Page 1

User Manual

Weather Stations

Parts 1723-XB X-11X (Firmware version 2436-4.01.01)

Parts 1723-XB X-11X (Firmware version 2436-4.02.04 Modbus units only)

Doc No: 1723-PS-0022 Issue 1

Gill Instruments Limited

Saltmarsh Park, 67 Gosport Street, Lymington,

Hampshire, SO41 9EG, UK

Tel: +44 1590 613500, Fax: +44 1590 613555

Email: 1 Website: www.gillinstruments.com

MetPak

MetPak Pro

MetPak RG

Page 2

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 2 Issue 1

Doc. No. 1723-PS-0022 October 2018

Contents

1. FOREWORD ............................................................................................ 4

2. INTRODUCTION...................................................................................... 4

2.1. MetPak Part Numbers and Parameters ............................................................ 5

2.1.1. MetPak Part Number Structure. ............................................................... 5

2.1.2. MetPak Derived Parameters and Sensors. ............................................... 5

2.1.3. Wind Speed and Direction Sensor ........................................................... 6

2.1.4. Radiation Shield ...................................................................................... 6

2.1.5. Temperature, Relative Humidity and Dewpoint ......................................... 7

2.1.6. Barometric Pressure ................................................................................ 7

2.1.7. Precipitation (Digital Input 1). ................................................................... 7

2.1.8 PRT Temperature (PRT Input) ................................................................. 8

2.1.9 Analogue Sensor 1 .................................................................................. 8

2.1.10 Analogue Sensor 2 .................................................................................. 8

2.1.11 Status of MetPak Sensors ....................................................................... 8

2.1.12 Supply Voltage ........................................................................................ 8

2.2. MetPak Sensors default ASCII Output Summary .............................................. 8

3. TECHNICAL SPECIFICATION ................................................................ 9

4. PRE-INSTALLATION ............................................................................ 12

4.1. Equipment supplied ........................................................................................ 12

4.1.1. Optional Extras: ..................................................................................... 12

4.2. Connector and Cable Assembly. ..................................................................... 13

4.3. Communication Cabling .................................................................................. 13

4.3.1 Cable type ............................................................................................. 13

4.3.2 Cable length .......................................................................................... 14

4.4. Cable Connections General ............................................................................ 14

4.5. Earthing .......................................................................................................... 14

4.6. Power supplies ............................................................................................... 15

4.7. Power and Communication Connections ........................................................ 15

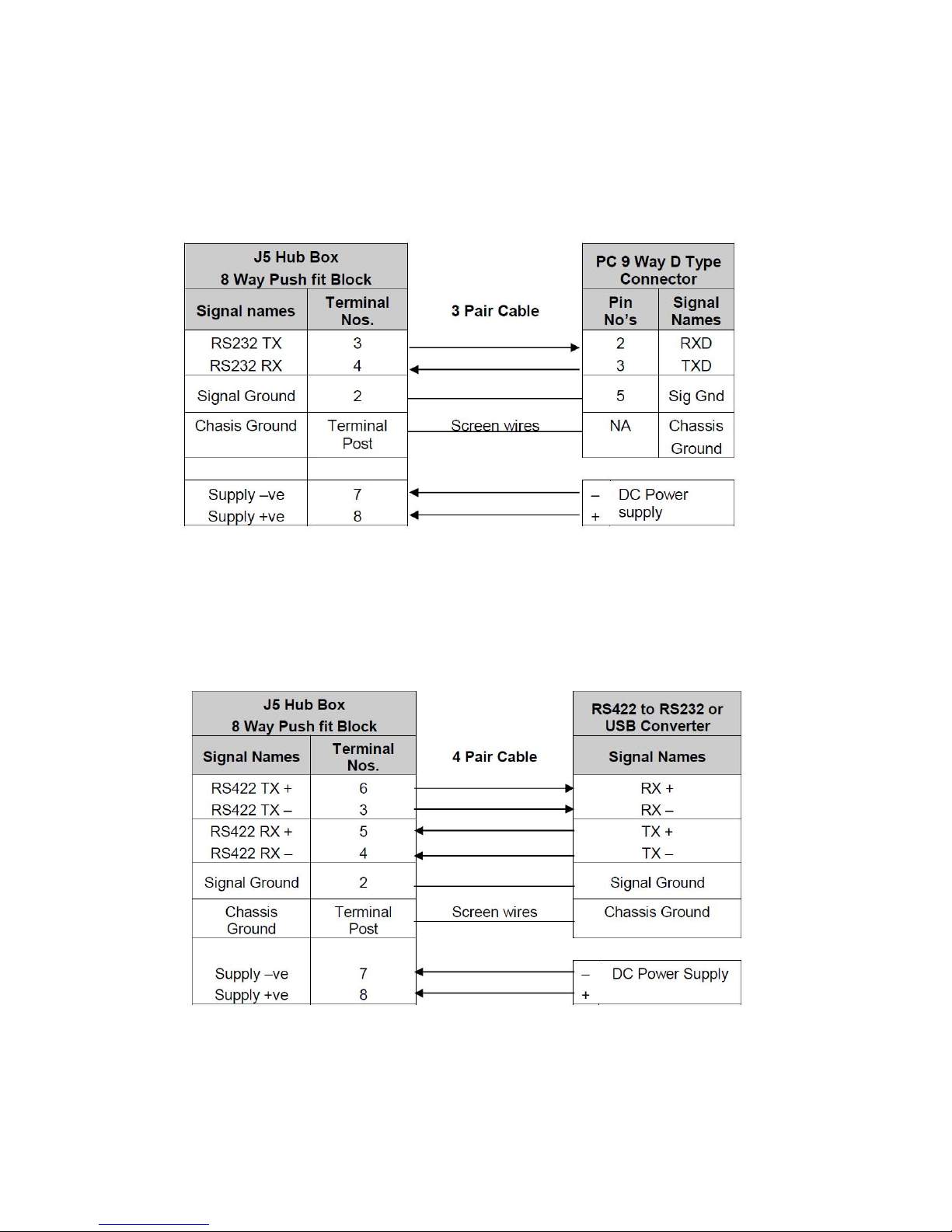

4.8. Connecting to a PC using Gill RS232 to USB Configuration Cable ................. 16

4.9. Connecting to a PC using RS232 (Default setting) .......................................... 19

4.10. Connecting to a PC using RS422 (Not a Default Setting) ................................ 19

4.11. Using RS485 (2 wire point to point only, not a default setting.......................... 20

4.12. Using SDI-12 (2 wire network) not a default setting......................................... 20

4.13. Analogue, Digital and PRT Input Connections ................................................ 21

4.14. MetPak Pro Junction Box (Part 1723-PK-021) ................................................ 25

4.15. Set up requirements ....................................................................................... 29

4.15.1. Host System: ........................................................................................ 29

4.15.2. Software: .............................................................................................. 29

4.15.3. Bench system test ................................................................................ 29

4.16. Packaging ....................................................................................................... 29

5. INSTALLATION ..................................................................................... 30

5.1. Example Installation Guidelines ...................................................................... 30

5.1.1. Non Heated Wind Sensor System .......................................................... 30

5.2. Interference .................................................................................................... 31

5.3. Wind Sensor Installation ................................................................................. 31

5.4. MetPak Range Mounting and Dimensions (in mm) ......................................... 32

5.5. MetPak Pro Junction Box Mounting (1723-PK-021) ........................................ 34

5.6. Solar Installation ............................................................................................. 35

Page 3

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 3 Issue 1

Doc. No. 1723-PS-0022 October 2018

5.7. Rain Gauge Installation ................................................................................... 35

6. CONFIGURING WITH METSET ............................................................ 38

6.1. MetPak Default Configurations ....................................................................... 38

6.2. Configuring MetPaks with MetSet ................................................................... 42

6.3. Polled Mode .................................................................................................... 53

6.3.1 To Configure a MetPak Unit for Polled Mode:......................................... 53

6.4. Configuring MetPak for SDI-12 ....................................................................... 54

6.4.1. SDI-12 Units of Measure ........................................................................ 54

6.4.2. SDI-12 Commands ................................................................................ 55

6.4.3. SDI-12 Commands with CRC ................................................................ 57

6.5. Configuring MetPak for MODBUS ................................................................... 59

6.5.1 MetPak Supported Modbus Specification ............................................... 59

6.6. Configuring a MetPak for NMEA Output.......................................................... 63

6.7. Safe Mode ...................................................................................................... 65

6.7.1. Safe Mode Method 1 ............................................................................. 65

6.7.2. Safe Mode Method 2 ............................................................................. 69

7. VIEWING METPAK DATA .................................................................... 70

7.1. Use MetView to View the MetPak Data ........................................................... 70

7.1.1. Opening MetView .................................................................................. 70

7.1.2. Scanning for Devices ............................................................................. 71

7.1.3. The MetView Console ............................................................................ 72

7.1.4. MetPak Pro User External Sensor Display ............................................. 73

7.1.5. MetView Console Display Options ......................................................... 74

7.1.6. MetView Gauge Ranges and Graphs ..................................................... 75

7.1.7. Data logging .......................................................................................... 77

7.2. Use a Terminal Program to View the MetPak Data ......................................... 79

7.2.1. Setting up a logging file.......................................................................... 81

7.2.2. To stop logging ...................................................................................... 81

8. MAINTENANCE & FAULT-FINDING .................................................... 82

8.1. Cleaning and Handling.................................................................................... 82

8.2. Servicing ......................................................................................................... 82

8.2.1. Wind Sensor (WindSonic) ...................................................................... 82

8.2.2. UV Radiation Shield (MetSpec).............................................................. 82

8.2.3. Barometer ............................................................................................. 83

8.2.4. Temperature, Humidity and Dewpoint Probe (Rotronic HC2-S3-GI)........ 83

8.2.5. Tipping Bucket Precipitation Sensor. ...................................................... 84

8.2.6. Tipping Bucket Spare Parts ................................................................... 86

8.2.7. Solar Sensor.......................................................................................... 86

8.2.8. Calibration ............................................................................................. 87

8.2.9. Returning the MetPak ............................................................................ 87

8.3. Fault-finding .................................................................................................... 87

8.3.1. Fault Symptons/Solutions ...................................................................... 87

8.3.2. MetPak Range Sensor Status Codes ..................................................... 88

8.4. Safe Mode ...................................................................................................... 89

8.5. Bench Test ..................................................................................................... 89

8.6. Returning Units ............................................................................................... 89

8.7. Guarantee....................................................................................................... 89

9. APPENDICES ........................................................................................ 90

9.1. Glossary & Abbreviations ................................................................................ 90

9.2. Electrical Conformity ....................................................................................... 91

Page 4

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 4 Issue 1

Doc. No. 1723-PS-0022 October 2018

ARG100 Rain Gauge

supplied with MetPak RG

1. FOREWORD

Thank you for purchasing a MetPak unit manufactured by Gill Instruments Ltd.

To achieve optimum performance we recommend that you read the whole of this manual before

proceeding with use.

Gill products are in continuous development and therefore specifications may be subject to change

and design improvements without prior notice.

The information contained in this manual remains the property of Gill Instruments and should not

be copied or reproduced for commercial gain.

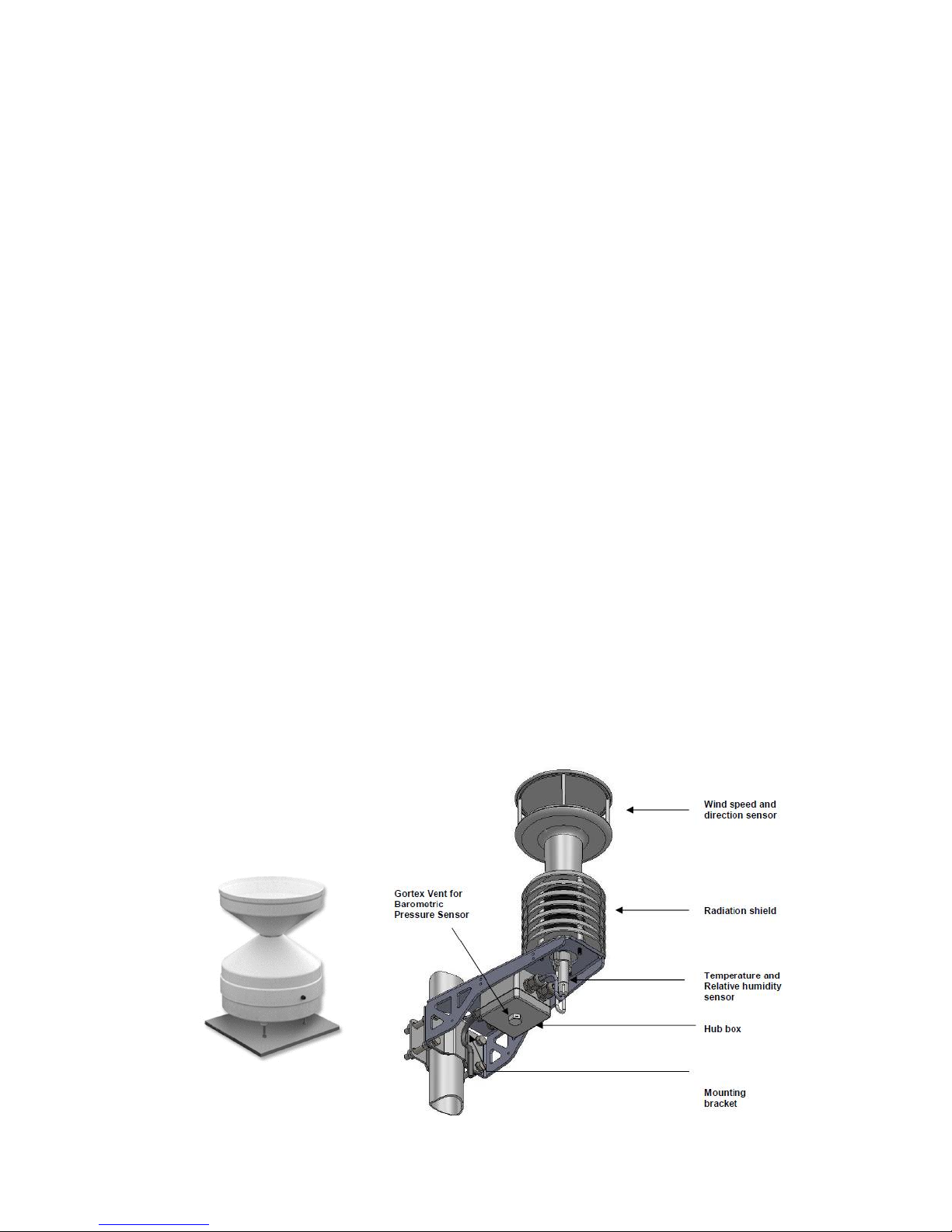

2. INTRODUCTION

All the MetPak range equipments are Professional multi-sensor instruments that measure the most

essential weather parameters. They also provide a data collection system that allows customers to

add their own selection of sensors to meet local requirements. Gill ultrasonic technology, as used

in the proven WindSonic instrument, measures wind speed and direction. Temperature and

Humidity are measured and Dewpoint calculated using an industry standard probe housed in a

naturally aspirated radiation shield. Barometric pressure is measured using an industry standard

sensor.

The MetPak RG allows in addition for the customer to use an aerodynamic tipping bucket for Rain

measurements.

The MetPak Pro in addition allows the customer to add up to four additional sensors. One PRT

(temperature sensor), one digital (contact closure rain gauge) and two analogue inputs (4-20mA or

0-5V) e.g. water level sensor, Pyranometer, pressure sensor, soil temperature etc. Other types of

sensors may be added limited by the number of inputs available.

MetPak range units combines all the instrument data into a single combined data string. This may

be configured for digital ASCII RS232/RS422/RS485 (2 wire point to point), digital MODBUS

RTU/ASCII and SDI-12 outputs.

The instrument uses a rugged mounting clamp that attaches to any vertical pipe up from 30mm to

58mm diameter.

An electrical Hub box is fitted to the mounting bracket for termination of sensors limited to cable

gland entry, data and power cables. A separate Junction box is optionally available for easier

termination of external sensors, power and communication cables.

