Gigo Water Power 7323 Instruction Manual

What’s on

technology

15

165

pieces

#7323

models

to build

WATER

power

WATER power | Contents

Parts List ................................................................................................................. 1

Learning about Gears............................................................................................ 2-4

Learning about Chain Gears ................................................................................... 5

Tips and Tricks for Model Building .......................................................................... 6

About the Main Components of HYDRO-PNEUMATIC .......................................... 7

Notes for Assembly ..................................................................................................8

Notes for Operation ..................................................................................................9

Hydro-Pneumo ...................................................................................................... 10

Hydro-Pneumo Models (with water-recycling system)

How to Operate .................................................................................................. 11

Model 1 Cutting Machine ............................................................................. 12-13

Model 2 Grinder ............................................................................................ 14-15

Model 3 Truck ............................................................................................... 16-17

Model 4 Excavator ........................................................................................18-19

Model 5 Detective ........................................................................................ 20-21

Model 6 Tank ................................................................................................ 22-23

Model 7 Antique Car .....................................................................................24-25

Hydro-Pneumo Models (without water-recycling system)

Water-Jet Vehicles ............................................................................................. 26

Experiment ......................................................................................................... 27

Model 8 Rocket Car ..................................................................................... 28-29

Model 9 Excavator .......................................................................................30-31

Model 10 Heavy Motorbike ...........................................................................32-33

Model 11 Helicopter .....................................................................................34-35

Model 12 Detective Car ................................................................................ 36-37

Model 13 Lift .................................................................................................. 38-39

Model 14 Antique Car .................................................................................. 40-42

Model 15 Propeller Aircraft ......................................................................... 43-45

RECOMMENDATIONS

Please read these instr uctions, follow the s afety rules and keep them for r eference. We

recommend that you ma ke the models in the or der that is given. You will then be able to

understand assembly of parts and soon many more different models you wish.

WARNING TO PARENTS

• This is a toy that has been designed for children over 8 years of age. It is not suitable for children unde r 3 years of age. It cont ains small par ts that a chi ld could

swallow. It must be kept out of the reach of very young children.

• Discuss the safet y warnin gs and poss ible ris ks involved with the chil dren before

allowing them to build these models.

