Page 1

GILDERFLUKE & CO. • 205 SOUTH FLOWER ST. • BURBANK, CALIF. 91502-2102 • 818/840-9484 • FAX818/840-9485

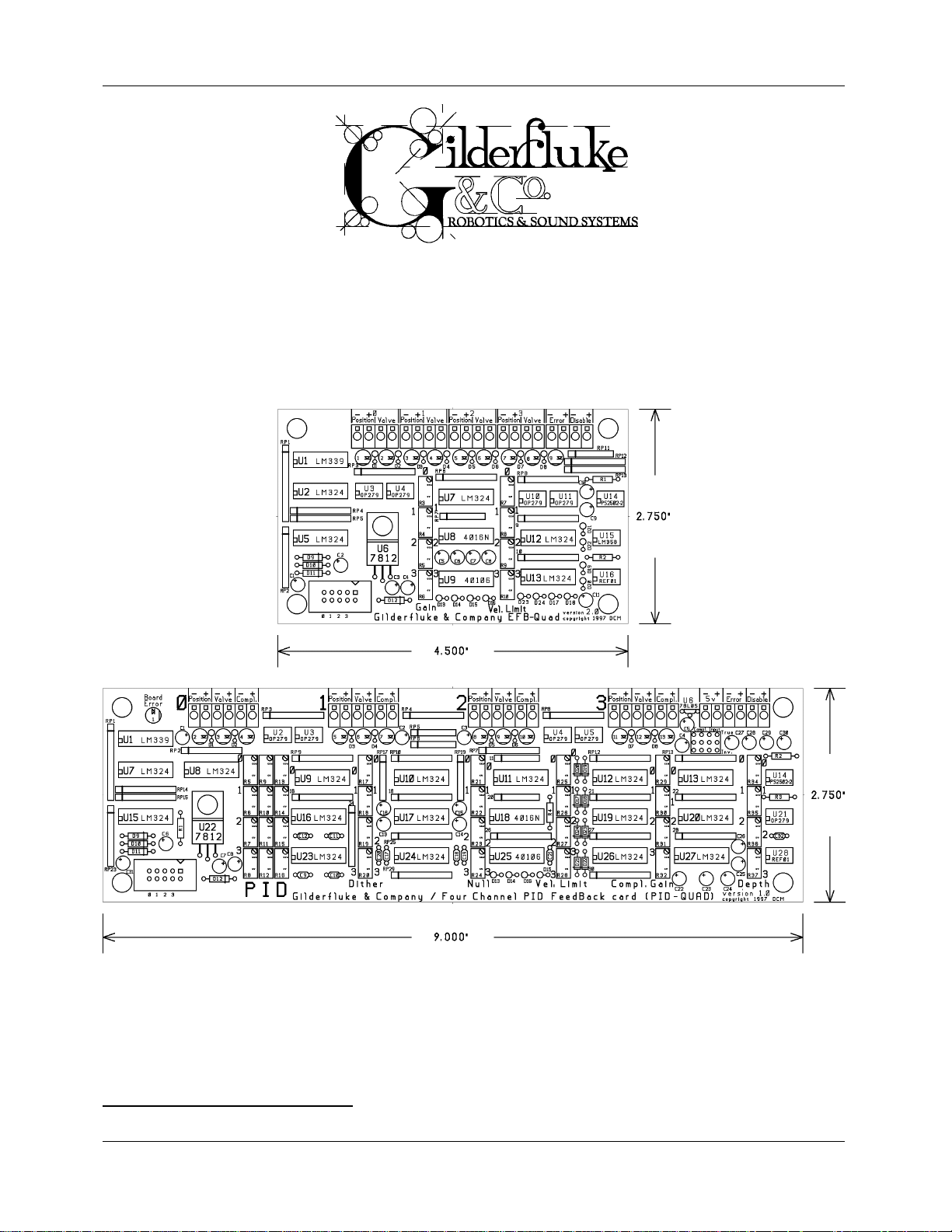

- OPERATINGINSTRUCTIONS-

- for -

- EFB-QUAD ELECTRONIC FEEDBACK CONTROLLER -

- PID-QUAD E

LECTRONIC FEEDBACK CONTROLLER -

- printed February 27, 2006 -

Animation movements come in two basic flavors: 1) Analog, and 2) Digital. Although

we are used to thinking of everything ‘digital’ being superior to anything analog (like

digital CDs vs. analog LP records), this is the one case where it just ain’t so 1. Analog

movements are used in almost all high-end animated figures. They give you a fluid,

lifelike motion that digitals just can’t do.