MetPak/MetPak RG/MetPak Pro

Page 5

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 5 Issue 1

Doc. No. 1723-PS-0022 October 2018

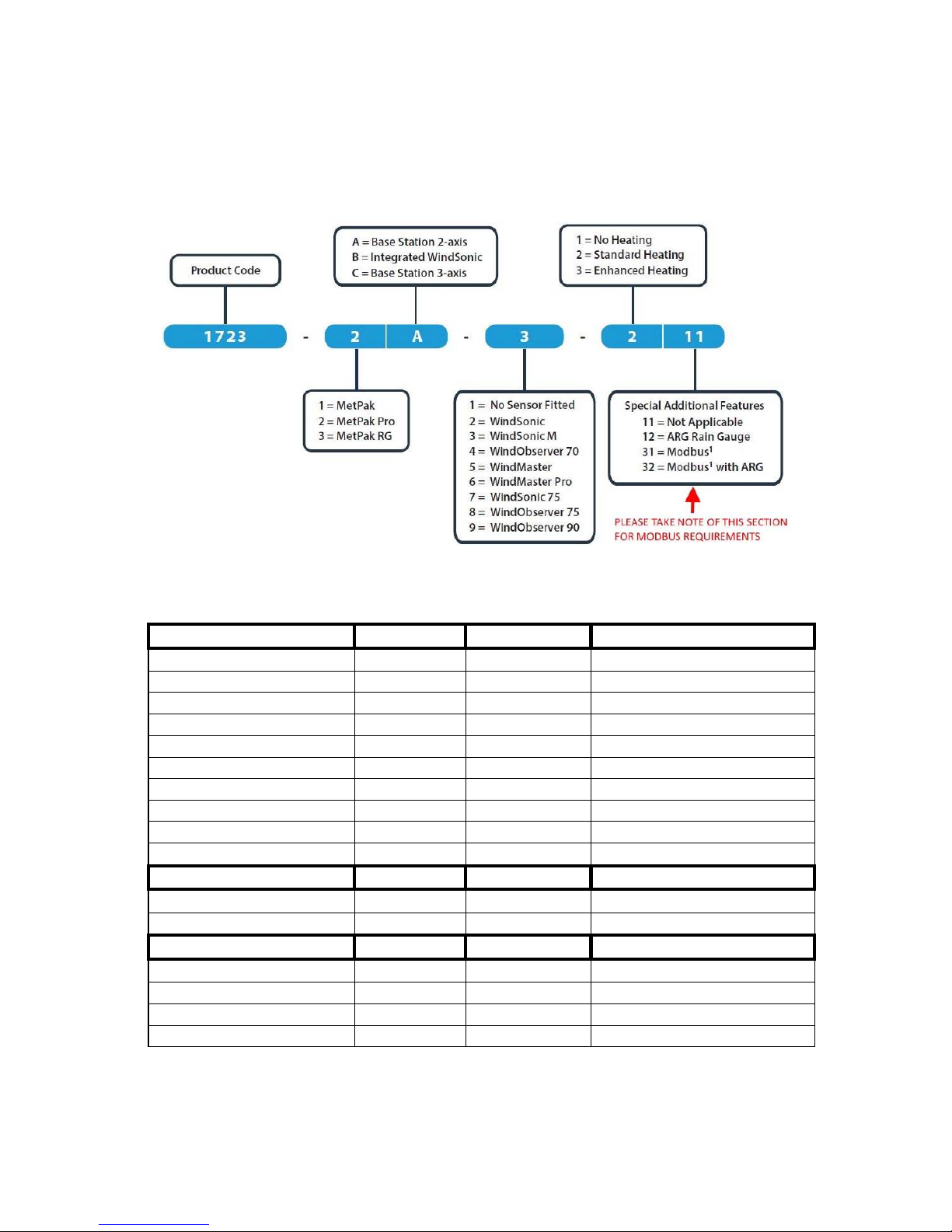

2.1. MetPak Part Numbers and Parameters

2.1.1. MetPak Part Number Structure.

2.1.2. MetPak Derived Parameters and Sensors.

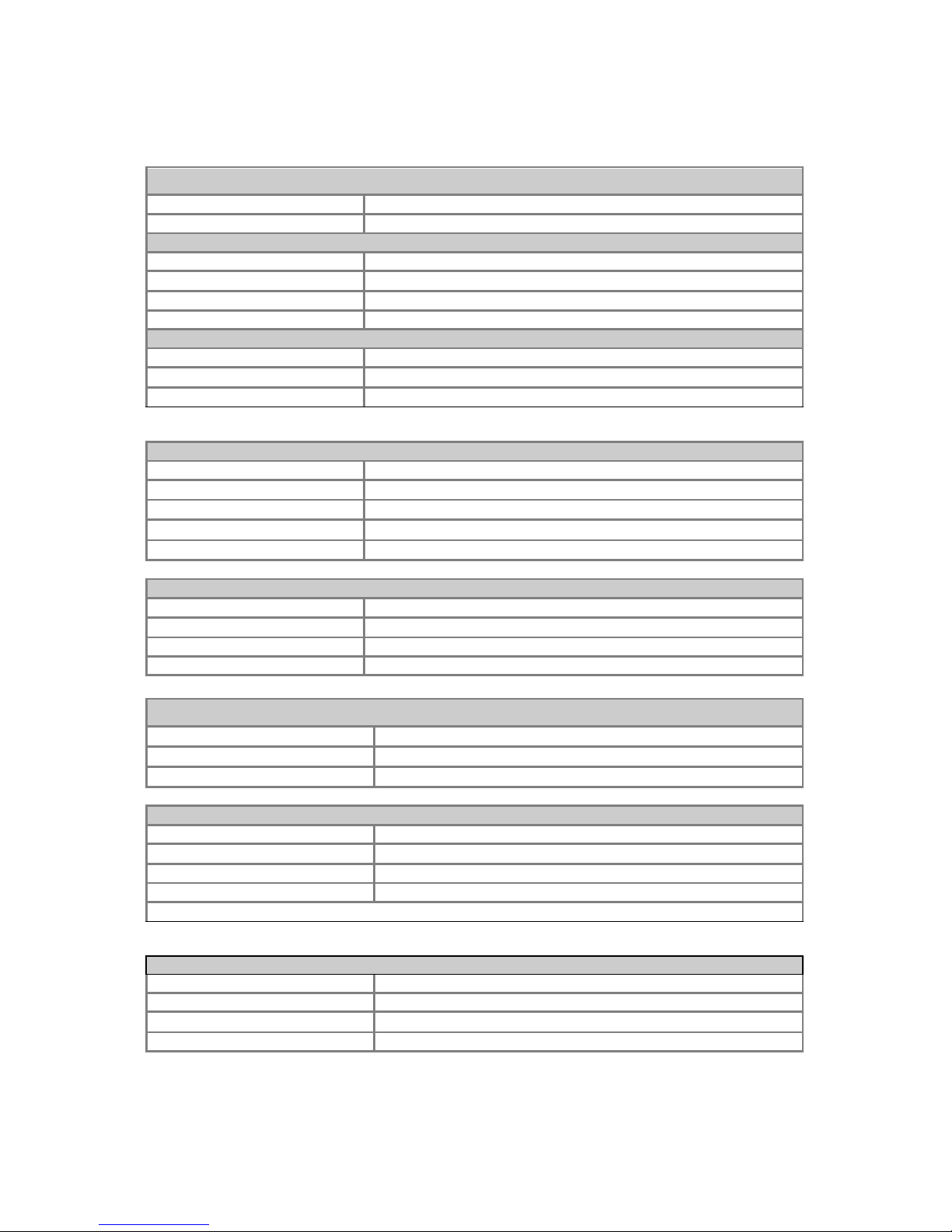

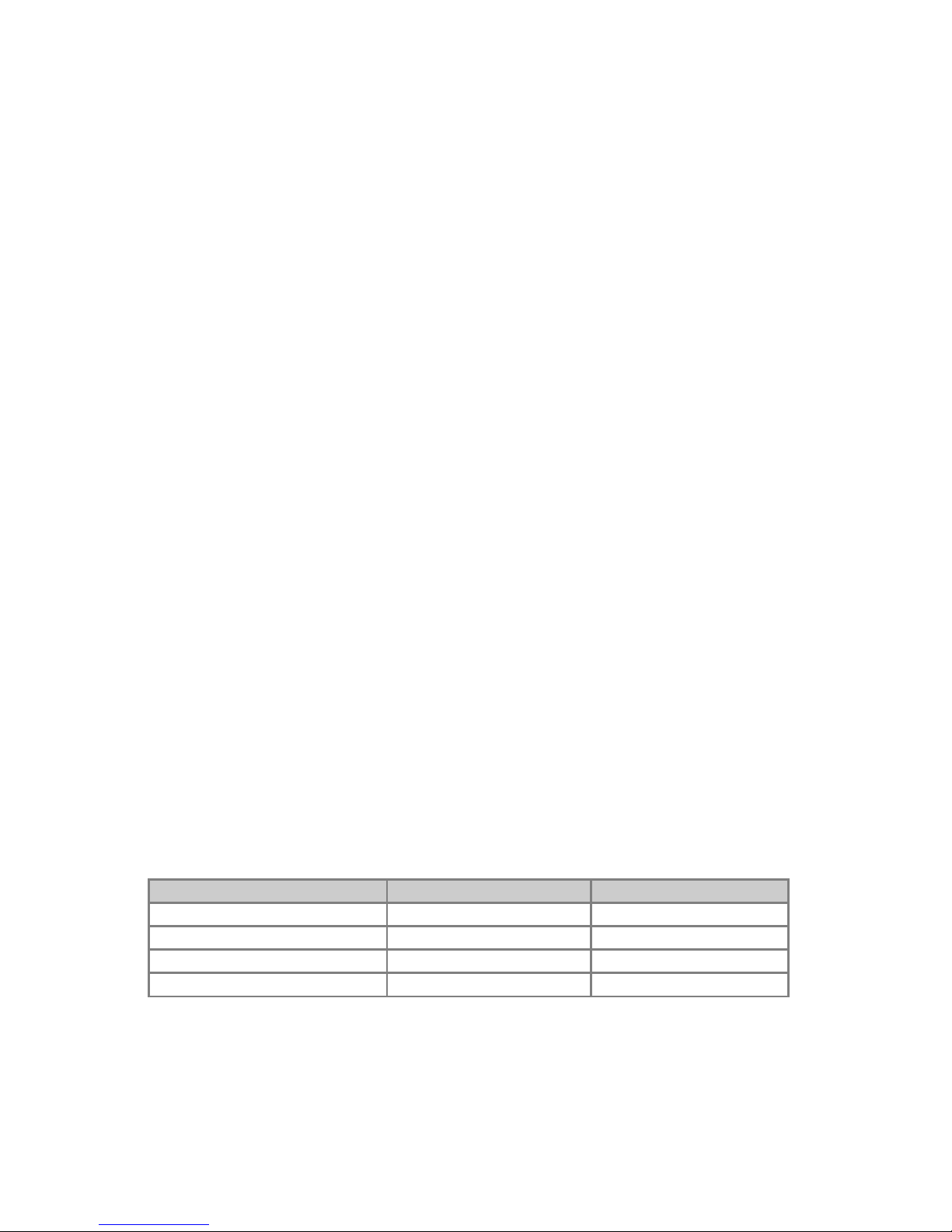

MetPak Sensor Parameter MetPak MetPak RG MetPak Pro

Wind Speed, Relative

Yes Yes

Yes

Wind Direction, Relative

Yes Yes

Yes

Temperature, Air

Yes Yes

Yes

Humidity, Relative

Yes Yes

Yes

Dewpoint

Yes Yes

Yes

Barometric Pressure

Yes Yes

Yes

Rain/Precipitation No Yes Yes with user supply Rain Gauge

Temperature from a PRT

No

No Yes with user supply PRT

Analogue Sensor 1

No

No Yes with user supply Sensor

Analogue Sensor 2

No

No Yes with user supply Sensor

MetPak Derived Parameter

MetPak

MetPak RG

MetPak Pro

Status (Sensors)

Yes

Yes Yes

Volts (Supply) Yes Yes Yes

MetPak Outputs

MetPak

MetPak RG

MetPak Pro

Gill ASCII

Yes Yes Yes

Modbus

Yes Yes Yes

SDI-12

Yes Yes Yes

NMEA

Yes No No

Page 6

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 6 Issue 1

Doc. No. 1723-PS-0022 October 2018

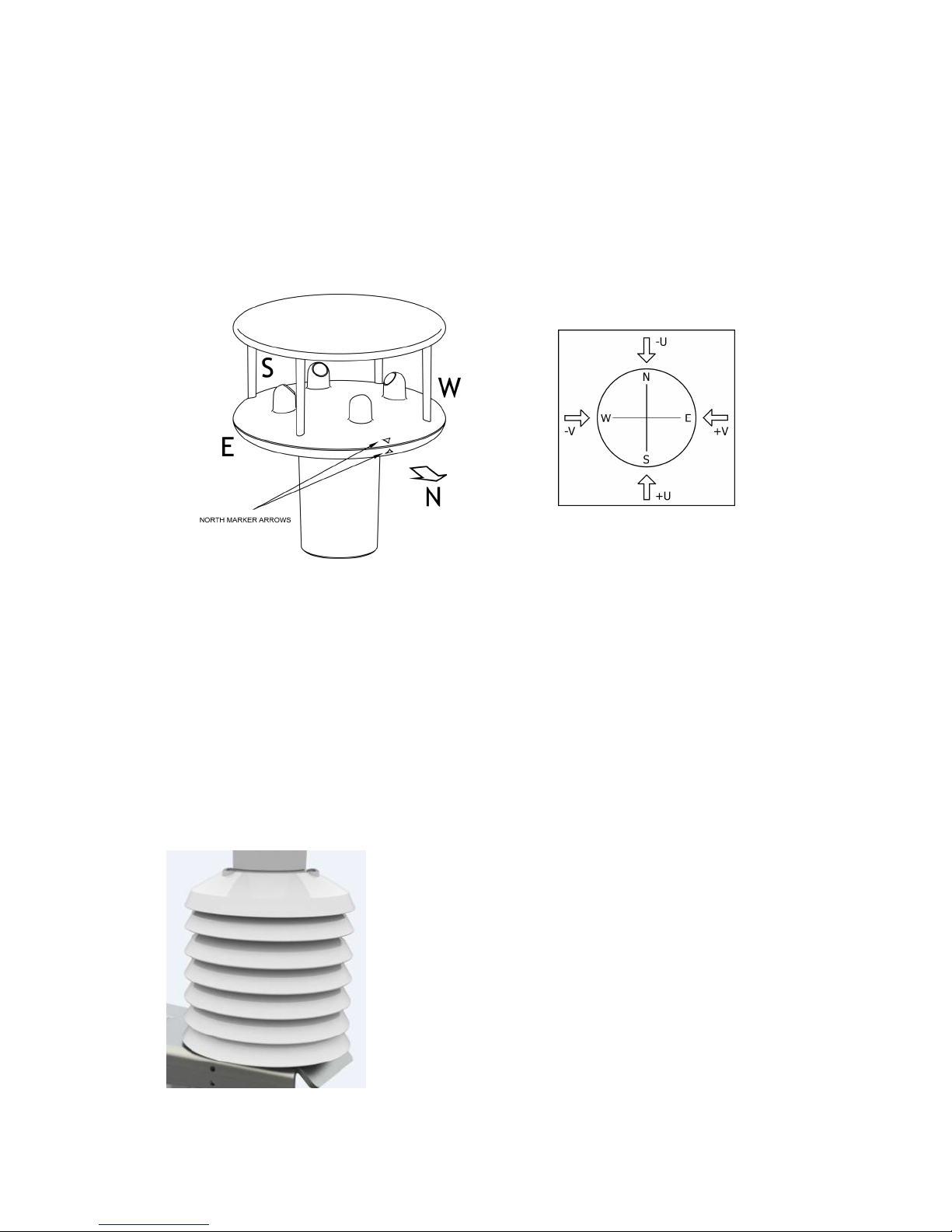

2.1.3. Wind Speed and Direction Sensor

The MetPak uses the Gill WindSonic wind speed and direction sensor. The WindSonic measures

the times taken for an ultrasonic pulse of sound to travel from the North (N) transducer to the

South (S) transducer, and compares it with the time for a pulse to travel from S to N transducer.

Likewise times are compared between West (W) and East (E), and E and W transducer.

If, for example, a North wind is blowing, then the time taken for the pulse to travel from N to S will

be faster than from S to N, whereas the W to E, and E to W times will be the same. The wind

speed and direction can then be calculated from the differences in the times of flight on each axis.

This calculation is independent of factors such as temperature.

Compass points

The compass point and polarity of U and V if the wind components along the U and V axis are

blowing in the direction of the respective arrows.

MetPak outputs Relative wind – wind speed and/or direction relative to the north marker, which

may not be facing north.

2.1.4. Radiation Shield

A MetSpec Multi-Plate Radiation Shield provides excellent

protection to the Rotronics temperature and relative humidity

sensor, shielding the probe from unwanted errors, especially

from secondary upward reflecting solar radiation and/or wind

blown precipitation/airborne contaminants. The special shield

plate geometry, with its double louvre design, provides excellent

response time performance of quick ambient temperature

changes while still working effectively as a baffle to stop larger

contaminants such as salt or dirt from reaching the Rotronics

probe. Due to the increased protection offered to the Rotronics

probe by the MetSpec shield, the maintenance cycle can be

extended. The shield benefits from very robust material choice

and extremely high UV protection requiring no maintenance. A

further benefit of the MetSpec shield design is that the measured

temperature is now even closer to reference temperature

measurements made using artificially aspirated motors without

the drawbacks of such systems (power and the maintenance of

moving parts).

Page 7

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 7 Issue 1

Doc. No. 1723-PS-0022 October 2018

2.1.5. Temperature, Relative Humidity and Dewpoint

The MetPak MetSpec shield contains a Rotronic Hygroclip module. It is a complete instrument,

with integrated temperature compensation. Calibration data is maintained within the integrated

electronics. It provides digital output signals for Relative Humidity, Temperature and Dewpoint.

2.1.6. Barometric Pressure

Barometric pressure output is provided by a solid-state device fitted on to the circuit board in the

MetPak Unit Hub box. Vent to atmosphere is via a Gore-Tex type filter which also protects the

pressure sensor from the effects of wind and rain.

2.1.7. Precipitation (Digital Input 1).

MetPak RG and MetPak Pro:-

Rainfall is measured by the well-proven tipping bucket method. Rain is

collected by a funnel and is passed to one of the two buckets situated

at either end of a short balance arm. The balance arm tips when the

first bucket is full, emptying this bucket and positioning the second

bucket under the funnel. The tipping process repeats indefinitely as

long as the rain continues to fall, with each tip corresponding to a fixed

quantity of rainfall; at each tip the moving arm forces a magnet past a

reed switch, causing contact to be made for a few milliseconds.

An ARG100 Rain Gauge is supplied with a MetPak RG to connect to the Digital input (DIG1),

which detects when two dedicated terminals are short circuited (less than 1k ohm).

Rain levels are provided by reading the number of switch closures taking place over each output

rate time period (default one reading per second). Then multiplying this number by the Rain Gauge

count figure set using MetSet (e.g. 0.2mm per switch closure) and outputting the result in the data

string.

