Introduction

Purpose

This manual provides inst ructi on for inst alli ng Transmitter /Recei ver In Dis penser (TRIND™)

T exas Instrument s Registration and Ident ification (TIRIS™) Retrofit Kits C0001 1-010-XXXX

in The Advantage

monochrome CRIND™ device, or single-line CRIND device.

The TRIND option allows customers to automatically authorize CRIND-equipped units, using

either a hand-held or auto-mount ed transp onder provided by a major oil company (MOC). Use

these kits for one- or two-sided units. Kits are customer specific, depending on unit type,

number of sides, and MOC.

TRIND™ TIRIS™

Retrofit Kits C00011-010-XXXX

Installation Manual

August 2001

®

Series and MPD®-3 Multi-Pr oduct Dispen ser with InfoSc reen®,

ry

MDE-4063

Retrofit Kits C00011-010-XXXX are configured according to specific unit requirements.

Prerequisites

Before installing any TRIND kit, ensure that the existing CRIND device cont ains the

following.

• Z-180 logic board and software (T17764-XX), which is not configured in TRIND retrofit

kit. Refer to MDE-2628, Cash Acceptor Retrofit Assemblies for The Advantage Series.

• Plastic options doors for single-line/cash acceptor InfoScreen/cash acceptor and

monochrome/cash acceptor

Important Notice

This equipment has been tested and found to comply with the limits for a Class A digital

device pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses and can radiate radio frequency energy, and if

not installed and used in accordance with the instruction m anual, may cause harmful

P

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense. Changes or modifications not expressly approved by the

manufacturer could void the user ’s authority to operate this equipment.

na

i

m

4-01

eli

08-2

r

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 1

Introduction

Required Reading

Before installing the equipment, the installer must read, understand, and follow:

• this manual

• NFPA 30A, The Automotive and Marine Service Stat ion Code

• NFPA 70, The National Electric Code

• applicable federal, state and local codes and regulations

• ASC TRIND Technology Update on page 20

Failure to do so may adversely effect the safe use and operation of the equipment.

Note: These kits must be installed by a Marconi ASC (Authorized Service Contractor)

Related Documents

Manual Description

MDE-2531 Pump and Dispenser Start-Up and Service Manual

MDE-2562 CRIND Service Manual

MDE-2628 Cash Acceptor Retrofit Assemblies for The Advantage Series

MDE-2620 Graphics Panel Application for The Advantage Series

MDE-3640 Authorized Service Contractor (ASC) TRIND Installation Tool Kit

MDE-3664 TRIND Start-Up and Service Manual

PT-1728 The Advantage Series Illustrated Parts Manual

PT-1736 CRIND Card Reader Illustrated Parts Manual

PT-1810 MPD Series Illustrated Parts Manual

r

P

-01

4

liminary

e

08-2

Page 2 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Required Tools

The following equipment is needed to install TRIND™ kit C00011:

• Allen wrench set, American standard

• square (carpenter’s, 12'')

• clean cloth or rag

• center punch

• chip extraction tool, e.g., IC extraction, Digi key Part No. K158-ND or equivalent

• cutting oil

• deburring tool or rounded file

• drill motor, pneumatic (air)

• electric tape, black vinyl

• fish-tape, standard 1/8"

• hammer

• hacksaw

• hole saw, 7/8'' (for units with stop or call buttons on right option door)

• isopropyl alcohol (part number END-1082)

• knock-out punch set

• ladders, style ‘A’, quantity of two (2)

• multimeter

• pencil or marker

• pilot hole drill bits

• pliers

• pocket knife

• putty knife or scraper

• Q12534 CRIND diagnostic card

• ratchet set, standard

• screwdrivers, flat and Phillips head

• shears or snips, sheet metal

• static guard wrist strap

• TRIND ASC tool kit (refer to MDE-3640, ASC TRIND Installation Tool Kit K94577-01)

Introduction

4-01

8-2

0

Preliminary

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 3

Parts Lists

Parts Lists

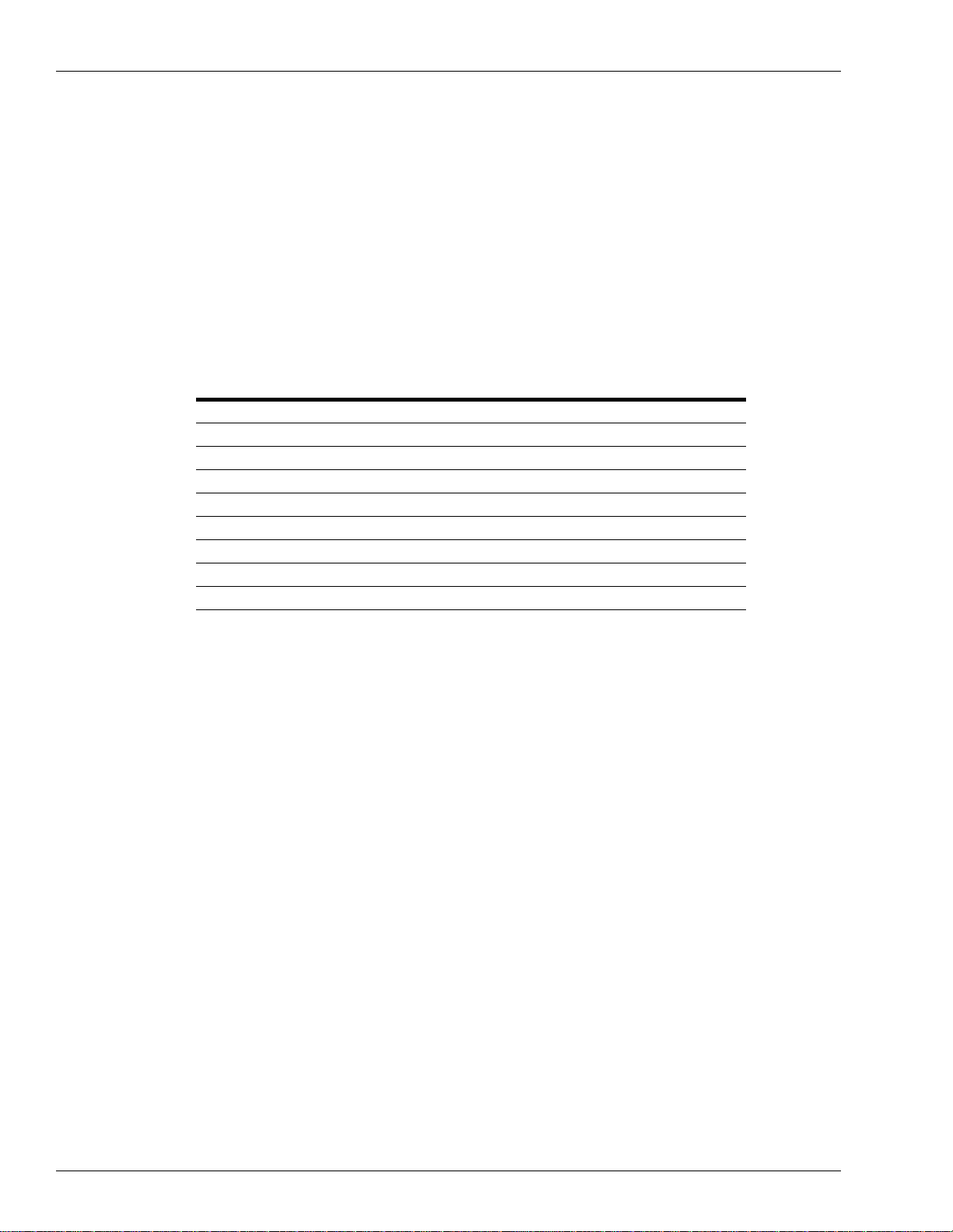

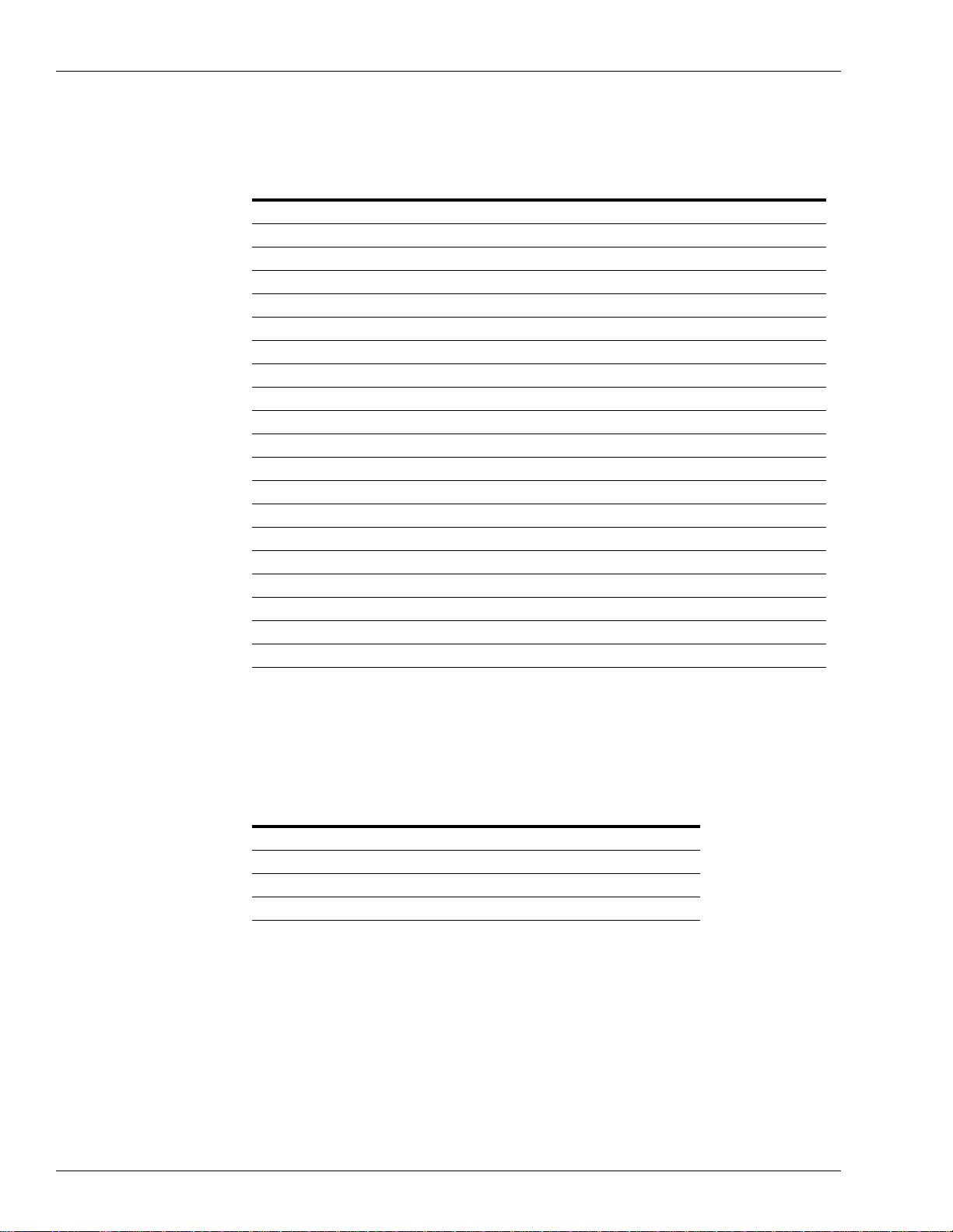

C00011-XXXX Kit Configurations by Suffix

-Suffix Configured For See

-WF_S The Advantage Series 48" (wide frame) single-sided page 5

-WF_D The Advantage Series 48" (wide frame) double-sided

-NF_S The Advantage Series 36" (narrow frame) single-sided

-NF_D The Advantage Series 36" (narrow frame) double-sided

-MPDS MPD-3 single-sided with PMI bezel (slide-in faceplate) page 7

-MPDD MPD-3 double-sided with PMI bezel (slide-in faceplate)

