Page 1

Manual Part Number:

Revision:

Print Date:

21568

F

March 2008

Series 8035XA Peak Power Sensors

Operation & Maintenance Manual

8035XA

............................................Certified Product

Registrar: BSI, Certification No. FM 34226 v Registered 04 June 1996 v Amended 01 March 2000

Giga-tronics Incorporated v 4650 Norris Canyon Road v San Ramon, California 94583

925.328.4650 or 800.726.4442 v 925.328.4700 (Fax) v 800.444.2878 (Customer Service) v 925.328.4702 (CS Fax)

www.gigatronics.com

ISO 9001.................................................. Certified Process

Page 2

All technical data and specifications in this manual are subject to change without prior notice and do not represe nt a

commitment on the part of Giga-tronics Incorporated.

© 2001 Giga-tronics Incorporated. All rights reserved.

Printed in the USA

WARRANTY

Giga-tronics Series 8035XA Peak Power Sensors

are warranted against defective materials and

workmanship for one years from date of shipment .

Giga-tronics will at its option repair or replace

products that are proven defective during the

warranty period. This warranty DOES NOT cover

damage resulting from improper use, nor

workmanship other than Giga-tronics service.

There is no implied warranty of fitness for a

particular purpose, nor is Giga-tronics liable f or any

consequential damages. Specification and price

change privileges are reserved by Giga-tronics.

Page 3

Declaration of Conformity

Application of Council Directive(s)

Standard(s) to which Conformity is Declared:

89/336/EEC and 73/23/EEC EMC Directive and Low Voltage Directive

EN61010-1 (1993) Electrical Safety

EN61326-1 (1997) EMC - Emissions & Immunity

Manufacturer’s Name: Manufacturer’s Address:

Giga-tronics, Incorporated 4650 Norris Canyon Road

San Ramon, California 94583

U.S.A.

Type of Equipment: Model Series Number:

Peak Power Sensors 8035XA

Model Numbers In Series:

80350A, 80351A, 80352A,

80353A, 80354A, 80355A

Declaration of Conformity on file. Contact Giga-tronics, Inc.

4650 Norris Canyon Rd.

San Ramon, CA 94583

Ph: 1-925-328-4650

Fx: 1-925-328-4700

Page 4

Page 5

1

Introduction

2

Operation

Table of Contents

About This Manual .................................................................................................. 1-vii

Conventions ........................................................................................................... 1-viii

Record of Manual Changes ........................................................................................1-x

Special Configurations ..............................................................................................1-xi

1.1 Description....................................................................................................1-1

1.1.1 Accessories ..................................................................................1-1

1.1.2 Product Returns ...........................................................................1-1

1.2 Specifications ...............................................................................................1-2

1.2.1 Performance Specifications ...........................................................1-3

1.2.2 Compatible Power Meters ............................................................1-5

3

2.1 Introduction ..................................................................................................2-1

2.2 Power Sweep Calibration ..............................................................................2-1

2.2.1 5, 25 and 50 Watt Peak Power Sensors ........................................2-2

