MDE-5361A

October 2020

FlexPay™ IV CRIND® (with Omnia) Retrofit Kit

Installation Instructions for The Advantage

®

Series

This page is intentionally left blank

Table of Contents

SECTION 1 - INTRODUCTION

PAGES 1-2

S E C T I O N 2 - I M P O R T A N T S A F E T Y I N F O R M AT I O N

PAGES 3-4

S E C T I O N 3 - R E M O V I N G C O M P O N E N T S

PAGES 5-10

S E C T I O N 4 - I N S T A L L A T I O N

PAGES 11-22

S E C T I O N 5 - R E F E R E N C E I N F O R M A T I O N

PAGES 23-24

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Intended Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Configured Kits - Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Configured Kit Optional Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

i

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Left Option Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CRIND Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

AFP/HIP 2/DCM2/DCM2.x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

FlexPay IV CRIND Retrofit Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Left Option Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Omnia Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connecting Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

The Advantage Series Units Built Prior to 1999 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

AC Power Distribution Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

The Advantage Series Units Built After 1999 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Completing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Registering Kits with Gilbarco Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Abbreviations and Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

MDE-5361A

S E C T I O N 6 - A P P E N D I X

PAGES 25-40

ii

Appendix A: PCB, Connections, and LED Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Omnia PIP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Omnia Assembly Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Omnia PIP LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Omnia LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

UPM Board Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Appendix B: System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Appendix C: Verifying Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cable Connections on Display Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Appendix D: DCM3 Assembly (M15724A001) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

FCC Compliance Statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

FCC Supplier’s Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

MDE-5361A

1

SECTION 1 - INTRODUCTION

1

Purpose

This manual provides instructions to install a 5.7-inch Color Screen FlexPay™ IV CRIND® (with Omnia)

Retrofit Kit into The Advantage® Series. The Advantage Series includes configurations with or without

CRIND. The FlexPay IV CRIND provides a secure payment platform that is EMV®-certified and Payment Card

Industry PIN Entry Device (PCI-PED)-certified.

This manual also includes instructions for installing the Omnia board, which replaces the Dispenser

Communication Module (DCM)2.X [including Gilbarco Systems on Module (GSoM) Printed Circuit Board

(PCBs)] in the FlexPay IV units.

Intended Users

This manual is intended for Gilbarco®-trained and certified Authorized Service Contractors (ASCs).

Required Tools

• Phillips® and Flat-blade Screwdrivers

• 1/4-inch Socket Set (Nut Driver)

• 7- and 8-mm Socket (Nut Driver or Socket Set)

• Diagonal Cutters

• Needle Nose Pliers

• T15 or T20 Torx Driver, depending on the Universal Payment Module (UPM)

• Universal Joint Socket Adapter

• Putty Knife or Scraping Tool (if required)

Configured Kits - Parts List

FlexPay IV CRIND Retrofit Kits are configured based on the serial number of the pump/dispenser unit for

which they are intended. Therefore, the parts list will vary for each configured kit and unit/option type.

For additional part details, refer to the Bill of Materials (BOM) in the kit, contact your distributor, or contact

Gilbarco Customer Service.

A common FlexPay IV CRIND (with Omnia) Retrofit Kit will include the following parts:

• CIM™ insert with UPM assembly (keypad), UX300, display card reader, Omnia Peripheral Interface PCB

(PIP) Assembly

• T-rail assembly with Omnia assembly

• Universal Serial Bus (USB) Printer assembly

• Applause™ Media System, Omnia assembly

MDE-5361A

2

SECTION 1 - INTRODUCTION

1

Configured Kit Optional Components

The following parts are potential configured kit optional components:

• UX400 Contactless Card Reader

• Cabinet Heater (optional for 5.7-inch display)

For a complete parts list of the configured kit, refer to the build ticket that is provided with the kit.

Note: Printers will be needed for all units.

Components

For a complete parts list, see the packing list. The following parts are critical components for

FlexPay IV with Omnia:

Location Description Part # Notes

Located on Left Door Assembly, Advantage Door M14500 Variants are color

5.7” Softkeys M01254A003

5.7” Color Display M10369B001

PCA, Omnia PIP M15649A001

®

Card Reader, VeriFone

Contactless Card Reader, VeriFone,

UX400

Printer Assembly M12479A001 Print head: M13832A001

Cable, Wire and Speaker M09259A001

Located on CRIND Tray Assembly, UPM M13888AXXX “XXX” varies based on

Omnia Assembly Omnia M16181A002

DCM3 M15724A001

Phoenix Supply M04161B001

Fuse Board M05748A001

UX300 M14330A001

M10369B003

M14331A001

Ampire

AM320240SNTN-QW16H

customer r

equirement

MDE-5361A

SECTION 2 - IMPORTANT SAFETY INFORMATION

2

Important Safety Information

The EMERGENCY STOP, ALL STOP, and PUMP

STOP buttons at the cashier’s station WILL NOT

shut off electrical power to the

pump/dispenser. This means that even if you activate

these stops, fuel may continue to flow uncontrolled.

You must use the TOTAL ELECTRICAL

SHUT-OFF in the case of an emergency and not the

console’s ALL STOP and PUMP STOP or similar

keys.

!

WARNING

!

Gilbarco Veeder-Root encourages the recycling of

our products. Some products contain electronics,

batteries, or other materials that may require special

management practices depending on your location.

Please refer to your local, state, or country

regulations for these requirements.

3

Notes: 1) Save this Important Safety Information section in a

readily accessible location.

2) Although DEF is non-flam

Therefore, for DEF cabinets that are atta ch e d to

Diesel dispensers, follow all the notes in this section

that pertain to flammable fuels.

This section introduces the hazards and safety precautions

ssociated with installing, inspecting, maintaining or servicing this

a

product. Before performing any task on this product, read this safety

information and the applicable sections in this manual, where

additional hazards and safety precautions for your task will be found.

Fire, explosion, electrical shock or pressure release could occur and

cause death or serious injury, if these safe service procedures are

not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

f

lammable fuels, vapors, and high voltage or pressures. Only trained

or authorized individuals knowledgeable in the related procedures

should install, inspect, maintain or service this equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is how to

st

op all fuel flow to the pump/dispenser and island. Locate the swi tc h

or circuit breakers that shut off all power to all fueling equipment,

dispensing devices, and Submerged Turbine Pumps (STPs).

mable, Diesel is flammable.

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical components or th

electronics of the dispenser requires total electrical shut off of that

unit. Understand the function and location of this switch or circuit

breaker before inspecting, installing, maintaining, or servicing

Gilbarco equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or STPs

req

uires the following actions:

• An evacuation of all unauthorized persons and vehicles from the

work area

• Use of safety tape, cones or barricades at the affected unit(s)

• A total electrical shut-off of the affected unit(s)

MDE-5361A

Read the Manual

Read, understand and follow this manual and any other labels or

re

lated materials supplied with this equipment. If you do not

understand a procedure, call a the Gilbarco Technical Assistance

Center (TAC) at 1-800-743-7501. It is imperative to your safety and

the safety of others to understand the procedures before beginning

work.

Follow the Regulations

Applicable information is available in National Fire Protection

Asso

ciation (NFPA) 30A; Code for Motor Fuel Dispensing Facilities

and Repair Garages, NFPA 70; National Electrical Code (NEC),

Occupational Safety and Health Administration (OSHA) regulations

and federal, state, and local codes. All these regulations must be

followed. Failure to install, inspect, maintain or service this

equipment in accordance with these codes, regulations and

standards may lead to legal citations with penalties or affect the safe

use and operation of the equipment.

Replacement Parts

Use only genuine Gilbarco replacement parts and retrofit kits on

pump/dispenser. Using parts other than genuine Gilbarco

replacement parts could create a safety hazard and violate local

regulations.