1

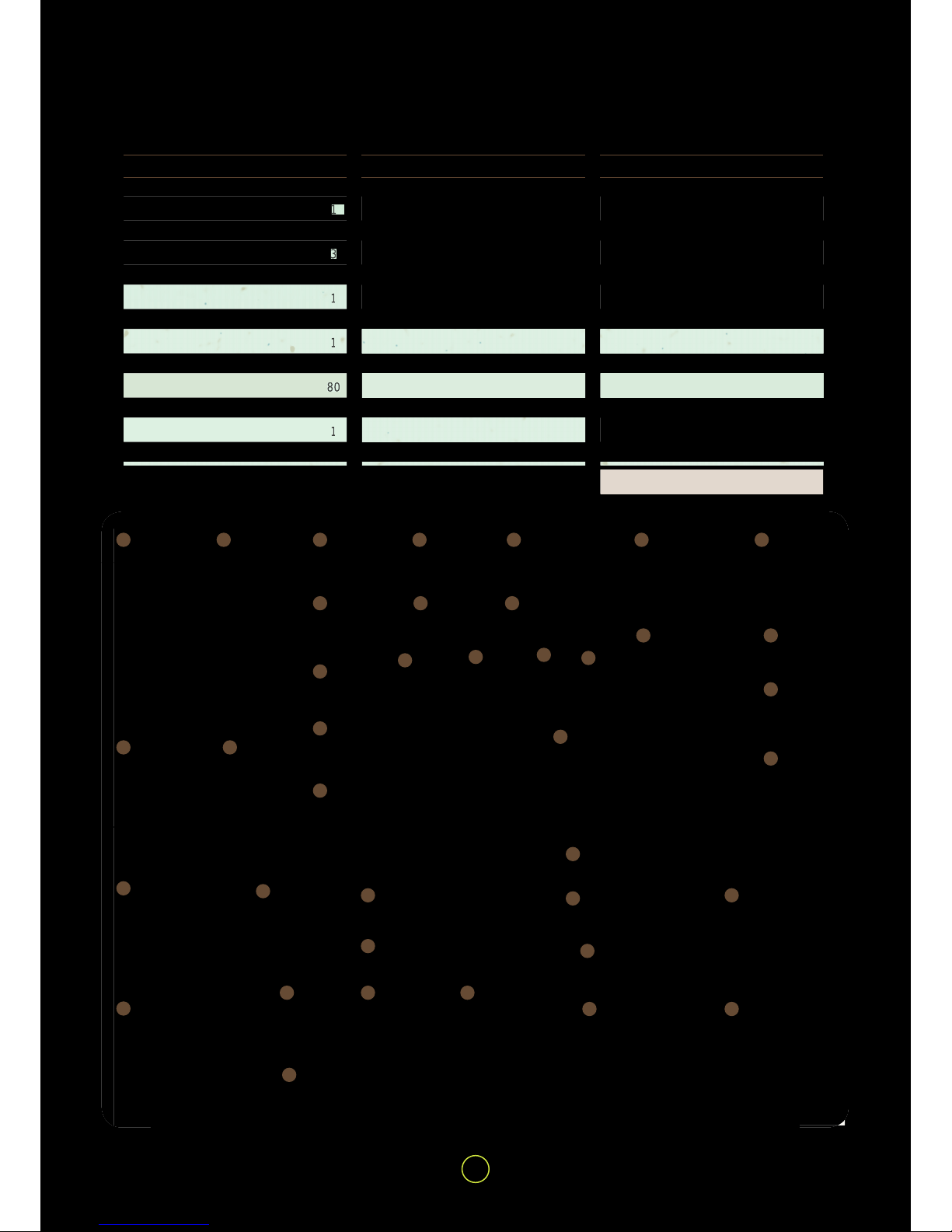

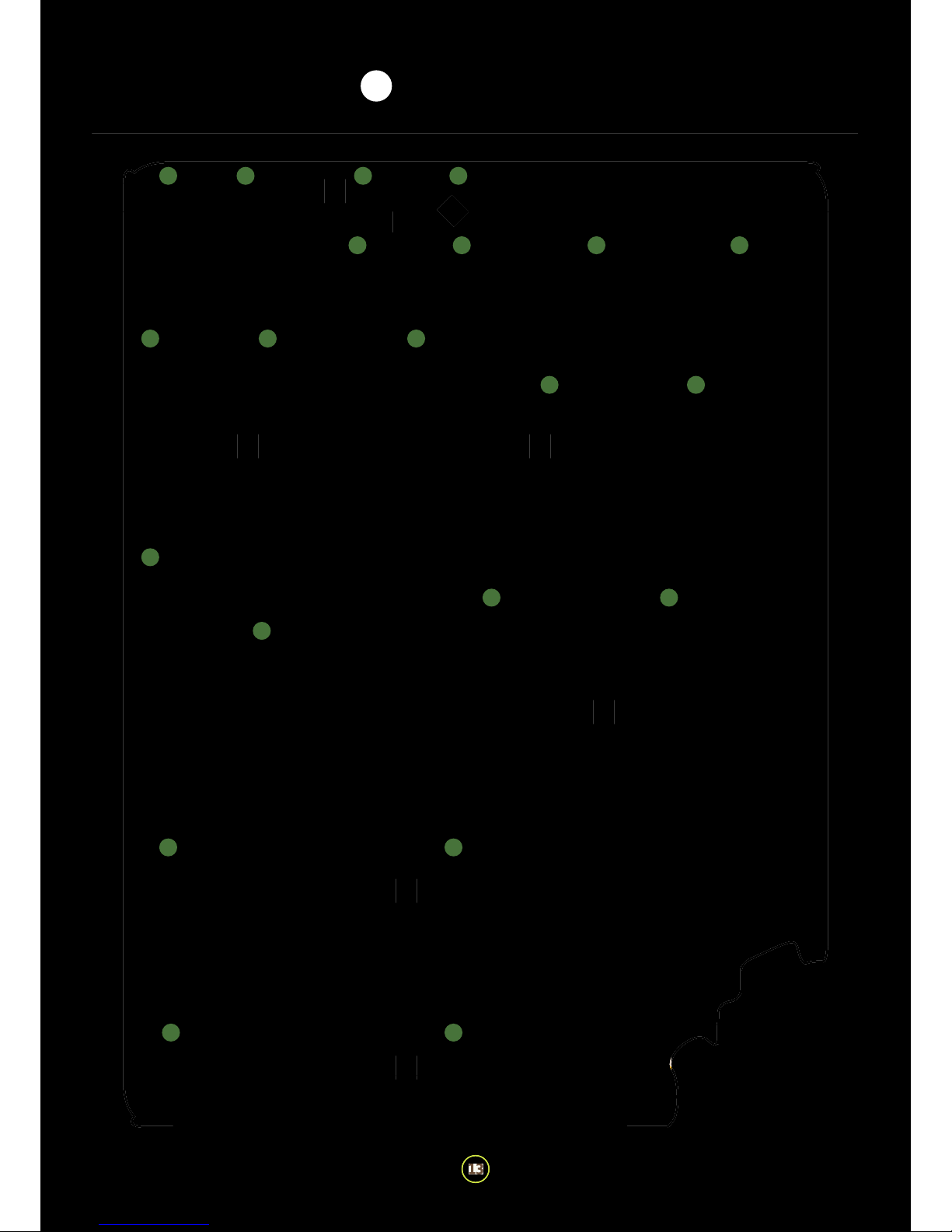

Parts List | WATER power

PCS

1

1

2

3

1

1

1

1

1

80

2

1

1

No

1

2

3

4

5

6

7

8

9

10

11

12

13

PARTS NAMES

SECURED AIR-WATER STORAGE

RECYCLED WATER STORAGE

RACING TIRE

SHORT FRAME

SECURED PUMP

AIR-WATER POWER PACK

STORAGE CAP

NOZZLE

WASHER

UNIT CHAIN

90 DEGREE CONVERTER - L

S DR. AXLE

ROD

No

14

15

16

17

18

19

20

21

22

23

24

25

26

PARTS NAMES

LONG FRAME

L DR. AXLE

XL DR. AXLE

SECURED ONE-WAY SWITCH

BENDED ROD

90 DEGREE CONVERTER - R

L SECURITY NUT

GEAR FIXING

5-HOLE ROD

DUAL ROD

S SECURITY NUT

PEG

O RING L

PCS

5

2

2

1

4

2

2

4

2

2

2

20

2

TOTAL 165

No

27

28

29

30

31

32

33

34

35

36

37

38

39

PARTS NAMES

L PULLEY

SQUARE FRAME

S CHAIN GEAR

S GEAR

M CHAIN GEAR

DOUBLE-SIDED BASE GRID

LONG ROD

PEG /AXLE REMOVER

TUBE - B 120CM

M GEAR

CAR LAUNCHER

L CHAIN GEAR

TUBE - A 200CM

PCS

2

1

2

2

2

1

1

1

1

2

1

2

1

1

2

4

5

6

7

8

9

10

11

12

15

2319

24

25

26

27

28

32

33

36

37

38 39

31

34

35

20

21

22

29

16

17

18

13

14

30

3

x 1

x 1x 1

x 1

x 1

x 1

x 1

x 1

x 1

x 1

x 1

x 1

x 1

x 1

x 1

x 1

x 5

x 2

x 2x 2

x 2

x 2

x 2x 2

x 2

x 2

x 2

x 2

x 2

x 3

x 4

x 4

x 80

x 20

x 2

x 2

x 2

x 1

x 2

2

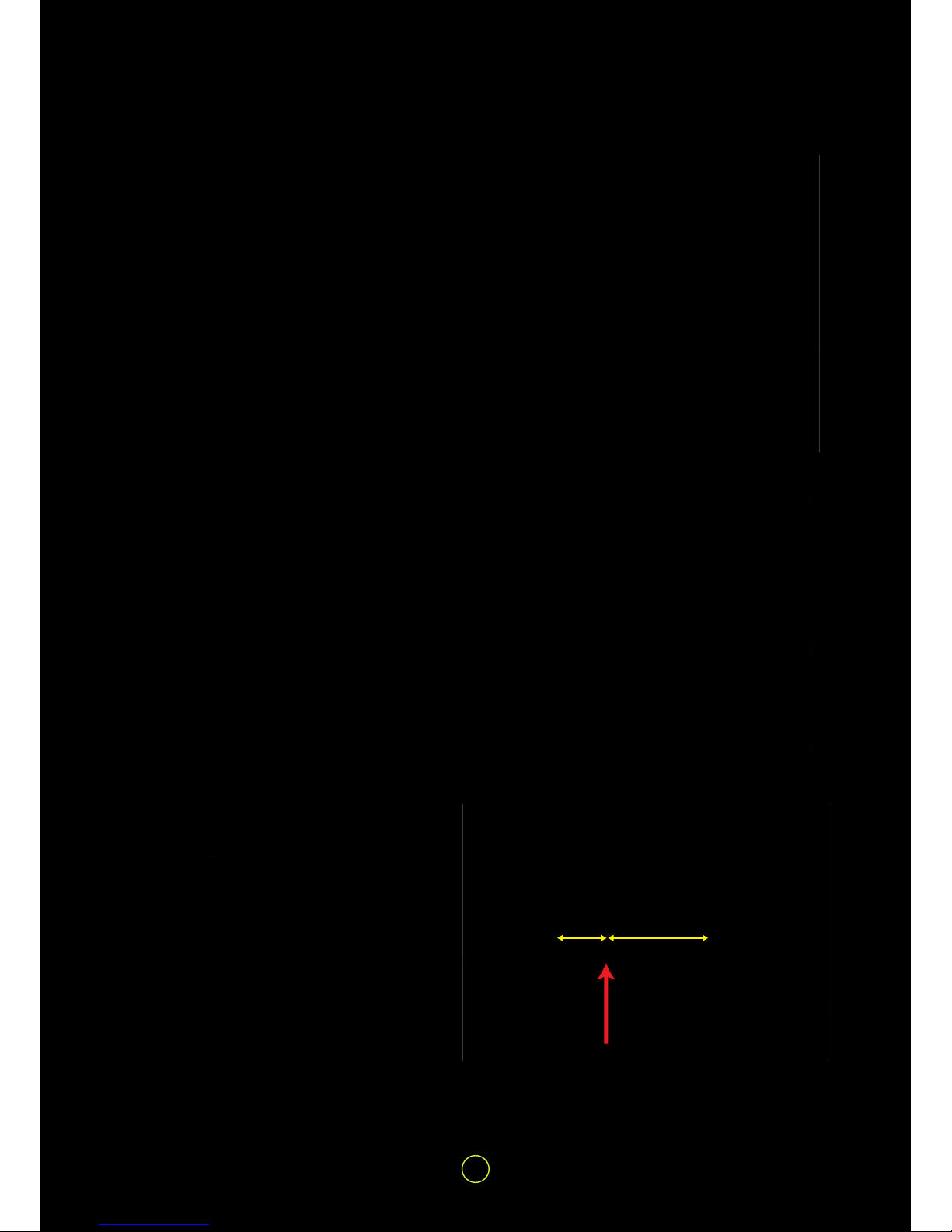

WATER power | Learning about Gears

Every transmissio n system (gear train) contains gears. A gear i s a useful and impor tant tra nsmission c ompo nent, as it is a transmission method that applies to two shafts, or between a wheel and a shaft.

You can obs e rve the transmission of meshi ng g e a rs inside old toys or old clocks. There is a g e arbox within the

transmission system of c ars, which c ombines meshing g ears of dif ferent sizes. In this way, to change among

different speeds becomes easy.