2.2.2 Triggering .....................................................................................2-3

2.2.3 Zeroing .........................................................................................2-4

2.2.4 Sensor Triggering .........................................................................2-5

2.3 Sample Delay ................................................................................................2-6

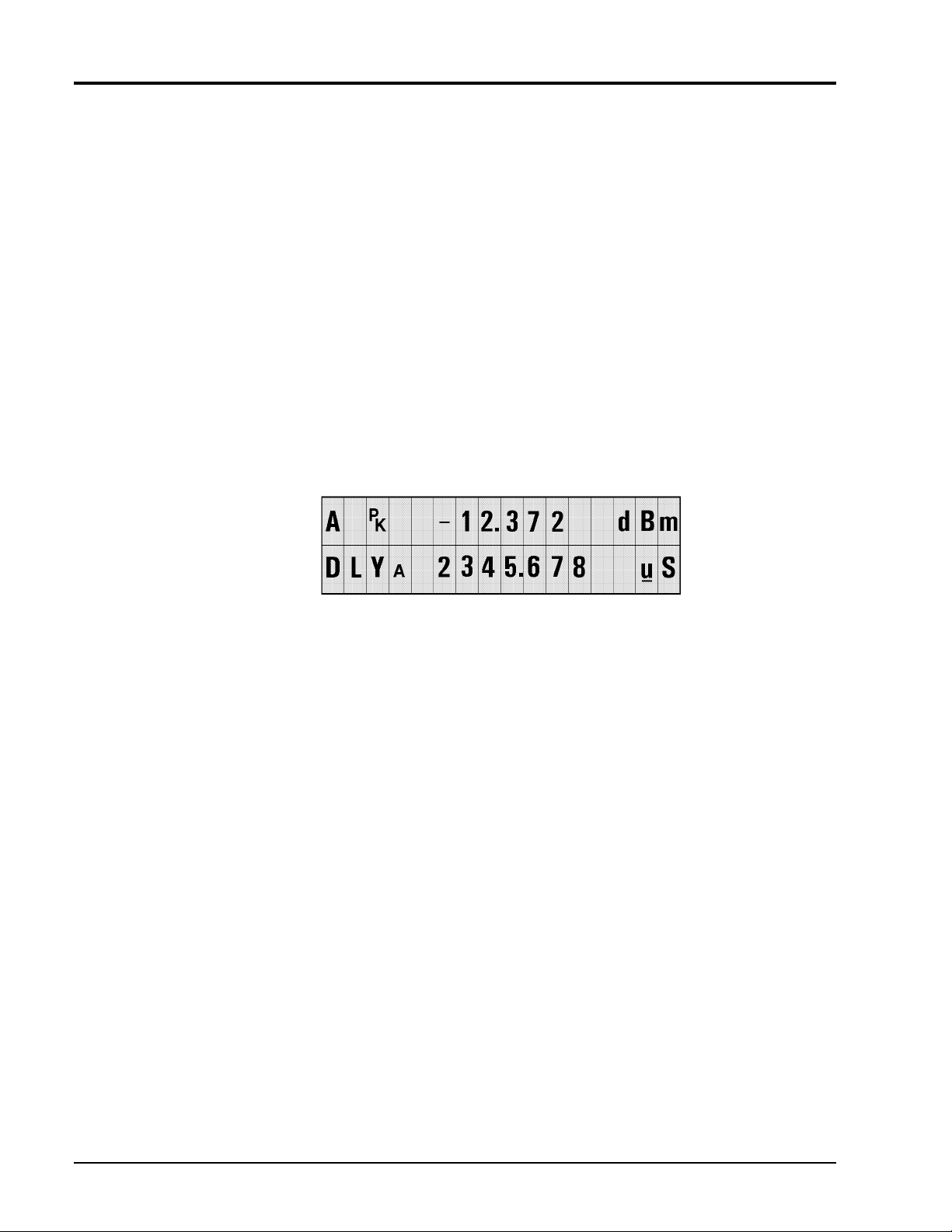

2.3.1 Sample Delay Display ...................................................................2-7

2.3.2 Setting Sample Delay ...................................................................2-8

2.3.3 Sample Delay Limits .....................................................................2-9

2.3.4 Setting Sample Delay Offset .......................................................2-10

2.3.5 Single Peak Sample Measurements ............................................2-10

2.3.6 Real Time Pulse Profile and Sample Position Display ..................2-11

2.3.7 Sample Delay Offset ...................................................................2-12

2.3.8 Measuring Pulse Droop ..............................................................2-13

2.3.9 Measuring 3 dB Pulse Width ......................................................2-14

2.3.10 Measuring Rise-Time ..................................................................2-15

2.4 GPIB Commands.........................................................................................2-15

2.4.1 Setting Trigger Modes ................................................................2-15

2.4.2 Setting Delays ............................................................................2-16

2.4.3 Reading Values ...........................................................................2-17

2.4.4 Commands for the 58542 ...........................................................2-18

Theory of Operation

Manual 21568, Rev. F, March 2008 i

Page 6

Series 8035XA Peak Power Sensors

3.1 Introduction...................................................................................................3-1

3.2 Analog Assembly Description........................................................................3-2

3.3 Digital Assembly Description.........................................................................3-5

3.3.1 Overview ......................................................................................3-5

3.3.2 Description ...................................................................................3-6

Calibration and Testing

4.1 Introduction...................................................................................................4-1

4.2 Equipment Required......................................................................................4-1

4

4.3 Power Linearity Test......................................................................................4-2

4.3.1 CW Linearity Test .........................................................................4-2

4.3.2 Peak Linearity Test ........................................................................4-3

4.4 Trigger Modes Tests .....................................................................................4-4

4.4.1 Detector Output Test ....................................................................4-4

4.4.2 Trigger Level Test .........................................................................4-4

4.4.3 Delay Test ....................................................................................4-6

4.4.2.1 100 mW Power Peak Sensors..................................... 4-4

4.4.2.2 High Power Peak Sensors........................................... 4-5

Maintenance

5

6

Parts Lists

5.1 Introduction...................................................................................................5-1

5.1.1 Rise-Time Adjustments .................................................................5-1

5.1.2 Zero Adjustment ...........................................................................5-2

5.2 Troubleshooting ............................................................................................5-2

5.2.1 Sensor Not Present .......................................................................5-4

5.2.2 Calibration ....................................................................................5-4

5.2.3 INTernal ........................................................................................5-5

5.2.4 EXTernal .......................................................................................5-6

5.2.5 Delay ............................................................................................5-6

5.2.6 Output Problems ..........................................................................5-6

5.3 Sensor Element Replacement ........................................................................5-7

5.3.1 Disassembly of the Sensor ...........................................................5-7

5.3.2 Replacing the Sensor Element ......................................................5-7

5.3.3 Reassembly of the Sensor ............................................................5-8

6.1 Introduction...................................................................................................6-1

80350A PEAK POWER SENSOR, TYPE N, Rev. F....................................... 6-1

80351A HI PWR PEAK POWER SENSOR, 5W, Rev. C................................ 6-2

80352A HI PWR PEAK POWER SENSOR, 25W, Rev. C.............................. 6-3

80353A PEAK POWER SENSOR, TYPE K, Rev. D....................................... 6-4

80354A PEAK POWER SENSOR, TYPE K, Rev. E....................................... 6-5

80355A HI PWR PEAK POWER SENSOR, 50W, Rev. C.............................. 6-6