1

Digital electronics are used to create most analog Animation Control Systems.

1 of 12

Page 2

GILDERFLUKE & CO. • 205 SOUTH FLOWER ST. • BURBANK, CALIF. 91502-2102 • 818/840-9484 • FAX818/840-9485

A Digital control is either off or on, just like a light switch. A typical digital animation

movement is at either one end of its travel or the other, or moving between these two

positions 2. The speed of the action is set by the flow controls that control how fast the air

(or oil) can get into and out of the cylinder.

An analog control is like the light dimmer on the wall of your dining room. It can be off,

on, or at any point in between. The rate at which it is moving (within the maximum flow

limitations of the valve) is controlled by how fast you are turning the knob. If you stop

turning the knob half way through the rotation, the movement will stop there too. An

analog movement will follow every nuance of how you turned that knob during

programming and will be able to repeat it exactly. If something tries to push an analog

away from where it was programmed to be, it will actually fight to get back to where it

belongs.

How does it do this? Unlike open loop controls (digital movements are almost always

open loops), the command signal to an analog movement does not control the valve

directly. Instead, the command signal goes to some sort of Electronic Feed Back (EFB)

card. Examples of these are our EFB-Quad, PID-Quad and BS-EFB. Here the command is

compared with the actual position of the movement as measured by a device that is

mounted on the movement (typically a potentiometer). If the movement is off by just a

little, the EFB card will open the valve by just a little to get it back into the proper position. If

the movement is off by a lot, then the EFB card will open the valve as needed until it starts

getting close to where it should be. It then ramps the valve fully closed as the final position

is reached to slow the movement smoothly to a stop.

Despite their added complexity, analog functions tend to be more reliable than digital

moves. The reason for this is simple. Their closed servo loop allows them to adjust

themselves (within limits) to compensate for cylinder wear, leakage and pressure

variations. They are also smoother than digital functions. With less banging into the end

stops of the cylinders, there is simply less wear and tear on the mechanics of the figure.

The two most common failures in an analog movement are a break in the wires leading

to the feedback pot on the cylinder or a clogged valve. A unique feature of all of our

Electronic FeedBack cards is the ability to sense wire breaks, sound an alarm and to turn

‘off’ the affected axis until help arrives.

So why aren’t analog moves used for all animation? One reason. Price. The cost of the

cylinder and its associated hardware is virtually identical for an analog or digital

movement. The analog function does need a bit more electronic control, but this no

longer represents a major cost. The servo valve does. The cost of a solenoid valve for a

digital function might be between $20 and $30. The cost for a servo valve to do the same

movement as an analog would be in the $500 to $1000 range. In addition there needs

to be some sort of ‘feedback’ on the cylinder to tell the EFB card where the movement is at

2

There are variations in digital movements that use more than a single digital valve or cylinder. These

allow some variation in speed and/or stopping mid stroke. With open loop controls, the repeatability can

not be guaranteed as it can with an analog function. It is also possible to use a pair of four way valves or

a single five way valve in a closed loop servo system. This will give you positional repeatability, but not

the smoothness you get from a real ServoValve.

2 of 12

Page 3

GILDERFLUKE & CO. • 205 SOUTH FLOWER ST. • BURBANK, CALIF. 91502-2102 • 818/840-9484 • FAX818/840-9485

any given instant. When using a potentiometer, this can add from $25 (for a rotary pot) to

$100 or more (for a linear pot or LVDT).

Electronic FeedBack cards typically use what is called a ‘PID’ loop to control the

position of a movement. This type of loop is available on our new four channel PID-Quad

and BS-EFB Electronic FeedBack cards. The ‘P’, ‘I’ and ‘D’ stand for Proportional, Integral

and Derivative. Forget that. This is what they do:

The basic feedback loop is the Proportional (or ‘gain’). It is what is found on the simple

EFB cards like our EFB-Quad. A simple loop like this has been traditionally used for

controlling most analog functions in animated figures. This is because most figures’

positional requirements are not stringent enough to demand a higher performance

feedback loop.