Federal Communications Commission (FCC) Warning

This equipment has been tested and found to comply with the

limits for a Class A digital device pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and

can radiate radio frequency energy, and if not installed and used

in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in

case the user will be required to correct the interference at his

expense. Changes or modifications not expressly approved by the

manufacturer could void the user’s authority to operate this

equipment.

e

Safety Symbols and Warning Words

This section provides important information about warning symbols

and boxes.

Alert Symbol

This safety alert symbol is used in this manual and on

warning labels to alert you to a precaution which must be

f

ollowed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible

injury or death.

Signal Words

These signal words used in this manual and on warning labels tell

you the seriousness of particular safety hazards. The precautions

below must be followed to prevent death, injury or damage to the

equipment:

DANGER: Al

!

will result in death or serious injury.

WARNING:

could result in death or serious injury.

!

CAUTION

practice which may result in minor injury.

!

CAUTION

unsafe practice which may result in property or equipment

damage.

erts you to a hazard or unsafe practice which

Alerts you to a hazard or unsafe practice that

with Alert symbol: Designates a hazard or unsafe

without Alert symbol: Designates a hazard or

your

which

own

4

SECTION 2 - IMPORTANT SAFETY INFORMATION

2

The pump/dispenser contains a chemical known to the State

of California to cause cancer.

WARNING

!

The pump/dispenser contains a chemical known to the State

of California to cause birth defects or other reproductive

harm.

WARNING

!

Gasoline/DEF ingested may cause unconsciousness

and burns to internal organs. Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene. Seek medical

advice immediately.

DEF generates ammonia gas at higher temperatures. When

opening enclosed panels, allow the unit to air out to avoid

breathing vapors.

If respiratory difficulties develop, move victim away from source

of exposure and into fresh air. If symptoms persist, seek medical

attention.

WARNING

!

WARNING

!

Gasoline inhaled may cause unconsciousness and

burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled in eyes may cause burns to eye

tissue.

Irrigate eyes with water for approximately

15 minutes.

Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled on skin may cause burns.

Wash area thoroughly with clear water.

Seek medical advice immediately.

WARNING

!

DEF is mildly corrosive. Avoid contact with eyes, skin, and

clothing. Ensure that eyewash stations and safety showers are

close to the work location. Seek medical advice/recommended

treatment if DEF spills into eyes.

WARNING

!

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled

leaking fuels cause vapors. Even filling customer tanks will cause

potentially dangerous vapors in the vicinity of the dispenser or

island.

DEF is non-flammable. Therefore, explosion and fire safety

gs do not apply to DEF fluid lines.

warnin

No Open Fire

Open flames from matches, lighters, welding torches or

other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and the

vapors. Static electricity, including an electrostatic charge on your

body, can cause a spark sufficient to ignite fuel vapors. Every time

you get out of a vehicle, touch the metal of your vehicle, to

discharge any electrostatic charge before you approach the

dispenser island.

Working Alone

It is highly recommended that someone who is capable of rendering

fi

rst aid be present during servicing. Familiarize yourself with

Cardiopulmonary Resuscitation (CPR) methods, if you work with or

around high voltages. This information is available from the

American Red Cross. Always advise the station personnel about

where you will be working, and caution them not to activate power

while you are working on the equipment. Use the OSHA Lockout/

Tagout procedures. If you are not familiar with this requirement,

refer to this information in the service manual and OSHA

documentation.

or

ir

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

• Location of accident (for example, addr

building, and so on)

• Nature of accident (for example, possible heart attack, run

by car, burns, and so on)

• Age of victim(for example, ba

• Whether or not victim has rec

by, teenager, middle-age, elderly)

eived first aid (for example,

stopped bleeding by pressure, and so on)

• Whether or not a victim has vomited (for example, if swallow

or inhaled something, and so on).

ess, front/back of

over

ed

Working With Electricity Safely

Ensure that you use safe and established practices in working with

electrical devices. Poorly wired devices may cause a fire, explosion

or electrical shock. Ensure that grounding connections are properly

made. Take care that sealing devices and compounds are in place.

Ensure that you do not pinch wires when replacing covers. Follow

OSHA Lockout/Tagout requirements. Station employees and service

contractors need to understand and comply with this program

completely to ensure safe

Hazardous Materials

Some materials present inside electronic enclosures may present a

health hazard if not handled correctly. Ensure that you clean hands

after handling equipment. Do not place any equipment in the mouth.

MDE-5361A

ty while the equipment is down.

IMPORTANT: Oxygen may be needed at scene if gasoline has been

ingested or inhaled. Seek medical advice immediately.

Lockout/Tagout

Lockout/Tagout covers servicing and maintenance of machines and

eq

uipment in which the unexpected energization or start-up of the

machine(s) or equipment or release of stored energy could cause

injury to employees or personnel. Lockout/Tagout applies to all

mechanical, hydraulic, chemical, or other energy, but does not cover

electrical hazards. Subpart S of 29 CFR Part 1910 - Electrical

Hazards, 29 CFR Part 1910.333 contains

provision for electrical hazards.

specific Lockout/Tagout

5

SECTION 3 - REMOVING COMPONENTS

3

Ensure that the unit is functional. Check with the manager for any existing

operational issues. If the unit has any special features, such as TRIND

®

,

barcode scanner, and so on, verify proper operation before removal. Print a

system health report to verify printer and CRIND functions.

IMPORTANT INFORMATION

CAUTION

A properly grounded Electrostatic Discharge (ESD) wrist strap must be worn

while servicing any electronic devices or components. Failure to use

electrostatic precautions may damage electronic components and void

warranty.

Before You Begin

To prepare the site and unit for the installation:

1 Perform an inventory of the parts list provided. Ensure that there is no damage to the parts and that all

the parts are accounted for based on the BOM shipped with the kit. Ensure that you carry the

recommended spare parts to the installation site.

Note: Retain all parts (including cables, nuts, bolts, screws, and so on) that are removed. These are

required in case the unit must be reverted to the original as a fallback mitigation.

2 Read all the safety information found in “Important Safety Information” on page 3. Perform a Job

Safety Analysis (JSA) before beginning the installation.

3 Inform the manager.

4 Barricade the unit to be worked on.

5 Check the current state of the unit.

a Verify that the printer firmware is version 3.00 or later by removing and refeeding paper to the

printer while it is still powered.

Note: If the software is not V3.00 or later, be prepared to update the printer software.

b Verify site and dispenser operation.

c Perform a fueling transaction, including printing a receipt.

d Check Applause for idle and busy media (if applicable). Verify video and audio.

e Verify all unit options are functional (for example, intercom).

f Check the pump software version and update to the latest version, if necessary.

MDE-5361A

6

SECTION 3 - REMOVING COMPONENTS

3

Failure to turn off the power to the unit during kit installation may cause injury or bodily

harm from electrical shock. Ensure that all power to the unit is turned off before

opening the door to the unit and during installation.

WARNING

6 Remove power to the unit at the breaker panel. Follow OSHA lockout/tagout procedures.

7 Isolate the two-wire, any Ethernet®

Left Option Door

To remove the left option door:

1 Open the main door by loosening the lower screws that secure the lower portion of the main door and

then open the left and right option doors. Release the four main door latches.

2 Disconnect all the cables from the left option door, CRIND display, card reader, and Contactless Smart

Card (CSC) antenna (if applicable).

Note: Discard the CSC antenna cables as they cannot be reused.

Figure 1: Opening Left Option Door

cabling, and any network connections from the unit.

3

Remove the left option door by pulling the hinge pin up through the hole.

Note: The left option and the main door must be open to gain access to the hinge pin.