32133 SENSOR-S-CLOCK-BUFFER PCA, Rev. A...................................... 6-6

21471 SENSOR HOUSING ASSY, Rev. C................................................. 6-7

ii Manual 21568, Rev. F, March 2008

Page 7

7

Diagrams

Index

Preface

21350 ANALOG PCB ASSY (A1), Rev. P.................................................. 6-8

21353 DIGITAL PCB ASSY (A2), Rev. Z................................................. 6-10

6.2 List of Manufacturers..................................................................................6-12

7.1 Introduction ..................................................................................................7-1

Series 8035XA Peak Power Sensors Index........................................................... Index-1

Manual 21568, Rev. F, March 2008 iii

Page 8

Series 8035XA Peak Power Sensors

Illustrations

Figure 2-1: Sensor Setup Menu Tree ......................................................................2-2

Figure 2-2: Internal Triggering Levels......................................................................2-3

Figure 2-3: 8035XA Sensor Timing Diagram...........................................................2-4

Figure 2-4: Sample Delay Adjustment Display ........................................................2-6

Figure 2-5: Channel A Default Sample Delay ..........................................................2-7

Figure 2-6: Channel B Default Sample Delay...........................................................2-7

Figure 2-7: Channel A & B Default Sample Delay....................................................2-7

Figure 2-8: Sample Delay with Uncalibrated Sensor ...............................................2-7

Figure 2-9: Sample Delay with No Trigger Display..................................................2-9

Figure 2-10: Sample Dely Over-Range Indication......................................................2-9

Figure 2-11: Sample Delay Over-Range Offset Display............................................2-10

Figure 2-12: Pulse Profile and Sample Delay Test Setup.........................................2-11

Figure 2-13: Sample Delay......................................................................................2-12

Figure 2-14: Using SD to Offset a 0 ns Time Reference...........................................2-12

Figure 2-15: SD Setting for Measuring Pulse Droop................................................2-13

Figure 2-16: Using SD to Measure a 3 dB Pulse Width...........................................2-14

Figure 3-1: 8035XA High Level Block Diagram........................................................3-2

Figure 3-2: Analog PC Assembly Block Diagram.....................................................3-3

Figure 3-3: Analog Circuit Timing Diagram.............................................................3-4

Figure 3-4: Digital PC Assembly Block Diagram......................................................3-5

Figure 3-5: Digital Timing Diagram, INT/EXT Trig Mode..........................................3-7

Figure 3-6: Digital Timing Diagram, CW Mode .......................................................3-8

Figure 3-7: Digital Serial Data Cycle Timing Diagram..............................................3-8

Figure 4-8: Power Linearity Test Setup...................................................................4-2

Figure 4-9: Detector Output and Trigger Level Setup..............................................4-4

Figure 5-10: Principal Test Component Locations.....................................................5-2

iv Manual 21568, Rev. F March 2008

Page 9

Tables

Preface

Table 1-1: Peak Power Sensor Selection Guide..................................................... 1-2

Table 1-2: Power Sensor Cal Factor Uncertainties ................................................ 1-5

Table 6: Sample Delay Limits ............................................................................ 4-6

Table 7: 80350A, 80353A, 80354A Trigger Test............................................... 4-9

Table 8: 80351A Trigger Test............................................................................ 4-9

Table 9: 80352A, 80355A Trigger Verification................................................... 4-9

Table 10: External Trigger Verification................................................................. 4-9

Table 11: Sample Delay Test............................................................................. 4-10

Table 5-1: Sensor Malfunction Symptoms............................................................ 5-3

Table 5-2: Digital Board Components and Signals................................................ 5-6

Table 6-1: List of Manufacturers ........................................................................ 6-12

Manual 21568, Rev. F, March 2008

Page 10

Series 8035XA Peak Power Sensors

vi Manual 21568, Rev. F, March 2008

Page 11

About This Manual

This manual contains the following chapters and appendices to describe the operation and

maintenance of Giga-tronics Series 8035XA Peak Power Sensors:

Preface:

In addition to a comprehensive Table of Contents and general information abou t the manual,

the Preface also contains a record of changes made to the manual since its publication, an d

a description of Special Configurations. If you have ordered a user-specific manual, please

refer to page

Chapter 1 – Introduction:

This chapter contains a brief introduction to the instrument and its performance parameters.

Chapter 2 – Operation:

This chapter is a guide to operating the sensor with the Series 8540X Universal Power

Meters and the Model 58542 VXIbus Universal Power Meters.

Chapter 3 – Theory of Operation:

xi for a description of the special configuration.