Hygroclip

Gore-Tex

type filter

Page 8

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 8 Issue 1

Doc. No. 1723-PS-0022 October 2018

2.1.8 PRT Temperature (PRT Input)

An external 2 or 4 wire PT100 device can be connected to a MetPak Pro to provide an additional

remote temperature measurement.

2.1.9 Analogue Sensor 1

An external remote analogue sensor, 0-5v/4-20mA output, can be connected to a MetPak

Pro AN1 input.

2.1.10 Analogue Sensor 2

An external remote analogue sensor, 0-5v/4-20mA output, can be connected to a MetPak

Pro AN2 input.

2.1.11 Status of MetPak Sensors

Outputs the MetPak Sensors Status Code (see para 8.3.2).

2.1.12 Supply Voltage

The DC Supply voltage measured at the MetPak unit is output in the MetPak Digital Data Output

string.

2.2. MetPak Sensors default ASCII Output Summary

MetPak Default Data String

Node, Relative Wind Direction, Relative Wind Speed, Pressure, Humidity, Temperature, Dewpoint,

Supply Voltage, Status, Checksum.

STX>Q,170,000.08,1019.5,035.0,+024.7,+008.3,+04.9,00,<ETX>55 & (CR,LF)

MetPak RG Default Data String

Node, Relative Wind Direction, Relative Wind Speed, Pressure, Humidity, Temperature, Dewpoint,

Digital Input 1, Supply Voltage, Status, Checksum.

<STX>Q,014,000.06,1011.2,042.1,+023.0,+009.4,0000.000,+04.9,00,<ETX>40 & (CR,LF)

MetPak Pro Default Data String

Node, Relative Wind Direction, Relative Wind Speed, Pressure, Humidity, Temperature, Dewpoint,

PRT, Analogue Input 1, Analogue Input 2, Digital Input 1, Supply Voltage, Status, Checksum.

<STX>Q,249,000.01,1017.3,049.2,+021.4,+010.3,+040.45,+000.06,+000.04,0000.000,+11.6,00,<

ETX>7C & (CR,LF)

Page 9

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 9 Issue 1

Doc. No. 1723-PS-0022 October 2018

3. TECHNICAL SPECIFICATION

Wind Measurement

Parameters Polar Wind Speed & Direction or U and V Vectors

Units of Measurement m/s, knots, mph, kph, ft/min

Wind Speed

Range 0.01 to 60m/s

Accuracy

2% @12m/s

Resolution 0.01m/s

Threshold 0.01m/s

Wind Direction

Range 0-359 Degrees – No dead band

Accuracy

3 @12 m/s

Resolution

1

Air Temperature

(Hygroclip)

Type Pt 100 1/3 Class B

Range

-35C to +70C

Accuracy

0.1C

Resolution

0.1C

Units of Measure

C or F

Relative Humidity

(Hygroclip)

Range 0-100%

Accuracy

0.8% @ 23C

Resolution 1%

Units of Measure % RH

Dew Point

Resolution

0.1C

Accuracy

0.15C (23C ambient temperature @ 20C dew point)

Units of Measure

C or F

Barometric Pressure

Range 600 to 1100hPa

Accuracy

0.5hPa

Resolution 0.1hPa

Units of Measure hPa, mbar, mmHg, InHg

Compensated for Temperature dependency –20C to +70C

Rain

with

ARG100

Rain Gauge

connected to MetPak RG

Precipitation Intensity 0 to 1000mm per hour.

Resolution 0.2mm/tip

Accuracy

2% (ARG100)

Units of Measure millimetres, inches per tip

Page 10

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 10 Issue 1

Doc. No. 1723-PS-0022 October 2018

Inputs

MetPak Pro (MetPak RG Digital Input only).

Analogue 1 (AN1) 0 to 5V or 4 to 20mA MetPak Pro powered or Analogue Sensor

Powered

Analogue 2 (AN2) 0 to 5V or 4 to 20mA MetPak Pro powered or Analogue Sensor

Powered

Analogue Input A-D

Conversion

12 bit resolution with an accuracy of 0.1% of reading, +35uV

offset (voltage inputs) or 0.5uA (current inputs).

Analogue Input Impedance Input impedance for 0-5v input is 330 k ohm.

Input impedance for 4-20mA input is 47 ohms.

PRT 4 wire PRT, Pt100 conforms to IEC 60751

Digital Input (DIG1)

Rain Gauge

Contact Closure input (tipping bucket rain gauge) capable of

capturing events up to 10Hz

Digital Input Capable of detecting an event with a duration of greater than

1.4mS.

Digital Input Capable of detecting a space between events (i.e. terminals

open-circuit) with a duration of greater than 11mS.

Digital Input Capable of reading a switch contact closure providing the total

Digital Switch contact resistance (contact and cabling) is less

than 1k ohm.

Outputs

Digital Outputs RS232, RS422, *RS485 (*2 wire point to point) or SDI-12.

(RS232 point to point and RS485 2 wire networkable –

MODBUS RTU/ASCII)

Baud Rates 1200 (SDI-12), 4800-57600 (ASCII RS232, RS422, *RS485)

9600-19200 (MODBUS RTU/ASCII)

Protocols ASCII, SDI-12 V1.3, NMEA 0183 (MetPak only) or MODBUS

RTU/ASCII

Data Output 1 reading per second (1 Hz), 1 reading per 2 seconds, 1

reading per 4 seconds or Polled Mode

MetPak Status Status codes provided within the data message string

*

RS485 2 wire point to point only.

Power Supply

Input voltage (RS232, RS422,

RS485)

4.5v to 30v dc

Current at 12v MetPak - 22mA

MetPak RG - 26mA

MetPak Pro - 26mA

Input Voltage SDI-12 9.6v to 16v dc (12v nominal)

Current MetPak - 30mA

MetPak RG - 35mA

MetPak Pro - 35mA

Page 11

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 11 Issue 1

Doc. No. 1723-PS-0022 October 2018

Environmental

MetPak Range

Protection Class IP65

EMC BS EN 61326

Operating Temperature

-35C to +70C

Storage Temperature

-40C to +80C

Humidity 0-100%

RoHS Compliant Yes

Environmental

ARG100 Rain Gauge

Protection Class Not applicable

EMC BS EN 61326

Operating Temperature

-35C to +70C

Storage Temperature

-40C to +80C

Humidity 0-100%

Mechanical

MetPak Range

External Construction UV Stabilised white thermoplastic (Wind Sensor and Hygroclip

Mountings) and anodized Aluminium bracket

Fittings

Overall Dimensions

MetPak

MetPak RG

MetPak Pro

364mmx287mmx142mm (excluding bracket clamp)

364mmx287mmx142mm (excluding bracket clamp)

364mmx287mmx142mm (excluding bracket clamp)

Weight

MetPak

MetPak RG

MetPak Pro

2.2kg (including bracket)

2.2kg (including bracket)

2.2kg (including bracket)

Mechanical ARG100

Rain Gaug

e

External Construction UV Resistant white thermoplastic

Fittings Rain Gauge Baseplate (RGB1) and 6 Metres of twisted pair

overall screened cable.

Overall Dimensions Funnel Diameter: 254mm (10.0 Inches)

Funnel Rim: 340mm (13.4 Inches)

Weight 1.0kg

Software

MetSet Configuration

MetView

Free PC Software providing the means of configuration of the

MetPak Unit.

Free PC Software providing the means of Viewing data and

providing a basic logging facility.

Page 12

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 12 Issue 1

Doc. No. 1723-PS-0022 October 2018

4. PRE-INSTALLATION

4.1. Equipment supplied

1723-xB-x-11x MetPak Variant unit

and 8 way connector inside the hub box for power and communication.

and Mounting bracket plate/nuts and bolts in a box.

and Tipping bucket rain gauge ARG100 with 6 Metre lead (MetPak RG only).

and MetPak Range User Manual and MetSetMetViewSoftware on a CD in the MetPak box

(this manual).

and Product Test Report.

4.1.1. Optional Extras:

Item Part Number

Barometric Pressure Hub Box Gore-Tex filter spares kit 1723-PK-024

Hygroclip Temperature and Humidity Filter Replacement Kit (two filters) 1723-PK-025

Hygroclip HC2-S3-GI

037-04263

Junction Box with internal terminating pcb (for MetPak Pro). 1723-PK-201

Rain Gauge. ARG100 Tipping bucket (no cable attached) 1723-PK-076

Terminating pcb (to mount in customer box) for MetPak Pro. 1723-PK-202

Pack of 4 brackets for Pole Mounting the Junction Box for MetPak Pro 1723-PK-203

Pack of 4 feet for Panel Mounting the Junction Box for MetPak Pro. 1723-PK-204

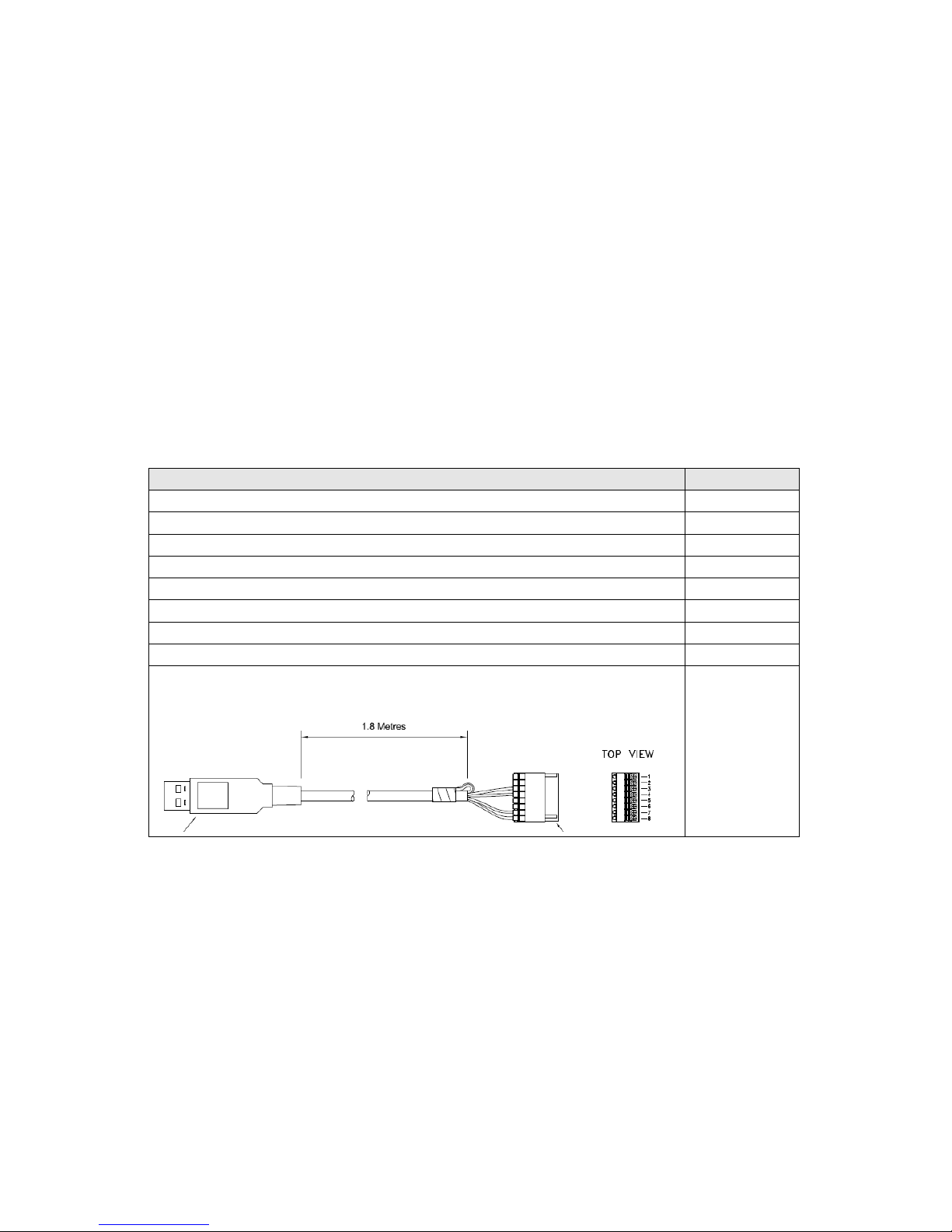

MetPak Range 1.8 Metre RS232 to USB converter including 5v dc power and

communication configuration cable (8 way MetPak connector fitted one end and

USB connector at the other end).

1723-10-051

Page 13

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 13 Issue 1

Doc. No. 1723-PS-0022 October 2018

4.2. Connector and Cable Assembly.

The MetPak is supplied with a mating 8 way connector for power and communication connections.

4.3. Communication Cabling

MetPak, MetPak RG and MetPak Pro have five communication connection options:

USB (using the 1.8m MetPak RS232 to USB cable, Part No. 1957-10-065).

RS232.

RS422.

RS485 (two wire point to point) or networkable if using Modbus.

SDI-12.

MetPak RG and MetPak Pro have a contact closure input connection:

DIG1 (Digital Switch).

MetPak Pro has in addition various Sensor Input connection options:

AN1 and AN2, Analogue inputs (0-5v or 4-20mA).

PRT. Platinum Resistance Thermometer Input.

It is important that the cable is appropriate for the chosen communication network. The following

sections describe the recommended types and maximum lengths of cable in each case.

4.3.1 Cable type

Wire type: 24 AWG

Wire size: 7x32 AWG.

Cable outer diameter: 6- 8mm (to match the connector gland).

For RS422/485 operation the cable should have twisted pairs with drain wire, screened with

aluminised tape, with an overall PVC sheath. Typical wire size 7/0.2mm (24 AWG).

The following table shows an example manufacturers’ reference; other manufacturers’ equivalents

can be used.

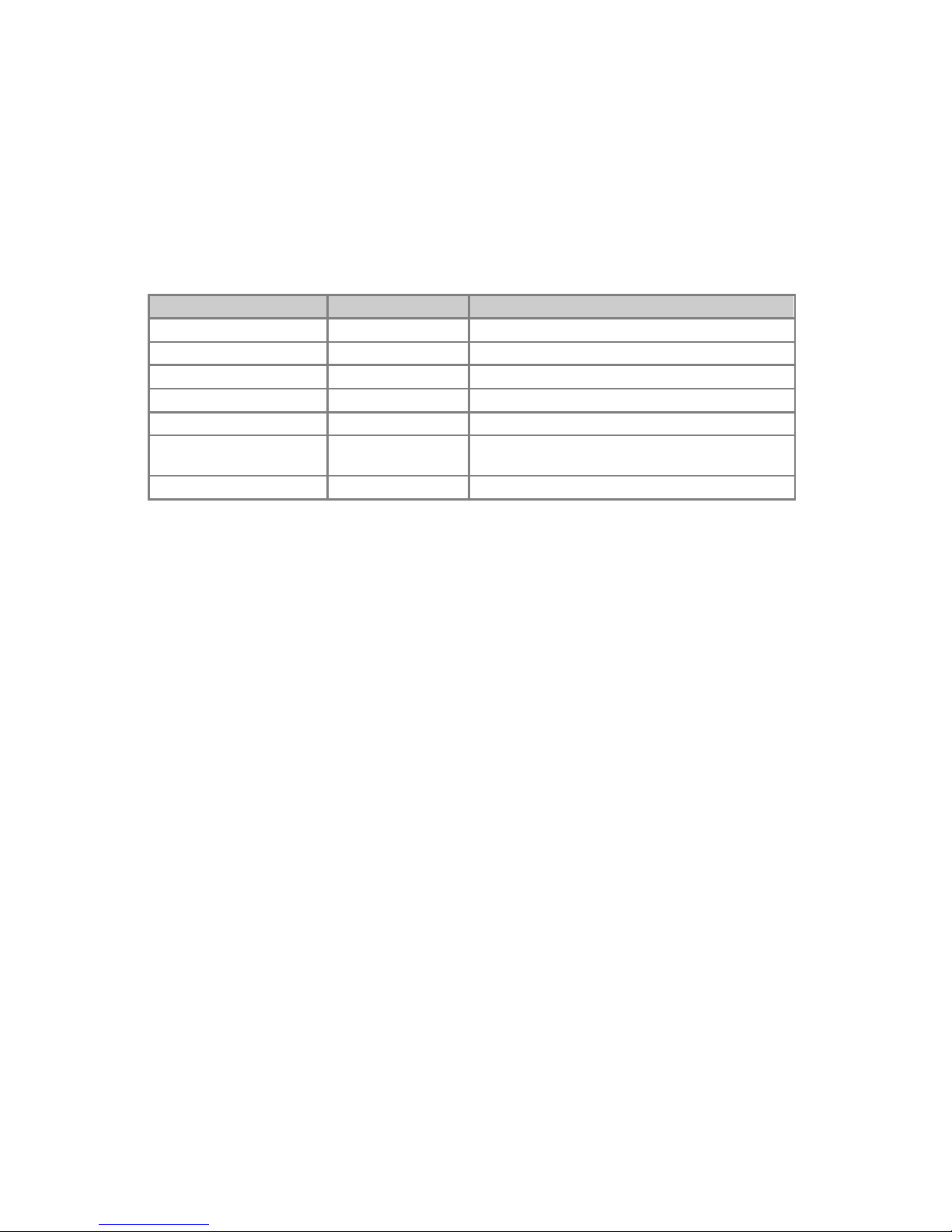

Recommended Belden cable types

Application No. of Pairs 24 AWG Belden Ref.

SDI-12 2

9729

Digital RS232 or RS485 3 9503

Digital RS422 4 9504

Multiple External Sensors 6 9506

Page 14

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 14 Issue 1

Doc. No. 1723-PS-0022 October 2018

4.3.2 Cable length

The maximum cable length is dependent on the chosen communication method.