4 Remove any existing old gaskets on the option door opening using a putty knife or scraping tool.

5 Remove any customer supplied locks and add to the new option door.

MDE-5361A

7

SECTION 3 - REMOVING COMPONENTS

3

(ii)

(i)

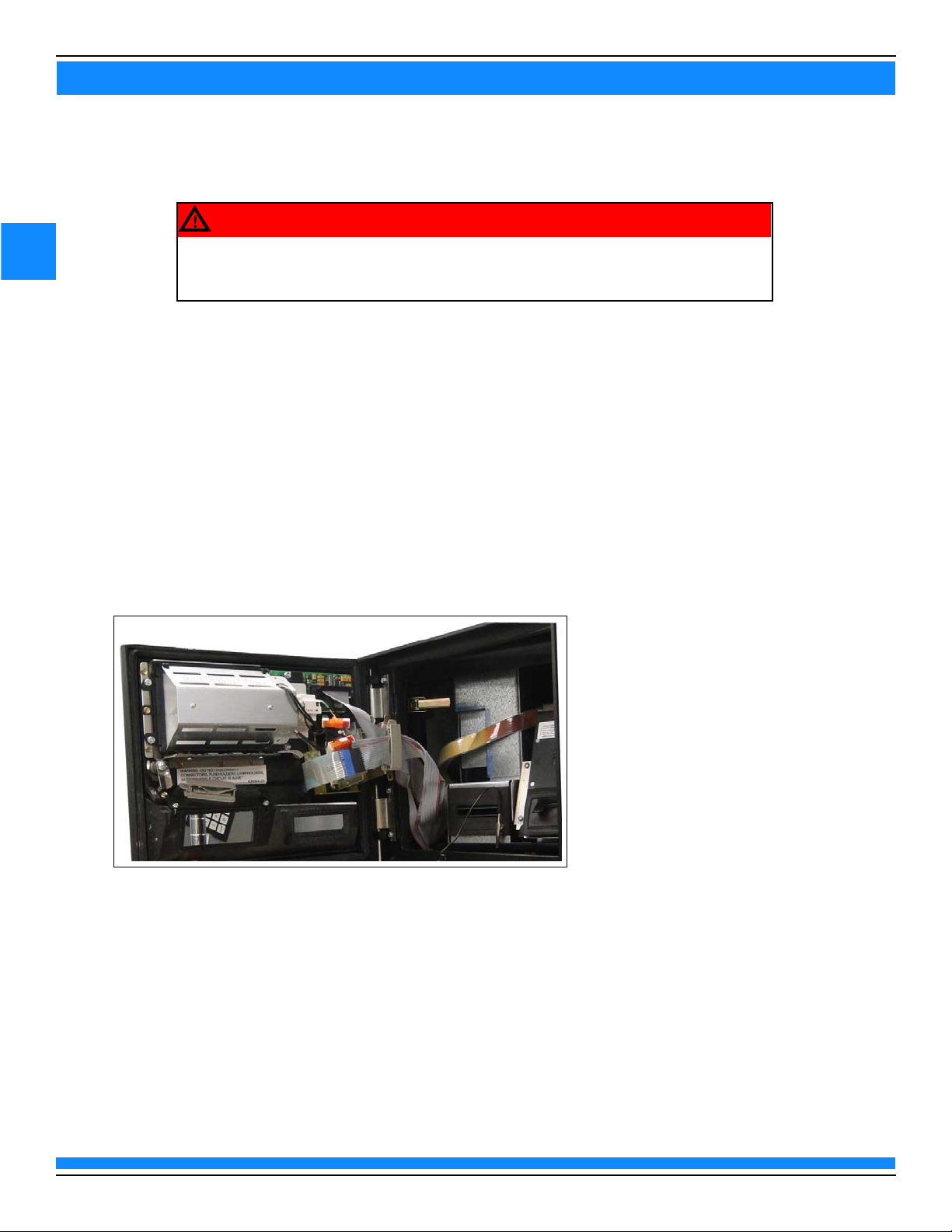

CRIND Electronics

Note: If the unit is not equipped with CRIND, proceed to the installation instructions beginning with

“FlexPay IV CRIND Retrofit Kit” on page 11.

To remove the existing CRIND electronics from the cabinet:

1 Disconnect all the cables connected to the CRIND tray.

2 Disconnect the cables that are connected to the printer. Then remove all the CRIND cables and place

with the CRIND tray, when removed.

3 Remove the CRIND tray by pulling it out toward you and lifting it out of the support bracket

(see Figure 2 (i) and (ii)).

Figure 2: Removing CRIND Tray

MDE-5361A

8

SECTION 3 - REMOVING COMPONENTS

3

Tray Support

Slide Rail

(i)

(ii)

Printer Front View

Printer Rear View

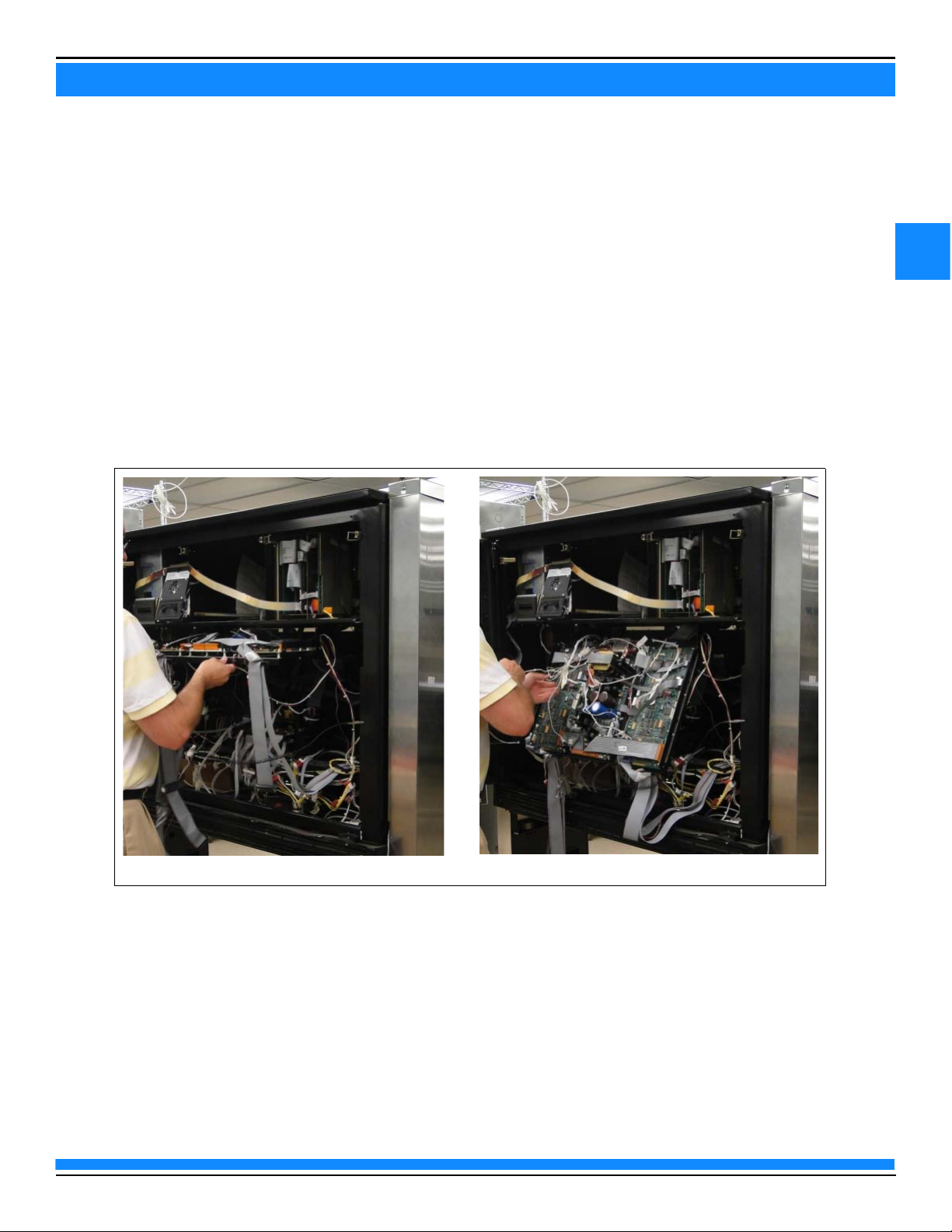

4 Remove the tray and carefully place it in a safe location.

5 Remove the tray support slide rails.

Figure 3: Removing Tray Support Slide Rails

Printer

To remove the printer, disconnect all printer cables and remove the existing printer(s) by removing the three

or four nuts underneath.