The ‘P’ function compares the desired position with the actual position (as measured

by a potentiometer or other measuring device that is attached to the movement). The

difference is amplified and fed to a servo valve to open or close it as needed. If the ‘gain’

of the ‘P’ is turned up too high, then the movement will overshoot, and then try to get back,

and overshoot again, and again, and again..... This is what is known as oscillation, and it

is not a good thing. If the gain is tuned too low, then the movement will follow the

commands sluggishly.

The ‘I’ function is the one that is used to suck a movement in when it is too close to the

desired position for the ‘P’ function to open the valve enough to overcome the ‘stiction’ of

the cylinder. If the movement isn’t perfectly positioned, the ‘I’ function generates a slowly

rising voltage to the valve until it opens enough for the cylinder to move the last little bit to

the desired position. If the ‘I’ function is turned up too high, then the movement will

constantly seek the desired position, overshoot, and seek again. Unlike the oscillation that

occurs when the ‘P’ is set too high, the ‘I’ oscillation occurs at a low speed. Although

entertaining, it is rarely destructive. If the ‘I’ is adjusted too low, then the ‘dead band’

around the desired position will be wider.

The ‘D’ function is used so that you don’t have to turn the ‘P’ up too high to get the

movement to accurately follow fast changing commands. The ‘D’ gives an extra ‘kick’ to

the valve when a movement is commanded to start quickly. If it is set too high, then the

movement will start too quickly, overshoot the commanded position, and then slow down

as the ‘P’ error takes over.

Another adjustment that is available on our EFB-Quad or PID-Quad cards is a ‘Velocity

Limit’. This control allows you to set the maximum a valve can be opened by the

FeedBack card. On the EFB-Quad it allows you to set the gain a bit higher to control

oscillations by limiting the maximum opening of the valve. By raising the gain higher and

limiting the velocity, you can narrow the ‘dead band’ of the servo loop.

The PID-Quad also has adjustment to add a 60 Hz dither signal or offset (null) to the

output. The dither is used with some valves whose performance is increased remarkably

when such a signal is applied. The nulling allows you to center the spool of the valve

electronically if it wasn’t centered properly in the factory.

3 of 12

Page 4

GILDERFLUKE & CO. • 205 SOUTH FLOWER ST. • BURBANK, CALIF. 91502-2102 • 818/840-9484 • FAX818/840-9485

The PID-Quad also features what are called ‘Compliance’ inputs. This adds a second

‘force’ feedback to an analog movement. This is usually a strain gauge or accelerometer

mounted on the cylinder in addition to the normal position sensor. This measures the force

being applied by the cylinder and feeds this to the FeedBack card. Sometimes an

accelerometer on the movement or differential pressure transducer on the valve are used

for a lower cost.

As a compliant movement is commanded to accelerate quickly, the inertia of the

mass of the movement applies a force to the strain gauge. This gets amplified and

added to the signal that the PID-Quad sends to the valve to open it further than just the

positional error would have made it open. Conversely, when the movement is

commanded to decelerate quickly, the strain gauge picks up the mass of the movement

in the opposite direction and the feedback card can open the valve in the reverse

direction to apply active braking to the movement as it approaches its target position.

The other thing that compliance does to a figure is to ‘soften’ it. If you press on a

compliant movement (one that uses a strain gauge), it will sense this external pressure

and the feedback card will actually open the valve to allow the movement to move out

of your way. In complex figures, as one movement applies forces to other movements,

they will respond to this force and all give a little. Of course, using pneumatics instead of

hydraulics gives this effect even without compliance feedback. With pneumatic figures,

the compliance feedback can be reversed to make the figure act a little stiffer, or a little

more like a hydraulic figure.

An EFB-Quad or PID-Quad controller is used to control up to four independent servo

loops. Each of these loops consists of a servo valve or motor controller, an actuator

(hydraulic or pneumatic cylinder or electric motor), and a transducer (typically a 10 Kohm

variable resistor) linked to the actuator.

In operation, a control voltage (nominally 0 to 10 VDC) is sent to the EFB-Quad or PIDQuad controller. The card’s circuitry compares this incoming voltage with the current

position of the actuator as sensed by the transducer.

The most common failure in animated figures which use EFB analog movements are

broken wires leading to the transducer. For that reason Gilderfluke's EFB-Quad and PIDQuad controller were designed so that they only needs two wires to each transducer

(three are usually required) and it constantly checks the status of these wires. If there is a

wire break, it will immediately switch off that axis. When a break is sensed, or when power is

first applied to the EFB-Quad or PID-Quad controller, it will stay in the error condition for

approximately 10 seconds. This will keep circuits with loose wire connections from jumping

in and out of error condition.