The following table shows the maximum cable lengths for the supported communication protocols

at the given baud rates, using the recommended cable. If any problems of data corruption etc. are

experienced, then a slower baud rate should be used. Alternatively, a higher specification cable

can be tried.

Suggested maximum cable lengths for supported communication networks

Communication format Baud rate Max. cable length

RS232 19200

6.5M

RS422/485 19200 1000M

SDI-12 1200 90M

0-5v Analogue Input Not Applicable Refer to user Analogue Sensor data sheet

4-20mA Analogue Input Not Applicable Refer to user Analogue Sensor data sheet

Digital Switch Input

Not Applicable

Switch contact and cable resistance to be less

than 1k ohm

PRT Input Not Applicable Refer to user PRT data sheet

4.4. Cable Connections General

Any cable wires not used should be isolated and grounded at the terminating equipment/user end.

Digital OV should be used in conjunction with RS422 TX/RX lines in order to improve noise

immunity.

The Cable should be secured:-

With cable clamps or equivalent at regular intervals such that the hub box cable gland

does not support the cable weight.

Away from the mounting bolts to prevent chaffing of the cable.

NOTES:-

Install appropriate strain relief support to the cable. If possible, pass the cable through the

mounting pole.

The MetPak unit Hub Box cable glands contain spring loaded metal leaves that are designed to

make a ground contact with cables that have an overall braid screen. Care is therefore required

when inserting and removing cables through the glands to prevent damage to the metal leaves.

4.5. Earthing

To ensure correct operation and for maximum protection from lightning, a separate lightning rod

system is recommended to protect the system.

You can also earth the MetPak through its mountings or by connecting a grounding cable

(minimum of 6mm² copper wire) to a spare MetPak metalwork bolt hole. Clean off any paint that

might prevent a good connection.

When you connect the communications cable ensure that the screen has a connection to the hub

box case.

The Junction Box accessory has a plastic case, hence ensure continuity of cable screens into and

out of the Junction Box using the common Earthing terminals provided in the box.

Page 15

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 15 Issue 1

Doc. No. 1723-PS-0022 October 2018

WindSonic J4 Pin 1

4.6. Power supplies

Supply Voltage: 4.5v to 30v DC.

Average Current at 12v dc:-

MetPak 22mA.

MetPak RG 26mA.

MetPak Pro 26mA.

MetPak Units have reverse voltage polarity protection.

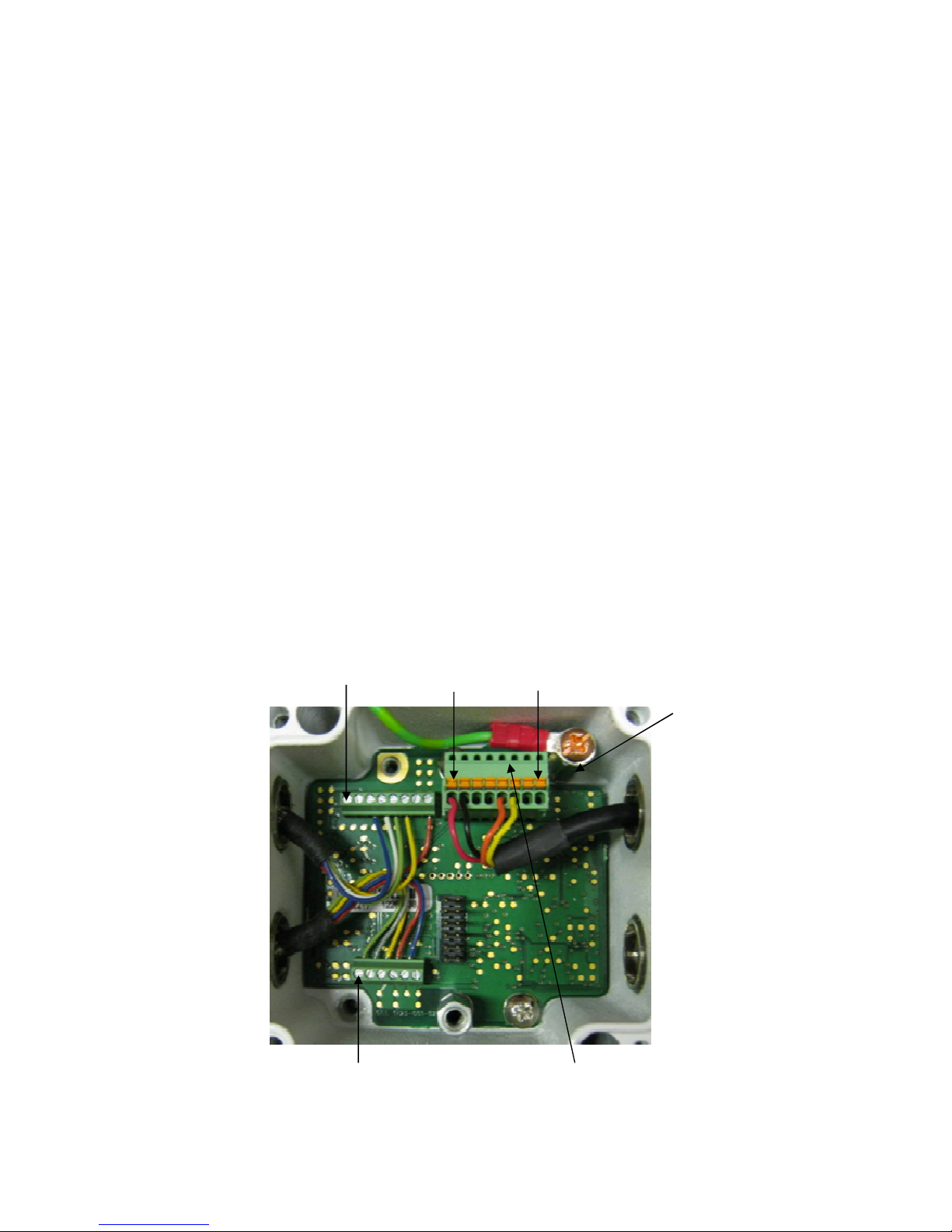

4.7. Power and Communication Connections

To connect Power and Communication to the MetPak Range:

Open MetPak hub box by unfastening the four screws.

Strip the power and communication cable wires to have 8mm of exposed soldered wire.

Pass the cable through one of the gland nuts (please refer to para 4.4. Notes).

Locate the green 8 way plug in connector J5 (see below).

Connect the cable to J5 for the required communication type e.g. RS232, RS422 etc.

Attach the cable’s screen wires to the Hex terminal post (see below).

After connection, securely tighten the gland nut to prevent moisture ingress.

NOTE: The MetPak Range Hub Box cable glands contain spring loaded metal leaves that are

designed to make a ground contact with cables that have an overall braid screen. Care is therefore

required when inserting and removing cables through the glands to prevent damage to the metal

leaves.

Re-fit the Hub box lid.

J5 Pin 8

J5 Pin 1

Hex

Terminal

Post

Hygroclip J1 Pin 6

J5, RS232 to USB and Power

Configuration Cable Wires

Page 16

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 16 Issue 1

Doc. No. 1723-PS-0022 October 2018

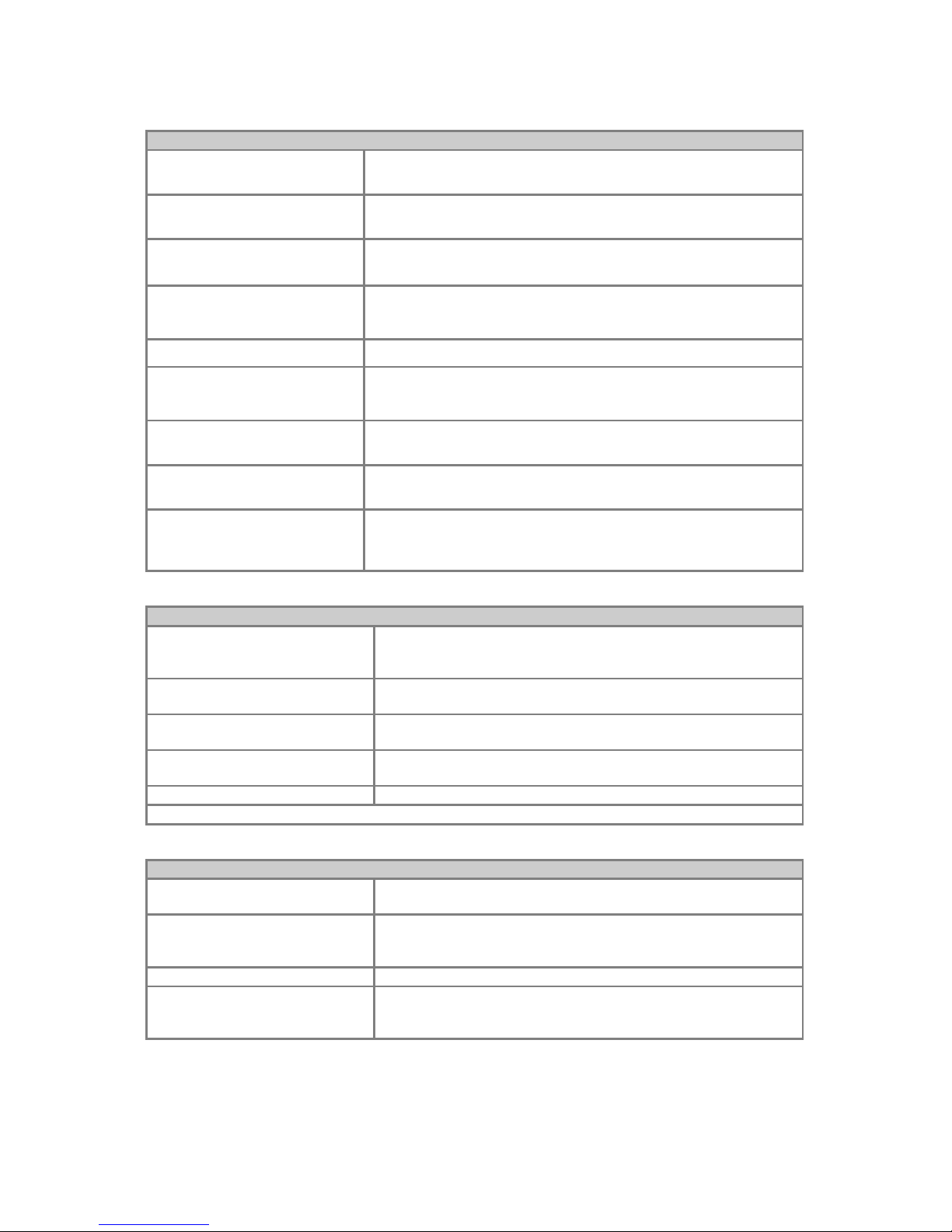

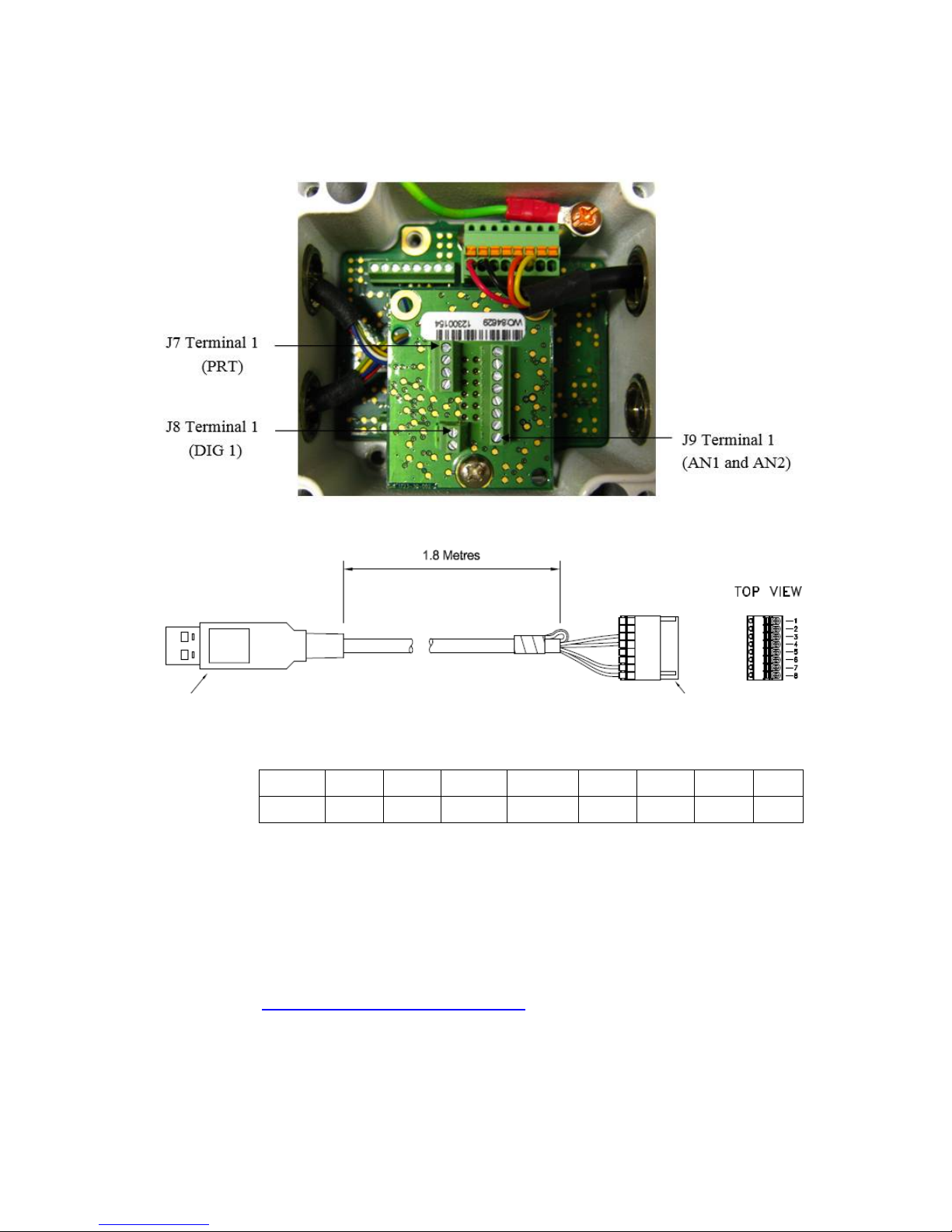

4.8. Connecting to a PC using Gill RS232 to USB Configuration Cable

Connect MetPak to a PC USB port using the Gill Configuration Cable 1723-10-051.

J5 Pin 1 2 3 4 5 6 7 8

Colour None None Yellow Orange None None Black Red

Connection of Gill USB Cable (Part No. 1723-10-051), the J5, 8way Phoenix connector part

number is 1881383.

NOTES:- If upon connecting the USB lead to a PC the driver is not found by the PC, then the

