IC Radio Standards Specification: RSS-210

Certification Exhibit

FCC ID: N6SLFADV

IC: 827B-LFADV

FCC Rule Part: 15.209

ACS Report Number: 13-0073

Manufacturer: Gilbarco Inc.

Model: LFADV

Manual

5015 B.U. Bowman Drive Buford, GA 30518 USA Voice: 770-831-8048 Fax: 770-831-8598

The Advantage® Series, MPD® -3, Encore®, and

Eclipse

®

Units

nary

i

TRIND® Start-Up, Service, and

m

i

3

/1

Parts Manual

rel

P

22

3/

0

MDE-3664B

ECR™MultiLine

Tank Monitor

Eclipse®MPD

TRIND

EMC™Optimum™Series

TCR

Encore®Passport

VaporVac

FlexPay™PAM™1000

Titan

G-SITE®Performer

G-CAT™PAM

Ultra-Hi

Gilbarco®The Adv antage®Series

Gilbert

SMART Connect

™

ValueLine

Computer Programs and Documentation

All G ilbarco Inc. and/or Veeder Root Company computer programs (including software o n diskettes and within me mory chips) and documentation are copyrighted by, and shall

remain the property of, Gilbarco Inc. and/or VeederRoot Company.Such computer programs and documents may also contain trade secret information. The duplication, disclosure,

modification, or unauthorized use of computer programs o r documentationis strictly proh ibited, unless otherwise lice ns ed by Gilbarco Inc. and/or Veeder Root Company.

Federal Communications Commission (FCC) Warning

This equipment has bee n tested and found to comply with the limits for a Class A digitaldevice pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmf ul inter ference when the eq uipment is operated in a commercial environment. This equipment generate s, uses, and can radiate radio frequency

energy,and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to c

the manufacturer could void the user’s autho rity to operate this e quipm e nt.

ause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modificat ions not expressly approved by

Industry Canada Warning

This device compl i es with I ndustr y Canada licence-exempt RSS standard(s). Operation i s subject to the following two conditions:

(1) this device may no t cause interference, and

(2) this device must accept any interference, inc lu d ing int e rference that may cause undesired operatio n of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence. L'exploitation est autorisée aux deu x conditions suivantes :

(1) l'appareil ne doit pas produire de brouillage, et

(2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, mê me si le brouillage est susceptible d'en co mpromettre le fon ctionnement.

Under Industry Canada regulations, this radio t ransmitter may only operate using an antenna of a type and maximum (or lesser) gain approved for the transmitter by Industry Canada.

To reduce potential radio interference to other users, the antenna type a nd its ga in should be so chose n that t he equ ivalent isot ro p ically rad iat ed po wer (e.i.r. p.) is not more than that

necessary for successful communication.

Conformément à la réglementation d'Industr ie Ca nada, le présent émetteur radio peut fonctionner avec une antenne d'un type et d'un gain maximal (ou inférieur) approuvé pour

l'émetteur par Industrie Canada. Dans le but de réduire les risques de brouillage radioélectrique à l'intention des autres utilisateurs, il faut cho isir le t ype d'antenne et son gain de sorte

que la pu issance isotrope rayonnée équivalente (p.i.r . e.) ne dépasse pas l'inten s ité néces saire à l'établissement d'une communication satisfaisante.

Approvals

Gilbarcois anISO 9001:2008registeredcompany.

Underwriters Laboratories (UL):

U L File# Products listed withU L

MH1941

MH8467 Transac System 1000 and PAM 1000

E105106 DellDHM Minitower

E165027 G-SITEandPassport Systems

All Gilbarco pumps and dispensers that bear

theUL listing mark.

California Air Resources Board (CARB):

ExecutiveOrder# Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

National Conference of Weights and Measures (NCWM) - Certificate of Conformance (CoC):

Gilbarco pumps and dispensers areevaluated by NCWM u nder the NationalType Evaluation Pro gram (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model #

02-019 Encore Nxx 02-036 Legacy Jxxx

02-020 Eclipse Exx G-SITE Printer (Epson) PA0307

02-025

02-029 CRIND — G-SITE Mini Tower PA0301

Meter - C Series PA024NC10 G-SITE Distribution Box PA0306

Meter - C Series PA024TC10 G-SITE Keybo ard PA0304

02-037

TS-1000 Console — G-SITE Monitor PA0303

TS-1000 Controller PA0241 G-SITE Printer (Citizen) PA0308

02-030 Distribution Box PA0242 02-038 C+ Meter T19976

Meter - EC Series PA024EC10 02-039 Passport PA0324

VaporVac Kits CV 02-040 Ecometer T20453

05-001 Titan KXXY Series

Trademarks

Non-registered

Applause™Media Sys tem G-SITE®Lite™SMART Meter

™

CIM

™

C-PAM

™

G-SITE®Link

trademarks

™

™

Highline

™

Horizon

™

™

SMART CRIND

™

™

SmartPad

Surge Management System

™

™

™

™

™

™

Registeredtrademarks

CRIND

Dimension®Series Legacy

™

e-CRIND

®

®

®

InfoScreen

®

Transac

Transac®System 1000

Making Things Better®Trimline

®

®

®

®

®

®

®

Additional US and fo r eign trademarks pending.

Other brand or product names s ho wn m a y be

trademarks or registered trademarks of their

respective ho ld ers.

This document is subject to c hange without notice.

E-mail: literature@gilbarco.com · Internet: http://www.gilbarco.com

2013 Gilbarco Inc. All Rights Reserved

Table of Contents

Table of Contents

1 – Introduction 1

TRIND Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

About TRIND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

How TRIND Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Related Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

TRIND Kit Coverage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2 – Important Safety Information 5

ry

3 – Systems Overview 9

Full Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Hand Held Only Tag System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4 – Major Hardware Components 13

Card Cage Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

T20229-G1 Card Cage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

T20229-G1 Card Cage Assembly Parts List 4- . . . . . . . . . . . 14

T20606-G2 Card Cage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

T20606-G2 Card Cage Assembly Parts List 4-. . . . . . . . . . . . .15

re

T20606-G3 Card Cage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

T20606-G3 Card Cage Assembly Parts List 4- . . . . . . . . . . . . .16

P

T20606-G5 Card Cage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

T20606-G5 Card Cage Assembly Parts List 4- . . . . . . . . . . . . .17

Disassembly and Installation For MPD®-3 Units with SID Displays . . . .17

Disassembly and Installation For All MPD-3 Units. . . . . . . . . . . . . . . . . .17

AC EMI Line Filter Q10895 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Transformers R20600 and R20719 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Power Supply Boards T20138 and T20314. . . . . . . . . . . . . . . . . . . . . . .18

T20138 Power Supply Board. 4-. . . . . . . . . . . . . . . . . . . . . . . . .18

T20314 Power Supply Board. 4-. . . . . . . . . . . . . . . . . . . . . . . . .19

Data Control Boards Q13563 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

UHF Receiver Board Q13564 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Transmitter Board Q13579. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Gateway Boards T20128, T20678 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Card Cage Cable Harness T20662-G2 . . . . . . . . . . . . . . . . . . . . . . . . . .23

Full System TRIND R20520-G1 Transmitter Cable . . . . . . . . . . . . . . . . .23

Full System TRIND R20525-G1 RS-485 Communication Cable. . . . . . .24

Full System TRIND R20763-GX Power Supply Cables. . . . . . . . . . . . . .24

Hand-Held TRIND System M00507 Ribbon Cable . . . . . . . . . . . . . . . . .25

Hand-Held TRIND System M01366 Power Cable . . . . . . . . . . . . . . . . . .25

TRIND Overhead Antennas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

T20231 Mobil Overhead Antenna Assembly . . . . . . . . . . . . . . . . . . . . . .26

T20231 Mobil Overhead Antenna Assembly Parts List 4- . . . . .26

T20231 Mobil Overhead Antenna Bracket Assemblies and

Hardware for The Advantage Series 4-. . . . . . . . . . . . . . . . . . . .28

im

l

na

i

MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013 Page 1

Table of Contents

T20231 Mobil Overhead Antenna Bracket Assemblies and

Hardware for the MPD-3 4- . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

T20632 Single-Loop Overhead Antenna Assembly . . . . . . . . . . . . . . . . 29

T20632 Single-Loop Overhead Antenna Assembly Parts

List (Domestic) 4-. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

T20632 Single-Loop Overhead Antenna Assembly

Parts List (International) 4-. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

T20632 Single Loop Antenna Assembly Bracket Kits for

The Advantage Series 4- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

T20632 Single Loop Antenna Assembly Bracket Kits for

the MPD-3 Series 4-. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

T20632 Single Loop Antenna Assembly Bracket Kit for

the Encore Unit 4- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Ultra High Frequency Antenna Q13851-01 and Q13851-02. . . . . . . . . . 33

Antenna Tuning Board T20579-GX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

TRIND Option Doors With Antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

MPD-3 Bezel Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

T20616-G1 MPD-3 Bezel Assembly Parts List 4-. . . . . . . . . . . 35

T20616-G2 MPD-3 Bezel Assembly Parts List 4-. . . . . . . . . . . 36

T20251-G1 MPD-3 Bezel Assembly Parts List 4-. . . . . . . . . . . 37

Advantage Wide Frame Option Door Assemblies. . . . . . . . . . . . . . . . . . 38

T20228-G1 Advantage Wide Frame Option Door Assembly

Parts List 4- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

T20613 Advantage Wide Frame Option Door Assembly

Parts List 4- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Advantage Narrow Frame Option Door Assemblies. . . . . . . . . . . . . . . . 40

T20614 Narrow Frame Option Door Assembly Parts List 4- . . . 40

T20253-G1 Narrow Frame Option Door Assembly Parts List 4- 41

Encore CIM Door Option Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Encore CIM Door Option Assembly Parts List 4-. . . . . . . . . . . . 42

Eclipse Ovendoor Option Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Light/Microreader PCB T20446-G1, T20601-GX, M01580A001,

and M01580A002 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Light/Microreader PCB M01218A001 and M01218A002 . . . . . . . . . . . . 45

Hand-Held Antenna PCB T20143-G1. . . . . . . . . . . . . . . . . . . . . . . . . . . 46

TRIND Antenna PCA T20524-G1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

System Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

M00878 Low/High Frequency Antenna Cable . . . . . . . . . . . . . . . . . . . . 47

R20773 Power and Data Option Door Cable . . . . . . . . . . . . . . . . . . . . . 47

R20437-G01 TRIND to CRIND Logic Cable (Advantage and MPD-3) . . 48

M00515A002 TRIND to CRIND Logic Cable For Encore 500

and Eclipse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

M001804A001 TRIND to CRIND Logic Cable for Encore 300 . . . . . . . . 49

R20580 and M00811A001 AC Power Cables. . . . . . . . . . . . . . . . . . . . . 49

Full System Cable Connections on the Legacy Advantage

Series Dispensers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Full System Cable Connections on the MPD-3 Dispensers . . . . . . . . . . 51

Full System Cable Connections on The Advantage Series and

MPD-3 Dispensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Hand-Held System Cable Connections on The Advantage Series

and MPD-3 Dispensers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Full System Cable Connections on Encore 500 Dispensers. . . . . . . . . . 54

Hand-Held System Cable Connections on Encore 500 and

Eclipse Dispensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

relim

Eclipse Ovendoor Option Assembly Parts List 4- . . . . . . . . . . . 43

P

na

i

y

r

Page 2 MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013

Table of Contents

M00878A001 and M00878A002 Antenna Cable Pin-to-Pin

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

M00515A002 Ribbon Cable Pin-to-Pin Connections . . . . . . . . . . . . . . . .56

R20509-G1 Antenna Cable, Low Frequency Pin-to-Pin Connections . . .56

R20519-G1, -G2 and -G3 Light/Microrea d er Cabl es Pin-to -Pin

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

R20521-G1 and -G2 Interface Microreader Cables Pin-to-Pin

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

R20522-G1 Interface Hand Held Antenna Cable Pin-to-Pin

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

R20522-G2 Interface Hand Held Antenna Cable Pin-to-Pin

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

R20526 TI/RFID Dummy Load Transmitter Cable Pin-to-Pin

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

R20437-G01 TRIND to CRIND Logic Cable Pin-to-Pin Connections . . .58

Advantage Option R20773-G2 TRIND Data and Power Cable

Pin-to-Pin Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Encore Option R20773-G2 TRIND Data and Power Cable

Pin-to-Pin Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

T20662-G2 TRIND Card Cage Cable Harness Cable Pin-to-Pin

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

na

i

ry

5 – System Accessories 61

ASC TRIND Tool Kit K94577-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Standalone Jumper Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Standalone Jumper Cable R20602-G1 For LF/UHF Full System . . . . . .61

Standalone Jumper Cable R20602-G2 For Enhanced Gateway. . . . . . .63

Dummy Load Transmitter R20526 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Co-Axial Cable Tool Q13628-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Field Strength Sensor Board Q13626-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Test Tags Q13630-01 and Q13630-02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Tuning Tool Q13631-01 and Q13631-02. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

6 – Procedures for Factory Installed TRIND 69

Positioning Overhead Antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

7 – Dispenser Set-Up 71

Addressing Dither Sync Address for LF/UHF Full System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Setting Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Addressing the Gateway/Enhanced Gateway Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

CRIND Address Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Preparation for Tuning Antennas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Tuning Antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Tuning Single-Loop Antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Mobil Antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

re

P

Q13630-01 Hand-Held Test Tag 5-. . . . . . . . . . . . . . . . . . . . . . .66

Q13630-02 Car-Mount Test Tag 5-. . . . . . . . . . . . . . . . . . . . . . .66

im

l

8 – Testing and Troubleshooting 79

MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013 Page 3

Table of Contents

Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

T20128 Gateway Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

T20678 Enhanced Gateway Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Q13563 Data Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

T20601/M01560 Light/Micro Reader Boards . . . . . . . . . . . . . . . . . . . . . 83

Isolating TRIND from CRIND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Tag Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Car Mounted Test Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Hand Held Test Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Alternative Testing Using Laptop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Troubleshooting Printed Circuit Boards on the T202 29 - G 1 Card Cage Assembly. . . . . . . . . . . . . . . . 87

Light/Micro-Reader Board T20295-G1 . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Gateway PCB T20128-G1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Transmitter PCB Q13579-01. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Data Control Board Q13563-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

TI/RFID Power Supply T20138-G1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Troubleshooting Flow Charts for the T20606 Card Cage System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

TRIND Troubleshooting Flow Chart (Sheet 1 of 4). . . . . . . . . . . . . . . . . 90

TRIND Troubleshooting Flow Chart (Sheet 2 of 4). . . . . . . . . . . . . . . . . 91

TRIND Troubleshooting Flow Chart (Sheet 3 of 4). . . . . . . . . . . . . . . . . 92

TRIND Troubleshooting Flow Chart (Sheet 4 of 4). . . . . . . . . . . . . . . . . 93

Field Problem Survey. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

na

i

y

r

9 – Glossary Glossary-95

Appendix A - Radio Frequency Identification Defined A-97

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-97

What is RFID? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-99

Wireless Communication and Air Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-100

Data Transfer Rate and Bandwidth. . . . . . . . . . . . . . . . . . . . . . . . . . A-101