This chapter provides a block diagram level description and its circuits for maintenance and

applications.

Chapter 4 – Calibration & Testing:

Procedures for inspection, calibration and performance testing are outlined in this chapter.

Chapter 5 – Maintenance:

This chapter contains procedures for main te na nce and troubleshooting.

Chapter 6 – Parts Lists:

This chapter lists all components and parts and their sources.

Chapter 7 – Diagrams:

This chapter contains schematics and parts placement diagrams for all circuits.

Index:

A comprehensive word index of the various elements of the 8035XA manual.

Changes that occur after publication of the manual, and Special Configuration data will be

inserted as loose pages in the manual binder. Please insert and/or replace the indicated

pages as detailed in the Technical Publication Change Instructions included with new and

replacement pages.

Manual 21568, Rev. F, March 2008

Page 12

Series 8035XA Peak Power Sensors

The following conventions are used in this product manual. Additional conventions not included

here will be defined at the time of usage.

Warning

The WARNING statement is encased in gray and centered in the

page. This calls attention to a situation, or an operating or

maintenance procedure, or practice, which if not strictly corrected

or observed, could result in injury or death of personnel. An

example is the proximity of high voltage.

Caution

Conventions

WARNING

CAUTION

The CAUTION statement is enclosed with s ingle lines and c entered

in the page. This calls attention to a situation, or an ope rating or

maintenance procedure, or practice, which if not strictly corrected

or observed, could result in temporary or permanent da mage to the

equipment, or loss of effectiveness.

Notes

*

Logic Not

A logic NOT or LOW condition used in text will be indicated by an overscore, such as LOADCTR. Elsewhere, such as in schematics, a logic NOT or LOW condition may be indicate d by a

forward slash bar, such as /LOAD-CTR.

Key Press Commands

Commands requiring specific keys to be pressed on the supporting device, such as power

meter, are indicated by square brackets. For example, [ENTER] means to press the Enter Key.

NOTE: A NOTE Highlights or amplifies an essential operating or maintenance procedure,

practice, condition or statement.

viii Manual 21568, Rev. F, March 2008

Page 13

Manual 21568, Rev. F, March 2008

Page 14

Series 8035XA Peak Power Sensors

This table is provided for your convenience to maintain a permanent record of manual change

data. Corrected replacement pages will be issued as Technical Publication Change

Instructions, and will be inserted at the front of the binder. Remove the corresponding old

pages, insert the new pages, and record the changes here.

Record of Manual Changes

Change Instruction

Number

Change Instruction

Date

Date

Entered

Comments

x Manual 21568, Rev. F, March 2008

Page 15

Special Configurations

When the accompanying product has been configured for user-specific applicatio n(s),

supplemental pages will be inserted at the front of the manual binder. Remove the indicated

page(s) and replace it (them) with the furnished Special Configuration supplemental page(s).

Manual 21568, Rev. F, March 2008

Page 16

Series 8035XA Peak Power Sensors

xii Manual 21568, Rev. F, March 2008

Page 17

Manual 21568, Rev. F, March 2008

Page 18

Series 8035XA Peak Power Sensors

xiv Manual 21568, Rev. F, March 2008

Page 19

1.1 Description

The 8035XA Series Peak Power Sensors perform true sample-based peak power

measurements on pulsed signals. The sensors are compatible with Giga-tronics Series 8540,

and the 8650 series Universal Power Meters and the Model 58542 VXIbus Universal Power

Meter (see Section

power versions of 5, 25 and 50 Watts, are available to 18 GHz. (see Table 1-1).

Peak Power sensors have three modes of operation: (1) CW, (2) Peak, internally triggered , and

(3)

Peak, externally triggered. When operated in the pea k mode s, trigge r- point to sam ple- point

delay (sample delay) is adjustable from -20 ns to 100 ms in 0.5 ns steps. T rigger levels are also

adjustable.

The Giga-tronics proprietary power sweep calibration system provides excellent linearity from

-20 dBm to +20 dBm in Peak modes, and from -30 dBm to +20 dBm in CW mode. Cal Factors

stored in EEPROMs in the power sensors automatically compensate for sensor frequency

response variations. This unique approach can be configured for automatic frequency

response correction. A detector output signal is provided for viewing the detected envelope of

the pulsed RF waveform on an oscilloscope. Use of a digital oscilloscope is recommended.

1

Introduction

1.2.2). The sensors operate from 45 MHz to 18, 26.5, and 40 GHz. High

1.1.1 Accessories

Included: 3 each SMB (plug) to BNC (m) cables, 2 m (6 ft) long

Optional: Option 02: 12 ft SMB (plug) to BNC cable

1.1.2 Product Returns

Should it be necessary to return the product to Giga-tronics, use the original shipping container.

If this is not possible, use a strong carton (350 lbs/in

Wrap the instrument in heavy paper or plastic before placing it in the shipping container.

Completely fill the areas on all sides of the instrument with packaging material, taking extra

precautions to protect the front and rear panels. Seal the package with strong tape or metal

bands. Mark the outside of the package “FRAGILE — DELICATE INSTRUMENT”.