appropriate driver to match the PC Windows version may be downloaded from:-

http://www.ftdichip.com/Drivers/VCP.htm

Page 17

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 17 Issue 1

Doc. No. 1723-PS-0022 October 2018

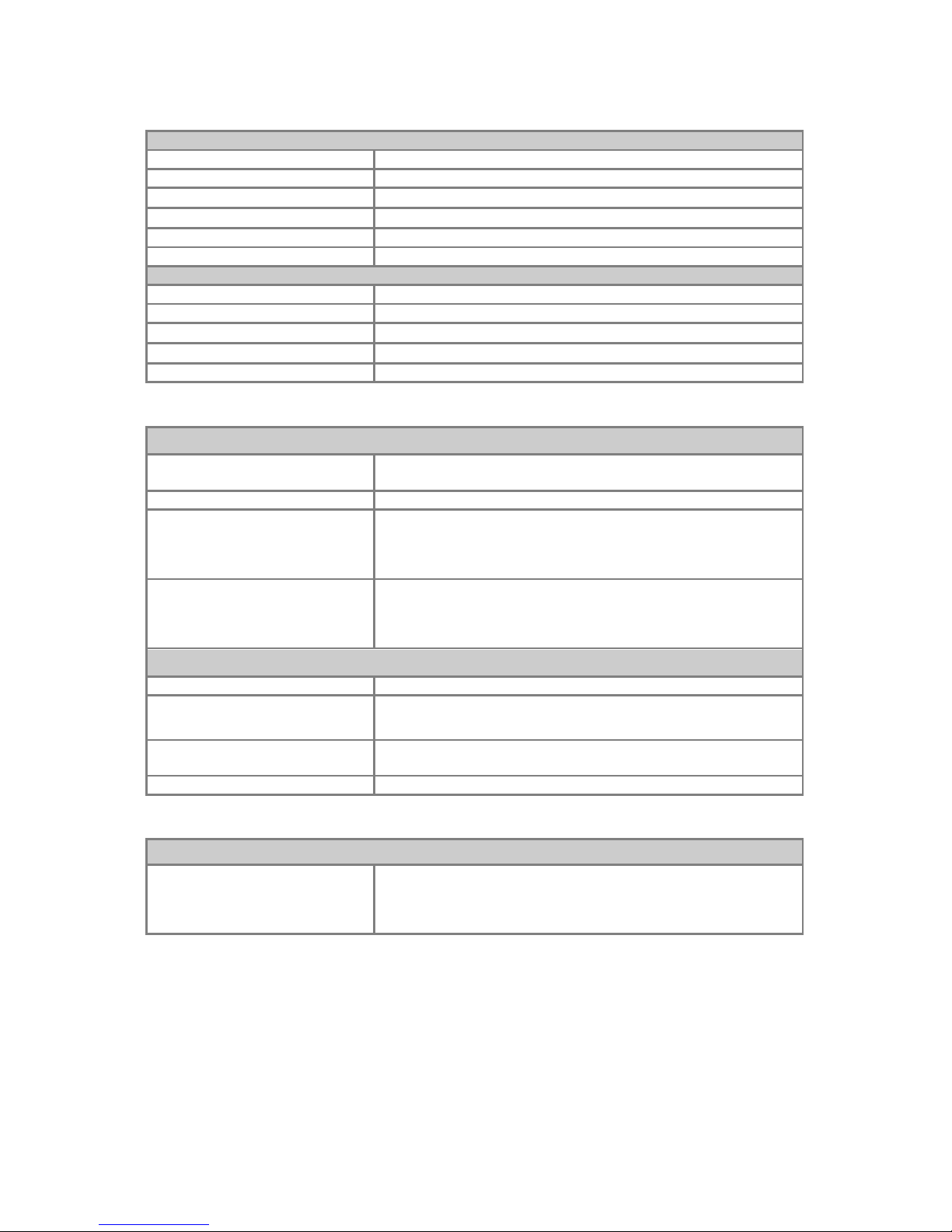

Hub Box Factory Connections

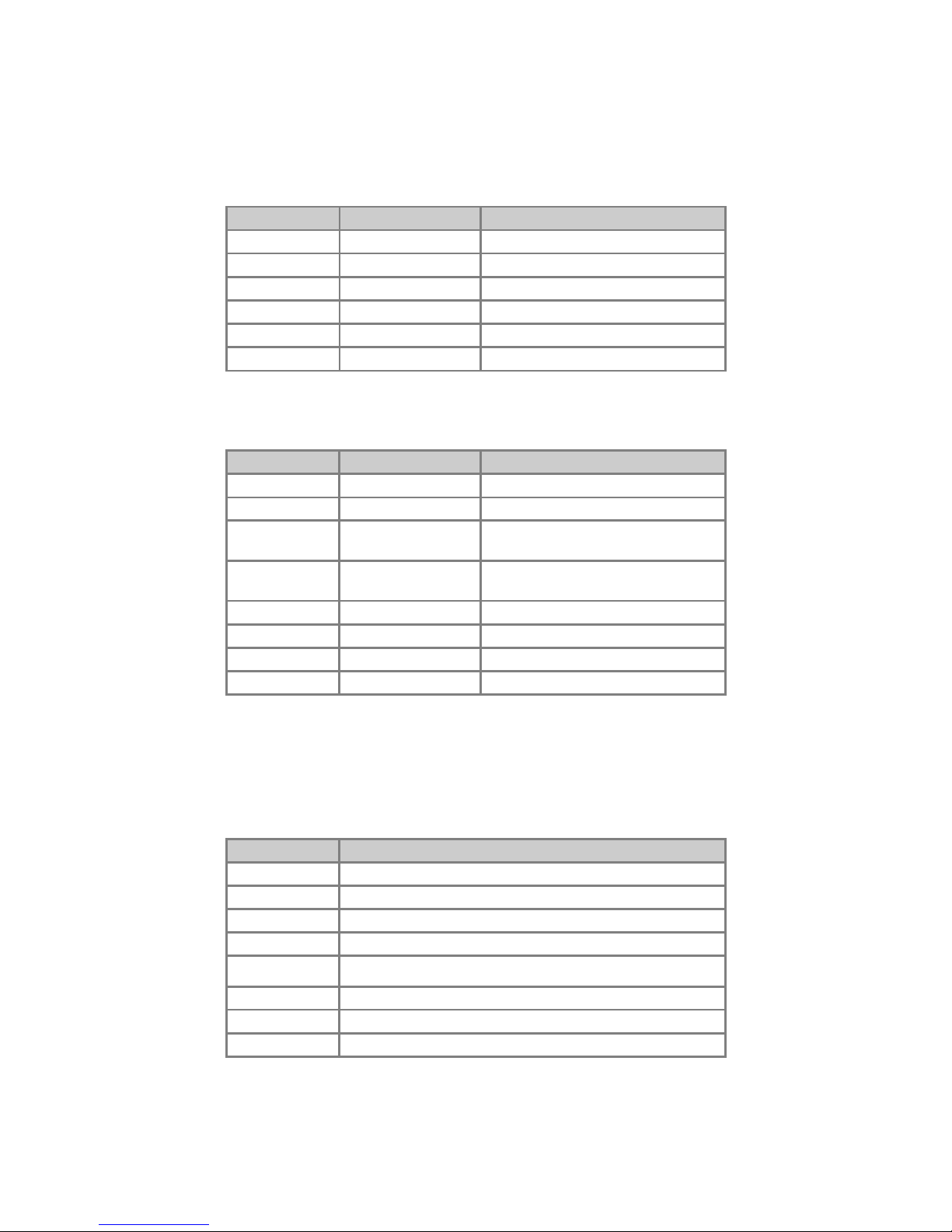

Hygroclip connections (6-way connector J1)

WindSonic anemometer connections (8-way connector J4)

Hub Box User Connections

Power and Communications (8-way connector, J5) all units

Connector J1

Wire Colour

Signal Name

1 - No Connection

2 Blue RXD from Hygroclip UART

3 Red TXD to Hygroclip UART

4 Yellow Analogue 0V (Not Used)

5 Grey Supply/Signal 0V

6 Green Supply +ve (+3.3V DC)

Connector J4

Wire Colour

Signal Name

1 - No Connection

2 - No Connection

3

Blue

RS232 TX+ Anemometer Output to

Hub

4

White

RS232 RX+ Hub Output to

Anemometer

5 Green Signal 0v

6 Yellow Supply 0v

7 - No Connection

8 Red Supply +ve (4.5v to 30V dc)

Connector J5

Signal Name

1 SDI-12 TX/RX

2 Signal 0V

3

RS232 TX

-

, (or RS422/RS485 TX

-

) HUB to user

4

RS232 RX

-

, (or RS422 RX

-

) User to HUB

5

RS422 RX+, User to HUB

6 RS422/RS485 TX+, HUB to User

7

Supply 0v

8 Supply

+ve (4.5v to 30v dc)

Page 18

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 18 Issue 1

Doc. No. 1723-PS-0022 October 2018

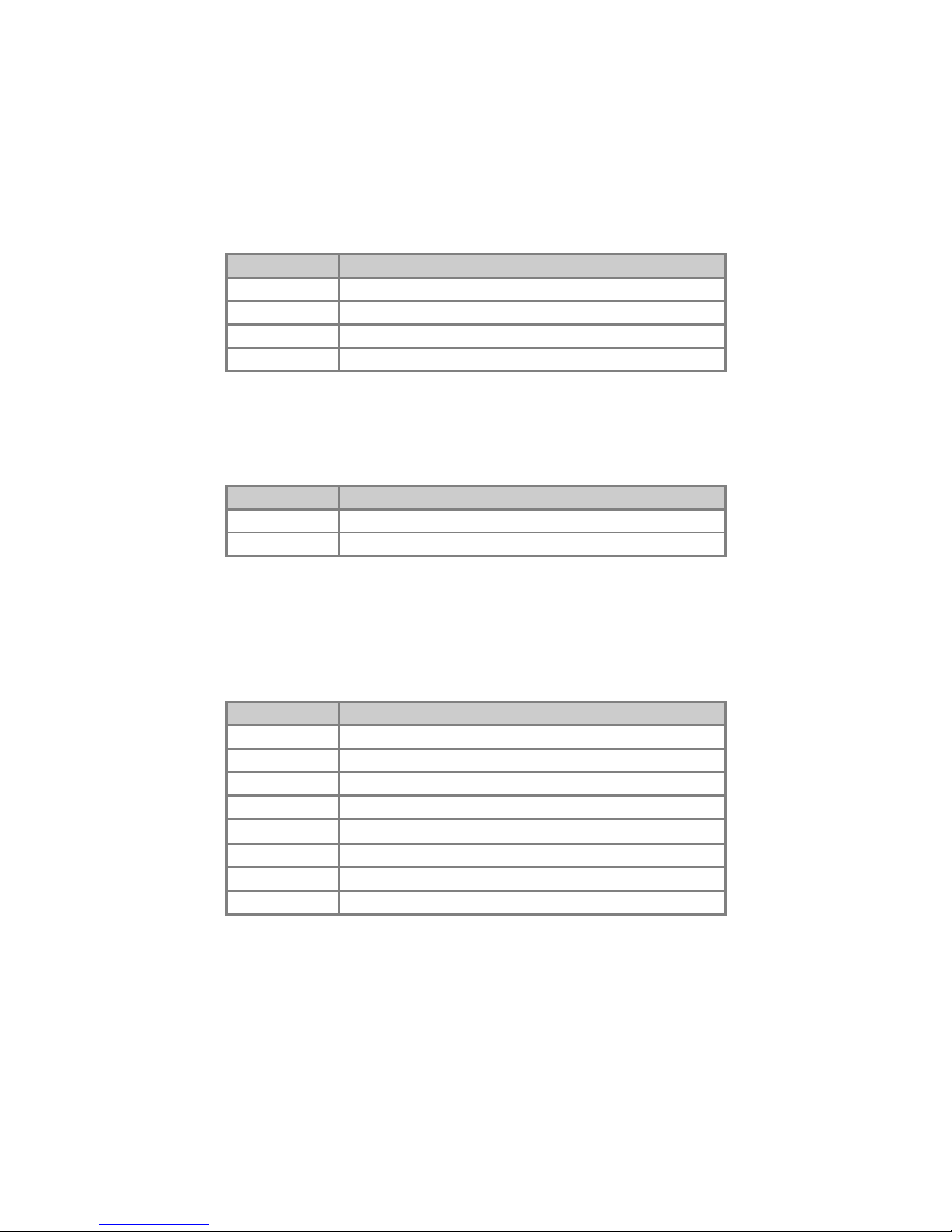

MetPak Pro PRT Sensor (4-way connector, J7)

MetPak RG and MetPak Pro Digital Switch Input, DIG1 (2-way connector, J8)

MetPak Pro Analogue Sensors Input, AN1 and AN2 (8-way connector, J9)

Connector J7

Signal Name

1 PWR (PRT Power Supply +ve)

2 PRT +

3 PRT 4 GND (PRT Power Supply Ground)

Connector J8

Signal Name

2 DIG1 (Digital Switch Contact Input)

1 GND (Ground)

Connector J9

Signal Name

1 VI 1 (Voltage Input 1)

2 GND (Voltage Input 1 Ground)

3 VI 2 (Voltage Input 2)

4 GND (Voltage Input 2 Ground)

5

II PWR (Current Supply for Analogue Input 1)

6 II 1 (Analogue Input 1)

7 II PWR (current Supply for Analogue Input 2)

8 II 2 (Analogue Input 2)

Page 19

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 19 Issue 1

Doc. No. 1723-PS-0022 October 2018

4.9. Connecting to a PC using RS232 (Default setting)

1. MetPak Range default factory comms setting is RS232.

2. The recommended cable length for reliable operation is limited to 6.5m (20ft).

3. For longer cable runs, we recommend use of RS422 output.

4.10. Connecting to a PC using RS422 (Not a Default Setting)

1. MetPak Range default factory comms setting is RS232.

2. To use the MetPak Range with RS422 comms use MetSet to change the COMMS

Interface setting to RS422.

Page 20

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 20 Issue 1

Doc. No. 1723-PS-0022 October 2018

4.11. Using RS485 (2 wire point to point only, not a default setting.

1. MetPak Range default factory comms setting is RS232.

2. To use the MetPak Range with RS485 2 wire point to point communication use MetSet to

change the COMMS Interface setting to RS485P 2W.

3. Use MetSet to change the Message setting from CONT (Continuous) to POLL, the node

address letter may be changed if required.

4. Note that it is not possible to network other devices on this 2-wire RS485 link unless the

unit has been set for Modbus operation and application.

4.12. Using SDI-12 (2 wire network) not a default setting.

1. MetPak Range default factory comms setting is RS232.

2. Use MetSet to change the COMMS Interface setting to SDI 12.

Page 21

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 21 Issue 1

Doc. No. 1723-PS-0022 October 2018

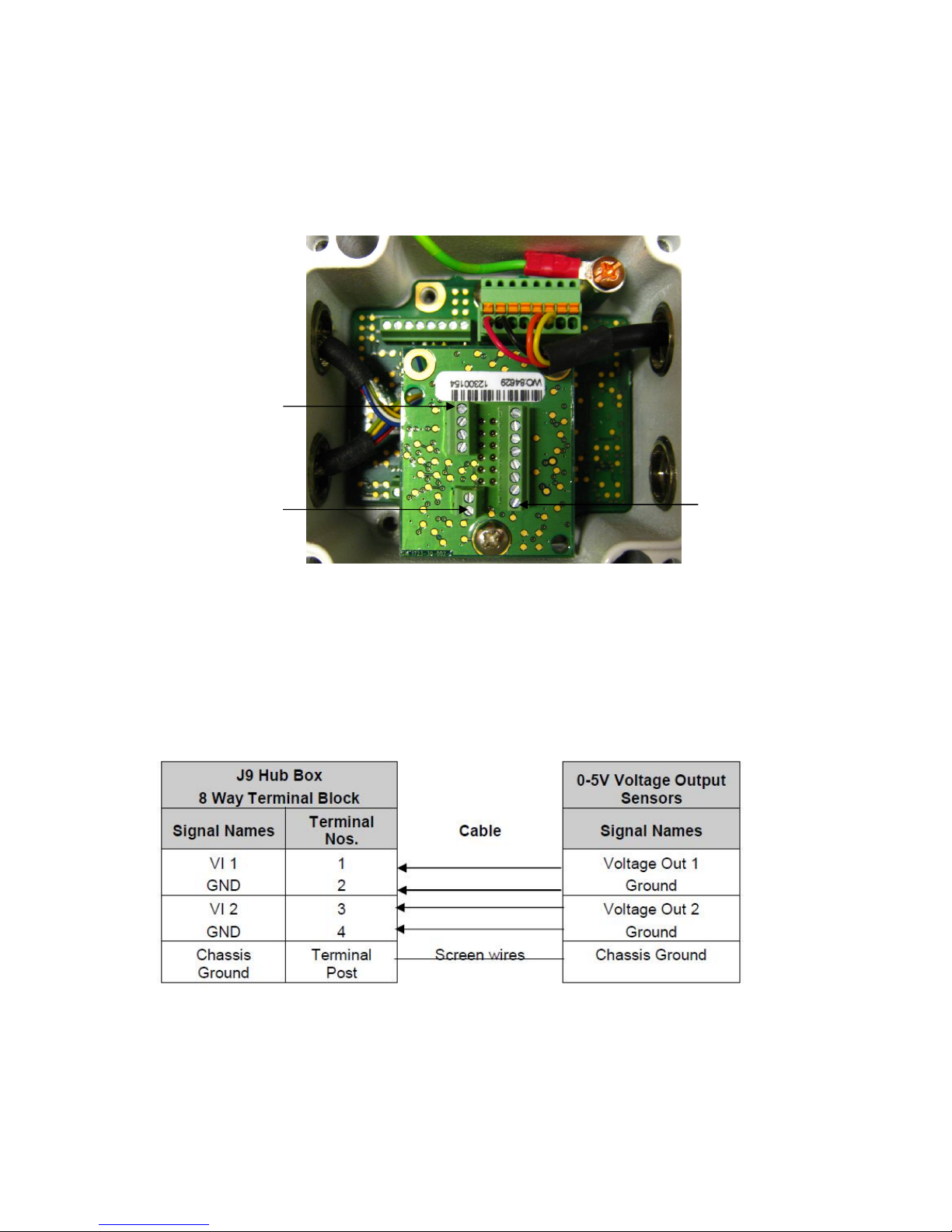

J9 Terminal 1

(AN1 and AN2)

4.13. Analogue, Digital and PRT Input Connections

NOTE:

MetPak - This section is Not Applicable.

MetPak RG - Digital input connection applicable only.

MetPak Pro - Analogue, Digital and PRT Input connections all applicable.

Analogue 0-5 volt Input Connections AN1 and AN2

This is not a default setting; ensure the MetPak Pro has been configured for this input requirement

before wiring sensors to the MetPak Pro.

(See picture above for Power and Communication Connections).

