Page 1

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

Kp-300

Operator Control Panel

The Kp-300 has all the controls that are needed to run any motion base or other

Smart Brick system. It mounts in 5-1/4” of standard 19” rack space. Operator controls

include buttons for starting and stopping the Hydraulic Power Unit (HPU), pausing and

then continuing a paused show, for ʻloggingʼ occupied seats, and for selecting and playing up to eight different shows.

Because many of the functions of the Kp-300 are safety related, the Kp-300 has no

CPU of any kind. With no microcontroller, there is no possibility of a software crash.

Kp-300 Manual / September 4, 2012 4:29 PM / page 1 of 75

Page 2

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

Safety Disclaimer: Any electronic or mechanical sys-

tem has a potential to fail. Certain applications using

Gilderfluke & Company equipment may involve poten-

tial risks of death, personal injury, or severe property, or

environmental damage (“Critical Application”).

Gilderfluke & Company equipment is not designed, in-

tended, authorized, or warranted to be suitable in life

support applications, devices, or systems, or other

critical applications. Inclusion of Gilderfluke & Com-

pany products in such applications is understood to be

fully at the risk of the customer. In order to minimize

risks associated with the customer's applications, ade-

quate design and operating safeguards should be pro-

vided by the customer to minimize inherent or proce-

dural hazards.

Gilderfluke & Company assumes no liability for appli-

cations assistance, customer produced design, soft-

ware performance, or infringement of patents or copy-

rights. Nor does Gilderfluke & Company warrant or rep-

resent that any license, either express, or implied, is

granted under any patent right, copyright, mask work

right, or other intellectual property right of Gilderfluke &

Company covering or relating to any combination, ma-

chine, or process in which Gilderfluke & Company

products or services might be or are used.

Kp-300 Manual / September 4, 2012 4:29 PM / page 2 of 75

Page 3

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

...................................................................................Kp-300 Overview! 9

.....................................................................Kp-300 Panel Indicators! 11

..................................................................................Error Input Logged LEDs! 11

....................................................................................Error Input Status LEDs! 11

...................................................................................Error Input Events LEDs! 12

....................................................................................................Log Belts LED! 12

...................................................................................Show Start Button LEDs! 13

..................................................................................Show Cycle Counter LED! 13

...............................................................................................E-Stop Buss LED! 14

......................................................................................Show Pause Buss LED! 15

..........................................................................................HPU Stop Buss LED! 15

...........................................................................................Blocking Valve LED! 16

.........................................................................................Bypass Buss #1 LED! 16

.........................................................................................Bypass Buss #2 LED! 16

...............................................................................E-Stop Show Running LED! 18

......................................................................................Remote HPU Start LED! 18

......................................................................................Remote HPU Stop LED! 18

.....................................................................................Show Pause Reset LED! 18

.............................................................................................HPU Running LED! 19

..............................................................................................HPU Stopped LED! 19

..........................................................................................Show Continue LED! 20

...............................................................................................Show Pause LED! 20

.................................................................DMX-512 Receive LED (v3.0+ Only)! 21

..................................................................Kp-300 Operator Controls! 22

..................................................................................E-Stop Button/Keyswitch! 22

................................................................................................Log Belts Button! 22

...........................................................................................Show Start Buttons! 23

...............................................................................................HPU Start Button! 24

................................................................................................HPU Stop Button! 25

...........................................................................................Show Pause Button! 25

......................................................................................Show Continue Button! 25

...........................................................Kp-300 Jumper Configuration! 27

..................................................................................................Latched E-Stop! 28

.....................................................................................Internal/External Power! 28

..............................................................................................Seat Belt Logging! 29

.......................................................................................................E-Stop Buss! 29

..............................................................................................Show Pause Buss! 29

..............................................................................................Bypass Buss One! 31

..............................................................................................Bypass Buss Two! 31

..................................................................................................HPU-Stop Buss! 32

........................................DipSwitch settings on the Kp-300 (v3.0+)! 34

........................................DipSwitch #1: HPU Stopped LED Internal/External! 34

........................................DipSwitch #2: HPU Running LED Internal/External! 34

...................................................DipSwitch #3: E-Stop Disables Show Starts! 34

..............................................DipSwitch #4: HPU-Stop Disables Show Starts! 34

Kp-300 Manual / September 4, 2012 4:29 PM / page 3 of 75

Page 4

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

..........................................DipSwitch #5: Pause Buss Disables Show Starts! 35

.................................................DipSwitch #6: E-Stop Triggers Alarm Output! 35

............................................DipSwitch #7: HPU-Stop Triggers Alarm Output! 35

.........................................DipSwitch #8: Pause Buss Triggers Alarm Output! 36

.........................DMX-512 Address Selection on the Kp-300 (v3.0+)! 37

....................................................................................Sample Shows! 38

.....................................................................................................E-Stop Show1! 38

.....................................................................................................E-Stop Show2! 38

............................................................................................Load/Unload Show! 41

........................................................................................................Main Shows! 43

...........................................................AutoDownloading Shows for a Kp-300! 47

............................................Accessing More Than Eight Shows on a Kp-300! 50

..............................................................................................Delayed ʻHPU Offʼ! 50

...........................................................................Kp-300 Connections! 53

.............................................................Digital Inputs to the Kp-300 (v1.n & v2.n)! 53

.....................................................................DMX-512 Input to the Kp-300 (v3.0+)! 53

.........................................................................Show Start Button LED Inputs! 55

.....................................................................Show Start Button Enable Inputs! 55

...............................................Show Cycle Counter Advance Input to Kp-300! 57

........................................................................Blocking Valve Input to Kp-300! 57

......................................................................Bypass Buss #1 Input to Kp-300! 58

......................................................................Bypass Buss #2 Input to Kp-300! 58

............................................................E-Stop Show Running input to Kp-300! 59

...................................................................Remote HPU Start Input to Kp-300! 60

...................................................................Remote HPU Stop Input to Kp-300! 60

.................................................................Show Pause Reset Input to Kp-300! 60

....................................................24 vdc Power Input to the Kp-300 (v3.0+ Only)! 61

....................................................Kp-300 Expansion for the Kp-300 (v3.0+ Only)! 61

...................................................................................ʻAlarmʼ Output (v3.0+ Only)! 61

...............................................Kp-300 Outputs to Smart Brick Brain! 62

...................................................................Show Select Outputs from Kp-300! 62

..................................................................Green ʻPauseʼ Output from Kp-300! 63

....................................................................Blue ʻE-Stopʼ Output from Kp-300! 63

......................................................................J1 Inputs to the Kp-300! 64

....................................................J2 Inputs & Outputs to the Kp-300! 65

..........................................................................HPU Stopped Input to Kp-300! 65

..........................................................................HPU Running Input to Kp-300! 65

.................................................................Blocking Valve Output from Kp-300! 66

..........................................................................HPU Run Output from Kp-300! 66

...................................................................Remote Log Belts Input to Kp-300! 67

...............................................................Error Inputs Eleven Through Fifteen! 67

..............................................................................Kp-300 Expansion! 69

........................................................................Eight Medium Current Outputs! 69

Kp-300 Manual / September 4, 2012 4:29 PM / page 4 of 75

Page 5

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

...........................................................Six High Current Optoisolated Outputs! 70

.................................................................J1 Inputs To The Kp-300 Expansion! 70

............................Thirty-two Optoisolated Inputs To The Kp-300 Expansion! 71

....................................................Kp-300 Installation/Best Practices! 73

...........................................HEXadecimal to Decimal to Percentage! 75

This is not a blank page

Kp-300 Manual / September 4, 2012 4:29 PM / page 5 of 75

Page 6

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

A note about this manual:

This manual covers the specifics of the Kp-300. To pro-

gram the Kp-300 you will also want to refer to the

PC•MACs manual sections that cover the PC•MACs

software.

The Kp-300 is typically programmed in ‘Software-only’

or ‘Hardwareless RealTime’ mode. If you are using the USB-

DMX-512 for programming your Kp-300 through the DMX-

512 inputs, please refer to the PC•MACs ‘Unlimited’ mode.

The full PC•MACs manual can be downloaded from our

web site at:

http://www.gilderfluke.com

Kp-300 Manual / September 4, 2012 4:29 PM / page 6 of 75

Page 7

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

This isnʼt a blank page either

Kp-300 Manual / September 4, 2012 4:29 PM / page 7 of 75

Page 8

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

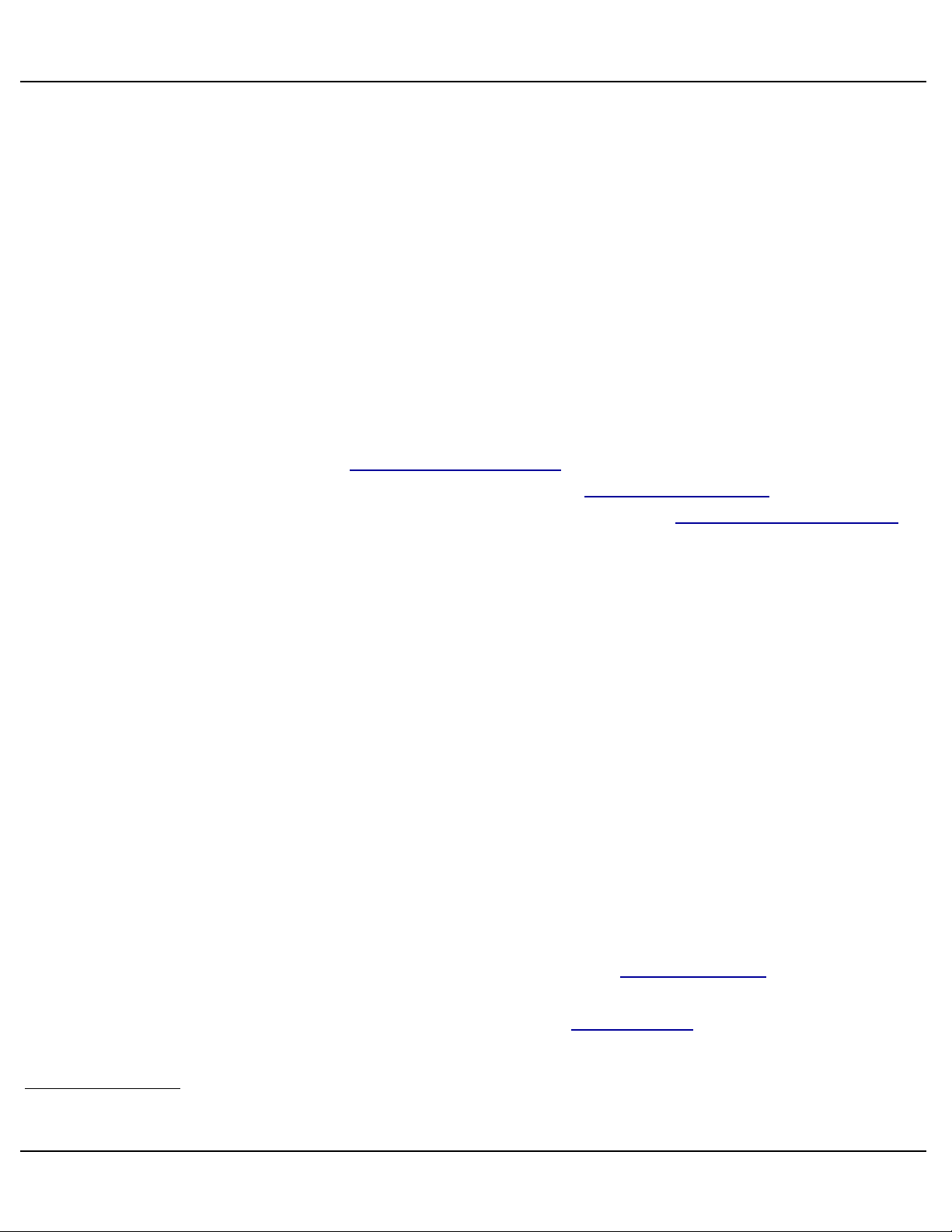

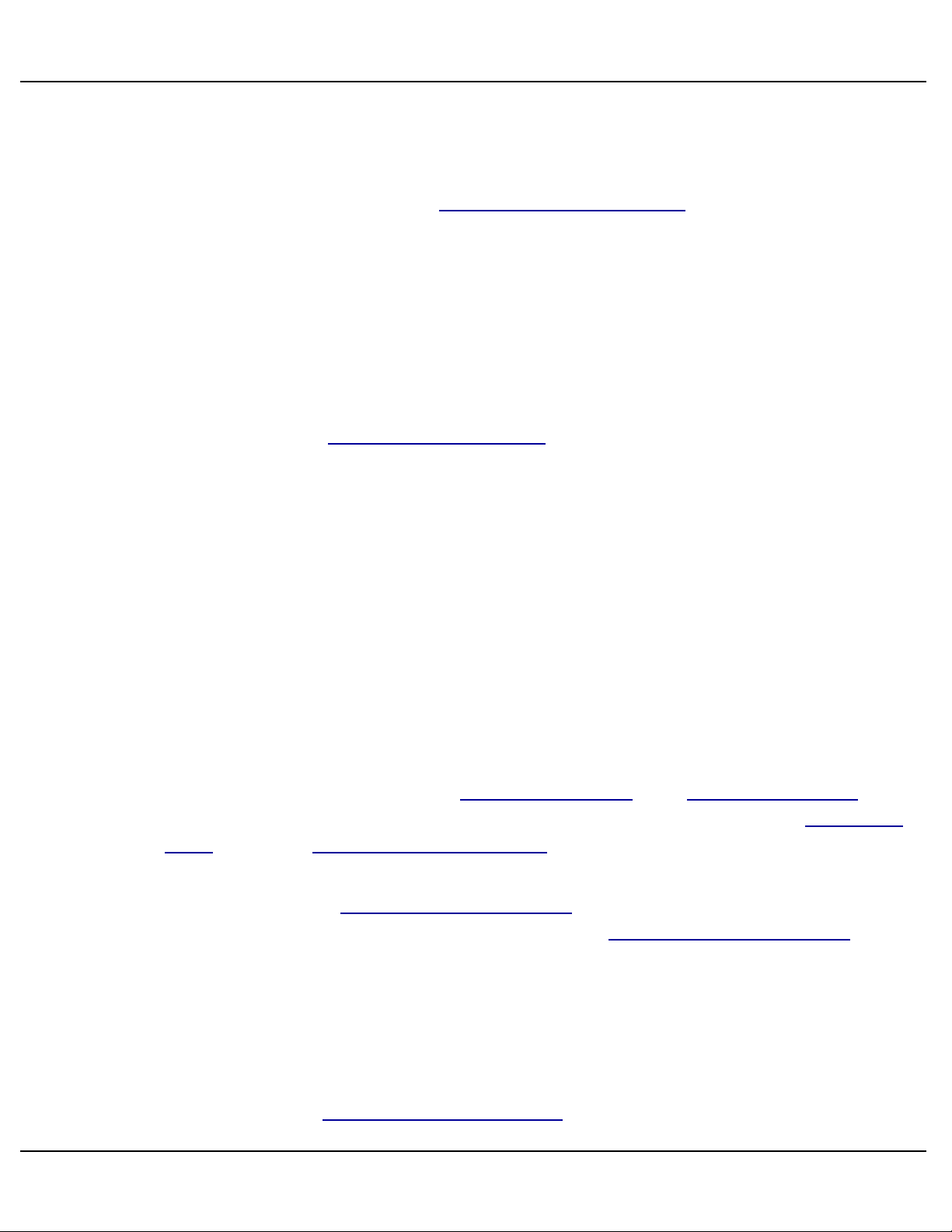

KP-300 Expansion • Gilderfluke & Company, Burbank, California

Relay Outputs

1/4 J6 Outputs

Inputs

J6 Inputs

3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7

2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7

1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

2019181716151413121110987654321

654321 6543210 7

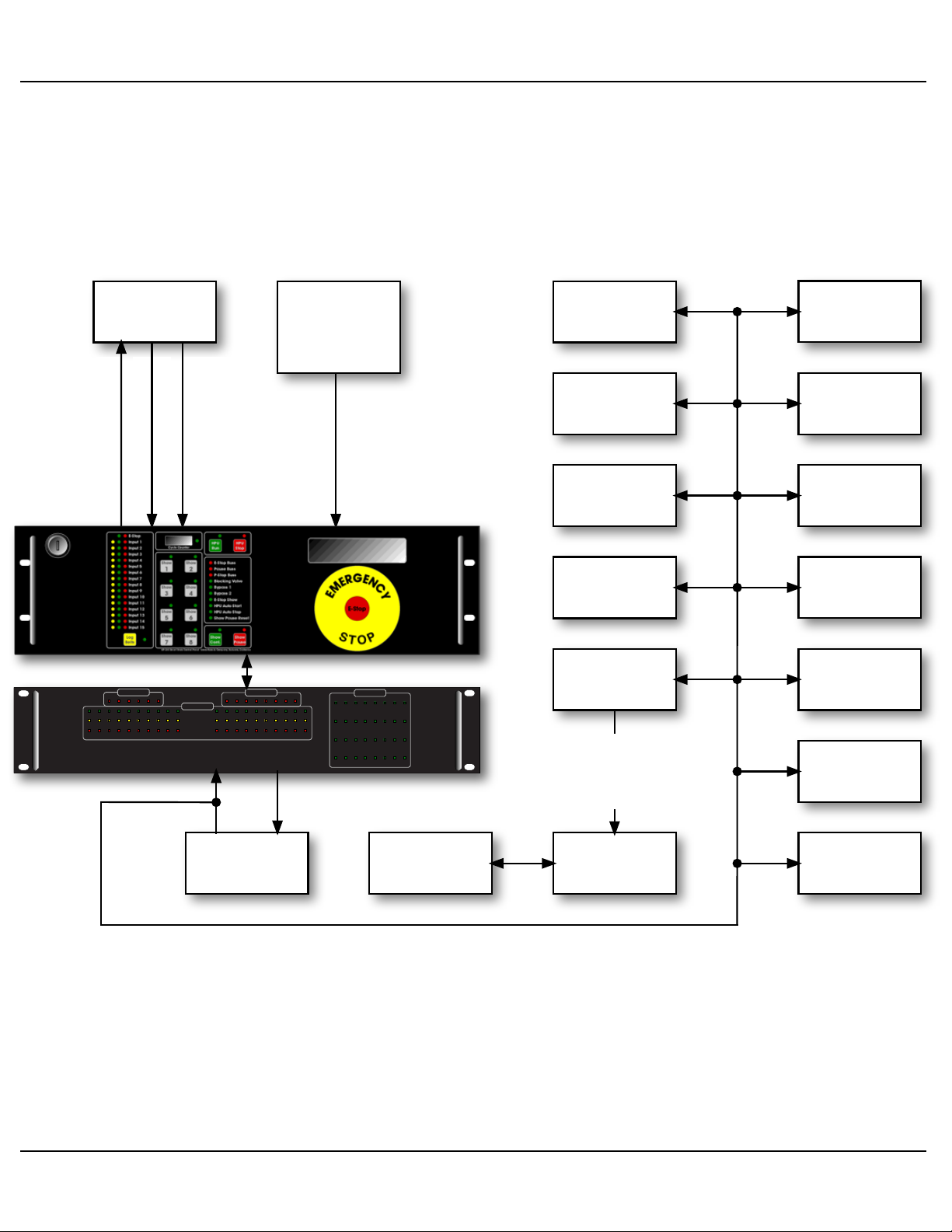

Kp-300 Typical Block Diagram for a Hydraulic Motion Base

HPU

Door, Ramp,

Seat Belt and

other 'Safety'

Switches

HPU error signals

(Oil low, overtemp,

filter dirty, etc.)

