Gillette Generators SPP-180 User Manual

OPERATION AND

INSTALLATION

GUIDE

FOR MODELS:

SPS-120 & SPP-180

GILLETTE GENERATORS

AUTOMATIC POWER SYSTEMS

Page

Introduction, General Cautions, Warnings, & Danger Points ------------------ 3-6

TABLE OF CONTENTS

Un-packing and Inspection of your Generator Set ------------------------------ 6-7

Pre-installation and Plot Planning of your Generator Set ----------------------- 7-9

Know your Gillette Generator Set---------------------------------------------------- 10

Know your Gillette Automatic Control System ------------------------------------ 11

Gaseous Dry Fuel System : Natural Gas (NG) ------------------------------------- 12-13

Gaseous Dry Fuel System : Liquid Propane Gas (LPG) ------------------------- 14-15

Prepare for Generator Operation: --------------------------------------------------- 15-18

Access to Interior, Battery Selection & Installation, Electricians Wiring

Installation, & Final Preparations before Start-up

Additional Hi-Lights of (8) Point Diagnostic Panel ------------------------------- 18

Changing Fuel from NG to LPG at Job-Site ---------------------------------------- 19-20

Initial Start-Up ---------------------------------------------------------------------------- 20-21

General Service Tips ------------------------------------------------------------------- 21-23

Dimensional Print: Models SPS-120 ------------------------------------------------- 24-25

Dimensional Print: Model SPP-180--------------------------------------------------- 26-27

Electrical Connection Prints ---------------------------------------------------------- 28-29

Service Schedule ------------------------------------------------------------------------ 30

Maintenance Record -------------------------------------------------------------------- 31

PAGE 2

SAVE THESE INSTRUCTIONS

THIS MANUAL CONTAINS IMPORTANT

INSTRUCTIONS THAT MUST BE FOLLOWED

DURING INSTALLATION, OPERATION, AND

MAINTENANCE OF THIS GENERATOR SET AND

ALL ASSOCIATED EQUIPMENT.

Thoroughly read this operators manual before

installing, operating, or servicing your generator set.

Safe operation and best performance can be

achieved only when this generator is operated and

maintained properly.

INTRODUCTION

Thank you for your purchase of this SENTRY-PRO

automatic start/stop home standby generator set by

GILLETTE GENERATORS, INC. This generator set is

intended for use as an alternative source of electric

power to operate normally required household

electric loads, during a utility power failure.

This generator set has an all weather protected metal

enclosure, MADE EXCLUSIVELY FOR OUTDOOR

INSTALLATION, and will operate on either vapor

withdrawal liquid propane gas (LPG) or natural gas

(NG). CAUTION: This generator does not comply

with emergency power as defined in NFPA 70 of

National Electric Code.

GILLETTE GENERATORS has made every effort to

present a modern, safe generator set that will give

you a safe, clean supply of an alternative source.

However, because each installation is different, it is

impossible for this manual and GILLETTE to know and

advise against all possible hazards. The listings,

warnings, and cautions in this manual and on tags and

decals affixed to the generator set, are therefore,

NOT ALL INCLUSIVE. If a certain procedure, work

method, test method, or operating procedure is used,

and is not recommended by GILLETTE, the person or

company responsible for the generator modification,

must assume all responsibility for safety and correct

operation for the operator, service technician, and all

others within generator area.

READ YOUR GENERATOR SET MANUAL, PLUS

SEPARATE ENGINE OPERATORS MANUAL AND

AUTOMATIC TRANSFER SWITCH MANUAL

CAREFULLY. KNOW YOUR EQUIPMENT

BEFORE YOU USE IT. CONSIDER ANY POSSIBLE,

POTENTIAL HAZARDS, BEFORE OPERATING

YOUR GENERATOR SET.

CAUTION: Only current licensed electrical and

plumbing contractors should install your home

standby generator. All phase of installation must

comply with all applicable local and national codes,

industry standards, and regulations.

THE GILLETTE WARRANTY IS AUTOMATICALLY

NULL AND VOID WITHOUT THE USE OF

LICENSED ELECTRICIANS AND PLUMBERS, AND

SO NOTED ON THE REGISTRATION FORM THAT

IS TO BE RETURNED TO GILLETTE

GENERATORS, INC.