Do you know how gears wor k? Pl ease c arefully r ead the de scr iptio ns below. You will learn the secrets of gear

trains from the world patent GIGO GEARS. The design of GIGO scientic educational building blocks ( that is

GIGO SCIENCE-TOOL KIT ) is based on the numb er of 10 and its multiples; whether o n the size of the co mponents, the distanc e betwe en the holes, o r the unique GIG O gear tooth numbe r. Therefore your child will be

a

ble to not only correctly assemble the gears, but also conveniently calculate the gear ratio or change the rotary

speed. Dif ferent from other gear desi gns adopting the number of 8 or 7 as the ir fundamental number, GIGO

gears are created with perfect designs for the use of scientic teaching, and express the care on children and

passion for scientic education.

We suggest a gradual learning with GIGO gears which starts from the basic structures to understand the combi-

nations of each component. Once you nish your practice following the examples in this instruction, and possess

t

he fundamental c oncepts of gear trains, you c an put your unlimited creativit y into action and create various

vehicles or airplanes on your own. Let’s enjoy the pleasure of creativity!

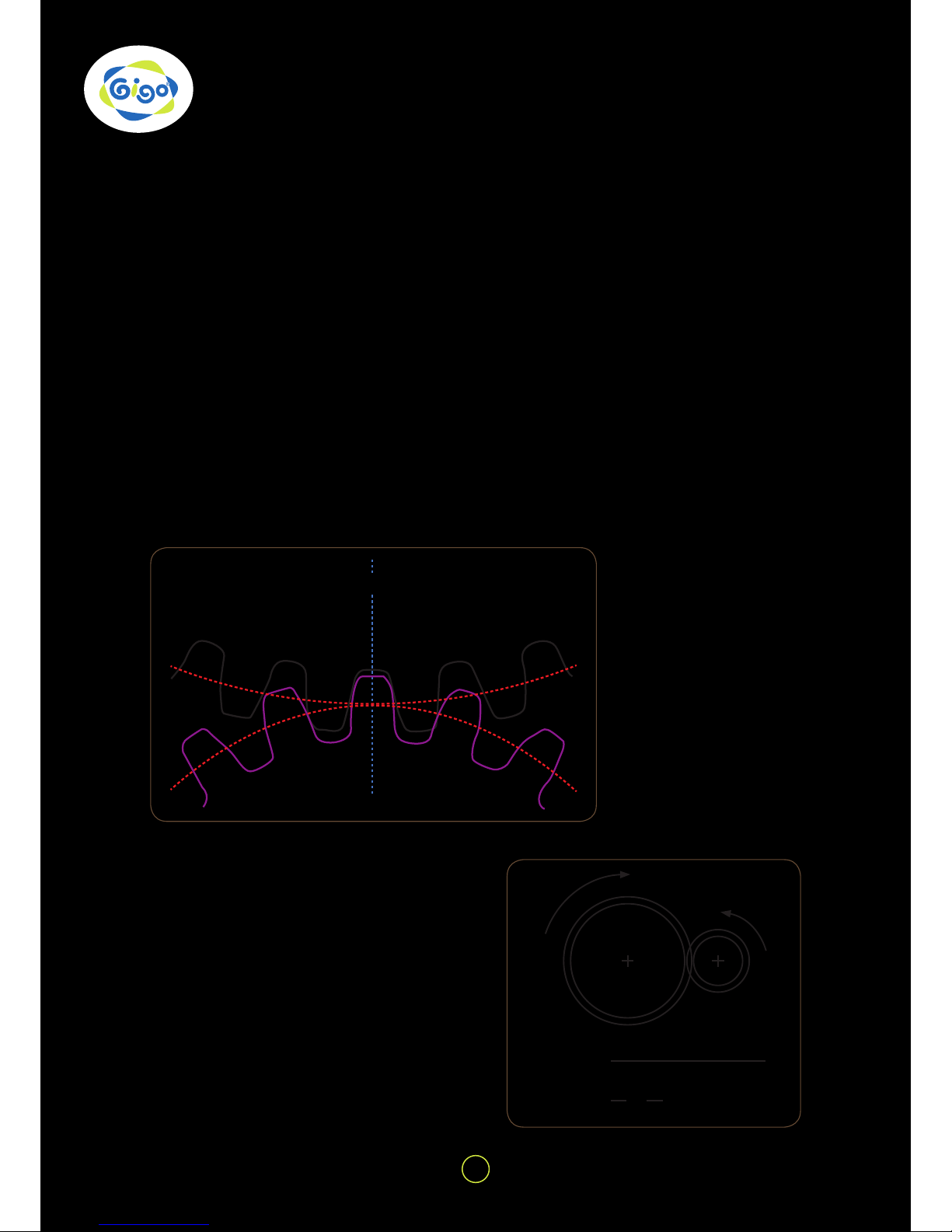

The wheel which has many tooth-shaped objects sticking out of the rim with the same size is called a “gear”. Two

gears can mesh with each other with the teeth on the rims. When a gear rotates, the other one wi l l be driven to

rotate as well. The intermeshing teeth of the two gears transmit rotation and torque.

A simple gear train uses two gears with the

same or diffe rent sizes. If one of th ese gear s is

attached to a motor o r a crank, it t akes the role

as the driver gear. The gear that is turned by

the driver gear is c alled the driven gear. Gears

are used to increase or de crease the speed or

the power of rotar y motion. The m echanism of

changing the speed o r power is call ed the gear

ratio (speed ratio).

Fig. B

Illustration of gear ratio calculation

Fig. A

The intermeshing of gears

can effectively transmit rotation. The red circle represents the actual diameters of the transmission,

w

hich is called the pitch

diameter. The tting shape

of the teeth as sures the in termeshing and transmits

p

ower along the pitch.

GEAR

40 teeth

driven gear

20 teeth

driver gear

(2:1)

Velocity

ratio

=

= =

Number teeth driven gear

Number teeth driver gear

40201

2

3

160 T

20 T

40 T

60 T

80 T

The secret of GIGO des igns for gears is

to place the distanc e between each hole

based on 10 or the multiples. In Fig. E, the

distance between the centers of the two

gears is

and therefore the two gears can be

smoothly assembled or transmitted. Other sizes of GIGO gears ar e also desig ned

with the same per fect concept, and their

holes and gears can be greatly meshed

and operated with each other!

Learning about Gears | WATER power

The number of teeth betwee n th e big g ear

and small gear is different. Despite the

teeth number or size of the gears, the teeth

of the gears in the sam e gear set should

have the same size. In simple gear trains,

the driver and driven gears will rotate in

opposite directions. When a third gear

is inserted between the driver gear and

driven gear, and makes them rotate in the

same direction, it is called an idler gear.

The world patent gears designed by GIGO

come in 5 dif ferent types: 20T, 40T, 60T,

80T, and 160T, the extra large gears.

Each of GIGO gear sets contains both

spur and bevel gears. Gear s of HYDRO-

PNEUMATIC contain “Spur Gears” (gear

wheel to gear wheel) meshing in the same

plane and regulating spe ed or direct ion of

turning of the shafts and “Bevel Gears”

(the rounded off sec tions on one edge of

your gears in the set) meshed together

to change directi on at right angles to the

initial turning plane of the gears and shafts

(axles).

The tooth shape of GIGO gears shares the

same speci cation of module pitches=1.

Namely, the pitch diameter of the 20T

gears is 20mm wh ile the pitc h diameter of

the 40T gears is 40 mm. The pitch diame ters refer to the imaginary circles between

the meshed gear teeth as sh own i n Figu re

E.

Fig. D Characteristics of GIGO gear teeth

Fig. E The transmission between the pitches

during the intermesh of two gears

Fig. C GIGO Gears

= 30mmR1+R2 = +

20mm

2

40mm

2

* According to th e instruction a bove, can

you gure out how many holes there are

between a 40T and a 60T gear when they

are meshed?

R1 R2

4

WATER power | Learning about Gears

1. Use two red 20-tooth gears and two yellow

60-tooth gears to make this system.

2. How many times do you have to turn the small

gear A in order to make the sec ond large gear D

turn once?

The small gear A turning the large gear B gives a 3

to 1 ratio as you found out on the table.

The second small g ear C is directly dr iven by the

arrangement and produces another 3 to 1 ratio

with the second large gear D.

Did you nd out that you had to turn the small gear

A 9 times to turn the second large gear D once?