-MPBS MPD-3 single-sided with Mack bezel (bolt-on faceplate) page 8

-MPBD MPD-3 double-sided with Mack bezel (bolt-on faceplate)

r

P

-01

4

liminary

e

08-2

Page 4 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

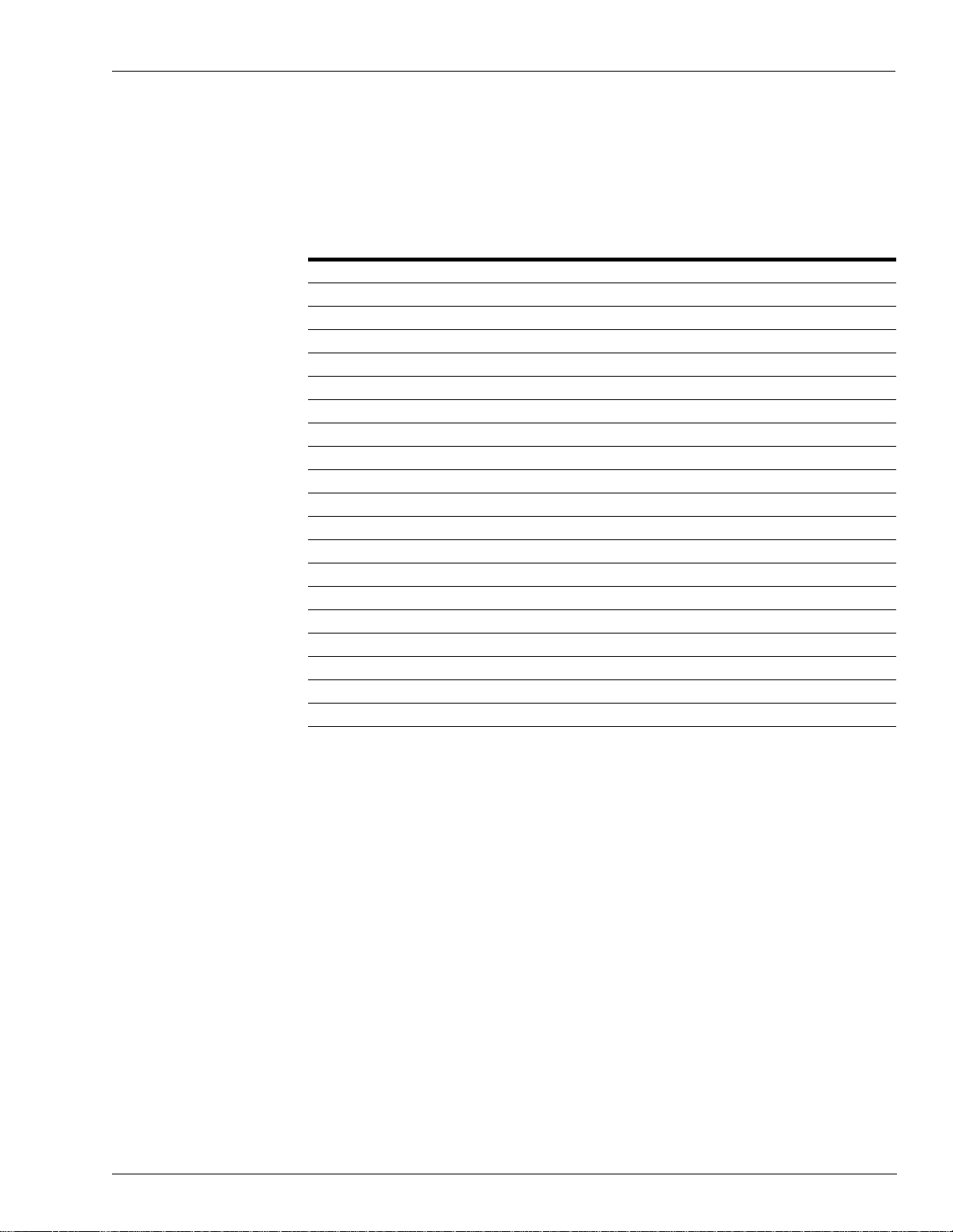

The Advantage Series Kit Parts

The Advantage Series Wide Frame (48’’) Kits

Kits C00011-WF_S (single-sided) and C00011-WF_D (double-sided) for The Advantage®

Series 48" units contain the following:

Description Part Number Quantity WF_S Quantity WF_D

1/4-20 bolt x 4” black K01914-70 4 8

1/4-20 nut, black Q11890-08 4 8

antenna assembly T20231-G1 1 2

bracket, antenna T20211-03 1 2

bracket, mounting T20211-02 1 0

bracket, positioning R20620-01 2 4

bracket, universal T20212-01 2 2

cable clamp, gray Q13558-04 10 10

cable group Q13863-06 (note 1) 1 1

card cage assembly T20606-G2 1 1

conduit, flexible black plastic Q13592-02 1 1

connector, tube fitting Q13591-01 1 2

cover, antenna top T20213-01 1 1

decal, UL N23951-06 1 1

door assembly T20613-G1 1 2

gasket, 1/2” x 1/16” strip Q11899-12 1.5 ft. 1.5 ft.

grommet, bulkhead seal Q13570-01 1 1

grommet, edge Q10315-06 1 ft. 1 ft.

grommet, heat shrinkable Q13570-01 1 1

grommet, round N15941-38 4 4

jump jack Q11011-01 9 9

label, UL certification N23957-G2 1 1

nameplate, FCC label N23949-09 1 1

screw, 10-32 black K85736 14 14

screw, sems, 6-32 x 3/8 Q12083-13 1 1

sealant, silicone END 1576 1 tube 1 tube

software, CRIND Bios TRIND K93744-XX (note 2) (note 2)

standoffs, circuit board (note 3) Q10651-16 4 4

tie-wrap Q10178-01 4 4

Preliminary

transmitter, dummy load R20526-G1 1

washer, flat N16599-48 1 1

Notes:

1. See “Cable Group Q13863-06” on page 6.

2. Order entry item.

3. For moving Gateway Board to top of card cage, see page “Relocate Gateway Board on Card Cage” on

page 24.

Parts Lists

4-01

8-2

0

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 5

Parts Lists

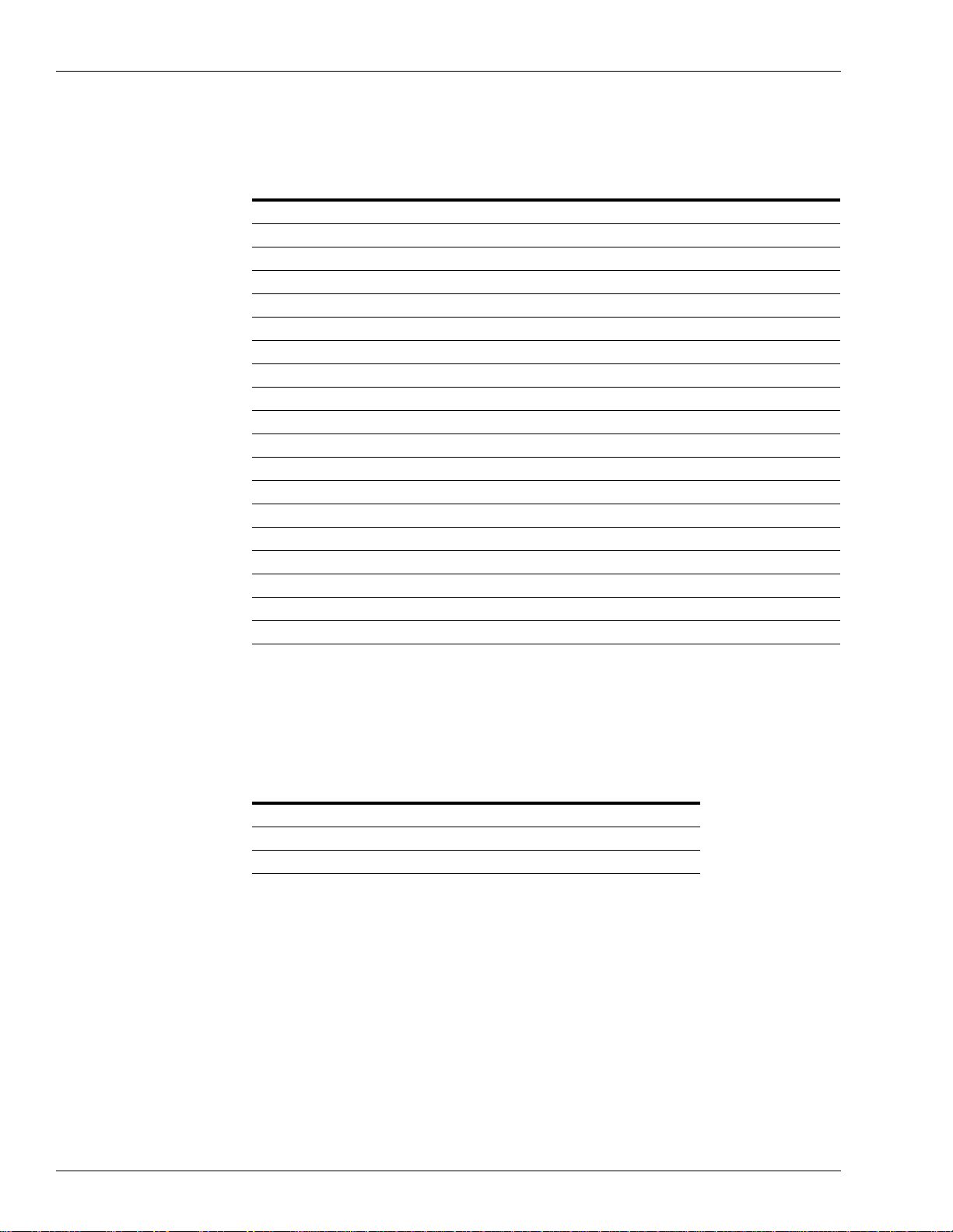

The Advantage Series Narrow Frame (36’’) Kits

Kits C00011-002-NF_S and C00011-002-NF_D kits for The Advantage Series 36" (narrow

frame) single-sided (NF_S) and double-sided (NF_D) units contain the following*:

Description Part Number Quantity NF_S Quantity NF_D

antenna assembly T20231-G1 1 2

bracket, antenna T20211-03 1 2

cable clamp, gray Q13558-04 10 10

cable group Q13863-06 (note 1) 1 1

card cage assembly T20606-G2 1 1

cover, top T20215-01 1 1

decal, UL N23951-06 1 1

door assembly T 20614-G 1 1 2

grommet, edge Q10315-06 1 ft. 1 ft.

grommet, heat shrinkable Q13570-01 1 1

jump jack Q11011-01 9 9

label, UL certification N23957-G2 1 1

nameplate, FCC label N23949-09 1 1

screw, sems, 6-32 x 3/8 Q12083-13 1 1

sealant, silicone END 1576 1 tube 1 tube

software, CRIND Bios TRIND K93744-XX (note 2) (note 2)

standoffs, circuit board Q10651-16 4 4

tie wrap Q10178-01 4 4

transmitter, dummy load R20526-G1 1

washer, flat N16599-48 1 1

Notes:

1. See “Cable Group Q13863-06” on page 6.

2. Order entry item.

-01

4

liminary

Cable Group Q13863-06

Cable group Q13863-06 for all The Advantage Series units contains the following parts:

Description Part Number Quantity

cable, AC Power R20580-G1 1

cable, antenna (hi and low freq) M00878A002 1

cable, light/microreader R20773-G2 2

cable, TRIND to CRIND R20437-G01 1

P

Page 6 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

e

08-2

r

• August 2001

MPD-3 Series Ki t Parts

MPD-3 Units with PMI Bezels (Slide-in Faceplates)

C00011-00 2-MPDS Kit s for single-sided units and C00011- 002- MPDD Kit s f or do ubl e- sided

units with PMI bezels and slide-in faceplates contain the foll owing*.:

Description Part Number Quantity MPDS Quantity MPDD

antenna assembly T20231-G1 1 2

bezel assembly T20616-G1 1 2

bracket, antenna T20211-03 1 2

cable assembly (J203/J806) R18163-G1 (notes 1 and 2) 1 1

cable clamp, gray Q13558-04 10 10

cable group (see note 2) Q13863-07 (note 2) 1 1

card cage assembly T20606-G2 1 1

cover, top T20214-01 1 1

decal, UL N23951-06 1 1

grommet, edge Q10315-06 1 ft. 1 ft.