Range and Power Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-102

Transponders/Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-103

Basic Features of an RFID Transponder . . . . . . . . . . . . . . . . . . . . . A-103

Powering Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-104

Data Carrying Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-104

Data Read Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-105

Data Programming Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-105

Physical Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-105

Costs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-106

Reader/Interrogator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-106

RF Transponder Programmers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-106

RFID System Categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-107

Appendix B - Cable Block Diagrams and Interconnects B-109

R20515 Cable Block Diagram, Revision F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-109

R20516 Interconnect Diagrams, Sheet 1 of 3, Revision E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-110

R20516 Interconnect Diagrams, Sheet 2 of 3, Revision C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-111

R20516 Interconnect Diagrams, Sheet 3 of 3, Revision E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-112

R20762 Cable Block Diagrams, Sheet 1 of 2, Revision J . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-113

R20762 Cable Block Diagrams, Sheet 2 of 2, Revision J . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-114

T20607 Interconnect Diagrams, Sheet 1 of 4, Revision H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-115

T20607 Interconnection Diagrams, Sheet 2 of 4, Revision H. . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-116

T20607 Interconnection Diagrams, Sheet 3 of 4, Revision H. . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-117

relim

P

Page 4 MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013

Table of Contents

T20607 Interconnection Diagrams, Sheet 4 of 4, Revision H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-118

R20775 Cable Block Diagrams, Sheet 1 of 2, Revision D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-119

R20775 Cable Block Diagrams, Sheet 2 of 2, Revision D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-120

T20663 Interconnect Diagrams, Sheet 1 of 3, Revision C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-121

T20663 Interconnection Diagrams, Sheet 2 of 3, Revision C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-122

T20663 Interconnection Diagrams, Sheet 3 of 3, Revision C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-123

ry

na

i

re

P

im

l

MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013 Page 5

Table of Contents

This page is intentionally left blank.

relim

P

y

r

na

i

Page 6 MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013

1 – Introduction

TRIND Overview

The TRIND system is similar to the technology successfully used by many toll ways. It uses

an electronic system located in the pump or register to “talk” with a miniature radio-like

device (a tag). Together, these electronic devices provide “cashless” access to gasoline, food

and merchandise by charging purchases to a credit card, check card, or other account you

already have. The TRIND system operates on a dedicated tag identification code. Your credit

card or check card account numbers are not typically used with the tag signal system, which

protects your account from unauthorized use. And if your tag is ever lost or stolen, your

liability is limited to the amount set by your financial institution.

The TRIND device is an option available as a retrofit kit or factory installed device for The

®

Advantage

connected to the CRIND

the TRIND device is a software slave to the CRIND and the associated Point Of Sale (POS)

Controller/Host. This means that a properly working TRIND system will look for and read

tags, but only when “told” to by the controller, through the CRIND application.

Series, MPD®-3, Eclipse®, and Encore™ lines of fuel dispensers. The device is

TRIND Overview

®

device via a Gateway or serial interface board. In this application,

ary

n

i

About TRIND

The TRIND devices are developed to utilize Texas Instruments Radio Frequency

Identification (RFID) technology. These devices provide two-way communications between

an interrogator system in the fuel dispenser and the consumer’s hand held or car mounted

transponder tag. This two-way communication authorizes and records sales, eliminating the

need for the consumer to engage in a cash or credit card transaction.

eli

r

m

P

MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013 Page 1

How TRIND Works

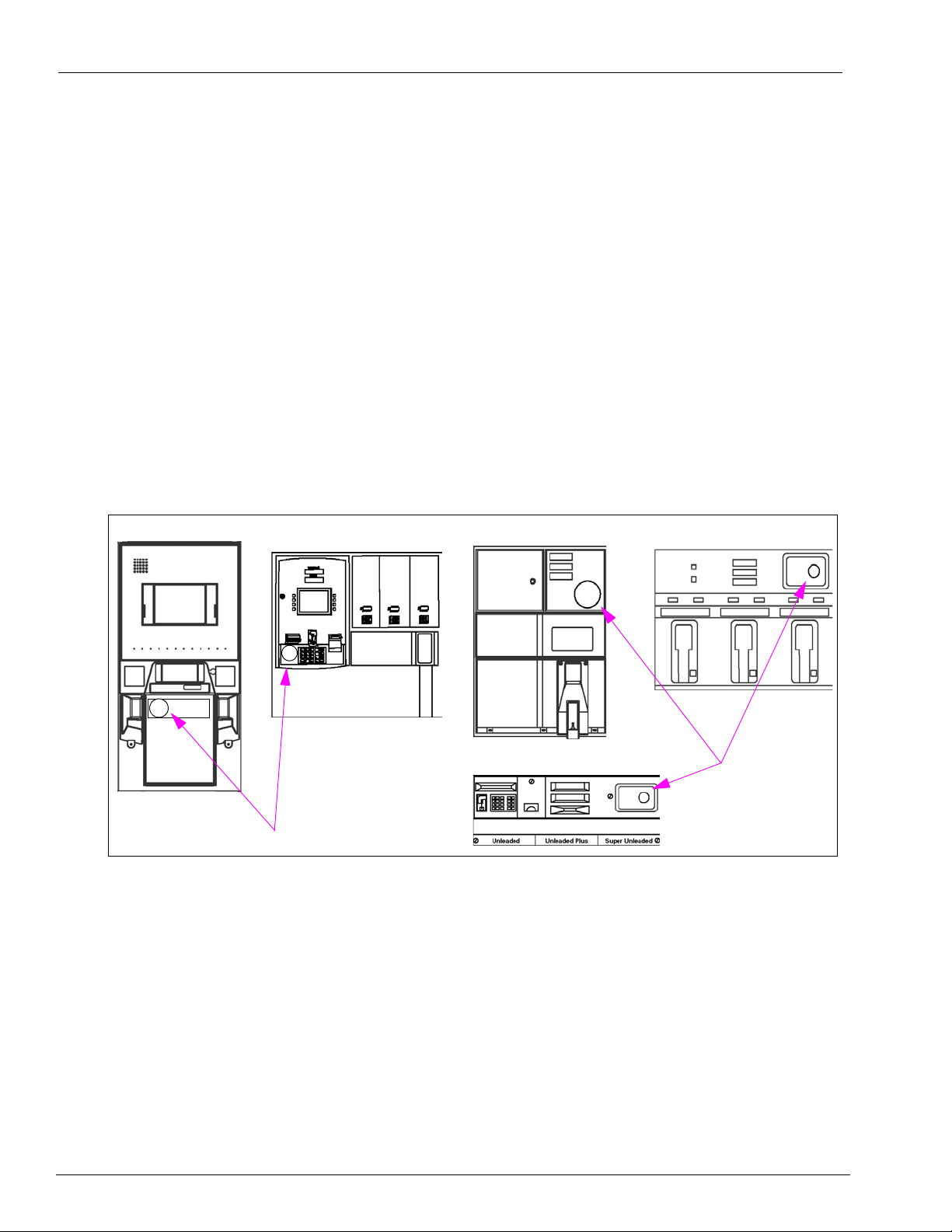

Eclipse

Target Graphic

Encore

MPD-3

Advantage Narrow Frame (36")

Advantage Wide Frame (48")

Target Graphic

How TRIND Works

TRIND utilizes radio frequency (RF) waves to communicate with a customer’s transponder.

Transmitters located on overhead assemblies transmit radio waves that serve as a “wake up”

call. As a car mounted transponder or hand held transponder enters the transmitter’s effective

read zone, the transponder is activated. The transponder then transmits a code which is

received by the TRIND antennas mounted overhead or on the option doors.

This transmitted code is communicated from the TRIND to the CRIND unit, and from there to

the POS (point of sal

Car mounted transponders are activated when they are within six feet of the front of the

dispenser perpendicular to front of dispenser. Hand held transponders, usually on a k ey chain,

function when pointed at a target graphic on the option door. Two-way communication is

indicated when the option door target graphic light comes on, whether by car mount or hand

held transponder signal.

Figure 1-1: Encore and Eclipse Target Graphic Location

e). The POS system communicates with a host to obtain authorization.

r

P

n

i

m

eli

ary

Page 2 MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013

Related Documents

Related Documents

Document

Number Title GOLD Library

MDE-2530 Pump and Dispenser Installation Manual Advantage & Legacy Models

MDE-2531 Start-up and Service Manual for The Advantage Series Service Manual

MDE-2540 The Advantage, Legacy & MPD Series Owners Manual Advantage & Legacy Models

MDE-2562 CRIND Service Manual CRIND and TRIND

MDE-3425 CRIND Retrofit Kit and CRIND Kit Selection Guide CRIND and TRIND

MDE-3591 TRIND Retrofits Kits C00011-002-XXXX CRIND and TRIND

MDE-3801 TRIND Multi 1 Retrofits Kits Manual CRIND and TRIND

MDE-3883 TRIND TIRIS C00011-005 Kit Installation Manual CRIND and TRIND

MDE-3917 TRIND TIRIS Encore 500 Retrofit Kit Installation Manual CRIND and TRIND

MDE-3920 Encore 300 & 500 TRIND Retrofit Kit Installation CRIND and TRIND

MDE-4063 TRIND TIRIS Advantage and MPD-3 Retrofit Kit

MDE-4073 TRIND TIRIS C00011-006 Retrofit Kit Installation CRIND and TRIND

PT-1728 The Advantage Illustrated Parts Manual Parts Manual

PT-1736 The Advantage/MPD/CRIND Illustration Parts Manual Parts Manual

nsta

I

CRIND and TRIND

llation Manual

ary

n

i

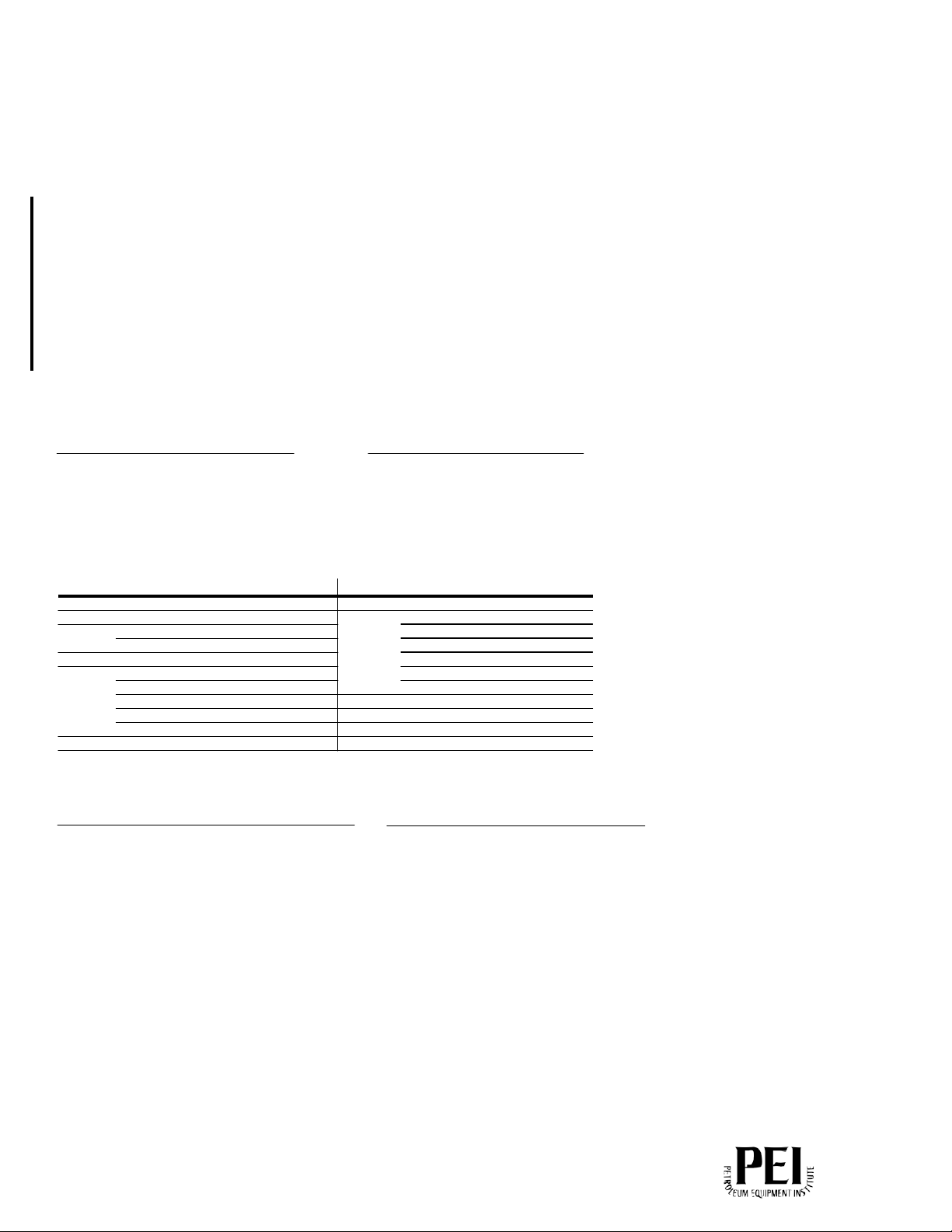

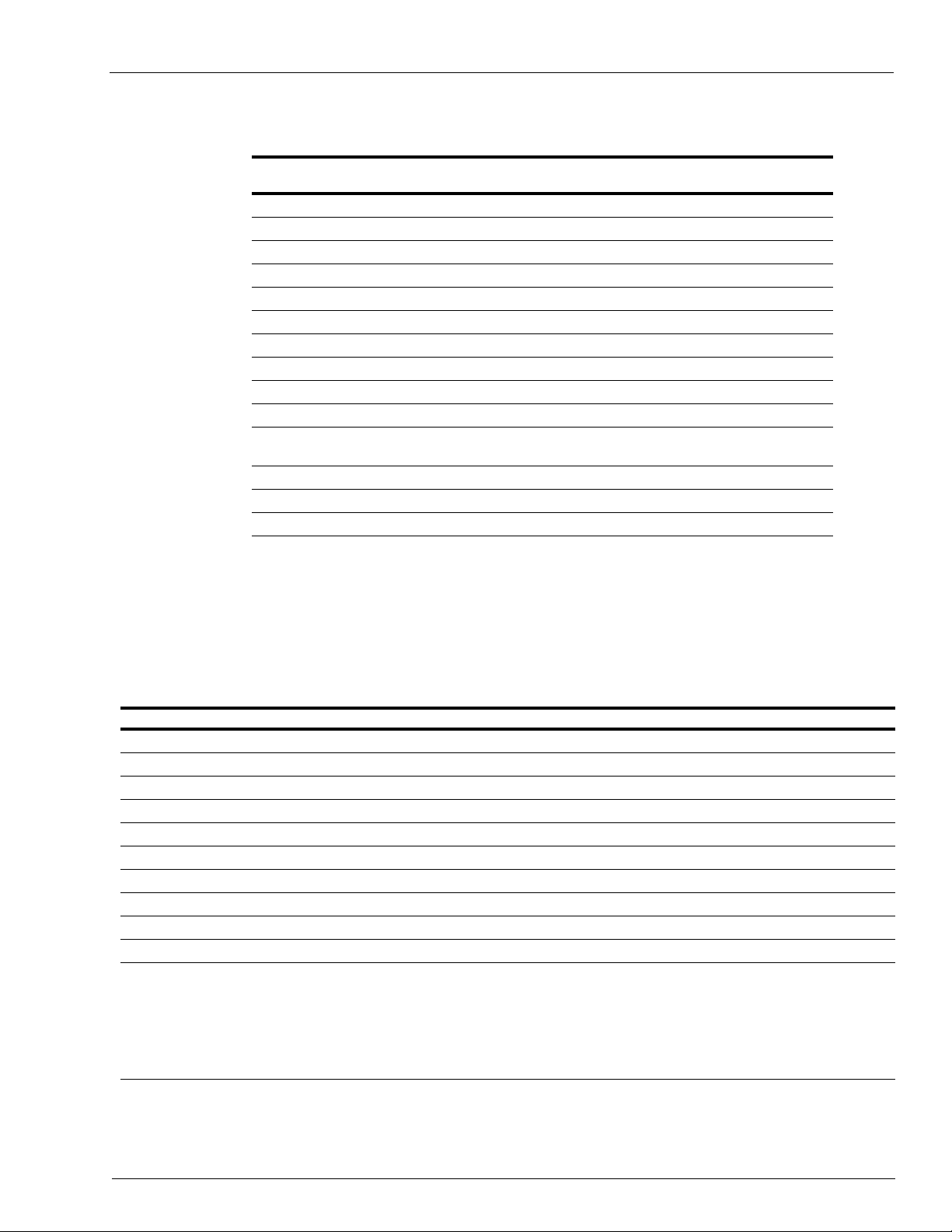

TRIND Kit Coverage

The following table provides TRIND kit numbers and the relative system coverage that

applies to each.

