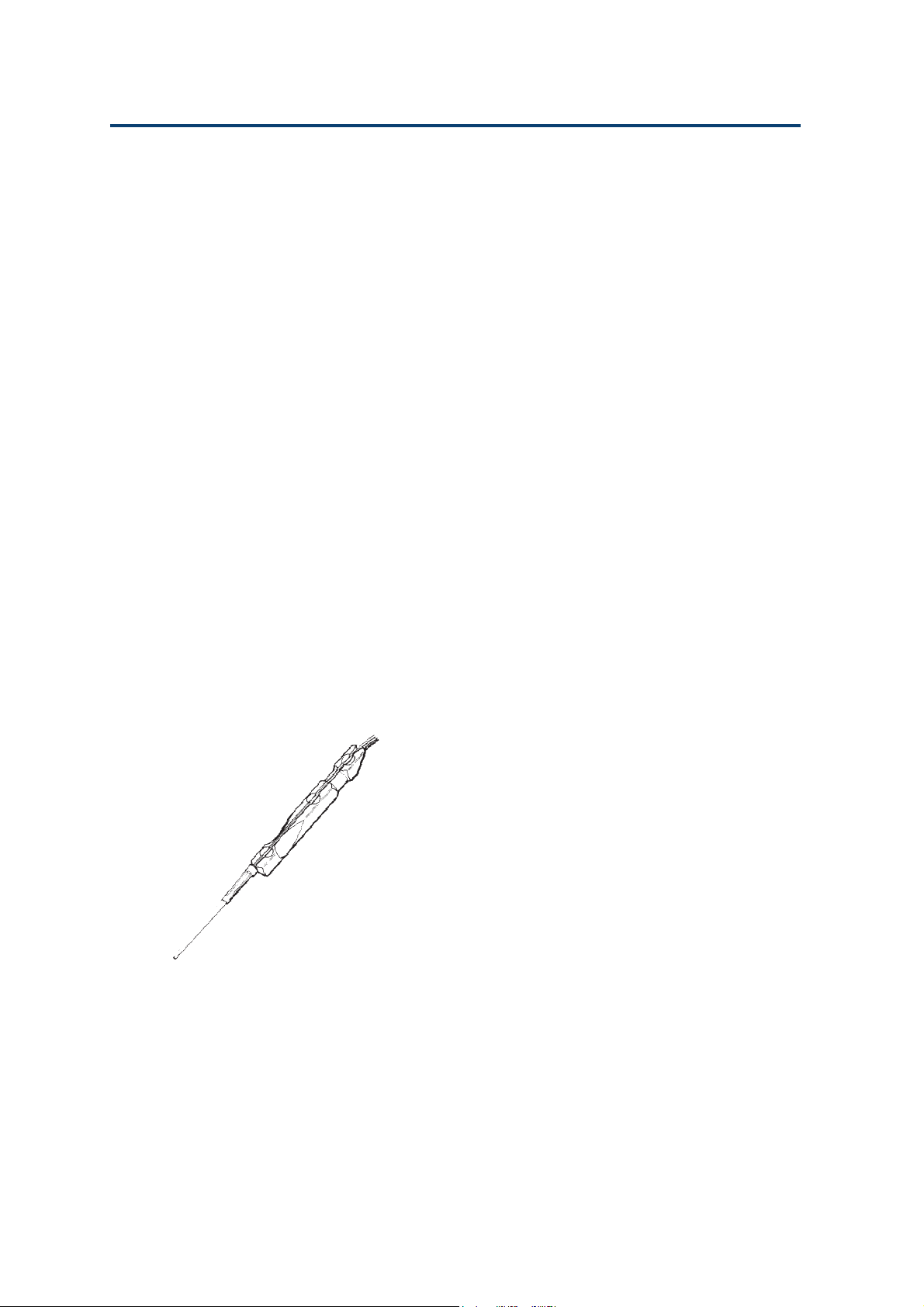

Probe

The assembled probe fitted with the standard probe

nozzle is shown opposite. Assembly and installation

of the standard probe is described in Chapter 3.

A kit is available to enable you to fit Gilson’s

Diamond® tips (D200, D1000) to the probe (see

Chapter 3).

2-4

Page 23

Description 2

Hydraulic Components

Valve

Hydraulic Components

The two-position valve, which is fitted to the lefthand side of the 402, has three ports. It switches

the syringe port to either the reservoir or to the

probe side (see opposite figure).

The valve, which has a 0.5 sec rotation period, is

driven by a stepper motor. It is designed to withstand a million rotations, when used with water.

The liquid contact surfaces of the valve, which is

autoclavable, are in PEEK and ceramic (121°C,

0.1 MPa, 20 min).

Tee Junction

The Tee-junction, which is fitted to the right-hand

side of the dual-syringe model, has three ports: the

inlet from the valve, the outlet to the probe, and the

syringe port (see opposite figure).

The Tee-junction, which has no internal moving

parts, includes 2 channels, each 1.5 mm in diameter oriented at 120°. The liquid contact surfaces of

the Tee-junction, which is autoclavable, are in PEEK.

From reservoir

To waste

From Valve

Probe (or Tee

junction)

Syringe

To Probe

Syringe

Syringes

The choice of syringe allows the 402 Dilutor-Dispenser

to handle volumes from 1 µL to 25 mL with low

values of systematic and random error. The 402

Dilutor-Dispenser is able to transfer liquid as

follows:

- from 1 µL to 10 mL from the probe (transfer

tubing volume of up to 10 mL),

- up to 25 mL from the reservoir, in one stroke,

- up to 99 mL from the reservoir, in several strokes.

When using the Dual-syringe model, a theoretical

dilution ratio of 1/25000 is achieved in one stroke

of both sample and diluent syringes. However, you

are advised not exceed a ratio of 1/500 for any

given dilution, in order to stay within the RSD

range (after efficient mixing).