jump jack Q11011-01 9 9

label, UL certification N23957-G2 1 1

manager keypad assembly T17549 1 1

nameplate, FCC label N23949-09 1 1

screw, sems, 6-32 x 3/8 Q12083-13 1 1

sealant, silicone END 1576 1 tube 1 tube

software, CRIND Bios TRIND K93744-XX (note 3) (note 3)

standoffs, circuit board Q10651-16 4 4

tie wrap Q10178-01 4 4

washer, flat N16599-48 1 1

Notes:

1. For Manager Keypad connection.

2. For detail refer to “Cable Group Q13863-07” on page 8.

3. Order entry item.

Parts Lists

4-01

8-2

0

Preliminary

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 7

Parts Lists

MPD-3 Units with Mack Bezels (Bolt-on Faceplates)

C00011-002-MPBS Kits for single-sided units and C00011-002-MPBD Kits for double-sided

units with Mack bezels and bolt-on faceplates contain the following*:

Description Part Number Quantity MPBS Quantity MPBD

antenna assembly T20231-G1 1 2

antenna bracket kit T20211-03 1 2

bezel assembly T20616-G2 1 2

cable assembly (J203/J806) R18163-G1 (note 1) 1 1

cable clamp, gray Q13558-04 10 10

cable group Q13863-07 (note 1) 1 1

card cage assembly T20606-G2 1 1

decal, UL N23951-03 1 1

grommet, edge Q10315-06 1 ft. 1 ft.

jump jack Q11011-01 9 9

label, UL certification N23957-G1 1 1

manager keypad assembly T17549 1 1

nameplate, FCC label N23949-02 1 1

screw, sems, 6-32 x 3/8 Q12083-13 1 1

sealant, silicone END 1576 1 tube 1 tube

software, CRIND Bios TRIND K93744-XX (note 2) (note 2)

standoffs, circuit board Q10651-16 4 4

tie wrap Q10178-01 4 4

washer, flat N16599-48 1 1

Notes:

1. For detail refer to “Cable Group Q13863-07” on page 8.

2. Order entry item.

-01

4

Cable Group Q13863-07

Cable Group Q13863-07 for all MPD-3 Series units contains the following parts:

Description Part Number Quantity

cable, AC Power R20580-G1 1

cable, antenna (hi and low freq) M00878A002 1

cable, TRIND to CRIND R20437-G01 1

e

r

liminary

08-2

P

Page 8 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

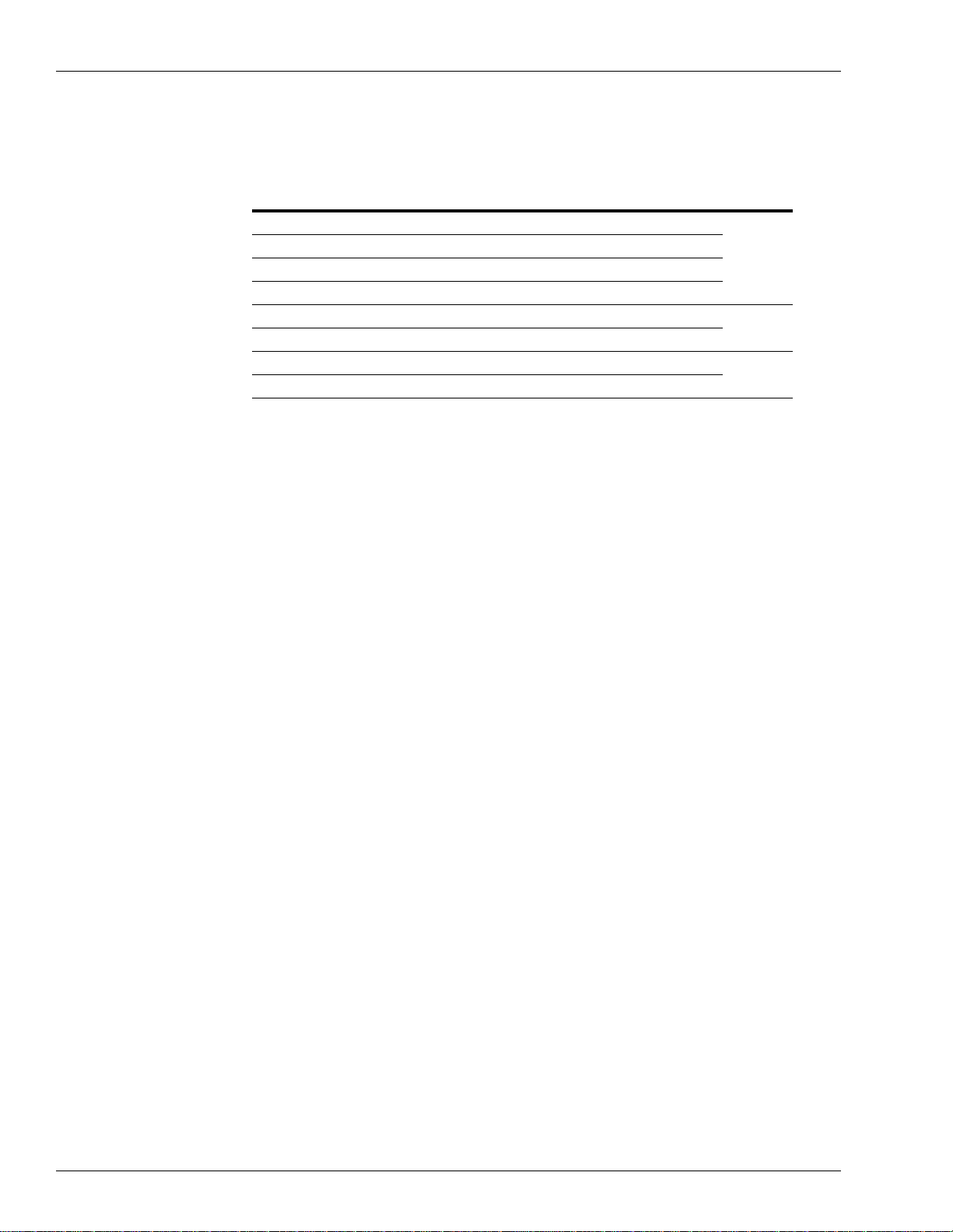

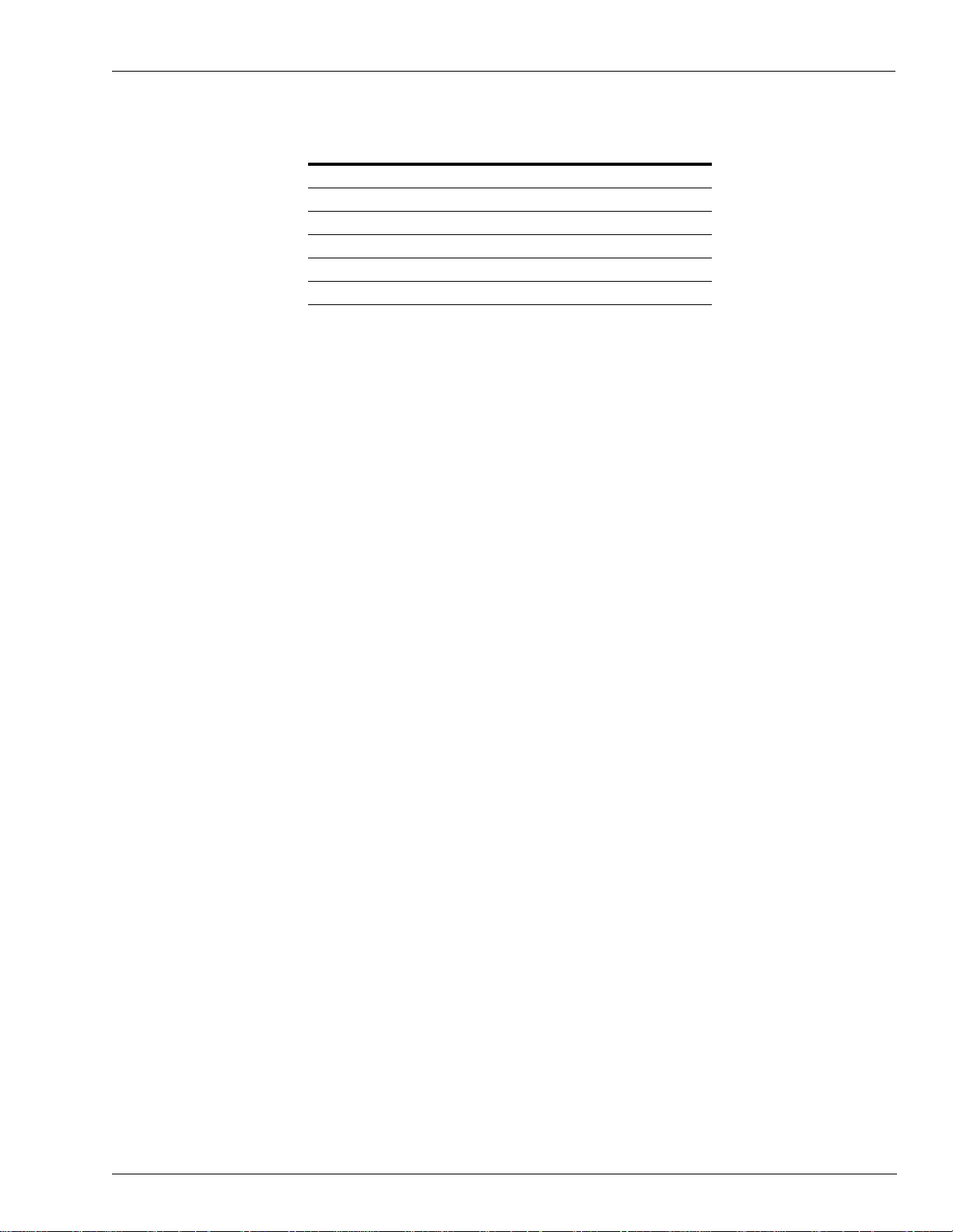

ASC TRIND™ Tool Kit K94577-01

Tool Description Part Number Quantity

co-axial cable tool Q13628-01 1

field strength sensor Q13626-01 1

test tag, TI/RFIDcar mount Q13630-01 1

test tag, TI/RFID hand held Q13630-02 1

threaded rod, 3/8-16 x 4" N23880-01 4

tuning tool, plastic tipped Q13631-01 1

Parts Lists

4-01

8-2

0

Preliminary

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 9

Important Safety Information

Important Safety Information

This section introduces the hazards and safety precautions associated with installing,

inspecting, maintaining or servicing this product. Before performing any task on this product,

read this safety information and the applicable sections in this manual, where additional

hazards and safety precau tions for your task will be found. Fire, explosion, electri cal shoc k or

pressure release could occur and cause death or serious injury if these safe service procedures

are not followed.

Preliminary Precau tio n s

You are working in a potentially danger ous environment of flammable fuels, vapors, and high

voltage or pressures. Only trained or authorized individuals knowledgeable in the rela ted

procedures should install, inspect, maintain or service this equipment.

The first and most important information you must know is how to stop all fuel flow to the

pump and island.

Emergency Total Electrical Shut-Off

Locate the switch or ci rcuit breakers that shut-off all power to all fueling equipment,

dispensing devices, and submerged turbine pumps (STPs). These you must operate in the

event of an emergency.

!

WARNING

The EMERGENCY STOP, ALL STOP, and PUMP STO P buttons at the cashier’s

station WILL NOT shut off electrical power to the pump/dispenser.

This means that even if you activate these stops, fuel may continue to flow

uncontrolled.

-01

4

liminary

You must use the TOTAL ELECTRICAL SHUT-OFF in the case of an

emergency and not only these cashier station “stops.”

e

r

08-2

Total Electrical Shut-Off Before Access

Any procedure requiring access to electrical components or the electronics of the dispenser

P

requires total electrical shut-off of that unit.

NFPA 30A, Section 4-1.2, published by the National Fire Protection Association, requires the

installation o f a n ea sily accessible switch or circuit bre aker to shut-off the power to all fueling

equipment, dispensing de vic es and ST Ps in th e event of an emergency. Know the func tion a nd

location of this switc h or circuit brea ker before inspe cting, instal ling, mainta ining, or servic ing

Marconi equipment.