m

eli

Kit Number Product Coverage Frequencies Interface Type Tag System

C00011-001 Advantage, MPD-3 LF/UHF T20229-G1 Card Cage Hand Held/Car Mounted

C00011-002 Advantage, MPD-3 LF/UHF (note 2) T20606-G2 Card Cage Hand Held/Car Mounted

C00011-005 Advantage, MPD-3 LF (note1) T20606-G3 Card Cage Hand Held

C00011-004 Encore 500 LF/UHF T20606-G2 Card Cage Hand Held/Car Mounted

C00011-006 Encore 500, Eclipse LF T20606-G3 Card Cage Hand Held

C00011-007 Advantage, MPD-3 LF/UHF (ETSI) (note 3) T20606-G5 Card Cage Hand Held/Car Mounted

C00011-008 Encore 500 LF/UHF (ETSI) T20606-G2 Card Cage Hand Held/Car Mounted

C00011-009 Advantage, MPD-3 LF/UHF T20606-G5 Card Cage Hand Held/Car Mounted

C00011-010 Advantage, MPD-3 LF/UHF T20606-G2 Card Cage Hand Held/Car Mounted

C00012-00X Advantage, MPD-3 HF (note 4) T20538-G1/G2 Card Cage Hand Held

Notes:

1. LF = Low Frequency (134 kHz) send and receive for Hand Held Tags.

2. LF/UHF = Low Frequency (134kHz) send, and Ultra High Frequency (902 MHz)

Held Tags.

3. LF/UHF (ETSI) = Low Frequency (134 kHz) send and Ultra High Frequency (868 MHz) rece

for Hand Held Tags.

4. HF = High Frequency (13.56 MHz) send and receive for Hand Held Tags.

r

P

receive for Car Tags. Low Frequency (134 kHz) for Hand

ive for Car Tags. Low Frequency (134 kHz)

MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013 Page 3

TRIND Kit Coverage

This page is intentionally left blank.

r

P

ary

n

i

m

eli

Page 4 MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013

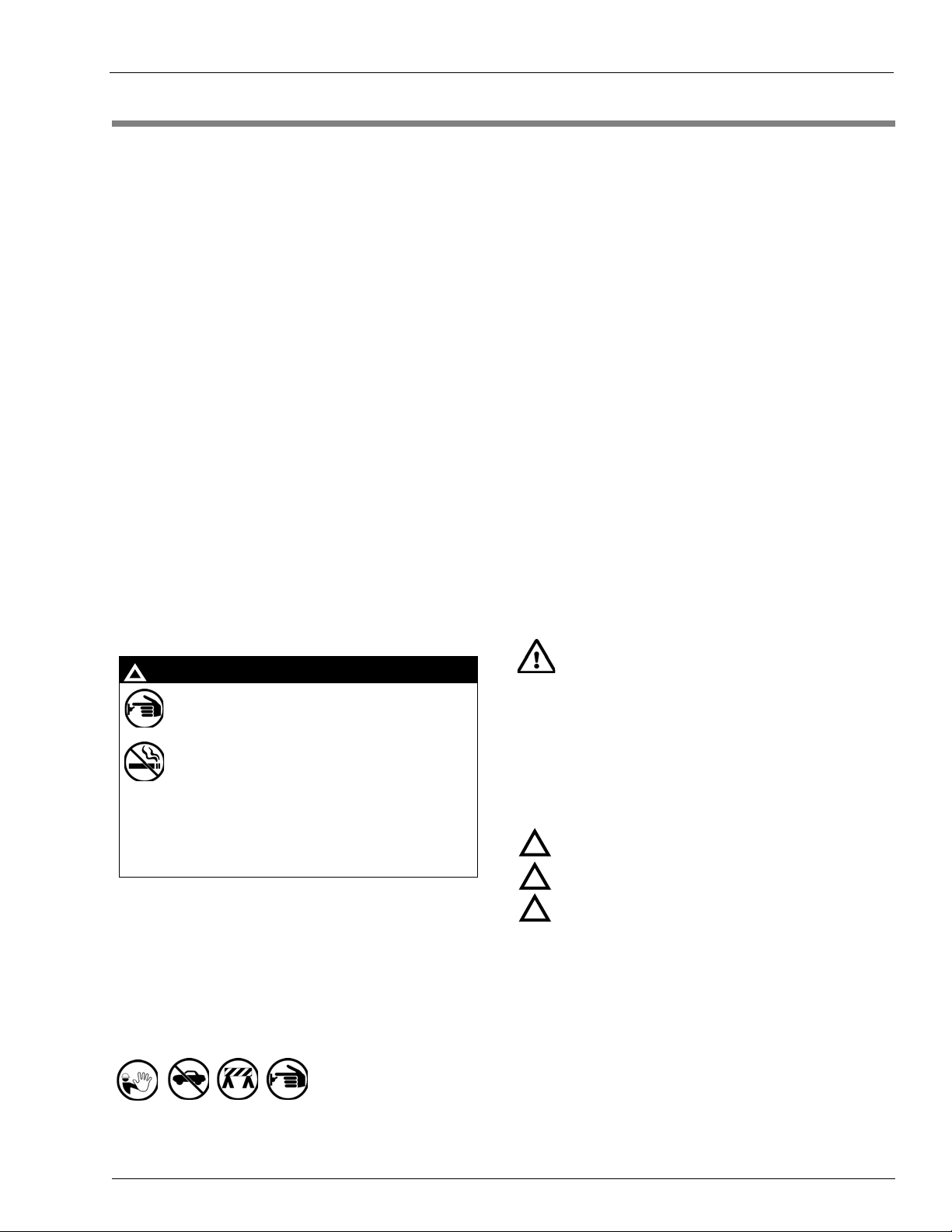

2 – Important Safety Information

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier ’s station

WILL NOT shut off electrical power to the

pump/dispenser. This means that even if you

activate these stops, fuel may continue to flow

uncontrolled.

You must use the TOTAL ELECTRICAL

SHUT-OFF in th e cas e of an emerge nc y a nd not

the console’s ALL STOP and PUMP STOP or

similar keys.

!

WARNING

!

Important Safety Information

Notes: 1) Save this Important Safety Information section

in a readily accessible location.

2) Although DEF is non-flammable, Diesel is

flammable

attached to Diesel dispensers, follow all the

notes in this section that pertain to flammable

fuels.

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death o r serious injury,

if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is how

to stop all fuel flow to the pump/dispenser and island. Locate

the switch or circuit breakers that shut off all power to all fueling

equipment, dispensing devices, and Submerged Turbine

Pumps (STPs).

. Therefore, for DEF cabinets that are

m

Read the Manual

Read, understand and follow this manua l and any other labels

or related materials supplied with this equipment. If you do not

understand a procedure, call a Gilbarco Authorized Service

Contractor or call the Gilbarco Support Center at

1-800-800-7498. It is imperative to your safety and the safe ty of

others to unders

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupatio nal Safety and Health Administr ation

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lead to legal citations

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gilbarco replacement pa rts and retrofit kit s on

your pump/dispenser. Using parts other than genuine Gilbarco

replacement parts could create a safe ty hazard and violate

ary

local regulations.

tand the procedures before beginning work.

n

Safety Symbols and Warning Words

i

This section provides important information about warning

symbols and boxes.

Alert Symbol

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical component s or

the electronics of the dispenser requires total electrical shut off

of that unit. Understand the function and location of this switch

or circuit breaker before inspecting, installing, maintaining, or

servicing Gilbarco equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

• An evacuation of all unauthorized persons and vehicles from

the work area

• Use of safety tape, cones or barricades at the affected unit(s)

• A total electrical shut-off of the affected unit(s)

MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013 Page 5

r

P

eli

This safety alert symbol is used in this manual and on

warning labels to alert you to a precaution which must be

followed to prevent po

safety directives that follow this symbol to avoid possib le inj ury

or death.

Signal Words

These signal words used in this manual and on warning labels

tell you the seriousness of particular safety hazards. The

precautions below must be followed to prevent death, injury or

damage to the equipment:

DANGER: Alerts you t

!

which will result in death or serious injury.

WARNING: Alert

!

that could result in death or serious injury.

CAUTION with Alert symbol: Designates a hazard or

!

unsafe

practice which may result in minor injury.

CAUTION without A

unsafe practice which may result in property or

equipment damage.

tential personal safety hazards. Obey

o a hazard or unsafe practice

s you to a ha

lert symbol: Designates a hazard or

zard or unsafe practice

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled or

leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

DEF is non-flammable. Therefore, explosion an

warnings do not apply to DEF fluid lines.

d fire safety

Important Safety Information

The pump/dispenser contains a chemical known to the

State of California to cause cancer.

WARNING

!

The pump/dispenser contains a chemical known to the

State of California to cause birth defects or other

reproductive harm.

WARNING

!

Gasoline/DEF ingested may cause

unconsciousness and burns to internal organs.

Do not induce vomiting. Keep airway open.

Oxygen may be needed at scene. Seek medical

advice immediately.

DEF generates ammonia gas at high er temperatures.

When opening enclosed panels, allow the unit to air out to

avoid breathing vapors.

If respiratory difficulties develop, move victim away from

source of exposure and into fresh air. If symptoms persist,

seek medical attention.

WARNING

!

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled in eyes may cause burns to

eye tissue.

Irrigate eyes with water for approximately

15 minutes.

Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled on skin may cause burns.

Wash area thoroughly with clear water.

Seek medical advice immediately.

WARNING

!

DEF is mildly corrosive. Avoid contact with eyes, skin, and

clothing. Ensure that eyewash stations and safety

showers are close to the work location. Seek medical

advice/recommended treatment if DEF spills into eyes.

WARNING

!

No Open Fire

Open flames from matches, lighters, welding torches or

other sources can ignite fuels and their vapors

No Sparks - No Smoking

Sparks from st arting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and their

vapors. Static electricity, including an electrostatic charge on

your body, can cause a spark sufficient to ignite fuel vapors.

Every time you get out of a vehicle, touch the metal of your

vehicle, to discharge any electrostatic charge before you

approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods, if

you work with or around high voltages. This information is

available from the American Red Cross . Alw ay s advise the

station personnel about where you will be working, and caution

them not to activate power while you are working on the

equipment. Use the OSHA Lockout/Tagout procedures. If you

are not familiar with this requirement, refer to this information in

the service manual and OSHA documentation.

Working With Electricity Safely

Ensure that you use safe and established practices in working

with electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Ensure that grounding

connections are properly made. Take care that sealing devices

and compounds are in place. Ensure that you do not pinch wires

when replacing covers. Follow OSHA Lockout/Tagout

requirements. Station employees and service contractors need

to understand and comply with this program completely to

ensure safety while the equipment is down.

.

eli

r

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

• Location of accident (for example, addre

building, and so on)

• Nature of accident (for example, poss

over by car, burn s, and so on)

• Age of victim (for example, baby, teenager, middle-age,

lderly)

e

• W

hether or not victim has received first aid (for example,

stopped

• Whether or not a victim has vomited (for example, if

swallowe

bleeding by pressure, and so on)

d or inhaled something, and so on)

ss, front/back of

ible heart attack, run

ary

n

i

m

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly . Ensure that you

clean hands after handling equipment. Do not place any

equipment in the mouth.

Page 6 MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013

P

IMPORTANT: Oxygen may be needed at scene if gasolin e ha s

been ingested or inhaled. Seek medical advice immediately.

Lockout/Tagout

Lockout/Tagout covers servicing and maintenance of machines

and equipment in which the unexpected energization or st art-up

of the machine(s) or equipment or release of stored energy

could cause injury to employees or personnel. Lockout/Tagout

applies to all mechanical, hydraulic, chemical, or other energy,

but does not cover electrical hazards. Subpart S of 29 CFR Part

1910 - Electrical Hazards, 29 CFR Part 1910.333 contains

specific Lockout/Tagout provision for electrical hazards.