HPU Run Output

HPU Run/Stop

Status Signals

Kp-300

Kp-300 Expansion(s)

(if needed)

Pb-DMX with

3.5 Amp

Relays

Audio/Video

Playback

Light Dimmers

RGB LED

Lamp Fixtures

Br-ANA or

DAC-Quad

EFB-Quad(s)

or PID-Quad(s)

Valves, Cylinders

and position

sensors

Moving Head

Light Fixtures

Smog

Machines

Moving head

Light Fixtures

Br-MiniBrick8

Strobe Lights

Fans

other DMX-512

compatible

equipment

Br-Brain4

(typically)

Network

(DMX-512)

Four or

sixteen

0-10 VDC

commands

Kp-300 Manual / September 4, 2012 4:29 PM / page 8 of 75

Page 9

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

Kp-300 Overview

The Kp-300 features fifteen safety inputs, plus an onboard E-Stop Button and

Keyswitch that can be used to lock the system. All the safety inputs are ʻfail safeʼ (they

want to see a closure on them and will be triggered by any wire break). With the one exception of the E-Stop Button and Keyswitch on the Kp-300, each safety input can be individually set to force the system to:

Enter an E-Stop condition

Pause the show

Turn the HPU off (if there is one)

The E-Stop Button and Keyswitch on the Kp-300 always force an E-Stop condition.

More safety inputs can be added if needed using the Kp-300 Expansion.

Safety inputs that trigger an E-Stop condition normally include only critical sensors.

An example of these would be a low hydraulic fluid level sensor. If the motion base is

running low on oil, this would trigger an immediate E-Stop, and as long as the oil level

remained low, the Kp-300 would not let you start the HPU. All E-Stops turn the HPU off.

The show always has to be started over from the beginning after an E-Stop.

A pause input is used for less critical sensors. An example of this is where a seat belt

was opened by a rider. The show would instantly be paused and could only be continued by the operator when the condition that caused the pause had been cleared. Alternatively, if after the pause was triggered the operator deemed it necessary to evacuate

the attraction, he could call up a show that parks the motion base or just E-Stop it to

bring it home.

Door sensors are actually a point where a pause is generally safer to use than a full

E-Stop. If a door is opened, instead of returning to home position the motion base will

just freeze. This is less likely to take a leg off someone who is trying to step through the

door.

Two bypass busses are available from the motion profile program. These are used to

temporarily disable inputs that might otherwise cause an error condition to be flagged.

An example of their use is on the door sensors. During the motion base ʻflightʼ, a door

sensor should trigger an error condition (either a pause or E-Stop), but during the Load/

Unload times it should not. For this reason this input would be bypassed during Load/

Unload times by one of the two bypass busses.

Seat belt logging allows any input which has been wired to a seat belt to be ignored

once it has been logged as an unoccupied seat. The seat belt logging can be done from

Kp-300 Manual / September 4, 2012 4:29 PM / page 9 of 75

Page 10

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

the Kp-300, remotely via a switch closure, or automatically as part of the motion profile

program.

Each safety input as well as the built in E-Stop Button and Keyswitch have indicator

LEDs that show their current status.

a) A green light means that the input is ʻOKʼ.

b) A yellow light means that the input has been logged as ʻtemporarily unusedʼ.

Typically this is used in an installation that has switches to monitor the seat

belts. Before starting the ride, any inputs from unoccupied seats would be

ʻloggedʼ so that they wonʼt cause an error condition.

c) If an input opens and triggers an error condition, then a red LED will flash

next to that input to flag it as the one that caused the failure. This allows you

to catch short lived error conditions like a HPU level sensor or pressure

switch kicking an E-stop for just an instant.

A solid state counter records the number of show cycles that are run. Shows that are

run with the HPU off or while the system is E-Stopped are not counted. The show cycle

count is retained even during power outages.

With the addition of a three slot card cage (which mounts on the back of the Kp-300),

a Smart Brick Brain, Analog or other Smart Brick (depending on the type of motion base

you are running) and a Z-Brick, the Kp-300 becomes a complete motion base control

system. When ordered in this way, the small LCD that normally is mounted on the front

of a Br-Brain4 is replaced by a large format LCD display on the front of the Kp-300.

Since the entire system is networked, you can put components wherever you like.

Dimmers and the controllers for your ʻ4Dʼ effects can be right in the cabin. The video

playback can be mounted near to the projector or video screen. Just a single shielded

twisted pair of wire connects the DMX-512 to control everything. This can be used to

minimize the number of bulky multi conductor cables that need to be run, especially

those that need to be run in a location that will require continuous flexing. All of this

makes the initial connections, as well as adding new features in the future as simple as

tapping into the existing cable.

Customized front panel artwork is available on the Kp-300. These can be custom

branded, or labeled for specific show names and error inputs. Please contact the

Gilderfluke & Company factory for details on generating custom Kp-300 labels.

Kp-300 Manual / September 4, 2012 4:29 PM / page 10 of 75

Page 11

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

Kp-300 Panel Indicators

There are sixty-one LED indicators and one or two LCD displays on the front of the

Kp-300. They are used as follows:

A) Error Input Logged LEDs

(One yellow LED for each Error Input)

! (Fifteen LEDs total)

These are lit to show that an input has been logged as inactive for the

current show. Once an input which is open (green LED is not on) has been

logged, it will be ignored until it is logged as active again. This feature is

typically used to log seat belt inputs. A seat which is unoccupied will be

logged so that it canʼt cause an E-Stop or Pause if it changes state during

the show.

Seat belts can be logged at any time that the Show Pause Reset Input

from the Smart Brick System is active. When this input is active, the safety

inputs can be logged by either pressing the Log Belts button or activating the

Remote Log Belts Input by pressing Remote Log Belts Button(s) attached to

it. If you want to automatically log belts from the motion profile, just set the

Remote Log Belts Input for Internal Power and attach the two wires for this

input together so it is always active. Whenever the Show Pause Reset Input

is programmed active, the inputs that are set to be logged will automatically

be logged.

Input logging actually takes place at the instant that the Log Belts Button,

Log Belts Remote Input, or Show Pause Reset Input are released. The LED

next to the Log Belts Button will light whenever the seat belts are being

logged.

B) Error Input Status LEDs

(One green LED for each Error Input, plus one for the E-Stop Button/

Keyswitch)

! (Sixteen LEDs total)

These are lit to show that an input is in its ʻsafeʼ condition. If any one of

these inputs is off and that input hasnʼt been logged as an unoccupied seat

(yellow LED IS on), then it is not safe to start the show.

Kp-300 Manual / September 4, 2012 4:29 PM / page 11 of 75

Page 12

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

All the inputs are configured to ʻfail safeʼ, which is to say that an error is

triggered by an open circuit on an input. This is true even for the Kp-300ʼs E-

Stop Button and Keyswitch. These are wired in series and trigger an E-Stop

if this connection is opened at any point.

C) Error Input Events LEDs

(One red LED for each Error Input, plus one for the E-Stop Button/Keyswitch)

! (Sixteen LEDs total)

These LEDs flash on the input(s) that triggered an error condition. They

allow you to find which input caused the error, even if it only existed for an

instant.

An example of this featureʼs use is in events like a HPU filter dirty sensor

which has been configured to trigger an E-Stop event. The dirty filter sensor

on the HPU is typically a differential pressure switch which measures the

pressure across the filter. If this pressure gets too high, then the switch

opens to indicate a clogged filter and triggers the E-Stop condition. The thing

that makes this hard to catch is that the E-Stop turns off the HPU, so the differential pressure immediately drops back into zero (the ʻOKʼ region, as far

as the switch is concerned), turning back on the green Error Input Status

LED for the input. To further complicate things, because the HPU potentially

turned off right in the middle of a show, the ʻlow pressureʼ error input (if there

is one) will turn off its green Error Input Status LED because the pressure

just went to zero. Under these circumstances the only Error Input Event LED

that will be flashing will be the original ʻDirty Filterʼ one that initiated the EStop in the first place. All the other Error Input Event LEDs will be off.

Once these LEDs are turned on by an E-Stop event, they can only be

cleared when the operator starts the next show. They will keep flashing until

the next show is started. If they were triggered by a Show Pause event, they

will stop flashing but remain lit after the error condition is cleared and the

show is ʻresumedʼ. They will be cleared when there is another E-Stop/Show

Pause event or the next show is started by the operator.

D) Log Belts LED

(One yellow LED)

This LED turns on when the error inputs are are being logged as temporarily unused. Seat belts can be logged at any time that the Show Pause

Reset Input from the Smart Brick System is active. When this input is active,

Kp-300 Manual / September 4, 2012 4:29 PM / page 12 of 75

Page 13

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

the safety inputs can be logged by either pressing the Log Belts Button or

activating the Remote Log Belts Input by pressing Remote Log Belts But-

ton(s) attached to it. If you want to automatically log belts from the motion

profile, just set the Remote Log Belts Input for Internal Power and attach the

two wires for this input together so it is always active. Whenever the Show

Pause Reset Input is programmed active, the inputs that are set to be

logged will automatically be logged.

Input logging actually takes place at the instant that the Log Belts Button,

Log Belts Remote Input, or Show Pause Reset Input are released.

