Page 1

GILDERFLUKE & CO. ¥ 205 SOUTH FLOWER ST. ¥ BURBANK, CALIF. 91502-2102 ¥ 818/840-9484 ¥ FAX818/840-9485

OPERATING INSTRUCTIONS

for

QUAD D/A and SERVO MOTOR CONTROLLER

and

SINGLE CHANNEL D/A

Printed February 27, 1999

A digital device is either on or off, like a light switch. An analog device is on, off, or at

any point in between. A common example of an analog device is a lamp dimmer. In animation, analog movements give the fluid, life-like movements needed to bring a figure to

life.

A Digital to Analog (D/A) converter takes the digital data stored in a MICRO MACs or Full-Sized MACs

animation system and turns it back into an analog voltage. The single channel D/A converter takes one

eight bit channel's worth of data and converts it into one analog control signal. The Quad D/A converter

takes four eight bit channels' worth of data and converts it into four independent analog control signals.

These analog voltages can then be used to control light dimmers, analog actuators like Atchley's MFB air

cylinders, Voltage Controlled Amplifiers (VCA's), Electronic Feedback Analog functions, or anything else

which can be controlled by a 0 to 10 VDC input signal.

Additionally, the Quad D/A converter includes the circuitry needed to control up to four model

airplane-style servo motors. These can be used to animate light weight or short lived pieces of animation

as are often used in motion picture special effects. This type of servo motor is not reliable enough to be

used in most permanent animation applications unless your are willing to replace them on a fairly regular basis.

Both the single channel and Quad D/A converters use the data from an eight bit wide data channel

to convert to an analog control voltage. This gives the analog control voltage 256 steps between it's two

extremes. This is called the 'resolution' of the function. Nominally this output swings between 0 and 10

VDC, which means that each step is approximately .039 volts. If less than a full 0 to 10 VDC output

swing is needed, either or both of the end limits can be set anywhere between 0 and 10 volts. Even with

the output swing reduced, there will still be 256 equal steps between the two end points.

For those few applications which require a higher resolution than eight bits allows, a single channel

12 bit D/A converter is available. This card gives 4096 steps between the two extremes. With a 0 to 10

volt output swing each step is approximately equal to .00244 volts. For even higher resolutions, please

contact the factory. A 128 output eight or twelve bit resolution output card is the standard analog output card for our PC¥MACs Animation Control Systems. This plugs into any standard ISA bus PC computer.

Each D/A channel has a red LED which brightens and dims to show the level of the analog output

for that channel.

Please note that the negative reference output from the D/A converters is at about 1-1/2 volts

above ground. It is not a ground signal and can not be attached to to ground. If it is attached to

ground, the D/A output will not be smooth and linear.

1

Page 2

Y

GILDERFLUKE & CO. ¥ 205 SOUTH FLOWER ST. ¥ BURBANK, CALIF. 91502-2102 ¥ 818/840-9484 ¥ FAX818/840-9485

- SINGLE CHANNEL D/A CONNECTIONS -

The single channel D/A converter gets it's data and power through a single 1/4 J-6 data cable. The

output is available on a 5 position molex connector on pins #1 and #3. Pin #2 is removed to be used

for a polarizing key if desired. If an external power supply is needed, it is attached to pins #4 and #5 of

the molex connector.

2"

1/4" 1/4"1 1/2"

1/4"

1

+ OUTPUT

- REFERENCE

- AUX. SUPPLY

5

3/4"

1 1/4"

1/4"

1/4

J-6

00H

Full ScaleMinimum Scale

FFH

If you need to optically isolate the analog output from the rest of the control system, cut the

1N4001 diode closest to the 1/4 J6 connecter and pin #1 of the 1/4 J6 connector (this is easiest to do

on the back of the J6 connector, rather than on the front). In this configuration you will need to use an

external power supply for the D/A.

A single channel D/A converter can be mounded by screwing it to where it is needed. Standoffs

should be used. A small card cage can be used when you need to hold a number of single D/A converters.