The overall gear ratio of the system is 9 to 1. ( A

gear ratio of 3 to 1 multiplied by another 3 to 1 =

9 to 1).

3. Add a third red 20 -tooth gear to the shor t drive

axle at (x). Why does it lock?

4. Add a blue 40-tooth and a red 20-tooth gear to the

system. Can you work out mathematically what the

gear ratio of system would be?

Count the number of turns. Were you right?

1. Th is gear box uses a c ombinati on of red 20 - tooth

gears and yellow 60-tooth gears.

There are four pairs of red 2 0 and yellow 6 0 - tooth

gears. Each pair produces a gear ratio of 3 to 1.

The overall gear ratio would th en be 3 x 3 x 3 x 3

= 81.

If gear B is turned 81 times the n gear A would turn

once.

2. If gear A c ould b e tur ned onc e then g ear B would

turn 81 times! Could you add anothe r pa i r of gears

to make a ratio of 243 to 1?

A

C

D

B

X

D

B

A

C

40

20

A

B

5

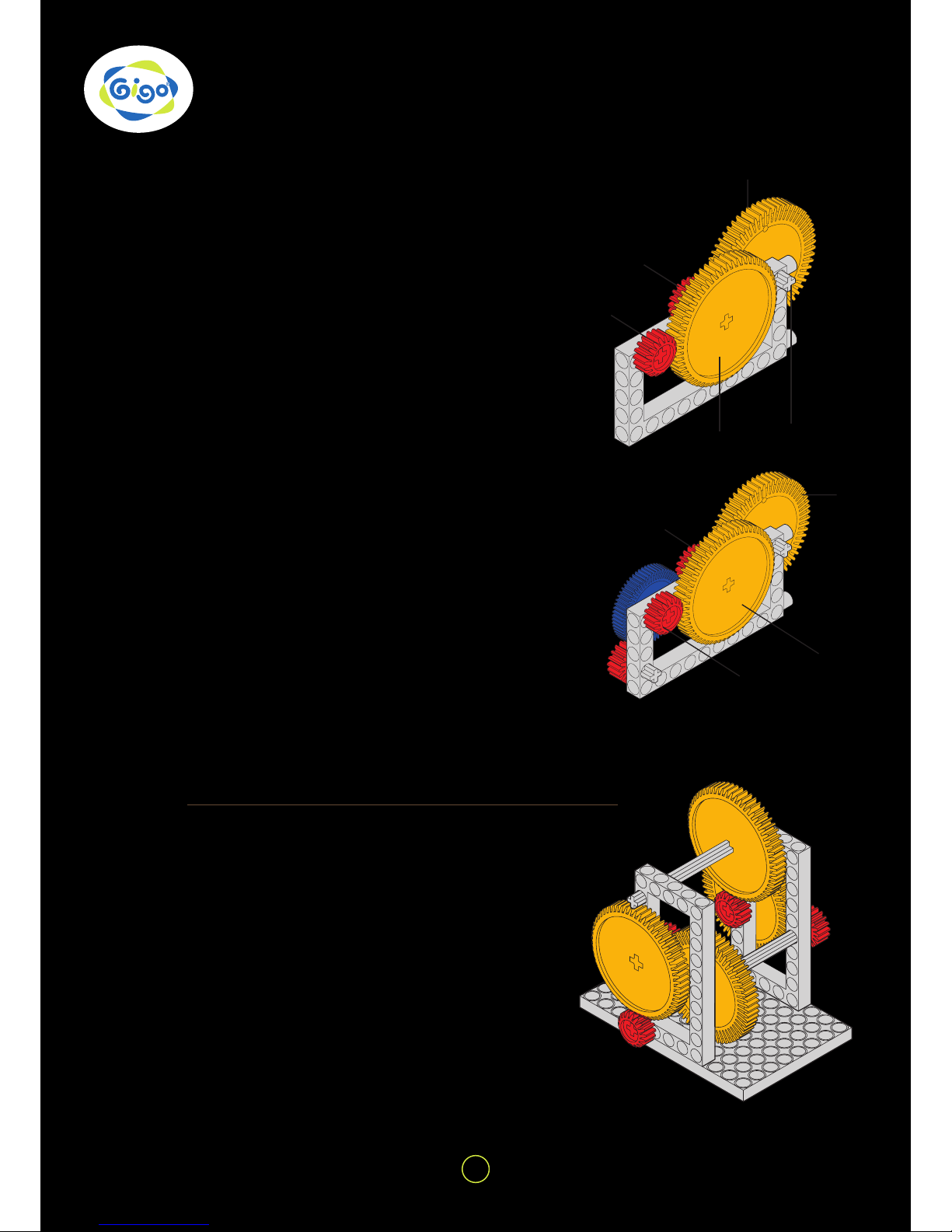

Learning about Chain Gears | WATER power

1. The power trans mis si o n of c hain g ea r s dep en ds on c h ains i n -

stead of meshing each other. The teeth of chain gears must go

with chains. The “ working” diameters of the chain gear s are

about 10mm (10-tooth), 20mm (20-tooth) and 30mm (30-tooth) .

Try to e nsure that when c onnecti ng drive chains t hey are neither too tight nor too loose so that the motion of one is transmit-

ted efciently to the other. If the lengths can not exactly t the

di

stance a litt le loos er will wor k bette r than a lit tle ti ghter, only

that the drive chains come off the chain gears. This system can

be found in normal bikes or escalators.

2. Connect a 10 -tooth chain gear to a 30 -tooth chain gear as

shown.

3. Use a pencil point, or something similar, to turn B.

Which way does A turn?

Would this be the same if A and B were two gears in mesh?

How many times would you have to turn A for B to rotate once?

The gear ratio of these two chain gears would be _ to _ ?

4. Repeat the experiment for the two other arrangements and

make a table of your results for all three.

5. Try ch aining a 10-tooth chain gear and t wo 30- tooth chain

gears together. Turn A clockwise.

What happens to B and C?

Do they turn in the same dire ction? Do they turn at the same

speed?

6. Try to chain the 10-tooth chain gear C as shown.

Turn A clockwise. What happens to B and C?

Do they turn in the same direction?

Do they turn at the same speed?

7. By connecting two sets of c hain gears tog ether three spee ds

can be obtained.

This system is widely used in tr ansmission bikes by adding a

gear shift in between.