2-5

Page 24

Description 2

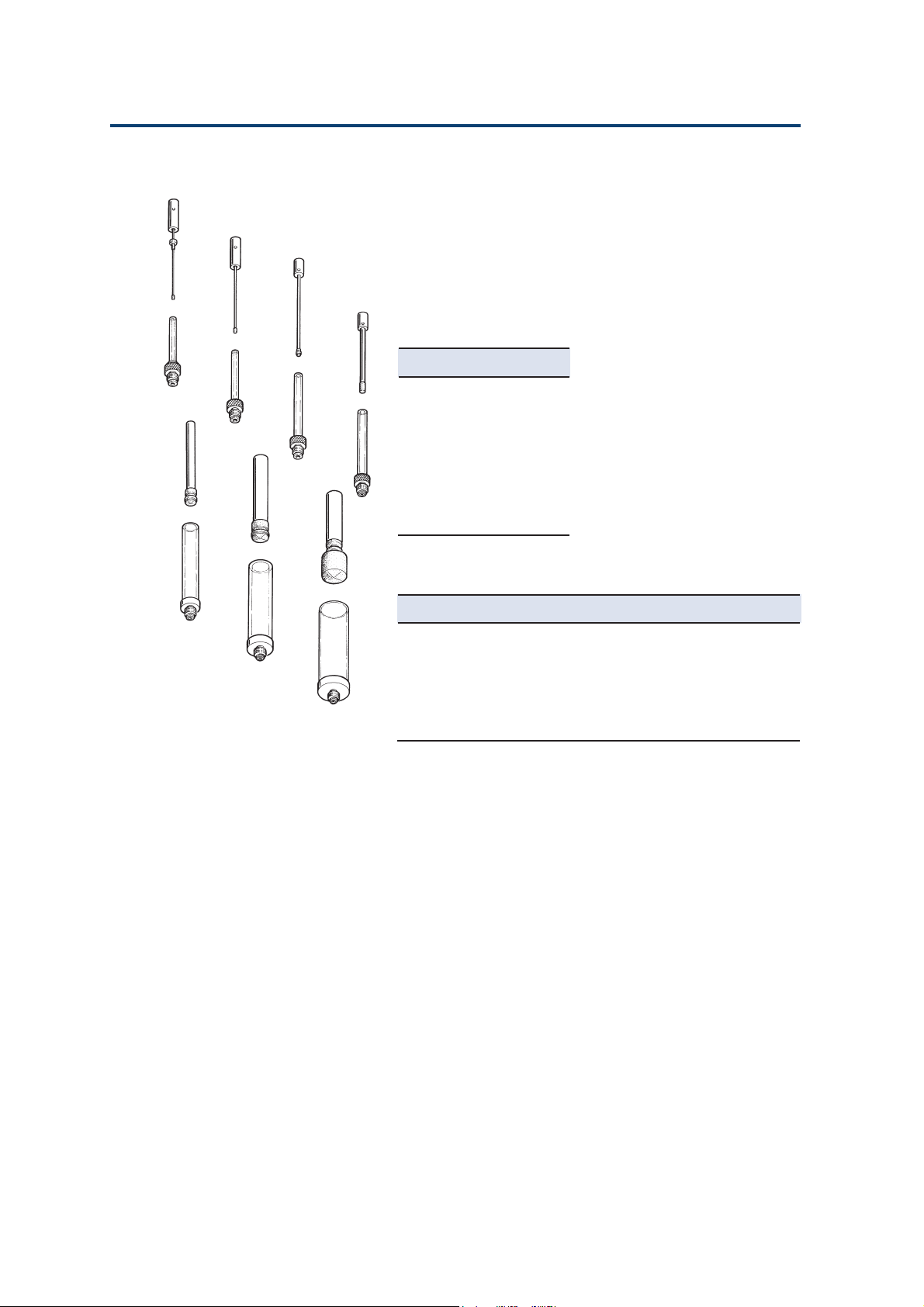

0.1 mL

0.25 mL

0.5 mL

Hydraulic Components

5 mL

10 mL

1 mL

25 mL

There are seven syringe sizes available for the 402,

all except the 25 mL are autoclavable. The lifetime

of all pistons (see Chapter 6), when they are used

with water at a pressure of up to 0.3 MPa is over

30000 cycles (each cycle contains 2 strokes: one up

and one down).

The available syringe sizes are:

Part Number Description

25025341 0.1 mL

25025342 0.25 mL

25025347 0.5 mL

25025343 1 mL

25025344 5 mL

25025345 10 mL

25025346 25 mL

Syringe Materials

Part of the syringe Material

Syringe body Borosilicate glass

Syringe adapter 316L stainless steel

Piston Stainless steel (models up to 1 mL)

Aluminum

Piston nose PTFE/Ekonol (PTFE for the 25 mL)

2-6

Page 25

Installation 3

This chapter explains how to install the fuses, syringes and hydraulics according to

your system requirements.

This chapter explains how to add the extra module to upgrade your 402 to a dual

syringe pump.

3-1

Page 26

Installation 3

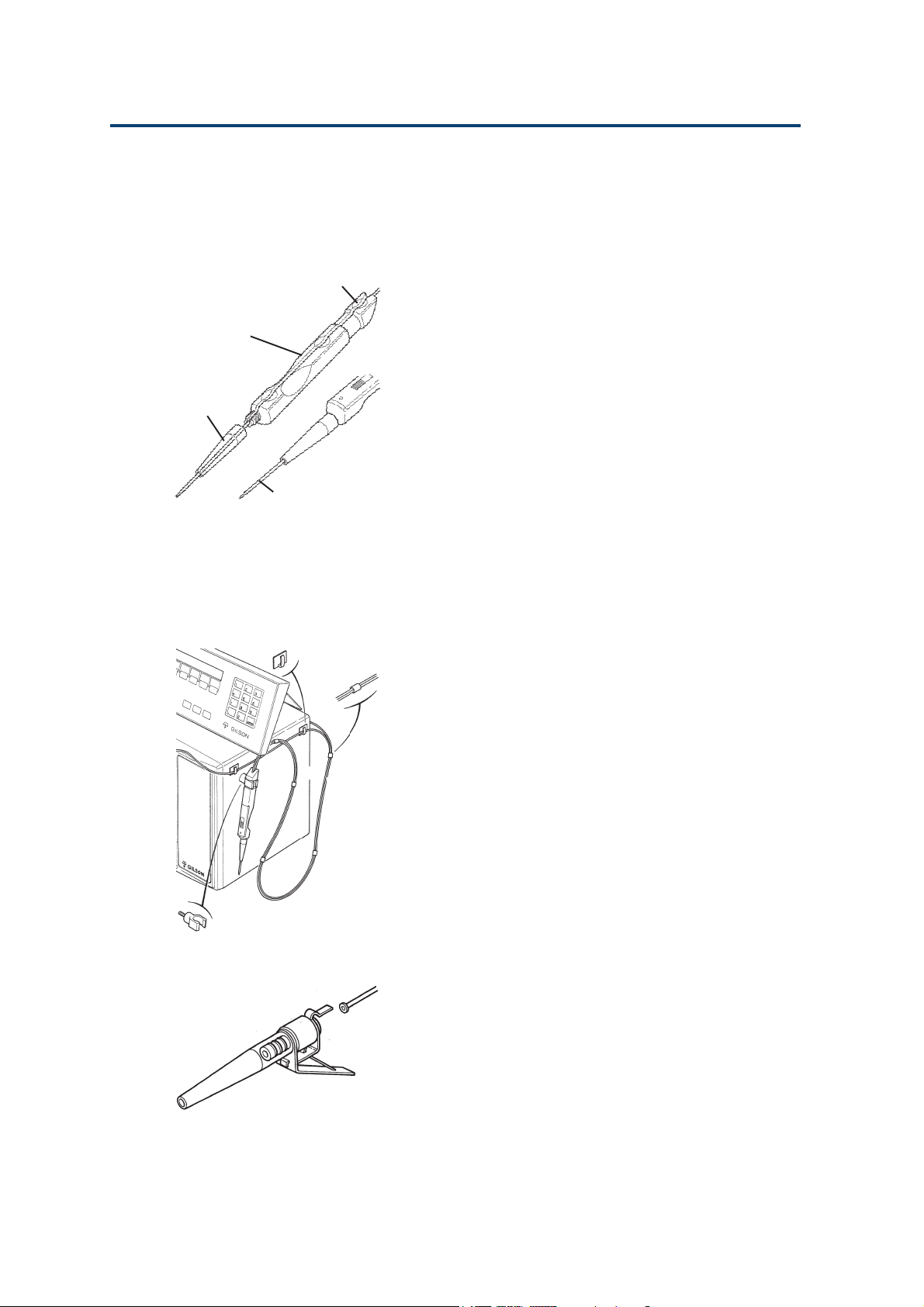

Assembling the Probe

For Standard Use

Access Point

Probe

Assembling the Probe

Probe

Nozzle

Transfer Tubing

When you want to increase the

length of tubing protruding

from the probe, you must first

carefully lift the tubing out of

the handle, otherwise you will

damage the tubing.

In standard use the probe is used with the 2 mL

tapered transfer-tubing (see opposite figure).

1. Thread the tapered end of the transfer-tubing

through the plastic ‘tunnels’ in each of the 5 premounted cable supports (see figure below).

2. Lay the tubing on the probe’s groove such that

about 4 cm of the tapered end protrudes from

the end of the probe.

3. Push the tubing into the groove in the probe at

the 3 round access points using (for example)

the rounded end of a pencil. Do not press on the

tubing with your fingernail.

4. Push the tapered end of the tubing through the

standard tip, then screw the tip onto the end of

the probe.

5. Plug the end of the control cable into the socket,

labeled ‘PROBE’ at the back of the 402.

6. Fit the clamp for probe at the right-hand side of

the 402 (see opposite figure).

7. Mount the probe on the clamp.

8. Connect the other end of the tubing to the outlet

of the Valve (Single-syringe) or the Tee-junction

(Dual-syringe).

9. Use the 402 Software to check (and change, if

necessary) the configuration using the Conf

(Vol) menu.

Adapter Kit for Disposable Tips

The ability to use Diamond Tips will extend the use

of your 402 into the biological field, where protection against cross-contamination is important, and

in the chemical field to protect the tubing from

corrosive liquids.

You must fit a tip-holder to the probe when you

want to use Gilson’s Diamond tips. An adapter kit

(reference F4015015) is available to permit you to

fit them to the probe. The kit includes two sizes of

tip-holder (with built-in tip ejector), and a special

non-tapered 2 mL transfer tubing, as follows.

