Gilian Gilibrator Instruction Manual

Instruction Manual

for the

Gilian”

Primary Standard Airflow Calibrator

with Interchangeable Flow Cell Assemblies

Flow Cell Assembly Ranges

Low : 1 to 250 cc/min.

Standard : 20 cc/min. to 6 LPM

High : 2 to 30 LPM

On-Site Instruments

l-8OO-7-On-Site

(l-800-766-7483)

689 North James Road - Columbus, Ohio 43219

Advanced Test Equipment Rentals

www.atecorp.com 800-404-ATEC (2832)

®

E

s

t

a

b

l

i

s

h

e

d

1

9

8

1

Prologue

This Instruction Manual describes the basic principles, installation,

operation/controls and maintenance for the Cilibrator, Primary Standard

Airflow Calibrator manufactured by Cilian Instrument Corp.

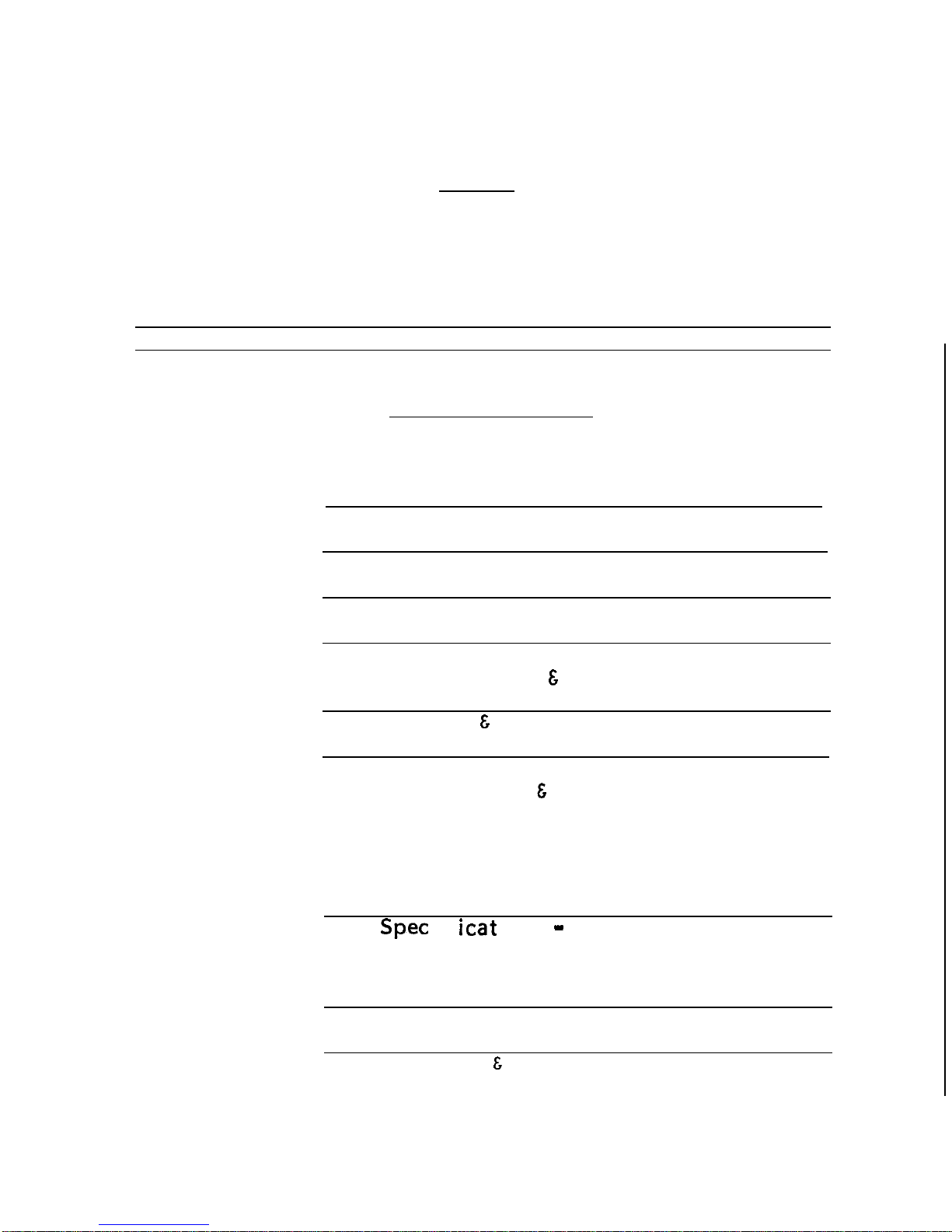

Table of Contents

The Gil ibrator

Section #

Page #

1

Introduct ion

2

2

General Description 2-6

3

Theory of Operation

7

4

Operating Procedures

8-12

Initial Set-up & Operation