If corresponding with the factory or the local Giga-tronics sales office regarding a product

return, please refer to the full model number and serial number. If the instrument is being

3 each Cable Harness Wraps, 1.2 m (4 ft) long

Option 03: SMB (plug) to SMA (jack) adapter

2

bursting strength), or a wooden box.

Manual 21568, Rev. F, March 2008

Page 20

Series 8035XA Peak Power Sensors

*

shipped for repair, be sure to enclose all available pertinent data regar ding the problem that

has been found.

NOTE: If you are returning an instrument to Giga-tronics for service, first contact Customer

Service so that a return authorization number (RMA) can be assigned via e-mail at

repairs@gigatronics.com or at 800.227-9764 (The 800 number is only valid within the US).

You may also try our domestic line at 925.328.4650 or Fax at 925.328.4702.

1.2 Specifications

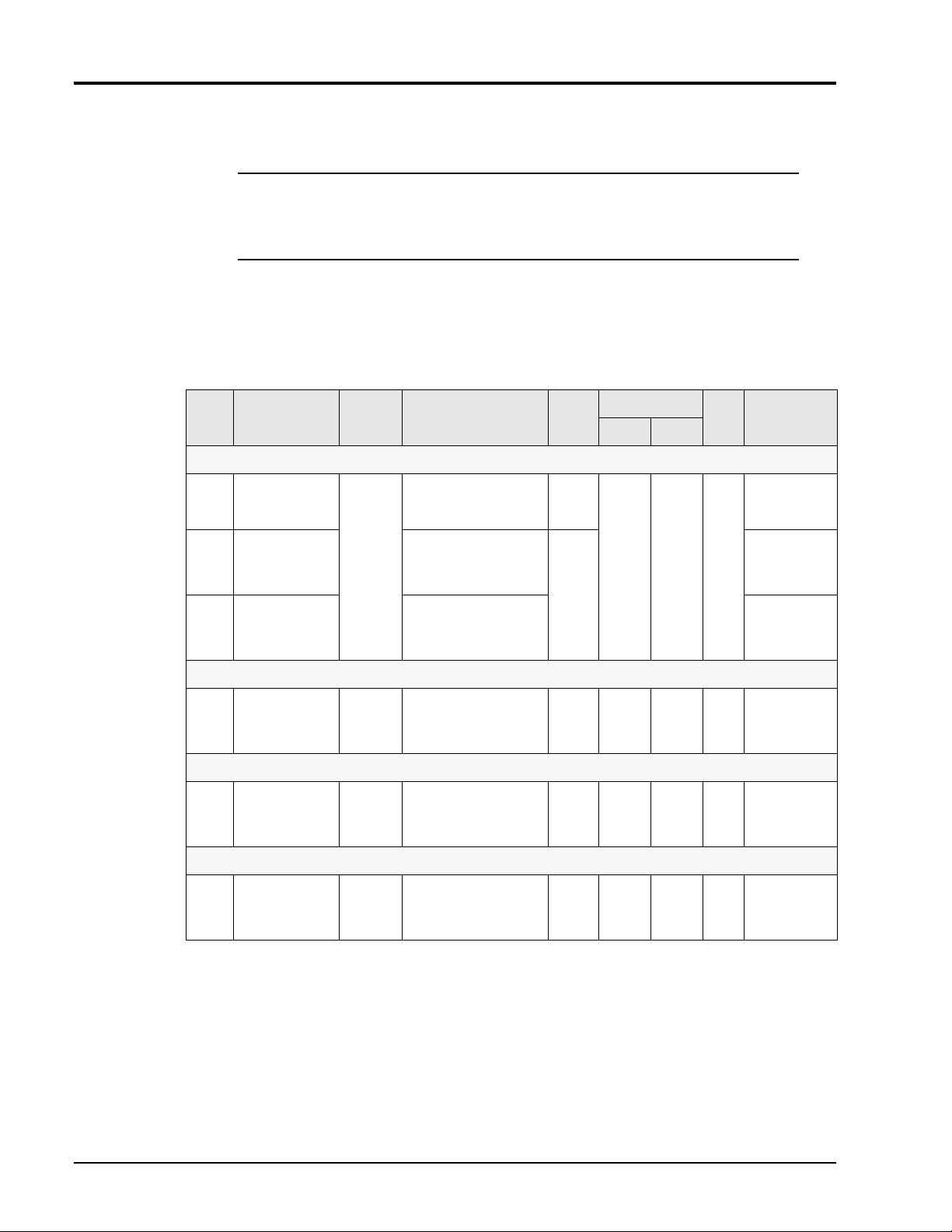

Table 1-1: Peak Power Sensor Selection Guide

Model

80350A

80353A

80354A

80351A

80352A

Freq. Range/

Power Range

45 MHz to 18 GHz

-20 to +20 dBm, Peak

-30 to +20 dBm, CW

45 MHz to 26.5 GHz

-20 to +20 dBm, Peak

-30 to +20 dBm, CW

45 MHz to 40 GHz

-20 to +0.0 dBm, Peak

-30 to +0.0 dBm, CW

45 MHz to 18 GHz

0.0 to +40 dBm, Peak

-10 to +37 dBm, CW

45 MHz to 18 GHz

+10 to +50 dBm, Peak

0.0 to +44 dBm, CW

Max.

