Page 1

GILDERFLUKE & CO. ¥ 205 SOUTH FLOWER ST. ¥ BURBANK, CALIF. 91502-2102 ¥ 818/840-9484 ¥ FAX818/840-9485

OPERATINGINSTRUCTIONS

for

SIXTEEN CHANNEL SERVO MOTOR CONTROLLER

and

SIXTEEN CHANNEL JOYSTICK AMPLIFIER

February 27, 1999

The 16 Channel Servo Motor Controller is used to adapt a 0 to 10 volt analog control

signal to the pulse width modulated signal required to control model airplane-style servo

motors. These can be used to animate light weight or short lived pieces of animation as

are often used in motion picture special effects. This type of servo motor is not reliable

enough to be used in most permanent animation applications unless your are willing to

replace them on a fairly regular basis.

The 16 Channel Joystick Amplifier is used to raise the small output swing of a joystick or

other potentiometer to a 0 to 10 volt level. It is often used in conjunction with the 16

Channel Servo Motor Controller. It can also be used to live puppet Atchley Mechanical

FeedBack (MFB) actuators, Electronic FeedBack (EFB) pneumatic and hydraulic actuators,

or any other type of device which requires a 0 to 10 VDC control input.

The Servo Motor Controller has 16 independent inputs and outputs. They can be used

with MACs full-sized animation control systems or with any other source of 0 to 10 VDC

control signals. Up to eight of these cards can be used directly with the outputs from each

analog output card in a full-sized PC¥MACs animation control system for up to 128 servo

motors per analog output card. A full-sized system can contain up to two of these analog

output cards to control up to 256 servo motors at one time.

The 16 Channel Servo Motor Controller is often used in motion picture special effects to

control servo motors through 'live' puppetry. In this case there is no computer or animation

control system used between the operator inputs and servo motor controller. The inputs

can come directly from a potentiometer if it is going to be moved most or all of its stroke.

When using joysticks and similar input devices, the potentiometer's wiper only travels a

small percentage of the overall stroke of the pot. To boost these relatively small voltage

changes up to the levels needed by the servo motor controller, the 16 Channel Joystick

Amplifier can be used.

A Joystick Amplifier can be paired with a set of joysticks and calibrated for a 0 to 10

VDC output. This rig can then be moved between a number of different animated figures

which are expecting this signal level without having to recalibrate them each time.

1

Page 2

GILDERFLUKE & CO. ¥ 205 SOUTH FLOWER ST. ¥ BURBANK, CALIF. 91502-2102 ¥ 818/840-9484 ¥ FAX818/840-9485

- SERVO MOTOR CONTROLLER CONNECTIONS -

The Servo Motor Controller gets its power and data through a standard J-6/A data cable. The pin out

of this cable is as follows:

Pin #1 BROWN GROUND

Pin #2 RED 15 Volt DC Supply Input

Pin #3 ORANGE Channel 16 (0FH) 0-10 volt DC Analog Input

Pin #4 YELLOW Channel 16 (0FH) Reference

Pin #5 GREEN Channel 15 (0EH) 0-10 volt DC Analog Input

Pin #6 BLUE Channel 15 (0EH) Reference

Pin #7 VIOLET Channel 14 (0DH) 0-10 volt DC Analog Input

Pin #8 GRAY Channel 14 (0DH) Reference

Pin #9 WHITE Channel 13 (0CH) 0-10 volt DC Analog Input

Pin #10 BLACK Channel 13 (0CH) Reference

Pin #11 BROWN GROUND

Pin #12 RED 15 Volt DC Supply Input

Pin #13 ORANGE Channel 12 (0BH) 0-10 volt DC Analog Input

Pin #14 YELLOW Channel 12 (0BH) Reference

Pin #15 GREEN Channel 11 (0AH) 0-10 volt DC Analog Input

Pin #16 BLUE Channel 11 (0AH) Reference

Pin #17 VIOLET Channel 10 (09H) 0-10 volt DC Analog Input

Pin #18 GRAY Channel 10 (09H) Reference

Pin #19 WHITE Channel 9 (08H) 0-10 volt DC Analog Input

Pin #20 BLACK Channel 9 (08H) Reference

Pin #21 BROWN GROUND

Pin #22 RED 15 Volt DC Supply Input

Pin #23 ORANGE Channel 8 (07H) 0-10 volt DC Analog Input

Pin #24 YELLOW Channel 8 (07H) Reference

Pin #25 GREEN Channel 7 (06H) 0-10 volt DC Analog Input

Pin #26 BLUE Channel 7 (06H) Reference

Pin #27 VIOLET Channel 6 (05H) 0-10 volt DC Analog Input

Pin #28 GRAY Channel 6 (05H) Reference

Pin #29 WHITE Channel 5 (04H) 0-10 volt DC Analog Input

Pin #30 BLACK Channel 5 (04H) Reference

Pin #31 BROWN GROUND

Pin #32 RED 15 Volt DC Supply Input

Pin #33 ORANGE Channel 4 (03H) 0-10 volt DC Analog Input

Pin #34 YELLOW Channel 4 (03H) Reference

Pin #35 GREEN Channel 3 (02H) 0-10 volt DC Analog Input

Pin #36 BLUE Channel 3 (02H) Reference

Pin #37 VIOLET Channel 2 (01H) 0-10 volt DC Analog Input

Pin #38 GRAY Channel 2 (01H) Reference

Pin #39 WHITE Channel 1 (00H) 0-10 volt DC Analog Input

Pin #40 BLACK Channel 1 (00H) Reference

To connect a potentiometer to the input of the Servo Controller, you will need to provide a 10 VDC

reference and 15 VDC power supply. The 10 volt DC and negative references can be shared by all of

the potentiometers attached to a Servo Controller. Its current requirements are minimal, since about the

only current flow is that through the potentiometers. The same 15 volt DC supply that powers the 10 volt

reference can also be used to power the Servo Controller through one or more of the Ô15 Volt DC SupplyÕ

input pins.

When using direct potentiometer inputs to the Servo Controller, the pot must travel all or nearly all of

its stroke. If it doesnÕt, or you canÕt get all of the stroke you need on the servos, a Joystick Amp may be

needed. A Joystick Amplifier or the output from a PC¥MACs Animation Control System will provide all of

the voltage references and power supplies needed by the Servo Controller.