There is a 'broken wire' indicator LED for each of the four channels in the EFB-Quad or

PID-Quad controller. If any of the circuits is in an error condition, then the 'error' LED will light.

This error signal can be be sent to a remote indicator or alarm through the optically

isolated ‘Error’ output. A remotely mounted LED or small relay can be used to indicate a

problem with the figure on a central indicator panel.

4 of 12

Page 5

GILDERFLUKE & CO. • 205 SOUTH FLOWER ST. • BURBANK, CALIF. 91502-2102 • 818/840-9484 • FAX818/840-9485

If any channels are left unused on the EFB-Quad or PID-Quad controller, you will need

to short together the transducer inputs on the unused channels to turn the ERROR LED off.

Installation:

Connections for channel 0 output shown. All other channels are identical.

K OHM

10

R

N/C

ESISTANCE

(TYPICAL)

TRANSDUCER

CYLINDER

STRAIN GUAGE

(if using

COMPLIANCE)

C2 C1

Hydraulic or

Pneumatic

Servo Valve

YELLOW

E

XHAUST

(or RETURN LINE FOR HYDRAULICS)

AIR OR

HYDRAULIC

SUPPLY

GREENWHITE

RED

The cylinder can be virtually any type of double acting cylinder available (rotary, linear, etc.). The

stroke and diameter of the cylinder can be used to determine the size of valve you need to use by

5 of 12

Page 6

GILDERFLUKE & CO. • 205 SOUTH FLOWER ST. • BURBANK, CALIF. 91502-2102 • 818/840-9484 • FAX818/840-9485

calculating the approximate displacement of the cylinder and comparing it to the cubic feet per minute

(CFM) capacity of the valve.

A number of different styles of position transducers are available. These include standard linear and

rotary potentiometers as well as 'string pots' in which a small steel cable extends to measure distances.

Whatever type of transducer is used, it must be linked to the actuator so that it closely follows the

movement and uses as much of its stroke as possible. For any permanent installation you must use a

potentiometer which is made for this type of heavy duty use. Typical life span ratings are in the 2 to 20

million cycle range.

The default value for the feedback pots is 10 Kohms. You can use feedback pots which have a

different value. To do so you will need to change the two SIP resistors RP1 and RP23 (RP2 on the EFBQUAD) to match the value of your feedback pots. They are socketed to facilitate this. RP1 is a ten pin

bussed SIP in which one end of all nine resistors are attached to pin number one. RP23 (RP2 on the EFBQUAD) is an eight pin SIP resistor which contains four independent resistors. If you can’t find a pair of SIP

resistors with the appropriate values or need to use different valuers for different channels, you can also

build them up from discrete resistors.

The input to the EFB card from the feedback pot is 0-5 volts, referenced to the negative reference

found on the “-” feedback connection pin. You should measure this voltage across these two pins as the

feedback element is moved. If you are using a feedback element other than a potentiometer (like a

LVDT or Tempasonic transducer), this is the voltage that needs to be applied.

When the voltage at the feedback “+” pin exceeds 7.5 volts, this will trigger the ‘wire break’ circuit.

This will immediately limit the output voltage swing to less than a volt, effectively turning off the axis.

Whenever the feedback card senses a wire break, there is a ten second (or so) delay until the channel is

turned back ‘on’.

Any wire break will also turn on the ‘Error’ output. This can be used to turn on a remotely located

indicator light or LED to alert the ride operators that there is a problem with this channel. The ‘Error’

outputs from multiple EFB cards can be paralleled to a single indicator. The Error output is an

optoisolated (to 1500 volts) transistor, suitable co controlling loads of up to about 50 milliamperes at up

to 24 volts.

All unused channels on an EFB card should have the feedback connections shorted together with a

short piece of wire. This will allow the wire break circuitry for the channel to time out and turn off the

‘Error’ outputs.