J8 Terminal 1

(DIG 1)

J7 Terminal 1

(PRT)

Page 22

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 22 Issue 1

Doc. No. 1723-PS-0022 October 2018

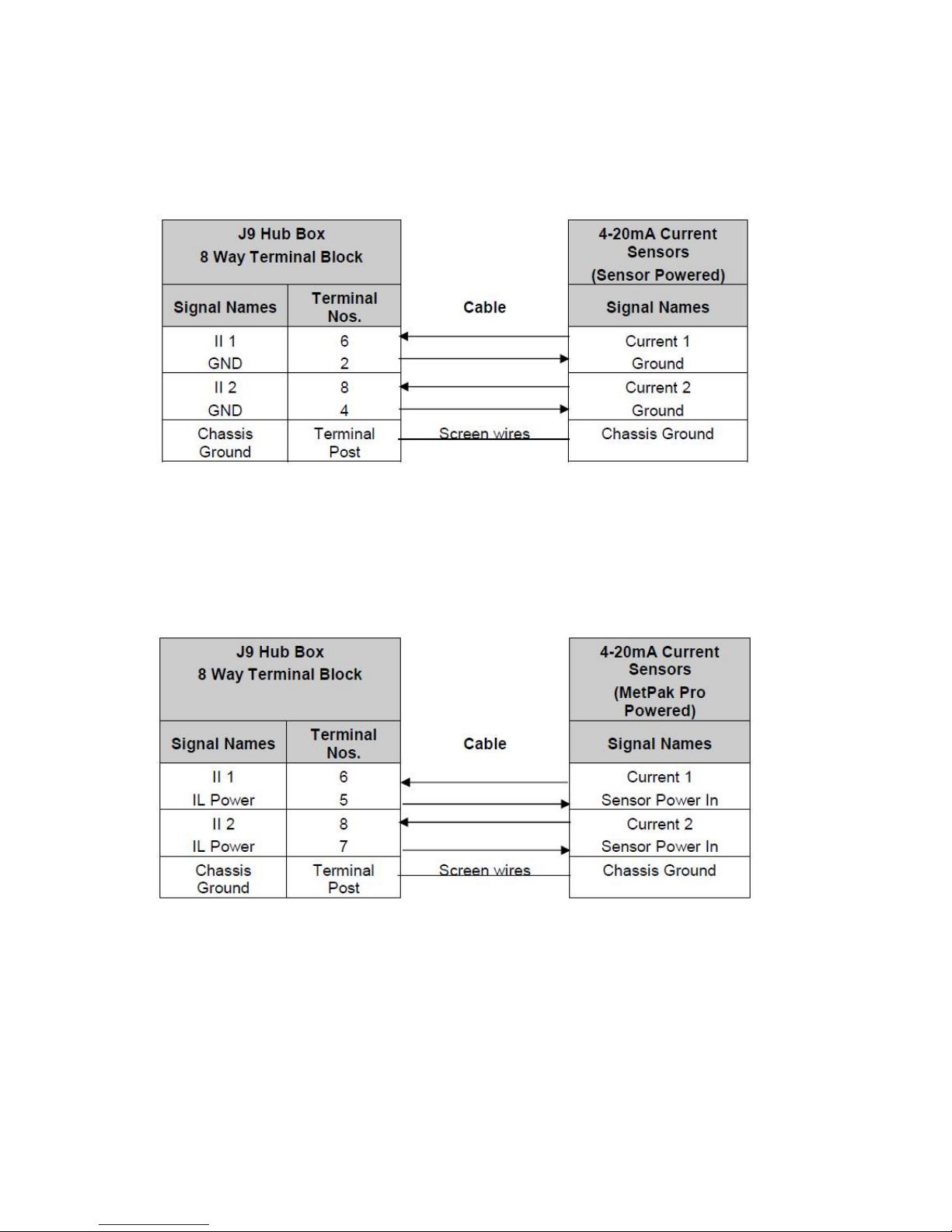

Analogue 4-20mA Input Connections (Sensor Powered) AN1 and AN2

This is not a default setting; ensure the MetPak Pro has been configured for this input requirement

before wiring sensors to the MetPak Pro.

See picture above for Power and Communication Connections.

Analogue 4-20mA Input Connections (MetPak Pro Powered) AN1 and AN2

This is not a default setting; ensure the MetPak Pro has been configured for this input requirement

before wiring sensors to the MetPak Pro.

See picture above for Power and Communication Connections.

NOTE: If the input current drops below 4mA, an X will be shown in the data string instead of

a valid reading. If the current rises above 20mA, an E will be shown in the data string

instead of a valid reading.

Page 23

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 23 Issue 1

Doc. No. 1723-PS-0022 October 2018

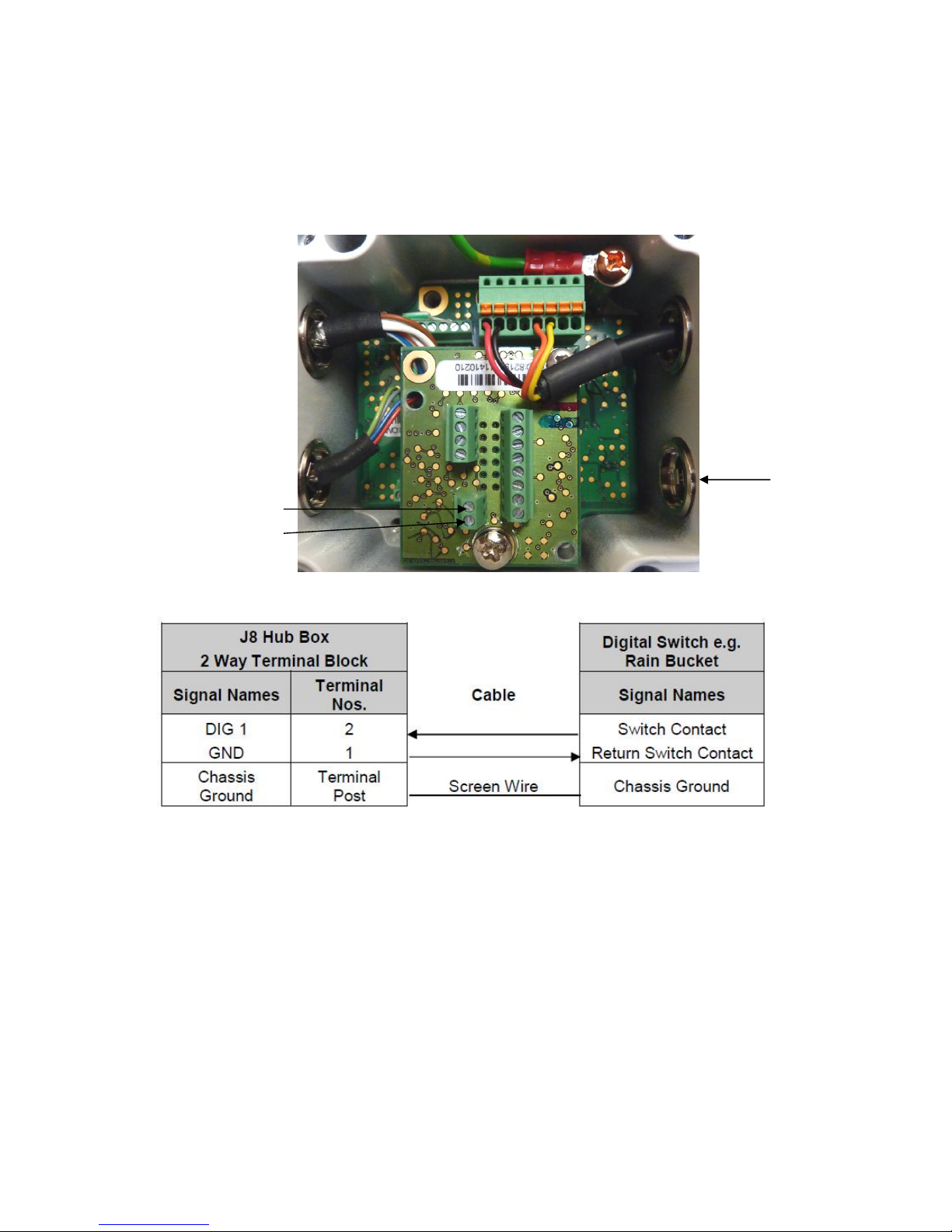

Digital Switch Connection (Rain Gauge) DIG1

Ensure the MetPak RG/MetPak Pro has been configured for this input requirement before wiring

sensors to the Unit.

Digital Rain Gauge Connections

To connect the MetPak RG ARG100 Rain Gauge 6 Metre lead to the Hub Box or another rain

gauge wiring.

1. Open the MetPak hub box by unfastening the four screws.

2. Locate connector J8.

3. Pass the cable through one of the gland nuts (see Note below).

4. Connect the cable to connections as detailed above.

5. Attach the cable’s screen wire to a terminal post.

6. After connection, securely tighten the gland nut to prevent moisture ingress.

7. Re-fit the hub box lid.

NOTE: The MetPak Range Hub Box cable glands contain spring loaded metal leaves that are

designed to make a ground contact with cables that have an overall braid screen. Care is therefore

required when inserting and removing cables through the glands to prevent damage to the metal

leaves.

J8 Terminal 2

J8 Terminal 1

Rain Gauge

Cable Entry

Gland.

Rain Gauge

Connections

Page 24

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 24 Issue 1

Doc. No. 1723-PS-0022 October 2018

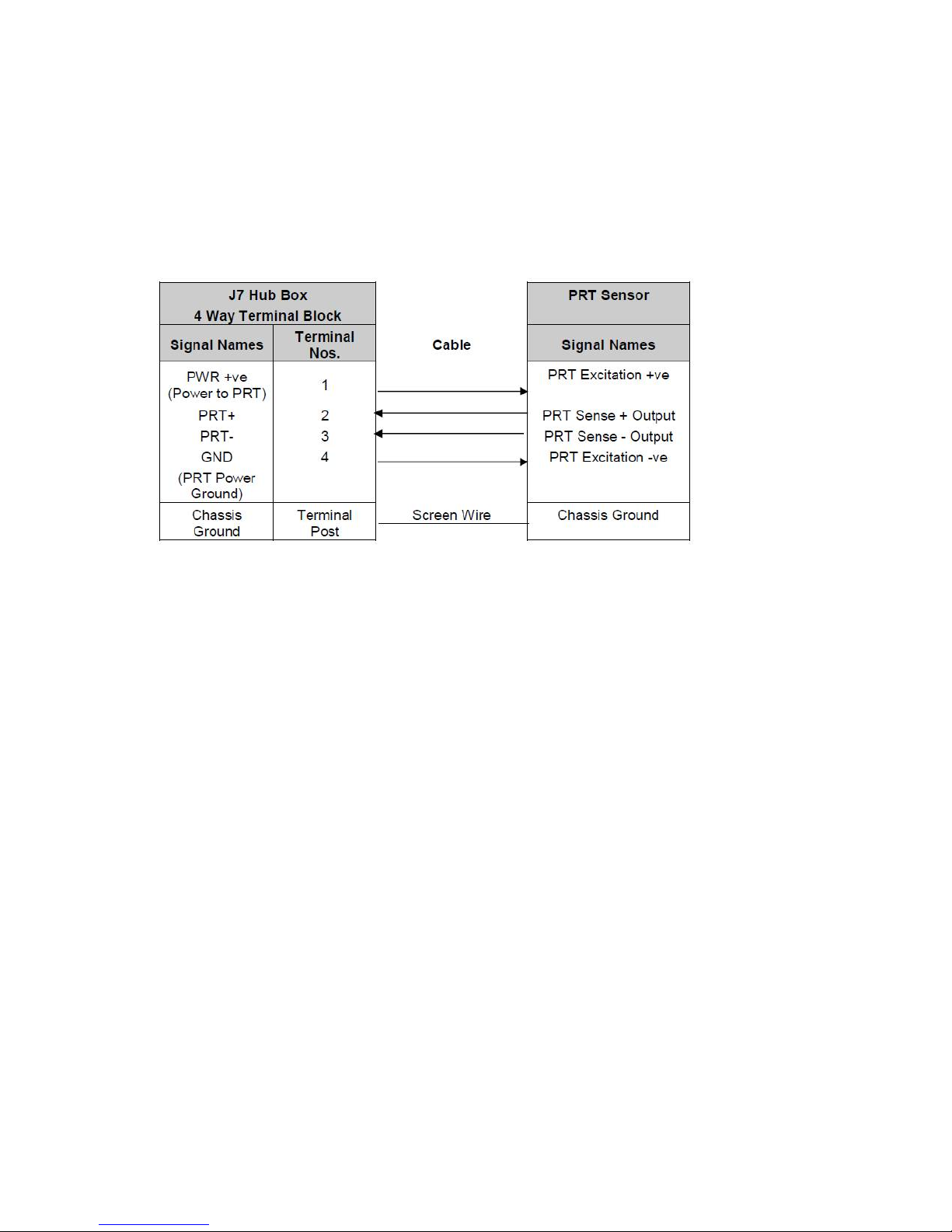

Platinum Resistance Thermometer (PRT) Input

This is not a default setting; ensure the MetPak Pro has been configured for this input requirement

before wiring sensors to the MetPak Pro.

See the previous picture for Power and Communication Connections.

Page 25

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 25 Issue 1

Doc. No. 1723-PS-0022 October 2018

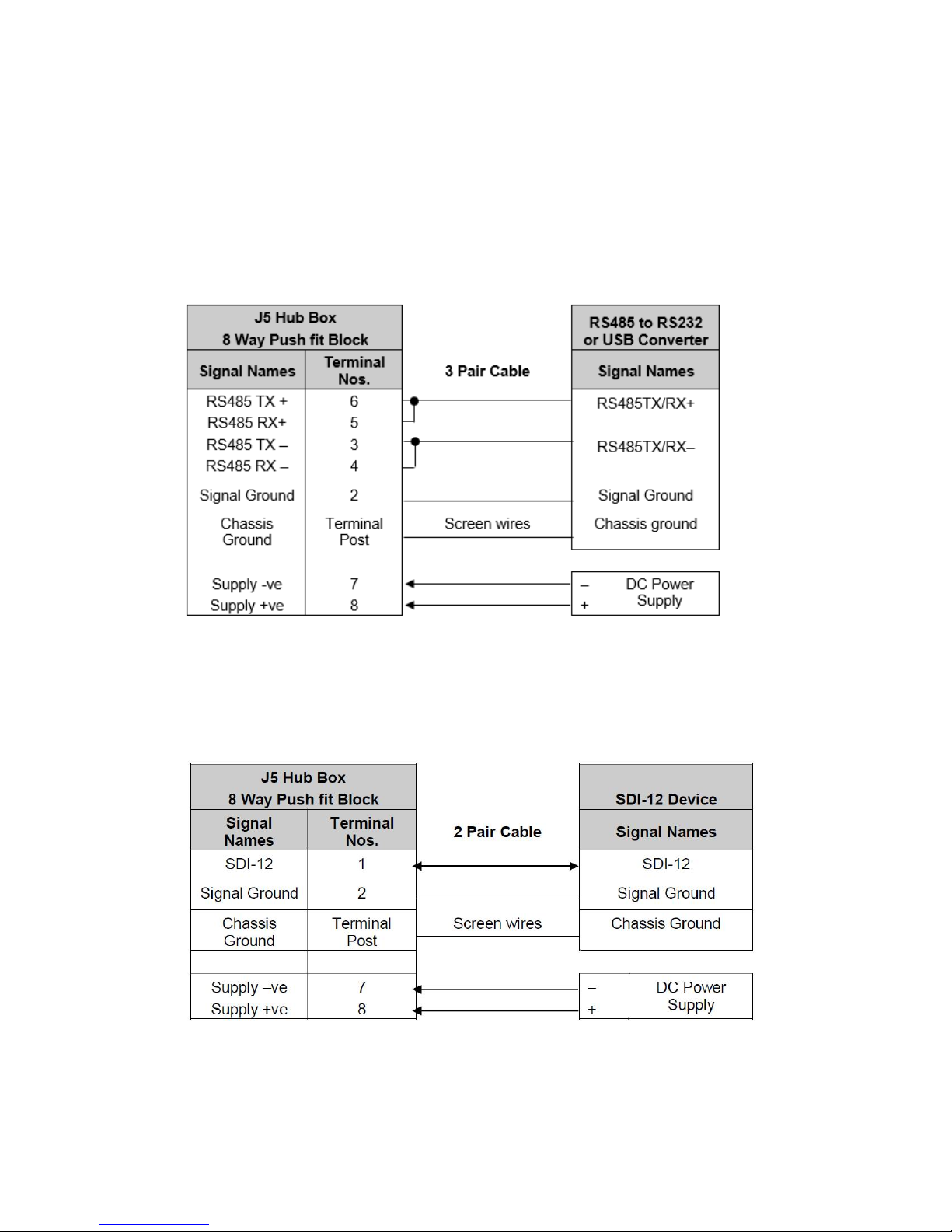

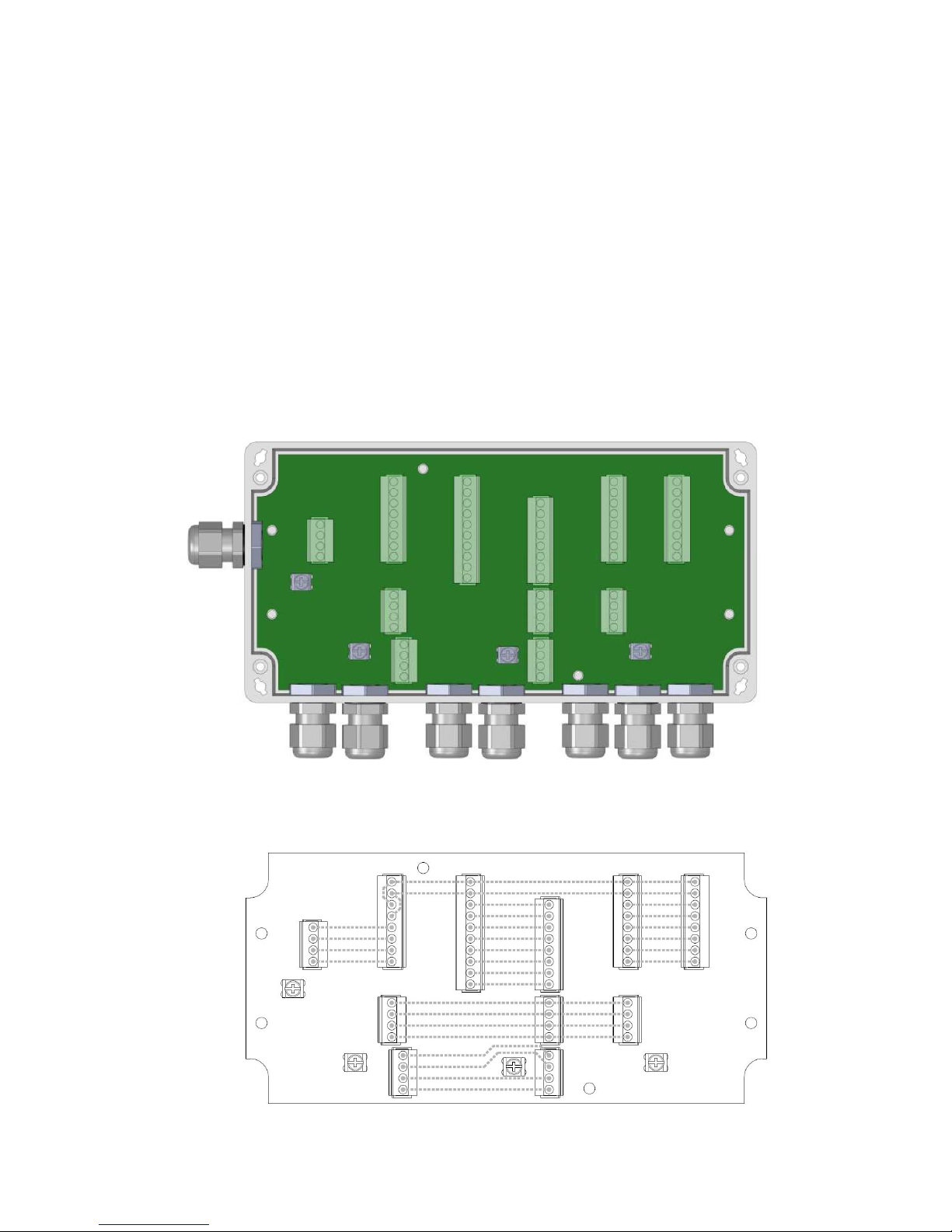

4.14. MetPak Pro Junction Box (Part 1723-PK-021)

As part of a MetPak Pro system, Gill Instruments can provide a Junction Box containing a pcb with

removable terminal connectors and optional mounting hardware to provide a means of connecting

external sensor and MetPak Pro wiring at a convenient common point.