3-2

Page 27

Installation 3

2 Special adapters for the probe

1 D200 tips, pack of 10

1 D1000 tips, pack of 10

1 Transfer-tubing (outlet) non-tapered, FEP (2 mL)

1. Lay the tubing on the probe’s groove such that

the end with the small washer is just at the

orifice of the probe.

2. Push the tubing into the groove in the probe at

the 3 round access points using the rounded end

of a pencil (for example). Do not press on the

tubing with your fingernail.

3. Screw the tip-holder onto the end of the probe.

4. Plug the end of the control cable into the socket,

labeled ‘PROBE’ at the back of the 402.

5. Fit the clamp at the right-hand side of the 402

(see on the previous page).

6. Mount the probe on the clamp.

7. Connect the other end of the tubing to the outlet

of the valve (Single-syringe) or the Tee junction

(Dual-syringe).

(1) The small washer is important

in that it helps to ensure that

fluid does not leak from the

junction between the tip-holder

and the orifice of the probe.

(2) The special ‘S’ shaped metallic

clips, which are pre-mounted, are

for supporting the tubing on the

black control cable. The tubing

for use with the tip-holder will

not pass through the plastic

‘tunnels’ in the pre-mounted

cable supports. However, to

make the metallic clip easier to

attach, you can push these black

tubing-supports to the end of

the cable.

Assembling the Probe

8. Inform the 402 Software of the new configuration using the Conf (Vol) menu.

9. Fit a tip to the holder. In use, when you change

a tip, wipe the end of the tip-holder first, to

remove any liquid from the orifice. Do not

twist the probe to the left, when fitting a tip,

otherwise the tip-holder will unscrew itself.

3-3

Page 28

Installation 3

Connecting the T ubing

Tubing connectors should be hand-tightened,

tools should not be used as their use will damage

the connector’s thread.

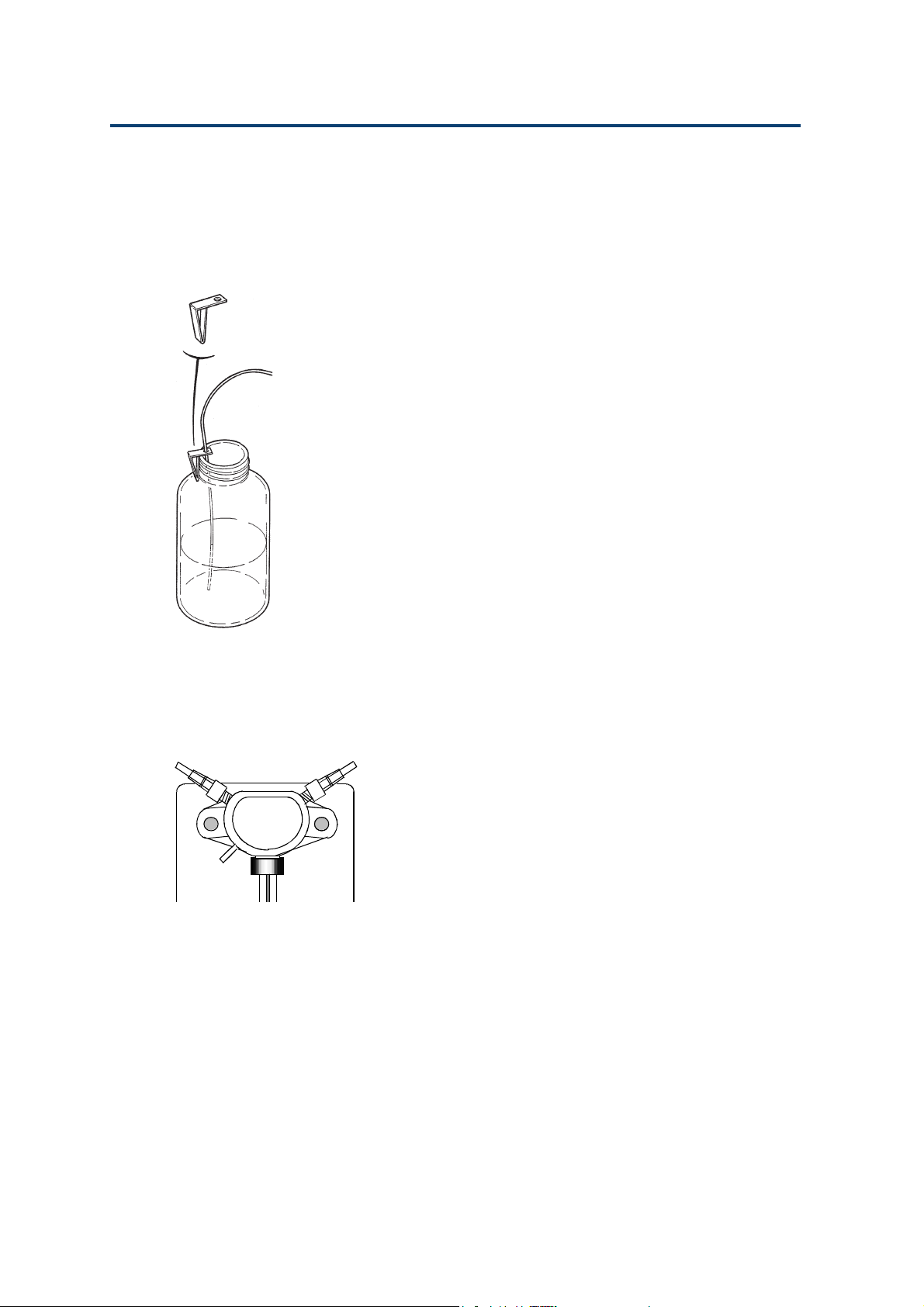

Single-syringe Model

Connecting the T ubing

From

reservoir

Transfer tubing

to probe

Valve Inlet Tubing

A length of Fluoride Ethylene Propylene (FEP)

tubing, supplied with the 402, is used to connect

the inlet port to the solvent reservoir. Screw the

connector into the inlet port (left-hand) of the valve

and put the other end into the reservoir. A bottle

clip is provided to hold the tubing securely in the

reservoir (see opposite Figure).

An alternative tubing, fitted with a connector at

one end and a 20 µm filter at the other, is available

as an accessory (reference 3645357).

Waste Tubing

Connect a suitable length of tubing from the waste

outlet of the valve to a suitable receptacle. The valve

releases liquid through the waste outlet if the pressure

inside the valve is too high. For the pressure limits

of the valve, refer to Appendix C, Technical Data.

Transfer Tubing (Probe)

3-4

To waste

V alve

This tubing (FEP) allows the transfer of samples

aspirated from the probe and prevents the contamination of the syringe(s). The size of transfer tubing

is chosen as a function of the volumes of samples,

reagents, and air gaps that have to be handled via

the probe. The total volume transferred must be less

than the volume of the transfer tubing.

The transfer tubing connects the outlet port (righthand) of the valve to the probe. A 2 mL tapered

tubing is supplied as standard; 1 mL, 5 mL, and

10 mL are available as additional accessories.

Self-adhesive clips are provided for holding the

transfer tubing securely against the side of the 402.

The 1 mL transfer tubing is recommended for transferring volumes smaller than 1 mL. To avoid movements of the tubing that could affect the precision,

the 5 mL and 10 mL transfer tubings are rolled and

held by magnets on the left-side of the 402.

Page 29

Installation 3

After assembling the probe, the other end of the

tubing is installed by screwing the connector into

the right-hand port of the valve. When you use

Gilson Diamond Tips, the special non-tapered

tubing, included in the kit, must be fitted.

