Gilbarco MRIR2 Installation Manual

Installation

Introduction

Purpose of this Manual

Prerequisites

MDE-3591A

TRIND™ Transmitter/Receiver in Dispenser

Retrofit Kits C00011-002-XXXX

Using TIRIS™ Technology

This manual provides instruction for installing TRIND™/TIRIS™ Retrofit Kits

C00011-002-XXXX in The Advantage

monochrome CRIND™, or single-line CRIND.

The TRIND option allows customers to automatically authorize CRIND-equipped units, using

either a hand-held or auto-mounted transpon der provided b y a major oil comp any (MOC). Use

these kits for one- or two-sided units.

Retrofit Kits C00011-002-XXXX are configured according to specific unit requirements.

Before installing any TRIND kit, ensure that the existin g CRIND contains the following.

• Z-180 logic board and software (T17764-XX), which is not configured in TRIND retrofit

kit. Refer to MDE-2628, Cash Acceptor Retrofit Assemblies for The Advantage Series

Units with CRIND Card Reader in Dispenser Kit C00007-002.

• Plastic options doors for single-line/cash acceptor InfoScreen/cash acceptor and

monochrome/cash acceptor

®

Series wide frame units with InfoScreen®,

Important Notice

PRELIMINARY

Required Reading

This equipment has been tested and found to comply with the limits for a Class A digital

device pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses an d can radiate r adio frequency en ergy, and if not

installed and used in accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his

own expense. Changes or modifications not expressly approved by the manufacturer could

void the user’s authority to operate this equipment.

Before installing the equipment, the installer mus t read, un derstand, and follow:

•this manual

• NFPA 30A, The Automotive and Marine Service Station Code

• NFPA 70, The National Electric Code

• applicable federal, state and local codes and regulations

• ASC TRIND Technology Update on page 9

Failure to do so may adversely effect the safe use and operation of the equipment.

Note: These kits must be installed by a Gilbarco ASC (Authorized Service Contractor)

MDE-3591A TRIND™ Retrofit Kits C00011-002-XXXX for The Advantrage Series • 3/00 Page 1

Introduction

Related Documents

Required Tools

MDE-2531 Pump & Dispenser Start-Up & Service Manual

MDE-2562 CRIND Service Manual

MDE-2628 Cash Acceptor Retrofit Assemblies for The Advantage Series with CRIND

MDE-2620 Graphics Panel Application for The Advantage Series

MDE-3640 Authorized Service Contractor (ASC) TRIND Installation Tool Kit K94577-01

PT-1728 The Advantage Series Illustrated Parts Manual

PT-1736 CRIND Card Reader Illustrated Parts Manual

The following equipment is needed to install TRIND™ kit C00011-002

• Allen wrench set, American standard

• clean cloth or rag

• chip extraction tool, e.g., IC extraction, Digikey Part No. K158-ND or equivalent

• isopropyl alcohol (part# END-1082)

• ladders, style ‘A’, quantity of two (2)

•multimeter

• pencil or marker

•pliers

• pocket knife

• putty knife or scraper

• Q12534 CRIND diagnostic card

• ratchet set, standard

• screwdrivers, flat and Phillips head

• static guard wrist strap

• straight edge, 24"

• TRIND ASC tool kit (See “ASC TRIND™ Tool Kit K94577-01” on page 3 and refer to

MDE-3640, ASC TRIND Installation Tool Kit K94577-01)

• work bench or saw horses (packaging cartons may be used as bench)

PRELIMINARY

Page 2 MDE-3591A TRIND

™ Retrofit Kits C00011-002-XXXX for The Advan trage Serie s • 3/00

Parts Lists

C00011-002-XXXX Kit Configurations by Suffix

-Suffix Configured Fo r See

®

-WF_S The Advantage

-WF_D The Advantage Series 48" (wide frame) double-sided page 4

Series 48" (wide frame) single-sided page 4

Common Parts for All C00011-002-XXXX Kits

Description Assembly Contains Part Number Quantity

cable clamp, gray Q13558-04 16

cable clamp, gray Q13558-06 4

cable group assembly

(parts shown in columns at right)

card cage assembly T20606-G1 1

grommet, edge Q10315-06 1.5 ft.

grommet material, strip Q10277-02 1 ft.