IMPORTANT SAFETY RULES

The safety alert symbol is used as a signal for

possible danger, caution warning, or general hazard.

DANGER:

will result in death or serious injury.

WARNING:

avoided, could result in a death or serious injury.

CAUTION:

might result in minor or moderate injury.

NOTICE:

could result in general damage.

Read and understand the above listed safety alert

symbols, plus the following symbols that are used

through out this manual.

Indicating a hazard that, if not avoided,

Indicating a hazard that, if not

Indicating a hazard that, if not avoided,

Indicating a hazard that, if not avoided,

A LIST OF HAZARD SYMBOLS

AND THEIR MEANINGS

Explosion

Toxic Fumes

Fire

Rotating Parts Hot Surface

Electrical Shock

Chemical Burn Explosive Pressure

PAGE 3

WARNING

The engine exhaust from this product contains

chemicals known to the state of California to cause

cancer, birth defects, or other reproductive harm.

NOTICE

● For all safety reasons to the equipment, GILLETTE

recommends installation, start-up and service be

performed by experienced personnel.

● Sufficient, un-obstructed flow of cooling air is

critical for correct generator operation.

● The generator must be installed outdoors, away

from an over-hang roof where ice and snow could

avalanche onto generator and away from sprinklers

that could throw water up into cooling vents of

generator.

● Electric load applied to generator should be no

more that 75% of generator maximum rating to avoid

constant maximum generator load use.

● Generator should not be exposed to excessive and

constant moisture, dust, dirt, or corrosive

environments.

● If connected loads cause over heating or excessive

vibration, an overload condition exists. Remove

loads until condition stabilizes.

● Do not sit, step, or load heavy items on generator

roof. Added stress can cause breakage.

● Do not start generator with air cleaner, air cleaner

cover, or oil dipstick removed, nor with oil drain hose

in open drain position.

● Keep a fire extinguisher rated “ABC” close by your

generator and be familiar on how to use it. Consult

your local fire department, for additional fire

prevention ideas.

● Be sure that a positive manual fuel valve be

installed in fuel line feeding generator.

● Do not tamper with engine controls, generator is

factory adjusted to supply rated voltage and speed.

● Never operate generator when ambient

temperature is over 105º F, as electrical insulation

system may fail.

WARNING

STARTING BATTERY

PRECAUTIONS

Starting batteries are not furnished with

your generator set, but they are available

through your installing contractor. The

home standby generator requires a Group

36, 12 VDC fully charged battery with

minimum 390 cold cranking amps.

● Released battery electrolyte can burn your skin

and eyes and is toxic.

● When electrolyte touches skin, wash it off

immediately with water and seek medical attention.

When electrolyte contacts eyes, flush thoroughly with

water and seek medical attention.

● Spilled electrolyte must be washed away with an

acid neutral agent. Use a solution of one pound

bicarbonate of soda to one gallon of water, and wash

down acid effected areas until evidence of acid

foaming reaction has ended.

● A battery provides risk of electric shock. Remove

watches, rings, or other metal items when working

with batteries. Use tools with insulated handles.

● When disconnecting battery cables, always

disconnect the battery charger first, the positive

battery cable second, and negative battery cable last.

When reconnecting cables, always reconnect the

positive battery cable first, then negative cable, and

reconnect battery charger last, to reduce possible

arching.

● Discharge body static electricity by touching a

grounded metal surface on generator before touching

battery.

● Do not dispose of batteries in a fire and do not

open or mutilate a battery, as the battery is capable of

exploding.

● Lead acid batteries present a risk of fire or

explosion because they generate hydrogen gas,

within. Do not smoke, nor have flame or spark in a

battery area.

PAGE 4

DANGER

ELECTRICAL HAZARDS

A generator produces dangerous electric

voltages and can cause a fatal electric

shock and will cause sudden illness, dizziness, and

incoherent actions.

● Despite the safe design of this GILLETTE

generator, operating it carelessly, neglecting its

normal maintenance, or being ill informed of proper

operations can cause possible serious injury or death.

● Avoid contact with bare wires, connection points,

etc., while generator is running.

● Do not touch any kind of electrical circuit while

standing in water, while barefooted, or while hands or

feet are wet or moist.