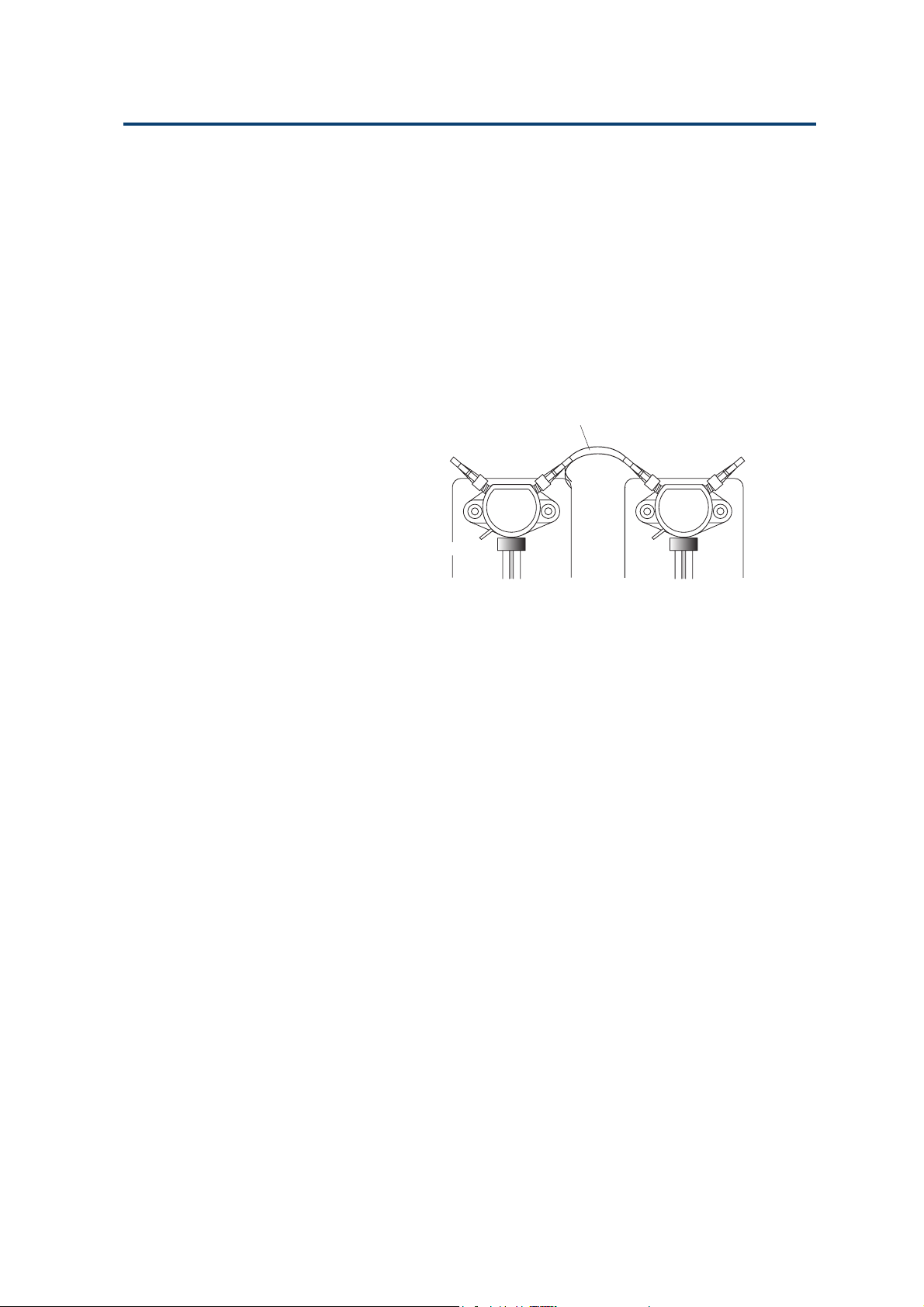

Dual-syringe Model

Valve Inlet Tubing

A length of Fluoride Ethylene Propylene (FEP) tubing, supplied with the

402, is used to connect the inlet port

to the solvent reservoir. Screw the

connector into the inlet port (lefthand) of the valve and put the other

end into the reservoir. A bottle clip is

provided to hold the tubing securely

in the reservoir.

An alternative tubing, fitted with a

connector at one end and a 20 µm

filter at the other, is available as an

accessory (reference 3645357).

From

reservoir

To waste

Connection tubing

Transfer tubing

to probe

Left

Syringe

V alve Tee-junction

Right

Syringe

Connecting the T ubing

Valve Waste Tubing

Connect the length of tubing (supplied as standard)

to the waste outlet of the valve, and put the other

end into the waste or any other suitable receptacle.

The valve releases liquid through the waste outlet,

if the pressure inside the valve is too high (see

Appendix C, Technical Data).

Connection Tubing (Valve to Tee-junction)

This tubing has connectors at both ends and is used

to connect from the valve outlet port (right-hand) to

the Tee-junction inlet port (left-hand). It is made of

FEP and has the following dimensions: 70 x 3 x 2 mm.

It is autoclavable (20 min. at 0.1 MPa, 121 °C).

Transfer Tubing (Probe)

This tubing (FEP) allows the transfer of samples

aspirated from the probe and prevents the contamination of the syringe(s). The size of transfer tubing

is chosen as a function of the volumes of samples,

reagents, and air gaps that have to be handled via

the probe. The total volume transferred must be

less than the volume of the transfer tubing.

3-5

Page 30

Installation 3

The transfer tubing connects the outlet port (righthand) of the Tee-junction to the probe. A 2 mL

tapered transfer-tubing is supplied as standard ;

1 mL, 5 mL, and 10 mL are available as additional

accessories.

Self-adhesive clips are provided for holding the

transfer tubing securely against the side of the 402

(see previous page).

Connecting the T ubing

The 1 mL transfer tubing is recommended for

transferring volumes smaller than 1 mL. To avoid

movements of the tubing that could affect the

precision, the 5 mL and 10 mL transfer tubings are

rolled and held by magnets on the left-side of the

402.

After assembling the probe, the other end of the

tubing is installed by screwing the connector into

the right-hand port of the Tee-junction. When you

use Diamond tips, the special non-tapered tubing,

included in the kit, must be fitted.

3-6

Page 31

Installation 3

Electrical Connections

The rear panel of the 402 Dilutor-Dispenser houses:

- sector block containing the power socket, fuse

drawer and ON/OFF switch,

- keypad connector,

- probe connector,

- GSIOC connector.

Sector Block

The sector block contains the power socket, fuse

holder and ON/OFF switch. Your 402 can be

connected to a 100-120 VAC or a 220-240 VAC

supply. In either case, two 1A type “T” slow blow

fuses must be installed (reference 6730104006).

Electrical Connections

Voltage Selector

The instrument has no physical voltage selector.

The 402 Dilutor-Dispenser can be connected to 100

or 240 V. Power control is carried out electronically

on the power supply board.

Installing the Fuses

For safety reasons, your 402 is delivered without

the fuses installed. You must install two 1A type

“T” slow blow fuses (reference 6730104006), as

follows:

1) Disconnect the power lead from the instrument.

2) Use a small screwdriver to pry open the fuse

holder drawer.

3) Pull the drawer gently towards you, to open the

fuse receptacle.

4) Push the fuses into position.

5) Push the fuse holder back into the sector block.

ON/OFF switch

Fuse holder

In the figure, the drawer containing the fuses is

shown separated from the sector block. In fact the

drawer hinges downwards; it is not advisable, nor

necessary, to remove it completely from the block.

3-7

Page 32

Installation 3

Connecting the Power Cord

Make sure that the ON/OFF switch is in the OFF

(down) position. Connect the power cord to the

power socket at the rear of the instrument and then

to the power supply source. When the ON/OFF

switch is put to the ON position, the instrument

initializes; the valve motor rotates the spindle and

stops with the valve set to the outlet position. The

Electrical Connections

piston motor raises the piston to the upper position.

Connecting the Keypad

Switch off the 402 Dilutor-Dispenser, before connecting or disconnecting the keypad.

Grip the connector, at the end of the coiled connection cable, so that you squeeze the clip between

your thumb and index finger. Then, plug the

connector into the socket on the rear panel labeled

‘KEYPAD’ (see figure). You must grip the connector

in the same way when disconnecting the keypad.

The coiled connecting cable enables you to use the

keypad beside the 402 (as in Chapter 2), or even at

some distance away from it. However, you can also

install the keypad on top of the 402; to do this you

should insert the tab on the rear support of the

keypad into the slot on top of the 402 and then

gently push the tab in as far as it will go.