jump jack Q11011-01 10

label plate, FCC N23949-01 1

nut, Keps Q12068-03 2

screw, sems, 6-32 x 3/8 Q12083-13 1

screw, 8-32 x 3/8 Q12083-26 2

silicone sealant, RTV, tube END 1576 1

software, CRIND™ Bios TRIND K93744-01 1

tie wrap Q10178-01 4

washer, flat N16599-48 1

cable, TRIND to CRIND R20437-G01 1

cable, TRIND AC power R20580-G1 1

cable, light/multi-protocol M00857A001 1

cable, light/multi-protocol M00857A002 1

cable, antenna/low frequency M00878A002 1

PRELIMINARY

ASC TRIND™ Tool Kit K94577-01

Parts Lists

Q13863-01 1

Tool Description Part Number Quantity

co-axial cable tool Q13628-01 1

field strength sensor Q13626-01 1

test tag, TI/RFIDcar mount Q13630-01 1

test tag, TI/RFID hand held Q13630-02 1

threaded rod, 3/8-16 x 4" N23880-01 4

tuning tool, plastic tipped Q13631-01 1

MDE-3591A TRIND™ Retrofit Kits C00011-002-XXXX for The Advantrage Series • 3/00 Page 3

Parts Lists

C00011-002-WF S

C00011-002-WF D

For The Advantage® Series 48" (wide frame) single-sided units.

Kit contains all parts from “Common Parts for All C00011-002-XXXX Kits” on page 3 plus

the following.

Description Part Number Quantity

antenna assembly T20632G1 1

bracket assembly, antenna mounting T20625-01 2

gasket, 1/2" x 1/16" strip Q11899-12 1.5 ft.

grommet, bulkhead seal Q13570-01 1

grommet, round N15941-38 4

load connector, dummy transmitter R20526-G1 1

option door assembly T20613-G1 1

screw, 10-32 black K85736-45 14

For The Advantage® Series 48" (wide frame) double-sided units.

Kit contains all parts from “Common Parts for All C00011-002-XXXX Kits” on page 3 plus

the following.

Description Part Number Quantity

antenna assembly T20632G1 2

bracket assembly, antenna mounting T20625-01 2

gasket, 1/2" x 1/16" strip Q11899-12 3 ft.