A B

A B

A B

A B

C

A B

C

6

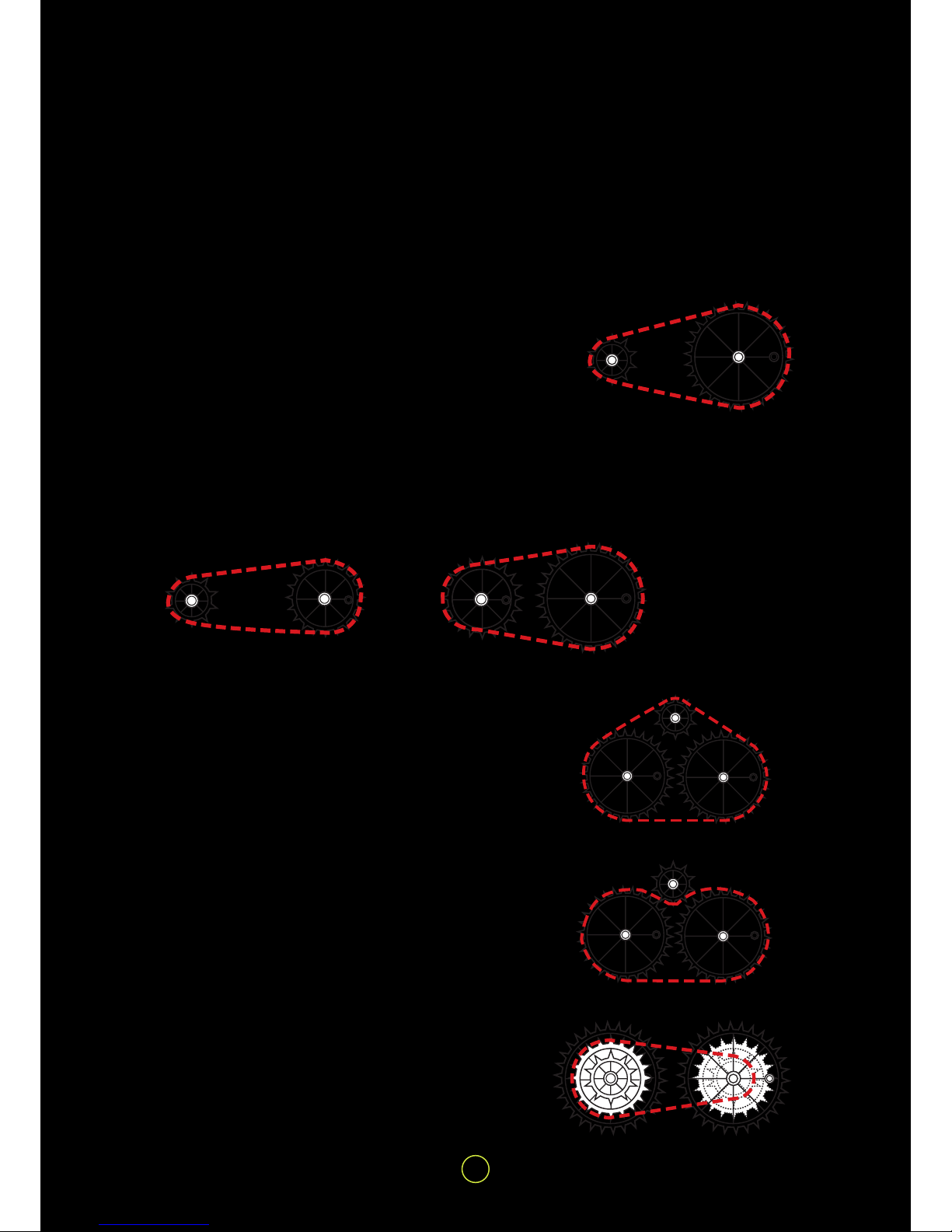

WATER power | Tips and Tricks for model building

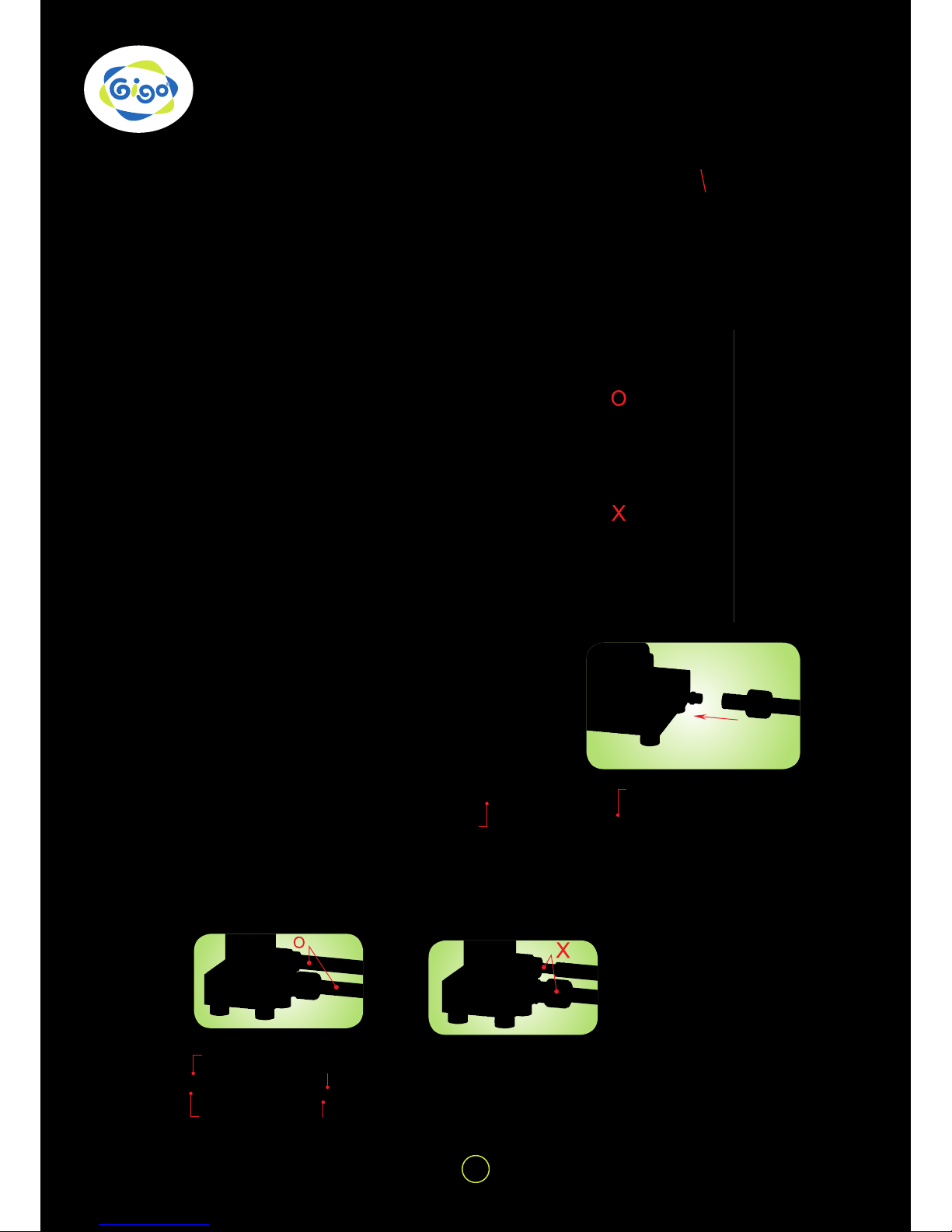

FIXING BASE GRID, RODS AND FRAMES

FIXI N G GEARS

1. The peg c an be used to join rods and

frames (Fig. 1).

2. Frames can be connected directly to

each other end to end (Fig. 2).

3. Using the end “A” of the peg/axle re-

mover to pull a peg off as Fig. 3 shows.

When xing gears onto the frame with a drive axle,

be sure to keep a proper space (about 1mm) between the gears and the frames. Try to turn the gear

and con rm if every gear in the gear train can turn

smoothly so that the least friction will be created and

then the most ef cient power transmission can be

expected (Fig. 4 & 5).

When you use a power pack to dri ve a whee led ve hicle, the gear whee ls should be arranged in sym metry (the holes on the two opposite chain gear

wheels must be kept in a horizontal line) and be

kept at the same driven speed, or the motor will stall

and the vehicle won’t move (Fig. 8).

Fixing gears to the frame Arranging gear wheels in symmetry

NG! (without a space)

TIP! These

two holes

must be kept

in a horizontal

line.

Gear fi xing

Gear xings are designed

to prevent a pulley or gear

from moving along the

axle, or slipping. They are

easy to be installed without removing any wheel or

axle (Fig. 6).

Meshing gears at 90°

When the two red gears

mesh with each other at 90°

the one on the drive axle

must be assembled as close

as possible to the outer end

of the axle so that the mesh

can be ensured (Fig. 9).

Use a chain gear to connect two drive axles to

lengthen when necessary (Fig. 7).

Lengthening drive axles Connecting unit chains

Ensure to get the face of each unit c hai n w he n connecting them to one another as a drive chain so

that the transmission can be done ef ciently and

smoothly (Fig. 10).

Fig. 1

Fig. 4 Fig. 5

Fig. 6

Fig. 7

Fig. 9

Fig. 10

Fig. 8

Fig. 2 Fig. 3

OK! (with a space)

7

About the main components of Hydro-Pneumatic | WATER power

Air-Water Power Pack

“A” is the entrance and “B” is the exit. Air

and water enter the power pack throug h the

entrance to strike the water wheel directly

and drive the mechanism behind it. Then

the water ows back to the Recycled Water

Storage through the exit for repeated use.

Secured Pump

“A” is the entrance and “B”

is the exit. The water in the

Recycled Water Storage is

driven by the Secured Pump

to come into the Air-Water

Storage.