Page 10 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Important Safety Information

Evacuation, Barricading and Shut-Off

Any procedures requiring accessing the pump/dispenser or STPs requires the following three

actions:

• An evacuation of all unauthorized persons and vehicles

• Using safety tape or cones as barricades to the effected units

• A total electrical shut-off of that unit

Read the Manual

Read, understand and foll ow this manual and any other labels or related materials supplied

with this equipment. If you do not under st and a pro cedure, call a Marconi Authorized Service

Contractor or call the Marconi Call Center at 1-800-800-7498. It is imperative to your safety

and the safety of others to understand the procedures before beginning work.

Follow the Regulations

There is ap plicable information in: N FPA 30A: Automotive and Marine Service Code; NFPA

70: National Electrical Code (NEC); OSHA regulations; and federal, state, and local codes

which must be followed. Failure to install, inspect, maintain or service this equipment in

accordance with these codes, regulations and standards may lead to legal citations with

penalties or affect the safe use and operation of the equipment.

Safety Symbols and Warning Words

This section provides important information about warning symbols and boxes.

Alert Symbol

This safety alert sym bol is used in this manual and on warning labels to alert you to

a precaution which must be follo wed to pre ven t poten tial person al saf ety haz ard s. Obey saf ety

directives that follow this symbol to avoid possible injury or death.

8-2

0

Preliminary

4-01

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 11

Important Safety Information

Signal Words

These signal words used in this manual and on warning labels tell you the seriousness of

particular safety hazards. The precautions that follow must be followed to prevent deat h,

injury or damage to the equipment.

This signal word is used to alert you to a hazard or unsafe practice which will result in

death or serious injury.

This alerts you to a hazard or unsafe practice that could res ult in death or serious injury.

!

This signal word d esign ates a h azard or unsa fe prac tice whi ch may res ult in minor injury.

!

DANGER

!

WARNING

CAUTION

CAUTION

When used by itself, CAUTIO N designate s a hazard or unsafe p ractice wh ich may re sult in

property or equipment damage.

Prevent Explosions and Fires

Fuels and their vapors will become explosive if ignited. Spilled or leaking fuels cause vapors.

Even filling customer tanks will cause explosive vapors in the vicinity of dispenser or island.

No Open Flames

e

r

Open flames from matches, lighters, welding torches or other sources can ignite

fuels and their vapors.

P

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools, burning cigarettes,

cigars or pipes can also ignite fuels and their vapors. Sta tic electricity, including an

electrostatic charge on your body, can cause a spark sufficient to ignite fuels and their vapors.

After getting out of a vehicle, touch the metal of your vehicle to discharge any electrostatic

charge before you approach the dispenser island.

-01

4

liminary

08-2

Page 12 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Prevent Electrical Shock and Sparks

Dispensing devices use high voltage. A potential shock hazard exists when working on or

around a dispensing device.

Follow OSHA lock-out and tag-out procedures.

Always turn OFF power to the dispensing device and associated submerged turbine pumps

(STPs) when servicing or making electrical wiring connections. Multiple disconnects may be

required.

WARNING

!

The EMERGENCY STOP, ALL STOP, and PUMP STOP buttons at the

cashier’s station WILL NOT shut off electrical power to the pump/dispenser.

This means that even if you activate these stops, fuel may continue to flow

uncontrolled.

You must use the TOTAL ELECTRICAL SHUT-OFF in the case of an

emergency and not only these cashier station “stops.”

Important Safety Information

Close Junction Boxes Tightly

Spilled or leaking fuels in the vicinity of electrical junction boxes can be hazardous if boxes

are not properly c losed. Replace all bolts and tighten junction box cover before turning on AC

power. Do not use gaskets on junction box covers.

Field Wiring

Poorly wired pumps or dispensers could cause a fire, explosion or electrical shock. Place all

power and lighting wire s in thre aded, ri gid met al condu its. Pl ug all unused jun ction b ox hole s.

Never use knockout boxes or flexible conduit. Tighten all threaded connections and covers.

Do not use gaskets wit h junction box covers . Do not disturb sealing c ompound around wi res at

junction box entrances. Use factory method of routing wires. Use tie wraps to keep unruly

wires away from pinch point and hinges. Tuck wires into enclosure before closing doors,

bezels, junction boxes, covers and breaker panels. Follow wiring recommendations in

installation or service manuals.

Preliminary

Proper Grounding is Required

Proper grounding is required for safe operation. See installation manual and applicable NEC,

NFPA and local electrical codes for requirements.

Avoid Pinched Wires

Pinched or cut wires (cabl es) may damage components. Ex posed wires could create sparks and

electrical shorts when applying power.

8-2

0

4-01

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 13

Important Safety Information

Hydraulic Press ure Releases and Fue l Leakage

Working on hydraulic systems can result in leakage of fuel that may also be under pressure.

Turn off all circuit breakers for unit being worked on, all dispensers using the same

grades of fuel, and all associated STPs.

Do not allow unauthorized or untrained individuals to service hydraulic equipment.

Shear valves, require d by NFPA 30A, are int en ded t o s hut -off the flow of fuel at the dispenser

base (hydraulics area ) during vehicl e impact or fir es. A single-poppe t shear valve pr events fuel

from flowing from the underground tank. A double-poppet shear valve prevents fuel from

flowing from the underground tank and from the dispenser.

Protect Your Eyes

Spraying fuel from res idual pressure in lines can cause ser iou s ey e i njuries. Always

wear eye protection. Gasoline spilled in eyes may cause burns to eye tissue. Rinse eyes with

water for approximately 15 minutes. Seek medical advice immediately. It is not necessary to

wear eye protection unless performing hydraulic service.

React Quickly to Fuel Spills, Fir es or Vehicle Impact

Follow these steps in the event of a fuel spill, fire, or vehicle impact.

1 Use station EMERGENCY TOTAL ELECTRICAL SHUT-OFF immediately. Turn off all

system circuit breakers to the island.

-01

4

liminary

!

WARNING

e

The EMERGENCY STOP, ALL STOP, and PUMP ST OP buttons a t the cashier’s

station WILL NOT shut off electrical power to the pump/dispenser.

r

This means that even if you activate these stops, fuel may continue to flow

uncontrolled.

P

You must use the TOTAL ELECTRICAL SHUT-OFF in the case of an

emergency and not only these cashier station “stops.”

08-2

2 Call emergency numbers for fires, vehicle impact or any significant spills.

3 Use safety tape, cones or barricades t o block the wor k area . Do not go ne ar fu el spi ll

or allow anyone else in the area.

Page 14 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Important Safety Information

4 Take precautions to avoid igniting fuel . Do not allow

starting of vehicles in the area and immediately stop use of open flames, smoking or power

tools in the area.

5 Provide emergency and first aid assistance.

!

WARNING

If any gasoline has been inhaled, seek emergency help immediately.

Inhaled gasoline may cause unconsciousness and burns to lips, mouth and lungs.

!

WARNING

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clean water.

Seek medical advice immediately.

6 Use approved and safe procedures to clean up all spills with a “fuel or gasoline absorbent”

material approved b y your local r egulator y agenci es. (Dispo se of fu el an d hazardo us absorbe nt

material promptly and according to the requirements of the fire department, local EPA, and

federal, state or local resources.)

4-01

8-2

0

Preliminary

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 15

Important Safety Information

Emergency and First Aid Information

Refer to phone book for emergency phone numbers. If needed, follow first aid instructions as

outlined in American Red Cross Standard First Aid manuals.

!

WARNING

Gasoline ingested may cause unconsciousness and burns to

internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

Gasoline

Ingestion

!

WARNING

Gasoline inhale d may c ause unc onsciou sness a nd burns to lip s,

mouth and lungs.

Keep airway open.

Seek medical advice immediately.

Gasoline Vapor

Inhalation

WARNING

!

Gasoline In

Eyes

r

!

WARNING

P

Gasoline On

Skin

-01

Gasoline spilled in eyes may cause burns to eye tissue.

Irrigate eyes with water for approximately 15 minutes.

Seek medical advice immediately

4

liminary

e

08-2

Gasoline spilled on sk in ma y caus e burn s.

Wash area thoroughly with clear/water.

Seek medical advice immediately.

Page 16 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Warning Labels

Several types of warning labels appear on Marconi products to inform and remind users of

important safety information. Read, understand and follow these warnings.

Sample Warning Label

The following labels are typical of those you may find on Marconi’s products:

Important Safety Information

Working Alone

It is highly recommended th at someone who is capabl e of render ing fi rst aid be present during

servicing. Be f amili ar with Car diopulmonar y Resusc itat ion ( CPR) met hods i f yo u are worki ng

with or around high voltages. This information is available from the American Red Cross.

Always advise the st ation perso nnel a bout whe re you will be wor kin g, and c autio n them not to

activate power while you are working on the equipment. Use the OSHA tag out and lock out

procedures discussed later in this section.

Contacting Emergency Personnel

Keep the following emergency phone numbers at hand.

Ambulance:_____________________________________

Fire:___________________________________________

Preliminary

Police:_________________________________________

Poison Control Center:____________________________

0

4-01

8-2

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 17

Important Safety Information

Informing Emergen cy Personnel

Compile the following information for emergency personnel:

• Location of accident (e.g. address, front/back of building, etc.)

• Nature of accident (e.g. possible heart attack, run over by car, burns, etc.)

• Age of victim (e.g. baby, teenager, middle-age, elderly)

• Whether or not victim has received first aid (e.g. stopped bleeding by pressure, etc.)

• Whether or not victim has vomited (e.g. if swallowed or inhaled something, etc.)

IMPORTANT: Oxygen may be needed at scene if gasoline has been ingested or inhaled. Seek

medical advice immediately.

Other Useful Safety Information

This subsection provides additional safety information.

OSHA Lock-Out and Tag-Out Requirements

OSHA Standard 29 CFR 1910-147 Control of Hazard ous Energy Sour ces (Lock-Out/ T ag-Out )

covers ways to avoid personal injury because power was turned on or fuel pressure was

applied unexpectedly while servicing equipme nt. The rule requires:

(1) Turning off equipment power and fuel under pressure.

(2) Use of a locking device (breaker, valve, etc.) or label device with a warning tag.

Station employees and service contractors need to understand and comply with this program

completely to ensure sa fety while th e equipment is down.

-01

Breakaways

Required by NFPA 30A, breakaways are emergency devices designed to retain liquid on both

sides of the breakaway point installed on each hose. Refer to manufacturer’s instructions for

proper installation.

Collection of Fuel in Approved Containers

NFPA 30A, Section 2, requir es us e of approved containers to collec t, t ra nsport, and dispose of

fuel. Containers must be specifically designed and labeled for handling hazardous fuels.

P

Read Material Safety Data Sheets (MSDS)

Before working with any chemicals or fuels in and around a dispensing facility, read the

MSDS pertaining to those chemicals as prescribed in the Occupational Safety and Health

Administration Standard, 29 CFR 1910.1200. Refer to the supplier’s literature.

e

r

liminary

08-2

4

Replacement Parts

Use only genuine Marconi replacement parts and retrofit kits on your pump/dispenser. Using

parts other than genuine Marconi replacem ent parts could create a safety hazard and violate

local regulations.