E) Show Start Button LEDs

(One green LED for each Show Start Button)

! (Eight LEDs total)

These LEDs are controlled directly by the motion control profile stored in

the Smart Brick System. This allows the LEDs to be programmed on, off or

flashing as desired at any point in time. They are programmed to indicate

which shows are available to the operator, or to indicate which show is already running. We typically program them in a chase pattern, lighting only

the valid show selections. Once a show has started, we typically program all

but the selected Show Start Button LEDs off, and flash the selected show

LED a few times before turning it on through the rest of the show. If any

other show selection is valid while another show is running, we then flash it

discretely throughout the show that is running.

Whenever a Show Start Button LED is programed to indicate that a Show

Start Button is valid, it is also necessary to actually enable the correspond-

ing Show Start Button Enable Input output from the Smart Brick System to

make the Show Start Buttons active. If this is not done, then the Show Start

Buttons will remain inactive.

F) Show Cycle Counter LED

(One green LED)

This LED lights to show that the show cycle counter has been commanded to advance by the motion control profile stored in the Smart Brick

System. The count on the LCD counter will advance by one if the Kp-300 is

not currently in any type of E-Stop condition and the HPU is running, as indicated by 24 vdc being received on the HPU Running Input.

Kp-300 Manual / September 4, 2012 4:29 PM / page 13 of 75

Page 14

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

The Show Cycle Count Advance Input pulse is typically programmed to

take place towards the end of the motion base program. This lets a show

which is aborted for any reason not be counted.

The LCD module that displays the current show cycle count permanently

stores the count each time it is advanced. The count will be retained even if

power is removed from the Kp-300. Please contact the Gilderfluke & Co. factory if you need a resettable cycle counter.

G) E-Stop Buss LED

(One red LED)

This LED lights to show that the Kp-300 currently has an unresolved EStop condition. The beginning of any E-Stop event stops the HPU (if there is

one), disables the Blocking Valve output and triggers the Smart Brick Sys-

tem to play the E-Stop Show through the Blue ʻE-Stopʼ Input to the Smart

Brick Brain. Calling up the E-Stop show sets the ʻE-Stop Show Runningʼ

output from the Smart Brick System (this must be programmed into the motion profile of the E-Stop show). This resets the first of the two E-Stop

latches on the Kp-300. At this point you can start the HPU and any shows

that have been enabled in the motion control profile of the E-Stop Show.

If this LED is ON, you should not run the show unless you just want to

see the video and sound, without any motion. If a show is started while there

is still an unresolved E-Stop condition, the Kp-300 can be configured to:

a) Lock out the ʻBlocking Valveʼ output until another show is started

with the E-Stop Buss LED off. This is the safer of the two options, because the motion base will not start moving until a show

is started cleanly.

b) Lock out the ʻBlocking Valveʼ output until the E-Stop condition is

cleared. This can allow the motion base to spring into movement

if the E-Stop condition is resolved half way through the show.

If you want to disallow shows to be run at all if there is an E-Stop condition present, you can configure one of the two bypass busses to momentar-

ily (for just one frame) bypass all the possible E-Stop error inputs at the very

beginning of all shows1. At the end of the bypass buss pulse, any error conditions that remain will trigger the E-Stop to keep even the video and audio

1

This technique is flexible enough that you can even leave it out of any maintenance shows that you want to be able to run without

motion

Kp-300 Manual / September 4, 2012 4:29 PM / page 14 of 75

Page 15

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

from running. This technique should be used in applications that donʼt use

the Blocking Valve Output. Typical of these are most electric motion base in-

stallations.

H) Show Pause Buss LED

(One red LED)

This LED lights to show that the Kp-300 currently has an unresolved

Show Pause condition. If this LED is ON, you should not run the show.

When the Show Pause Reset Input from the Smart Brick System goes

away2, the Kp-300 will be paused. The condition that caused the Show

Pause will then have to be cleared before the current show can be resumed.

Alternatively, the operator can bail out by pressing the E-Stop or running another show that simply gets the operator back to the Load/Unload shows

without triggering an E-Stop.

I) HPU Stop Buss LED

(One red LED)

This LED lights to show that the Kp-300 currently has an unresolved HPU

Stop condition. If this LED is ON, you should not run the show. The Kp-300

will keep the operators from starting the HPU until this condition is resolved.

The error conditions that are typically used to trigger a HPU Stop Buss event

are those which might cause damage to the HPU, Motion base or their riders. Typical of these are ʻHPU Oil Level Lowʼ or ʻHPU Over Temperatureʼ

sensors.

It is not unusual for operators to try to override this type of safety feature.

For this reason, many HPU applications use a number of techniques to lock

out the show if the HPU is turned on locally:

a) The primary technique is to run the HPUʼs 24 vdc ʻHPU Stoppedʼ

and ʻHPU Runningʼ outputs through the ʻAutoʼ position of the

HPU ʻHand/Off/Manualʼ switch on the way to the Kp-300. By doing this, both the HPU LEDs on the Kp-300 will be off unless the

HPU is in the ʻAutoʼ mode. This has the added advantage of giving the operators a remote indication of the position of the HPUʼs

ʻHand/Off/Manualʼ switch.

b) The ʻAutoʼ position of the HPUʼs ʻHand/Off/Manualʼ switches on

2

Usually at the start any of the Main shows. It is normally programmed as active during the E-Stop and Load/Unload shows

Kp-300 Manual / September 4, 2012 4:29 PM / page 15 of 75

Page 16

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

the HPUs wired into one of the error inputs of the Kp-300. This

input is configured to keep the motion base from running if the

HPU ʻHand/Off/Manualʼ switch is in anything but the ʻAutoʼ position.

c) The Blocking Valve Output from the Kp-300 can be run through

the ʻAutoʼ position of the HPU ʻHand/Off/Manualʼ switch. Unless

the HPU is started by the Kp-300, this too will prevent the motion

base from moving. This will only work on hydraulic motion bases

that use a blocking valve.

J) Blocking Valve LED

(One green LED)

This LED lights to show that the motion control profile stored in the Smart

Brick System has enabled the Blocking Valve to allow the motion base to

move. If the Kp-300 is still in an E-Stop condition or the HPU is not running

(as indicated by 24 vdc being received on the HPU Running Input), this LED

will simply flash and the Blocking Valve output will not be activated. If a show

is started while there is still an unresolved E-Stop condition, the Kp-300 can

be configured to:

a) Lock out the ʻBlocking Valveʼ output until another show is started

with the E-Stop Buss LED off. This is the safer of the two options, because the motion base will not start moving until a show

is started cleanly.

b) Lock out the ʻBlocking Valveʼ output until the E-Stop condition is

cleared. This can allow the motion base to spring into movement

if the E-Stop condition is resolved half way through the show.

K) Bypass Buss #1 LED

L) Bypass Buss #2 LED

(Two green LEDs)

These LEDs lights to show that the motion control profile has been programmed to bypass some or all the Safety inputs which have been configured to create an E-Stop or Show Pause. Typical examples of the use of the

bypass buss are:

a) HPU Startup/Shutdown: If the HPU is started and stopped as

part of the motion profile, there will usually be a time just after it

Kp-300 Manual / September 4, 2012 4:29 PM / page 16 of 75

Page 17

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

is started and a time after it is stopped where any HPU pressure

sensors inputs will need to be bypassed. Do this by programming the Bypass Buss you are using and Remote HPU Start In-

put to be active at the beginning of the show. The Bypass Buss

needs to be active for the time it takes for the HPU to build up

pressure. If the pressure doesnʼt come up during the time allotted, the Kp-300 will automatically trigger an error condition (either E-Stop or Show Pause, as configured).

# If the HPU is to be turned off at the end of the show, then the

Bypass Buss which is being used would be programmed active

along with a pulse on the Remote HPU Stop Input. This allows

the HPU to be stopped without triggering an error condition. If

configured to trigger an E-Stop, the Bypass Buss will also need

to be programmed active during the E-Stop and Load/Unload

shows so that the HPUʼs low pressure wonʼt trigger an error during these shows when the HPU is off.

b) Door Sensors: If the door or floor mat sensors inputs are set to

trigger an E-Stop, they will need to be bypassed during the EStop and Load Unload shows. This is because although you

want these inputs to trigger an error while the motion base is in

flight, you donʼt want this to trigger an E-Stop when the doors are

opened for the passengers to be loaded and unloaded.

c) Electric Motion Bases and other Installations that donʼt use

the Kp-300 Blocking Valve Output: If you donʼ t want to allow

shows to be run if there is an E-Stop condition present, you can

configure one of the two bypass busses to momentarily (for just

one frame) bypass all the possible error inputs at the very start

of all shows3. At the end of the Bypass Buss pulse, any error

conditions that remain will trigger the E-Stop. This technique

should be used in applications that donʼt use the Blocking Valve

Output. Typical of these are most electric motion base installa-

tions.

If you are using the Seat Belt Logging features of the Kp-300, be sure you

donʼt configure the Kp-300 to bypass any inputs that are to be logged during

the time during which they need to be logged. Bypassing an input will con-

3

This technique is flexible enough that you can even leave it out of any maintenance shows that you want to be able to run without

motion.

Kp-300 Manual / September 4, 2012 4:29 PM / page 17 of 75

Page 18

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

vince the Kp-300 that the inputs are in the ʻsafeʼ position, and so they will not

be logged as ʻunoccupiedʼ.

The Show Pause functions are usually disabled during the E-Stop and

Load/Unload shows by the Show Pause Reset Input from the Smart Brick

System. Inputs that trigger a Show Pause are never needed during the EStop and Load/Unload shows anyway, so there is no need to bypass them

separately during these shows.

M)E-Stop Show Running LED

One green LED

This LED lights to show that the motion control profile is running the EStop Show. The E-Stop Show Running output is normally only programmed

active during the E-Stop Show, and is used reset one of the Kp-300ʼs onboard latches to allow the HPU to be started and the E-Stop conditions to be

cleared.