2

Page 3

GILDERFLUKE & CO. ¥ 205 SOUTH FLOWER ST. ¥ BURBANK, CALIF. 91502-2102 ¥ 818/840-9484 ¥ FAX818/840-9485

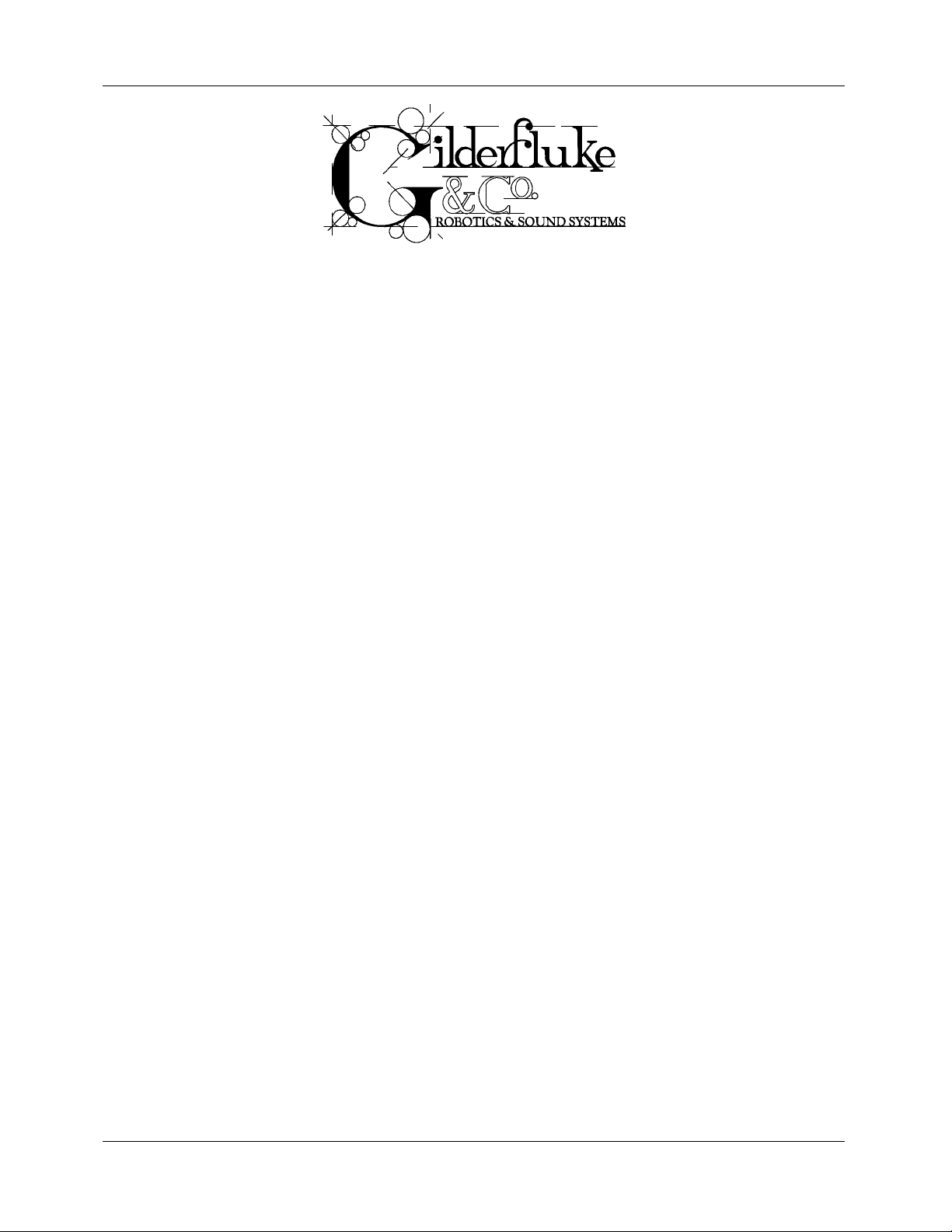

15 VDC supply

to Servo Controller Analog Input

(2) 1N4001 (typically) needed

on one input only. (These

provide the negative reference

voltage needed by the circuit.)

10 VDC

positive reference

10 volt

Regulator

negative reference

Potentiometer

(10KΩ typically)

If you need to reverse the direction of any of the potentiometer inputs, you can reverse the positions of the positive and negative references for that input potentiometer. A Double Throw, Double Pole

(DPDT) switch can be added if you will need to change it regularly:

15 VDC supply

to Servo Controller Analog Input

10 VDC

positive reference

10 volt

Regulator

Potentiometer

(10KΩ typically)

(2) 1N4001 (typically) needed

on one input only. (These

provide the negative reference

voltage needed by the circuit.)

negative reference

Back of DPDT switch

The pot must swing symmetrically around its middle point when this option is used.

The 16 servo motors are connected to the standard three pin sockets used by many brands of servo

motors. Some newer servo motors use a slightly different connector, and an adapter for this style of connector is available from the servo motor manufacturers. The pin out for these servo motor connections is

as follows:

SIGNAL

SERVO

+ SUPPLY

SERVO

- SUPPLY

The last remaining connector is for attaching the power supply which is used to power the servo motors. The power for these must come from an external source as they can potentially use a lot more current than the animation system can normally supply. Most servo motors run from a voltage between 3.5

volts and 7.5 volts. The lower the voltage the less strength and speed a given servo motor will have. A

higher voltage will give that same servo motor greater speed and strength.

3

Page 4

GILDERFLUKE & CO. ¥ 205 SOUTH FLOWER ST. ¥ BURBANK, CALIF. 91502-2102 ¥ 818/840-9484 ¥ FAX818/840-9485

5 5/16"

12345678 910111213141516

SERVO MOTOR OUTPUTS

SERVO MOTOR

POWER INPUT

STROKE ADJUSTMENTS

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

4"

RETRACT ADJUSTMENTS

1 2 3 4 5 6 7 8 9 10111213141516

J-6A INPUT

In some cases a lower speed is desired for the smoothness of the movement, while in other cases

the need for high speed or strength may be paramount. The chief disadvantages of running the servo

motors in high voltage / high speed applications are that the servo motor will run hotter and is much

more likely to have a mechanical failure.

The size of the servo motor, the load it is driving, and the amount of movement it is doing can all effect the amount of current it will require. Most of the smaller servo motors draw about an amp of current

at stall (This is when the servo motor shaft is held against the motor's best efforts to move it.). This condition isn't often encountered in any real world applications, but if you are planning on really abusing your

servo motors you should allow about an amp per motor when selecting a power supply. Under most normal conditions, 1/4 to 1/2 an amp per servo motor will be sufficient. If your power supply is undersized,

you will see a certain amount of interaction between servo motors when a number of them are moving

at the same time.