Page 18 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

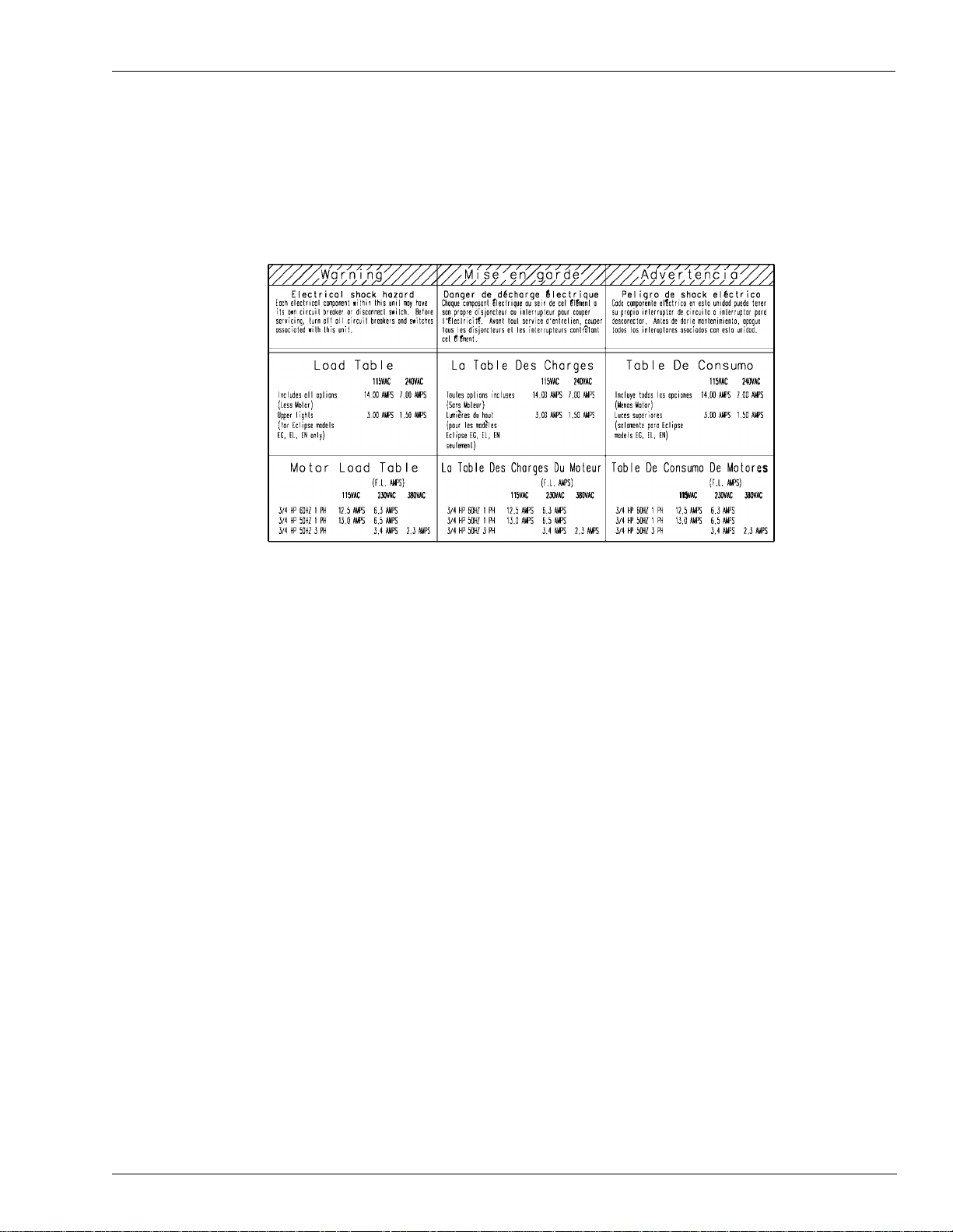

Classifying Hazardous Locations

Any activity that can cause an explosion (e.g., smoking, drilling, etc.) must be done well

outside the vapor area.

The following diagrams ar e based on NFPA 30A, section 6 and NFPA 70, section 514.

Fuel is present.

(Flammable Liquid)

Class 1 Division 1

(Hazardous Location)

Class 1 Division 2

(Hazardous Location)

The Advantage

Series with

Air Gap

Fuel Containing

Components

Vapor Areas

20'

20'

18"

Important Safety Information

20'

20'

Vertical Vapor Barrier

Unclassified location

area within electronics cabinet

above Air Gap.

Class 1 Division 1

within boot area.

MPD-3 Series

with

Vapor Barrier

Preliminary

18"

8-2

20'

0

18"

Air Gap

Pit box.

4-01

Vertical Vapor Barrier

Unclassified location

Electronics Head

Vapor Barrier

Class 1 Division 1

within boot area.

Pit box.

18"

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 19

ASC TRIND Technology Update

ASC TRIND Technology Update

Note: AUTHORIZED SERVICE CONTRACTORS READ THIS SECTION BEFORE

PROCEEDING WITH INSTALLATION

The TRIND system utilizes technology and devices not commonly used in the industry. Read

the following carefully to familiarize yourself with relatively unique aspects of TRIND

systems and prevent field problems.

RF Tr ansmission and Antennas

Located in the TRIND card ca ge is a trans mit ter pr inte d circ uit boa rd (PCB). The RF a ntenna s

are connected to this board during installation.

Applying power to the card cage with either antenna disconne ct ed will result i n da mage to the

transmitter PCB.

• The transmitter PCB may be burned up immediately, or its effective life shortened

drastically.

• The PCB may perform properly at i nstalla tion, but wil l require pr emature fi eld servi ce at a

later date.

For single-sided units, a ‘dummy load’ connector R20526-G1 is provided for unused ‘B’ side

of the PCB.

Note: Power must never be ap plied to the car d cage withou t a load, e ither ant ennas or d ummy

load connector.

-01

Coaxial Cable

Coaxial antenna cables in cable harness M00878A002 used for TRIND systems are more

flexible and smaller diameter than more familiar coaxial cable, such as that used for cable

television. However, all coaxial cables share this feature:

liminary

4

e

Too severe a turn or bend in the cable will break the center (solid) wire.

08-2

r

This can result in a seemingly good but in actuality intermittent signal. It may also result in

what appears to be proper pe rforma nce at inst allati on that is fol lowed by premat ure fail ure and

field service. Replacing damaged cable in the field is an extensive task.

P

In addition, a damaged cable will cause a situation where the transmitter PCB is powered

without load, and damage the PCB.

Note: Tu rns or ben ds in coaxial cables must be gr adual lo ops, no sharper than a 1" radi us (2"

diameter).

Page 20 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Installation Instructions For The Advantage Series Units

Installation Instructions For The Advantage Series Units

Important Preinstallation Instruction.

Before beginning, read “Important Safety Information” on page 10 and “ASC TRIND

Technology Update” on page 20.

For MPD-3 Series, go to “Installation Instru ctions For MPD-3 Units” on page 38.

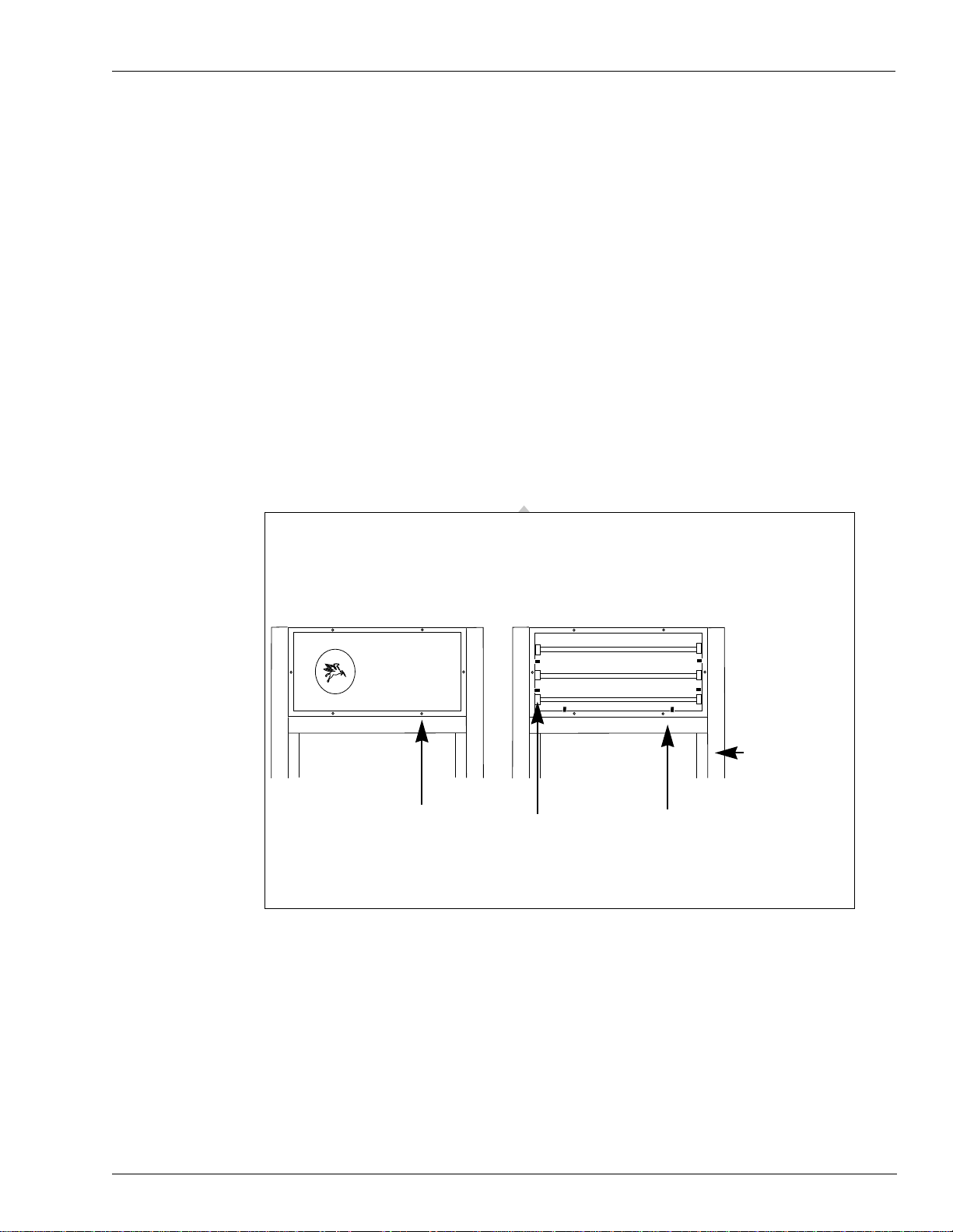

Removing Mobil Logo Display Cabinet

Use these procedures for dispensers with Mobil lighted logo display cabinets only. For units

without logo display cabinet (blue hat), proceed to ‘Preparing for Installation’ on page 22.

1 Remove framed logo faceplates from both long sides of display cabinet by removing six

screws per side. See Figure 1. Save screws and logo faceplates for reassembly.

Figure 1:

Removing logo display cabinet

With logo faceplate

With logo faceplate removed

4-01

Side cladding

fastened to

outside sheathing

8-2

Faceplate screws,

total of 6

0

Fastener assemblies

securing cladding to

display cabinet,

quantity of 8 each

Bolts and washers

securing logo display

cabinet to top of unit,

quantity of 4 each

Preliminary

2 Remove cover from electrical connection box in display cabinet and disconnect wires. Save

cover, screws and wire connectors for reassembly.

3 Remove locking nut and washer from conduit nipple in display cabinet. Save nut and washer

for reassembly.

4 Disconnect side clad ding on b oth sides from ligh t box by remov ing eight sets (f our per si de) of

bolts, flat washers, lock washers, neoprene washers and cage nuts. Dispose of removed

hardware.

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 21

Installation Instructions For The Advantage Series Units

5 Remove four 3/8-16 bolts , lock washe rs, fl at was hers a nd soft alumin um flat washer s secur ing

display cabinet to top of unit. Save all hardware except bolts for reassembly. Dispose of bolts.

6 Carefully lift and remove display cabinet. Set cabinet aside for reassembly.

Note: Logo display cabinet weighs approximately seventy-five pounds. A crew of two, on

separate ‘A’ style ladders, are required to lift and remove cabinet.