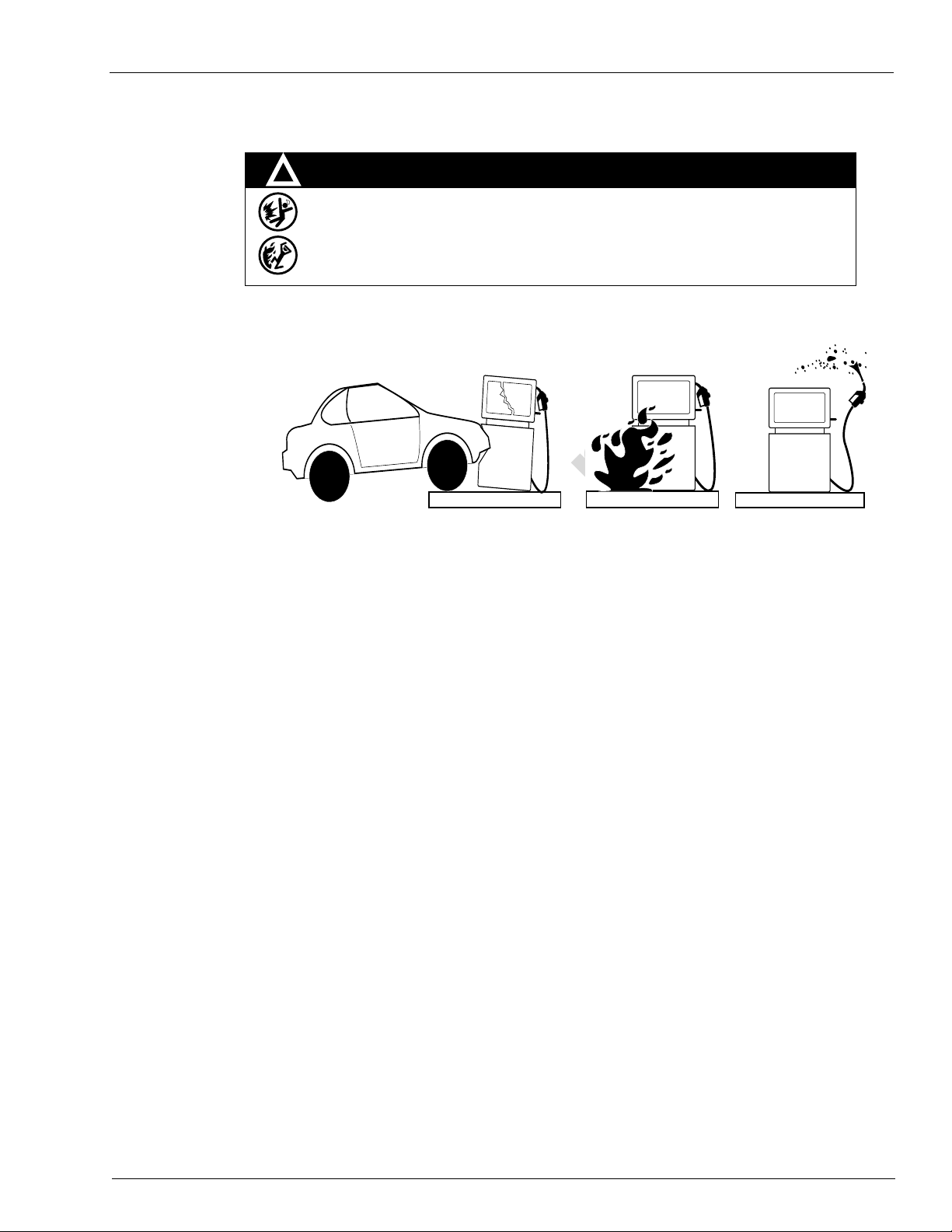

Hazards and Actions

WARNING

Spilled fuels, accidents involving pumps/dispensers, or uncontrolled fuel flow create a

serious hazard.

Fire or explosion may result, causing serious injury or death.

Follow established emergency procedures.

DEF is non-flammable. However it can create a slip hazard. Clean up spills promptly.

!

Collision of a Vehicle with Unit Fire at Island Fuel Spill

The following actions are recommended regarding these hazards:

Important Safety Information

ary

• Do not go near a fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately. Turn of

• Do not use console E-STOP, ALL STOP, and PUMP STOP to shut off power. These keys do not

remove AC power and do not always stop product flow.

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. Do not allow

open flames, smoking or power

• Do not expose yourself to hazardous conditions such as fire, spilled fuel or exposed wiring.

• Call emergency numbers.

tools in the area.

m

n

i

f all system circuit br

eakers to the island(s).

eli

r

P

MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013 Page 7

Important Safety Information

This page is intentionally left blank.

r

P

ary

n

i

m

eli

Page 8 MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013

3 – Systems Overview

Overhead Antenna Assembly

Side A

T20231-G1

LF Transmitter (134kHz Intentional

Radiator)

Q13579-01

Control Data

UHF Receiver Module

902 - 928 MHz

115 VAC

(FROM Dispenser

AC POWER

DISTRIBUTION)

RS-232 RS-232

Gateway Board

T20128

SERIAL DATA

to CRIND logic boards

(Dispenser Electronics)

J7 J8

J4

P187

P250

P185

22VDC,

5VDC, GND

5VDC,

GND

22VDC,

5VDC, GND

J6

J3

22VDC, 5VDC, GND

22VDC, 5VDC, GND

J5 J5

J2A J2B JA JB

LF TX

UHF RX

Overhead Antenna Assembly

Side B

T20231-G1

UHF RX

LF TX

POWER REGULATING

Circuit Board

T20138-G1

P177P179P176

P175

P178

Light Board Assembly

(T20295, T20446)

on Dispenser Bezel Face

(Side A)

P181

P180,

P182

RS-232, Digital

Control and Light

Control Circuit

P180,

P182

P181

RS-232, Digital

Control and Light

Control Circuit

When overhead antennas are not part of

the product, Dummy Load R20526-G1

plugs into JA and JB. J2A and J2B are

left unconnected.

DATA CONTROL BOARD

Q13563-01 or -02

60VAC

Power Supply

R20600-G1

AC Po wer

EMC Filter

Q10895-01

Micro-Reader

Q13551-01

(134 KHz

Intentional)

Micro-Reader

Q13551-01

(134 KHz

Intentional)

T20143

Bezel

Antenna

R20522-G2

Cable

T20143

Bezel

Antenna

R20522-G2

Cable

Light Board Assembly

(T20295, T20446)

on Dispenser Bezel Face

(Side B)

RS-232

LF TX/RX

LF TX/RX

RS-485

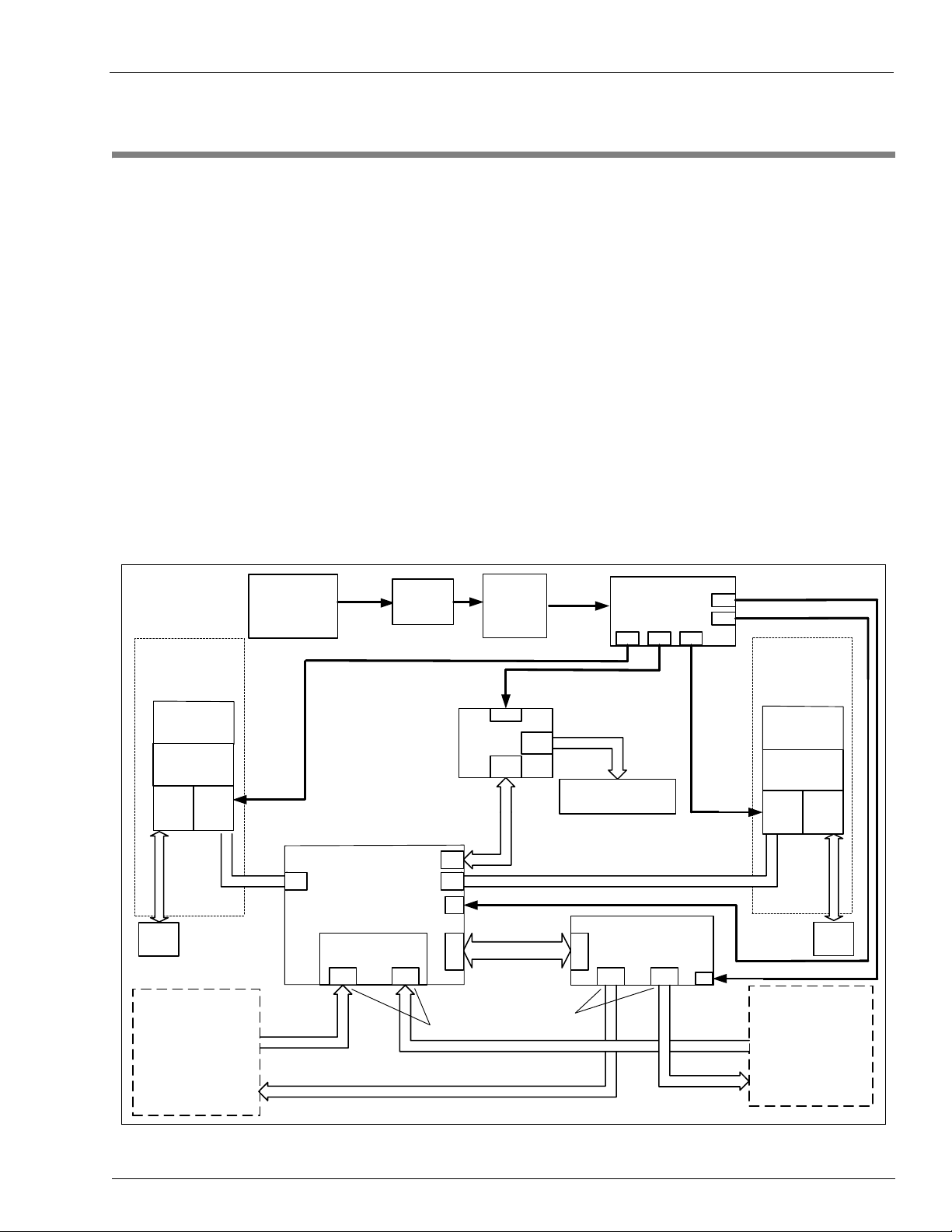

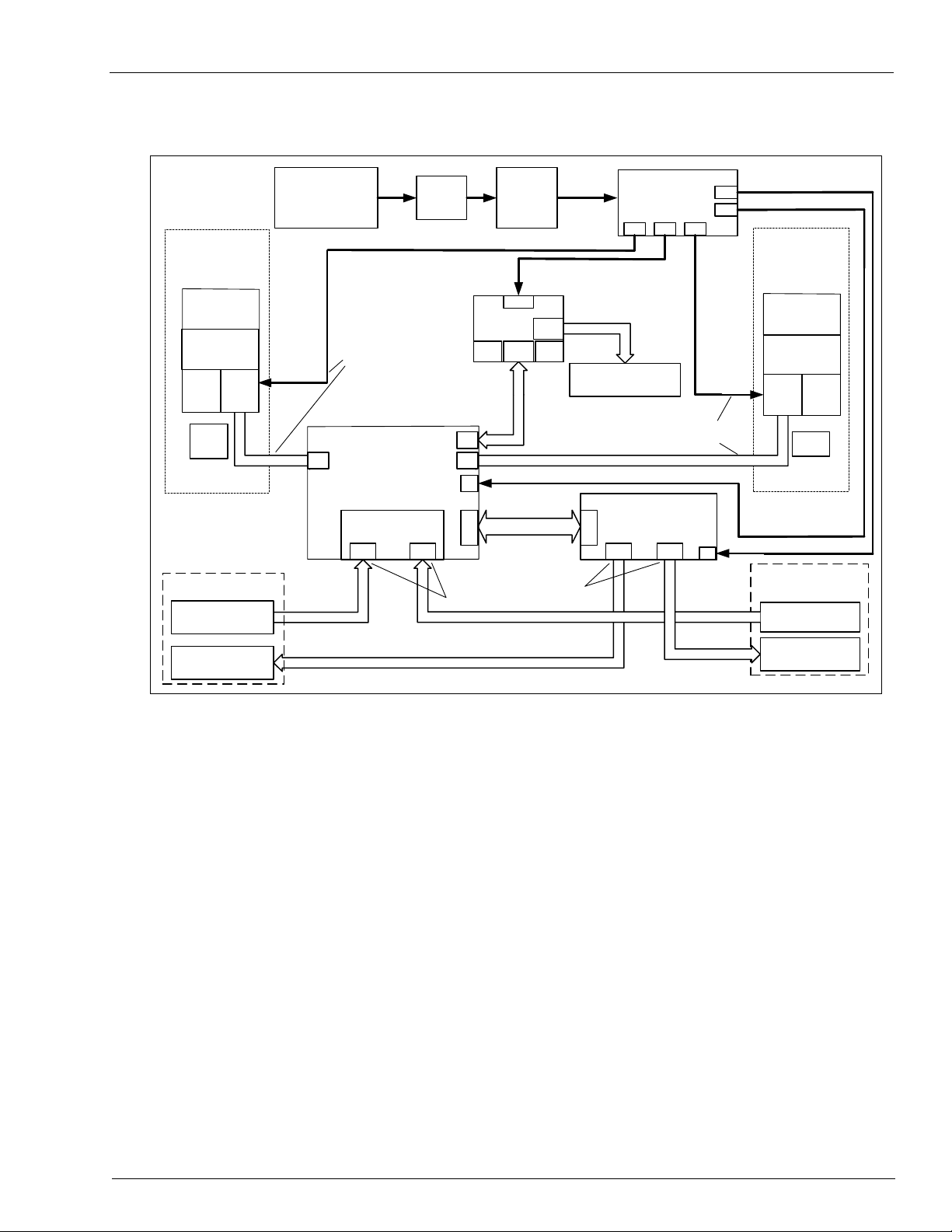

Full Systems

The Full System product is an option available as a retrofit kit or factory installed equipment

on the Advantage, MPD-3 and Encore, and Eclipse lines of fuel dispensers. The TRIND

device is connected to the CRIND via a gateway or serial interface board. In this application

TRIND is a software slave to the CRIND and the associated POS controller/host. This means

that a properly working TRIND system will look for and read tags, but only when told to by

the controller, through the CRIND application.

This system is to be installed in accordance with all Underwriter’s Laboratories (UL), Federal

Communications Commission (FCC), federal, state and local regulations associated with it.

The following illustrations depict the system component used in the Original, Advantage,

MPD-3, and Encore full systems.

Full Systems

Figure 3-1: Original Full System Block Diagram

ary

n

i

m

eli

r

P

MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013 Page 9

Full Systems

O

v

e

r

h

e

a

d

A

n

t

e

n

n

a

A

s

s

e

m

b

l

y

S

i

d

e

A

T

2

0

2

3

1

-

G

1

L

F

T

r

a

n

s

m

i

t

t

e

r

(

1

3

4

k

H

z

I

n

t

e

n

t

i

o

n

a

l

R

a

d

i

a

t

o

r

)

Q

1

3

5

7

9

-

0

1

C

o

n

t

r

o

l

D

a

t

a

U

H

F

R

e

c

e

i

v

e

r

M

o

d

u

l

e

R

I

-

R

F

M

-

H

R

E

A

9

0

2

-

9

2

8

M

H

z

1

1

5

V

A

C

(

F

R

O

M

D

i

s

p

e

n

s

e

r

A

C

P

O

W

E

R

D

I

S

T

R

I

B

U

T

I

O

N

)

R

S

-

2

3

2

R

S

-

2

3

2

G

a

t

e

w

a

y

B

o

a

r

d

T

2

0

1

2

8

S

E

R

I

A

L

D

A

T

A

t

o

C

R

I

N

D

l

o

g

i

c

b

o

a

r

d

s

(

D

i

s

p

e

n

s

e

r

E

l

e

c

t

r

o

n

i

c

s

)

J

7

J

8

J

4

P

1

8

7

P

2

5

0

P

1

8

5

2

2

V

D

C

,

5

V

D

C

,

G

N

D

5

V

D

C

,

G

N

D

2

2

V

D

C

,

5

V

D

C

,

G

N

D

J

6

J

3

2

2

V

D

C

,

5

V

D

C

,

G

N

D

2

2

V

D

C

,

5

V

D

C

,

G

N

D

J

5

J

5

J

2

A

J

2

B

J

A

J

B

O

v

e

r

h

e

a

d

A

n

t

e

n

n

a

A

s

s

e

m

b

l

y

S

i

d

e

B

T

2

0

2

3

1

-

G

1

L

i

g

h

t

B

o

a

r

d

A

s

s

e

m

b

l

y

(

T

2

0

6

0

1

-

G

X

o

r

M

0

1

5

6

0

A

0

0

X

)

o

n

D

i

s

p

e

n

s

e

r

B

e

z

e

l

F

a

c

e

(

S

i

d

e

A

)

P

O

W

E

R

R

E

G

U

L

A

T

I

N

G

C

i

r

c

u

i

t

B

o

a

r

d

T

2

0

3

1

4

-

G

1

P

1

7

7

P

1

7

9

P

1

7

6

P

1

7

5

P

1

7

8

L

i

g

h

t

B

o

a

r

d

A

s

s

e

m

b

l

y

(

T

2

0

6

0

1

-

G

X

o

r

M

0

1

5

6

0

A

0

0

X

)

o

n

D

i

s

p

e

n

s

e

r

B

e

z

e

l

F

a

c

e

(

S

i

d

e

A

)

P

1

8

1

P

1

8

2

R

S

-

2

3

2

,

D

i

g

i

t

a

l

C

o

n

t

r

o

l

a

n

d

L

i

g

h

t

C

o

n

t

r

o

l

C

i

r

c

u

i

t

P

1

8

2

P

1

8

1

R

S

-

2

3

2

,

D

i

g

i

t

a

l

C

o

n

t

r

o

l

a

n

d

L

i

g

h

t

C

o

n

t

r

o

l

C

i

r

c

u

i

t

M

0

0

8

7

8

A

0

0

2

M

0

0

8

7

8

A

0

0

2

M

0

0

8

7

8

A

0

0

2

C

a

b

l

e

C

a

b

l

e

C

a

b

l

e

W

h

e

n

o

v

e

r

h

e

a

d

a

n

t

e

n

n

a

s

a

r

e

n

o

t

p

a

r

t

o

f

t

h

e

p

r

o

d

u

c

t

,

D

u

m

m

y

L

o

a

d

R

2

0

5

2

6

-

G

1

p

l

u

g

s

i

n

t

o

J

A

a

n

d

J

B

.