Power

+23 dBm

(200 mW)

CW or Peak

CW:

+37 dBm

(5 W Avg.)

Peak:

+43 dBm

CW:

+44 dBm

(25 W Avg.)

Peak:

dBm

+53

Power Linearity

Standard Peak Power Sensors

-30 to -20 dBm ±0.00 dB

-20 to +20 dBm ±0.05 dB/10 dB

-30 to -20 dBm ±0.00 dB

-20 to +20 dBm ±0.1 dB/10 dB

-30 to -20 dBm ±0.00 dB

-20 to 0.0 dBm ±0.2 dB/10dB

-10 to +0 dBm ±0.00 dB

+0 to +40 dBm ±0.05 dB/10 dB

0.0 to +10 dBm ±0.00 dB

+10 to +50 dBm ±0.05 dB/10 dB

4

5W Peak Power Sensor

25W Peak Power Sensor

50W Peak Power Sensor

Type

N(m)

50Ω

Type

K(m)

50Ω

2,5

Type

N(m)

50Ω

3,5

Type

N(m)

50Ω

3,5

RF

Conn

1

Dimensions

Ln. Dia.

165 mm

(6.5 in)

200 mm

(7.9 in)

229.6mm

(9.05 in)

37 mm

1.25 in)

37 mm

(1.25 in)

41.15

mm

(1.62 in)

Wgt VSWR

1.12:0.045 - 2 GHz

1.22:2 - 12.4 GHz

1.37:12.4 -18 GHz

1.12:0.045 - 2 GHz

1.22:2 - 12.4 GHz

0.3 kg

1.37:12.4 -18 GHz

(0.7 lb)

1.50:18 - 26.5 GHz

1.12:0.045 - 2 GHz

1.22:2 - 12.4 GHz

1.37:12.4 -18 GHz

1.50:18 - 26.5 GHz

1.92:26.5 - 40 GHz

1.15:0.045 - 4 GHz

0.4 kg

1.25:4 - 12.4 GHz

(0.9 lb)

1.35:12.4 -18 GHz

1.20:0.045 - 6 GHz

0.4 kg

1.30:6 - 12.4 GHz

(0.9 lb)

1.40:12.4 -18 GHz

CW:

+47 dBm

(50 W Avg.)

Peak:

+53 dBm

0.0 to +10 dBm ±0.00 dB

+10 to +50 dBm ±0.05 dB/10 dB

Type

N(m)

50Ω

287.7

mm

(11.35 in)

41.15

mm

(1.62 in)

0.9 kg

(1.1 lb)

1.25:0.045 - 6 GHz

1.35:6 - 12.4 GHz

1.45:12.4 -18 GHz

80355A

45 MHz to 18 GHz

+10 to +50 dBm, Peak

0.0 to +47 dBm, CW

Notes:

1. The K connector is electrically and mechanically compatible with the APC-3.5 and SMA connectors.

2. Power coefficient equals <0.01 dB/Watt (AVG).

3. Power coefficient equals <0.015 dB/Watt (AVG).

4. For frequencies above 8 GHz, add power linearity to system linearity.

5. Peak operating range above CW maximum range is limited to <10% duty cycle.

1-2 Manual 21568, Rev. F, March 2008

Page 21

1.2.1 Performance Specifications

Performance specifications describe warranted performance. Typical performance shown in

italics is non-warranted. Specifications are subject to change without notice.

Rise-Time (10% to 90%, 0 dBm = 100%) < 100 ns

Fall Time (90% to 10%, 0 dBm = 100%) < 250 ns

System Linearity (50 MHz for Standard Peak Power Sensors:)

±0.13 dB from -30 to +16 dBm

±0.13 dB +(+0 dB, -0.05 dB/dB) from +16 to +20 dBm

Manual 21568, Rev. F, March 2008

Page 22

Series 8035XA Peak Power Sensors

Zero Accuracy

Applies to 80350A, 80353A and 80354; 80351A = 100x larger,

80352A = 1000x larger

Zero Set: < ±1.0 mW, Peak;

Zero Drift: < ±1.0 mW, Peak

Noise Uncertainty: < ±1.0 mW, Peak;

Sample Delay Timing

Delay Range: -20 ns to 104 ms

Delay Resolution: 0.5 ns

Delay Jitter: ±2.0 ns

Trigger Level Set Range:

Internal: -30 to +20 dBm

Resolution: ±0.01 dB

External: 0.0V to 4.0V

Trigger Jitter: < ±2.0 ns

Settling Time: (50% to within 3%) < 250 ns

Control Inputs and Outputs

< ±0.05 mW, CW

< ±0.05 mW, CW

in 1 hour at constant temperature, 24 hour warmup

< ±0.05 mW, CW at constant temperature, measured over a 1

minute interval, 24 hour warmup

Resolution to 0.01V

Trigger Input: [SMB (jack) connector]

Detector Out: [SMB (jack) connector]

Sample Delay: [SMB (jack) connector]

TTL External Trigger Input (absolute maximum = 10 V)

110 kΩ Impedance.