grommet, bulkhead seal Q13570-01 1

grommet, round N15941-38 4

option door assembly T20613-G1 2

screw, 10-32 black K85736-45 16

PRELIMINARY

Page 4 MDE-3591A TRIND

™ Retrofit Kits C00011-002-XXXX for The Advan trage Serie s • 3/00

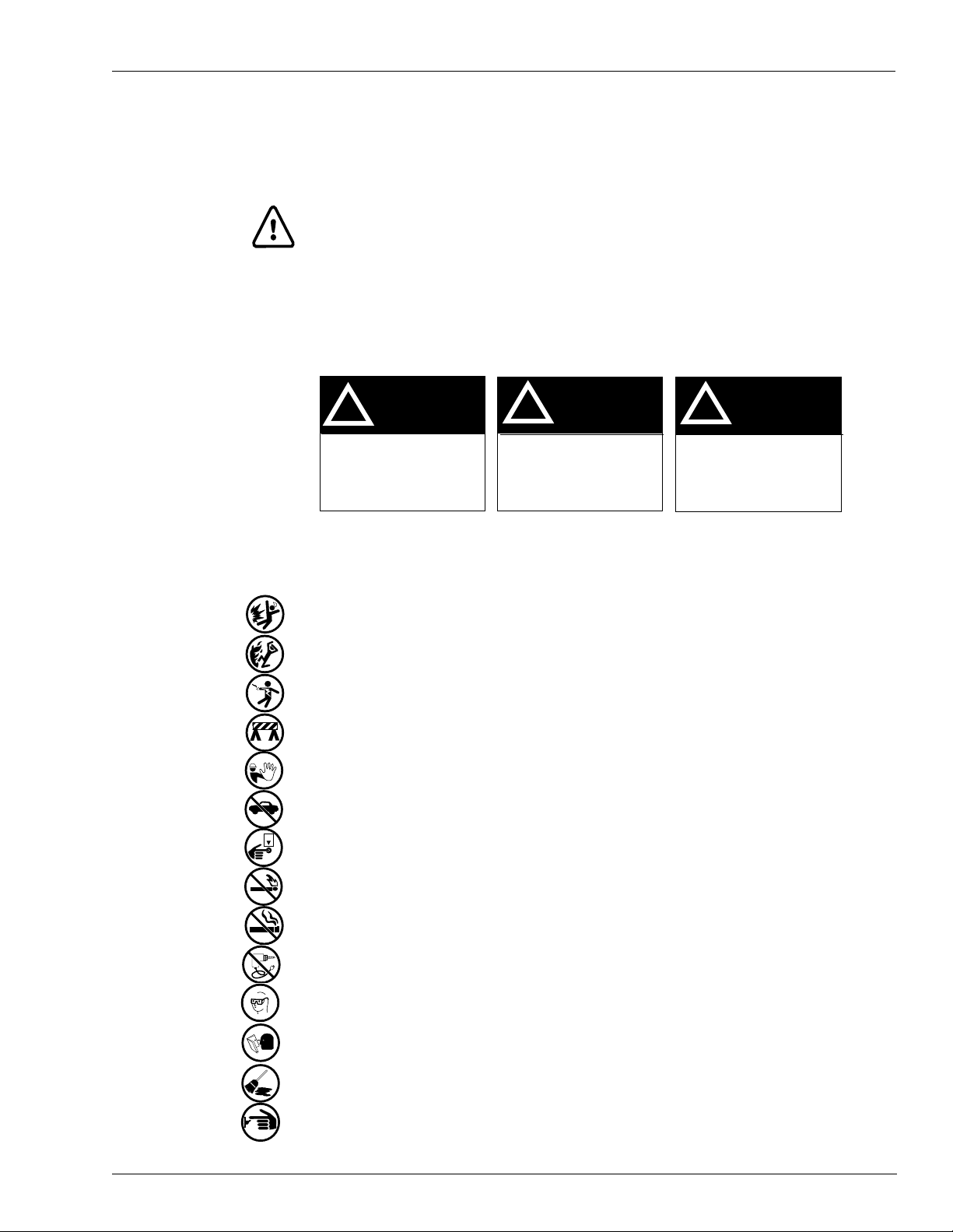

Safety Information

Alert Symbol and Signal Words

Alert Symbol:

This is a standard ANSI* approved alert symbol. When you see this symbol, be alert to the

potential for a personal injury.

* Reference American National Standard Bulletins ANSI Z535.

Signal Words:

These signal words alert you to important safety hazards.

Safety Information

Safety Symbols:

PRELIMINARY

WARNING

!

The hazard or unsafe

practice may result in

severe injury or death.

The following safety symbols are used throug hout this manual to alert you to personal safety

hazards and precautions.

Explosive

Flammable

Electrical hazard

Use safety barricades

No people in area

No vehicles in area

OFF

Use emergency power disconnect

CAUTION

!

The hazard or unsafe

practice could result in

minor injury.

DANGER

!

The hazard or unsafe

practice will result in

severe injury or death.

No open flames

No smoking

No power tools

Wear eye protection

Read all related manuals

Clean up spills

Turn power off

MDE-3591A TRIND™ Retrofit Kits C00011-002-XXXX for The Advantrage Series • 3/00 Page 5

Safety Information

OFF

Before Beginning

Do the following:

WARNING

!

Dangerous Environment! Failure to

install this equipment in accordance

with NFPA 30A and NFPA 70 could

result in severe injury or death.

Read, understand and follow NFPA

30A and NFPA 70.

Read all instructions before beginning.

Follow all safety precautions, including:

• Barricade work area.

• Do not allow vehicles or unauthorized people in work area.

• Do not use power tools in work area.

• Do not permit smoking or open flames in work area.

• Wear protective gear while performing this installatio n.

Record all mechanical and electronic totals.

OFF

Turn off all power to unit, unit lights and STPs.

• Use system circuit breakers.

• Multiple disconnects may b e req uired.

• Isolate each pump at distribution box.

• Refer to MDE-2531, Pump and Dispenser Start-up and Service for OSHA

lock-out/tag-out procedures.

!

PRELIMINARY

WARNING

Working on dispenser

electron ics with power

applied may result in

electrocution and

damage to electronic

components.

Power down unit before

beginning work.

When system battery is present, turn off system battery by pressing CLEAR then ENTER on

manager keypad.

Page 6 MDE-3591A TRIND

™ Retrofit Kits C00011-002-XXXX for The Advan trage Serie s • 3/00

Use Electrostatic Discharge Pr ecautions

Place yourself at a neutral static-free potential by doing the following:

1 Touch an unpainted metal surface.

2 Use a wrist strap connected to a grounded metal frame or chassis.

Safety Information

OFF

Note: Failure to use electrostatic discharge precautions may damage electronic components

and void warranty.