Connecting the Probe

Grip the connector, at the end of the black connection cable, between your thumb and index finger.

Then plug the connector into the socket on the rear

panel labeled ‘PROBE’.

3-8

Page 33

Installation 3

Syringes

Outlet

The 402 Dilutor-Dispenser is supplied without

syringes. Order a syringe (or syringes), appropriate

to your Method, for your 402 Dilutor-Dispenser.

Mount the syringe on the valve or Tee-junction.

Inlet

Valve

Syringes

Assembling a Syringe

The syringe and its piston are supplied assembled.

However, if you remove the syringe from the piston,

ensure that the piston and the piston nose are free

from dust and contamination before reinserting the

piston into the syringe.

Wet the piston nose (with water), insert the piston

nose into the syringe body, and then push the

piston into the syringe.

Fitting a Syringe

Before fitting one of the smaller syringes (100 µL,

250 µL, 500 µL and 1 mL), prime it manually by

placing its open end in the solvent reservoir, then

aspirate using the piston. This manual prime is not

necessary for the 5 mL, 10 mL and 25 mL syringes.

You must use the keypad software to lower the

piston operating rod. You should therefore refer to

Chapter 4, which describes the complete procedure

for fitting a syringe. When changing a syringe, you

should first undo the piston securing-screw in order to

free the piston assembly from the piston operating-rod.

Waste

Syringe

Piston

operating rod

Cover

seal

Valve

screw

The 100 µL, 250 µL and 500 µL syringes are supplied with a cover seal to ensure an airtight fit

between the syringe and the valve or Tee. Refer to

the opposite figure for the correct orientation of the

cover seal.

If you change the syringe size, don’t forget to

change the declared syringe volume in your software’s system configuration.

Syringe

body

3-9

Page 34

Installation 3

Upgrading to Dual-syringe Model

The single syringe 402 can be upgraded to improve

the versatility of the system.

To upgrade to the Dual-syringe 402, you must

install a Tee-junction module (kit reference F4015010)

at the right-hand-side of the 402. You must first

install the syringe module (includes motor etc.) and

then fit the Tee-junction.

Before installing the module: make sure that the ON/

OFF switch is in the OFF position, remove the power

Upgrading to Dual-syringe Model

cord, and disconnect any hydraulic connections

from the 402.

3-10

Page 35

Installation 3

Removing the Cover

1) Undo the four screws (with two washers) at the

base of the 402 that secure the top cover. Place

the 402 in the upright position, pull the sides of

the cover outwards, and then lift off the cover.

2) Undo the two nuts inside the front panel (near

the top) that secure the blanking plate, then

remove the blanking plate.

Connecting the Flat Cable

There is a flexible flat cable inside the 402 (attached

to the lower chassis with Velcro) that connects the

logic board to the Valve module. Detach the cable

from the lower chassis, then use the free connector

to connect to the motor drive board on the upgrade

module. With reference to the opposite figure, the

loose-end of the flat cable (with the second connector) and the connecting cable may be re-attached,

using their Velcro strips.

Upgrading to Dual-syringe Model

1. Hold the module upright, in front of the 402

front panel.

2. Thread the flat cable through the aperture for

the module and connect it to the syringe motor

drive board on the Tee module.

To tee module

Second

connector

is not used

3-11

Page 36

Installation 3

Inserting the Module

Do not try to force the module into position as this

may affect the alignment of the component parts.

You should proceed carefully as follows.

1) Tilt the top of the module inwards and carefully

insert the upper part of the module into the front

aperture. When the syringe drive motor is inside

the aperture, tilt the module into the upright

position.

2) Push the module into the aperture, making sure

that none of the cables become trapped between

Upgrading to Dual-syringe Model

the module and the edges of aperture. The module

rests on a rubber strip that dampens vibrations

and helps ensure the module is fitted correctly.

3) Secure the module in place at the top using the

two screws (provided).

4) Replace the cover by pulling the sides outwards

slightly and lowering the it over the 402. Insert

and tighten the four screws at the base of the 402

that secure the cover to the lower chassis. Do not

forget to reinstall the washers, which are designed

to ensure that the cover and chassis are connected electrically.

5) Install the Tee-junction on the front of the

module using the two screws provided.

6) Install the syringe as described page 3-9.

7) Connect the hydraulic tubing according to pages

3-4 and 3-5.

8) Reconnect the power cord and switch the

instrument ON.

3-12

Page 37

Operation - Standard Use 4

This chapter describes how to operate the 402 in standard use. Chapter 5 contains

more detailed and advanced information, together with less frequently used options.

You are advised to read the first section of Chapter 5, ‘Correct Use of the 402’, before

proceeding.

To use your 402 Dilutor-Dispenser, you must first install the hardware (syringe,

probe, keypad, etc.) suitable to your Method, and then inform the 402’s software of

the installation, this is called ‘Configuration’. Then, you write and run your Method,

which is stored as a file in your 402’s memory.

4-1

Page 38

Operation - Standard Use 4

Essential Steps

Here is a summary of the things you must do, and

the order in which you should do them.

1) Check that you have received all standard parts.

Essential Steps

2) Connect the keypad.

3) Fit the fuses and connect the power supply cord.

4) Assemble and connect the probe (including the

support).

5) Connect the tubings.

6) Switch on the power supply.

7) Enter the configuration details using the keypad.

8) Fit the syringe or syringes.

9) Create and save a Method as a numbered file.

10) Prime the Dilutor-Dispenser.

11) Run the Method.

Standard Parts

If you have a Single-syringe or a Dual-syringe, check

that you have received all the parts in Appendix A.

Connect the Keypad

Connect the keypad as described in Chapter 3.

Fit the Fuses and Connect the Power

Fit the fuses and connect the power supply cord

(see Chapter 3).

Assemble and Connect the Probe

4-2

Assemble and connect the probe (see Chapter 3).

Connect the Tubing

If you have a Single-syringe 402, install the tubings

as described in Chapter 3, page 3-4. You must connect 3 pieces of tubing: inlet (reservoir), transfer

(probe), and waste.

Page 39

Operation - Standard Use 4

If you have a Dual-syringe 402, install the tubings

as described in Chapter 3, page 3-5. You must

connect 4 pieces of tubing: inlet (reservoir), Valve to

Tee-junction, transfer (probe), and waste.

Switch-on

1) Switch on your 402 (the power switch is on the

back panel): the indicator light on the front panel

comes on, the keypad is illuminated, and briefly

displays messages giving the software version

numbers, Initialization Screen 1, for example. This

is followed immediately by Initialization Screen 2.

2) Put the end of the probe into any container

suitable for waste liquids, then press the white

key immediately below OK.

The syringe-piston operating-rod(s) move to their

uppermost positions, while the Homing Screen is

displayed on the keypad.

3) Then the Start-up Screen is displayed. After

switching on, Method 1 is always shown on the

screen even if the file has not yet been created

(New). [When you want to run or edit any other

file, you must first key in its number, then press

ENTER.]

Essential Steps

Initialization Screen 1

Initialization Screen 2

Homing Screen

Start-up Screen

Soft-keys

Four soft-touch keys are accessible from the Start-up

Screen: Conf (Configuration), Edit, Man (Direct

Manipulations), and File; the fifth ‘Run’ appears

after you save a Method file. They are called softkeys because they vary from screen-to-screen; you

must press the white key immediately below the

corresponding ‘label’ (e.g. Conf) in order to carry

out the desired action.

Pressing a soft-touch key leads you to a

series of screens containing menus and submenus that enable to perform functions

related to the key pressed.

To operate your 402, you must use Conf,

Man, and Run. Five prefabricated Methods

(files 90-94, see Chapter 5) are supplied as

part of the software; however, you will often

want to use Edit to create your own Method

files.

Function Press Key

Enter the configuration

of the Dilutor-Dispenser Conf

Create or modify a Method Edit

Save the Method as a file

in the 402’s memory Edit

Direct manipulation

of the Dilutor-Dispenser Man

Run a Method Run

File transactions

(Delete, Copy, Lock, Dir.) File

4-3

Page 40

Operation - Standard Use 4

Configuration (Conf)

You only have to enter the Configuration details

one-time; the 402 keeps this information in its

memory, even after you switch off. The next time

you switch on the 402, the Configuration and all

Essential Steps

Configuration Screen

Methods previously saved as files will be available

to modify or run.