N) Remote HPU Start LED

O) Remote HPU Stop LED

(Two green LEDs)

These LEDs light to show that the motion control profile on the Smart

Brick System has had the commands to start or stop the HPU embedded in

it. This is an optional feature. If you donʼt want the HPU to be started and

stopped automatically, just donʼt use them.

These outputs parallel the HPU Start Button and HPU Stop Button that

are on the front of the Kp-300. If the HPU is being forced off by a HPU Stop

Buss error, the Remote HPU Start Input can NOT override the error.

Any of the ʻstopʼ inputs take precedence over any of the ʻstartʼ inputs. You

can use an active Remote HPU Stop Input in the motion profile stored on the

Smart Brick System to keep the operator or Remote HPU Start Input from

starting the HPU.

P) Show Pause Reset LED

(One green LED)

This LED lights to show that the motion control profile on the Smart Brick

System has the Show Pause Reset Input command programmed to reset or

Kp-300 Manual / September 4, 2012 4:29 PM / page 18 of 75

Page 19

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

disable the Kp-300 Show Pause functions. This is normally programmed active only during the E-Stop and Load/Unload shows.

Seat belts can be logged at any time that the Show Pause Reset Input

from the Smart Brick System is active. When this input is active, the safety

inputs can be logged by either pressing the Log Belts button or activating the

Remote Log Belts Input by pressing Remote Log Belts Button(s) attached to

it. If you want to automatically log belts from the motion profile, just set the

Remote Log Belts Input for Internal Power and attach the two wires for this

input together so it is always active. Whenever the Show Pause Reset Input

is programmed active, the inputs that are set to be logged will automatically

be logged.

Input logging actually takes place at the instant that the Log Belts Button,

Remote Log Belts Input, or Show Pause Reset Input are released. The LED

next to the Log Belts Button will light whenever the seat belts are being

logged.

Q) HPU Running LED

(One green LED)

This LED lights to show that the Hydraulic Power Unit (HPU) is running.

This LED is turned on only when a 24 vdc signal is applied to the HPU Run-

ning Input. This signal normally comes from the HPU. If there is no HPU in

the system, this input can be permanently attached to a 24 vdc or the HPU

Run Output.

Unless this signal is received by the Kp-300, the Blocking Valve Output

will never turn on and the Show Cycle Counter will not advance.

To help keep shows from being run when the HPU has been started by its

local Hand/Off/Auto switch, the HPU Stopped Input and HPU Running Input

signals are often routed through the ʻAutoʼ position on the switch. If the

switch isnʼt in the ʻAutoʼ position, the HPU Stopped LED and HPU Running

LED wonʼt light and the Blocking valve wonʼt be enabled.

R) HPU Stopped LED

(One red LED)

This LED lights to show that the Hydraulic Power Unit (HPU) is not running. This LED is turned on only when a 24 vdc signal is applied to the HPU

Kp-300 Manual / September 4, 2012 4:29 PM / page 19 of 75

Page 20

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

Stopped Input. Unlike the HPU Running Input, this input is not used for any

other purpose than lighting this LED.

To help keep shows from being run when the HPU has been started by its

local Hand/Off/Auto switch, the HPU Stopped Input and HPU Running Input

signals are often routed through the ʻAutoʼ position on the switch. If the

switch isnʼt in the ʻAutoʼ position, the HPU Stopped LED and HPU Running

LED wonʼt light and the Blocking valve wonʼt be enabled.

S) Show Continue LED

(One green LED)

This LED lights to show that the Motion profile on the Smart Brick System

has been programmed with the Show Pause Reset Input inactive and that

the current show has not been paused.

When a show is paused, the Kp-300 sends a signal to the Smart Brick

Brain through its Green ʻPauseʼ Output. The Smart Brick Brain input must be

configured to pause the currently running show on a closure on this input4.

When a show is 'continued', the signal is dropped on the Green ʻPauseʼ

Output to the Smart Brick Brain. This input must be configured to continue

the currently running show on an opening on this input.

Once a show has been paused, the only two ways to 'continue' a show

are to:

a) Send an active signal from the Smart Brick System to the Kp-

300ʼs Show Pause Reset Input.

b) Once the condition that caused the Show Pause has been re-

moved, the operator can press the Show Continue button.

T) Show Pause LED

(One red LED)

This LED lights to show that the Motion profile on the Smart Brick System

has been programmed with the Show Pause Reset Input inactive and that

the current show has been paused by the operator pressing the Show

Pause Button or an error condition.

When a show is paused, the Kp-300 sends a signal to the Smart Brick

Brain through its Green ʻPauseʼ Output. The Smart Brick Brain input must be

4

In some applications, you may want to call up a different show using this input, instead of pausing the current show.

Kp-300 Manual / September 4, 2012 4:29 PM / page 20 of 75

Page 21

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

configured to pause the currently running show on a closure on this input5.

When a show is 'continued', the signal is dropped on the Green ʻPauseʼ

Output to the Smart Brick Brain. This input must be configured to continue

the currently running show on an opening on this input.

Once a show has been paused, the only two ways to 'continue' a show

are to:

a) Send an active signal from the Smart Brick System to the Kp-

300ʼs Show Pause Reset Input.

b) Once the condition that caused the Show Pause has been re-

moved, the operator can press the Show Continue button.

U) DMX-512 Receive LED (v3.0+ Only)

(One red LED, Located on back of Kp-300)

To support the DMX-512 input, the v3.0+ Kp-300 adds an LED that

flashes on each update via the DMX-512.

The Kp-300 requires DMX-512 that includes GilderChecksums.

If receiving DMX-512 without valid checksums, the DMX-512 Receive

LED on the back of the Kp-300 will not flash and only the Show Start Button

LEDs will follow the incoming the DMX-512. The signals like the Show Start

Button Enable Inputs, blocking valve enable, and automatic HPU start/stop

will not work if the GilderChecksums are invalid.

5

In some applications, you may want to call up a different show using this input, instead of pausing the current show.

Kp-300 Manual / September 4, 2012 4:29 PM / page 21 of 75

Page 22

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

Kp-300 Operator Controls

The Kp-300 has just a small number of operator controls. Most of these have LEDs

that can be lit under program control, or indicate their current status.

A) E-Stop Button/Keyswitch

These two switches are wired in series. Opening either one will cause an

E-Stop and HPU Stop event on the Kp-300. The beginning of any E-Stop

event stops the HPU (if there is one), disables the Blocking Valve output and

triggers the Smart Brick System to play the E-Stop Show through the Blue

ʻE-Stopʼ Input to the Smart Brick Brain. Calling up the E-Stop show sets the

ʻE-Stop Show Runningʼ output from the Smart Brick System (this must be

programmed into the motion profile of the E-Stop show). This resets the first

of the two E-Stop latches on the Kp-300. At this point you can start the HPU

and any shows that have been enabled in the motion control profile of the EStop Show.

The E-Stop switch has a red mushroom-style cap. Once pushed, the button latches in the E-Stopped position. To release the cap, it is rotated clockwise. The E-Stop button has a spare set SPDT set of contacts available for

your use. Users of Moog electric motion bases can use this switch closure

for the hardware E-Stop input they require.

The Keyswitch is typically used to lock unauthorized users from starting

the HPU or running shows with motion. The Keyswitch can be turned to one

of two positions. The key can be removed in either of these two positions.

The show can be run without motion while the keyswitch is turned off or

the E-Stop button has been pushed in. If you want to disallow shows to be

run at all if there is an E-Stop condition present, you can use the DipSwitch

#3, DipSwitch #4 or DipSwitch #5 to disallow running shows if there is an er-

ror condition.

B) Log Belts Button

Seat belts can be logged at any time that the Show Pause Reset Input

from the Smart Brick System is active. When this input is active, the safety

inputs can be logged by either pressing the Log Belts button or activating the

Remote Log Belts Input by pressing Remote Log Belts Button(s) attached to

it. If you want to automatically log belts from the motion profile, just set the

Remote Log Belts Input for Internal Power and attach the two wires for this

Kp-300 Manual / September 4, 2012 4:29 PM / page 22 of 75

Page 23

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

input together so it is always active. Whenever the Show Pause Reset Input

is programmed active, the inputs that are set to be logged will automatically

be logged.

Input logging actually takes place at the instant that the Log Belts Button,

Remote Log Belts Input, or Show Pause Reset Input are released. The LED

next to the Log Belts Button will light whenever the seat belts are being

logged.

C) Show Start Buttons

(Eight Buttons)

The Kp-300 has been designed to support up to eight shows which can

be directly accessed. If more shows are needed, these Show Start Buttons

can be bypassed with a Kp-100 or Kp-200 to allow access to the Smart Brick

Systemʼs 255 show capacity.

Which shows are available to the user (which of these eight Show Start

Buttons are enabled), is controlled as a function of the motion profile running

on the Smart Brick System. Enabling a Show Start Buttons just requires set-

ting the appropriate Show Start Button Enable Inputs in the motion profile.

Any or all of the Show Start Buttons can be enabled/disabled at any time.

The Show Start Button LEDs next to these buttons are also controlled as

part of the motion profile. This allows the Show Start Button LEDs to be pro-

grammed on, off or flashing as desired at any point in time.

Typically the Show Start Buttons are programmed as active during the E-

Stop and Load/Unload shows. During the main shows, typically none of

them are enabled. If any are enabled, then the user can jump directly out of

the currently running show and into the one(s) that have been enabled. This

is sometimes used to enable a ʻparkʼ show that brings the motion base home

without having to do anything as drastic as an E-Stop. Any show that is enabled while another show is running will be enabled even during a show

pause. Make sure that if you are using this technique, that the show that is

jumped into has the Show Pause Reset Input set for at least a few frames at

the beginning. Otherwise the new show will begin running, but the Show

Pause functions of the Kp-300 wonʼt be reset (the Show Pause LED will remain lit, and the next Show Pause event will be ignored). At the end of the

pulse on the Show Pause Reset Input, the Kp-300 will check for an outstanding Show Pause condition. If one still persists, then the new show will

be paused.