5

Storage E Maintenance

13-17

6

The Printer Module

18

Introduction

E

General Description

18-19

Theory of Operation

19

Operation Procedures

19-21

Storage and Maintenance

21

7

Spec

if icat ions

-

The Gil ibrator

22

The Printer Module

23

8

Cilibrator Parts List

23

9

Warranty E Service Policy

24

1

Section 1

Introductih

The Gilibrator is a high accuracy, electronic bubble flowmeter that

provides instantaneous air flow readings and a cumulative averaging of

multiple samples.

The Gilibrator system provides a large dynamic range

through the use of 3 interchangeable flow cell assemblies. A delete

function, on the Control Unit, subtracts eroneous readings to insure

accurate data. The Control unit also supports a hard copy print out through

the use of a printer accessory-.

Section 2

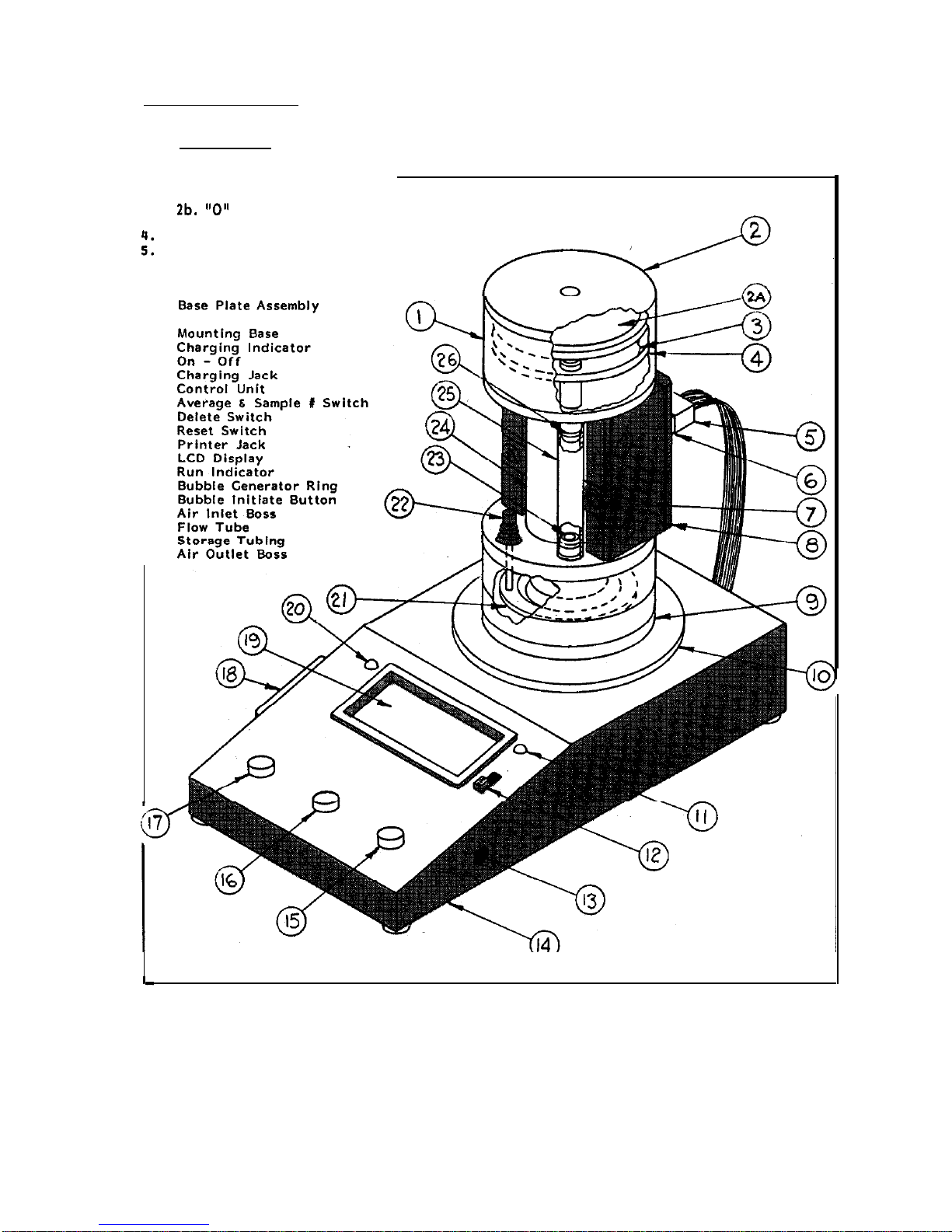

General Description (See fig. la)