The software must be given details about syringe

sizes, flow rates, etc. You enter this information

using the configuration function, which you access by

pressing the Conf soft-key (see Configuration Screen).

As a minimum, you must enter the volume of

syringe(s) that you are going to fit to your 402,

check that the default flow rates are appropriate

(or enter suitable values), and check the transfer

(probe) tubing volume is correctly specified (standard

is 2 mL).

Tubing Volume Screen

Air Gap Volume Screen

The use of the soft-keys is as follows:

• Vol is used for the probe (transfer) tubing and

‘Air gap’ volumes,

• Syr is used to enter syringe related parameters

and activate the syringe exchange function.

• Flow is used to enter default flow rates for liquid

coming from the reservoir,

• Count is used to consult or to reset various counters

(see Chapter 5),

• Etc is used to switch on and off the Beeper and

Autorefill function.

Volume(s)

Check that the configured volume for the probe

tubing is the same as the size fitted.

Press the Vol soft-key, you see the Tubing Volume

Screen.

Next is used to go to the next screen,

Chge is used to select the tubing size (see Tubing

Volume Screen),

Prev is used to go to the previous screen (see Air

Gap Volume Screen).

4-4

Page 41

Operation - Standard Use 4

If you want to change the configured volume, press

Chge (until you reach the correct value); when the

volumes are the same press ENTER, press the ESC

key to return to the Configuration Screen, or press

Next, after which you see the Air Gap Volume Screen.

Key in the ‘Air gap volume’, press ENTER to confirm

then press the ESC key to return to the Configuration

Screen (see Chapter 5, for a definition of Air Gap).

Syringe(s)

You must check that the configured volumes are the

same as the sizes to be fitted. Press the Syr soft-key.

The use of the soft-keys is as follows:

Next is used to go to the next screen,

Prev is used to go to the previous screen,

Corr is used to supply a correction factor (see

Chapter 5),

Chge is used to select the size(s) of syringe(s),

Exch is used to lower the piston rods.

To change a syringe size, press the Chge soft-key

until you reach the corresponding volume, then

press ENTER to confirm. Press Exch if you are

ready to lower the piston rods, or when you have

two syringes, press Next. Check that the configured

volume for the right syringe is the same as the size

to be fitted. Press the Chge soft-key until you reach

the corresponding volume, then press ENTER to

confirm. Press Exch if you are ready to lower the

piston rods or press the ESC key to return to the

Configuration Screen.

Essential Steps

Syringe Screen

Whenever you change the configured volume, the

software reminds you to ‘Exchange Syringes’ before

allowing you to quit the configuration screen. Go

directly to page 4-7, which explains how the ‘Exchange Syringes’ function works, unless you need

to change flow rates, etc.

Flow Rates

Flow rates should be specified according to the

sizes of syringe and tubing fitted to the 402. Refer

to Chapter 5 for more details, the maximum values

are given in the Tables, these are used as default

values by the software.

Press the Flow soft-key; the Air Flow Screen appears.

Air Flow Screen

4-5

Page 42

Operation - Standard Use 4

Next is used to go to the next screen (see Air Flow

Screen),

Prev is used to go to the previous screen (see Resv

flow Screen).

Air Flow is the rate in mL/min. that air is drawn

Essential Steps

Resv Flow Screen

into the transfer tubing when aspirating air.

Key in the required value, then press ENTER. Press

the ESC key to return to the Configuration Screen or

press Next to go to the Resv Flow Screen.

Resv (Reservoir) Flow is the rate in mL/min. that

solvent is aspirated from the reservoir by the left

syringe.

Prime Flow Screen

Beeper Screen

Autorefill Screen

Key in the required value, then press ENTER. Press

the ESC key to return to the Configuration Screen or

press Next to go to the Prime Flow Screen.

Prime Flow is the rate in mL/min. that liquid is

transferred by either syringe when priming.

Key in the required value, then press ENTER. Press

the ESC key to return to the Configuration Screen.

Other Items

Press the Etc soft-key; the Beeper Screen appears.

This is to set an alarm when an error occurs, and to

warn that liquid is going to be dispensed to waste.

To switch between ON and OFF, press the Chge

soft-key, then press ENTER to confirm.

Press Next to go to the Autorefill Screen. Press the

ESC key to return to the Configuration Screen.

When you set Autorefill to ON, the left-hand

syringe re-aspirates diluent automatically for the

next cycle, while you are (for example) aspirating

air via the probe. This feature enables you to work

faster with the 402.

4-6

Start-up Screen

To switch between ON and OFF, press the Chge

soft-key, then press ENTER to confirm. Press Prev

to go to the Beeper Screen. Press the ESC key to

return to the Configuration Screen.

This completes the basic configuration process,

press ESC to return to the Start-up Screen.

Page 43

Operation - Standard Use 4

Fit the Syringe(s)

Essential Steps

1) First you must lower the piston rod(s), as follows:

- press the Conf key to access the Configuration

Screen:

- press the Syr soft-key (ensure that the size is

correct before continuing),

- press the Exch soft-key.

‘Please wait ...’ appears on the screen whilst the

piston rod(s) descend; then ‘Exchange the

Syringe(s)’.

2) Screw the assembled syringe into the valve or

Tee until tight (do not over-tighten).

3) Align the threaded recess on the piston-button

with the piston holding screw.

4) Tighten the piston holding screw.

5) Press the Done soft key: ‘Put probe into waste’

appears on the screen.

6) Put the end of the probe into the waste or any

other suitable container.

7) Press the Run soft key:

Whilst the syringe-piston operating-rod(s) move

to their uppermost positions, the Homing Screen

is displayed. When they reach their uppermost

positions a Counter Screen appears.

Configuration Screen

Syringe Screen

Counter Screen

8) Press the ESC key: the Configuration Screen

reappears.

9) The next step is described below.

Creating a Method (Edit)

Introduction

In this section you will find the basic information

required to enter and save your Method as a file.

The steps are as follows:

- describe the Method on paper (protocols and

parameters),

- use the keypad to enter the Method as a file (one

or more tasks used sequentially),

- save the Method as a file.

Alternatively, you could run an

adapted copy of one of the five

pre-fabricated files (90-94). See

Chapter 5 for details.

4-7

Page 44

Operation - Standard Use 4

In-run Prompts

You can defer some parameters (volumes and flow

rates) by entering a question mark (?) in place of the

value. You enter the actual value after pressing the

RUN key. This feature is particularly useful when

Essential Steps

optimizing parameters. In the following example,

the aspirate flow rate (Asp Flow) is submitted as an

unknown. Then, each time the Method is run, you

can submit a different value (6, 12, 18). After which

you evaluate the results and select the most appropriate value for use in the Method.

Method Example

Dispense equal volumes of various samples, rinse

the probe after distribution.

Common (Fraction) Volume = 20 µL,

Number of fractions = 3.

Start-up Screen

Task Selection Screen

Aspirate flow rate from 6 to 18 mL/minute,

dispense flow rate = 6 mL/minute.

In this example ‘Aspirate flow rate’ will be submitted as an in-run prompt.

Extra volume = 5 µL.

You aspirate an extra volume of sample, to avoid

diluting the last fraction with solvent. This extra

volume is sent to the Waste, after distributing the

last fraction.

Rinse with 500 µL of solvent.

When using the software, remember that the

‘HELP’ key is available with most screens.

Entering the Method

Beginning at the Start-up Screen, key in the file

number for your Method, then press ENTER.

Then press Edit; the Task Selection Screen appears.

You can now access the screens for the required

task and enter the task related parameters. The

following screens show how to enter the information (described above) for each task.

4-8

In general you must press the Chge soft-key to

select an option, then press ENTER to confirm the

option selected. Press the Next soft-key to cycle

forward through the screens, press Prev to cycle

backwards, or ESC when you reach the extremity

of a software branch.

Page 45

Operation - Standard Use 4

For the Dispense task, press Disp; you see the first

parameter screen, Dispense Screen (1).

Press Chge until you see ‘Source: PROBE’, press

ENTER to confirm, then press Next.