The Single Twelve Bit D/A converter is identical to the Eight Bit Single D/A converter except that its

twelve bit resolution gives it 4096 steps of resolution instead of 256. Twelve bit analog channels take one

and one half eight bit channels (twelve bits worth of data). The arrangement of the data within these

channels is as follows:

base Channel 00h (bits 0-3 = output 1’s lower 4 bits, bits 4-7 = output 2’s lower 4 bits)

base+01h Channel 01h (analog output #1 MSB)

base+02h Channel 02h (analog output #2 MSB)

base+03h Channel 03h (bits 0-3 = output 3’s lower 4 bits, bits 4-7 = output 4’s lower 4 bits)

base+04h Channel 04h (analog output #3 MSB)

base+05h Channel 05h (analog output #4 MSB)

+ AUX. SUPPLY

Mounting Holes

.156" dia. 4 places

2"

1/4" 1/4"1 1/2"

1/4"

Channel 00h

(bits 0-3 = output #1 LSB)

2 1/2" 2"

Channel 01h

(output #1 MSB)

1/4"

LSB

1/4

J-6

MSB

1/4

J-6

Move optoisolators

to use bits 0-3 or 4-7

Full ScaleMinimum Scale

LSB

1/4

J-6

MSB

1/4

1

5

Channel 00h

(bits 4-7 = output #2 LSB)

+ OUTPUT #1

- REFERENCE

- AUX. SUPPLY

+ AUX. SUPPLY

Channel 02h

(output #2 MSB)

J-6

Mounting Holes

FFH00H

.156" dia. 4 places

Move optoisolators

to use bits 0-3 or 4-7

bits 4-7 bits 0-3bits 4-7 bits 0-3

1

+ OUTPUT #2

- REFERENCE

- AUX. SUPPLY

5

+ AUX. SUPPL

Full ScaleMinimum Scale

FFH00H

2

Page 3

GILDERFLUKE & CO. ¥ 205 SOUTH FLOWER ST. ¥ BURBANK, CALIF. 91502-2102 ¥ 818/840-9484 ¥ FAX818/840-9485

- QUAD D/A and SERVO MOTOR CONTROLLER CONNECTIONS -

The quad D/A converters get their data and power through a single J-6 data cable. The analog output is available on a 1/4 J6/A analog output connection. The pin out for this connector is as follows:

Pin #1 GROUND

Pin #2 UNREGULATED 12 VDC (fused at 1 amp)

Pin #3 + CHANNEL 4 (03H) ANALOG OUTPUT

Pin #4 - CHANNEL 4 (03H) REFERENCE

Pin #5 + CHANNEL 3 (02H) ANALOG OUTPUT

Pin #6 - CHANNEL 3 (02H) REFERENCE

Pin #7 + CHANNEL 2 (01H) ANALOG OUTPUT

Pin #8 - CHANNEL 2 (01H) REFERENCE

Pin #9 + CHANNEL 1 (00H) ANALOG OUTPUT

Pin #10 - CHANNEL 1 (00H) REFERENCE

The GROUND and 12 VDC outputs are used to supply power to a Quad EFB (Electronic FeedBack)

servo controller when it is used with the Quad D/A. They can also be used to feed in 15 VDC from an

auxiliary power supply if needed. In most user applications, these two outputs won't be needed. The

negative reference outputs for all four channels are connected in common inside the Quad D/A. If your

application requires it, a single negative reference wire may used for all four channels.

If you are using servo motors, these are connected to the standard three pin sockets used by many

brands of servo motors. Some newer servo motors use a slightly different connector, and an adapter for

this style of connector is available from the servo motor manufacturers. The pin out for these servo

motor connections is as follows:

SIGNAL

SERVO

+ SUPPLY

SERVO

- SUPPLY

The last remaining connector is for attaching the power supply which is used to power the servo mo-

tors. The power for these must come from an external source as they can potentially use a lot more current than the animation system can normally supply. Most servo motors run from a voltage between 3.5

volts and 7.5 volts. The lower the voltage the less strength and speed a given servo motor will have. A

higher voltage will give that same servo motor greater speed and strength. In some cases a lower speed

is desired for the smoothness of the movement, while in other cases the need for high speed or strength

may be paramount. The chief disadvantages of running the servo motors in high voltage / high speed

applications are that the servo motor will run hotter and is much more likely to have a mechanical failure.