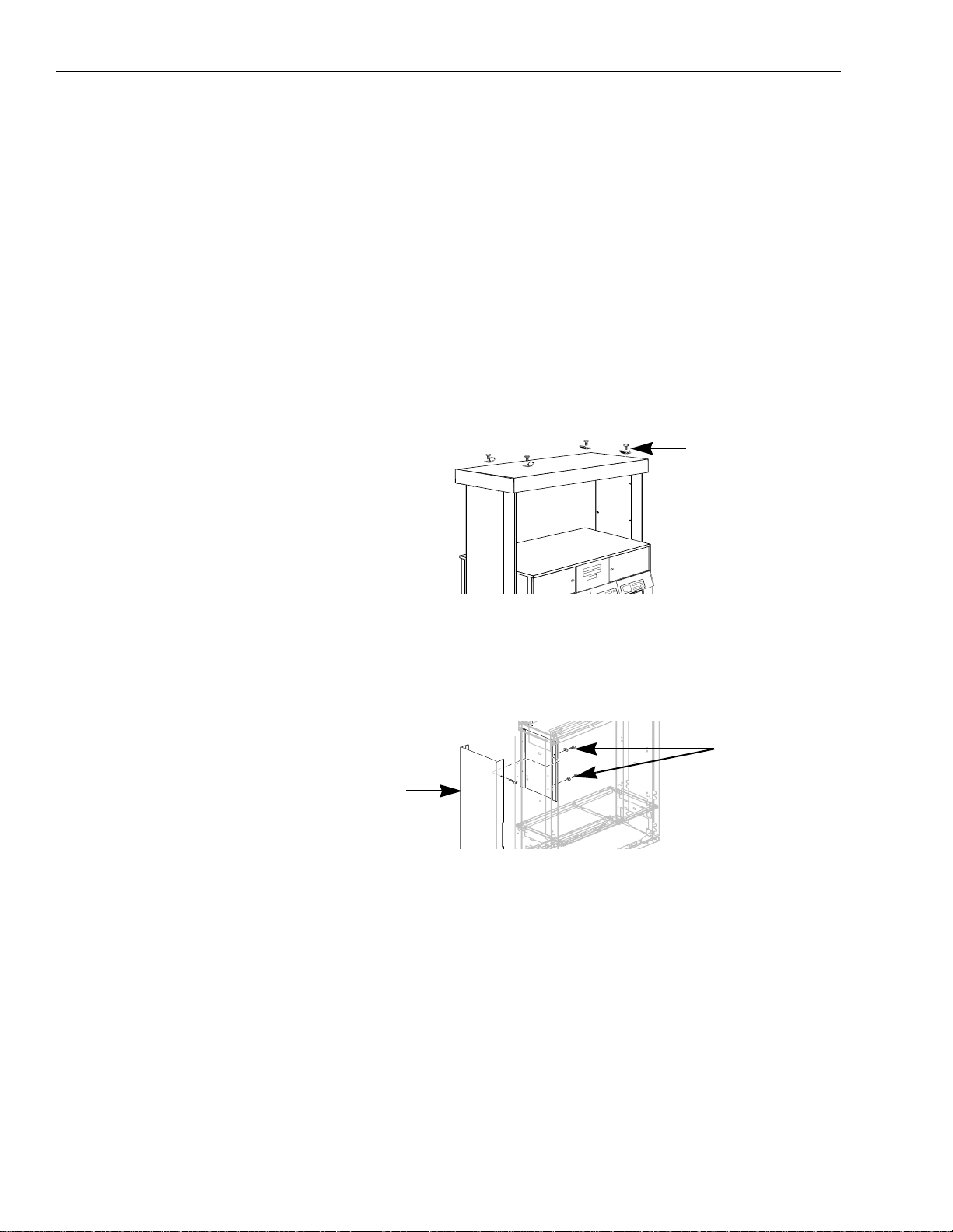

Preparing For Installation

Perform these steps for all The Advantage® Series units

1 Remove four hoisting brac kets from top of unit by removing four bolts and washers. Dispose

of hoisting brackets. Save hardware for reassembly.

Note: On units with logo display cabinet, hoisting brackets have already been removed.

Figure 2:

Removing hoisting

brackets

Hoisting brackets

and 3/8” bolts

2 From ‘A’ side of unit, remove inner sheathing on left column. Set sheathing and screws aside

for reassembly.

-01

Figure 3:

Removing inner

sheathing

Outside sheathing

liminary

4

Inside sheathing

and screws

e

08-2

‘A’ side

r

3 Open main access doors. Refer to MDE-2531, Pump and Dispenser Start-Up/Service Manual

for access instructi ons .

P

Page 22 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Installation Instructions For The Advantage Series Units

4 Remove top cover from main panel by accessing mounting hardware from inside main

cabinet. See Figure 4. Save top cover and fastening hardware for reassembly.

Top cover

Figure 4:

Removing cabinet

top cover

5 Remove any call or stop buttons, or magnetic switch hardware from door. Save all

removed hardware for reassembly.

6 Remove door mounting pin and right options door. See Figure 5.

7 Dispose of door. Save pin for reassembly.

Figure 5: Removing options door

4-01

Access to top cover

fastening bolts from

inside main cabinet

Door mounting pin

8-2

0

Right options door

Preliminary

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 23

Installation Instructions For The Advantage Series Units

Removing Knockout in Unit Top Cover

1 Remove knockouts from the near left side of unit top cover while facing each side of unit to

have antenna installed.

• For units without end plate, lift left side of top cover for access to knockout from bottom.

• For units with nine bolt end plates, remove plate for access.

Figure 6:

Unit Top Cover

Top cover knockout

2 Lower top cover to original position.

Note: For units with end plate, do not replace plate at this time.

Relocate Gateway Board on Card Cage

Figure 7:

Gateway Board on

Card Cage

Gateway Board location as

shipped

Gateway board reinstalled on top

P250 side of

-01

board

4

liminary

Gateway board is shipped mounted to side of card cage. This accommodates imm ediate use

with the Encore

the following steps:

1 Remove Gateway board and standoffs from side of card cage.

Note: Existing standoffs do not need to be reused and should be removed.

2 Secure gateway board to top of card cage as shown, using four Q10651-16 standoffs provided

P

with kit.

3 Dispose of door. Save pin for reassembly.

™ Series dispensers. Relocate gateway board to top of card cage according to

e

08-2

r

Page 24 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Modifying Right Options Door

For all units without stop or call button on right opt i ons door, go to ‘Re-installing Door Alarm

Switches’ on page 28, if unit h as door al arm. If uni t does not have doo r alarm, go to “Installing

Right Options Door” on page 28.

For 48" units with stop or call buttons previously installed, perform the following steps.

Remove all hardware from new right options door according to the following steps and save

all parts for reassembly.

• Remove two screws mounting door shield on rear of door.

• Disconnect cable R20522-G2 from light/microreader printed circuit board (PCB) by

disconnecting J181 on cable from P181 on board.

• Remove Light/Microreader PCB.

• Remove screws and antenna board.

Installation Instructions For The Advantage Series Units

Clear door assembly

Antenna PCB

T20524

Door

shield

4-01

Light/Microreader

PCB T20601

Strip grommet

8-2

0

Preliminary

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 25

Installation Instructions For The Advantage Series Units

For 36" units with stop or call buttons previously installed, perform the following steps.

Remove all hardware from new right options door according to the following steps and save

all parts for reassembly.

• Remove two screws mounting door shield on rear of door.

• Disconnect cable R20522-G2 from light/microreader printed circuit board (PCB) by

disconnecting J181 on cable from P181 on board.

• Remove Light/Microreader PCB.

• Remove screws and antenna board.

• Remove d i splay PCB

Clear door assembly

Antenna PCB

T20524

Door

shield

Display PCB

Light/Microreader

PCB T20601

-01

4

liminary

For all units, do the following:

1 Mark placement of pump stop or call button on new right options door by measuring from

door edges as shown.

P

e

r

08-2

Hole location for pump stop or call button

Wide Frame

Door measured

from front

10 1/64"

13/16

8

"

Narrow Frame

Door measured

from rear

1 9/16"

3

/16"

3

2 Away from fuel island, drill a 7/ 8 inch di ameter hole i n the lo cation sh own above . Remove any

burrs around hole with deburring tool or rounded file.

Page 26 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Reinstalling Button

1 Hold contact base on back of door and align with hole drilled earlier.

2 Insert push button from front of door by aligning tabs with slots in base.

Installation Instructions For The Advantage Series Units

Re-installing

button(s)

Push button

base assembly

Wide Frame Door

Narrow Frame

Door

BaseContact switch

Contact Block

3 Turn push button 45° clockwise to lock button to base.

4 Tighten two screws on base to secure push button and base assembly to door.

Note: Do not overtighten screws.

5 Attach contact block to base with center screw if not already installed.

6 Reinstall all ne w righ t opt ions door ha rdwa re by reve rsing proce dures in St ep 1 of “Modifying

Right Options Door” on page 25.

4-01

8-2

0

Preliminary

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 27

Installation Instructions For The Advantage Series Units

Reinstalling Door Al arm Sw it ch es

For units with cash acceptors, follow these steps to reinstal l door alarm assemblies on TRIND

right option doors. Refer to diagram on this page for more information. Perform each step for

both ‘A’ and ‘B’ side right option doors. If unit does not have door alarm, go to ‘Installing

Right Option Door’ on page 28.

1 Reinstall C-clips removed from old right side option doors.

2 Install door alarm assembly to door alarm assembly bracket with screw previously removed.

3 Attach door alarm assembly bracket to display board with screw previously removed.

Note: Replace the piece of fiberboard between door alarm bracket assembly and display

board.

4 Be sure magnet does not touch door alarm door bracket. Slightly move door alarm door

bracket away, if necessary.

Back View of 36" Unit

Option Door s

Door alarm

assembly bracket

5 Reinstall all new right options door TRIND hardware by reversing procedures in Step 1 of

Back View of 48" Unit

Option Doors

Door alarm assembly

liminary

e

Door alarm assembly

Door alarm

assembly bracket

08-2

r

“Modifying Right Options Door” on page 25.

P

Right option door

-01

4

Fiber

board

C-clip

Left option door

Door alarm door bracket

Installing Right Options Door

Install new TRIND/TIRIS right options door (one per side for two-sided units), using pin(s)

removed and saved in Step 7 on page 23.

Page 28 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Installing Bulkhead Grommet

1 Disconnect two cables and remove ground connector to ‘A’ side printer. Remove printer from

unit and save for reinstallation.

2 While facing ‘A’ side of unit, measure 6" in toward center of cabinet top from outside edge of

top, and draw a line on top cover.

Installation Instructions For The Advantage Series Units

Locating

bulkhead

grommet hole

3 Measure 10.5" in from left side of top, and draw a line. Intersection of both lines is pilot hole

location.

4 In packaging materials, locate thick rubber packing that can be broken into flat sided pieces,

approximately six inches round, square or random.

5 On one flat side of thick rubber piece, apply light coating of cutting oil.

6 With oil coated surfaces in contact with metal surfaces, heavily tape one each foam piece to

top and bottom of main cabinet top, above and below drilling point marked.

Note: For foam piece taped to top, mark foam with marking pen or pencil to identify drilling

point under foam. Dril ling point location accuracy of plus or minus 1/2" is acceptable.

.

Drilling point marked

'A' Side

10.5"

4-01

8-2

6"

'B' Side

Pneumatic (air) drill

0

Cutting oil

Preliminary

Gusset

on

cabinet

top, seen

from side

7 Cover shelf area under drilling position with plastic. Kit packaging materials may be used.

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 29

Foam pieces taped to

cabinet above

and below drilling point

Installation Instructions For The Advantage Series Units

8 Follow these mandatory safety guidelines:

• Do not use electric dril l. Use only pne umatic (ai r) drill set or cont rolled f or low speed onl y

(300-500 rpm) or hand operated drill.

• Deposit a few drops of cutting oil at drilling point and on drill bit, to keep bit from

binding, to quench sparks and to bind drill shavings.

9 Drill through foam pieces, going only as deep as required to penetrate top cover, beginning

with small diameter bit (approximately 1/8") and gradually increasing bit size until adequate

pilot hole is made.

Note: Hole 3/8" in diameter should be sufficient as pilot for knockout.

10 Remove both top and bottom foam pieces, being careful that all drilling residue and oil is

removed from cabinet area. Wipe off cabinet surface, top and bottom, with clean cloth or rag.

Note: Use file or deburring tool to remove burrs or edges that may cut hands.

11 Using hydraulic or manual knockout punch, make one inch (1") diameter hole.

12 Remove plastic covering hardware by folding inwards to retain any drilling residue, and

dispose of plastic.

13 Carefully check interior of main cabinet for trash or residue and clean as needed.

14 Position bulkhead seal grommet (Q13570-01) with O-ring beneath hole.

15 Secure grommet in place with locking nut from top of cabinet.

16 From ‘A’ side of unit, drop (lower) CRIND tray.

-01

4

liminary

e

r

08-2

P

Page 30 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Installing Card Cage Assembly

Install card cage assembly from ‘B’ side of unit according to the fo llowing step s:

1 Carefully pry out printer cable retainer from underside of printer shelf.

2 Pull printer cable out of 2 3/4" round hole from bottom, and install piece of strip grommet

Q10315-06 around perimeter of hole.