J

2

A

a

n

d

J

2

B

a

r

e

l

e

f

t

u

n

c

o

n

n

e

c

t

e

d

.

R

2

0

7

7

3

-

G

2

,

d

o

o

r

c

a

b

l

e

,

p

r

o

v

i

d

e

s

p

o

w

e

r

a

n

d

R

S

2

3

2

c

o

m

m

u

n

i

c

a

t

i

o

n

s

R

2

0

7

7

3

-

G

2

,

d

o

o

r

c

a

b

l

e

,

p

r

o

v

i

d

e

s

p

o

w

e

r

a

n

d

R

S

2

3

2

c

o

m

m

u

n

i

c

a

t

i

o

n

s

X

i

s

c

o

l

o

r

o

f

L

E

D

s

D

A

T

A

C

O

N

T

R

O

L

B

O

A

R

D

Q

1

3

5

6

3

-

0

2

o

r

-

0

4

5

M

H

z

(

U

H

F

C

l

o

c

k

-

s

e

l

e

c

t

e

d

b

y

j

u

m

p

e

r

)

1

0

M

H

z

(

L

o

c

a

l

C

l

o

c

k

-

n

o

t

s

e

l

e

c

t

e

d

f

o

r

t

h

i

s

a

p

p

l

ic

a

t

i

o

n

)

2

4

V

A

C

P

o

w

e

r

S

u

p

p

l

y

A

C

P

o

w

e

r

E

M

C

F

i

l

t

e

r

Q

1

0

8

9

5

-

0

1

M

i

c

r

o

-

R

e

a

d

e

r

Q

1

3

5

5

1

-

0

1

(

1

3

4

K

H

z

I

n

t

e

n

t

i

o

n

a

l

)

M

i

c

r

o

-

R

e

a

d

e

r

Q

1

3

5

5

1

-

0

1

(

1

3

4

K

H

z

I

n

t

e

n

t

i

o

n

a

l

)

M

0

0

8

7

8

A

0

0

2

C

a

b

l

e

T

2

0

5

2

4

B

e

z

e

l

A

n

t

e

n

n

a

R

2

0

5

2

2

-

G

2

C

a

b

l

e

T

2

0

5

2

4

B

e

z

e

l

A

n

t

e

n

n

a

R

2

0

5

2

2

-

G

2

C

a

b

l

e

R

S

-

2

3

2

L

F

T

X

/

R

X

L

F

T

X

/

R

X

U

H

F

R

C

V

U

H

F

R

C

V

L

F

T

X

L

F

T

X

R

S

-

4

8

5

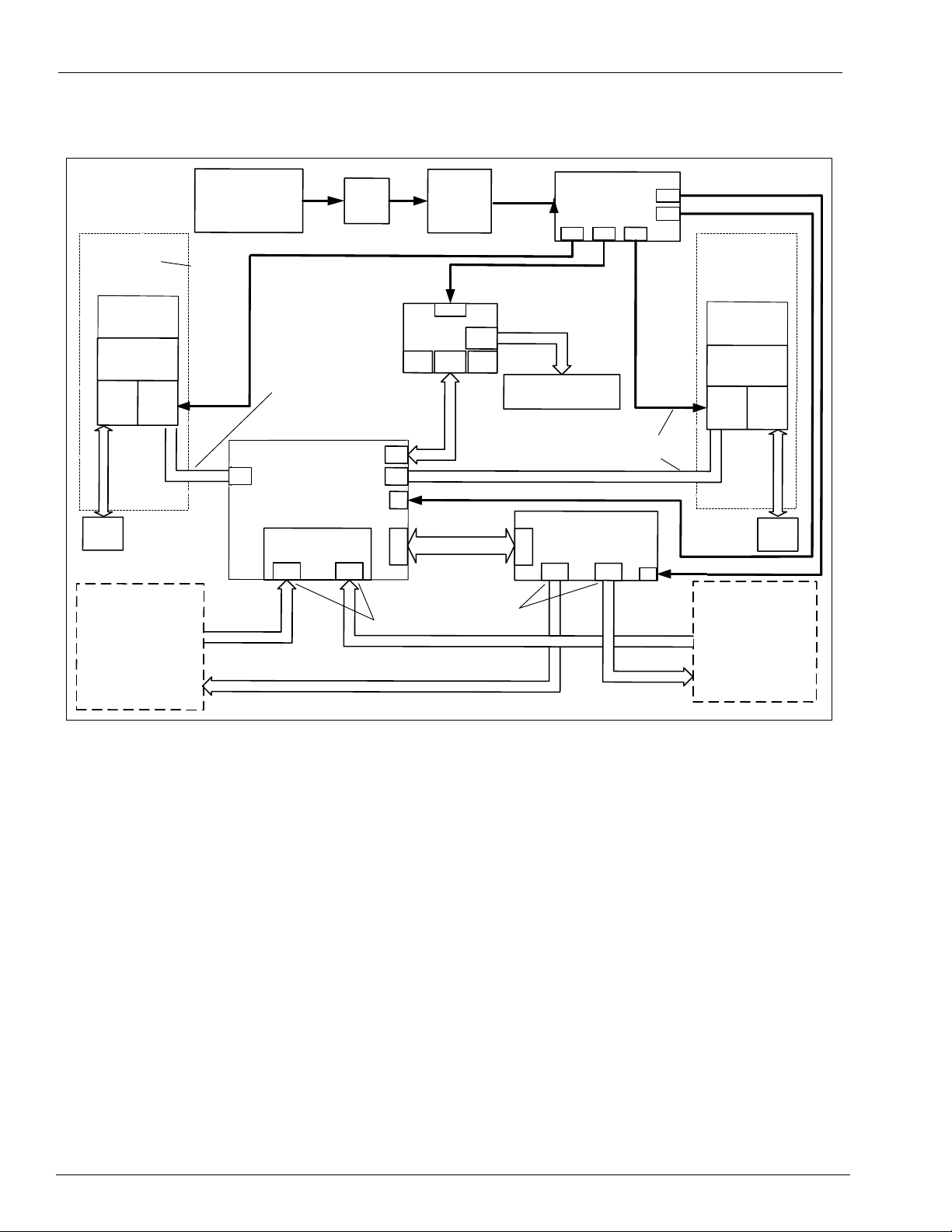

Figure 3-2: Advantage Series Full System Block Diagram

ary

n

i

m

Page 10 MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013

P

r

eli

Figure 3-3: Encore Full System Block Diagram

Overhead Antenna Assembly

Side A

LF Transmitter (134kHz Intentional

Radiator)

Q13579-01

Control Data

UHF Receiver Module

RI-RFM-HRUA

902 - 928 MHz

115 VAC

(FROM Dispenser

AC POWER

DISTRIBUTION)

RS-232

RS-232

Gateway Board

T20128

SERIAL DATA

to CRIND logic boards

(Dispenser Electronics)

P187

P250

P185

22VDC, 5VDC,

GND

5VDC,

GND

22VDC,

5VDC, GND

22VDC, 5VDC, GND

22VDC, 5VDC, GND

J2A J2B

LF Transmit Antenna

UHF Receive Antenna

Overhead Antenna Assembly

Side B

LF Transmit Antenna

UHF Receive Antenna

Light Board Assembly

M01218A00X

on Dispenser Bezel Face

(Side A)

POWER REGULATING

Circuit Board

T20314-G1

P177P179P176

P175

P178

Light Board Assembly

M01218A00X

on Dispenser Bezel Face

(Side A)

P182

RS-232, Digital

Control and Light

Control Circuit

P182

RS-232, Digital

Control and Light

Control Circuit

J1A

J3A

J3B

J1B

M00878A001

M00878A001

M00878A001

Cable

Cable

Cable

Tuner Board T20579

Tuner Board T20579

Q13851-01

Q13851-01

WO3889

WO3889

When overhead antennas are not part of

the product, Dummy Load R20526-G1

plugs into JA and JB. J2A and J2B are

left unconnected.

R20773-G2, door cable,

provides power and RS232

communications

R20773-G2, door cable,

provides power and RS232

communications

X is color of LEDs

DATA CONTROL BOARD

Q13563-02 or -04

5 MHz (UHF Clock - selected

by jumper)

10 MHz (Local Clock - not

selected for this application)

24 VAC

Power Supply

AC Power

EMC Filter

Q10895-01

Micro-Reader

Q13551-01

(134 KHz

Intentional)

Micro-Reader

Q13551-01

(134 KHz

Intentional)

M00878A001

Cable

Encore

Antenna

(on board

Encore

keytag

Antenna

(on board

RS-232

RS-485

UHF RCVUHF RCV

LF TX

LF TX

Full Systems

r

P

eli

i

m

ary

n

MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013 Page 11

Hand Held Only Tag System Overview

115 VAC

(FROM Dispenser

AC POWER

DISTRIBUTION)

R20580-G1

24 VAC

Class II Energy

Limiting

Transformer

R20719-G1

115 VAC

T20524

Bezel

Antenna

T20524

Bezel

Antenna

Enhanced Gateway

Board

T20678

S

e

r

i

a

l

D

a

t

a

to CRIND™ logic boards

(Dispenser Electronics)

RS-232, +22VDC, +5VDC, GND

RS-232, +22VDC, +5VDC, GND

P282A P282BP250

P185

22VDC,

5VDC,

GND

Light Board Assembly

(T20601-G1)

on Dispenser Bezel Face

(Side B)

RFID Power Supply

T20314-G1

P174

P177P178P176

P175

P179

Light Board Assembly

(T20601-G1)

on Dispenser Bezel Face

(Side A)

P181P182

RI-STU-MRD1

Micro-Reader

(134kHz

Intentional

Radiator)

RS-232, Digital

Control and Light

Control Circuit

P182P181

RI-STU-MRD1

Micro-Reader

(134kHz

Intentional

Radiator)

RS-232, Digital

Control and Light

Control Circuit

EMI Line Filter

Q10895-01

115 VAC

Hand Held Only Tag System Overview

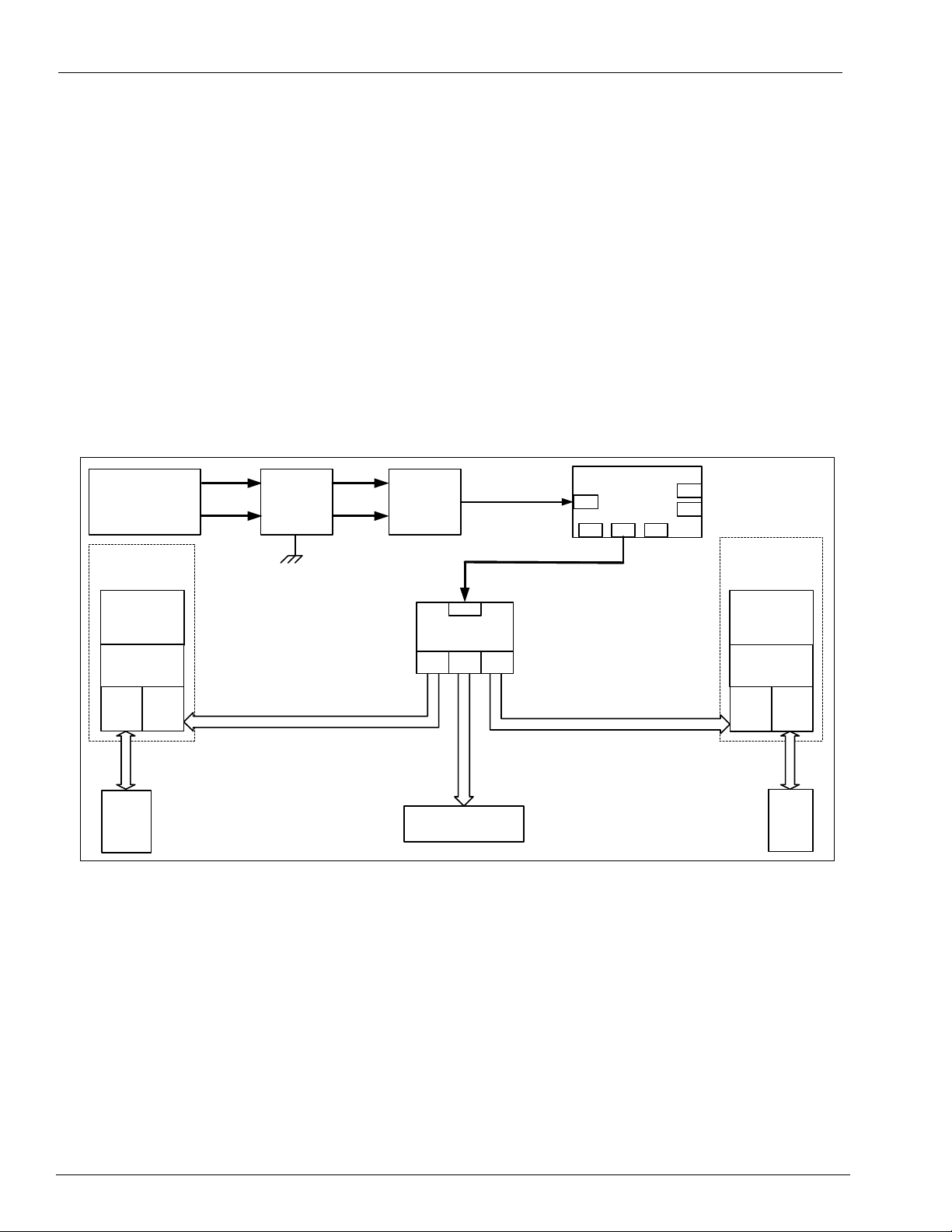

This product is an option available as a retrofit kit or factory installed equipment in

Advantage, MPD-3, and Encore lines of fuel dispensers. The TRIND Enhanced Gateway

Board (T20678) manages RFID processing and provides simple, generic event messages to the

pump electronics via Transistor-Transistor Logic (TTL). In this application, TRIND is a

software slave to the CRIND and the associated POS controller/host. This means that a

properly working Low Frequency (LF) TRIND system will look for and read tags, but only

when told to by the controller, through the CRIND application.