The size of the servo motor, the load it is driving, and the amount of movement it is doing can all ef-

fect the amount of current it will require. Most of the smaller servo motors draw about an amp of current

at stall (This is when the servo motor shaft is held against the motor's best efforts to move it.). This condition isn't often encountered in any real world applications, but if you are planning on really abusing your

servo motors you should allow about an amp per motor when selecting a power supply. Under most normal conditions, 1/4 to 1/2 an amp per servo motor will be sufficient. If your power supply is undersized,

you will see a certain amount of interaction between servo motors when a number of them are moving

at the same time.

To reduce the number of wires needed to run into a servo motor-controlled figure it is not uncom-

mon to run the high current power supply leads directly from the power supply to the servos in the figure

and gang the signal lines. When this is done, it is still necessary to run low current leads from the power

supply to the power supply connections on the quad D/A board. If the signal line runs to the servo motors are long, it may be necessary to use shielded lines to prevent noise and cross-talk between the servos. You can tell when you have this problem when some servo motors are tending to jitter uncontrollably.

3

Page 4

GILDERFLUKE & CO. ¥ 205 SOUTH FLOWER ST. ¥ BURBANK, CALIF. 91502-2102 ¥ 818/840-9484 ¥ FAX818/840-9485

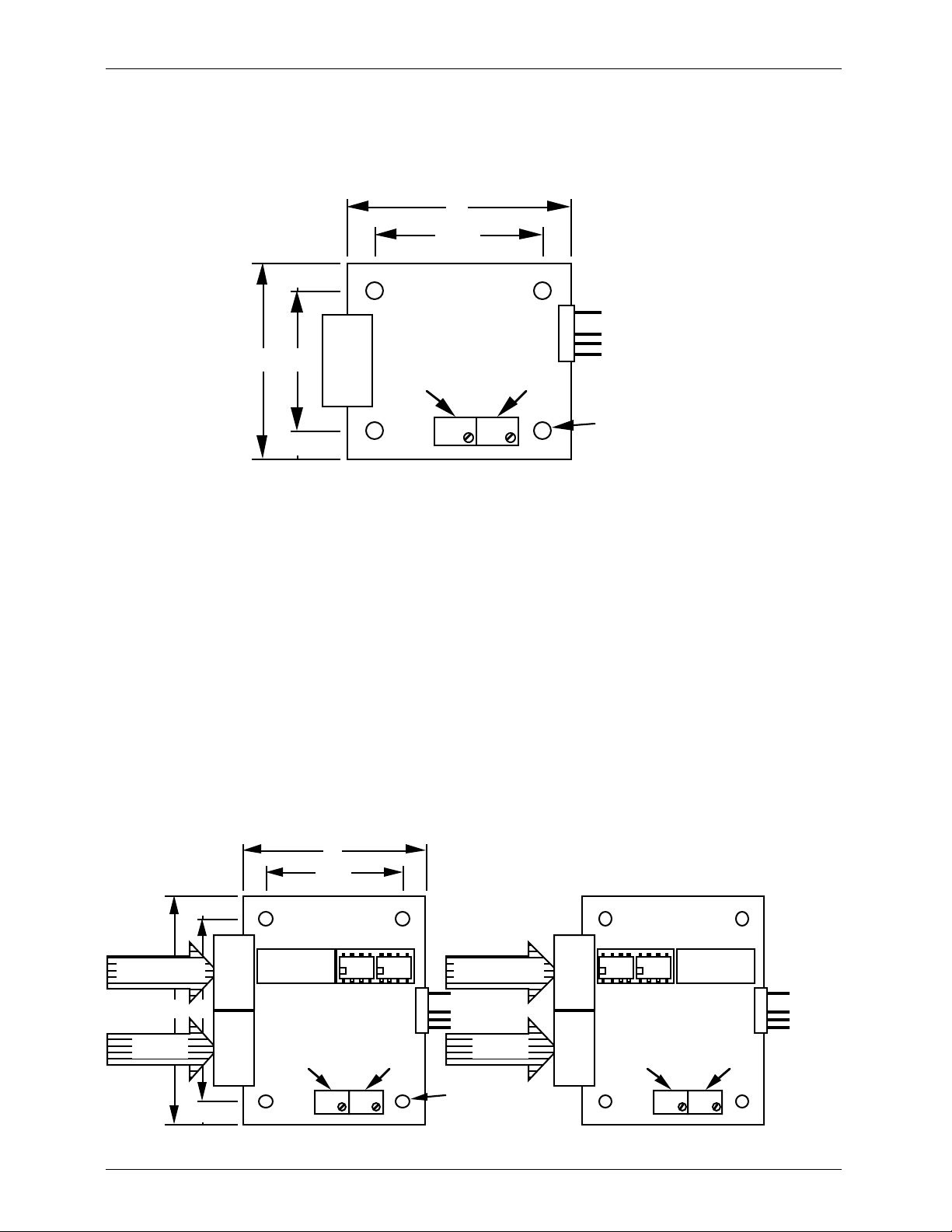

5 5/16"

J-6 INPUT

4"

CHANNEL 1

(00H)

CHANNEL 2

(01H)

CHANNEL 3

(02H)

CHANNEL 4

(03H)

FULL

SCALE

MIN.

SCALE

FULL

SCALE

1/4 J-6A

OUTPUT

MIN.

SCALE

SERVO

MOTOR

POWER IN

FULL

SCALE

MIN.

SCALE

3210

SERVO

MOTOR

OUTPUTS

FULL

SCALE

MIN.

SCALE

Be aware that the servo motor input signals are notoriously bad travelers. They are susceptible to any

power supply noise, radio frequency (RF) interference, and even the noise from other servo motors. Try

to keep these lines as short as possible. Anything over 10 feet can cause problems. Even shorter lengths

can have problems under the right circumstances. Possible solutions include large capacitors across the

power supply leads and pullup resistors between the signal input and the positive supply line. These must

be located as close as possible to the servo motors.

If you need to optically isolate the analog outputs from the rest of the animation control system, you

will need to cut the four 1N4001 diodes D1 through D4 (the four diodes closest to the J6 connector)