If you are using a potentiometer and can’t change the values of RP1 and RP23 (RP2 on the EFBQUAD) to match (or your feedback pot doesn’t work well as a voltage divider) you can tie the pot’s

unused side to a 5 volt reference on the feedback card. On the EFB-Quad, you can find a five volt

reference on U15 pin #1. On a PID-Quad, the 5 volt reference can be found on U21, pin #1. When

operating in this mode, you will need to clip RP1’s pins #2, #3, #4 and/or #5 (for channels 0 through 3,

respectively) so that they no longer make contact with the SIP socket. On the PID-QUAD there is a screw

terminal with 5 volts on it. This is normally used to provide power to the strain gauge used for compliance

feedback. Note that this 5 volts is not as accurate or clean as the 5 volts found on U21, but it can

provide a good deal more current and is a lot easier to get to.

All four channels on an EFB card can be disabled by applying a 12 to 24 VDC signal to the ‘Disable’

screw terminals. This signal is optoisolated (to 5000 volts) from the rest of the feedback card. There will

be a ten second (approximately) delay after this signal is removed before the feedback channels return

to normal operation.

The output which goes to the valve is +/- 10 volts at a current up to 50 milliamperes This is

compatible with the 250 ohm coils on most servo valves.

6 of 12

Page 7

GILDERFLUKE & CO. • 205 SOUTH FLOWER ST. • BURBANK, CALIF. 91502-2102 • 818/840-9484 • FAX818/840-9485

EFB-Quad and PID-Quad Inputs:

The inputs to the EFB-Quad and PID-Quad are a standard 1/4 J6/A cables. This typically comes from a

BS-ANA or other analog output control system. It is fed to the feedback card through the ten position

ribbon cable connector.

The pinout for the 1/4 J6/A is as follows:

1 brown circuit ground

2 red 15 to 24 VDC Power Supply

3 orange Channel 3 Positive Analog Input

4 yellow Channel 3 Negative Reference

5 green Channel 2 Positive Analog Input

6 blue Channel 2 Negative Reference

7 violet Channel 1 Positive Analog Input

8 gray Channel 1 Negative Reference

9 white Channel 0 Positive Analog Input

10 black Channel 0 Negative Reference

The ‘positive analog inputs’ are typically 0 to 10 VDC, referenced to the ‘negative references’. This

‘negative reference is nominally at about 1 1/2 volts above the ground level, and is common for all four

channels. This reference is provided by the analog outputs of all Gilderfluke & Company Animation

Control Systems. If you are using these feedback cards with another control system, you will need to

supply this reference voltage along with the 15 to 24 VDC supply. If the negative reference is attached

to the real ground, the card will not operate properly.

7 of 12

Page 8

GILDERFLUKE & CO. • 205 SOUTH FLOWER ST. • BURBANK, CALIF. 91502-2102 • 818/840-9484 • FAX818/840-9485

EFB-Quad and PID-Quad Adjustments:

There are two adjustments available on each of the four channels on an EFB-Quad, and eight

adjustments per channel on an PID-Quad. These are:

1) Proportional (‘P’) or Gain: This controls how much the valve will be opened for a given distance

between the commanded and actual positions of a movement. This control is bypassed when

there is an error condition in the feedback transducer wiring or on power-up.

Turning this control clockwise will increase its effect. Turning it counterclockwise reduces its

effect. When turned fully counter clockwise, it has no effect at all.

When the Proportional control is turned too high, the movement will oscillate

uncontrollably. Set it too low and the movement will move sluggishly.

2) Integral (PID-Quad only): This is the control that sets the final ‘suck in’ to the commanded

position. When a motion stops near the commanded position, but not exactly on it, the Integral

comes into play. When the position error is small, the voltage sent to the valve is usually too

small to overcome the valve/cylinder ‘stiction’ to get the movement to reach the final position.

What the integral does is to provide a gradually increasing voltage to the valve until it

overcomes the valve/cylinder stiction and the movement moves that last little bit to reach the

final position.

Turning this control clockwise will increase its effect. Turning it counterclockwise reduces its

effect. When turned fully counter clockwise, it has no effect at all.

When the Integral on a movement is set too low, the movement will not reach the

commanded position when the distance between the commanded position and the actual

position is small. This will widen the deadband of the movement. If the Integral is turned too high,

you will see the movement constantly ‘seeking’ the commanded position. This looks like a low

speed oscillation on the movement.

3) Derivative (PID-Quad only): This controls the PID feedback loop’s ability to respond to quickly

changing commands. Think of the derivative as the accelerator pump in an automobiles’

carburetor. When you step on the gas quickly, it gives an extra little squirt of gas to the engine to

get it to accelerate quickly. When you accelerate slowly, the accelerator pump (and the

Derivative term of the PID loop) have no effect.