Make sure all power has been removed from unit and CRIND.

Follow OSHA Lock-Out and Tag-Out Requirements

OSHA Standard 29 CFR 1910-147 Contro l of Hazar dous Energy Sources (Lock-Out/Tag-Out)

covers ways to avoid personal injury if power is turned on or fuel pressure is applied

unexpectedly while servicing equipment. The rule requires that equipment power and fuel

under pressure be turned off and the device (breaker, valve, etc.) locked or labeled with a

warning tag.

Read OSHA Standard 29 CFR 1910-147 Control of Hazardous Energy Sources (Lock-Out/

Tag-Out). Station employees and service contractors need to understand and comply with this

program completely to ensure safety while the equipment is down.

Tag-Out and Lock-Out Procedure

Use plastic warning tags with signature/date b lanks for Tag-Out. Sign and date them at shut

down. Attach tags with plastic connectors.

Use metal screw-down lock clamps or plastic single or multi-pole devices for Lock-Out of

breakers and switches. Always use a lock-out device whenever possible.

When working on electronics and electrical connections (junction box):

• Turn of f unit po wer, light breakers, an d all disp ense rs shari ng th e same isolat ion r ela y box.

• Install lock-out device and tag on breaker(s).

PRELIMINARY

Note: If station does no t use STP control wire isolation relays, multiple disconnects may be

required to shut off all power supplied to the unit.

MDE-3591A TRIND™ Retrofit Kits C00011-002-XXXX for The Advantrage Series • 3/00 Page 7