When the pump rod is pull ed

up, air and water will come

into the Secured Pump

through the entrance and

then go out to the Air-Water Storage through the exit

w

hen the pump rod is pushed

down.

Recycled Water Storage

Secured Air-Water Storage

“A” is the entrance

and “B” is the exit. Air

and water in the Secured Recycled Water Storage come into

the Air-Water Storage

through the entrance

and go out through the

exit.

Secured One-Way

Switch

“A” is the entrance and

“B” is the exit. W hen the

switch rod is in the middle, the exit is closed, and

air and water come into

One-Way Switch. When

the switch rod is turned to

the side of the entrance,

the exit is opened and the

air and water ow out.

Exit

Hose B Entrance

Hose A Entrance

Water Wheel Mechanism

Front Back

8

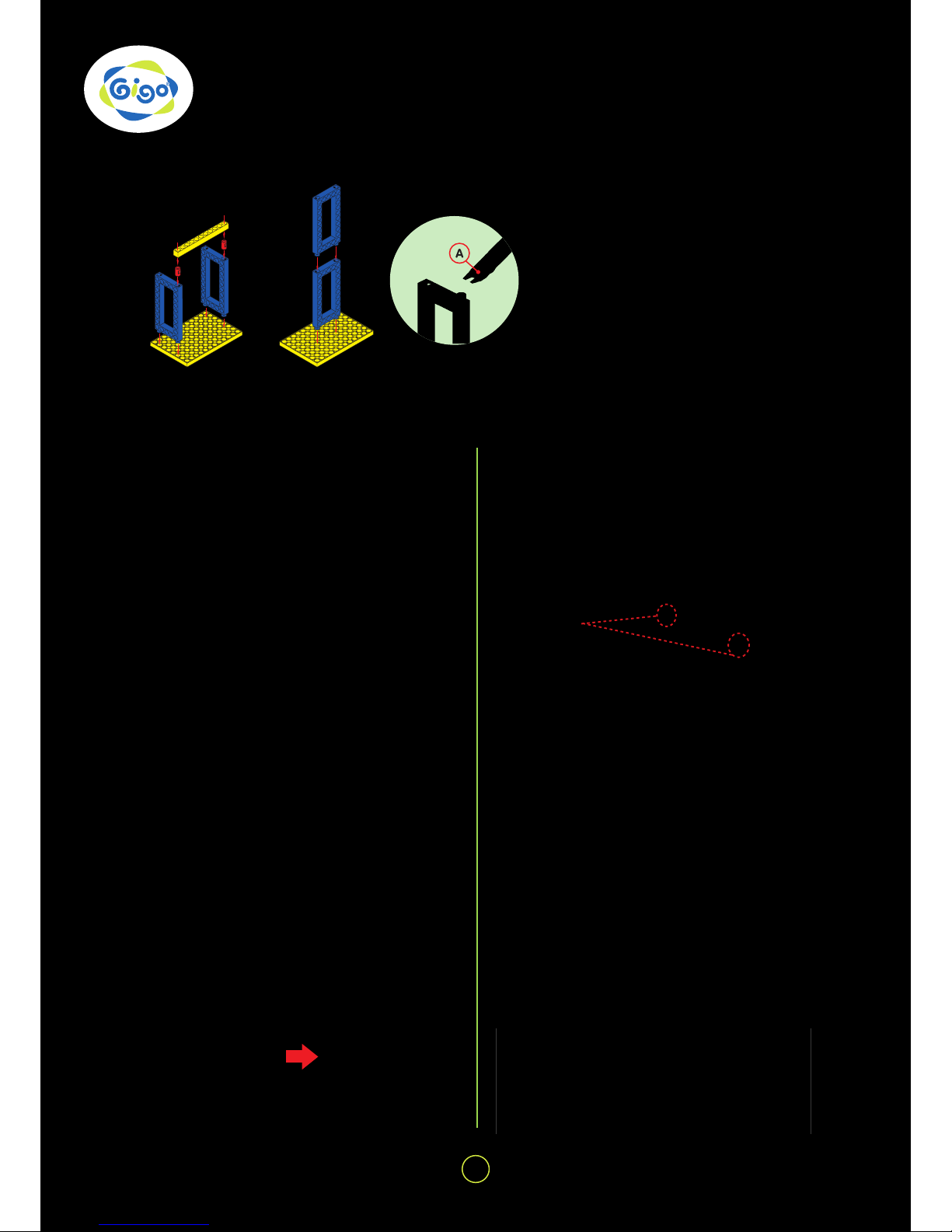

WATER power | Notes for assembly

1. NOTES FOR ASSEMBLY:

• Insert a 9.5 cm long Tube A into

the protrudent hole on the reverse side of the lid of the Recy cled Water Storage, and cut its

the other end on the bias (Fig.

11). To attach the bias -c ut end to

the inside bottom of t he storage

so that water will easily enter the

hose when pumping.

• The lengths of hoses for the mod-

els given in this guide are for reference only. Be sure not to make

the hoses too tight no r tw isted or

pressed (Fig. 12) in connection so

that water can go through them

smoothly.

• Put a Security Nut through a hose

and screw it completely when

connecting the hose to a secured

basic part (Fig. 13 & 14).

• Use an L Securit y Nut for Tube

A, and an S Security Nut for Tube

B. The hoses might become stubborn and easily come off the connected part after repeated use.

The solution is to cut off the stubborn end about 1-1.5cm long. Be

sure to wipe the conne cted part

dry with tissue paper before the

refreshed hose is used again.

• The cut hoses c an be repeatedl y

used for different models.