● Never wear any type of jewelry while working on a

generator. Jewelry will conduct electricity, causing

electric shock.

● If generator must be serviced while it is running,

stand on a dry, insulated surface from ground to

reduce shock hazard. Never service a generator in

the rain or snow.

● Do not allow unqualified or ill-experienced

persons to operate or service generator.

● Remain alert at all times. Never work on a

generator when you are physically or mentally

fatigued.

● This generator is equipped with a ground terminal.

Always complete the grounding path from generator

to an external grounding source to prevent possible

electric shock.

● In case of electric shock, shut the generator down

at once. If this cannot be done, free the victim from

source of live electric power. AVOID ANY DIRECT

CONTACT WITH VICTIM OR THE LIVE

ELECTRIC POWER. Use a dry piece of wood, a dry

rope, or any other such non-conductive item, to free

the victim from source of power. If victim is semi or

totally unconscious, apply CPR (cardio-pulmonary

resuscitation) and call for medical help immediately.

DANGER

Breathing carbon monoxide will cause fatigue,

headache, dizziness, vomiting, fainting, and in

prolong conditions, even death.

● Operate generator only outdoors, where adequate

ventilation is available. Avoid generator installations

under decks, inside garages or carports, in

basement, along side home exterior within five feet of

home vent, roof overhang vent, a window that can be

opened, or other such home invasion points. Use

same precautions when installing generator at

property line, close to a neighbor’s home, or any

buildings that house animals.

WARNING

POTENTIAL BURN OR FIRE

CONDITIONS

Contact with exhaust muffler and exhaust

pipe can result in serious burns.

Exhaust heat may ignite combustibles such as leaves

or other such debris that is allowed to accumulate

around base of generator where exhaust exits.

● Do not touch hot exhaust or engine parts, and

avoid hot exhaust gases.

● Keep at least a three foot clearance on all sides of

generator.

● Do not install generator any closer than five feet

from any combustibles or buildings with walls having

less than one hour, fire rating.

● Code of Federal Regulation (CFR), Title 36, states

that generators must have a spark arrestor attached to

muffler outlet pipe, to eliminate sparks from engine

operation. USDA Forest Service standard #5100-C

requires spark arrestor protection when generator is

operated within federal parks and forests.

● Generator installation must always comply with

local codes, standards, laws, and regulations. Check

with your local fire department to learn of these

precautions. Keep a fire extinguisher (rated “ABC”

by NFPA as appropriate use on generator fires)

nearby, at all times. Keep the extinguisher properly

charged and become familiar with its use.

CARBON MONOXIDE POISON

A running engine produces a poisonous gas from its

muffler exhaust pipe. This is an odorless, invisible,

and colorless poison that cannot easily be detected.

PAGE 5

WARNING

FIRE OR EXPLOSION CONDITIONS

Gaseous fuels such as natural gas (NG) and

liquid propane (LP) are extremely

explosive. Make sure the fuel supply

system is installed in compliance with local

and state fuel codes and regulations. Fuel leaks when

ignited, can cause fire and explosion, resulting in

harm or possible death.

● Before initial generator start-up, all fuel system

lines must be purged and leak tested according to

applicable codes by experienced service personnel.

No leaks are permitted.

● Do not smoke or allow open flame near generator

while servicing fuel system or battery. Lead acid

battery will emit a highly explosive hydrogen gas that

can be ignited. Leaks in LP or NG system can be

ignited. Both are conditions that can cause fire and/or

explosion, leading to possible death.

● Do not operate generator if smell of fuel is

detected.

● Wipe up any oil spills immediately. Remove any

debris that has accumulated inside or around

generator base and housing.

● Always maintain a scheduled inspection of entire

fuel system and starting battery, looking for leaks or

other negative conditions.

CAUTION

Following is a list of potential events that might result

in minor or moderate injury or damage to the

generator.

● Never operate generator with oil dipstick partially

seated or completely missing.

● Never operate generator without air cleaner and

cover in place.

● Always check oil drain hose or radiator drain hose

for leaks.

● Generator operating speeds beyond 3750 RPM

increase risk of operator injury and engine damage.

● Never insert any objects through generator

cooling slots.