and pins 1, 11, 21, and 31 on the J6 connector. This is easiest to do on the back of the J6 connector,

rather than on the front. You will need to use an external power supply for the Quad D/A when operating

in this mode. The four channels of the Quad D/A are not isolated from one another. If you need complete isolation between channels, you should use four single channel D/A converters with separate

power supplies for each.

The Quad D/A comes in a plastic case which can be mounted by simply double face taping it

where ever you need. If you need to mount it more solidly, then put screws through the back of the

case as needed. The front of the case can be removed for service and adjustment after the box has

been mounted.

4

Page 5

GILDERFLUKE & CO. ¥ 205 SOUTH FLOWER ST. ¥ BURBANK, CALIF. 91502-2102 ¥ 818/840-9484 ¥ FAX818/840-9485

- D/A CONVERTER ADJUSTMENTS -

Each channel of every D/A converter has two adjustments. One of these two sets the level of the

output when a minimum scale digital input (00H) is sent to the D/A, while the other sets the level of the

output when a full-scale (FFH) signal is sent to it. Both of these adjustments are completely independent

of one another. Moving one doesn't affect the other, although it does change the positions of all the

steps in between the two. Either of these setting may be adjusted to put it anywhere in the 0 to 10 VDC

output range. Adjusting the minimum scale level above that of the full scale level has the effect of 'reversing' the movement. By doing this the output can be set so that a full scale signal will be at a lower

voltage than a minimum scale signal. All D/A converters are factory calibrated to 0 to 10 VDC before

shipping.

To adjust the full and minimum scale outputs, you need to send either a full or minimum scale signal

to the D/A. This can come from a Micro Console, Full-sized Programming Console, Togglodyte,

Hand/Off/Auto (HOA) test switches, or a number of other sources. You then adjust the appropriate trimpot on the D/A board to set the desired level (Full scale trimpot if you are sending a full scale signal, minimum scale trimpot if you are sending a minimum scale signal). If you are setting the signal to a desired

voltage, measure the output voltage between the negative and positive output connector on the D/A

and adjust the trimpot until the signal is at the desired level. If you are adjusting the signal for setting the

end points of a mechanical movement or servo motor, you simply need to watch the movement and

adjust the trimpot until the movement is at the desired position.