Alternatively the pcb with removable terminal connectors can be supplied as a standalone item for

mounting in a customer supplied box.

Junction Box parts if required are:

1723-PK-201 Junction Box with internal terminating pcb.

1723-PK-202 Terminating pcb (to mount in customer box).

1723-PK-204 Pack of 4 feet for Panel Mounting the Junction Box.

1723-PK-203 Pack of 4 brackets for Pole Mounting the Junction Box.

Junction Box 1723-PK-201 (containing Terminating pcb 1723-PK-202)

Junction Box terminating pcb circuit track layout

Page 26

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 26 Issue 1

Doc. No. 1723-PS-0022 October 2018

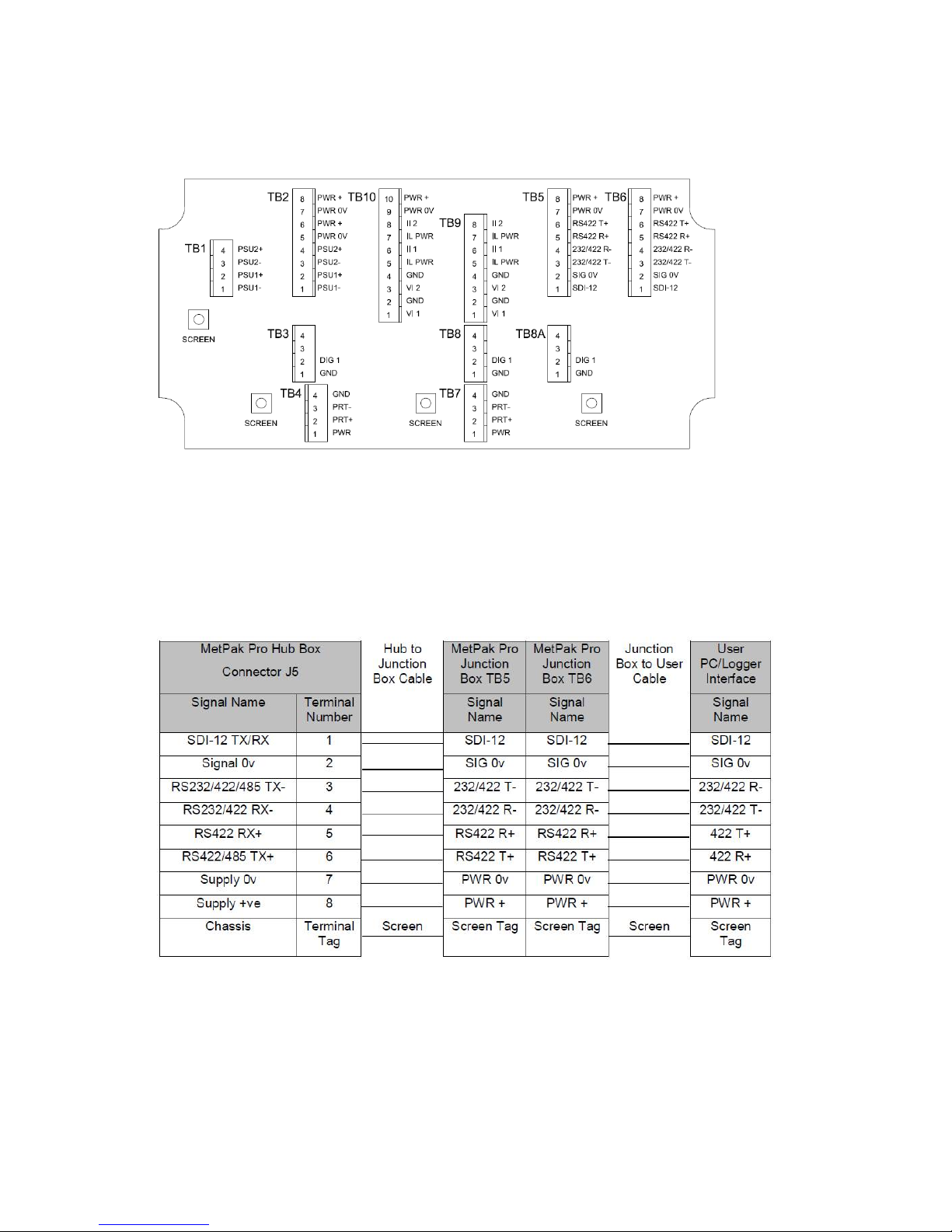

Junction Box Terminal Block Connections

Note that the Junction box glands will accept cables with an outer diameter between 3-10mm. If a

smaller diameter cable is to be used bulk out with heat shrink or suitable sleeve to ensure the

gland can secure the cable and provide an environmental seal.

Communication System Connections

Only connect cables that meet the required data interface requirement (e.g. RS232 etc.).

Page 27

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 27 Issue 1

Doc. No. 1723-PS-0022 October 2018

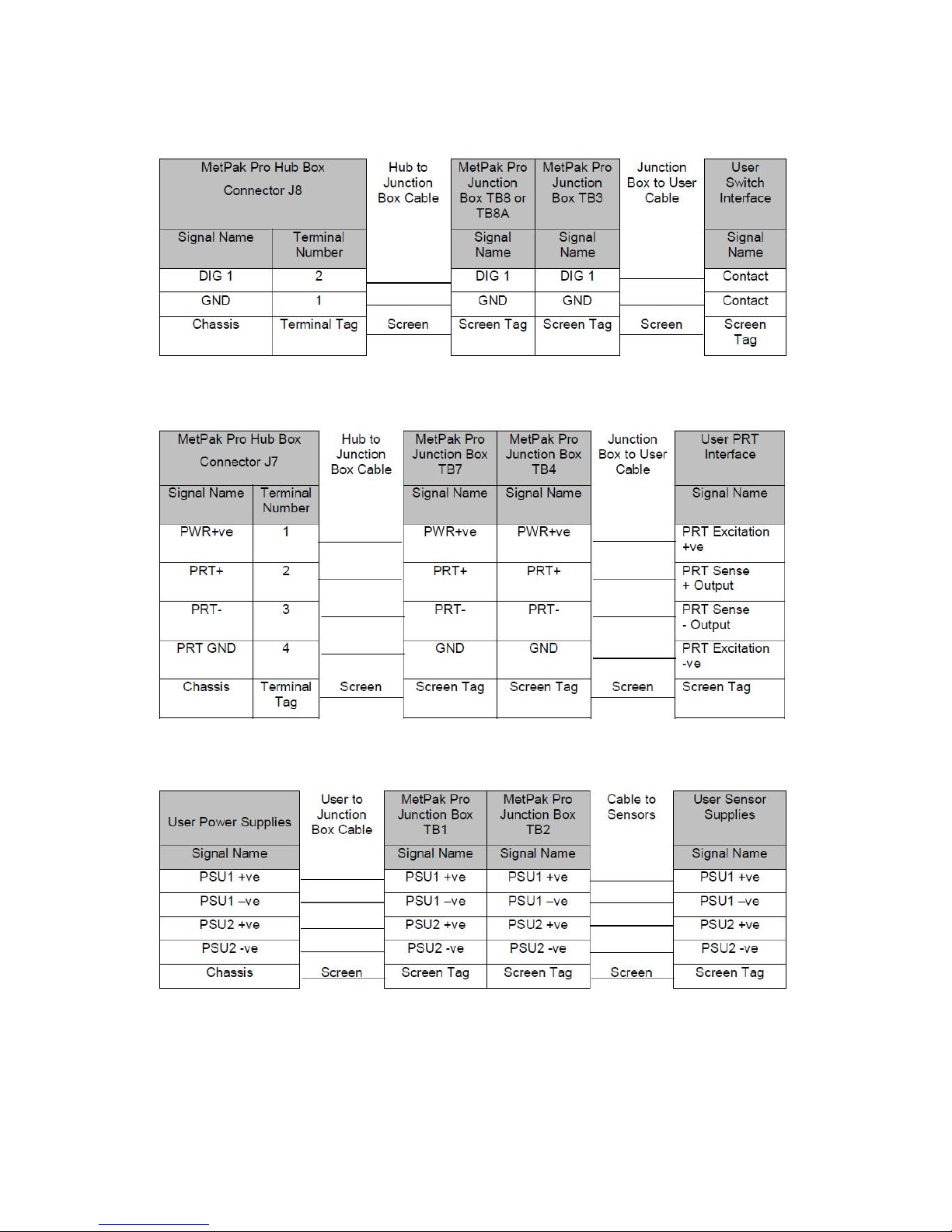

4-20mA Current Sensor System Connections (Sensor Powered)

4-20mA Current Sensor System Connections (MetPak Pro Powered)

0-5 Volt Voltage Sensor System Connections

Page 28

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 28 Issue 1

Doc. No. 1723-PS-0022 October 2018

Digital Switch Sensor System Connections

PRT System Connections

External Power Supply Connections

Page 29

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 29 Issue 1

Doc. No. 1723-PS-0022 October 2018

4.15. Set up requirements

4.15.1. Host System:

Note: The default delivery output communication (COMMS) setting of MetPak units is RS232.

Use an RS232 to USB converter e.g. Gill part 1957-10-065, 1.8M configuration cable fitted with 8

way Hub Box connector and with integral 5v USB connector power for MetPak (see Para 4.8).

If an install driver is required for this cable it can be obtained from the supplied CD or downloaded

from:-

http://www.ftdichip.com/FTDrivers.htm

Or

Use an RS232 to USB adaptor or equivalent for example EasySynch part ES-U-1001-A (if not

using Gill part 1957-10-065) or connect directly to an RS232 COM port.

Use a PC running Windows software up to and including Windows 10 and with an internal or

external interface compatible with the output from the MetPak.

Use a Power Supply, 5V to 30Vdc at 200mA if not using the Gill Instruments Configuration cable.

Use 3 pair cable e.g. Belden 9503 (if not using Gill Part 1723-10-051), length as required if not

using the Gill Instruments Configuration cable.

4.15.2. Software:

Gill MetSet Software used as a configuration Tool (supplied on MetPak CD), will run on PC’s with

up to and including Windows 10 and can be downloaded free from:-

http://www.gillinstruments.com/main/software.html.

4.15.3. Bench system test

The CD supplied in the MetPak box contains a copy of the manual and relevant software to check

and set up the MetPak unit.

Prior to physically mounting the MetPak in its final location, we strongly recommend that a bench

system test be carried out to confirm the system is configured correctly, is fully functional and

electrically compatible with the selected host system and cabling (preferably utilising the final cable

length). The required data format, units, output rate, and other options should also all be

configured at this stage.

Connect the MetPak to a PC wired as per RS232 connections in Para 4.9.

Alternatively use a Gill configuration cable part 1957-10-065 with a 9 way connector fitted on one

end and USB converter at the other end if required to simplify set up between MetPak and a PC.

Open Gill MetSet software provided to read, check settings or change settings as per para 6.2.

Use MetSet View Output button to check the data string and confirm that the Status field reads 00.

4.16. Packaging

Whilst the MetPak is being moved to its installation site, the unit should be kept in its packaging.

Retain the packaging for use if the unit has to be moved or returned to Gill Instruments.

Page 30

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 30 Issue 1

Doc. No. 1723-PS-0022 October 2018

5. INSTALLATION

General Installation Guidelines are as follows:-

5.1. Example Installation Guidelines

5.1.1. Non Heated Wind Sensor System

MetPak Pro System Connections - A Typical MetPak Pro system might look like the following

illustration.

Page 31

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 31 Issue 1

Doc. No. 1723-PS-0022 October 2018

5.2. Interference

As with any sophisticated electronics, good engineering practice should be followed to ensure

correct operation.

Always check the installation to ensure the MetPak is not affected by other equipment operating

locally, which may not conform to current standards, e.g. radio/radar transmitters, boat engines,

generators etc.

Do NOT mount the MetPak in close proximity of high-powered radar or radio transmitters. A site

survey may be required if there is any doubt about the strength of external electrical noise.

Guidelines –

Avoid mounting in the plane of any radar scanner – a vertical separation of at least 2m should be

achieved.

Radio transmitting antennas, the following minimum separations (all round) are suggested

VHF IMM – 1m

MF/HF – 5m

Satcom – 5m (avoid likely lines of sight)

Ensure the product is correctly earthed in accordance with this manual.

Use cables recommended by Gill, keeping the length below the maximum allowed. Where the

cables are cut and re-connected (junction boxes, plugs and sockets) the cable screen integrity

must be maintained, to prevent the EMC performance being compromised.

Earth loops should not be created – earth the system in accordance with the installation

guidelines.

Ensure the power supply operates to the MetPak specification at all times.

5.3. Wind Sensor Installation

Avoid turbulence caused by surrounding structures that will affect the accuracy of the MetPak such

as trees, masts and buildings.

The World Meteorological Organisation makes the following recommendation:

The standard exposure of wind instruments over level open terrain is 10m above the ground.

Open terrain is defined as an area where the distance between the sensor and any

obstruction is at least 10 times the height of the obstruction.

If mounting on a building then theoretically the sensor should be mounted at a height of 1.5

times the height of the building.

If the sensor is to be mounted on a mast boom, part way up a tower or mast, then the boom

should be at least twice as long as the minimum diameter or diagonal of the tower. The boom

should be positioned on the prevailing wind side of the tower.

It is important to ensure that the MetPak is mounted in a position clear of any structure, which may

obstruct the airflow or induce turbulence.

Mount MetPak so as to have a clear view of prevailing winds.

The MetPak anemometer should be set to point North (or to another known reference direction),

using the North Pointers, which are identified by two arrows, a coloured rectangle, and an

alignment notch to aid alignment (see the illustration in para 2.1.3).

Page 32

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 32 Issue 1

Doc. No. 1723-PS-0022 October 2018

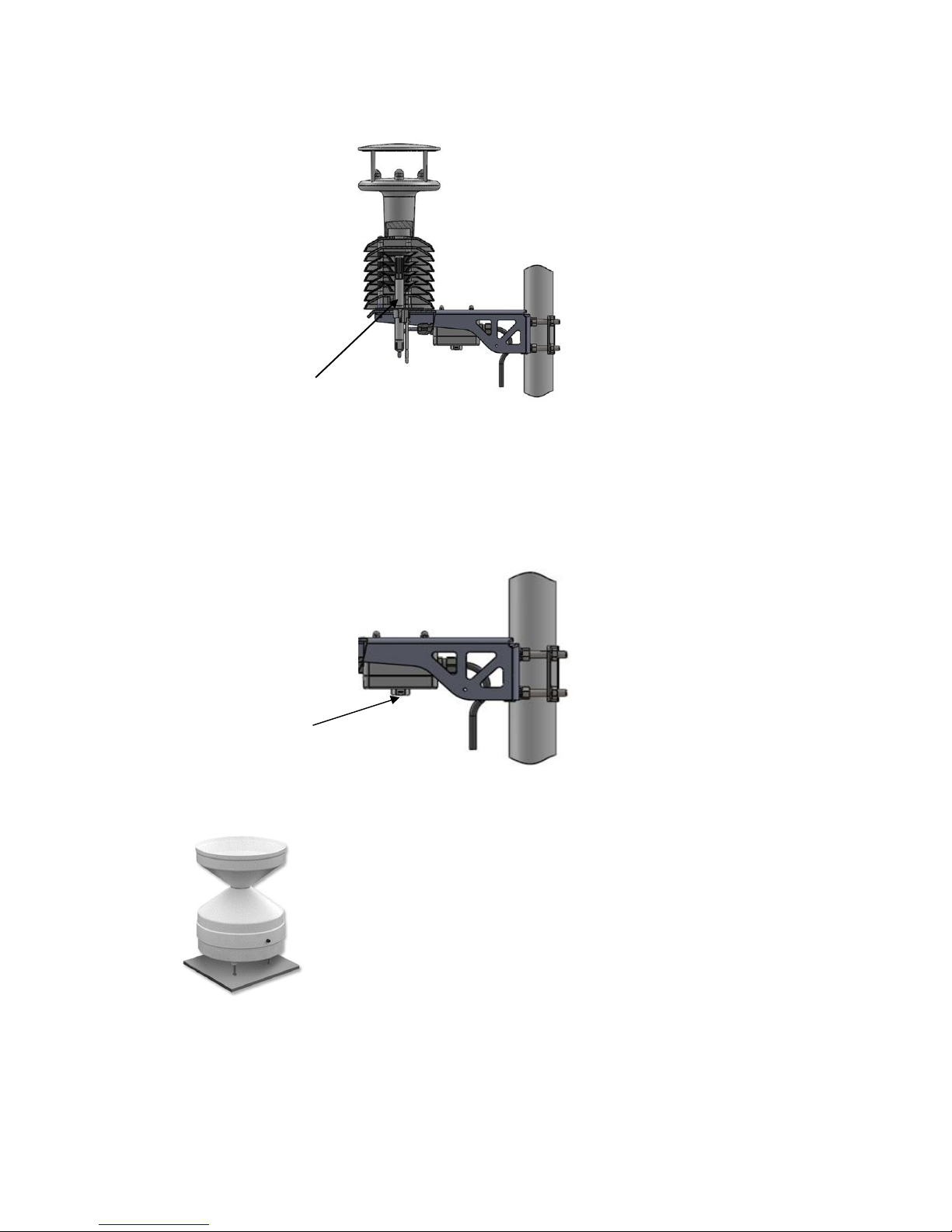

5.4. MetPak Range Mounting and Dimensions (in mm)

MetPak uses a mounting clamp suitable for attaching to a vertical pipe with a diameter of 3058mm. When mounting the MetPak, consider the position, orientation and alignment of the unit.