3 For all single-sided units, connect dummy load connector R20526-01 to JB on low frequency

transmitter PCB Q13579-01 in card cage. See “Card Cage Assembly T20606-G2” on page 62

for connection point.

4 Install card cage assembly fuse side first on printer shelf and against center divider behind

right options door, as shown.

Installation Instructions For The Advantage Series Units

Tab

Card cage assembly location behind

right options door of 48" wide unit

5 Position card ca ge s o that tab on upper left side of housing fits over latch cutout for main door

latch, securing card cage to divider.

6 From ‘B’ side of unit, feed screw Q12083-1 3 and washe r N16599 -48 up through hole in shelf

into threaded hole in card cage bottom.

7 Feed three prong femal e end of po wer supply cable R2 0580-G1 up t hrough grommet ed hole i n

printer shelf to recessed receptacle on card cage assembly. Refer to “Card Cage Assembly

Preliminary

T20606-G2” on page 62 for connection points.

Card cage assembly

front side

8-2

0

Tab

Card cage assembly location behind

right options door of 36" wide unit

Tab fits over cutout behind

door latch: see step 4

4-01

8 Secure power cable R20580-G1 in cable retainer removed in Step 1, so that power cable and

printer cable are both secured, and reinstall cable retainer in grommeted hole.

9 Feeding J182 ends of cables R20773-G2 for A and B sides up through grommeted hole and

connect P1 to J1 and P2 to J2 on T20662-G2 card cage harness.

10 Return printer to shelf and reconnect two printer cables and ground connector.

11 Reorient printer and secure to shelf.

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 31

Installation Instructions For The Advantage Series Units

Installing Transmitter Cables

M00878A002 Cable Assembly

PB

P2B

P2A

PA

P1B

P3B

P3A

P1A

Before proceeding be sure to be able to easily identify A and B side cable ends. Electric tape,

wire numbers or other suitable device may be used.

Note: Sharp bends in antenna cables will caus e damage . All cable tur ns must be in loo ps and

gradual. Refer to “ASC TRIND Technology Update” on page 20.

1 Feed P1A/B and /P3A/B en ds of cable h arness M0087 8A002 up thr ough bulkhe ad grommet in

main cabinet.

2 Be sure that there is sufficient length (24") of M00878A002 harness remaining in electrical

cabinet to reach connection points on card cage. Cables must be routed through underside of

card cage to connection point s on ‘B’ side. See “Card Cage Assembly T20606-G2” on pag e 62

for connection points.

3 Lay cable harness fl at acr oss top of ma in cabi net , t hrou gh gus set opening to column as shown.

Routing cables to

main cabinet

-01

Cables

secured with

electrical

tape

4

Cables fed through gusset

opening to column and up

inside of column.

liminary

e

4 Use electrical tape to secure cable harness flat to top of cabinet and in gusset opening. See

illustration above.

P

5 Route cables from top of main cabinet up along inside of column, keeping cables flat and

parallel.

6 Loop cable harness 3" down into spac e between column and main cabi net and back up again to

allow for reinstallation of inside sheathing.

Note: Turn in cables must be gradual, not sharp, to prevent damage to cables.

7 Feed cables up through knockout openings in unit top cover.

Page 32 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

r

08-2

• August 2001

Installation Instructions For The Advantage Series Units

8 Without removing upper piping housing sheathing, install piece of edge grommet Q10315-06

along edge of sheathing where cables pass in column. See exploded illustration below.

Note: Carefully check for any points along cable harness run where cables may come in

contact with sheet metal edges, and install edge grommet to prevent cable damage.

Installing edge grommet

Edge grommet Q10315-06 to

protect cables from metal

edge of upper piping housing

sheathing

9 Leave cable ends in upper housing.

10 Press cable harness flat and parallel to column and secure with electric tape as shown.

Cables on column

shown without

main cabinet

Strip grommet

Q10315-06 on

bottom edge of

inner

sheathing

cable ends in upper housing

4-01

Exploded View:

Do Not Remove

Upper Piping

Housing

Sheathin g From

Unit

Electrical tape

Sufficient cable

to make loop, not

sharp turn, back

up to top of main

cabinet. Sharp

bend will damage

cables

8-2

0

11 Install edge grommet Q10315-06 on bottom edge of inner sheathing and replace inner

sheathing, using screws saved during disassembly.

Preliminary

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 33

Installation Instructions For The Advantage Series Units

Replacing Main Cabinet Top Cover

1 Use hacksaw to cut 3/8" slots in cabinet top cover to allow strip a minimum of 6" wide to be

folded back with pliers and hammered fl at as shown, to al low cables to pass under top cover to

grommet.

Note: Remove top cover from work area to cut slot. Do not cut metal in proximity to

dispensers. Place top cover on cardboard while hammering to prevent damage to paint.

Slotting top cover

cables

6” strip

hammered flat

under top cover

2 Clean edges and burrs around cuts in cover with file or deburring tool.

3 Thoroughly seal spaces around and between cables in main cabinet bulkhead grommet with

RTV sealant.

Note: Place some packaging pl astic inside bul khead gr ommet fr om top t o pr event sealant fr om

running out bottom when applied.

Routing R20773-G2 Cables

Note: Retrofit kit comes with ten (10) adhesive-backed cable clamps (Q13558-04). Note the

following variations for routing cables to main cabinet:

e

Horse Shoe style CRIND Device

For these units, utilize opening in printer shelf bo ttom for rout ing.

P

r

Horse Shoe style

CRIND device

-01

4

liminary

08-2

Opening for cable

routing

Printer shelf

Horse shoe style module

Page 34 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Installation Instructions For The Advantage Series Units

Pull Out CRIND Tray

For these units utilize round 2-3/4" hole in printer shelf bottom, used for printer cable. Use

cable clamps to secure cables to underside of printer shelf.

Pull Out

CRIND Tray

Cable Routing Along Option and Main Doors

When routing door cable s to ca rd c age, l eav e exce ss ca ble on door, routing cable aro und ed ges

of printed circuit board.

Note: It is critical that door cables do not get crimped or pulled when either options door or

main door are opened or closed. Be sure that door cables are secured such that they

cannot be caught in ma in door. when door is cl osed, and alwa ys clo se main d oor bef ore

options door.

Printer shelf with

2-3/4" round hole

Pull out CRIND

electronics tray

1 Remove option door shield

2 Connect J182 connectors on R20773-G2 cables to P182 on Light/Microreader PCB for each

side right options door.

4-01

P182 connection

and cable route

Indicator light

PCB T20601

Hole to secure cable with tie wrap

8-2

0

Hole to secure cable

with tie wrap

Preliminary

R20773-G2 cable

3 Loosely secure cables using tie wrap Q10178-01 and hole on indicator light printed circuit

board.

4 Leaving sufficient cable to reach connection points on card cage, use clamps to secure cables

to underside of lighting frame. Be sure clamps are secured to non-removable part of frame, so

access is maintained for lighting service.

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 35

Installation Instructions For The Advantage Series Units

5 Ensure that option door opens and closes freely without stressing or crimping cables, use tie

wrap Q10178-01 to loosely secure cables to small fixed tab at end of light frame, forcing

cables between light frame and door gasket.

R20773-G2 Cable routing on

option door

Loosely secure

cables to tab on

light frame with

tie wrap

Attach clamps and

cables to underside

of panel light frame

6 Secure J1/J2 end of each R20773-G2 cable to existing cable clamp (for door cabling) just

inside main cabinet, allowing enough slack for main door to open and close freely without

pulling on or crimping cable. See illustrations below and on next page.

r

P

liminary

e

-01

4

08-2

Secure cable

to existing

door cable

clamp

Page 36 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Installation Instructions For The Advantage Series Units

T20662-G2 Cable Routing In Main Cabinet

Card Cage cable harness T20662- G2 contai ns two cab les wit h conn ectors P1 and P2. P1 for A

Side is shorter of the t wo. Eac h cable is desi gned to ext ended to the poin t where t he main doo r

and electronics cabinet are hinged. Feed cables through 2-3/4" round hole in printer shelf.

A Side

Viewed from above

A Side

J182/P182

door cable

clamp

R20773-G2 cable

Stress or

crimping

point for

cables

B Side

T20662-G2

cable routing

from card

cage under

printer shelf

Use clamps

to secure

cables to

underside of

shelf

2-3/4"

round hole

for printer

cable

Use clamps to

secure cables to

underside of

shelf

Go to “Preparing Antenna Cable Connections” on page 49.

8-2

4-01

kit cable clamps

P2/J2

R20773-G2 cable

0

T20262-G2

cable fed

under shelf

through

grommeted

2 3/4’’ hole

cable clamps under shelf

B Side

card

cage

kit cable

clamps

J182/P182

P1/J1

Preliminary

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 37

Installation Instructions For MPD-3 Units

Installation Instructions For MPD-3 Units

Before beginning read “Classifying Hazardous Locations” on page 19 and “ASC TRIND

Technology Update” on page 20.

The TRIND™ retrofit can only be done on MPD-3 units with CRIND™ printer on left.

Preparing For Installation

1 From ‘A’ side, remove left column outside sheathing (or top section only for two piece

sheathing).

Outside sheathing left column

-01

4

A side

liminary

2 Temporarily secure inner sheathing to frame using tape.

e

3 Open main access door. Refer to MDE-2531 for instruct ions.

08-2

r

P

Page 38 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Removing Main Cabinet

1 Locate four nuts on each side of main cabinet, ‘A’ and ‘B’, that secure cabinet to frame.

Removing main cabinet

Installation Instructions For MPD-3 Units

Four nuts each side, ‘A’

and ‘B’, on mounting

studs behind lip

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

2 Remove all eight nuts and washers, and save for reassembly.

3 Disconnect barrel connectors to allow cabinet to be removed from unit.

Note: If barrel connectors are mounted to holding plate(s), remove plates and discard.

4 Carefully lift cabinet up and off studs, and remove from fuel island.

5 Remove inner sheathing on lef t column (viewed fr om ‘A’ side). Set sheathing and sc rews aside

for reassembly. See illustration below.

®

Note: For units with VaporVac

, VaporVac pan does not need to be removed. Sheathing can be

carefully pulled out from center until top bends clear of pan.

4-01

8-2

0

Preliminary

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 39

Installation Instructions For MPD-3 Units

Installing Transmitter Cables

cables connections to card cage

PB

P2B

P2A

PA

Before proceeding be sure yo u can easily identify A and B side cable ends. Electric tape, wire

numbers or other suitable device may be used as needed.

Note: Sharp bends in antenna cables will caus e damage . All cable tur ns must be in loo ps and

Routing M00878A002 cable

harness to main cabinet

Harness fed

up through

hole

enlarged

using

knockout

M00878A002 Cable Assembly

gradual. Refer to “ASC TRIND Technology Update” on page 20.

M00878 cable assembly splitting

inside upper housing to exit

through two knockouts

Cable harness

cable connections for upper housing

P1B

P3B

-01

P3A

P1A

4

Harness looped

in column

liminary

e

1 Feed cable ends PA/B and P2A/B (see illustration above) down from upper piping housing

into left column seen from ‘A’ side. Leave a minimum of 12'' of cable in upper housing.

2 Feed cables down between piping brackets and inside column.

r

08-2

P

3 There are several holes in column above or below main cabinet level, approximately 7/16" in

diameter. Locate hole that provides acce ss fo r u sing k nockout and i s most close ly al igned with

bottom of cabinet, and open hole to 7/8" diameter or larger.

Note: Various units have different holes and configurations. Any hole on column, square,

rectan gular or r ou nd, of suf fici ent size or made s o with knoc kout ca n be used fo r cable s.

4 Use rounded file or deburring tool to round edges of hole. Cover edges of hole with electric

tape.

5 Loop cables below hole and back up through hole and out of column.

Page 40 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

6 Feed cable ends into vapor barrier, dressing and securing cables in place with electrical tape.

7 Away from island, use snips or shears to cut slits 1-1/2" apart in bottom center of inside

sheathing at 45 degree angles. See illustration below.

8 Fold pieces forward on cabinet side of shea thing. Use hammer to flatten folded pieces as

shown.