Turning this control clockwise will increase its effect. Turning it counterclockwise reduces its

effect. When turned fully counter clockwise, it has no effect at all.

The Proportional (Gain) control and the Derivative must be adjusted interactively. When the

Derivative is set too low, the movement won’t follow fast changes in commands as quickly as it

would otherwise. If the Derivative is set too high, then the movement may start quite quickly, but

then get ahead of the commanded position and will have to decelerate to allow the

Proportional term to catch it.

4) Dither (PID-Quad only): This control adds an approximately 60 Hertz ‘triangular’ signal to the

output sent to the valve. Some valves can benefit from such a signal in that by keeping moving,

they will then respond to actual commands much more quickly.

Turning this control clockwise will increase its effect. Turning it counterclockwise reduces its

effect. When turned fully counter clockwise, it has no effect at all.

If the valve you are using will benefit from a dither signal, the specification sheet will usually

indicate this. If there is no indication whether a dither signal will help your valve, adjust the

movement as usual, but keep it a little more sluggish than you want the final speed. Then crank

in some dither. If the speed of the movement increases, then there is probably some benefit to

keep it in. If there is no change, then there is no reason to use it.

5) Null (PID-Quad only): Nulling is used to set the valve so that when it has no voltage being sent

to it, there is no movement in the cylinder.

Ideally the valve should be adjusted mechanically with the wires from the feedback card

8 of 12

Page 9

GILDERFLUKE & CO. • 205 SOUTH FLOWER ST. • BURBANK, CALIF. 91502-2102 • 818/840-9484 • FAX818/840-9485

completely disconnected. Most valves have some sort of setscrews or other mechanical

adjustments which will allow you to center the valve until there is no movement in the cylinder. If

you can’t disconnect the valve from the feedback card, you can attach a voltmeter across the

valve outputs and position the movement until it stays at mid-stroke. Then mechanically adjust

the valve until the voltmeter reads zero volts.

The Null control on the PID-Quad is used to center valves that can not be adjusted

mechanically. It can also be used to offset movements that are so heavily loaded in one

direction that they move more slowly in one direction than the other.

The null control must be set to provide zero volts before any of the other controls have

been set. To do this, turn the P, I, D and Dither controls fully counter clockwise. Attach a meter

across the valve outputs for the channel being adjusted. Adjust the Null control until the meter

reads zero volts.

If your valve needs to be nulled electronically, then attach the valve and apply air or

hydraulic pressure. Adjust the Null control until the cylinder stays stationary (or nearly stationary).

6) Velocity Limit: This control limits the maximum amount the valve may open by limiting the

voltage that is sent to the valve.

Turning this control clockwise will increase its effect. Turning it counterclockwise reduces its

effect. When turned fully counter clockwise, it has no effect at all.

The Velocity control can be used to limit the speed of a movement by limiting the voltage

that can be sent to the valve. This has the same effect as electronically reducing the size of the

valve. You may want to limit the velocity of a movement for safety reasons (as when you just

don’t want a movement to move too fast), or by limiting the velocity of a movement, you may

be able to increase the gain of the movement to a point higher than you otherwise could. This

can give you a movement that follows the commanded position more sharply, albeit more

slowly at maximum speed.

7) Compliance Gain (PID-Quad only): This sets the gain of the compliance input. It is adjusted

interactively with the Compliance Depth control.

Turning this control clockwise will increase its effect. Turning it counterclockwise reduces its

effect. When turned fully counter clockwise, it has no effect at all. This should be done to turn

off the compliance if it is not being used.

8) Compliance Depth (PID-Quad only): This sets the length of time that a compliance input will

have an effect on the output. Increasing the Compliance depth will not only affect the length

of time that it has an effect, it will also increase the amount of effect that it has. It is adjusted

interactively with the Compliance Gain control.

Turning this control clockwise will increase its effect. Turning it counterclockwise reduces its

effect. When turned fully counter clockwise, it has no effect at all. This should be done to turn

off the compliance if it is not being used.

A green/red bicolor LED shows the compliance inputs and their effect on the outputs. A

compliance input is usually attached to a strain gauge or accelerometer. Voltage input ranges

that are acceptable are 0-5 or 0-10 volts. When the compliance input has a changing signal

applied to it, it will have a momentary effect on the output. This will then fade away over time

until it has no more effect. The amount of time the input effect takes to fade away is set using

the Compliance Depth control. The Compliance Depth and Compliance Gain both have an

effect on how much of an effect the compliance input has on the output.