Kp-300 Manual / September 4, 2012 4:29 PM / page 23 of 75

Page 24

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

If shows must be run in a certain order, you can program this into the motion profile stored on the Smart Brick System. An example of this would be a

motion base that has separate entrance and exit doors. The main shows all

lead into a show that leaves the exit doors opened6. The only show that is

enabled for the operator is a short show that closes the exit doors (and

maybe turns off the cabin lights) so that the system is ready to be parked or

loaded with the next group of riders. The operator would start this show once

he confirmed that the cabin was clear. At the end of this show another show

is enabled that opens the entrance door (and turns on the cabin lights). The

operator would call this up when it is time to load the next batch of riders. At

the end of this short show, the main shows are enabled for the operators.

One of these would be started once all the riders were safely seated (and

the belts logged, if needed). All of these short shows can have accompanying audio and/or video if it has been programmed on whatever audio/image

source is being used.

The Br-ANA Analog Output Smart Brick can be configured to do an Ease

In whenever the Smart Brick System jumps from one show to another. This

makes it safe for you to configure the system to jump between shows as described above.

D) HPU Start Button

This Button is used to set the latch on the Kp-300 that turns on the HPU

Run Output. This is an optional feature. If you donʼt want the HPU to be

started and stopped remotely, just donʼt use this button.

The HPU Start Button parallels the Remote HPU Start Input from the

Smart Brick System. If the HPU is being forced off by a HPU Stop Buss error

or a Remote HPU Stop Input from the Smart Brick System, the HPU Start

Button can not override them.

Any of the ʻstopʼ inputs take precedence over any of the ʻstartʼ inputs. You

can use an active Remote HPU Stop Input in the motion profile stored on the

Smart Brick System to keep the operator or Remote HPU Start Input from

starting the HPU.

6

If the motion base has exit doors that must be operated only when the operator deems it safe, all the main shows can leave only

the button to jump to a short show that opens the doors for the operators.

Kp-300 Manual / September 4, 2012 4:29 PM / page 24 of 75

Page 25

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

E) HPU Stop Button

This Button is used to reset the latch on the Kp-300 that turns on the HPU

Run Output. This is an optional feature. If you donʼt want the HPU to be

started and stopped remotely, just donʼt use this button.

The HPU Stop Button parallels the Remote HPU Stop Input from the

Smart Brick System.

F) Show Pause Button

This button is used to set the latch on the Kp-300 that sends a pause

command to the Smart Brick Brain through the Green ʻPauseʼ Output. This

latch can also be set by any error condition that has been configured to start

a Show Pause event. If the Show Pause Reset Output from the Smart Brick

System is active, then the Show Pause latch can not be set by either this

button or an error condition.

When a show is paused, the Kp-300 sends a signal to the Smart Brick

Brain through its Green ʻPauseʼ Output. The Smart Brick Brain input must be

configured to pause the currently running show on a closure on this input7.

When a show is 'continued', the signal is dropped on the Green ʻPauseʼ

Output to the Smart Brick Brain. This input must be configured to continue

the currently running show on an opening on this input.

Once a show has been paused, the only two ways to 'continue' a show

are to:

a) Send an active signal from the Smart Brick System to the Kp-

300ʼs Show Pause Reset Input.

b) Once the condition that caused the Show Pause has been re-

moved, the operator can press the Show Continue button.

G) Show Continue Button

This button is used to reset the latch on the Kp-300 that sends a pause command to the Smart Brick Brain through the Green ʻPauseʼ Output. This latch can

also be set by any error condition that has been configured to start a Show Pause

event.

When a show is paused, the Kp-300 sends a signal to the Smart Brick Brain

through its Green ʻPauseʼ Output. The Smart Brick Brain input must be configured

7

In some applications, you may want to call up a different show using this input, instead of pausing the current show.

Kp-300 Manual / September 4, 2012 4:29 PM / page 25 of 75

Page 26

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

to pause the currently running show on a closure on this input8. When a show is

'continued', the signal is dropped on the Green ʻPauseʼ Output to the Smart Brick

Brain. This input must be configured to continue the currently running show on an

opening on this input.

Once a show has been paused, the only two ways to 'continue' a show are to:

a) Send an active signal from the Smart Brick System to the Kp-

300ʼs Show Pause Reset Input.

b) Once the condition that caused the Show Pause has been re-

moved, the operator can press the Show Continue button.

8

In some applications, you may want to call up a different show using this input, instead of pausing the current show.

Kp-300 Manual / September 4, 2012 4:29 PM / page 26 of 75

Page 27

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

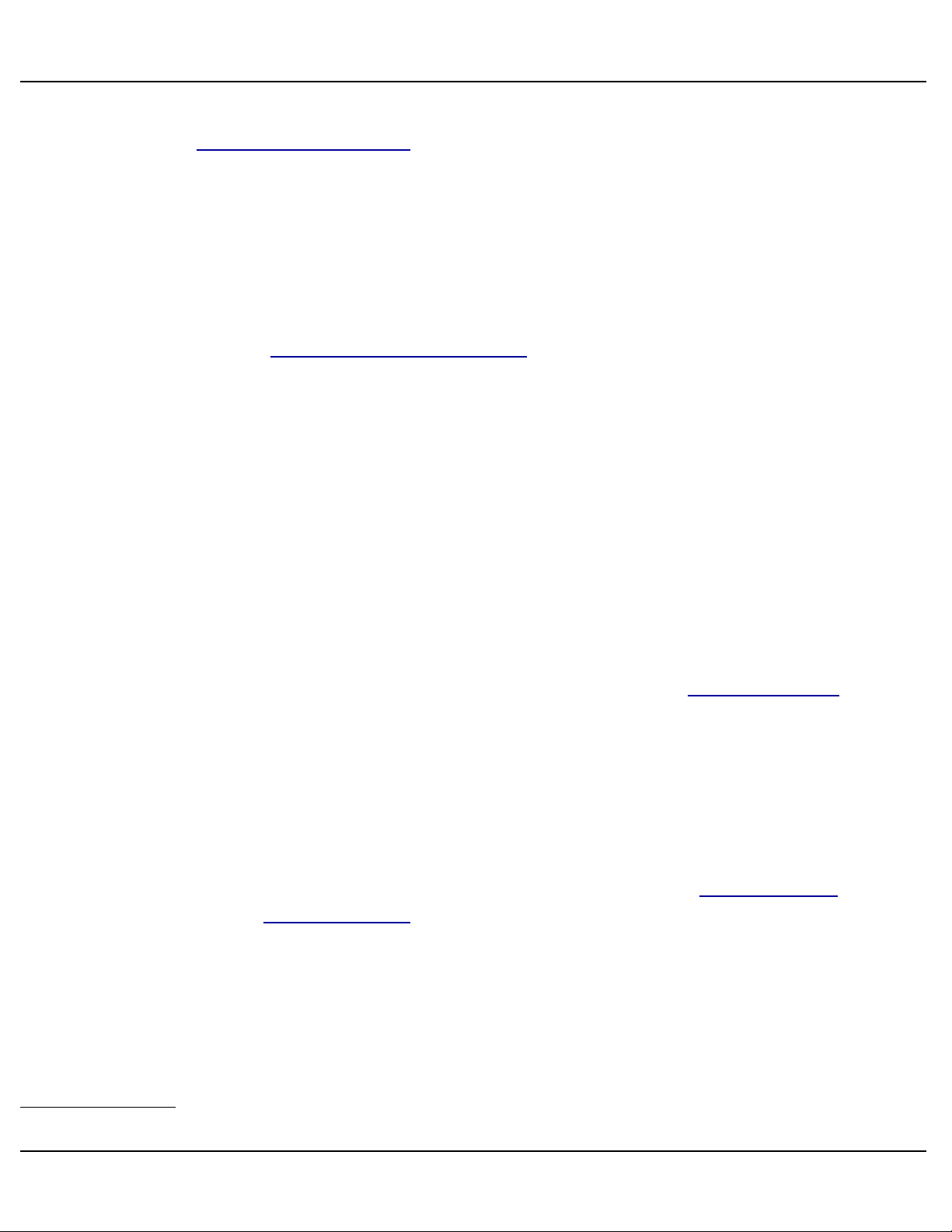

Kp-300 Jumper Configuration

There are about seventy-five jumpers that must be set on the Kp-300 before it can be

used. Not to worry though, each of the fifteen safety inputs has only five options that you

can choose. There is also one jumper that globally affects the E-Stop latches. The

jumpers are located on the back of the printed circuit board that is used in the Kp-3009.

If larger quantities of Kp-300s are to be ordered, we can provide them with jumpers already in the desired positions or permanently soldered into place so that they can not be

easily moved.