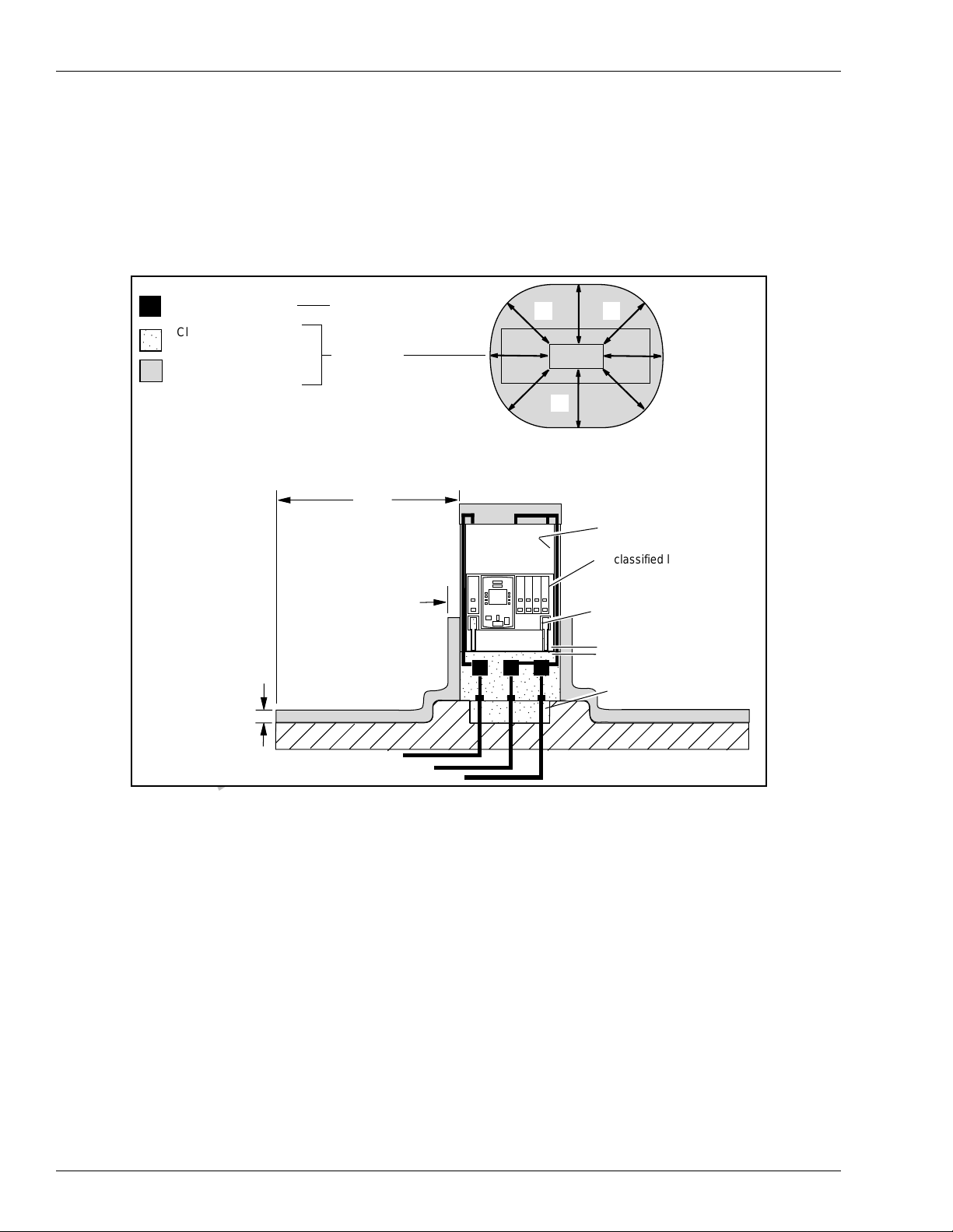

Classifying Hazardous Locations

Classifying Hazardous Locations

Any activity that can cause an explosion (such as smoking or drilling) must be done well

outside the vapor area.

The following diagram is based on NFPA 30A, section 6 and NFPA 70, section 514.

Fuel is present.

(Flammable Liquid)

Class 1 Division 1

(Hazardous Location)

Class 1 Division 2

(Hazardous Location)

18"

Fuel Containing

Components

Vapor Areas

20'

18"

20'

20'

20'

Vertical Vapor Barrier

Unclassified location

area within electronics cabinet

above Air Gap.

Class 1 Division 1

within boot area.

Air Gap

Pit box.

PRELIMINARY

Page 8 MDE-3591A TRIND

S0001866

™ Retrofit Kits C00011-002-XXXX for The Advan trage Serie s • 3/00

ASC TRIND™ Technology Update

ATTENTION: AUTHORIZED SERVICE CONTRACTORS

READ THIS SECTION BEFORE PROCEEDING WITH INSTALLATION

The TRIND™ system utilizes technology and devices not commonly used in the industry.

Read the following carefully to familiarize yourself with relatively unique aspects of TRIND

and prevent field problems.

RF Transmission and Antennas

Located in the TRIND card cage is a transmitter printed circuit board (PCB). The RF antennas

are connected to this board during installation.

Applying power to the card cage with either antenna disconnected will result in dam age

to the transmitter PCB.

• The transmitter PCB may be burned up immediately, or its effective life shortened

drastically.

• The PCB may perform properly at installation, but will require premature field service at a

later date.

For single-sided units, a ‘dummy load’ connector R20526-G1 is provided for unused ‘B’ side

of the PCB.

ASC TRIND™ Technology Update

Note: Power must never be applied to the card cage without a load, either antennas or

dummy load connector.

Co-Axial Cable

Co-axial antenna cables Q13756-01, part of cable assembly M00878, used for TRIND are

more flexible and smaller diameter than more familiar co-axial cable, such as that used for

cable television. However, all co-axial cables share this feature:

Too severe a turn or bend in the cable will break the center (solid) wire.

This can result in a seemingly good but in actu a lity intermittent signal. This too ma y result in

what appears to be proper performance at installation that is followed by premature failure and

PRELIMINARY

field service. Replacing damaged cable in the field is an extensive task.

In addition, a damaged cable will also cause a situation w here the transm itter PCB is powered

without load, and damage the PCB.

Note: Turn s or ben ds in co-axi al cabl es Q13556 -01 must be gr adual l oops, n o shar per than a

1" radius (2" diameter).

For installation instructions, proceed to page 10.

MDE-3591A TRIND™ Retrofit Kits C00011-002-XXXX for The Advantrage Series • 3/00 Page 9