Monitor real time pulse waveform on an oscilloscope with this

voltage output (uncalibrated)

(High Impedance - Do Not Terminate)

High, 5 V, between trigger and sample points. Connect to digital

oscilloscope channel 2 for triggering and sample point

identification

(High Impedance - Do Not Terminate)

Maximum cable length = 3 meters

1-4 Manual 21568, Rev. F, March 2008

Page 23

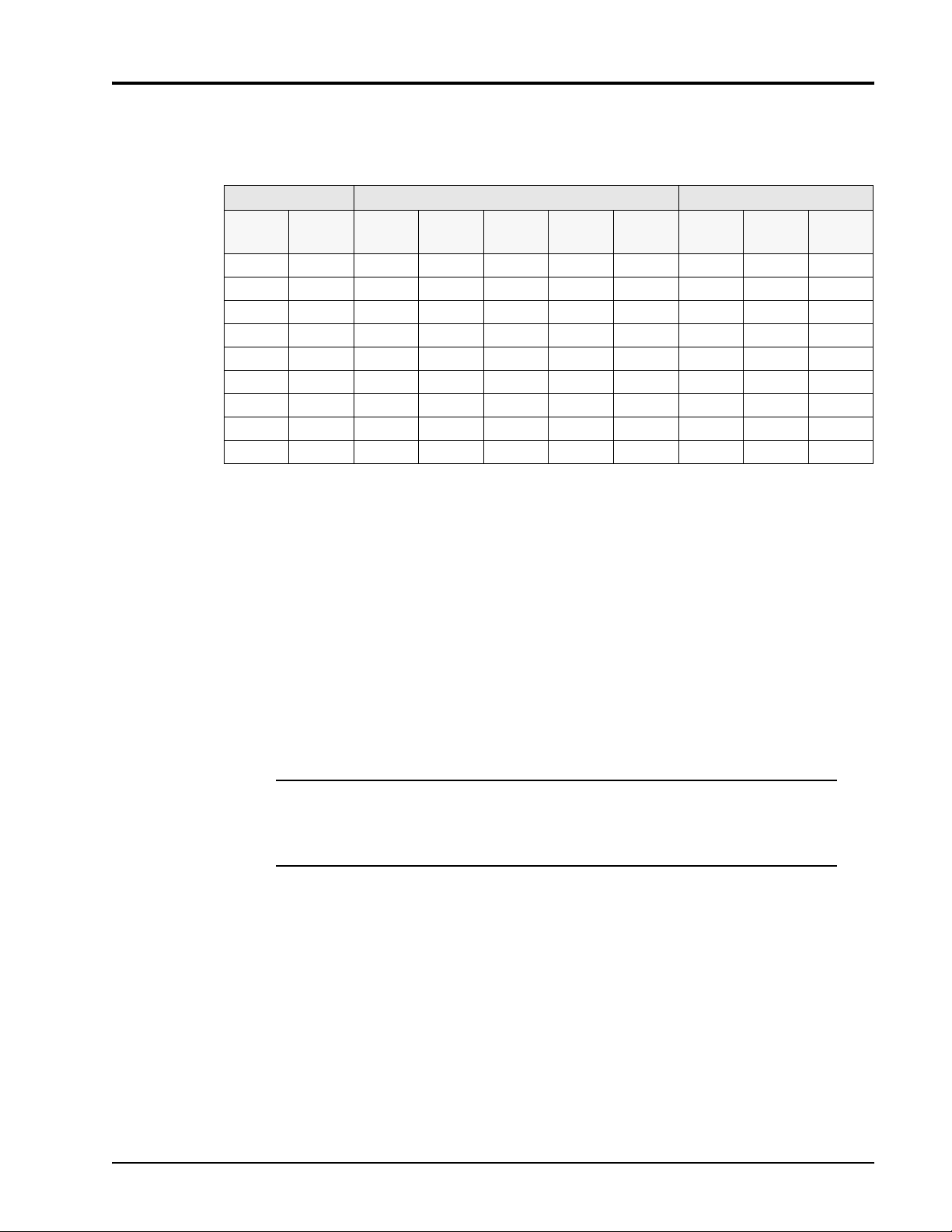

Table 1-2: Power Sensor Cal Factor Uncertainties

Freq. (GHz) Sum of Uncertainties (%)