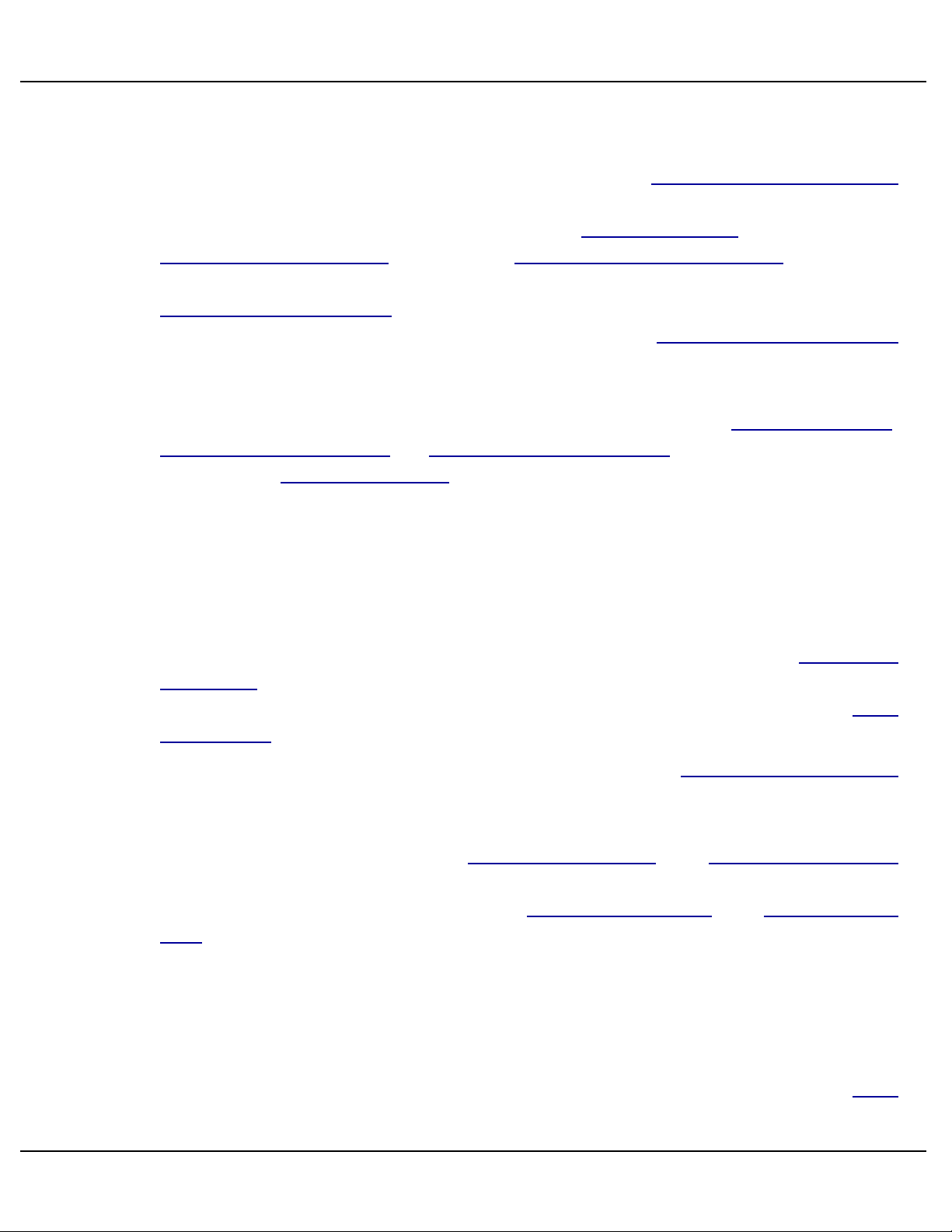

Kp-300 PCB (Rear View)

The jumpers for all the error inputs are arranged in a series of horizontal rows. As

you can see, the number of the input is shown next to the row which it configures. The

function of each jumper position is also silkscreened next to the jumpers. We would rec-

9

We can build Kp-300s with the jumpers on the front of the printed circuit board to restrict access if so desired. Please contact the

factory if you would be interested in such a modification.

Kp-300 Manual / September 4, 2012 4:29 PM / page 27 of 75

Page 28

Latched E-Stop

Yes

Latched E-Stop

No

External Power Internal Power

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

ommend that you document the final positions of all jumpers by marking them on the

drawing above (or a copy of it) The jumpers are:

A) Latched E-Stop

This is the only jumper that is not related to the fifteen individual safety

inputs.

In the ʻYesʼ position, if a show is started while there is an E-Stop condition

still present, the Kp-300 will not allow you to enable the Blocking Valve Out-

put until the show has finished, even if the E-Stop input is cleared. This al-

lows you to safely run test shows without movement after an E-Stop10.

If this jumper is in the ʻNoʼ position, if a show is started while there is an

E-Stop condition still present, the Kp-300 will allow you to enable the Block-

ing Valve Output once the E-Stop input is cleared. This means that the

movement may be enabled by the Blocking Valve Output part way through a

show when the E-Stop condition is cleared.

B) Internal/External Power

(One set of jumpers for each safety input and one set for the Remote Log Belt

Input)

Sixteen sets of jumpers in total

The fifteen Safety Inputs and one Remote Belt Log Input are optically iso-

lated to 1500 volts. This jumper sets whether the optoisolators use the same

power as the Kp-300 or if you must provide them with an external source of

24 vdc power. Use the Internal Power if you are going to be attaching these

inputs to a simple switch closures. Use the External setting if you are using a

device that provides power.

When possible try to use external power. When doing so, a high voltage

spike on an externally powered input line cannot get into the Kp-300 and

damage it.

10

# Assuming that the Blocking Valve Output is used in the installation.

Kp-300 Manual / September 4, 2012 4:29 PM / page 28 of 75

Page 29

Not Logging Input Logged

E-Stop Show Pause

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

C) Seat Belt Logging

(One jumper for each safety input)

The fifteen Safety Inputs can be set to be ʻLoggedʼ either manually or

automatically.

Once an input which is open (green LED is not on) has been logged, it

will be ignored until it is logged as active again. This feature is typically used

(as its name implies) to log seat belt inputs. A seat which is unoccupied will

be logged so that it canʼt cause an E-Stop or Pause if it changes state during

the show. A yellow LED indicates an input which has been logged.

The jumper for an input should be placed in the Log Belts position if it is

to be logged. The jumper should be placed on the No Logging position if it is

not to be logged.

Seat belts can be logged at any time that the Show Pause Reset Input

from the Smart Brick System 1/3 J6 is active. When this input is active, the

safety inputs can be logged by either pressing the Log Belts button or activating the Remote Log Belts Input by pressing Remote Log Belts Button(s)

attached to it.

If you want to automatically log belts from the motion profile, just set the

Remote Log Belts Input for Internal Power and attach the two wires for this

input together so it is always active. Whenever the Show Pause Reset Input

is programmed active, the inputs that are set to be logged will automatically

be logged.

Input logging actually takes place at the instant that the Log Belts Button,

Remote Log Belts Input, or Show Pause Reset Input are released. The LED

next to the Log Belts Button will light whenever the seat belts are being

logged.

D) E-Stop Buss

E) Show Pause Buss

(One jumper for each safety input)

Any or all of the fifteen Safety Inputs can be set to trigger either an EStop or Show Pause.

Kp-300 Manual / September 4, 2012 4:29 PM / page 29 of 75

Page 30

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

By moving the jumper to the E-Stop position, an input will trigger an EStop show when it opens. Moving it to the Show Pause position will cause

an input to pause the show when it opens. If this input is not being used for

either an E-Stop or Show Pause, it should be removed.

Any condition that triggers an E-Stop will set two latches on the Kp-300

and turn on a flashing red LED for the input that triggered the error condition.

The first of these latches stops the HPU (if there is one) and triggers the

Smart Brick System to play the E-Stop Show through the Blue ʻE-Stopʼ Input

to the Smart Brick Brain. Calling up the E-Stop show sets the ʻE-Stop Show

Runningʼ output from the Smart Brick System (this must be programmed into

the motion profile of the E-Stop show). This resets the first of the two E-Stop

latches on the Kp-300. At this point you can start the HPU and any shows

that have been enabled in the motion control profile of the E-Stop Show.

Starting the next show will reset the second E-Stop latch in the Kp-300.

This will turn off the red LED indicator for the input that triggered the E-Stop

and enable the Kp-300ʼs pause functions (because it has the Show Pause

Reset Input programmed active, the E-Stop show cannot be paused).

When a Show Pause occurs, it turns on a flashing red LED to indicate the

input that caused the error condition. A Show pause can also be initiated by

pressing the ʻShow Pauseʼ button. Initiating a Show Pause sets a latch on

the Kp-300 that tells the Smart Brick System to pause the current show

through a signal on the Green ʻPauseʼ Output to the Smart Brick Brain11.

This latch can be reset by using the ʻShow Continueʼ button (but only if the

condition that caused the pause has been cleared) or the Show Pause Re-

set Input from the Smart Brick System. This tells the Smart Brick System to

continue the current show through a signal on the Green ʻPauseʼ Output to

the Smart Brick Brain

Clearing the Kp-300 Show Pause latch will stop the red LED that indicates the input which caused the Show Pause from flashing, but not turn it

off. The LED will be turned off only when:

a) The next show is started

b) Another input triggers an E-Stop or Pause condition

The Show Pause Reset output from the Smart Brick System can be programmed to be active during any show that you donʼt want to be able to

11

In some applications, you may want to call up a different show using this input, instead of pausing the current show.

Kp-300 Manual / September 4, 2012 4:29 PM / page 30 of 75

Page 31

Bypass #1 Bypass #2

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

ʻPauseʼ. Typically this is done during the E-Stop and Load/Unload shows to

prevent these shows from being paused.

F) Bypass Buss One

G) Bypass Buss Two

(One jumper for each safety input)

The fifteen Safety Inputs can be temporarily disabled from causing a

Show Pause or E-Stop from the motion profile programmed into the Smart

Brick System.

To keep an input from triggering a Show Pause/E-Stop when Bypass

Buss #1 is active, move the jumper to the middle and left two pins. To keep

an input from triggering a Show Pause/E-Stop when Bypass Buss #2 is active, move the jumper to the middle and right two pins. If this feature is not to

be used on an input, remove the jumper altogether.