● The control panel and wiring access area doors

must be installed at time of operation.

● If connected electrical items overheat, disconnect

them immediately.

● Immediately shut down generator if it looses

electrical output, shows sparks, smokes, emits flames,

vibrates, or shows any other abnormal operation.

● Do not modify generator design.

● Do not modify carburetion system, as it is factory

set for C.A.R.B./EPA emissions certification.

This concludes the limited hazard listing. However,

GILLETTE cannot possibly anticipate every possible

hazard. Therefore, the warnings in this manual, plus

the warning tags and decals attached to the generator

are not all inclusive. If the generator operator has a

different operating method, other than described in

this manual, than operator becomes responsible to

make sure that different procedure, work method, or

operating method is totally safe, against harm and

hazards to operators, buildings or environments.

UNPACKING AND INSPECTION

After receiving the generator, note that it is mounted

on a heavy wood skid base and protected by a

multiply cardboard container. While the

transportation carrier is still present, note the

condition of skid and cardboard box. If noticeable

damage is apparent, immediately remove cardboard

box and inspect generator for possible freight

damage. If damage occurs, make a note of damage

on carrier’s freight bill and have truck driver sign his

name on the freight bill, under “Consignor’s memo of

loss or damage”.

If shipping container shows damage of any kind, and

time does not permit container removal for actual

generator inspection, while transportation carrier is

still available, be sure to:

• Make note of container damage “with possible

interior product damage” on carrier’s freight bill.

• Have truck driver sign his name on freight bill

under “Consignor's Memo of Loss or Damage”.

This action will help prove your case against shipper.

Always save shipping materials in the event that genset must be sent back to factory due to need of

extensive repairs.

If damage is noticed after carrier leaves, contact the

carrier for “concealed damage” form. NOTE:

Missing or damaged parts on generator, is not a

warranty claim.

PAGE 6

GENERATOR CONTENTS

The GILLETTE home generator set is supplied with

the following components:

● Home generator system within soundproofed all

weather metal enclosure (Depending on option

choice, this can be an open set or a super-silent

enclosure add).

● Residential muffler system for quiet operation.

● Choice of (3) gen-set mounting systems:

A) Base direct mounting to concrete slab.

B) Base direct mounting to crushed gravel base,

secured in ground with ground stakes.

C) Base with plastic pad for floating mount on

crushed gravel.

● 3/4” NPT female coupling for gas connection.

● Four lifting holes with cover plugs.

● Two locking door keys (NOTE: One key fits all

locks.)

● One spare 20 amp fuse. (Located just above fuse

holder in control panel wiring area)

● Diagnostic LED panel.

● One owner/operator panel.

NOTE: All accessory items will be pre-mounted and

wired to generator. If separate automatic transfer

switch (ATS) is ordered, it is placed on top of

generator shipping box and steel banded in place.

AUTOMATIC TRANSFER SWITCH (ATS)

DANGER

If this generator set is used to provide

temporary electric power to circuits when

loss of normal utility power occurs, it is required by

National Electric Code, to install an automatic transfer

switch (ATS).

The ATS must isolate the home electrical system from

the utility electrical distribution system when the

home generator is operating (see NEC 700, 701, and

702). Failure to isolate an electrical system with an

approved ATS will result in damage to home

generator and also can result in severe injury or

death to utility power workers who may receive

electrical back-feed shock from the home

generator set.

The automatic transfer switch is an optional selection

and can be used with any model GILLETTE home

generator set. All installation procedures, operating

cautions, and warranties are responsibility of the

separate manufacturers of the ATS.

PRE-INSTALLATION PLANNING

The beginning installation requires some thought and

planning. The following illustrations are meant to

familiarize reader with typical installation

circumstances and to plan the best installation

possible.

First, Federal, State, and local codes may be a factor.

The local fire department can be of help on learning

these codes. As with all generators, your generator

must be installed in accordance with current NFPA-37

and NFPA-70 standards. Contact your local electrical

inspector or city hall to insure you are aware of all

codes and regulations. Contact your natural gas

supplier to verify that increased BTU gas demand can

be handled with existing NG gas meter. The same is

true for LPG fueled generators.

The most common fuel mistakes are:

A) Not a dedicated fuel line from fuel source to

generator, on either LPG or Natural Gas fuel.