Fig. 11

Fig. 12

Fig. 14

Fig. 13

cut on

the bias

S Security Nut

L Security Nut

No Security Nut

L Security Nut

Tube A

Tube B

Tube B

Tube A

9

Notes for operation | WATER power

Fig. 15

Fig. 16

Fig. 17

Fig. 18

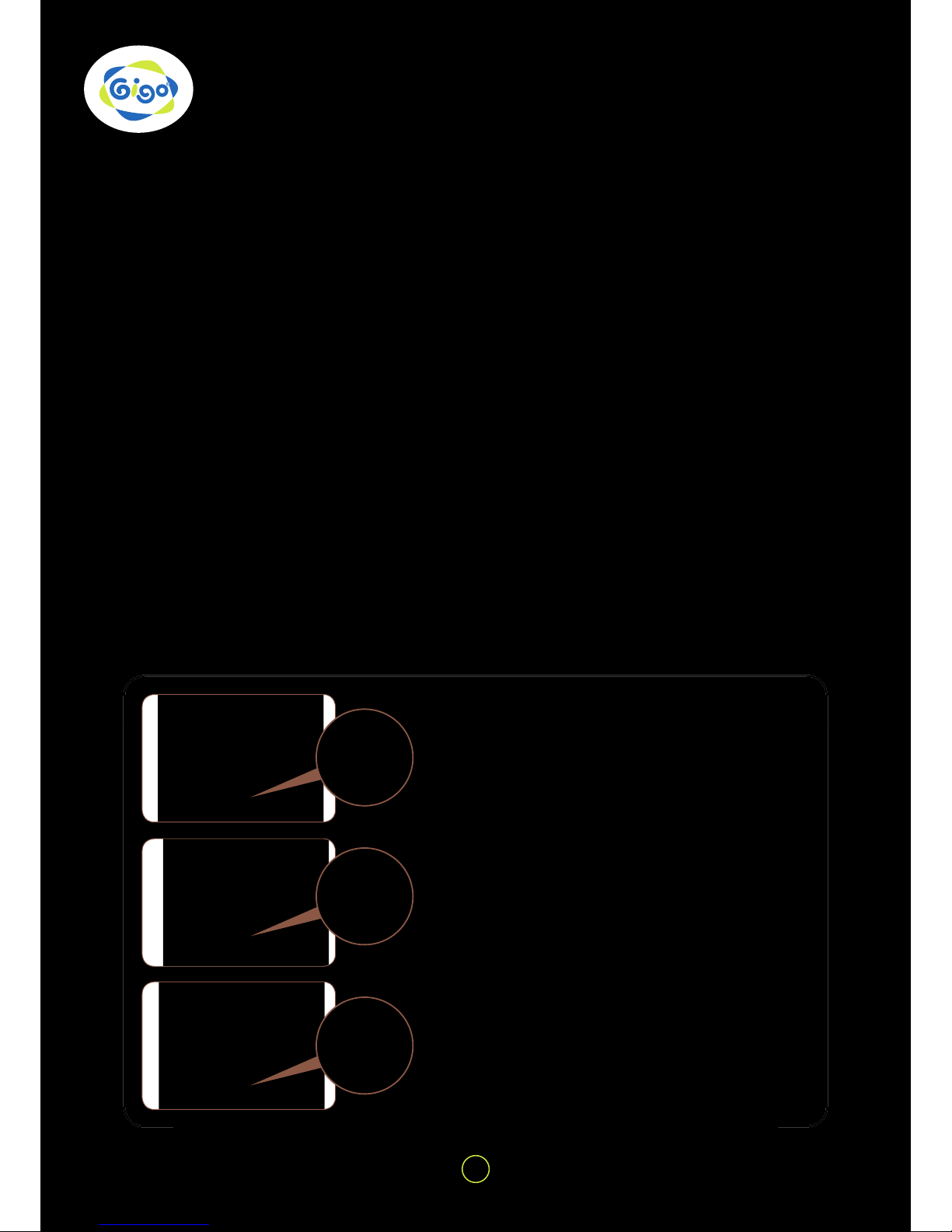

2.N OT ES FOR OPERATION:

• Check if all the hoses are xed to the

right positions before pumping.

• Check if all Switch Rods are put in

the middle of the Swi tches (i.e. in a

closed condition as Fig. 16 shows)

before pumping so that the pu mped

air/water won’t escape.

• The Switch Rod should be xed a lit-

tle tight so that air/ water leaking c an

b

e avoided. Don’t hesitate if it needs

some strength to move it.

• Check if the Air/Water Storage is

screwed to the end (Fig. 15).

• Move the Pump from the model to the

tabletop whenever you pump it, and

put it back after you nish pumping

(Fig. 17).

• The rst 10 pumping is for pushing

the water from the Recycled Water

Storage to the Secured Air-Water

Storage. Try to hold the pump rod up

for 2-3 seconds before you push it

down so that the most water c an be

driven into the pump cylinder in e ach

pumping (Fig. 18).

• Pump no more or less th en 5 0 t i me s.

If pumping over 50 times, the basic

parts might b e under too muc h pres

sure and become dama ged. On the

c

ontrary, if pumping less than 50

times, the power might be too weak to

lead to a smooth operation. The more

the air is pumped into the basic p ar t,

the bigger the air pressure and the air

power are caused (PV=nRT).

• Don’t pull off any hose eit her during

the operation or b efore all the water

gets back to the Recycled Water Storage. Ontherwise, the water stream

w

ill spurt from the hose and might

hurt you or spoil the surroundings.

• Once if hoses come off during the

operation, please tu rn off the switch

by shifting the switc h rod back to t he

middle to stop the spur t of the water,

and wipe the hose opening dry before

rexing it on.

• Use the secured One-Way Switch

to release the air/ water left in the

Air-Water Storage before you put the

models away.

Screw Air/Water

Storage to the end.

In the Close

Condition

10

WATER power | Hydro-Pneumo

PRINCIPLES:

Each time as the Secured Pump drives the water from the Recycled Water Storage into the Secured AirWater Storage, the water shall squeeze upward the enti re air inside the Secured Ai r-Water Storage. Air is a

compressible uid, in other words, the volume of air can be reduced by compressing, whereas water cannot.

When more and more water is added into the Secured Air-Water Storage, the water shall occupy more and more

capacity. Since the space within the Secured Air-Water Storage is limite d, the water w hic h eventually oc c up ie s

more and more space compresses the air inside the Secured Air-Water Storage. As a result the pressure inside

is exceedingly higher than th e air out si de t he S ec ure d A ir-Water Storage. This hi gh -pressurized air pushes the

entire water within the Sec ured A i r-Water Storage, where the water sh oves the latera l side s of the sto rag e and

attempt to escape to recover pressure equilibrium.

After the air pump draws water into the Secured Air-Water Storage and is then pumped for another 40 times, more

air is pumped into the remaining xed space occupied by water, and thus the inside air pressure is even higher.

These phenomena include many physical principles:

1. Water is incompressible, whereas air is compressible.

2. Boyle’s law:

For a xed amount of gas kept at a xed temperature, the product of the volume and pressure is constant.

(P1 · V1 = P2 · V2) (P1 : P2. = V2 : V1)

As more air is pressed inside the xed volume, the air pressure shall rise.

3. Pascal’s principle, also called Pascal’s Law, is a term in uid (gas or liquid) mechanics. It indicates pressure

variation occurred with a part of the static uid within the closed container, and transfers to every part of the

uid and to a part of the container wall without any loss.

How much energy is stored within the Secured Air-Water Storage?

According to th e experime nt, when the S ecured Pum p draws water into the Sec ured A ir-Water Storage and is

then pumped for another 40 times, the value is approximately 3.5kg/cm

2

EXPERIMENT

1. Use a pressure gauge not included in this set for inspection.

2. At initial state the value of the pressure gauge is zero.

3. Pump the water fr om the Recycl ed Water Storag e into the Sec ured Air-

Water Storage. By evenly pressing the Secured Pump for about 10 times.

4. At this point, the pressure is approximately 0.9kg/cm

2

.

5. Each time as the Secured Pump drives the water from the Recycled Water

Storage into the Secured Air-Water Storage, the water shall squeeze

upward the entire air inside the Secured Air-Water Storage. Air is a

compressible uid, in other words, the volume of air can be reduced by

compressing, whereas water cannot. When more and more water is a dded

into the Secured Air-Water Storage, the water shall occupy more and more

capacity. Since the space within the Secured Air-Water Storage is limited,

the water whic h eventually oc cupies m ore and mor e space co mpresse s

the air insid e the Secured Air-Water S torage. As a result the p ressure

inside is exce edingly higher t han the air outsid e the Secured A ir-Water

Storage.

6. Pump the Secured Pump another 40 times.

7. Pumping steadily to pe r fo r m a co mpl eted s tro ke as po ssi ble a s you c an,

the value is approximately 3.5kg/cm

2.

8. When more air is pumped into the remaining xed space, the air pressure

inside is even higher.

11

Hydro-Pneumo Models (with water-recyling system) | WATER power

1 atmospheric pressure (atm)

= 76 cm-Hg

= 76*13.6 (density of mercury)

= 1033.6 cm-Hg = 10.336 m-Hg

3.5kg/cm

2

compressed air is equal to

3.4 atm. If it is compare d to potential energy, 1 atmospheric pressure

(atm) = 10.336m-Hg, 3.5kg/cm2 = 35

m height of water column pressure

(it can be compar ed to the height of

a 10-story building). Therefore the

created energy via air pum ping and

stored within the pressure storage

tank, can push and r un your various

unique assembled models.