Notching inner sheathing

Step 7:

Cut two slits 3/8"

deep at 45 degree

angle approximately

1 1/2" apart in

bottom center of

sheathing

Installation Instructions For MPD-3 Units

Step 8: Use pliers to fold pieces in direction of cabinet

and away from column. Use hammer to flatten

Finished inner

sheathing - side

facing main cabinet

9 Reposition inner sheathing and tape in place, being sure that cables pass through opening at

bottom.

10 Replace outside sheathing, and remove tape fr om inner sheathing.

11 Dress and secure cables on cabinet top with electrical tape.

4-01

8-2

0

Preliminary

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 41

Installation Instructions For MPD-3 Units

Removing Faceplate

MPD-3 units have two types of faceplates; slide-in (PMI bezel) and bolt-on (Mack bezel).

Follow directions for the type of faceplate and bezel that applies.

For units with slide-in faceplates on PMI bezels, do the following:

1 Release right side fa ceplate using keyswitch.

2 Open manager keypad door and remove single screw.

Removing faceplate

3 Gently force face plate up, and s lide t ip of k nife o r fla t blad e sc rewdri ver und er bo ttom ed ge of

faceplate.

4 Pry bottom of faceplate away from unit, until faceplate can be removed from unit.

Screw

5 Dispose of faceplate.

For units with bolt-on faceplates on Mack bezels, do the following:

1 Open bezel door and lift until door is latched open.

2 Disconnect cable between manager keypad and logic board on bezel door, and discard cable.

-01

3 Locate six sets of nuts and washers on studs securing faceplate to bezel door, and remove

hardware.

Note: This may re quire removing mounting hardware from price per unit (PPU) and CRIND

logic boards to gain access.

liminary

e

4

Stud locations behind faceplate

08-2

r

Faceplate stud

locations on

Mack bezels

P

Stud locations behind faceplate

4 Remove 6 sets of nuts and washers from faceplate studs and remove faceplate. Dispose of

hardware and faceplate.

5 With putty knife, remove keypad door gasket and any adhesive residue.

Page 42 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Routing Cables into Main Cabinet

1 Open bezel doors on main cabinet.

2 Locate indent on rear of door behind 3/4" diameter unopened access point.

3 Use 3/4" drill bit to open hole in plastic door from rear of door.

Note: If electric drill is used work must be 20’ from fuel island.

4 Use deburring tool or file to round edges of hole.

Reinstalling mai n

cabinet

Center of left side

wrapper, slotted for

cable feed

Installation Instructions For MPD-3 Units

5 On left side of main cabinet (viewed fr om ‘A’ side), in center bottom of wrapper, use snips to

cut two 3/8" slits at 45 degree angle.

Note: Slots and folds duplicate those done on inner sheathing. See illustration on page 41.

6 Fold pieces out from cabinet and press flat against wrapper from outside.

7 Carefully return cabine t to unit, and lower cabinet on to studs.

4-01

8 Feed cables up into cabinet under slot made in wrapper.

9 Secure cabinet in place with nuts and washers removed with cabinet.

10 Heavily seal around cable entry slot with RTV sealant from inside cabinet.

8-2

0

11 Reconnect barrel connectors.

Preliminary

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 43

Installation Instructions For MPD-3 Units

Installing Card Cage Assembly

Install card cage assembly from ‘A’ side of unit, according to th e following steps:

1 Begin to separate card cage assembly into two pieces by removing one screw on top and two

nuts at bottom, one each front and rear.

Card cage

assembly

Nut

2 Disconnect cables joining two sides of card cage.

3 From ‘A’ side, place bottom section of card cage fuse side first on to left shelf.

Screw

Nut

Installing disassembled

card cage

Top section of

card cage

-01

4

+

+

+

Bottom section of

liminary

card cage, fuse side

+

e

r

08-2

Tie wraps (2) at each corner

to reassemble card cage

rather than screw

P

4 Reassemble card cage using nuts removed in Step 1 and two (2) tie wraps in place of screw

and reconnect cables.

Card cage installation location from ‘A’ side

5 For all single-sided units, connect dummy load connector R20526-01 to JB on transmitter

PCB. See “Card Cage Assembly T20606-G2” on page 62 for connection point.

Page 44 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Installation Instructions For MPD-3 Units

6 For units with Screened Image Display (SIDs) only, do the following:

Note: If these directions are not followed printed circuit boards will be damaged.

• From ‘B’ side of unit, install screw up through hole under card cage. Align screw with

mounting hole on card cage, but do not fasten.

• Tilt card cage away from screw, and secure screw to shelf by installing two nuts under

card cage.

• Let card cage rest on nuts with screw protruding up through hole in card cage.

Note: This will result in card cage tilting down toward the ‘A’ side.

7 For all units, from ‘A’ side of unit, fasten card cage to shelf using 6-32 x 3/8" screw (Q12083-

13) supplied with kit.

4-01

8-2

0

Preliminary

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 45

Installation Instructions For MPD-3 Units

Installing TRIND Faceplate Assembly.

Perform the following steps for each side of unit.

For installing TRIND slide-in faceplates on PMI bezels, do the following:

1 Remove new TRIND faceplate assembly from box. For ‘B’ side facep lates only, feed faceplate

cables back into faceplate housing through round hole in shield to shorten cable leads.

Note: ‘B’ side cables have a shorter run to card cage than ‘A’ side.

2 Peel adhesive backing off round gasket N23881-01. Install gasket adhesive side first to sheet

metal shield on back of faceplate to form seal around hole for cables on faceplate assembly.

3 Peel paper backing of f adhes ive stri p on rectangu lar locki ng plate N23873 -G1 and ins tall plate

along top lip of manager keypad recess.This plate provides a bearing surface for lock cam on

new TRIND faceplate.

Installing

locking

plate

Locking plate N23873-G1

with adhesive backing

4 Feed ends of cables R20773-G2 through 3/4 inch hole on bezel door drilled in Step 3 of

“Routing Cables into Main Cabinet” on page 43. Pull slack cable through hole.

5 Follow these directions to install new TRIND faceplate:

• Feed top edge of faceplate in to groove on top of door.

• Gently push bottom of faceplate in until faceplate drops into bottom groove.

Note: Faceplate may be tight fit. If needed, with faceplate forced up into top groove, firmly hit

faceplate along bottom edge with palm of hand until faceplate is in bottom groove.

• Secure in place with keylock.

liminary

-01

4

e

6 Refer to MDE-2620, Graphics Panel Application for instructions on installing graphics.

08-2

r

For installing TRIND™ bolt-on (stud type) faceplates, do the following:

P

1 Remove new TRIND faceplate assembly from box. For ‘B’ side facep lates only, feed faceplate

cables R20773-G2 back into faceplate housing through round hole in shield to shorten cable

leads.

Note: ‘B’ side cables have a shorter run to card cage than ‘A’ side.

2 Remove existing manager keypad from bezel door, and use putty knife to remove keypad

gasket and adhesive residue from door.

3 Replace the door gasket removed in step 2 with adhesive backed gasket Q11659-01.

Page 46 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Installation Instructions For MPD-3 Units

4 Replace existing keypad and keypad cable with T17549-G1 keypad and long cable R18163-

G1, but do not install keypad on bezel door.

Note: At user’s discretion, new keypad can be placed behind brand panel lighting or in the

well behind the printer door, on either s ide of printe r, pr ov ided ca ble is run and secured

properly and safe access is maintained.

5 Remove yellow tape on back of bezel door covering round hole.

6 Peel adhesive backing off round gasket N23881-01. Install gasket adhesive side first to seal

around hole on back of bezel door.

7 Feed ends of cables R20773-G2 through 3/4" hole on door and pull slack cable through hole.

8 Install 6 split s pac ers K874 04-01 on the f acepla te si de o f the bezel door, in the mounting holes

for the faceplate. See illustration on this page.

9 Install faceplate as sembl y T17534-XX sec uring in place fro m back sid e of bezel door using in

this order:

• 6 adhesive backed gasket s, Q11659-01.

Note: Do not remove paper backing on adhesive side, and install paper side to bezel door.

• 6 flat washers, N16599-01

• 6 self-locking nuts, Q10218-04

10 Refer to MDE-2620, Graphics Panel Application for instructions on installing graphics.

Faceplate mounting hardware

TRIND faceplate

Washer

4-01

Nut

8-2

0

stud

Split spacer Gasket, adhesive

BezelFaceplate

backed with paper left

on and facing bezel

Preliminary

11 Peel paper backing of f adhes ive strip on re ctangu lar locki ng plate N23873- G1 and instal l plate

along top lip of manager keypad recess.This plate provides a bearing surface for lock cam on

new TRIND faceplate.

Installing

locking

plate

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 47

Locking plate N23873-G1

with adhesive backing

Installation Instructions For MPD-3 Units

Routing Cables in Main Cabinet

Kit comes with ten cable clamps (Q13558-04).

Routing cables in

main cabinet

Existing snap-in 1 1/2" bushings- use for routing

Bundle cables

between shelf wall

and card cage,

using clamp

Install Q10277-02

strip grommet for

power cable

R20580-G1

‘B’ side

Install strip grommet Q10277-02 in 1-1/2" hole for power cable R20850-01.

Note: Route cables on ‘B’’ side to card cage so that all cables are between card cage and

shelf where possible, or door will not close without potential damage to cables or

hardware.

-01

4

liminary

e

r

08-2

P

Page 48 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Preparing Antenna Cable Connections

For all units, gain access to upp er housin g from un dersi de, by r emoving u pper ho using b ottom

sheathing or VaporVac belly pan, as required. Refer to MDE-2531 Service Manual for

instructio ns. Save all parts and hardware for reas sembly. For

For additional information refer to “Cable Block Diagram R20762” on page 60 and “Cabinet

Cable Connections” on page 61.

M00878A002 Cable Assembly

Preparing Antenna Cable Connections

PB

P2B

P2A

PA

P1B

P3B

Do the foll owing:

1 Locate previously installed P1A/B and P3A/B ends (4 total) of cables on cable harness

M00878A002 in upper housing.

2 Be sure that all connectors can be identified for A and B sides, respectively.

Upper Housing Connections

Do the following to connect M00878A002 cable harness assembly to antenna:

1 For A Side, inside upper housing:

• Connect P1A on harness to J1 low frequency antenna cable.

• Connect P3A on harness to J2 high frequency antenna cable.

4-01

2 For B Side, inside upper housing:

• Connect P1B on harness to J1 low frequency antenna cable.

• Connect P3B on harness to J2 high frequency antenna cable.

8-2

3 Use tie wraps supplied with kit to secure cables to frame in upper housing, away from

maintenance access areas for piping and valves.

0

P3A

P1A

Preliminary

MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual• August 2001 Page 49

Preparing Antenna Cable Connections

If power tools are used

for assembly work must

be done at least 20" from

fuel island

CAUTION

Assembling Antenna Mounting Brackets

Use saw horse, work bench or even packaging boxes as platform to assemble antenna related

parts on a flat surface. Use packaging materials under parts to protect against dirt or scratches.

Assemble antenna and universal mounting brackets at ground level according to the following

steps.

Note: If power tools are used for assembly, work must be done at least 20’ from fuel island.

1 For assembly detail for 48" or 36" wide units, with or without light box, see Figures 6 (48") on

page 50 or Figure 8 on page 51 for (36").

Note: For single-sided units, antenna bracket T20211-03 does not have antenna mounting

arms; it has straight lip that goes to unit side with out antenna.

Figure 8: Assembling universal and antenna brackets for The Advantage Series 48" (wide) frame units

48" wide unit without logo display cabinet

Antenna bracket

(T20211-03)

Self-threading screws

(K85736-45)

Universal bracket

(T20212-01)

Invert universal

brackets as shown

to provide platform

for logo display

cabinet.

Holes (2 per bracket)

for grommets N15941-38

liminary

e

r

08-2

48" wide unit with logo display cabinet

P

-01

Note: for single-sided units

4

antenna bracket T20211-03 does

not have antenna mounting arms

Page 50 MDE-4063 TRIND TIRIS Retrofit Kit C00011-010-XXXX Installation Manual

• August 2001

Preparing Antenna Cable Connections

Figure 9: Assembling universal and antenna brackets for The Advantage Series 36" (narrow) frame units

36" wide unit without logo display cabinet

Use antenna brackets

without universal brackets