B) Not having a dedicated primary fuel regulator for

only the generator, while using LPG tank.

C) Wrong fuel pressures. (See fuel pressure

information on page 14)

D) Not understanding that fuel pipe diameter must

increase in direct proportion to fuel line length. (See

gas charts on page 12 for further details)

E) Wrong primary regulator. This is a common

problem, using an existing regulator on a LPG Tank is

typically too small for the supply needed for a

generator.

Locate the generator site. It should be as close as

possible to the natural gas meter, and as close as

possible to the home electrical distribution panel.

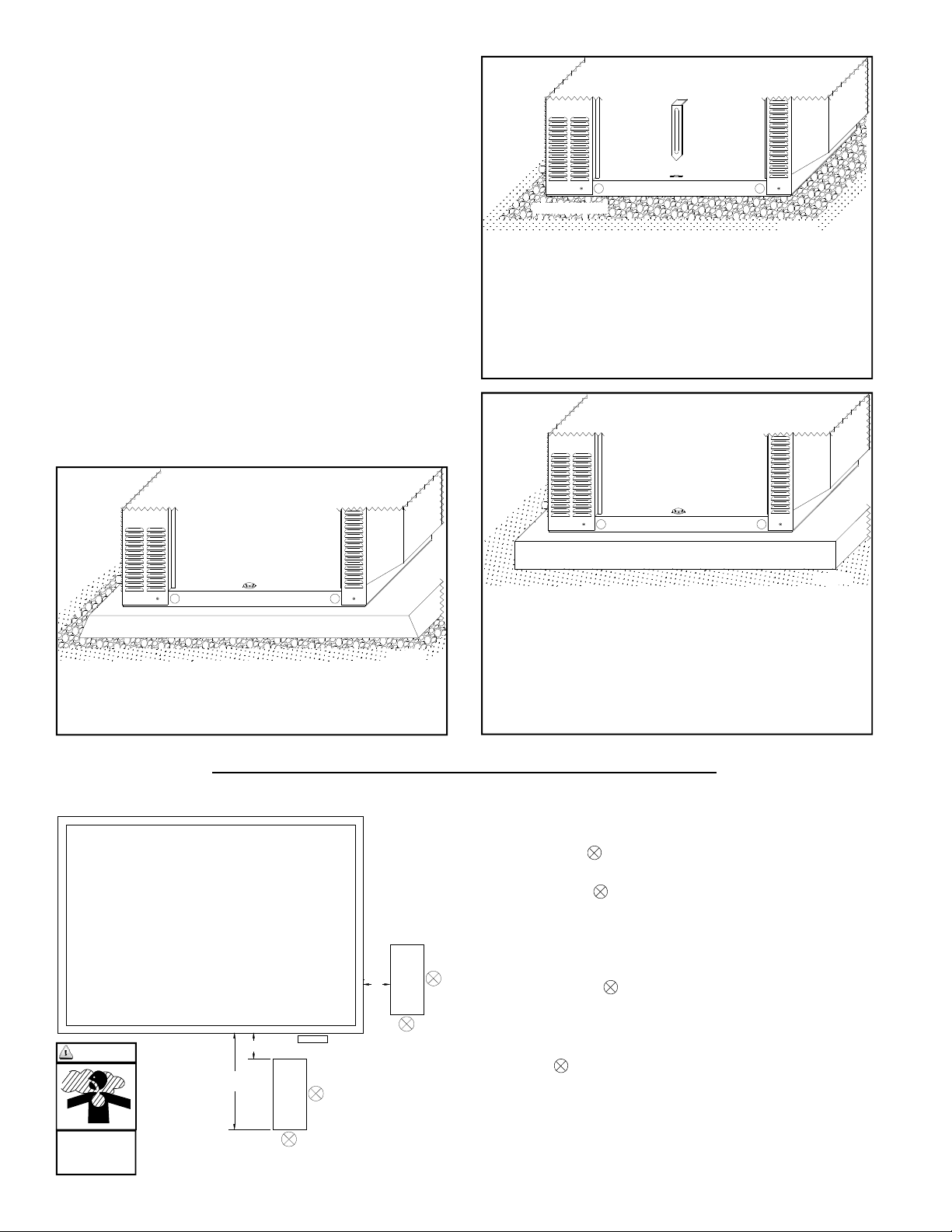

Determine the type of generator anchoring. There

are three types:

1) ACCEPTABLE: Generator is mounted on a

composite (plastic) pad, placed on a bed of pea

gravel or crushed stone. It “floats” in place. (See

Illustration #1)

2) ACCEPTABLE: Generator is mounted directly on a

bed of pea gravel or crushed stone (no composite

PAGE 7

3) PREFERRED: Generator is mounted directly on a

concrete slab, 4 inches thick, extending 6 inches

beyond generator perimeter, and bolted in place.

This method is for those locals with “high wind”

considerations. (See Illustration #3)

If gravel bed is chosen, its perimeter must be eight

inches larger than generator base. Dig a rectangular

area six inches deep, cover with landscape cloth (so

drainage can take place) and fill with pea gravel or

crushed stone. Final gravel level must be two to three

inches higher than original level to ensure water runoff away from generator. A normal plastic landscape

border can be used between grass and gravel area to

provide a more attractive installation.

Compact and level the stone. Place generator on

stone using either the “composite” pad (optional

equipment) or place aluminum generator base

directly on gravel, using ground stakes for a fixed

installation.

GROUND

GENERATOR BASE

GRAVEL BED

GRASS

ILLUSTRATION #2: Generator is placed on top of

gravel bed. The ground stakes are driven through

the slots in generator base, to hold it in place on

gravel bed. CAUTION: Make sure there is no

underground electric wires, gas lines, sprinkler

lines, or any other vulnerable items, directly in

the path of these two ground stakes.

BOLTED TO

CEMENT PAD

BOLTED TO

PAD

GENERATOR BASE

COMPOSITE PAD

GRAVEL BED

GRASS

ILLUSTRATION #1: Composite pad bolted to

generator base and placed over a bed of crushed

stone or gravel.

SUGGESTIONS FOR GENERATOR LOCATIONS

OCCUPIED

BUILDING

#2

5'

GENERATOR

(B)

DANGER

TOXIC FUMES

MAY ENTER

BUILDING

APPROX.

10'

5'

PREFERRE D

GAS

METER

(A)

#1

GENERATOR

(B)

ACCEPTAB LE

(A) = SPS M ODELS

(B) = SPP MO DELS

GENERATOR BASE

CEMENT PAD

ILLUSTRATION #3: Generator base is bolted

directly to a poured concrete slab (provided by

others). Notice that all three illustrations provide

bolting or staking methods that are always secured

from inside the generator housing, behind locked

doors. This is designed to deter theft of your home

standby generator set.

1) Always install your generator within 20 feet from natural

gas meter. Further distances may cause “starving” of fuel

from generator engine.

2) Exhaust end must always be turned away or parallel

with building and minimum 5 feet away.

3) Exhaust end is not to be directed towards play

areas, patios, under canopies or overhangs, or where

people or animals congregate.

4) Do not install generator under deck of house.

5) Furnace and other air intakes should be minimum 10 feet

(A)

from exhaust end

6) Windows and doors on adjacent walls, to be closed at all

times, during generator operation.

7) Nearest roof overhang vent should be 10 feet from

exhaust end

8) If electrical distribution center panel is far away from

gas meter, locate generator close to gas meter. Installation

costs are lower, if electric wiring is oversized for long

distances, to utility point rather than oversized fuel lines to

gas meter.