Note: The printer cables can be discarded.

Figure 4: The Advantage Series Printer

MDE-5361A

9

SECTION 3 - REMOVING COMPONENTS

3

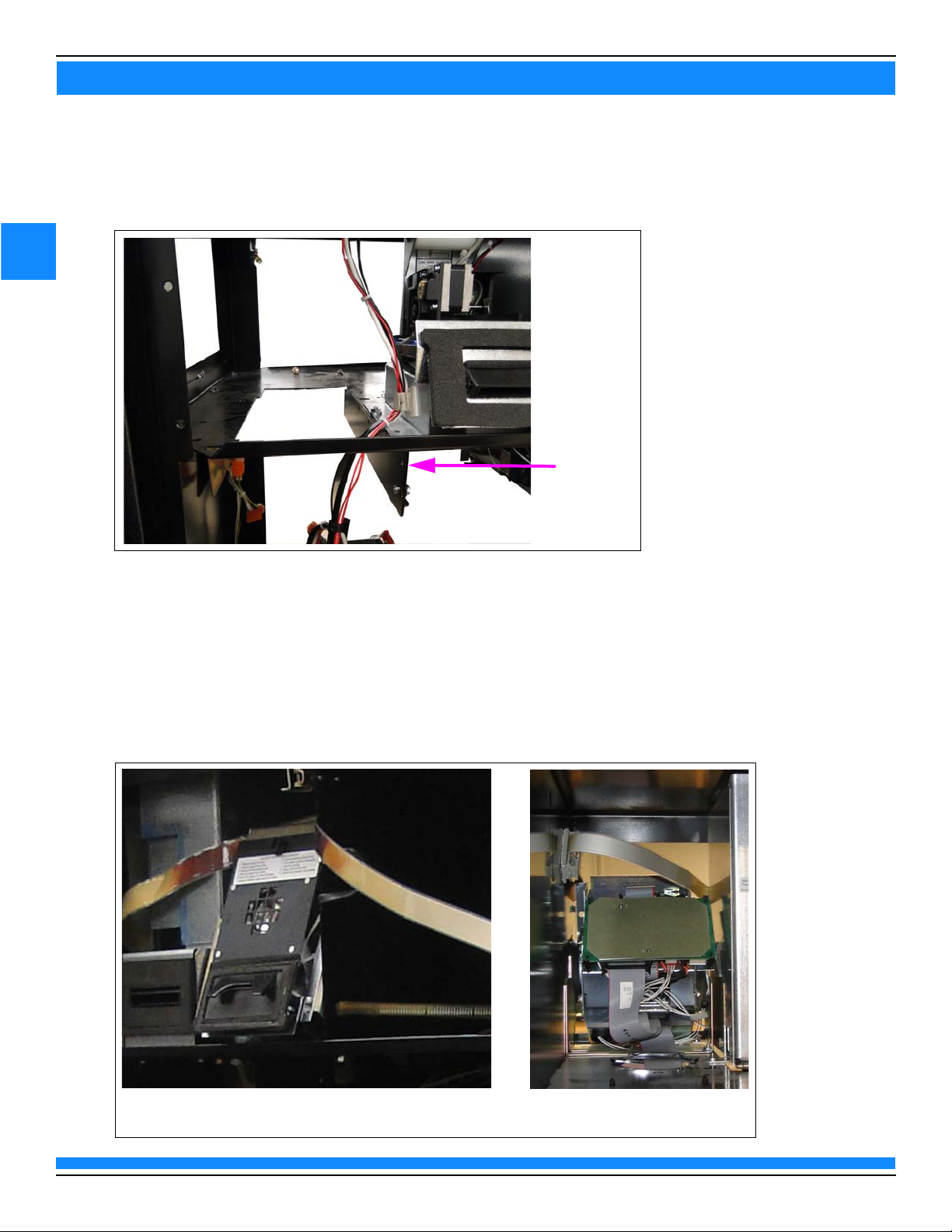

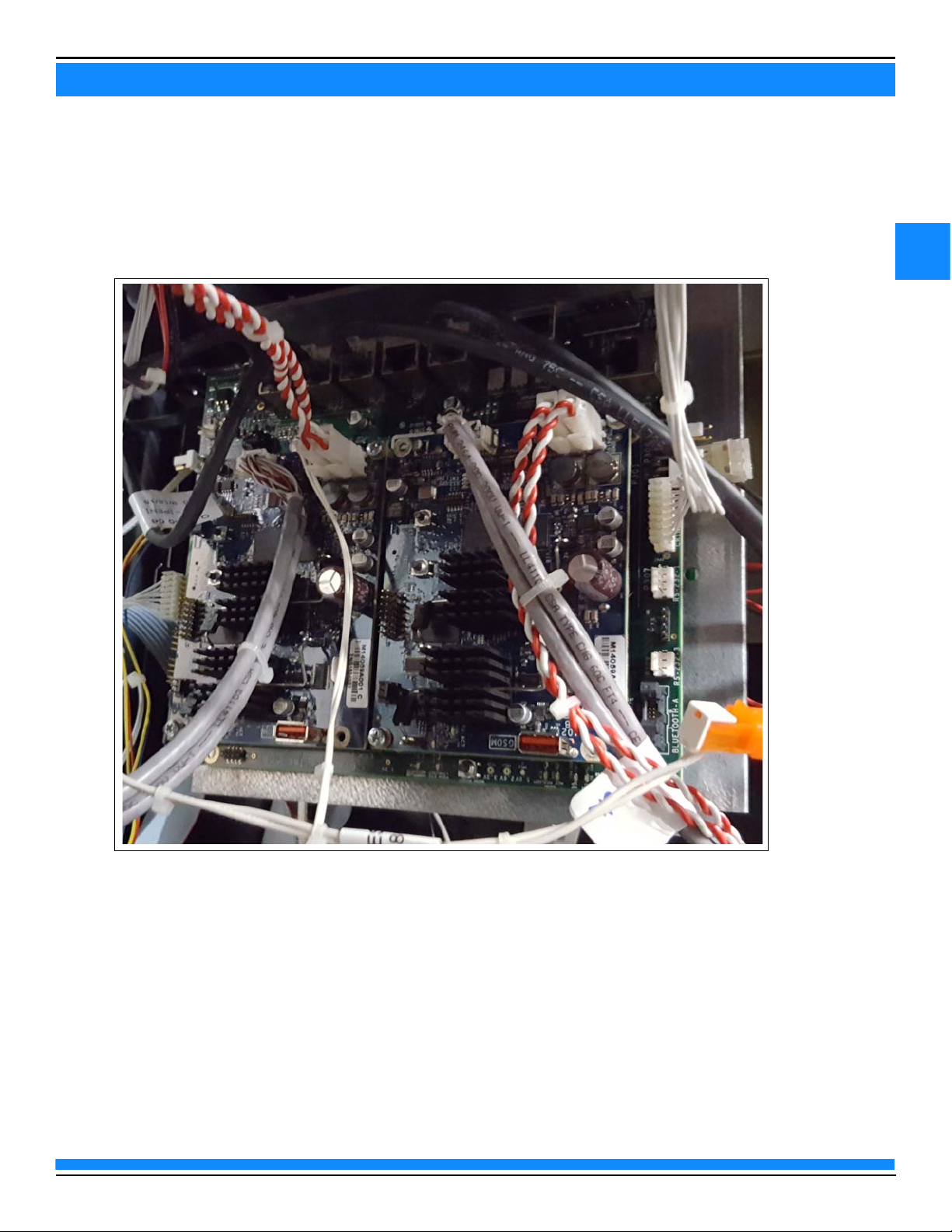

AFP/HIP 2/DCM2/DCM2.x

To remove the Hub Interface PCB (HIP) 2/AFP/DCM2/DCM2.x bracket:

1 Disconnect all the cables from the AFP, HIP 2, or DCM2/DCM2.x (see Figure 5).

Figure 5: Disconnecting Cables (DCM2)

MDE-5361A

10

SECTION 3 - REMOVING COMPONENTS

3

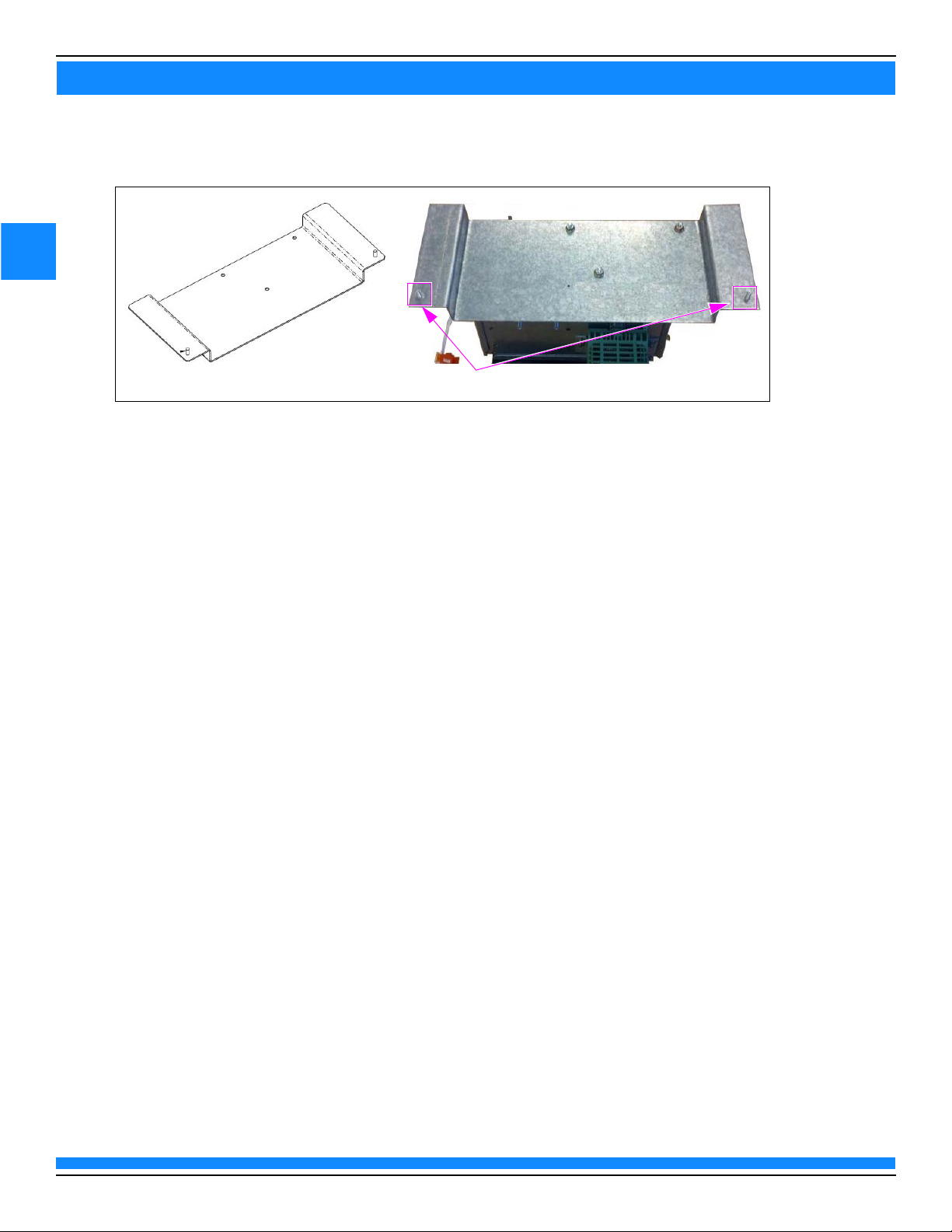

(i)

(ii)

M4 Nuts

2 Remove the two M00414B005 M4 Nuts to detach the AFP, HIP 2, or DCM2/DCM2.x bracket.

Figure 6: Mounting Bracket

MDE-5361A

11

SECTION 4 - INSTALLATION

4

(i)

(ii)

Rear View of Left Option Door

Front View of Left Option Door

New Left Option

Door Installed

FlexPay IV CRIND Retrofit Kit

Left Option Door

To install the new left option door:

1 Place the new left option door in the opening.

2 Re-insert the hinge pin to secure the new left option door.

Figure 1: Installing Left Option Door

MDE-5361A

12

SECTION 4 - INSTALLATION

4

(i)

(ii)

Printer Shelf

Adapter Bracket

Omnia Assembly

To install the Omnia assembly, proceed as follows:

1 Attach the Omnia bracket to Advantage Adapter Bracket (M15122A001) using three M00414B005 M4

Nuts supplied in the kit.

Figure 2: Attaching Omnia Bracket

2 Attach this assembly underneath the Advantage printer shelf, opposite of the main power supply,

using the two holes vacated by the right side CRIND tray rail. Secure with two M00414B005 M4 Nuts.

Figure 3: Mounting Omnia Assembly

3 Continue with instructions to connect cables.

MDE-5361A

13

SECTION 4 - INSTALLATION

4

Omnia PWR Input-J6001

DCM3-J511

AC Input -P104

Side A J301A

Connecting Cables

To connect the cables:

Note: Ensure that the AC cables are not bundled with any non-AC cables.

1 Connect J104 of the M12777A004 Cable to the M04406A001 AC Distribution Cable in the U-channel.

2 Connect P301A/B of the M14340 Cable side A to J301A of the M12777A004 Cable.

3 Connect P301A/B of the M14340 Cable side B to J301B of the M12777A004 Cable.

4 Connect the Ethernet cable to the card reader. The yellow Category 5 (CAT5) cable in the kit matches

the yellow connector on the Omnia PCB (for dedicated side).

Figure 4: Connecting Ethernet Cable to the UX300 Card Reader

Figure 5: M12777A004 Cable Connection

MDE-5361A

14

SECTION 4 - INSTALLATION

4

Display Power

P219 - Audio

Input from

Omnia

P212 - Audio

Output from

Speaker

P214D - USB

P214F - USB

Uplink from

UPM

JP1 - Beeper

Input from

UPM

P213 - Beeper

Input from

UPM

P204 - TRIND

Serial

connection

P214A - USB

P214C - USB

P213 - Video

Input from

UPM

P214B USB to

Printer

JP2 - Side

Select

Jumper

P220 - 24

VDC Input

5 Connect the USB cable from the printer to Omnia PIP, using the port on the left side.

Note: Ensure that the USB printer cable is seated.

Figure 6: Omnia PIP (M15649A001) Connections

MDE-5361A

15

SECTION 4 - INSTALLATION

4

6 Connect P212 to speaker.

Figure 7: Omnia Speaker Connection

Notes: 1) If Applause Media System is installed, there will also be a new audio cable from Omnia PIP and a

video cable from Omnia to UPM. Audio Cable (M14425A002) goes from P419L to Omnia PIP P219.

Video Cable (M14338A00X) goes from Omnia P1 for Side A UPM and Omnia P2 for Side B UPM to

UPM P6.

2) On the Omnia PIP, the J202 connection (RS-232 Serial Cable) will not be used. The cable can be

removed or tucked away neatly on the door.

MDE-5361A

16

SECTION 4 - INSTALLATION

4

7 Connect all the applicable cables to the Omnia assembly as shown in Figure 8. For additional details

regarding direct CAT5 connections, refer to MDE

Service Manual Insite360™ Forecourt with Applause Media System.