To reduce the number of wires needed to run into a servo motor-controlled figure it is not uncommon to run the high current power supply leads directly from the power supply to the servos in the figure

and gang the signal lines. When this is done, it is still necessary to run low current leads from the power

supply to the power supply connections on the Servo Motor Controller board. If the signal line runs to the

servo motors are long, it may be necessary to use shielded lines to prevent noise and cross-talk between

the servos. You can tell when you have this problem when some servo motors are tending to jitter uncontrollably.

Be aware that the servo motor input signals are notoriously bad travelers. They are susceptible to any

power supply noise, radio frequency (RF) interference, and even the noise from other servo motors. Try

to keep these lines as short as possible. Anything over 10 feet can cause problems. Even shorter lengths

can have problems under the right circumstances. Possible solutions include large capacitors across the

power supply leads and pullup resistors between the signal input and the positive supply line. These must

be located as close as possible to the servo motors.

Each channel of the Servo Motor Controller has two adjustments. The first sets the 'retracted' position

4

Page 5

GILDERFLUKE & CO. ¥ 205 SOUTH FLOWER ST. ¥ BURBANK, CALIF. 91502-2102 ¥ 818/840-9484 ¥ FAX818/840-9485

for the servo motor. The other sets the length of the 'stroke' away from the retract position, and therefore

the extended position. The retract position is always set before you try to set the 'extend' position.

Some caution must be used when adjusting servo motors or mechanical movements which may be

damaged by being commanded to go to a position beyond that which they are designed to move. In

these cases it is sometimes best to adjust both the retract and stroke trimpots to a center position for the

movement and then adjust them slowly outward from there.

The 16 Channel Servo Motor Controller comes in a plastic case which can be mounted by simply

double face taping it where ever you need. If you need to mount it more solidly, then put screws

through the back of the case as needed. The front of the case can be removed for service and adjustment after the box has been mounted.

The capabilities of the Servo Motor Controller outputs are as follows:

OUTPUT: OPEN COLLECTOR SWITCH TO GROUND

PULLUP: 4.7K PULLUP TO + SERVO POWER SUPPLY

OUTPUT CURRENT: 16 ma MAXIMUM

OUTPUT/SERVO VOLTAGE: 5 VDC NOMINAL / 36 VDC MAXIMUM

5

Page 6

GILDERFLUKE & CO. ¥ 205 SOUTH FLOWER ST. ¥ BURBANK, CALIF. 91502-2102 ¥ 818/840-9484 ¥ FAX818/840-9485

- JOYSTICK AMPLIFIER CONNECTIONS -

The inputs to the Joystick Amplifier is designed to be attached to up to 16 potentiometers. Typical

value for the pots is 10 Kohm. To ease the job of wiring to the pots, a 50 wire ribbon cable is used for the

input. Starting from the number one wire position, the first wire goes to one side of the pot, the next goes

to the middle (wiper) pole of the pot, and the third wire goes to the third connection of the pot. This then

repeats for the other 15 pots. The pin out for the connector is as follows:

PIN #1 BROWN Negative Reference #16

PIN #2 RED Joystick Amplifier Input #16

PIN #3 ORANGE Positive Reference #16

PIN #4 YELLOW Negative Reference #15

PIN #5 GREEN Joystick Amplifier Input #15

PIN #6 BLUE Positive Reference #15

PIN #7 VIOLET Negative Reference #14

PIN #8 GRAY Joystick Amplifier Input #14

PIN #9 WHITE Positive Reference #14

PIN #10 BLACK Negative Reference #13

PIN #11 BROWN Joystick Amplifier Input #13

PIN #12 RED Positive Reference #13

PIN #13 ORANGE Negative Reference #12

PIN #14 YELLOW Joystick Amplifier Input #12

PIN #15 GREEN Positive Reference #12

PIN #16 BLUE Negative Reference #11

PIN #17 VIOLET Joystick Amplifier Input #11

PIN #18 GRAY Positive Reference #11

PIN #19 WHITE Negative Reference #10

PIN #20 BLACK Joystick Amplifier Input #10

PIN #21 BROWN Positive Reference #10

PIN #22 RED Negative Reference #9

PIN #23 ORANGE Joystick Amplifier Input #9

PIN #24 YELLOW Positive Reference #9

PIN #25 GREEN Negative Reference #8

PIN #26 BLUE Joystick Amplifier Input #8

PIN #27 VIOLET Positive Reference #8

PIN #28 GRAY Negative Reference #7

PIN #29 WHITE Joystick Amplifier Input #7

PIN #30 BLACK Positive Reference #7

PIN #31 BROWN Negative Reference #6

PIN #32 RED Joystick Amplifier Input #6

PIN #33 ORANGE Positive Reference #6

PIN #34 YELLOW Negative Reference #5

PIN #35 GREEN Joystick Amplifier Input #5

PIN #36 BLUE Positive Reference #5

PIN #37 VIOLET Negative Reference #4

PIN #38 GRAY Joystick Amplifier Input #4

PIN #39 WHITE Positive Reference #4

6

Page 7

GILDERFLUKE & CO. ¥ 205 SOUTH FLOWER ST. ¥ BURBANK, CALIF. 91502-2102 ¥ 818/840-9484 ¥ FAX818/840-9485

PIN #40 BLACK Negative Reference #3

PIN #41 BROWN Joystick Amplifier Input #3

PIN #42 RED Positive Reference #3

PIN #43 ORANGE Negative Reference #2

PIN #44 YELLOW Joystick Amplifier Input #2

PIN #45 GREEN Positive Reference #2

PIN #46 BLUE Negative Reference #1

PIN #47 VIOLET Joystick Amplifier Input #1

PIN #48 GRAY Positive Reference #1

PIN #49 WHITE NO CONNECTION

PIN #50 BLACK NO CONNECTION

A typical connection for a pot is as follows:

Potentiometer

(10KΩ typically)

10 VDC positive reference

to Joystick Amplifier input

negative reference

If you need to reverse the direction of any of the potentiometer inputs, you can reverse the positions of the positive and negative references for that input potentiometer. A Double Throw, Double Pole

(DPDT) switch can be added if you will need to change it regularly:

Potentiometer

(10KΩ typically)

10 VDC positive reference

to Joystick Amplifier input

negative reference

Back of DPDT switch

The pot must swing symmetrically around its middle point when this option is used.

All of the positive and negative references fed to the pots are wired in parallel. If needed, a single

pair of wires may be used for the references to a number of different pots.

7

Page 8

GILDERFLUKE & CO. ¥ 205 SOUTH FLOWER ST. ¥ BURBANK, CALIF. 91502-2102 ¥ 818/840-9484 ¥ FAX818/840-9485

5 5/16"

J-6A OUTPUT

STROKE ADJUSTMENTS

1

3

5

7

9

11

13

15

2

4"

1

2

4

6

8

10

12

14

16

RETRACT ADJUSTMENTS

3

5

4

7

6

9

8

10

11

12

13

14

15

16

POT INPUTS

The output of the Joystick Amplifier is a standard J-6/A output. The pin out for this connection can be

found above in the Servo Motor Controller wiring instructions.

Each channel of the 16 Channel Joystick Amplifier has two adjustments. The first sets the output

level for the 'retract' end of the pot. This is where the Joystick Amp is usually adjusted for a 0 VDC output.

The second adjustment sets the 'stroke' length, and therefore the high level output for the channel. This

is normally adjusted to 10 VDC. These two adjustments interact somewhat, so each will need to be adjusted in turn until the desired output levels are achieved. When used with a 16 Channel Servo Motor

Controller, the adjustments on the Joystick Amplifier must be made first.

Power for the Joystick Amplifier comes from a small wall mount-style transformer attached to it. When

used with the 16 Channel Servo Motor Controller, this transformer supplies power for both units through

the Joystick Amp. A LED on the front of the Joystick Amp shows that it has power to it.

The 16 Channel Joystick Amplifier comes in a plastic case which can be mounted by simply double

face taping it where ever you need. If you need to mount it more solidly, then put screws through the

back of the case as needed. The front of the case can be removed for service and adjustment after the

box has been mounted.

The output capabilities of all Joystick Amplifiers are as follows:

OUTPUT VOLTAGE: 0 TO 10 VDC

OUTPUT CURRENT: 0 TO 24 ma

OUTPUT DEVICE: LM324

OUTPUT PROTECTION: OVERVOLTAGE/CURRENT PROTECTION

INHERENT TO LM324

8

Loading...

Loading...