Press Chge until you see ‘Fraction vol: SAME’,

press ENTER to confirm, then press Next.

Key in the number of fractions (up to 99 are possible) to dispense (3 in this example), press ENTER to

confirm, then press Next. Key in the ‘Common vol:’

(20), press ENTER to confirm, then press Flow.

At ‘Asp. Flow’, key in a typical flow rate (6), then

press the question mark (?) soft-key, press ENTER.

Press Next, key in the flow rate (6), press ENTER;

Dispense Screen (5) appears.

Press ESC Dispense Screen (4a) reappears. Press

Extra; Dispense Screen (6) appears.

Key in the ‘Extra vol: ’(5), press ENTER to confirm,

then press ESC, Dispense Screen (4) reappears.

Press ESC, Dispense Screen (7) appears.

Dispense Screen (1)

Essential Steps

Dispense Screen (2)

Dispense Screen (3)

Dispense Screen (4a)

Dispense Screen (4b)

Dispense Screen (5)

Dispense Screen (6)

This completes the parameter set for the first task

(Dispense). If you need to verify (or change) any of

the parameters, you would press the Param key.

However, in this example you continue by pressing

ADD; Task Selection Screen 2 appears.

Press soft-key for required task: Rinse; you now see

the Rinse Screen.

Key in the rinse volume (500), press ENTER. Press

ESC; Task Edit Screen appears.

Press ESC, the Save Screen appears.

Press Yes; Run Screen appears (the name of the first

task to be run appears, in this example ‘Dispense’);

you are now ready to prime the 402, after which

you can run the Method that you have just created.

Dispense Screen (7)

Task Selection Screen 2

Rinse Screen

Task Edit Screen

Save Screen

Run Screen

4-9

Page 46

Operation - Standard Use 4

Prime the 402 (Man)

Prime is used to thoroughly clean out all fluid

pathways with fresh solvent and to clear bubbles

Manipulation Screen

from the tubings.

Essential Steps

Initialization Screen 2

Press the Man soft-key, the Manipulation Screen

appears.

Press Prime, Initialization Screen 2 appears.

[Measure and Titrate are described in Chapter 5.]

You should prime the 402 before each run, to

ensure that all fluid pathways contain fresh solvent

and no air bubbles.

Put the probe-end of the transfer-tubing into a

suitable the waste container, then press OK.

Priming starts immediately and the message

‘Priming ...’ appears on the screen; during which

time solvent is expelled at the probe-end of the

transfer tubing.

Press STOP, or the End soft-key, when you are

satisfied that all fluid pathways have been primed

with fresh solvent and are free of air bubbles.

Abort Screen

Pressing End

When you press End, the motion of the syringe(s)

ceases and ‘Homing ...’ appears on the screen until

the syringe(s) have returned to their uppermost

positions.

Pressing STOP

You can press STOP at any time, however, this key

is more for use if a problem arises (such as a leak).

When you press STOP, the motion of the syringe(s)

ceases and the Abort Screen appears. Press Proceed,

when you want to continue the prime from the

point at which it was stopped (for example, to refill

the solvent reservoir).

Press Abort, when you want to stop priming;

Initialization Screen 2 reappears. Ensure that the

probe-end of the transfer-tubing is in a suitable

waste container, then press OK.

4-10

Page 47

Operation - Standard Use 4

‘Homing ...’ appears on the screen until the syringe(s)

have returned to their uppermost (home) positions,

during which time any liquid contained in the

transfer-tubing is expelled from the probe-end.

After this the Action Screen reappears.

Press ESC to return to the start-up screen for the

current file.

Whenever you see ‘Homing’ on the screen, the

syringe piston(s) are returned to their uppermost

position(s). As a result, some (or all) of the liquid

contained in the transfer-tubing will be expelled

from the probe-end. You must ensure that the

probe end of transfer-tubing is already in a

suitable waste container.

Running a Method (Run)

Introduction

The Run soft-key appears, after you have entered

your Method. Press Run to start the Method currently shown on the screen (at the first task, in this

example Dispense).

If you want to run a different program, you must

key in its file number and press ENTER, before

pressing Run.

Essential Steps

Run Screen (1)

Run Screen (33)

After pressing Run, a series of in run screens

appears. During the run, you must follow the

instructions on the screen, and press the command

button on the probe when prompted to do so by

the command light on the probe.

You press the command button on the probe to

aspirate and to dispense:

- a steady light means you are going to aspirate or

dispense liquid,

- a flashing light means you are going to aspirate air.

When you have finished, or wish to change programs, press STOP, to instantly halt the program.

Pressing STOP

When you press STOP, the motion of the syringe(s)

ceases and the Abort Screen appears. Press Proceed,

when you want to continue with your Method.

Press Abort, when you want to stop. Unless the

syringe(s) are already at their uppermost (home)

positions, Initialization Screen 2 reappears.

Abort Screen

4-11

Page 48

Operation - Standard Use 4

Ensure that the probe-end of the transfer-tubing is

in a suitable waste container, then press OK.

‘Homing ...’ appears on the screen until the

syringe(s) have returned to their home positions,

during which time any liquid contained in the

transfer-tubing is expelled from the probe-end.

Essential Steps

After this the Action Screen reappears.

Press ESC to return to the start-up screen for the

current file.

Whenever you see ‘Homing’ on the screen, the

syringe piston(s) are returned to their uppermost

position(s). As a result, some (or all) of the liquid

contained in the transfer-tubing will be expelled

from the probe-end. You must ensure that the

probe end of transfer-tubing is already in a

suitable waste container.

Method Example

In Run Screen (1)

In Run Screen (2a)

In Run Screen (2b)

This section describes how to run Method 33

(created as above).

(i) Press Run, you see In Run Screen 1.

M33/T 1: DISPENS/1 means Method 33 Task 1,

Dispense Task, first cycle.

The cursor moves from side-to-side below the

parameter value field, indicating that you must

enter a value (or validate the current value, in

this example 6 mL/min.). Key in the required

flow rate (for example, 12 mL/min.) and press

ENTER. [Similar screens would appear for any

other parameters that you had entered as a

question mark (?).] The command light flashes

and you see alternately In Run Screens 2a and 2b

(about every half a second).

In the Dispense task, you aspirate an air gap, then

liquid. After aspirating, you dispense the liquid

in several fractions, finally the ‘Extra volume’ is

sent to waste.

1

air gap

6

fraction 4

7

to waste

Extra Volume

4-12

2

liquid

fraction 2

3

fraction1

fraction 3

4

5

Page 49

Operation - Standard Use 4

(ii)Press the command

button to aspirate AIR.

The command light is

steady and you see

alternately In Run

Screens 3a and 3b.

(iii) Put the tip of the

transfer-tubing into

the sample then press

the command button

to aspirate liquid. The

command light is

steady and you see

alternately In Run

Screens 4a and 4b.

(iv) Put the tip of the

transfer-tubing into a

recipient vessel then

press the command

button to dispense the

fraction, the command

light is steady. Repeat

for the other fractions.

The command light is

steady and you see

alternately In Run

Screens 5a and 5b.

In Run Screen (3a)

In Run Screen (4a) In Run Screen (4b)

In Run Screen (5a) In Run Screen (5b)

In Run Screen (3b)

Essential Steps

(v)Put the tip into the

waste then press the

command button to

dispense the ‘Extra

volume’. The command light is steady

and you see alternately In Run Screens

6a and 6b.

M33/T 2: RINSE 1

means Method 33 Task 2, Rinse, first cycle.

(vi) Put the tip of the transfer-tubing into the waste

then press the command button to rinse. The

command light goes out while the tubing is

being rinsed. Then, you are returned to In-run

Screen 1 for the next sample. At his point you

may continue to cycle through In-run Screens 1 to

6, or end the run by pressing STOP, in which

case you see the Abort Screen.

In Run Screen (6a) In Run Screen (6b)

Abort Screen

4-13

Page 50

Operation - Standard Use 4

Press ‘Abort’ to confirm that you wish to stop and

you are returned to the Run Screen. Alternatively,

you can bring the 402 to a halt by switching off

the power, in which case you must ensure that

the probe end of transfer-tubing is in a suitable

waste container before switching on again.