When installing a compliance feedback element (either a strain gauge or accelerometer),

you have a 50%/50% chance of installing it backwards. The effect of the compliance inputs

can be reversed by moving the jumpers labeled ‘compliance inputs’. The jumpers can be

moved to either the ‘true’ or ‘inverted’ positions as needed.

9 of 12

Page 10

GILDERFLUKE & CO. • 205 SOUTH FLOWER ST. • BURBANK, CALIF. 91502-2102 • 818/840-9484 • FAX818/840-9485

EFB-Quad Adjustment:

Adjusting an EFB movement is part skill and part art. Unfortunately it must be done to taste, so there

are no set rules about making these adjustments. The following procedure will usually yield satisfactory

results 3:

1) When you first turn on a EFB circuit to start testing it, you should first turn the Proportional (Gain)

controls all the way down (counter-clockwise) and the velocity control all the way out (counterclockwise).

2) Turn the Proportional (Gain) control clockwise as you apply a varying command voltage to the

movement to sweep it back and forth. As the gain comes up, you will start to see the valve

indicator LEDs start to glow green/red as the valve opens and the actuator starts to follow the

position commands . Continue turning the Proportional (Gain) up until the movement starts to

show signs of oscillation.

3) Turn velocity control clockwise to stop the oscillation. Now turn it back down (counter-clockwise)

until you find the point just above where the movement can be made oscillate by applying fast

moving command voltages.

At this point the movement should be adjusted reasonably well. Depending on the nature of the

movement, you may want to continue to tweak it to taste.

PID-Quad Adjustment:

Before adjusting a PID-Quad, you should first set all of the controls for the channel fully counter

clockwise. Then adjust the Null control for zero voltage output measured on the valve outputs. This

should be somewhere near the center of the range of this potentiometer. You should then null the valve

mechanically or electronically, as needed.

The basic adjustment is performed pretty much as on the EFB-Quad. If when the Proportional gain is

first turned up the movement tends to slam to one end or the other, then there is probably a phase

reversal problem. This can be corrected by either reversing the two wires that lead to the valve, or

switching the wire that runs to one end of the feedback pot to the other end of the feedback pot. Do

not move the wire on the wiper of the pot or just reverse the two wires that run to the feedback card, as

this will have no effect.

After the basic adjustment is made, you can then start cranking in some Integral and Derivative. As

these are added, you may find that the Proportional and Velocity Limit controls may need to be adjusted

higher or lower.

If you are using a compliance input, you will need to start by adjusting in some of the Compliance

Gain and Compliance Depth. If the compliance input needs to be reversed, you will find that the

movement will start oscillating or fight you as you press against the movement (if you are using a strain

gauge for the compliance feedback). Normally when you press against a compliant movement that

uses a strain gauge, it will momentarily move in the same direction you are pushing on it. As the

Compliance Depth times out, only then will it begin fighting to get back to the commanded position.

3

If this is the first time the circuit has been turned on, you may find that the movement turns the

valve on hard in one direction and just wants to stay there. This means that there is something crossed in

the EFB's hookup. To correct this problem you will need to reverse the connections at one and only one

of the following points:

1) Switch the wiring on the transducer. One of the two wires to the transducer is attached to the

wiper. Leave this one alone. The other wire is attached to one end of the resistor. Move this wire

to the opposite end of the resistor (this would be the connection marked 'N/C' on the

illustration).

2) Switch the two wires on the valve. If the valve is opening in the wrong direction, reversing the

two wires to the valve will reverse the direction the valve opens.

3) Switch the plumbing between the valve and the cylinder. Just cross the two hoses at either the

valve or cylinder end of the hookup.