This system is to be installed in accordance with all UL, FCC, federal, state and local

regulations. The following block diagram depicts the components for the Hand Held Only Tag

System.

Figure 3-4: Hand Held Only Tag System Block Diagram

ary

n

i

m

eli

r

P

Page 12 MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013

Card Cage Assemblies Major Hardware Components

1

2

3

5

4

4 – Major Hardware Components

Card Cage Assemblies

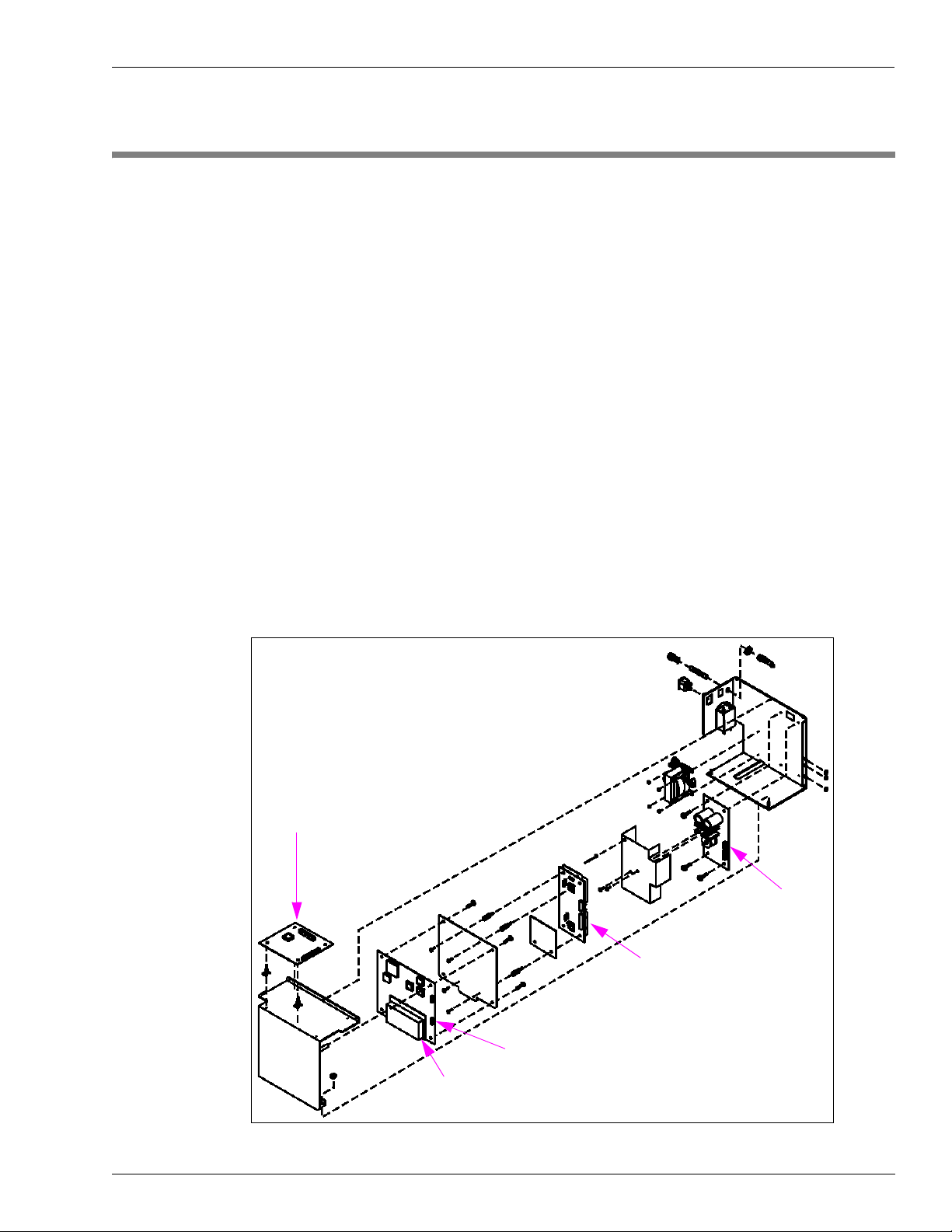

There are four main card cage versions used for the TRIND system. These four card cages are

the T20229-G1, T20606-G2, T20606-G3, and the T20606-G5. The T20229 card cage is no

longer available and is discussed in this manual simply for the service and support of the

installed base. There are other G-levels of the T20606 card cage, but these are variations of the

-G2 and -G3. Therefore, being familiar with these base card cages and their parts will provide

the technician with valuable information in servicing the other G-levels if encountered.

Note: Many parts look similar in the T20229 and T20606 card

same. Always replace the removed part with the same part number or risk voiding the

UL listings, FCC certifications, warranty, if applicable.

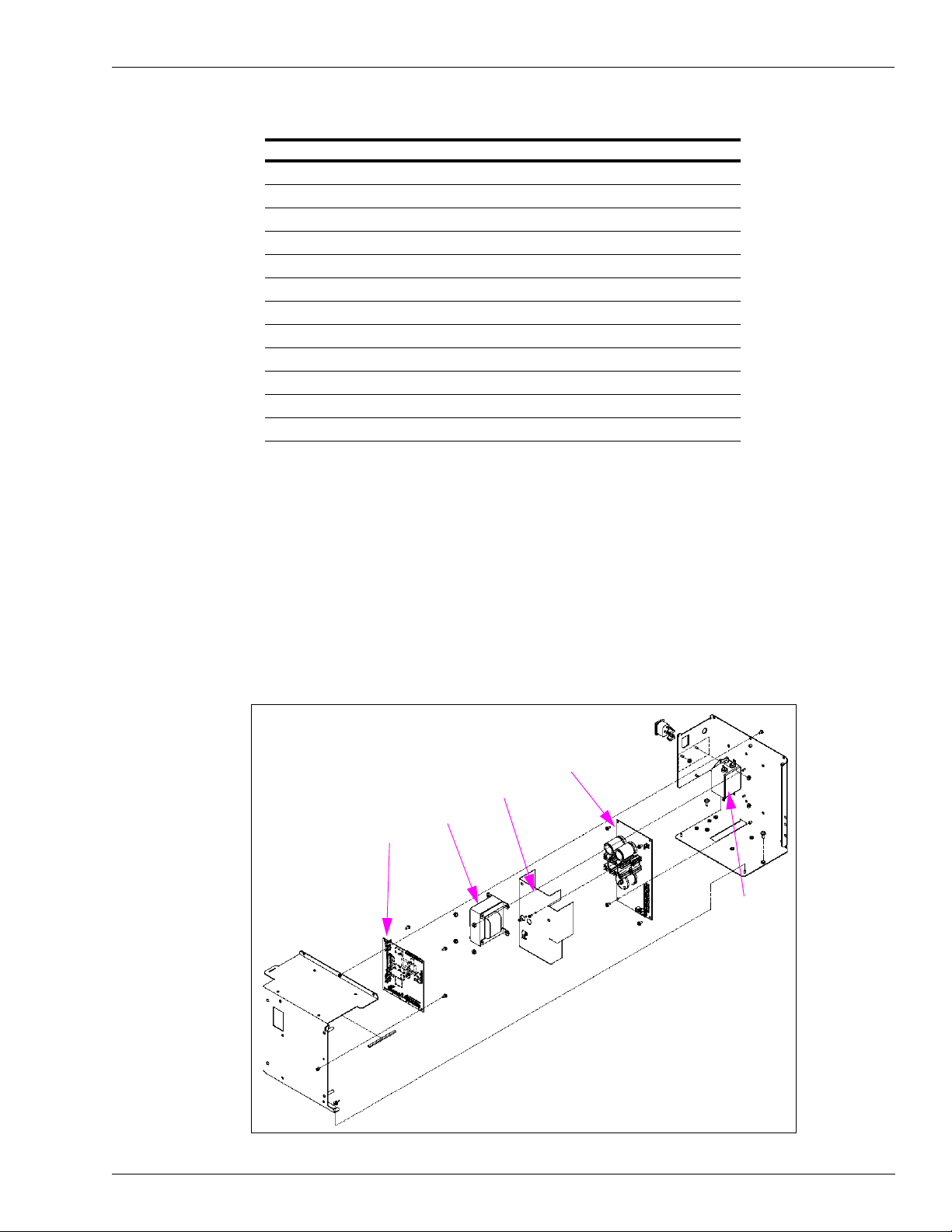

T20229-G1 Card Cage Assembly

The T20229 card cage was the installed card cage for the original Mobil Speedpass program.

With a few cable changes, this card cage can be replaced by the T20606-G2, which contains

the new Multi-Port DCB from T exas Instruments.

cages, but they are not the

Figure 4-1: Card Cage Assembly T20229-G1

Preliminary

MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013 Page 13

Major Hardware Components Card Cage Assemblies

1

8

9

10

11

7

6

5

4

3

2

12

13

T20229-G1 Card Cage Assembly Parts List

Item Description Part Number

1 Power Supply PCB T20138-G1

2 Transmitter PCB Assembly Q13579-01

3 Data Control Board Q13563-01

4 UHF Receiver Assembly on DCB Q13564-01

5 Gateway Board T20128-G1

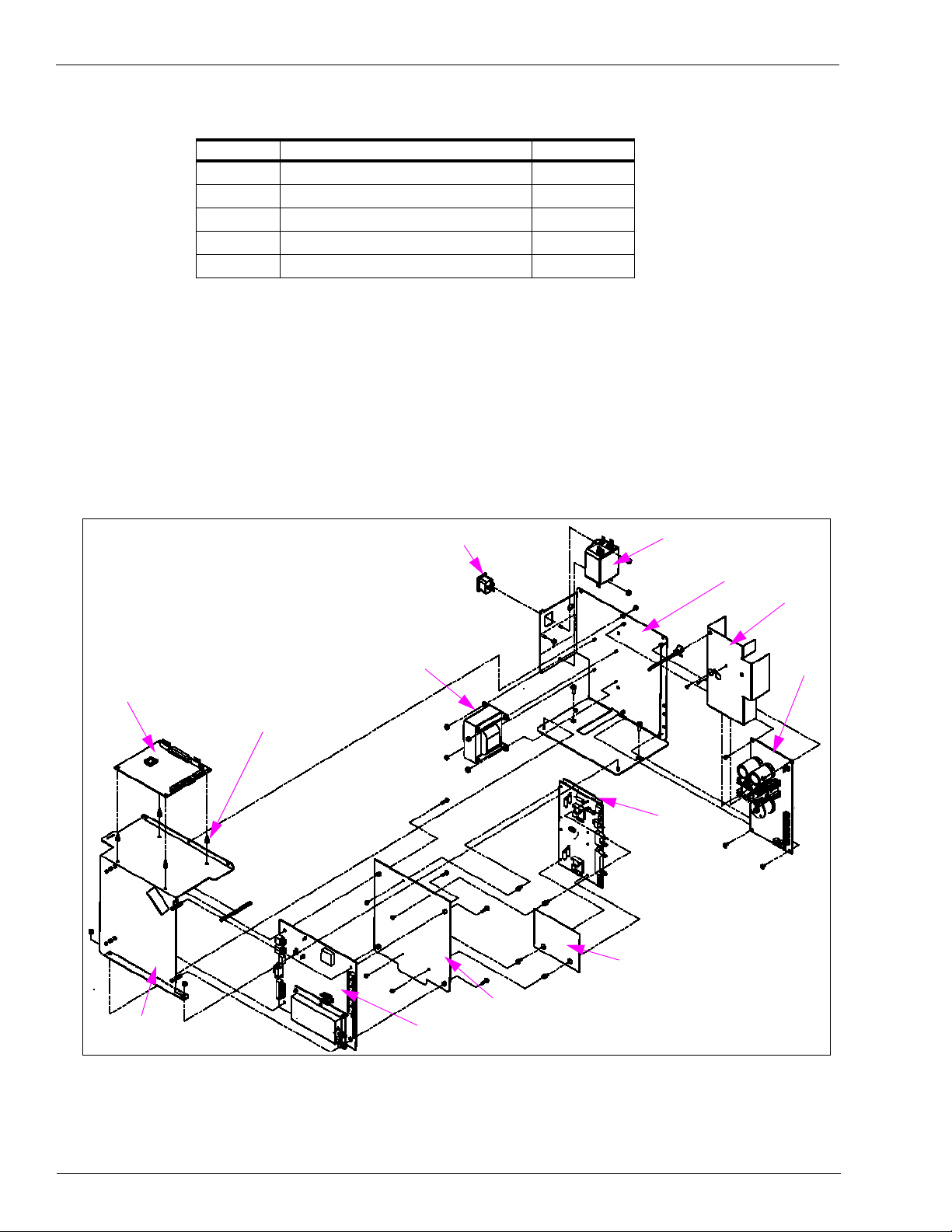

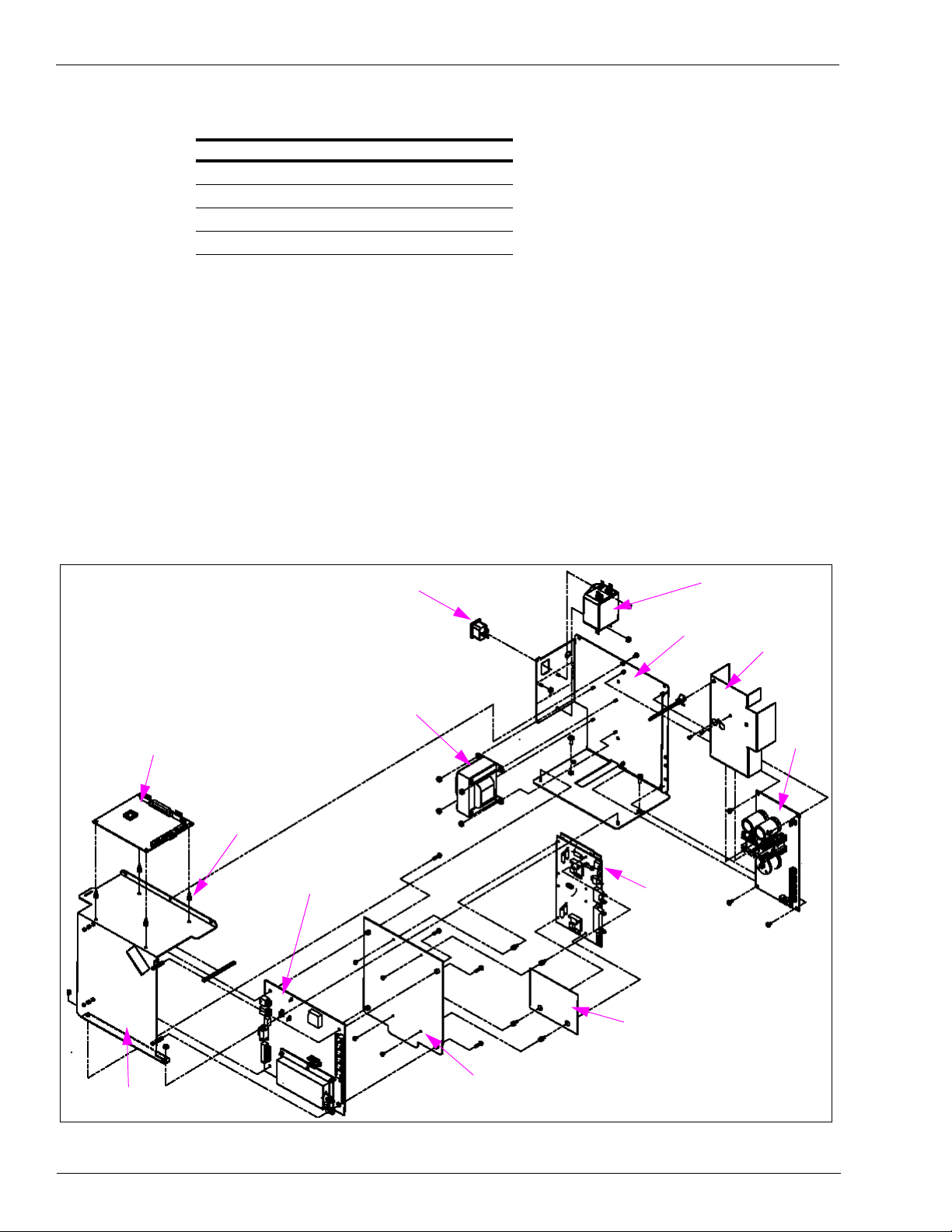

T20606-G2 Card Cage Assembly

The T20606-G2 card cage is the updated version of the T20229-G1. It features a Multi-Port