Figure 8: Omnia Board Connections

-5369F FlexPay IV (with Omnia) Programming and

MDE-5361A

17

SECTION 4 - INSTALLATION

4

Figure 9: Connecting Cables

8 Connect the Ethernet cable from each UPM to the Omnia board.

Note: These ports are dedicated. The UPMs and UX300 Card Readers must be connected to the

correct ports.

Figure 4 on page 13 shows the labels on the Omnia board.

Figure 10: Omnia RJ-45 CAT5 connections for UPMs and UX300s (+ Spares)

9 Route the two Braid Terminal Ground Cables [M04431A002 (one from the UX300 and one from the

UPM)] on each Advantage left-side door under the printer tray and secure on the underside with the

cable push mount provided.

MDE-5361A

18

SECTION 4 - INSTALLATION

4

Support Rail

10 Secure the two ring terminals to the support rail using a M00417B101 M5 Screw as shown in

Figure 11.

Figure 11: Securing Ring Terminals

11 Repeat steps 9 on page 17 through 10 for side B of the unit.

Power Supply Grounding Connection

To make grounding connection for the power supply, connect the M04431A002 Cable between the Omnia

assembly and the power supply support rail using a M00417B101 Screw.

MDE-5361A

19

SECTION 4 - INSTALLATION

4

AC Power

The Advantage Series has one of two different AC wiring schemes depending on the year the unit was built.

Refer to the steps below after identifying the configuration present.

The Advantage Series Units Built Prior to 1999

To make AC power connections for The Advantage Series units built prior to 1999:

1 Install the AC Power Adapter Cable (R20580-G3) by inserting it between J601 and P601

(see Figure 12).

2 Plug the AC power input of M04406 from the Omnia assembly into P601 of R20580-G3 Cable.

Figure 12: Plugging AC Power Input from Omnia to R20580-G3

AC Power Distribution Cable

The Advantage Series Units Built

To make AC power connections for The Advantage Series units built after 1999:

1 Locate the AC Adaptor Cable Assembly (T19612-G2) from the pump power supply located across the

bottom of the electronics cavity.

2 Plug M04406 into J550 or an available three-pin connection.

3 Ensure that all AC connections are paired as black-to-black, white-to-white, and green-to-green.

Note: After all the cables have been routed from the doors to the interior of The Advantage Series unit,

ensure to route the cables to avoid pinching.

After 1999

MDE-5361A

20

SECTION 4 - INSTALLATION

4

T19612 Cable Assembly AC Adaptor

J601

J708

J551

J404

J550

Tra nsf or mer A ssy

T19706-Gx

Auxiliary A/C Pickoff

Auxiliary A/C Pickoff

Vap orVa c

Connect To Frame

To A/C Distribution

Cable M04406 (Power

to CRINDS, Omnia

Assy)

Connection from conduit

Use the T19612 Cable Assembly AC Adaptor to connect to the other modules in the dispenser that require

AC voltage. The T19612 Cable Assembly AC Adaptor connects to the J401 connector attached to the

conduit, from where it is connected to the modules in the dispenser wherever AC voltage is required.

(see Figure 13 on page 20).

Figure 13: AC Power Distribution Cable Connection

Figure 14 shows internal connections for T19612-G2 in the dispenser.

Figure 14: T19612-G2 Internal Connections

MDE-5361A

21

SECTION 4 - INSTALLATION

4

To route the cables:

1 Secure the door cables underneath the printer paper holder.

Figure 15: Securing Door Cables Underneath Printer Paper Holder

2 Tie-wrap the cables to the printer shelf, near the main door hinge, keeping both doors completely

open. This will ensure there is sufficient space between the cables.

Figure 16: Securing Cables to Printer Shelf

MDE-5361A

22

SECTION 4 - INSTALLATION

4

For start-up information, refer to MDE-5221 FlexPay IV CRIND Start-up

Manual.

IMPORTANT INFORMATION

Cable routing is critical. It is very important to route and dress the cables

properly. Exercise care in routing the cables, keeping in mind that the door(s)

opens and closes for service. The cables must be dressed neatly. Ensure that

there is no interference after the cables are connected and routed.

ESD ground straps can be bundled together, but need to be separated from

data and power cables.

IMPORTANT INFORMATION

Completing Installation

To complete the installation, inspect all the connections and cable routing before applying power.

For detailed block diagrams of cable connections, refer to “Appendix C: System Block Diagram” on page 31.

Registering Kits with Gilbarco Warranty

To register the kits with Gilbarco Warranty:

1 After the kits are successfully installed, register kits through web commissioning within 30 days.

2 Provide the correct model and serial numbers.

Note: Registering the kits ensures that proper warranty is applied.

The Advantage Retrofit Kit part number is EPK M7 ADV.

MDE-5361A

23

SECTION 5 - REFERENCE INFORMATION

5

Related Documents

Document

No.

MDE-2531 Gilbarco Pump and Dispenser Start-up and Service Manual

MDE-5221 FlexPay IV CRIND Start-up Manual

MDE-5223 FlexPay IV CRIND Service/Troubleshooting Guide

MDE-5227 M7 Maintenance Tool User Guide

MDE-5369 FlexPay IV with Omnia Start-Up and Service Manual

PT-1728 The Advantage Series Pumps and Dispensers Illustrated Parts Manual

PT-1869 Gilbarco Products Recommended Spare Parts for Domestic Products

Title

Abbreviations and Acronyms

Ter m Description

AFP Auxiliary Feature PCB

ASC Authorized Service Contractor

BNA Bank Note Acceptor

BOM Bill of Material

BRCM Back Room Communication Module

CAT5 Category 5

CIM Customer Interface Module

CRIND Card Reader in Dispenser

CSC Contactless Smart Card

D-Box Distribution Box

DCM Dispenser Communication Module

®

EMV Europay

ESD Electrostatic Discharge

GSoM Gilbarco Systems on Module

JSA Job Safety Analysis

MOC Major Oil Company

OSHA Occupational Safety and Health Administration

PCB Printed Circuit Board

PCI Payment Card Industry

PCI-PED Payment Card Industry PIN Entry Device

POS Point of Sale

PIP Peripheral Interface PCB

SSoM Secure System on Module

TRIND Transmitter/Receiver in Dispenser

UPM Universal Payment Module

USB Universal Serial Bus

VDC Voltage Direct Current

W&M Weights and Measures

, MasterCard®, and Visa

®

MDE-5361A

24

SECTION 5 - REFERENCE INFORMATION

5

This page is intentionally left blank.

MDE-5361A

25

SECTION 6 - APPENDICES

6

Appendix A: PCB, Connections, and LED Information

Omnia Board Connections

Connector Port Number Function From To

7-pin MTA P60001 Power IN P60001 Power input

2-pin plug P6901 Audio out to Omnia

A

PIP

2-pin plug P6902 Audio out to Omnia

25-pin high density P1 Video out to UPM A P1 UPM-P6

25-pin high density P2 Video out to UPM B P2 UPM-P6

5-pin MTA P300 Two-wire connection

2-pin MTA P303 Two-wire to pump P303 Pump-P1109

7-pin MTA P304A Backroom

4-pin plug P304B Backroom

PIPB

POS

to

connection/DCM3

connection

P6901 Omnia PIP: P219

P6902 Omnia PIP: P219

P300 Conduit/POS

P304A DCM3-J17

P304B Conduit

Note: Verify P6001 of the Omnia board is on the same side as the Weights and Measures

(W&M) switch.

For more information, refer to “Appendix B: System Block Diagram” on page 30.