The Gilibrator is comprised of the following basic components: Flow

Cell Assembly, Control Unit (base), Battery Charger and Soap Solution. Dif-

ferent sized inter-changeable Flow Cell Assemblies are available for use as

follows:

Low Flow : 1 to 250

cc/min.

Standard Flow : 20

cclmin

to 6 LPM

High Flow : 2 to 30 LPM

In addition to the basic components, an optional Printer Module is

available. The printer provides a hard copy record of calibration data,

however, identical data is displayed on the LCD of the Cilibrator Control

Unit during calibration.

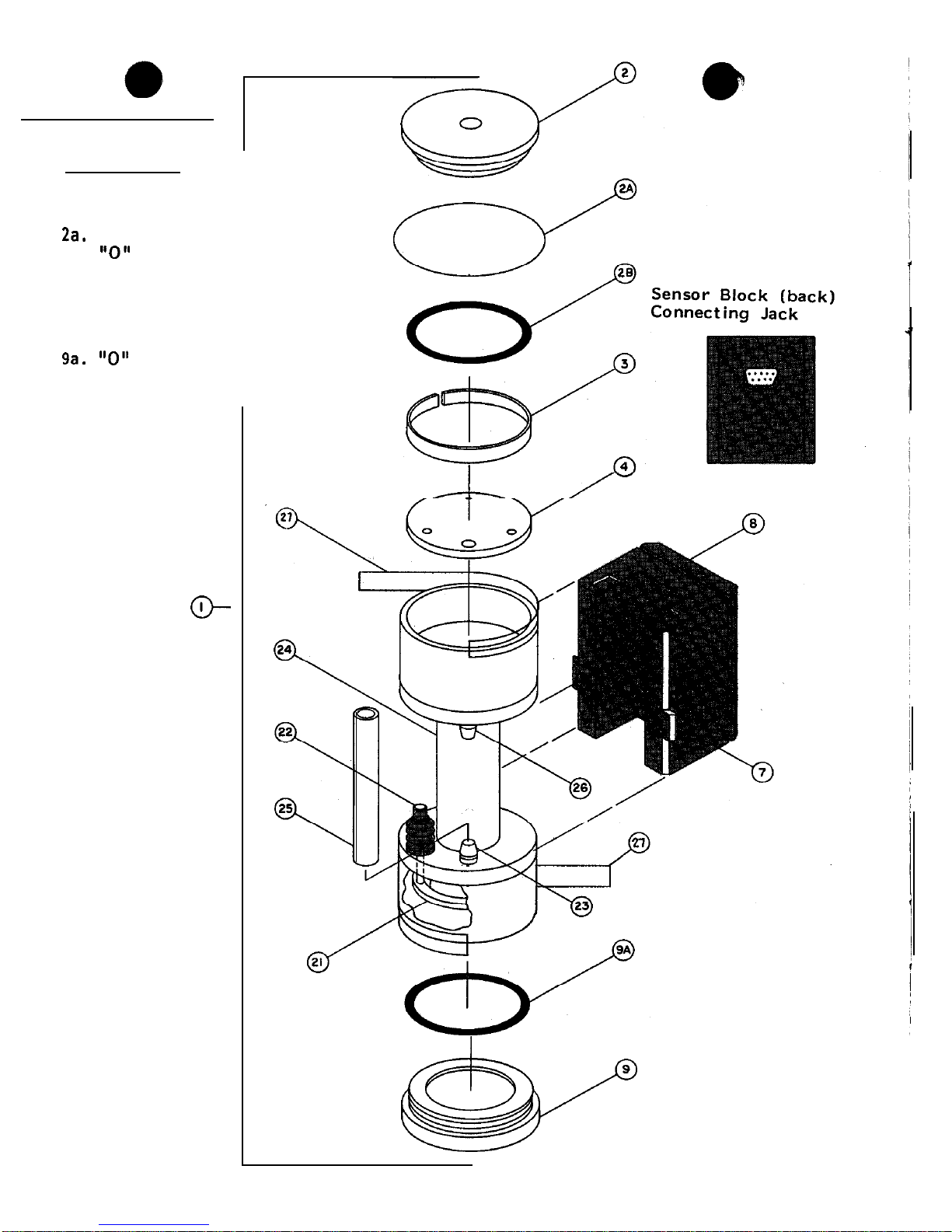

1. Flow Cell Assembly (See fig. lb)

The Flow Cell Assembly consists of a Bubble Generator and Sensor

Block. Each Bubble Generator is sized to produce a bubble film stretched

across the diameter of the flow cell tube which is carried by airflow from

the bottom to top of the tube. As the bubble traverses past two infrared

sensors, each sensor transmits a signal to the Control Unit (base) indicating the passage of the film. The Flow Cell Assembly incorporates a manual

bubble initiation push button which starts the film on its travel up the

tube.

A. Bubble Generator

1) Flow Ranges

Low Flow

: 1 to 250

cclmin.

Standard Flow

: 20

cc/min

to 6 LPM

I

High Flow

: 2 to 30 LPM

2) Pulsation Damper (2) - a built-in damper smoothes out any

pulsation’ within the airflow and reduces occilation of the bubble

film assuring maximum accuracy.

3) Bubble Initiate Button (22) - This pushbutton lowers the Bubble

Generator Ring (21) into the soap solution reservoir. Upon

releasing the button, the ring lifts out of the soap solution and

a film bubble is generated across the opening of the flow tube

(241.

2

4) Bubble Breaker (4)- The Bubble Breaker is a secondary chamber

in the upper chamber which provides the soap film a rapid expan-

sion path which is instrumental in breaking the bubble. ‘This

prevents excessive wall wetting by the soap film and allows it to

flow back into the cell.

5) Storage Tubing (25) - This anti-spill tubing connects upper and