When one end position is set, send the opposite full scale command to the D/A and adjust the ap-

propriate trimpot to set that end too.

Some caution must be used when adjusting servo motors or mechanical movements which may be

damaged by being commanded to go to a position beyond that which they are designed to move. In

these cases it is sometimes best to adjust both the full and minimum scale trimpots to a center position

for the movement and then adjust them slowly outward from there.

- ATCHLEY MFB CYLINDER ATTACHMENT -

An Atchley MFB actuator is a type of air cylinder which includes a jet pipe servo valve and

Mechanical FeedBack (i.e. MFB) system. It is used when there is a need for a strong, reliable, and simple

analog mechanical movement. The cylinder needs only be fed a 80 to 100 PSI supply of clean dry air

and a 0 to 10 VDC control signal. When given a 0 volt input, the cylinder will retract. When fed a 10

VDC signal, the cylinder will extend. If fed a 5 VDC signal, the cylinder will go to a mid-stroke position.

The MFB will follow a changing input voltage smoothly, reliably, and with a remarkable amount of

strength.

To connect an Atchley MFB actuator to a D/A converter, use the following to connect it's four wires:

ATCHLEY WIRES CONNECT TO:

RED ATTACH TO GREEN

GREEN ATTACH TO RED

YELLOW + OUTPUT FROM D/A

WHITE - REFERENCE FROM D/A

5

Page 6

GILDERFLUKE & CO. ¥ 205 SOUTH FLOWER ST. ¥ BURBANK, CALIF. 91502-2102 ¥ 818/840-9484 ¥ FAX818/840-9485

- TROUBLE SHOOTING -

If an analog movement is acting up and you suspect the D/A, the first thing to do is look at the LED

on each D/A channel. If it is not ramping up and down as smoothly as it should, then unplug the output.

If this fixes the problem, then the negative reference has most likely been attached to ground or some

other signal somewhere. If the LED is still uneven, then there is most likely one or more data lines feeding

the D/A with a bad connection. Check the cabling that feeds the data to the D/A. A Togglodyte or LED

Data Monitor can come in handy for this.

If the LED on the front doesn't change at all, even when the output cable has been disconnected,

then check that the fuse for that channel hasn't been blown in the animation system.

If the voltage measured on the output of a D/A changes appreciably when the output cable is dis-

connected, then there is a problem in the wires leading to whatever it is controlling, or in the controlled

device itself.

If the output randomly switches to a full on condition and stays there until you power the A/D down

(by powering down the whole system or just unplugging the D/A), this is a symptom of the output device

in the D/A receiving a electrical spike through the output cable. This is usually an indication of a problem

in the controlled device. If this problem persists, you may need to add spike protection to the D/A.

In most cases the D/A converters get the power they need from the J-6 data cables they are at-

tached to. In rare cases (as when they are attached at the end of long cables) the top end of the 0 to

10 volt swing may start to get lost. The symptom of this is the inability to get a full 10 VDC from the outputs. If your control signal doesn't need to go this high, then there is no problem. If it does then you will

need to add a supplemental power supply local to the D/A converter.

- OUTPUT SPECIFICATIONS -

The output capabilities of all D/A converters is as follows:

OUTPUT VOLTAGE: 0 TO 10 VDC

OUTPUT CURRENT: 0 TO 24 ma

OUTPUT DEVICE: LM324N

OUTPUT PROTECTION: OVERVOLTAGE/CURRENT PROTECTION

INHERENT TO LM324N

The capabilities of the servo motor outputs are as follows:

OUTPUT: OPEN COLLECTOR SWITCH TO GROUND

PULLUP: 4.7 K PULLUP TO + SERVO POWER SUPPLY

OUTPUT CURRENT: 16 ma MAXIMUM

OUTPUT/SERVO VOLTAGE: 5 VDC NOMINAL / 36 VDC MAXIMUM

6

Loading...

Loading...