Omnia PIP Connections

The following table lists the connections on the Omnia PIP:

Connector Port Number Function From To

10-pin MTA P201 Cash Acceptor P201 BNA

6-pin MTA P204 TRIND P204 TRIND J182

3-pin Plug P213 BEEP Connector P213 UPM P2

4-pin Plug P220 24 VDC IN P220 Power Supply Cable

Mini Universal

Bus (USB)

Serial

USB P214A USB Out P214A USB Expand

USB P214B USB Out P214B USB Expand

USB P214C USB Out P214C USB Expand

USB P214D USB Out P214D USB Expand

4-pin MTA P219 Speaker Input from Omnia P219 P6901A and P6901B

2-pin Mat-n-Lok P211 Audio to Left Speaker P211 Left Speaker

25-pin P205 Video Input from UPM P205 UPM P5

20-pin P206 LVDS Data to 10.4” P206 10.4”

33-pin P207 Video Data to 5.7” P207 5.7”

2-pin P215 Up/Down for 5.7”

10-pin P208 10.4” Backlight P208 10.4” Backlight

3-pin P210 5.7” Backlight P210 5.7” Backlightt

USB UPLINK USB IN USB UPLINK UPM P4

P215 DNP

(M1

4340)

MDE-5361A

26

SECTION 6 - APPENDICES

6

Omnia Assembly Jumpers

The following table lists the status and functions of jumpers:

Jumper Description

Omnia Board

J3 Jumper ON = Battery connected

Jumper OFF = Battery disconnected

Omnia PIP

JP2 Jumper ON = Side B

Jumper OFF = Side A

Omnia PIP LEDs

Reference

Designator Color Function Behavior

D1 Green USB link ON: U8 connected to USB Hub

D4

D5

D6

D7

D9

D11

D12

D14

D20

D21

D22

D23

D24

D25

D26

Red USB over current ON: Over current fault detected on P214D

Ye ll ow Serial

communication

Green Power good ON: 5 VDC power is good

ON: USB device plugged into P214A

OFF: No USB device connected

ON: USB device plugged into P214B

OFF: No USB device connected

ON: USB device plugged into P214C

OFF: No USB device connected

ON: USB device plugged into P214B

OFF: No USB device connected

OFF: Normal operation

ON: Over current fault detected on P214B

OFF: Normal operation

ON: Over current fault detected on P214C

OFF: Normal operation

ON: Over current fault detected on P214A

OFF: Normal operation

ON: UPM TX to BNA

OFF: UPM is not communicating with BNA

ON: BNA TX to UPM

OFF: BNA is not communicating with UPM

ON: UPM TX to TRIND

OFF: UPM is not communicating with TRIND

ON: TRIND TX to UPM

OFF: TRIND is not communicating with UPM

OFF: 5 VDC power fault or board not powered

ON: 3.3 VDC power is good

OFF: 3.3 VDC power fault or board not powered

ON: 24 VDC power is good

OFF: 24 VDC power fault or board not powered

Note: Install a jump jack on JP2 when Omnia PIP is located on Side 2 of the dispenser.

MDE-5361A

27

SECTION 6 - APPENDICES

6

Omnia LEDs

Reference Designator Color Function Behavior

D7 Green 1.5V power good LED ON: 1.5 V power is good

OFF: 1.5 V power is not good

D8 1.1V power good LED ON: 1.1 V power is good

OFF: 1.1 V power is not good

D17 1.8V power good LED ON: 1.8 V power is good

D18 1.35V power good LED ON: 1.35 V power is good

D22 Power Input LED ON: Omnia PCB has 24 VDC from power supply

D23 5V USB power good

LED

D24 5V power good LED ON: 5 V power is good

D25 5VPS power good LED ON: 5 VPS power is good

D26 3.3V power good LED ON: 3.3 V power is good

D37 Yel lo w CRIND 2W RX Blinking: Data received from POS

D38 CRIND 2W TX Blinking: Data sent to POS

D39 Green CRIND TX Enable ON: TX enable line is act

D45 Yel lo w Pump (POS) 2W RX Blinking: Data received from POS

D47 Pump (POS) 2W TX Blinking: Data sent to POS

D49 Green Pump (POS) TX Enable ON: TX enable line is act

D53 Yel lo w Pump 2W RX Blinking: Data received from pump

D56 Pump 2W TX Blinking: Data sent to pump

D57 Green Pump TX Enable ON: TX enable line is act

D58 Green Active Mode LED ON: Omnia configured correctly.

D73 Yel lo w 7.5V power good LED ON: 7.5 V power is good

OFF: 1.8 V power is not good

OFF: 1.35 V power is not good

OFF: Omnia PCB does not have 24 VDC from

ON: USB power is good

OFF: USB power is not good or the regulator is not

OFF: 5 V power is not good

OFF: 5 VPS power is not good

OFF: 3.3 V power is not good

OFF: Omnia will not send messages to the POS

OFF: Omnia will not send messages to the POS

OFF: Omnia will not send messages to the pump

OFF: Omnia not properly configured

OFF: 7.5 V power is not good or is not enabled by

r supply

powe

enabled.

ive. Omnia will

successfully communicate to the POS

ive. Omnia will

successfully communicate to the POS

successfully communicate to the pump

a

Omni

ive. Omnia will

MDE-5361A

28

SECTION 6 - APPENDICES

6

Keypad Connector Tab

Some of the connectors have a tab on the side that must be pressed prior to

removing the connector. You must depress and hold the tab on the side of the UPM

softkey connector if you want to remove it. If you do not press the tab, the wire might

be pulled out from the connector.

CAUTION

Keypad Connector Tab

(used on all systems)

Video Connector Tab (used only with Applause Media System)

UPM Board Connections

Figure 1: Keypad and Video Connector Tabs

MDE-5361A

29

SECTION 6 - APPENDICES

6

The following table lists the connections on the UPM:

Port Number To Function

P1 24 V Power into UPM UPM power (and keypad heater power, if equipped)

P2 Omnia PIP - (P213),

softkeys, door node

(P2111), door switch (192),

ADA, call

P3 Omnia Blue UPM

Omnia Yellow Card Reader

(see Figure 1 on page 28)

P4 Omnia PIP - USB uplink USB uplink to the Omnia PIP

P5 Omnia PIP - P205 Video out

P6 Omnia - P406 Applause

Media System video input

Input/Output (I/O) to multiple CRIND functions:

• Softkeys

•ADA

• Door switch

• Beeper

Ethernet to the Omnia board

Video input from the Omnia

The following table lists the peripherals for the cables:

Part Number Port Number Function

M03184A00X P201 Cash Acceptor

R20773-GX P204 TRIND

M09267A00X P213 BEEP Connector

M09794A00X P220 24 VDC Power In

M14337A001 P1 UPM Heater Cable

MDE-5361A

SECTION 6 - APPENDICES

MDE-5361A

6

30

Figure 2: Cable Block Diagram for FlexPay IV CRIND

Appendix B: System Block Diagram

31

SECTION 6 - APPENDICES

6

Appendix C: Verifying Cable Connections

Cable Connections on Display Assembly

Figure 3 shows the cable connections on the display assembly.

Figure 3: Cable Connections on Display Assembly

To verify the cable connections:

Power Cabling

Ensure that the power cables are connected as follows:

1 Omnia PIP: P220 port is connected to +24 V Cable (M14340A001).

2 UPM: P1 port is connected to +24 V cable.

3 Omnia: P6001 port is connected to +24 V cable.

Omnia PIP Cabling

Ensure that the Omnia PIP board cables are connected as follows:

1 Omnia PIP USB uplink port is connected to the USB Cable (M03695B004) and connected to the P4 port

on the UPM.

2 P213 port of Omnia PIP is connected to the M13119 Cable, which connects to the UPM P2.

3 P211 port is connected to the Speaker Cable (M09259A004) and to the left speaker.

4 P205 port is connected to M14136A00X Cable and to UPM P5.

MDE-5361A

32

SECTION 6 - APPENDICES

6

You must depress and hold the tab on the side of the UPM softkey connector to

remove it. If you do not depress the tab, you are very likely to pull out the wire from

the connector.