DCB, LF Transmitter and a High-Gain UHF receiver. It also has a card cage harness, which

reduces the number of field connections that must be made (compared to the T20229). This

card cage comes ready to mount in an Encore unit, and is easily modified to also work in

Eclipse, Advantage and MPD-3 units.

Figure 4-2: Card Cage Assembly T20606-G2

na

i

m

li

ry

re

P

Page 14 MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013

Card Cage Assemblies Major Hardware Components

1

4

2

5

3

T20606-G2 Card Cage Assembly Parts List

Item Description Part Number

1 TRIND Gateway PCB T20128-G3

2 Circuit Board Support Q10651-16

3 TRIND PCB Bracket M00624A001

4 Multi-Port Data Control Board Q13563-04

5 Radio PCB Shield R20545-G1

6 PCB Insulator Board R20590-01

7 Low Frequency Transmitter Module Q13579-01

8 24 VAC Transformer R20719-G1

9 Recessed Power Receptacle R20206-G14

10 10 AMP EMI Filter Q10895-01

11 TRIND PCB Shield Bracket M00621A001

12 Regulator PCB Shield T20198-01

13 Regulator PCB T20314-G1

T20606-G3 Card Cage Assembly

The T20606-G3 card cage supports “keytag only” operation and features an Enhanced

Gateway board, which serves as the local controller for the RF modules (taking the place of

the DCB) and the protocol handler for payment messaging (to CRIND or other Host

Controller device). This card cage comes ready to mount in Encore, Advantage, Eclipse and

MPD-3, with no modifications required.

Figure 4-3: Card Cage Assembly T20606-G3

Preliminary

MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013 Page 15

Major Hardware Components Card Cage Assemblies

1

8

9

10

11

7

6

5

4

3

2

12

13

T20606-G3 Card Cage Assembly Parts List

Item Description Part Number

1 Regulator PCB T20314-G1

2 Shield, Regulator, PCB T20198-01

3 Transformer, 24 VAC R20719-G1

4 Enhanced Gateway PCB T20678-G1

5 Filter, EMI, 10 AMP Q10895-01

T20606-G5 Card Cage Assembly

The T20606-G5 card cage is a variation of the T20606-G2 card cage required for many

international “full system” TRIND applications (Europe and southeast Asia). It features a

European Telecommunications Standards Institute (ETSI) Data Control Board (DCB), LF

Transmitter and a High-Gain UHF receiver. It also has a card cage harness, which reduces the

number of field connections that must be made (compared to the original T20229). This card

cage comes ready to mount in an Encore unit, and is easily modified to also work in Eclipse,

Advantage and MPD-3 units.

ry

Figure 4-4: Card Cage Assembly T20606-G5

na

i

m

li

re

P

Page 16 MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013

Card Cage Assemblies Major Hardware Components

1

2

2

T20606-G5 Card Cage Assembly Parts List

Item Description Part Number

1 TRIND Gateway PCB T20128-G3

2 Circuit Board Support Q10651-16

3 TRIND PCB Bracket M00624A001

4 ETSI Data Control Board Q13563-07

5 Radio PCB Shield R20545-G1

6 PCB Insulator Board R20590-01

7 Low Frequency Transmitter Module Q13579-01

8 24 VAC Transformer R20719-G1

9 Recessed Power Receptacle R20206-G14

10 10 AMP EMI Filter Q10895-01

11 TRIND PCB Shield Bracket M00621A001

12 Regulator PCB Shield T20198-01

13 Regulator PCB T20314-G1

Disassembly and Installation For MPD®-3 Units with SID Displays

In some older installations, a screw and two nuts were installed under the Card Cage on side B

of a unit. This causes the installed card cage to rest at an angle, higher on side B. This

hardware must remain in place in order to prevent contact between the Card Cage and the SID

boards when the bezel door is closed.

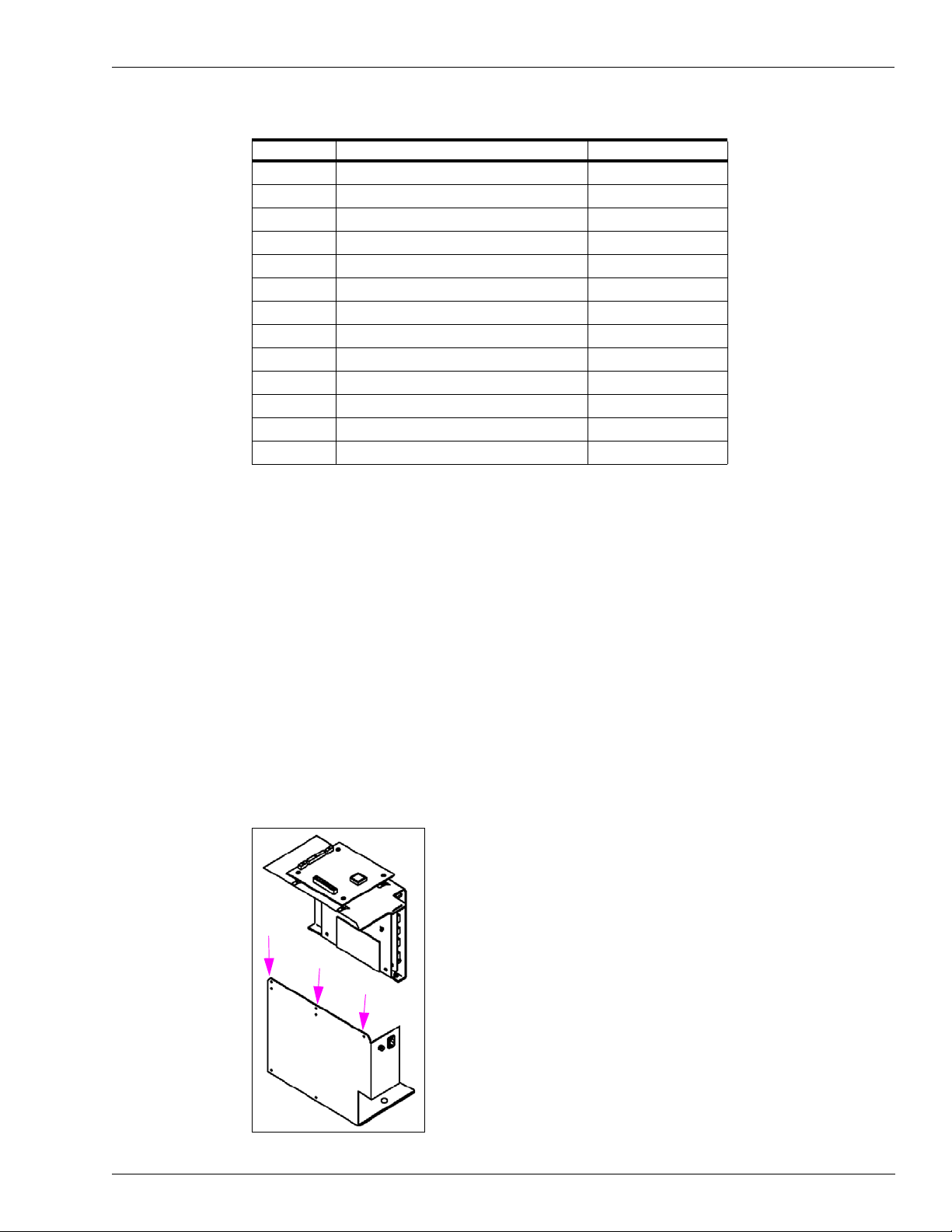

Disassembly and Installation For All MPD-3 Units

In field retrofits, the TRIND units’ top (center) screw from the card cage was removed, and

replaced by tie wraps at either side after the card cage was installed in the cabinet. The card

cage can only be removed or installed when separated into two pieces. See Figure4-5 for

locations of the screw (1) and tie wraps (2).

Figure 4-5: Screw and Tie Wrap Locat ions

Preliminary

MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013 Page 17

Major Hardware Components Card Cage Assemblies

5V

GND

22V

GND GND

5V

22V

GND

Note: P176, 177, and P178 are identical.

JP1 through JP4:

must be unique

address for each

dispenser at site

22V

5V

5V

AC EMI Line Filter Q10895

AC EMI Line Filter Q10895-01, is a Corcom dual T section RFI power line filter . These filters

are well suited for low impedance loads where noisy RFI environments are present. They

control pulsed, continuous and/or intermittent interference, insuring protection of the TRIND

equipment from power line noise in addition to protecting the line from equipment noise.

Transformers R20600 and R20719

Transformer R20600-G1 is used in T20229-G2 card cage assembly. Transformer R20719-G1

is used in T20606-G2 LF/UHF full system, and T20606-G2 Enhanced Gateway system card

cages. Each transformer performs step down of 120VAC to a usable level for the RFID Power

supply. The R20600 steps 120VAC down to 60VAC, which is used by the T20138-G1 Power

Supply board. The R20719 steps 120VAC down to 24VAC, which is used by the T20314-G1

Power Supply board.

Power Supply Boards T20138 and T20314

Power Supply Board T20138-G1 is used in T20229-G1 full system card cage assembly. Power

Supply Board T20314-G1 is used in T20606 line of card cages. The supplies take the outpu t of

their respective AC to AC transformers and make the proper DC voltages for use by the

TRIND system components. Both supplies utilize a gate-driven MOSFET (for +22VDC) and a

buck switched mode power supply (for +5VDC). Both supplies monitor the current on the

output to turn off the gate drive, rather than fail permanently, should one of the TRIND system

components develop a voltage problem. This arrangement allows for any of the outputs to be

shorted directly to ground with out harming the power supply because it turns itself off until

the problem is discovered and removed, and AC power is cycled.

m

li

na

i

ry

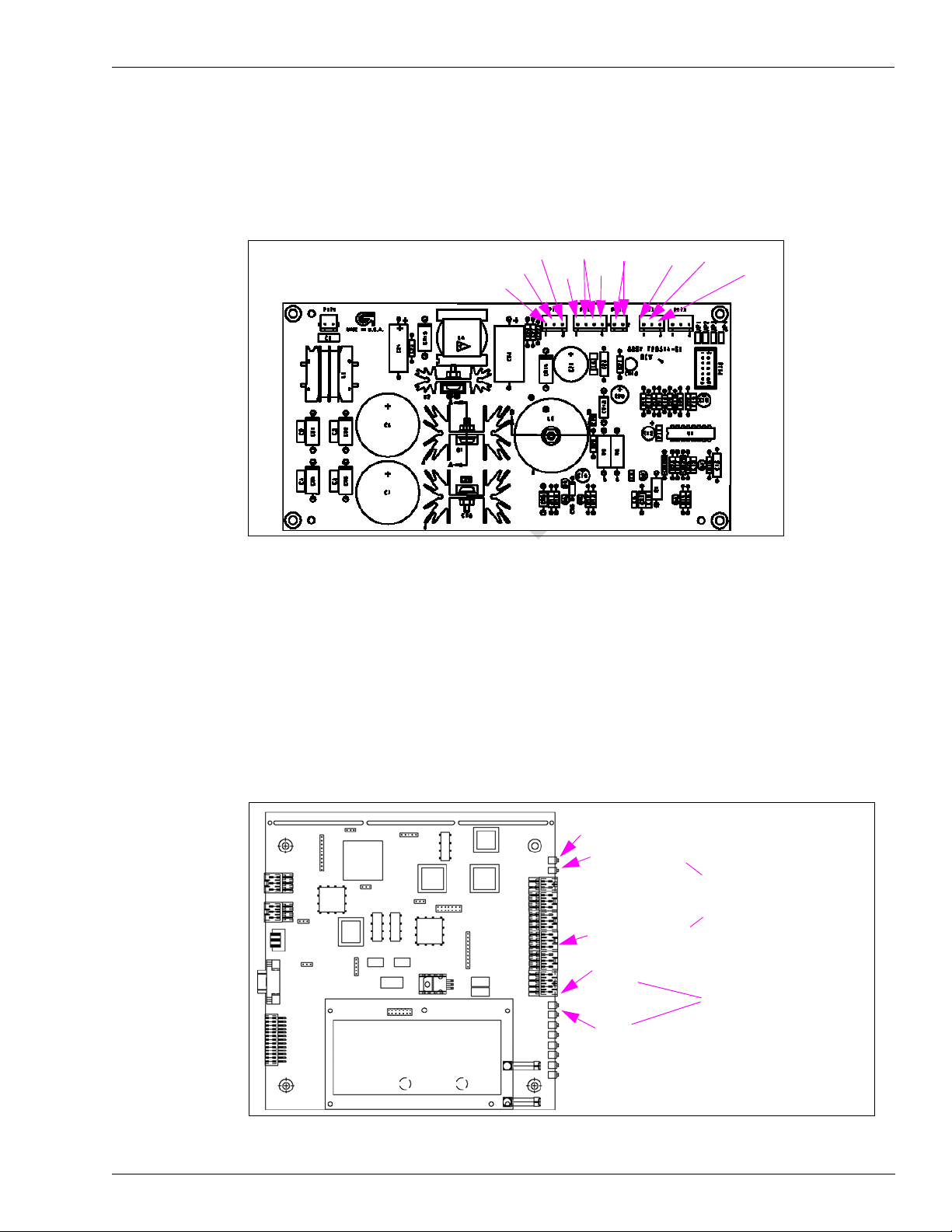

T20138 Power Supply Board.