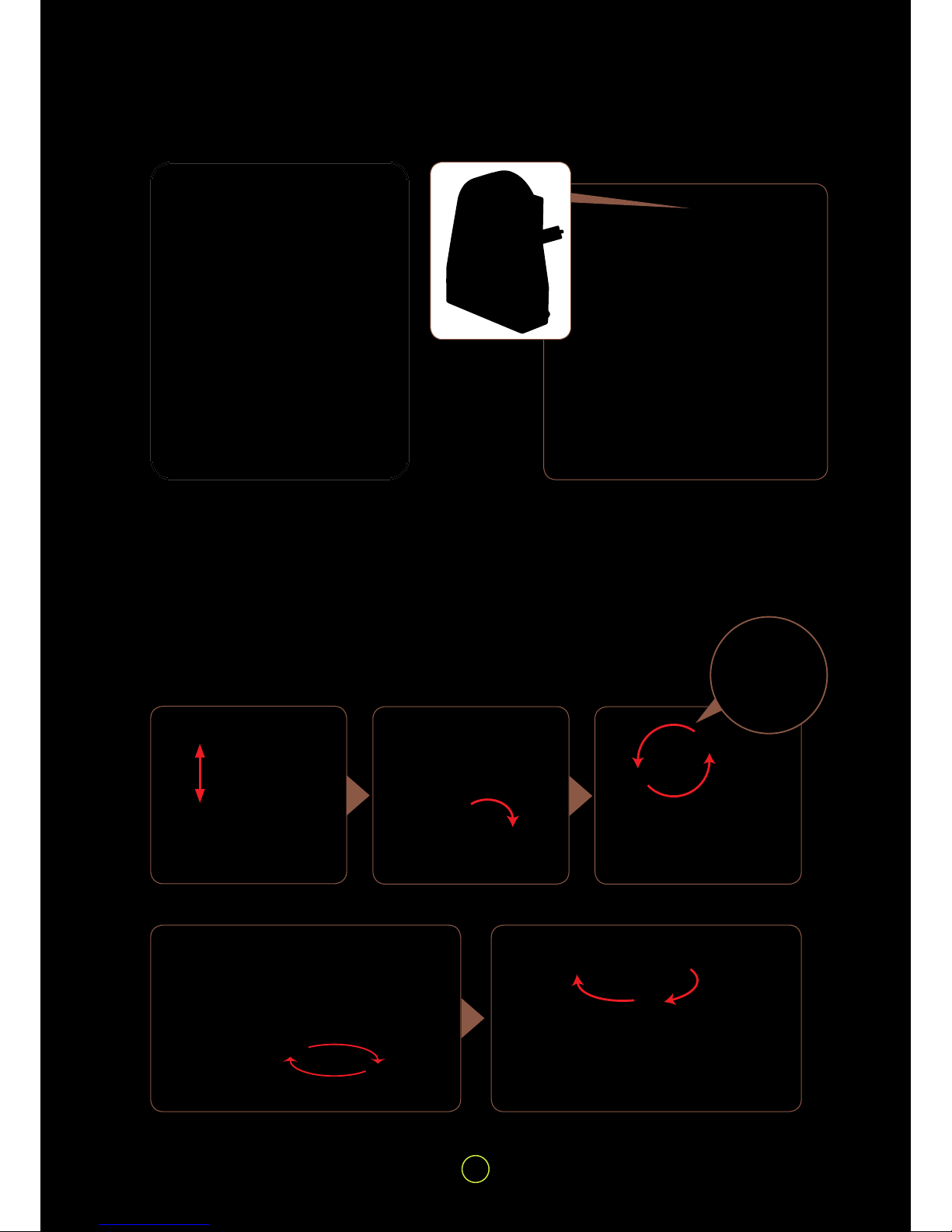

HOW TO OPERATE

1. Pump the Secu red Pum p abo ut 10 times to get all water f rom Water-Recycl ed S tora ge to Se c ure d A ir-Water

Storage and keep pumping another 40 times to compress the air in the Secured Air-Water Storage.

2. Then turn the rod of the Secured One-Way Switch to open it.

3. The released water will jet out to strike the blades of the water wheel to activate the

Air-Water Power Pack and drive the mechanism behind it, and then ows back through the

exit to the Recycled Water Storage for repeated use.

Step 1 Pump 50 times. Step 2 Turn on the switch.

Step 3 To activate the Air-

Water Power Pack.

To drive the mechanism behind it. The model works!

Back

View

The exit

Front

View

The entrance

12

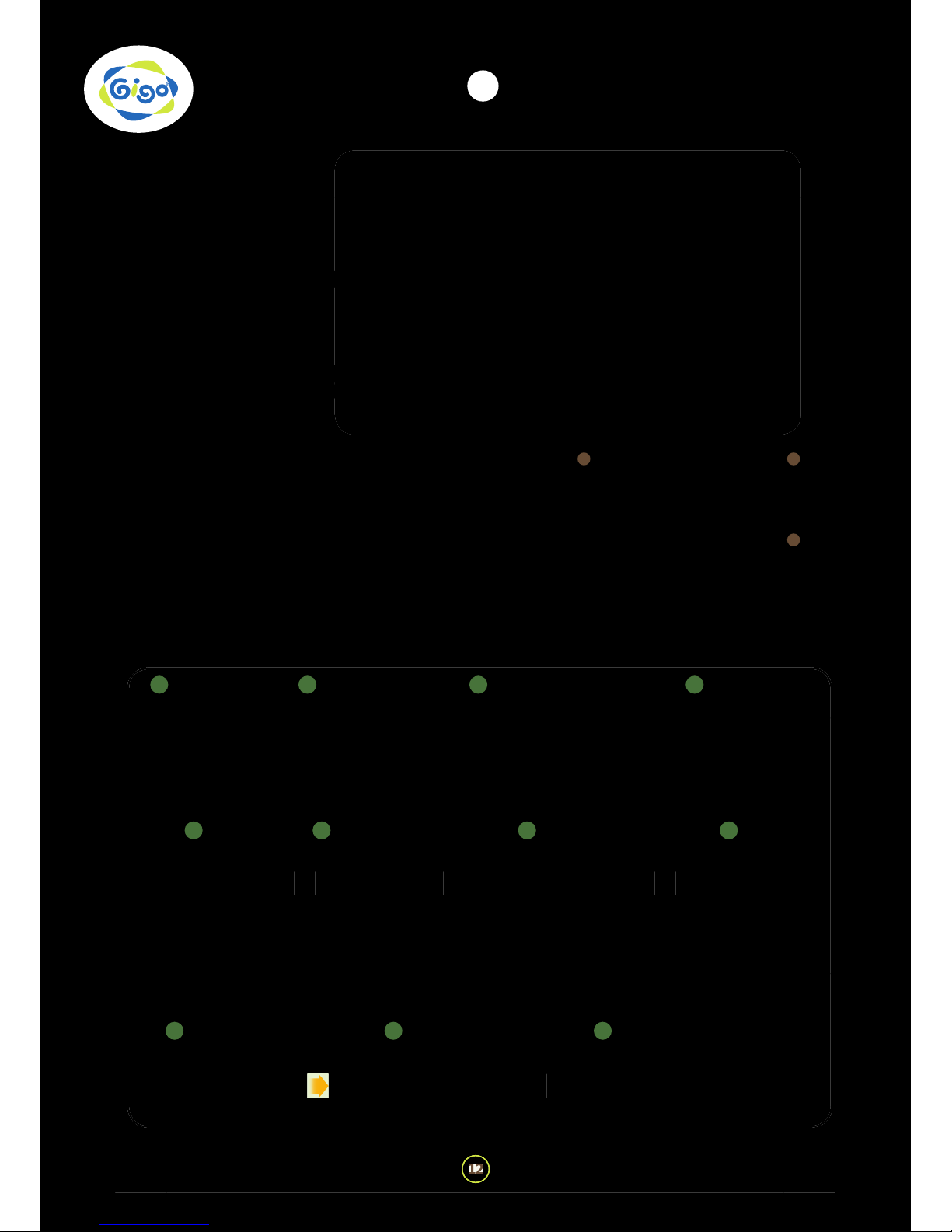

WATER power | MODEL 1 Cutting Machine

Notes for Assembly

Parts Needed

x 36

x 16

x 1

x 1

x 1

x 1

x 1

x 1

x 1

x 1

x 1

x 1 x 1

x 1

x 1 x 1

x 1

x 1

x 2x 2x 2

x 2

x 2

x 2

x 2 x 2

x 3

x 4

x 4

Cutting

Machine

1. The g ear s sho uld b e mes hed w ith e ach ot he r well in

order to operate smoothly.

2. Note that the chain gears are to be aligned in order for

the chain to operate smoothly.

3. Cut Tube A and Tube B to get t he tubes i n follow ing

lengths for this model.

Tube A : 9.5cm x1, 30cm x 1, 37cm x 1, 44cm x 1

Tube B : 25cm x 1, 35cm x 1

Tube BTube A

1 2

3

1

3 42

5 7

9 11

6 8

10

13

MODEL 1 Cutting Machine | WATER power

12 1413

15

19

20 21 22

16

17 18

23 24

25

26

27 28

29 30

31 32

Completed

Loading...

Loading...