Typical examples of the use of the bypass buss are:

a) HPU Startup/Shutdown: If the HPU is started and stopped as

part of the motion profile, there will usually be a time just after it

is started and a time after it is stopped where any HPU pressure

sensors inputs will need to be bypassed. Do this by programming the Bypass Buss you are using and Remote HPU Start In-

put to be active at the beginning of the show. The Bypass Buss

needs to be active for the time it takes for the HPU to build up

pressure. If the pressure doesnʼt come up during the time allotted, the Kp-300 will automatically trigger an error condition (either E-Stop or Show Pause, as configured).

# If the HPU is to be turned off at the end of the show, then the

Bypass Buss which is being used would be programmed active

along with a pulse on the Remote HPU Stop Input. This allows

the HPU to be stopped without triggering an error condition. If

configured to trigger an E-Stop, the Bypass Buss may also need

to be programmed active during the E-Stop and Load/Unload

shows so that the HPUʼs low pressure wonʼt trigger an error during these shows when the HPU is off.

b) Door Sensors: If the door or floor mat sensors inputs are set to

Kp-300 Manual / September 4, 2012 4:29 PM / page 31 of 75

Page 32

not used Pump Stop

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

trigger an E-Stop, they will need to be bypassed during the EStop and Load Unload shows. This is because although you

want these inputs to trigger an error while the motion base is in

motion, you donʼt want this to trigger an E-Stop when someone

opens the doors for the passengers to be loaded and unloaded.

c) Electric Motion Bases and other Installations that donʼt use

the Kp-300 Blocking Valve Output: If you donʼ t want to allow

shows to be run if there is an E-Stop condition present, you can

configure one of the two bypass busses to momentarily (for just

one frame) bypass all the possible error inputs at the very start

of all shows12 . At the end of the bypass buss pulse, any error

conditions that remain will trigger the E-Stop to keep even the

video and audio from running. This technique should be used in

applications that donʼt use the Blocking Valve Output. Typical of

these are most electric motion base installations.

If you are using the Seat Belt Logging features of the Kp-300, be sure you

donʼt configure the Kp-300 to bypass any inputs that are to be logged during

the time during which they need to be logged. Bypassing an input will convince the Kp-300 that the inputs are in the ʻsafeʼ position, and so they will not

be logged as ʻunoccupiedʼ.

The Show Pause functions are usually disabled during the E-Stop and

Load/Unload shows by the Show Pause Reset Input from the Smart Brick

System. Inputs that trigger a Show Pause are usually not needed during the

E-Stop and Load/Unload shows anyway, so there is no need to bypass them

separately during these shows.

H) HPU-Stop Buss

(One jumper for each safety input)

Any or all of the fifteen Safety Inputs can be set to force the HPU off, regardless of the E-Stop and Show Pause busses.

When the jumper for an input is set to the HPU Stop position, the HPU

cannot be started until this error condition is reset. This jumper is normally

used only on inputs that are also configured to trigger an E-Stop.

12

This technique is flexible enough that you can even leave it out of any maintenance shows that you want to be able to run without

motion.

Kp-300 Manual / September 4, 2012 4:29 PM / page 32 of 75

Page 33

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

Although any E-Stop error will stop the HPU, as soon as the E-Stop show

has started running the HPU can be restarted. By using this jumper in addition to the E-Stop jumper, the HPU cannot be restarted until the error condition is cleared. A typical example of this featureʼs use is on the input used for

the HPU oil level sensor. If the oil level is low, the Kp-300 will E-Stop the

system and not allow the HPU to be restarted until some more oil is added

to the system.

Kp-300 Manual / September 4, 2012 4:29 PM / page 33 of 75

Page 34

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

DipSwitch settings on the Kp-300 (v3.0+)

(EIGHT POSITION DIPSWITCH)

The DipSwitch is used to select several options on the v3.0+ Kp-300s:

A) DipSwitch #1: HPU Stopped LED Internal/External

OFF# = HPU Stopped LED controlled by an external switch

ON# = HPU Stopped LED controlled internally

If your HPU has a switch that closes when the HPU is not running, you

should wire this switch to the HPU Stopped Input pins #1 and #14 on the J2

connector. If your HPU doesnʼt have a ʻstoppedʼ switch output, or you donʼt

even have a HPU in your application, turning this switch on will light the

ʻHPU stoppedʼ LED when the Kp-300 thinks the HPU shouldnʼt be running.

Unlike the HPU Running Input, the HPU Stopped Input is not used for any

other purpose than lighting this LED.

B) DipSwitch #2: HPU Running LED Internal/External

OFF# = HPU Running LED controlled by an external switch

ON# = HPU Running LED controlled internally

If your HPU has a switch that closes when the HPU is not running, you

should wire this switch to the HPU Running Input pins #2 and #15 on the J2

connector. If your HPU doesnʼt have a ʻstoppedʼ switch output, or you donʼt

even have a HPU in your application, turning this switch on will light the

ʻHPU Runningʼ LED when the Kp-300 thinks the HPU shouldnʼt be running.

C) DipSwitch #3: E-Stop Disables Show Starts

OFF# = Does nothing

ON# = E-Stop Buss disables new show starts

When on, this DipSwitch will keep any shows from being started When

the E-Stop buss is active (the E-Stop Buss LED is lit) using the ʻShow Startʼ

buttons, even if the ʻShow Startʼ Enables are active.

D) DipSwitch #4: HPU-Stop Disables Show Starts

OFF# = Does nothing

Kp-300 Manual / September 4, 2012 4:29 PM / page 34 of 75

Page 35

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

ON# = HPU-Stop Buss disables new show starts

When on, this DipSwitch will keep any shows from being started When

the HPU-Stop buss is active (the HPU-Stop Buss LED is lit) using the ʻShow

Startʼ buttons, even if the ʻShow Startʼ Enables are active.

E) DipSwitch #5: Pause Buss Disables Show Starts

OFF# = Does nothing

ON# = Pause Buss disables new show starts

When on, this DipSwitch will keep any shows from being started When

the Show Pause buss is active (the Show Pause Buss LED is lit) using the

ʻShow Startʼ buttons, even if the ʻShow Startʼ Enables are active.

F) DipSwitch #6: E-Stop Triggers Alarm Output

OFF# = Does nothing

ON# = E-Stop Triggers Alarm Output

When on, when the E-Stop buss is active (the E-Stop Buss LED is lit), the

alarm output will be active too. The alarm output can be attached to a

buzzer, bell or other annunciator to give an audible/visual indication of an error condition.

G) DipSwitch #7: HPU-Stop Triggers Alarm Output

OFF# = Does nothing

ON# = HPU-Stop Triggers Alarm Output

When on, when the HPU-Stop buss is active (the HPU-Stop Buss LED is

lit), the alarm output will be active too. The alarm output can be attached to a

buzzer, bell or other annunciator to give an audible/visual indication of an error condition.

Kp-300 Manual / September 4, 2012 4:29 PM / page 35 of 75

Page 36

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

H) DipSwitch #8: Pause Buss Triggers Alarm Output

OFF# = Does nothing

ON# = Pause Buss Triggers Alarm Output

When on, when the Show Pause buss is active (the Show Pause Buss

LED is lit), the alarm output will be active too. The alarm output can be at-

tached to a buzzer, bell or other annunciator to give an audible/visual indication of an error condition.

Kp-300 Manual / September 4, 2012 4:29 PM / page 36 of 75

Page 37

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

DMX-512 Address Selection on the Kp-300 (v3.0+)

(TWO HEXADECIMAL DIPSWITCHES)

To support the DMX-512 input, the v3.0+ Kp-300 adds a two position rotary

DipSwitch which is used to set the DMX-512 address

The DMX-512 addressing is zero-based, HEXadecimal numbering.

Valid addresses between 00h and FFh. We typically set the Kp-300 to an address of

00h thru 02h, and then address the motion base legs and outputs for starting the videos,

lights and ʻ4dʼ effects starting at 03h.

The Kp-300 requires DMX-512 that includes GilderChecksums. If receiving DMX-512

without valid checksums, the DMX-512 Receive LED on the back of the Kp-300 will not

flash and only the Show Start Button LEDs will follow the incoming the DMX-512. The

signals like the Show Start Button Enable Inputs, blocking valve enable, and automatic

HPU start/stop will not work when the GilderChecksums are invalid.

Kp-300 Manual / September 4, 2012 4:29 PM / page 37 of 75

Page 38

Gilderfluke & Co.• 205 South Flower Street • Burbank, California 91502 • 818/840-9484 • 800/776-5972 • fax 818/840-9485

Sample Shows

Although the Kp-300 has no microcontroller on it of any kind, the Smart Brick System

does. Whether or not the Smart Brick System is mounted on the back of the Kp-300 or

remotely, the configuration for the Smart Brick Brains and motion profiles are identical.

The Kp-300 must be used with Smart Brick Brains with firmware revisions of 1.13 or

later.

When used with a Kp-300, the Smart Brick System is always playing one show or

another. Besides the ʻmainʼ shows that actually move the motion base, there are a

handful of ʻutilityʼ shows you will need to program (usually three). These are used to

prepare the motion base for the next show (turning on or off lights, opening and closing

doors, etc.), flashing the indicator LEDs on the front of the Kp-300 to indicate what the

next options available to the operator are, and to enable and disable the Show Start

Buttons to allow or disallow the operators to start only certain selected shows. Strictly

speaking, most of the utility shows can be as short as a frame or two. This would limit

your flexibility as far as flashing the LEDs on the Kp-300 in artistic patterns, so most are

two or three seconds long.

In the following sample shows, all twenty-four digital outputs that go to the Kp-300, as

well as all six analog axis that move the motion base are displayed. It is on these

twenty-four digital outputs that there must be a small amount of simple ʻhousekeepingʼ

programmed in for the control system to work. These Pc•MACs screen shots and the

sample shows available from www.gilderfluke.com show you what needs to be done. In