This board has jump-jack locations to set the dither sync (“Glossary” on page 1) address for

the TRIND unit, with a 10-position ribbon cable (at P173) that goes to the DCB (J6). These

addresses

Figure 4-6: Power Supply Board T20138

only matter to the site itself, not the pump or CRIND.

re

P

Page 18 MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013

Card Cage Assemblies Major Hardware Components

5V

GND

22V

GND

GND

5V

22V

GND

Note: P176, 177, and P178 are identical.

22V

5V

CR5 - pulsing (heartbeat)

CR11 - RS485 - TX

CR10 - RS485 - RX

Note: In normal operation will

be in sync.

CR3 - 12V

CR2 - 5V

On continuously

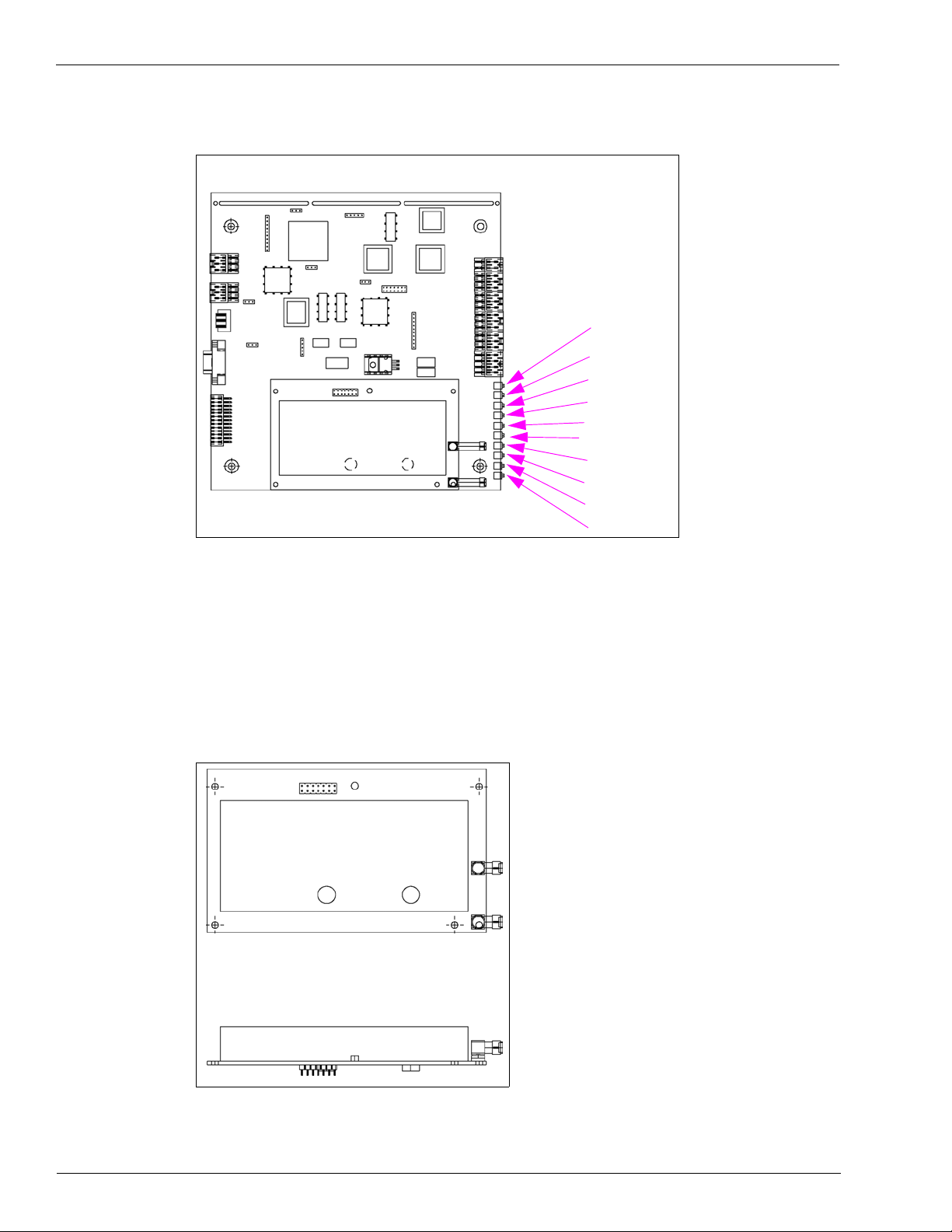

T20314 Power Supply Board.

Must be used in conjunction with R20719 transformer.

Figure 4-7: Power Supply Board T20314

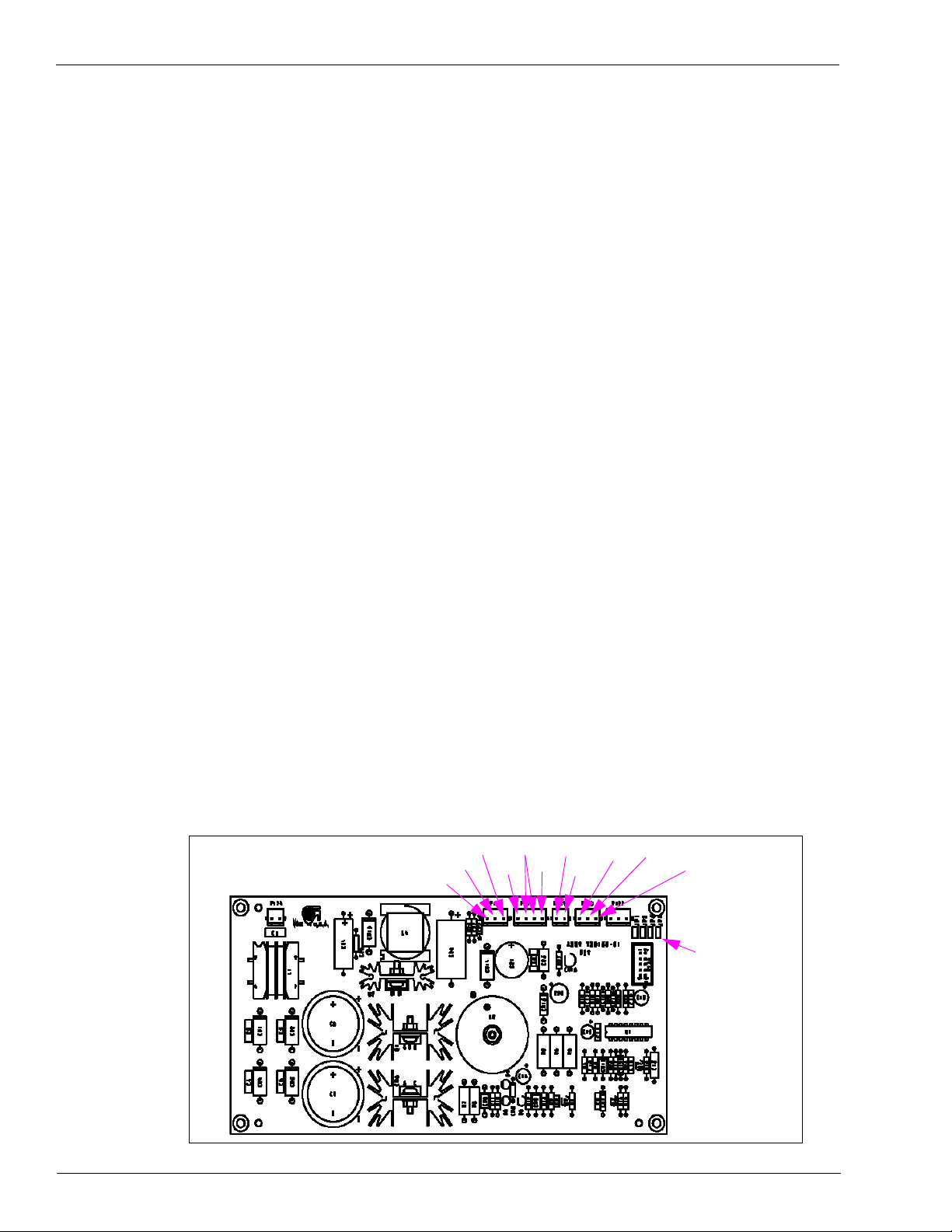

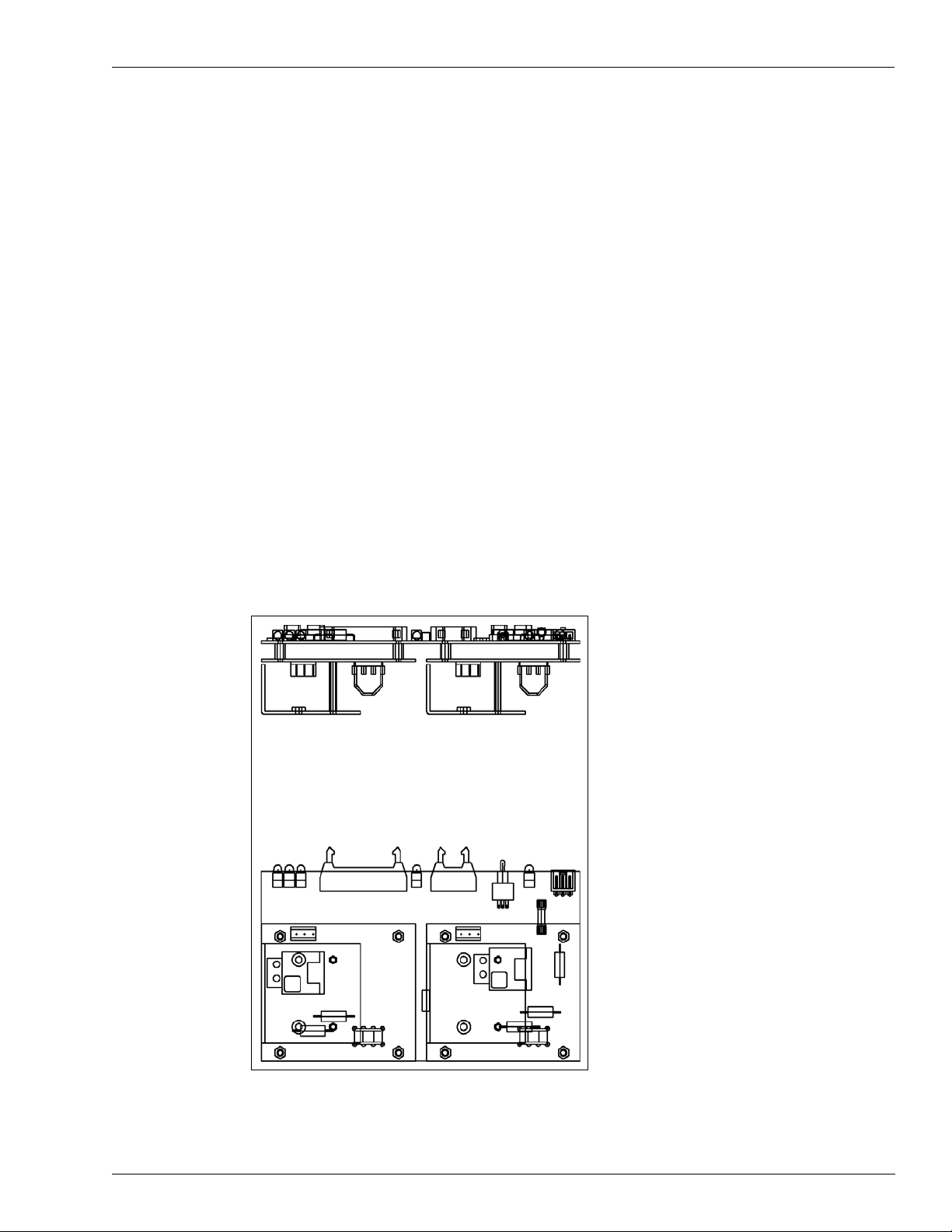

Data Control Boards Q13563

Data Control Boards Q13563-01 and Q13563-02 are used in T202 29-G1 full system card cage

assembly. The Q13563-04 board is used in T20606-G2 full system card cage assembly. These

DCBs handle tag reader control and pass the system status and tag data up to the Gateway

board. The earlier versions (-01, -02) of this board made use of jump jacks on the power

supply board for dither sync addressing, subsequent versions (-04 and above) contain dip

switches for this site-specific addressing.

Preliminary

Figure 4-8: Data Control Boards Q13563-01 and Q13563-02

MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013 Page 19

Major Hardware Components Card Cage Assemblies

Q13563-04 and Above

Heart Beat

RS-485 TX

Read ANT 1

Read ANT 3

Bezel I/0 Error

Bit Restore

Bit Fail

RS-485 RX

+12 Vdc

+5 Vdc

Figure 4-9: Data Control Boards Q13563-03 and Above

ry

UHF Receiver Board Q13564

Mounted on the DCB, the UHF Receiver Board receives 12VDC from the DCB. The board

also receives information from UHF antennas over J2A or J2B and processes the UHF signal.

This receiver has to comply with FCC and in-country communication protocols such as ETSI.

For this application the ETSI protocol is required for Asia and Europe.

re

Figure 4-10: UHF Receiver Board Q13564

P

na

i

m

li

Page 20 MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013

Card Cage Assemblies Major Hardware Components

The UHF Receiver Module contained on the DCB, handles the uplink signal from the vehicle

tag. It receives the signal from the vehicle tag that transmits data on a UHF carrier, and down

converts and demodulates this signal to binary data. The UHF Receiver also includes the

master oscillator for the DCB and provides all clock signals for other elements within the DCB

to keep signal paths as short as possible. The UHF receive antenna connections are made via

Sub Miniature A (SMA) connectors on antenna cables M00878A001, M00878A002, and

Q13578-01.

Transmitter Board Q13579

Transmitter Board Q13579-01 is used in the T20229-G1 and T20606-G2 full system card

cages. The Transmitter Board is actually a three board assembly containing two identical

transmitter modules (one each for Sides 1 and 2) mounted on a larger printed circuit board.

The Transmitter Module (Q13579-01) contains all the functions to activate vehicle tags. The

module includes a carrier board onto which are mounted two transmit-only Radio Frequency

Modules (RFMs), the power supply, oscillator and tuning connector for the RFMs, logic

circuitry to determine RFM selection, power level adjustment capability, and a pulse width

modulation circuit. This board receives +22VDC, +5VDC and GND through J6. If this board

is replaced, overhead antennas will need to be retuned. The transmitter provides an

approximate 134 kHz signal for TRIND antennas, through JA for Side 1 and JB for Side 2 of

the dispenser.

Figure 4-11: Transmitter Board Q13579

Preliminary

MDE-3664B TRIND Start-Up, Service, and Parts Manual . March 2013 Page 21

Major Hardware Components Card Cage Assemblies

TX = To A Side CRIND