Gilian LFS-113 Instruction Manual

LFS-113

Dual Mode Low Flow Air Sampler

1–350 cc/min. Constant Pressure

5–200 cc/min. Constant Flow

LOW FLOW SAMPLER

Patent Pending

MODEL LFS-113DC

TIME (MIN)

FLOW ADJ

DUAL

MODE

S/N–

PN 800098–

ON

OFF

B

F

Made in USA

LISTED 17G9

MODEL LFS-113D / LFS-113DC

®

Personal Air Sampler

Intrinsically Safe Portable Air Sampling Pump for use in

Hazardous locations: Class I Groups A,B,C,D; Class II

Groups E,F,G; Class III. Temperature Code T3.

WARNING

Substitution of components may impair Intrinsic Safety.

Use only with UL Listed Portable Air Sampling Pump

Battery Pack.

INSTRUCTION MANUAL

NOTE: Please read all warnings and instructions before operating this unit. Failure to follow these

instructions and procedures can result in permanent damage to the equipment.

WARNING:

This unit is designed specifically for use with Gilian LFS-113, UL, and SCS intrinsically safe battery

packs and equipment. The unit should only be operated in environments that the unit's intrinsic safety

labeling permits. Do not operate in excessive chemical or water vapor atmospheres. Do not charge

sampler outdoors or in a damp environment. Use specified Gilian chargers only when recharging the

battery system. Use of any other charger may short out the battery or cause permanent damage to the

electrical system. Do not leave unit charging for more than 16 hours. Overcharging cells may cause

overheating and subsequent damage to/or decrease in battery life and performance.

Sensidyne, Inc.

16333 Bay Vista Drive • Clearwater, FL 33760

800-451-9444 • 727-530-3602

FAX 727-539-0550

Operating manual for the

LFS-113 Air Sampling System

Includes models:

LFS-113D, LFS-113DC

Table of Contents

Sec. Title Page

WARRANTY/SERVICE INFORMATION 2

Fig. 1 - Flow/Timing Capabilities/Approvals 4

1.0 INTRODUCTION 5-8

1.1 Theory of Operation 5

1.2 General Description, nomenclature6

Fig. 2 - Sampler front, side & top 7

Fig. 3 - Sampler back & side 8

2.0 SET-UP 9

2.1 Charging 9

2.2 Filter Check 9

3.0 OPERATION 9-12

3.1 Mode Selection 9-10

3.2 Constant Flow Sampling 10-11

3.3 Multiple Flow Sampling 11-12

4.0 PERFORMANCE CHECKS 12-13

4.1 Constant Flow Check 12

4.1.1 Pressure Fault Check 12

4.1.2 Pressure Fault Clear Check 12-13

4.1.3 Battery Performance Check 13

4.2 Constant Pressure 13

4.2.1 Constant Pressure Check 13

5.0 MAINTENANCE 13-14

5.1 Battery Charging and Storage 13-14

5.2 Replacing the Battery 14

5.3 Changing the Pump Filter 14

Fig. 4 - Constant flow mode set-up 15

Fig. 5 - Multi-flow mode set-up 16

Fig. 6 - Pump test set-up 17

6.0 SPECIFICATIONS 18

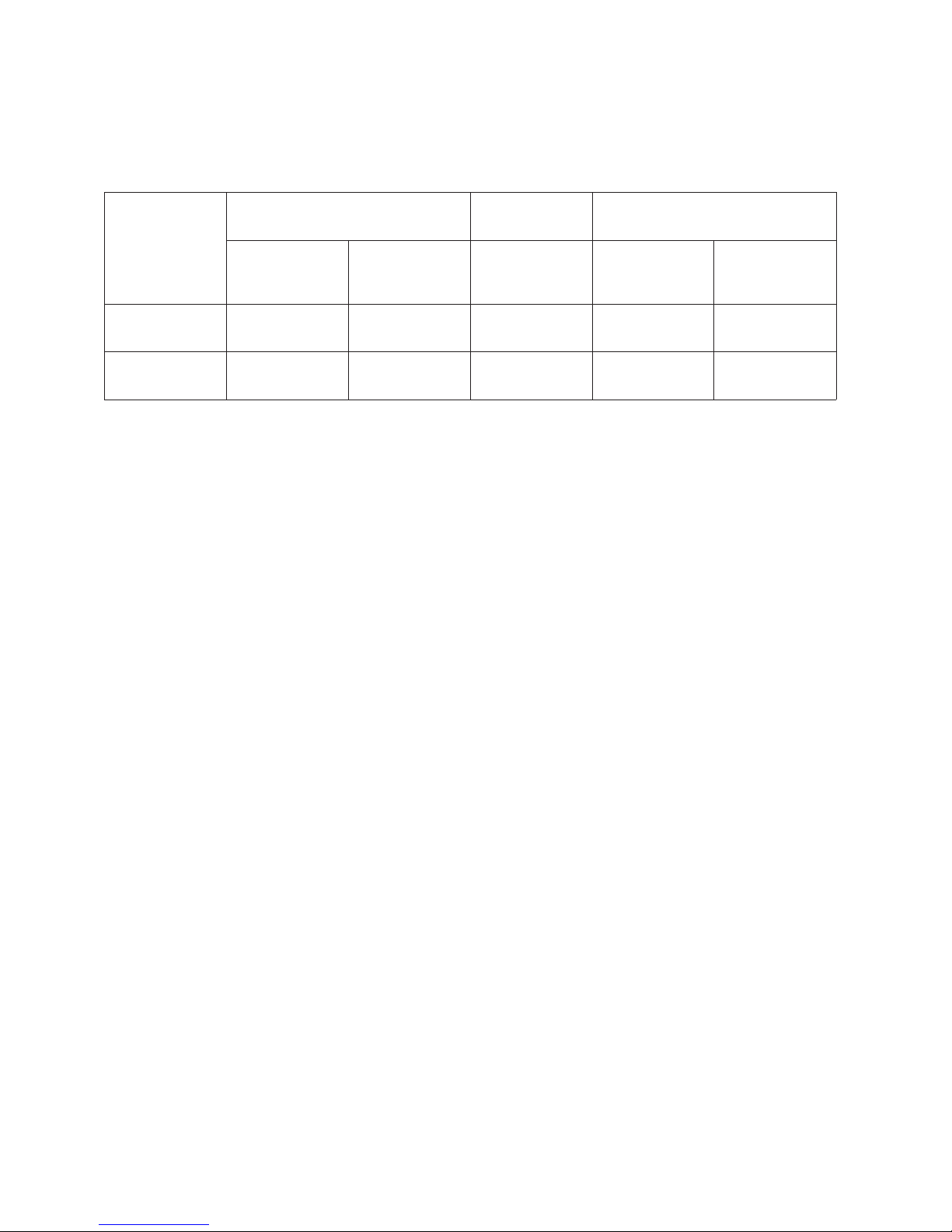

Figure 1

Flow/Timing Capabilities/Approvals

page 4

INTRINSIC SAFETY APPROVALS

See product labeling for specific intrinsic safety approvals.

UL

®

(Underwriters Laboratories, Inc.)

All LFS-113 series pumps are UL approved intrinsically safe for use in hazardous locations Class I, Groups A, B, C, & D, Class II, Groups E, F, & G and Class

III.

UL listed 17G9, Temperature Code T3C.

MSHA

®

(Mine Safety and Health Administration)

The designs of this air sampling pump meets the requirements of title 30 code

of Federal Regulations Part 18 and are hereby approved as permissible for use

in gassy mines, when used with a specified Gilian Battery pack

SCS

®

(SIRA Certification Service), Europe

Certificate No. Ex90C2011X, Coding: EEx iB IIC T4

ISO 9002 Quality Assurance Standard, International

All Gilian products are designed, manufactured and produced in accordance

with and comply with the ISO 9002 international quality assurance standard.

SWOLFWOLGNIMIT

ledoM

noitangiseDnoitangiseD

noitangiseD

noitangiseDnoitangiseD

tnatsnoC

wolFwolF

wolF

wolFwolF

tnatsnoC

erusserPerusserP

erusserP

erusserPerusserP

despalE

emiTemiT

emiT

emiTemiT

kcolCkcolC

kcolC

kcolCkcolC

tnatsnI

tluaFtluaF

tluaF

tluaFtluaF

noitcnuFnoitcnuF

noitcnuF

noitcnuFnoitcnuF

tnebroS

ebuTebuT

ebuT

ebuTebuT

rekaerBrekaerB

rekaerB

rekaerBrekaerB

D

•••••••••••••••

CD

•••••••••••••••••••••••••

page 5

1.0 INTRODUCTION

The LFS-113 series sampler provides a rugged, reliable and compact sampling

system for industrial hygiene and environmental sampling employment of single or

multiple sorbent tubes and gas sampling bags. Two low flow modes of sampling

allowconstant flows from 5-200 cc/min., as well as constant pressure for multiple

sorbent tube sampling from 1-350 cc/min. (combined flow rates). A compact and

lightweight sampler, the LFS combines convenience and useful functions for accurate

sampling.

1.1 Theory of Operation

The LFS low flow sampler offers two modes of sampling which are easily activated

by turning the selector dial located at the back of the sampler. A hex wrench is inserted

and turned to the desired position and a visual indicator displays the mode being used.

The sampler is turned on and will run continuously until manually shut down. An

optional LCD clock is available on DC models which offers elapsed run time and an

instant-fault function.The constant pressure (multi-flow) mode when used with a

multiple flow controller tube holder, offers a multi-tube sampling capability that is

adjusted individually at each tube position.

page 6

1.2 General Description (see figures 2 and 3)

Item Nomenclature Description

1 Charging Jack Receptacle provides means of connecting charger for recharging

internal battery pack.

2 Pump Filter 10 Micron Nylon filter protects pump assembly from dirt. Discolora-

tion indicates need for filter replacement.

3 Mode Indicator Visually confirms mode engagement via Black or White indication.

4 Mode Select Provides means of unlocking, indexing and re-locking mode selector

valve to change from constant low flow to the multiple low flow mode.

5 On/Off Switch Activates sampler operation.

6 Battery Check Green LED indicates sufficient battery power to run the pump for an 8-

hour period under normal load conditions.

7 Fault Indicator Indicates flow fault due to excessive pressure or insufficient battery

voltage to maintain flow.

8 Clock Display Indicates continuous run-time in minutes which will lock in the sample

(DC models only.) time upon fault indication. Time will reset to zero when the power

switch is turned OFF and back ON.

9 Flow Adjust Provides external means of adjusting the air flow rate.

10 Inlet Boss Air inlet is located on the clear filter housing and provides built-in

means of attaching tubing for suction sampling.

11 Outlet Port Receptacle for discharge air boss accessory. The cap screw prevents

dirt from entering the dischargeoutlet when not in use.

12 Discharge Boss An accessory which when installed into the discharge outlet, provides a

means of filling air sampling bags.

13 Belt Clip Built-in means of attaching sampler to worker’s belt.

14 Case Screws (4) Holds battery pack in place as well as case front and back.

15 Battery Pack Provides DC power to operate the unit.

Loading...

Loading...