Essential Steps

4-14

Page 51

Operation - Advanced Use 5

This chapter explains in details how liquids are aspirated and dispensed using the 402

Dilutor-Dispenser and gives in depth details of various software functions.

5-1

Page 52

Operation - Advanced Use 5

Correct Use of a 402

Single-syringe Model

• Samples and reagents are aspirated from the

probe side.

• Liquid aspirated from the probe side may not

enter the syringes. Thus, the tubing that connects

Correct Use of the 402

the syringe to the probe, called transfer tubing, has

to be carefully chosen to accommodate the

volumes of samples and reagents defined in the

Method.

• Liquids should be separated by an air gap to

minimize contamination.

• If a drop of liquid is present at the end of the

tubing after dispensing, you must include this

drop in the result vial.

• Syringe functionality is shown below.

(a) Aspirating from Reservoir (b) Aspirating from Probe (c) Dispensing

From Reservoir

Piston descends

to aspirate

From Probe

Piston descends

to aspirate

Piston ascends

to aspirate

Dual-syringe Model

• Samples and reagents are aspirated from the

probe side.

To Probe

5-2

• Liquid aspirated from the probe side may not

enter the syringes. Thus, the tubing that connects

the syringe to the probe, called transfer tubing, has

to be carefully chosen to accommodate the

volumes of samples and reagents defined in the

Method.

• Liquids should be separated by an air gap to

minimize contamination.

Page 53

Operation - Advanced Use 5

• If a drop of liquid is present at the end of the

tubing after dispensing, you must include this

drop in the result vial.

• The larger capacity syringe must always be

mounted on the left-hand side.

• Only the left-hand syringe aspirates the liquid

from the reservoir (diluent and rinsing liquid).

• If the capacity of the right-hand syringe is

superior to the total volume aspirated (volumes of

samples, reagents, air gaps), the right-hand

syringe aspirates and delivers liquids from the

probe.

• If the capacity of the right-hand syringe is inferior

to the total volume to be aspirated (including air

gaps), the left-hand syringe will be used to

aspirate all liquids.

• Syringe functionality is shown below,

steps (a) to (e).

From Reservoir

Left-hand Syringe Aspirating (from

Reservoir)

Correct Use of the 402

(a) Left-hand Syringe

Aspirating from Reservoir

1. The valve switches to connect the

left-hand syringe to the reservoir.

2. The piston of the right-hand syringe

remains in the top position.

3. The left-hand piston descends to

aspirate the specified volume of

liquid from the reservoir.

Left-hand Syringe Dispensing

(from Reservoir)

1. The valve switches to connect the

left-hand syringe to the Tee-junction

and probe.

2. The piston of the right-hand syringe

remains in the top position to

prevent liquid from entering the

syringe.

3. The left-hand piston ascends to

dispense the specified volume of

liquid from the reservoir.

Left piston

descends

to aspirate

(b) Left-hand Syringe

To Tee To Probe

Right piston

remains at

the top

Dispensing

Left piston

ascends

to dispense

Right piston

remains at

the top

5-3

Page 54

Operation - Advanced Use 5

(c) Left-hand Syringe

Aspirating from Probe

From Tee From Probe

Correct Use of the 402

Left piston

descends

to aspirate

(d) Right-hand Syringe

Aspirating from Probe

Valve switched

to Reservoir

Right piston

remains at

the top

From Probe

Aspirating Large Volumes via the

Probe

1. The valve switches to connect the lefthand syringe to the Tee-junction and

probe.

2. The piston of the right-hand syringe

remains in the top position to prevent

liquid from entering the syringe.

3. The left-hand piston descends to

aspirate the specified volume of sample

liquid.

Aspirating Small Volumes via the

Probe

1. The valve switches to connect the lefthand syringe to the reservoir, thus

disconnecting the left-hand syringe

from the right syringe.

2. The piston of the left-hand syringe

remains in the top position.

Left piston

remains

inactive

(e) Right-hand Syringe

Dispensing to Probe

Valve switched

to Reservoir

Right piston

descends to

aspirate

To Probe

3. The right-hand piston descends to

aspirate the specified volume of sample.

Right-hand Syringe Dispensing to

Probe

1. The valve switches to connect the lefthand syringe to the reservoir, thus

disconnecting the left-hand syringe

from the right-hand syringe.

2. The piston of the left-hand syringe

remains in the top position.

3. The right-hand piston ascends to

dispense the specified volume of

sample.

5-4

Left piston

remains

inactive

Right piston

ascends to

aspirate

Page 55

Operation - Advanced Use 5

Software

You must first enter the configuration details for

your 402 Dilutor-Dispenser. Then you may do one

of three things:

(i) Perform a direct manipulation (Prime, Measure,

Titrate).

(ii) Run a prefabricated Method (files 90 - 94).

(iii) Create your own Method.

A Method consists of a file saved in the 402’s

memory, which can hold up to 99 files. Each file

will contain one or more of the following tasks:

Dilute (Dil), Dispense (Disp), Pipette (Pip), Rinse,

and Mix. You can use Link to combine Methods so

that they operate sequentially.

Software

Each task consists of a series of instructions and

parameters. Some of the parameters may be

defined as in-run prompts (entered as a question

mark); in which case you are prompted to enter the

variable’s value each time you run the Method. To

make and run a Method file, you must follow the

procedures 1 to 5.

Each procedure is

activated by pressing

the appropriate softkey, each of which

gives access to a

specific menu. The

RUN key only appears

Function Press Key

1 Enter the configuration of the Dilutor-Dispenser Conf

2 Create or modify a Method Edit

3 Save the Method as a file in the 402’s memory Edit

4 Direct manipulation of the Dilutor-Dispenser Man

5 Run a Method Run

6 File transactions File

after you have saved

your Method (i.e. after

having entered the

tasks and parameters).

In carrying out these procedures, you must observe

some general rules.

1 Press ENTER, to confirm your entry, after

1

keying in any value or number

.

2 Press ENTER, to confirm your choice, after

1

selecting any option

.

1

After keying a value (or selecting

an option), you must press

ENTER to make the soft-keys

reappear.

3 Press the Prev soft-key to go back to the previous

screen.

5-5

Page 56

Operation - Advanced Use 5

4 Press the Next soft-key to go to the following

screen.

5 Press the Chge soft-key to choose an option or to

Software

select from a list of possible values.

6 Press the ESC key to return to the level of the

previous screen or menu.

7 Press CLEAR to remove the value (before

pressing ENTER) and return to the previous

value.

8 Press Deflt to select the default value or option.

Entering the Configuration (CONF)

Configuration Screen

Tubing Volume Screen

You have to tell the controlling software how your

402 Dilutor-Dispenser is configured (syringe sizes,

flow rates, etc.). Press the CONF key; you see the

Configuration Screen.

Press Key To Change What Items

Vol Volumes Transfer Tubing, Air Gap.

Syr Syringe Sizes, Correction, and to change.

Flow Flow-rates Air, Prime, Reservoir.

Count Counters Number of cycles for syringe(s) and valve.

Etc Switch On/Off Beeper and Autorefill function.

Volume(s)

Press the Vol soft-key, you see the Tubing Volume

Screen.

The use of the soft-keys is as follows:

Next is used to go to the next screen (from Tubing

Volume Screen),

Chge is used to select the tubing size,

Prev is used to go to the previous screen (from Air

Gap Volume Screen),

5-6

Check that the configured volume for the probe

tubing is the same as the size fitted. For the

standard probe, you can select from: 1, 2, 5, 10 mL

(tapered tubing).

When using disposable tips, you must select the size

of tip (Micro or Large Volume), and application

type for Micro Tips only (Air or Liquid). When you

use disposable tips, the ‘Extra Volume’ parameter is

automatically changed to ‘Air Push Volume’.

Page 57

Operation - Advanced Use 5

If you want to change the configured volume, press

Chge (until you reach the correct value); when the

volumes are the same press ENTER, press the ESC

key to return to the Configuration Screen, or press

Next, after which you see the Air Gap Volume

Screen.

Key in the ‘Air gap volume’, press ENTER to

confirm then press the ESC key to return to the

Configuration Screen.

Air gaps may be used to separate liquids in the

transfer tubing; the default value for ‘Air gap