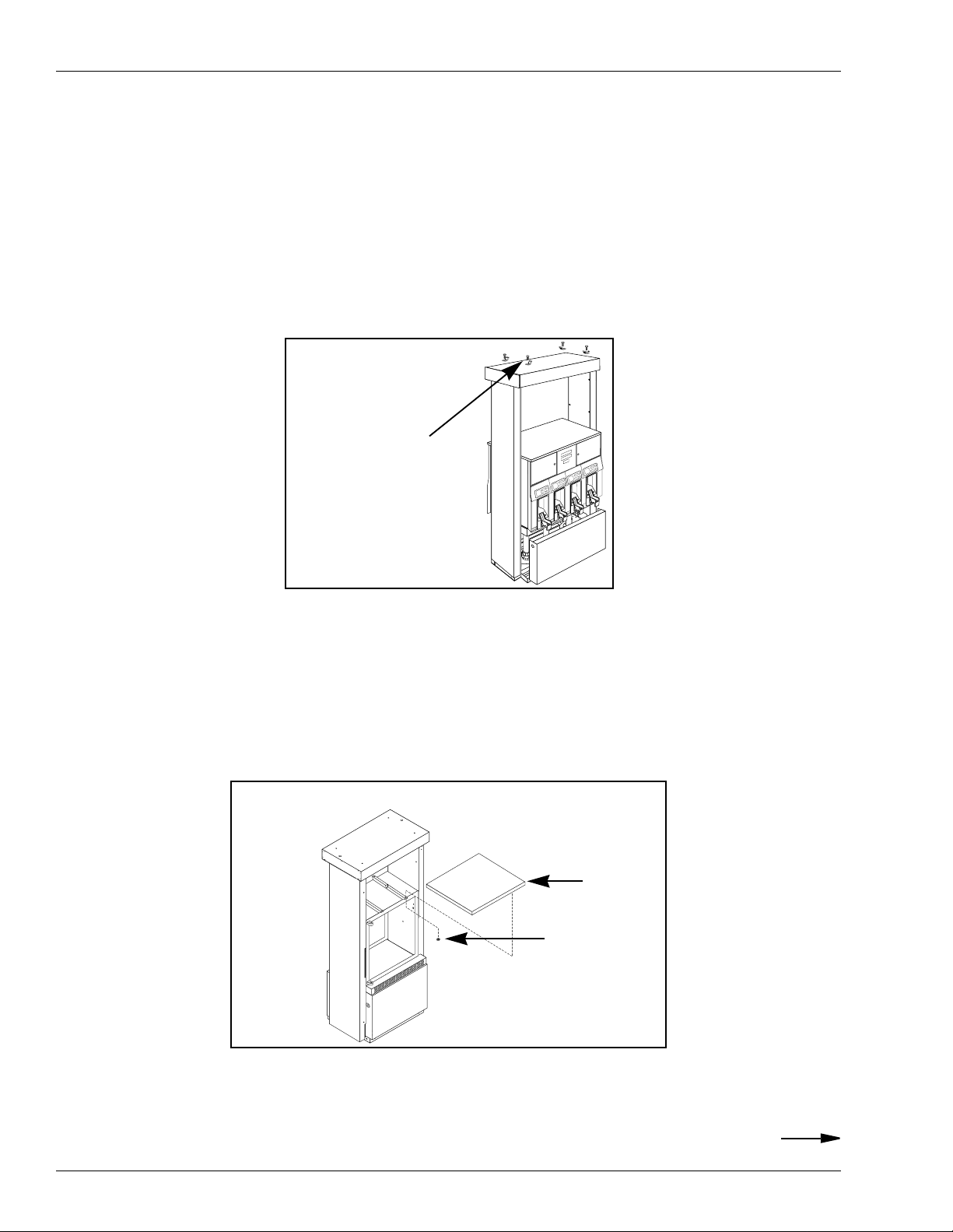

Installation

Installation

Before beginning read “Safety Information” on page 5.

Preparing For Installation

Perform these steps for all The Advantage® Series units

1 Remove four hoisting brackets from top of unit by removing four bolts and washers. Dispose

of hoisting brackets. Save hardware for reassembly.

Note: On units with logo display cabinet, hoisting brackets have already been removed.

Figure 1:

Removing hoisting

brackets

Hoisting brackets

and 3/8” bolts

S0000750

2 From ‘A’ side of unit, remove inner sheathing on left column. Set sheathing and screws aside

for reassembly.

3 Open main access doors. Refer to MDE-2531, Pump and Dispenser Start-Up/Service Manual

for access instructions.

4 Remove cabinet top cover fro m m ain p anel b y accessing mo unting h ardware from inside main

cabinet. See Figure 2. Save top cover and fastening hardware for reassembly.

PRELIMINARY

Figure 2:

Removing

cabinet

top cover

Top cover

Access to top cover

fastening bolts from

inside main cabinet

5 Remove door mounting pin and right optio ns door. See Figure 3.

Page 10 MDE-3591A TRIND

Continued

™ Retrofit Kits C00011-002-XXXX for The Advan trage Serie s • 3/00

Loading...

Loading...