lower cell chambers and prevents the soap solution from evaporating which may cause the solution concentration to change.’

CAUTION: If transporting by plane, be sure to disconnect this hosing from

upper or lower Flow Cell Chamber Bosses (23 & 26) to prevent pressurization

and possible rupture within the Bubble Generator.

8.

Sensor Block (8)

Surrounding the flow tube

(24),and

secured between the upper and

lower chamber of the bubble generator, is the Sensor Block (8).

The blockincorporates lower and upper sensors for time start and

time stop. Thesensors consist of an infrared emitter and detector

pairs whose sensitivity and accuracy is controlled by a “columna-

ting slot”. This block is secured to the Bubble Generator

Assembly (1) by means of two Locking Screws ((7) and allows easy

removal to facilitate cleaning.

1) Electrical Interface -The Electrical Interface provides power

to the sensing system as well as transmits timing information to

the Control Unit.

2. The Control Unit (base) (See fig. la)

The Control Unit (14) contains a crystal controlled timing system,

a micro processor control system,

and an LCD readout for displaying

flow and messages. The Control Unit also contains switches for Reset

(17),

Delete (16) and Auto-Averaging (15) functions as well as an

Printer Jack (18) interface port for direct connection to a hard copy

printer. LED indicators are provided to note Charging (11) and Run

calibration (20) operation.

a) Power (12) - switch turns the Control Units power on and off.

b) Charge Indicator LED (11) - lights when the charger is plugged

into the Charging Jack

c) Printer Jack (18) - provides interface for auxillary printer.

d) Reset (17)

-

push button deletes all current information for

themicro

processor in order to initiate a new sequence.

e) Delete (16) - push button automatically deletes false informa-

tion from the average and will reset the average and sample number

to the previous reading.

When a printer is in line, this will

indicate a minus symbol and the average will return to the

previous value.