GRASS

PAGE 8

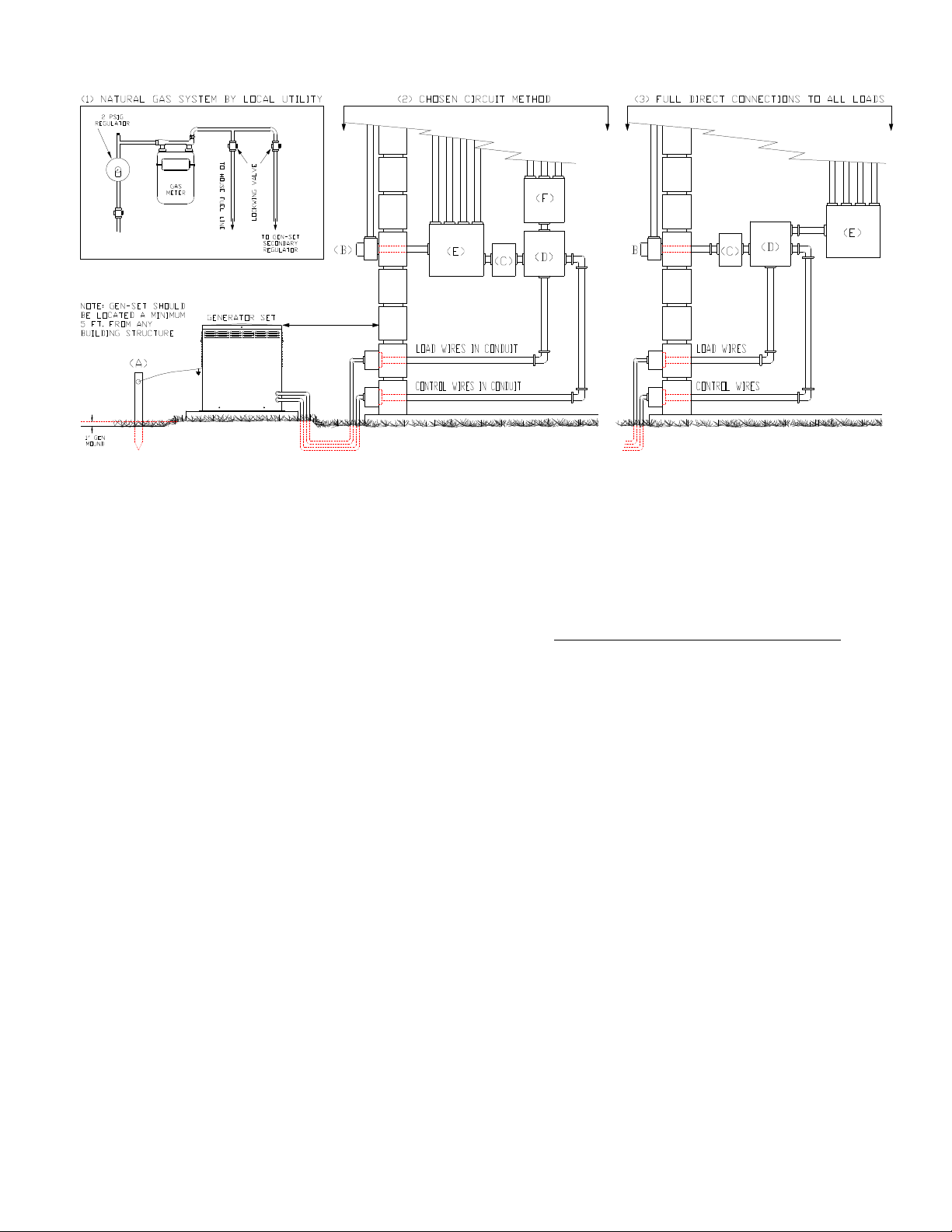

TYPICAL EMERGENCY GENERATOR INSTALLATION PRACTICES

MIN IMUM 5 FT

(1) Drawing shows a typical gas utility approach on how to

bring natural gas fuel to the gen-set. The fuel from utility is

connected by dedicated fuel line, to the installed 4 ounce, 7”

water column secondary regulator, inside gen-set housing.

CAUTION: Consult your natural gas supplier about your meter

size. Most meters must be replaced with a larger BTU size, due

to larger demand of BTU’s from generator. The same

procedure is also used with LPG: a 6 ounce, 11” water column,

dedicated primary regulator is placed at fuel outlet of “vapor

withdrawal” LPG tank. Fuel is piped directly to LPG 6 ounce,

11” water column secondary regulator, inside gen-set housing.

(2) Drawing shows chosen circuit connection: Load circuits are

selected based on importance of needs, plus the starting and

running amps. All connected loads should not exceed the amp

size of generator. The auto transfer switch should equal or

exceed total amp load of (F), smaller distribution panel.

When “Chosen” load is matched to gen-set amp size, the genset is never overloaded.