Note that the mounting pipe should first be degreased and when assembling the MetPak clamp

assembly the outer clamp nuts need to be tightened evenly to a torque figure of 3 Nm.

The moving plate part of the clamp needs to be reversed for poles below 38 mm diameter.

Mounting Bracket Assembly Exploded View

Mounting Bracket Assembled View

C Holes are 8.5mm diameter

Earthing Point for

supplied

screw/washer/tag

Page 33

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 33 Issue 1

Doc. No. 1723-PS-0022 October 2018

MetPak Units overall dimensions

Page 34

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 34 Issue 1

Doc. No. 1723-PS-0022 October 2018

5.5. MetPak Pro Junction Box Mounting (1723-PK-021)

The optional MetPak Pro Junction Box comes with two mounting arrangement options: Junction Box Pole Mount

Using Gill Instruments part 1723-PK-203 Pole Mount brackets set for Junction Box.

Page 35

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 35 Issue 1

Doc. No. 1723-PS-0022 October 2018

Junction Box Panel or Wall Mount

Using Gill Instruments part 1723-PK-204 Pack of 4 feet for Wall or Panel Mounting the Junction

Box.

5.6. Solar Installation

If a Solar Sensor is used with a MetPak Pro it should be mounted horizontally and as level as

possible.

A clear view of the sky is best for an optimal solar measurements. Mounting obstructions, tree

canopy, hills, mountains and tall buildings that obscure the view overhead or of the horizon can

impede solar readings.

If a solar sensor is incorporated with the MetPak then mount the unit as vertical as possible during

installation for optimal readings.

5.7. Rain Gauge Installation

The MetPak RG ARG100 rain gauge tipping bucket mechanism comes with a 6 metre lead and is

immobilised before shipping to prevent damage in transit.

To release the mechanism, remove the funnel from its base by unscrewing the three nylon

thumbscrews.

Remove the piece of foam from under the bucket mechanism. This foam may be saved and used

whenever the rain gauge is moved.

Panel/Wall Mounting

foot

Page 36

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 36 Issue 1

Doc. No. 1723-PS-0022 October 2018

ARG100 Rain Gauge Baseplate Mounting (Baseplate supplied)

Due to the low weight of the rain gauge (1kg approximately) it must be mounted securely, the use

of the Baseplate is recommended for this. However the gauge may be mounted via the three holes

in the base to a paving slab for example. It is suggested that rawlbolts are used for this purpose as

they provide a means of levelling the rain gauge.

Unscrew the 3 upper nylon thumb nuts and remove all the nylon spacers from the studs.

Lift off the tipping bucket base assembly to leave the metal baseplate and studs.

Fix the baseplate to level ground using the 4 pegs provided through the 4 corner holes. The

baseplate may be mounted to hard surfaces like concrete by replacing the 4 supplied pegs with

screws and rawlplugs.

For temporary mounting on hard surfaces use some bricks or heavy weights on the four corners of

the baseplate (the height of the weights should be kept as low as possible to cause the minimum

interference with the aerodynamics of the rain gauge).

Refit the tipping bucket base assembly.

Refit the nylon spacers over the 3 studs.

Loosely screw on the 3 nylon thumb nuts.

Leveling the Base Assembly

Upon completion of the above adjust the 3 leveling thumb nuts under the tipping bucket to align

the spirit level bubble to within the centre circle.

Now tighten the upper 3 thumb nuts ensuring that the spirit level bubble remains within the centre

circle.

NOTES:

Ensure that the Foam insert under the tipping bucket is removed before re-fitting the funnel.

No two rain gauge designs are ever likely to produce identical results, and identical rain gauge can

give slightly different catches even when sited close to each other.

Customers with 2 or more sets of equipment must not swap around rain gauges with MetPaks

without using MetSet to change the calibration figure.

Nylon Spacers

Spirit Level

Corner Hole

Upper Nylon

Thumb Nut

Tipping Bucket

Page 37

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 37 Issue 1

Doc. No. 1723-PS-0022 October 2018

Rain Gauge Dimensions

Rain Gauge Base plate Dimensions

Page 38

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 38 Issue 1

Doc. No. 1723-PS-0022 October 2018

6. CONFIGURING WITH METSET

MetPaks can be configured using Gill Instruments MetSet Software which is loaded on the CD

supplied with MetPak.

MetSet software can run on PC’s running up to and including Windows 10 and can also be

downloaded from the Gill Website: http://www.gillinstruments.com/main/software.html.

6.1. MetPak Default Configurations

MetPak Factory Default Data String

NODE DIR SPEED PRESS RH TEMP DEWPOINT VOLT STATUS.

Q,170,000.08,1019.5,035.0,+024.7,+008.3,+04.9,00, 55

Where

STX

Q Node Letter

170 Wind Direction

000.08 Wind Speed

1019.5 Pressure

035.0 Relative Humidity

+024.7 Temperature

+008.3 Dewpoint

+04.9 Supply Voltage

00 Status

ETX

55 Checksum

NOTES:

<STX> is the Start of String character (ASCII value 2).

<ETX> is the End of String character (ASCII value 3).

Checksum, the 2 digit Hex Checksum sum figure is calculated from the Exclusive OR of the bytes

between (and not including) the STX and ETX characters

MetSet Reading MetPak Default Settings

Setting

Function

Setting

Function

Comms Levels

RS232

Sensor WindSpeed

On

Baud Rate

19200

Wind Speed Units

MS (Metres/Second)

Data Connection

Dat

a Bits 8, Parity None, Stop

Bits 1, Flow Control None.

Temperature Sensor

On

Node ID

Q

Temperature Units

C (Degrees Celsius)

Output rate

1Hz Dewpoint Sensor

On

Message Mode

Continuous

Dewpoint Units

C (Degrees Celsius)

ASCII Set Up

Carriage return and

line feed,

Echo on

Pressure Sensor

On

North Alignment

0

Pressure Units

Hecto Pascals

Humidity Sensor

On

Status Message Output

On

Humidity Units

%

Report Message Output

On

Report Format

Node, Polar (Wind

Direction/Wind Speed),

Pressure, Humidity,

Temperature,

Dewpoint, Volts,

Status, Checksum.

Units Message Output

On

Inputs Message Output

On Output Sentence

Comma Separated Variable

Page 39

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 39 Issue 1

Doc. No. 1723-PS-0022 October 2018

MetPak RG Factory Default Data String:

NODE DIR SPEED PRESS RH TEMP DEWPOINT DIG1 VOLT STATUS.

Q,014,000.06,1011.2,042.1,+023.0,+009.4,0000.000,+04.9,00, 40

Where

STX

Q Node Letter

014 Wind Direction

000.06 Wind Speed

1011.2 Pressure

042.1 Relative Humidity

+023.0 Temperature

+009.4 Dewpoint

0000.000 Dig1 (Tipping Bucket reading)

+04.9 Supply Voltage

00 Status

ETX

40 Checksum

NOTES:

<STX> is the Start of String character (ASCII value 2).

<ETX> is the End of String character (ASCII value 3).

Checksum, the 2 digit Hex Checksum sum figure is calculated from the Exclusive OR of the bytes

between (and not including) the STX and ETX characters

MetSet Reading MetPak RG Default Settings

Setting

Function

Setting

Function

Comms Levels

RS232

Sensor WindSpeed

On

Baud Rate

19200

Wind Speed Units

MS (Metres/Second)

Data Connection

Data Bit

s 8, Parity None, Stop

Bits 1, Flow Control None.

Temperature Sensor

On

Node ID

Q

Temperature Units

C (Degrees Celsius)

Output rate

1Hz Dewpoint Sensor

On

Message Mode

Continuous

Dewpoint Units

C (Degrees Celsius)

ASCII Set Up

Carriage return and line

feed,

Echo on

Pressure Sensor

On

North Alignment

0

Pressure Units

Hecto Pascals

Humidity Sensor

On

Status Message Output

On

Humidity Units

%

Report Message Output

On

Report Format

Node, Polar (Wind

Direction/Wind Speed),

Pressure, Humidity,

Temperature,

Dewpoint, DIG1, Volts,

Status, Checksum.

Units Message Output

On Inputs Message Output

On Output Sentence

Comma Separated Variable

DIG1 Sensor Type

On

DIG1 Digital Count

10.000

DIG1

Substitute Name

- DIG1 Units

mm

Page 40

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 40 Issue 1

Doc. No. 1723-PS-0022 October 2018

MetPak Pro Factory Default Data String:

NODE, DIR,SPEED,PRESS, RH, TEMP, DEWPOINT,PRT,AN1,AN2,DIG1,VOLT, STATUS

Q,014,000.06,1011.2,042.1,+023.0,+009.4,,#,#,#,+04.9,00, 40

Where:-

STX

Q Node letter

014 Wind direction

000.06 Wind speed

1011.2 Pressure

042.1 Humidity

+23.0 Temperature

+009.4 Dewpoint

,, PRT (PRT not configured).

# Analogue Input 1 (not configured)

# Analogue Input 2 (not configured)

# Digital Input 1(not configured)

+04.9 Supply voltage

00 Status code

ETX

40 Checksum

NOTES:

<STX> is the Start of String character (ASCII value 2).

,, is the default output for PRT until configured by MetSet.

# is the default output for Analogue Inputs 1 & 2 and Digital Input 1 until configured by MetSet.

<ETX> is the End of String character (ASCII value 3).

Checksum, the 2 digit Hex Checksum sum figure is calculated from the Exclusive OR of the bytes

between (and not including) the STX and ETX characters.

Example configured string is:Q,249,000.01,1017.3,049.2,+021.4,+010.3,+040.45,+000.06,+000.04,0000.000,+11.6,00,7C

Page 41

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 41 Issue 1

Doc. No. 1723-PS-0022 October 2018

MetSet reading MetPak Pro Default Settings

Setting

Function

Comms Levels

RS232

Baud Rate

19200

Data Connection

Data Bits 8, Parity None, Stop Bits 1, Flow Control None.

Node ID

Q

Output rate

1Hz Message Mode

Continuous

ASCII Set Up

Carriage return and line feed, Echo on

North Alignment

0

Sensor WindSpeed

On

Wind Speed Units

MS (Metres/Second)

Temperature Sensor

On

Temperature Units

C (Degrees Celsius)

Dewpoint Sensor

On

Dewpoint Units

C (Degrees Celsius

) Pressure Sensor

On

Pressure Units

Hecto Pascals

Humidity Sensor

On

Humidity Units

%

Report Format

Node, Polar (Wind Direction and Wind Speed), Pressure, Humidity,

Temperature, Dewpoint, PRT, AN1, AN2, DIG1, Volts, Status,

Checksum.

Status Message O

utput On

Report Message Output

On

Units Message Output

On

Inputs Message Output

On

PRT Sensor

On

PRT Units

C (Degrees Celsius)

AN1 Sensor Type

Not Configured

AN1 Units

#

AN1 Analogue Input Type

Not Configured

AN1 Substitute Name

-

AN2 Sensor Type

Not Configured

AN2 Units

#

AN2 Analogue Input Type

Not Configured

AN2 Substitute Name

-

DIG1 Sensor Type

Not Configured

DIG1 Units

#

DIG1 Digital Count

Not Configured

DIG1 Substitute Name

-

Output Sentence

Comma Separated Variable

Page 42

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 42 Issue 1

Doc. No. 1723-PS-0022 October 2018

6.2. Configuring MetPaks with MetSet

Before you use MetSet check that MetPak is correctly connected to a Serial COM port or USB

COM port on your PC.

The optional Gill 1.8M, RS232 to USB cable (1957-10-065) can be used to power and provide a

suitable communication link for configuring a MetPak unit.

NOTES:

MetSet is compatible with RS232 and RS422 connected units only.

The availability of certain functions and parameters illustrated will depend on the MetPak

model and Options see Page 5, Para 2.1.2.

Opening MetSet

Click on the MetSet button on your PC’s desktop or choose:

Start > All Programs > MetSet > MetSet

The MetSet Control Centre window is displayed. If you have more than one MetPak connected to

your PC, MetSet, by default, selects the first device detected.

For most applications it is recommended to click on the MetSet Connect and Read button.

MetSet interrogates the MetPak and returns a summary of the device settings.

Depending on the MetPak Sensor connected only settings and parameters appropriate to the

connected MetPak unit will be shown.

Note that MetSet also saves a copy of this screen to the connected PC as a Session Report File

that can be accessed from the following destination.

C:\GillAppsData\Metset\SessionReports.

Disconnect MetPak and

create MetPak device

settings using MetSet

Offline

MetSet supported products list

Not Used

Connect the MetPak

output to MetSet without

reading its configuration

settings

Connect the MetPak

output to MetSet and

read its configuration

settings

Page 43

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 43 Issue 1

Doc. No. 1723-PS-0022 October 2018

Example Summary of MetPak Device Settings (MetPak Pro shown):-

SETTINGS ARE AS FOLLOWS:

PROTOCOL : GILL

COMMS : RS232

(BAUD) : 19200

NODE : Q

OUTFREQ : 1HZ

MSGMODE : CONT

ASCTERM : CRLF

ECHO : ON

ALIGN : 0

SENSOR WIND : ON

UNITS WIND : MS

NODIR : 0.00

SENSOR TEMP : ON

UNITS TEMP : C

SENSOR DEWPOINT : ON

UNITS DEWPOINT : C

SENSOR PRESS : ON

UNITS PRESS : HPA

SENSOR RH : ON

UNITS RH : %

REPORT NODE DIR SPEED PRESS RH TEMP DEWPOINT PRT AN1 AN2 DIG1 VOLT STATUS

PUPMSG STATUS : ON

PUPMSG REPORT : ON

PUPMSG UNITS : ON

PUPMSG INPUTS : ON

SENSOR PRT : ON

UNITS PRT : C

SENSOR AN1 : ON

SENSTYPE AN1 : NOT CONFIGURED

UNITS AN1 : #

ANIP AN1 : VOLTAGE 99999 99998

SUBST AN1 : NOT CONFIGURED

SENSOR AN2 : ON

SENSTYPE AN2 : NOT CONFIGURED

UNITS AN2 : #

ANIP AN2 : VOLTAGE 99999 99998

SUBST AN2 : NOT CONFIGURED

SENSOR DIG1 : ON

SENSTYPE DIG1 : NOT CONFIGURED

UNITS DIG1 : #

DIGCOUNT DIG1 : 10.000

SUBST DIG1 : NOT CONFIGURED

MODBUS : RTU

MODADDR : 1

DATABITS : 8

STOPBITS : 1

PARITY : NONE

MODTERM : 10

MODICT : 1000

Note changes to BAUD and COMMS settings will take place after next power-up.

Click on the Close button to continue to the MetSet set up screen.

Page 44

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 44 Issue 1

Doc. No. 1723-PS-0022 October 2018

MetSet Editing Screen

When connected correctly a MetSet editing screen is available to read configuration settings,

change configuration settings, save MetPak configuration settings to a PC file location, upload

MetPak configuration settings from a PC file and view the MetPak raw data string output.

MetSet Connection Status Information.

Reading Function

ONLINE ONLINE in green indicates the MetPak has been successfully

connected to MetSet.

OFFLINE in Grey indicates that MetSet is being used without a

MetPak in communication with MetSet.

19200 COM7 19200 is a report on the MetPak Baud rate setting.

COM 7 is a report on the MetPak COM Port connection number.

S/W ver 2436-4.01.01 2436 is the MetPak Firmware number.

4.01.01 is the firmware revision.

PV=4 is the Protocol Version (Gill Internal Reference).

Source:Device MetSet reads ‘Device’ when the source of the data that MetSet

has retrieved has come from the MetPak.

MetSet reads ‘File’ when the source of data has come from a

saved file.

MetSet reports on the connected MetPak device (METPAK

PRO) and reads the unit Serial Number (S/N: 16110011)

Connection

Source of MetSet Data

MetSet Editing Screen

MetPak Device

Setting

Options

View MetPak

Raw Data

Output String

Serial Number

Move mouse over exclamation

or question marks to read

setting comment

Return to

opening MetSet

Screen

Model

Page 45

Gill Instruments Ltd

_____________________________________________________________________________________________________________

________________________________________________________________________________________________

MetPak/MetPak RG and MetPak Pro Page | 45 Issue 1

Doc. No. 1723-PS-0022 October 2018

MetSet Online Settings.

Online Mode

Buttons

Function

Get Device

Settings

MetSet retrieves the MetPak Configuration settings.

Save Settings to

Device

MetSet configuration settings are saved to a