CAUTION

5 P206 port is connected to 10.4-inch LVDS Cable (M13722A002) and to 10.4-inch display.

6 P207 port is connected to 5.7-inch Parallel Cable (M9224B001) and to 5.7-inch display.

7 P209 port is connected to 10.4-inch Backlight Cable (M9224B001) and to 10.4-inch display.

8 P210 port is connected to 5.7-inch backlight leads from the 5.7-inch display.

UPM Cabling

Ensure that the UPM cables are connected as follows:

1 P1 port is connected to 24 V Power Cable (M14340A001).

2 P2 port of Softkey Cable (M13119AXXX) is connected to the softkeys, P213 of Omnia PIP for the

beeper, J2111 for the door node, and J192 for the door switch.

3 P3 port of Ethernet Cable (Q13850-XX) is connected to P303A/B on Omnia board.

4 P4 port of USB Cable (M03695B007) is connected to USB UPLINK on Omnia PIP board.

5 P5 port of LVDS Cable (M14136A00X) is connected to P205 on Omnia PIP board.

6 P6 port of LVDS Cable (M14338A001) is connected to P606A/B on UPM board.

7 Earth Ground Cable (M04431A002) is connected to the U-channel running across the bottom of the

unit cavity. These need to be mounted with separate bolts and not together.

MDE-5361A

33

SECTION 6 - APPENDICES

6

UX300/UX301/UX400 Card Reader Cabling

Ensure that the card reader cables are connected as follows:

1 P1 port is connected to 24 V Power Cable (M14340A001).

2 LAN port of Card Reader Cable (M13443B006) is connected to the Omnia.

3 If UX400 contactless reader is present, the RF port (UX400 RF) on the card reader connects to the RF

port (UX400 RF) on the contactless reader.

4 If UX400 contactless reader is present, power/data port (UX400 COMM) on the card reader connects

to the power/data (UX400 COMM) port on the contactless reader.

The card reader has an earth ground cable that is connected to the U-channel.

MDE-5361A

34

SECTION 6 - APPENDICES

6

J15 - 24 VDC

Power In

J16 - 24 VDC

Power Out

(Optional)

J21 - OLC in/

Two-Wire Out

J17 - Ethernet

to Omnia PCB

Appendix D: DCM3 Assembly (M15724A001)

The DCM3 is used when high-speed communication is required across the forecourt. The DCM3 is only used

with the BRCM2. Connect all the applicable cables to the DCM3 assembly as shown in Figure 4.

Figure 4: DCM3 Connections

LEDs

MDE-5361A

Reference Designator Color Function Behavior

D1 Green 1.2 V Power Good ON: 1.2 VDC ON

OFF: 1.2 VDC fault or board

not powered

D9 3.3 V Power Good ON: 3.3 VDC ON

OFF: 3.3 VDC fault or board

not powered

D8 24 V Power Good ON: 24 VDC ON

OFF: 24 VDC fault or board not

powered

D6 Yellow High Speed ACT ON: Link present

Blink: TX/RX data

OFF: No link present

D7 Green High Speed Link ON: Successful connection to

BRCM2

OFF: No link to BRCM2

35

SECTION 6 - APPENDICES

6

*CRIND Two-wire becomes inactive with EMV.

Connection Table (M15724A001)

Connector Port Number Function From To

RJ-45 J17 Ethernet J21 Omnia P304

5-pin MTA J21 OLC/two-wire Conduit/J21 Omnia P300

2-pin MTA J15 Power IN DCM3

2-pin MTA J16 Power Out N/A N/A-no current use

DCM3 Two-Wire Connections

These instructions detail how to perform two-wire connections when a DCM3 is used in the system. The

DCM3 is required when a BRCM2 is used to provide high-speed communication across the forecourt. The

BRCM2 when used with the DCM3 supports the following two modes:

• The option of merging the high speed data onto the same conductors used for current loop.

• The option of not merging high-speed data onto the same conductors used for current loop. This setup

requires additional wire pairs brought out to each dispenser.

DCM3 Two-Wire Connection (Merged)

Ensure that the two-wire connection when high speed data is merged onto the same conductors is as

follows:

1 Connect P21 of the M11961A004 cable to J21 of the DCM3.

2 Connect J300 of the M11961A004 cable to P300 of the Omnia.

3 Connect the Y/Y pair of the M11961A004 to the B/Y pair of wires coming from the conduit.

Figure 5: MOC (Merged), Pre-EMV*

MDE-5361A

36

SECTION 6 - APPENDICES

6

DCM3 Two-Wire Connection (Non-Merged)

Ensure that the two-wire connection when high speed data is not merged onto the same conductors is as

follows:

1 Connect P21 of the M11961A004 cable to J21 of the DCM3.

2 Connect the Y/Y pair of the M11961A004 to the designated wires coming out of the conduit.

3 Connect J300 of the M02993A005 cable to P300 of the Omnia.

4 Connect the B/Y pair of the M02993A005 to the B/Y pair coming from the conduit.

Figure 6: MOC (Non-Merged)

MDE-5361A

37

SECTION 6 - APPENDICES

6

*CRIND Two-wire becomes inactive with EMV.

Generic (Merged)

The Omnia board supports high speed communication via the BRCM2. When connection to a BRCM2 is

required, the kit will ship with a DCM3 (M15724A001) attached to the Omnia bracket assembly. See the

following wiring instructions.

Ensure that the connection to Omnia is as follows:

1 Connect P21 of the M11961A005 cable to J21 of the DCM3.

2 Connect the Y/Y pair of the M11961A005 to the R/Y pair of wires coming from the conduit.

3 Cut J300 off M11961A005.

4 Connect the R/Y pair of M11961A005 to the R/Y pair of M02993A005.

5 Connect J300 of the M02993A005 cable to P300 of the Omnia.

Figure 7: Generic (Merged), Pre-EMV*

MDE-5361A

38

SECTION 6 - APPENDICES

6

Generic (Non-Merged)

Ensure that the connection to Omnia is as follows:

1 Connect P21 of the M11961A005 cable to J21 of the DCM3.

2 Connect the Y/Y pair of the M11961A005 to the designated wires coming the conduit.

3 Connect J300 of the M02993A005 cable to P300 of the Omnia.

4 Connect the B/Y pair of M02993A005 to the B/Y pair of wires coming from the conduit.

5 Connect the R/Y pair of the M02993A005 to the R/Y pair coming from the conduit.

Figure 8: Generic (Non-Merged)

MDE-5361A

39

SECTION 6 - APPENDICES

6

FCC Compliance Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interferences that may cause undesired operation.

FCC Supplier’s Declaration of Conformity

47 CFR § 2.1077 Compliance Information

Unique Identifier: FlexPay IV CRIND Advantage Retrofit Kit

Responsible Party - U.S. Contact Information

Gilbarco Veeder-Root

7300 West Friendly Avenue

Greensboro, North Carolina, USA

27410-6200

1-336-547-5000

MDE-5361A

40

The Advantage® Series, CRIND®, Gilbarco®, and TRIND® are registered trademarks of Gilbarco Inc. Applause™ Media System, CIM™, E-CIM™, FlexPay™

Passport™ and InSite 360™are trademarks of Gilbarco Inc. EMV® is a registered trademark of EMVCo LLC. Ethernet® is a registered trademark of Xerox

Corporation. Europay® and MasterCard® are registered trademarks of MasterCard International Inc. Phillips® is a registered trademark of Phillips

Screw Company. VeriFone® is a registered trademark of VeriFone Inc. Visa® is a registered trademark of Visa Inc.

© 2020 Gilbarco Inc.

7300 West Friendly Avenue · Post Office Box 22087

Greensboro, North Carolina 27420

Phone (336) 547-5000 · http://www.gilbarco.com · Printed in the U.S.A.

MDE-5361A FlexPay™ IV CRIND® (with Omnia) Retrofit Kit Installation Instructions for The Advantage® Series

Loading...

Loading...