(3) Drawing shows full load connection: The gen-set output is

applied to the entire load of the utility electrical distribution

panel. For this installation, the auto transfer switch, must be of

same amp size as utility power. This is the easiest, lower

priced electrical installation, but subject to gen-set shutdown

whenever load amps exceed gen-set amp capacity.

(A) Drive a corrosion resistant steel stake, into ground and

attach a 10 gauge stranded copper wire from stake to ground

lug on outside of gen-set. This bleeds off any potential

lightning strike and any static electricity, which can occur on

metal parts of ungrounded generators. For a non-separately

derived system (where normal electric utility power is in

building and gen-set is a back-up emergency power

supply), the gen-set neutral must connect only to utility

power neutral and not to the ground stake. The best place

for these two neutrals to meet (generator and utility neutral), is

in the automatic transfer switch. However, still connect gen-set

mechanical ground to the stake. All factory gen-sets, have a

“floating neutral” ready to be connected to utility neutral, by

installer.

(B) Normal utility power meter and power inlet to panel.

(C) Safety disconnect switch, sized to ATS amp rating.

(D) Auto transfer switch with UL-1008 label and NEMA-1

housing for inside installation. Consult factory for NEMA-3R,

outside installations.

(E) Original electric utility distribution panel.

(F) Separate, smaller distribution panel, with chosen circuit

loads.

HELPFUL INSTALLATION TIPS

● Mound the gen-set location upwards at least 1 inch from

normal terrain, for proper drainage. Fill an area 6 inches

larger than gen-set mounting pad perimeter and 3 inches

deep, with crushed gravel. This provides flexible settling of

gen-set and mounting pad. NOTE: Specific locales may

require a cement pad installation.

● Gen-set must be located minimum 5 feet from all structures.

This clearance will provide for ample service room.

● Watch out for roof overhangs. Snow, ice, or rain should not

be allowed to accumulate on roof, and cascade onto gen-set

roof.

● Check prevailing wind direction. Winds should blow

toward the engine end of housing, which is the normal cool air

intake end. The opposite end is hot air discharge.

● Engine exhaust from generator end is hot and dangerous.

Exhaust must be allowed to dissipate into free air zone, with no

obstructions (air conditioner condenser, buildings, plants,

trees, living quarters, etc.) within 5 feet.

● Control wires and load wires should be made in (2)

different circuit runs to auto transfer switch, to avoid any

possible magnetic interference between the two. These lines

should be underground for best protection.

● Don’t allow snow, ice, or debris to accumulate around and

on gen-set. If possible, plant a short hedge or a series of

evergreens, as a protective “wall”, 5 feet from gen-set on

windward (engine) side, to stop such accumulation, and still

PAGE 9

KNOW YOUR GILLETTE HOME GENERATOR

Compare the following illustrations and individual component locations, with your actual GILLETTE home

generator system. This will help familiarize yourself with the entire generator set.

Control, Wiring,

& Generator End

2)

1)

Cool Air Input

LEFT SIDE FACING ENGINE END WITH SERVICE PANEL REMOVED

1) Ground Wire to Ground Stake (Electrician)

2) Two Electrical Knockouts (Electrician)

3) Oil fill.

4) Engine.

5) Spark plug (Replace every 300 hours of use).

3)

4)

5)

6)

7)

Engine End

8)

Cool Air Input

9)

6) Oil cooler.

7) Oil filter (Replace every 200 hours).

8) Oil drain with flexible drain hose. NOTE: Change

oil after every 50 hours of use.

9) Dry fuel gas input (Always use flexible fuel line).

12)

13)

14)

11)

Engine End

10)

Cool Air Input

RIGHT SIDE FACING ENGINE END WITH SERVICE PANEL REMOVED

10) 12 VDC battery charger. Installer must connect

120 volt, 1 phase utility power to this charger.

11) 12 VDC engine starter motor.

12) Spark plug (replace every 300 hours of use).

13) Air cleaner element (Clean every 50 hours,

replace at 300 hours).

15)

16)

Hot

Muffler

Area

17)

Generator End

Cool Air Input

18)

15) Oil dipstick.

16) Muffler. CAUTION: Hot to the touch when in use.

17) Generator.

18) Battery tray (see page 16 for installation and

caution use).

PAGE 10

Loading...

Loading...