10 of 12

Page 11

GILDERFLUKE & CO. • 205 SOUTH FLOWER ST. • BURBANK, CALIF. 91502-2102 • 818/840-9484 • FAX818/840-9485

Quad D/A and EFB (“George Board”):

This board combines the functions of a Quad D/A converter and a Quad EFB. The adjustments are a

combination of those you would find on both of these other products. The only function which was

eliminated is the ‘low gain’ control on the EFB. When a transducer wire break occurs, the gain will

immediately go to its lowest possible value, effectively shutting off the valve. The valve and transducer

connections, indicator LEDs, and adjustments are arranged as follows.

valve

feedback

yellow

red

black

green

CHANNEL 0

CHANNEL 1

CHANNEL 2

CHANNEL 3

level

valve

gain

velocity

ffh level

board error

00h level

As with the regular EFB-Quad or PID-Quad controller, the wire break error signal from all four channels

is summed to a single indicator LED and output. This is a optoisolated transistor output on pins 4

(collector) and 6 (emitter) of the backplane connector. This output can drive a LED, solid state relay, or

small electromechanical relay. There is also a four pin jumper header, which when two jumpers are

installed horizontally will bring these same signals out to pins 1(collector) and 6 (emitter) on the

backplane. These connect to the white and blue wires on the backplane’s RJ-11, which are unused if

the rest of the cage is populated with other Quad D/A&EFB boards or dumb bricks, but which is

incompatible with any smart bricks in the cage. These jumpers are normally left off.

Note: The Wire Break Collector & Emitter are the 2 wires used by the George Board to transmit

remote wire break indication. If you do not need this feature you can isolate the George board from the

back plane by removing the 2 jumpers located near edge pin #1.

Caution : Never connect edge pins 1& 2 of a George Board to edge pins 1 & 2 of a brick card

unless the 2 jumpers near edge pin 1 are removed.

wire # Edge pin # color wire function

J8 Black 1 N/A Wire Break Collector

J8 White 2 N/A Wire Break Emitter

#1 11 brown J6 out channel 0 Ground

#2 12 red J6 out channel 0 bit 7

#3 13 orange J6 out channel 0 bit 6

#4 14 yellow J6 out channel 0 bit 5

valve

wire break

3 N/A

4 N/A

5 N/A

6 N/A

7 N/A

8 N/A

9 N/A

10 N/A

ffh level

00h level

level

gain

velocity

wire break

valve

valve

00h level

ffh level

level

gain

velocity

wire break

valve

valve

00h level

gain

velocity

ffh level

level

valve

valve

wire break

11 of 12

Page 12

GILDERFLUKE & CO. • 205 SOUTH FLOWER ST. • BURBANK, CALIF. 91502-2102 • 818/840-9484 • FAX818/840-9485

#5 15 green J6 out channel 0 bit 4

#6 16 blue J6 out channel 0 bit 3

#7 17 violet J6 out channel 0 bit 2

#8 18 gray J6 out channel 0 bit 1

#9 19 white J6 out channel 0 bit 0

#10 20 black J6 out channel 0 + Supply

#11 21 brown J6 out channel 1 Ground

#12 22 red J6 out channel 1 bit 7

#13 23 orange J6 out channel 1 bit 6

#14 24 yellow J6 out channel 1 bit 5

#15 25 green J6 out channel 1 bit 4

#16 26 blue J6 out channel 1 bit 3

#17 27 violet J6 out channel 1 bit 2

#18 28 gray J6 out channel 1 bit 1

#19 29 white J6 out channel 1 bit 0

#20 30 black J6 out channel 1 + Supply

#21 31 brown J6 out channel 2 Ground

#22 32 red J6 out channel 2 bit 7

#23 33 orange J6 out channel 2 bit 6

#24 34 yellow J6 out channel 2 bit 5

#25 35 green J6 out channel 2 bit 4

#26 36 blue J6 out channel 2 bit 3

#27 37 violet J6 out channel 2 bit 2

#28 38 gray J6 out channel 2 bit 1

#29 39 white J6 out channel 2 bit 0

#30 40 black J6 out channel 2 + Supply

#31 41 brown J6 out channel 3 Ground

#32 42 red J6 out channel 3 bit 7

#33 43 orange J6 out channel 3 bit 6

#34 44 yellow J6 out channel 3 bit 5

#35 45 green J6 out channel 3 bit 4

#36 46 blue J6 out channel 3 bit 3

#37 47 violet J6 out channel 3 bit 2

#38 48 gray J6 out channel 3 bit 1

#39 49 white J6 out channel 3 bit 0

#40 50 black J6 out channel 3 + Supply

black 51 brown power supply ground

black 52 red power supply ground

black 53 orange power supply ground

black 54 yellow power supply ground

black 55 green power supply ground

red 56 blue + power supply input

red 57 violet + power supply input

red 58 gray + power supply input

red 59 white + power supply input

red 6 0 black + power supply input

12 of 12

Loading...

Loading...