3

f)

Average (15)- push button when pushed and held will display

the average of the previous sequence of readings. When released

will display the last actual reading and when re-pushed and held,

will show the numbe,r of samples in the sequence with display

information (S=sample #). Releasing the button will automatical-

ly bring the display back to the last reading.

g) Sequence Run Indicator LED (20) - indicates bubble sequence by

lighting as the bubble passes between the two sensors. The LCD

(19) will be blank. The Run signal will also light when turning

on the Control Unit and will extinguish after unit has finished

it’s initial sequence check.

h) Low Battery - will indicate on the LCD display (19) if insuffi-

cient battery voltage is available to operate the unit proper-

ly. Since power for all Control Unit functions is derived from the

rechargeable ‘NiCad battery, the batteries must be fully charged

for proper operation. A “Low Battery” indication will also appear

initially when turning the Control Unit ON as a sequence check of

the unit’s electronics.

i)

Cable Assembly (5) - mates with the Connecting Jack (6) in the

back of the Sensor Block. It provides power for the sensing

system, information regarding cell size , and control of the

timing information to the micro processor.

j)

Timing System - The quartz controlled timing‘system controls

infra-red sensor activation to assure maximum calculation

accura-

CY.

k) Micro Processor - controls the timing and mathematical data

processing to provide optimum flow measurement characteristics.

This programmable micro processor can be upgraded as new programs

become available.

3. Battery Charger

Standard wall operated 120V charger to charge Gilibrator Control

Unit for 14 hours prior to operation. The Charging LED on the Control

Unit will be illuminated while

,charging

is in progress.

4. Soap Solution

This specially compounded low residue soap is specifically

designed to provide high film strength and compatibility with the

materials used within the Flow Cell Assembly.

The Gilibrator System

The Gilibrator

Nomenclature

1.

2.

3.

::

6.

7.

6.

9.

10.

11.

12.

13.

14.

15.

16.

17.

16.

19.

20.

21.

22.

23.

24.

Bubble Generator Assembly

Damper Plate

2a. Pulsation Damper

2b.

“0” Ring

Spacer

Plate, Bubble Breaker

Cable Assembly

Sensor Block Connecting Jack

Sensor Block Locking Screw

Sensor Block

25.

26.

Figure la

The Gilibrator System

The Flow Cell Assembly

Nomenclature

I

I

Bubble Generator Assembly

Damper Plate

2a. Pulsation Damper

2b.

“0”

Ring

Spacer

Plate, Bubble Breaker

Sensor Block Locking Screw

Sensor Block

Base Plate Assembly

9a.

“0”

Ring

Bubble Generator Ring

Bubble Initiate Button

21.

22.

23.

Air Inlet Boss

24.

Flow Tube

25. Storage Tubing

26.

Air Outlet Boss

27. Safety Tape

1.

2.

3.

4.

7.

a.

9.

a---

6

Figure lb

w

Section 3

Theory of Operation

1. Primary Airflow Standard

To be a primary standard, all values must be absolute and measured as

absolute. A primary standard airflow measurement is a volume divided by a

time interval as performed by the Control Unit of the Gilibrator. The

volume, V, is measured volume of space between two infrared sensors. The

time is that interval needed for a soap film bubble to traverse between the

two sensors which bound the volume.

Therefore,

V/t,

the volume per unit of

time, becomes the airflow and is prime because all measurements are basic...

volume and time. In today’s technology, time is measured by an electronic

clock whose accuracy exceeds that of volume measurements by orders of

magnitude, hence, the control accuracy volume resides solely with volume

measurements.

2. Bubble Generation and measurement

a) The Gilibrator consists of two elements, the Flow Cell Assembly and

the Control Unit (base). The function of the Flow Cell Assembly

-is

to

generate a clean consistent bubble which traverses up the flow tube. Meas-

urement of the traverse time is done by infrared sensor pairs which are

mounted at the bottom and the top of the Sensor Block. The volume bound by

these sensors is specifically adjusted to a volume standard by allowing the

upper sensor blocks to move in unison so as to enable this calibration to be

set accurately to a primary volume standard,

A second function of the

sensor block provides the interfacing code to define the cell volume as well

as sensitivity adjustments for the optical sensor systems.

b)

As the bubble traverses between the sansors, first one and then the

second, sensors are tripped thereby providing the time for the bubble

traverse.

This timing information is sent to the micro processor of the

control base which in turn provides the crystal control time base for the

system.

The timing information along with the volu,me information are then

sent to the micro processor which in turn does the necessary mathematical

calculations which allow the flow to be displayed directly on the LCD

readout. In order to insure the highest accuracy possible, a Delete and

Average function are provided on the Control Unit. The Delete allows for

subtracting out an obvious malformed bubble and the average allows the user

to obtain average information without pencil or paper. A printer interface

allows connection of a Printer Module so that hard copy can be produced.

Loading...

Loading...