Lower Upper 8035XA

0.1 1 1.61 3.06 9.09 9.51 10.16 1.04 1.64 4.92

1 2 1.95 3.51 9.43 9.85 10.50 1.20 1.73 5.04

2 4 2.44 4.42 13.10 13.57 14.52 1.33 1.93 7.09

4 6 2.67 4.74 13.33 13.80 14.75 1.41 2.03 7.17

6 8 2.86 4.94 13.52 13.99 14.94 1.52 2.08 7.25

8 12.4 3.59 6.04 14.25 14.72 15.67 1.92 2.55 7.56

12.4 18 4.09 6.86 19.52 20.97 21.94 2.11 2.83 12.37

18 26.5 —— 9.27 —— —— —— —— 3.63 ——

26.5 40 —— 15.19 —— —— —— —— 6.05 ——

80353A

80354A

80351A

3

1

80352A

Probable Uncertainties (%)

3

80355A

3

8035XA

80353A

80354A

80351A

80352A

80355A

Notes:

1. Includes uncertainty of reference standard and transfer uncertainty. Directly traceable to NIST.

2. Square root of sum of the individual uncertainties squared (RSS).

3. Cal Factor numbers allow for 3% repeatability when connecting attenuator to sensor, and 3% for attenuator

measurement uncertainty and mismatch of sensor/pad combination. Attenuator frequency response is added to

the Sensor Cal Factors which are stored in the sensor’s EEPROM.

2

3

3

3

1.2.2 Compatible Power Meters

8541X Single Channel Universal Power Meter

8542X Dual Channel Universal Power Meter

8651A Single Channel Universal Power Meter

8652A Dual Channel Universal Power Meter

58542 Dual Channel VXI Universal Power Meter

NOTE: If the Series 8035XA sensors will be used with a Model 8542 (dual channel) Power

Meter, the 8542 must be configured to code 06 or higher, or an asterisk (*) must be appended

to the code number. The code number is printed next to the serial number on the label

located on the rear panel of the 8542.

Manual 21568, Rev. F, March 2008

Page 24

Series 8035XA Peak Power Sensors

1-6 Manual 21568, Rev. F, March 2008

Page 25

2.1 Introduction

When a sensor is first connected to a Model 8540 or 8650 Series Unive rsal Power Meter or to a

Model 58542 VXIbus Universal Power Meter, it is necessary to calibrate the sensor to the

meter’s sensor input, using the meter’s power sweep calibration system. The power meter will

not allow measurements to be performed until this calibration is completed successfully. It is a

good practice to repeat the calibration whenever the ambient operating temperature of the

sensor varies by more than ±5 °C (±9 °F), and whenever any external connections or external

loads are added or removed from the sensor. Always a llow a 30 minute warm-up perio d before

calibrating the sensor.

2

Operation

*

The operational description of the 8035XA Peak Power Sensor applies to applications with

either the Series 8540 or 8650 Universal Power Meters (8541 /2, B and C) or the Model 58542

VXIbus Universal Power Meter. Except where noted, the front panel descriptions apply only to

the Series 8540 Power Meters, and SCPI command sequences apply to the Model 58542

VXIbus Power Meter. The Series 8650 Power Meter display lines vary from the Series 8540 but

include the same parameters.

NOTE: These instructions show the Series 8540 Power Meter front panel keys in brackets

[ ] and menu displays in bold print.

2.2 Power Sweep Calibration

Procedures for calibrating sensors to the meter are detailed in the specific power meter

manual. The 8035XA Peak Power Sensors are calibrated to the meter using the same

procedure as other sensors used with the 8540, 8650 Series Power Meters or the 5854 2 VXI

Power Meter. Connect the channel A sensor to the calibrator port, and press [ZERO/CAL].

Following the successful completion of Power Sweep Calibration, the 8541/2 will automatically

display the current value of sample delay for your 8035XA Series Peak Power Sensor. If the

sample delay does not appear, press [RECALL], select PRESET, and press [ENTER].

If you are using the dual channel 8542 Universal Power Meter, verify that only one 8035XA

Series Peak Power Sensor is connected. The 8542 will automatically display peak power on

one line and sample delay on the other. When two sensors are attached, the display will default

to display the two power levels. Some test procedures, such as A/B ratio measurements, will be

easier after performing some configuration of the display parameters. Press [MENU], select A,

B, A/B . . . B-A with the arrow keys, and press [ENTER]. This menu will allow you to select

various power measurements as well as DLY

and DLYB for the two line display.

A

Manual 21568, Rev. F, March 2008

Page 26

Series 8035XA Peak Power Sensors

2.2.1 5, 25 and 50 Watt Peak Power Sensors

Power Sweep Calibration of the 5, 25 and 50 W Peak Power Sensors (80351A, 80352A and

80355A, respectively) require you to disconnect the high power attenuator before you connect

the sensor directly to the front panel calibrator connector. When power sweep calibration is

completed, reconnect the high power attenuator to the sensor.

Proper connector alignment is shown by small black arrows printed on the attenuator and

sensor labels. The serial number on the sensor housing and the serial number on the high

power attenuator should match. During manufacture, the frequency response of the attenuator

is calibrated and entered into the peak power sensor EEPROM as frequency calibration

factors. This technique improves the accuracy and repeatability of your measurements.

CAUTION

Do not exceed 200 mW (+23 dBm) Peak or Average. Excessive in-

put power will damage or destroy the power sensor element.

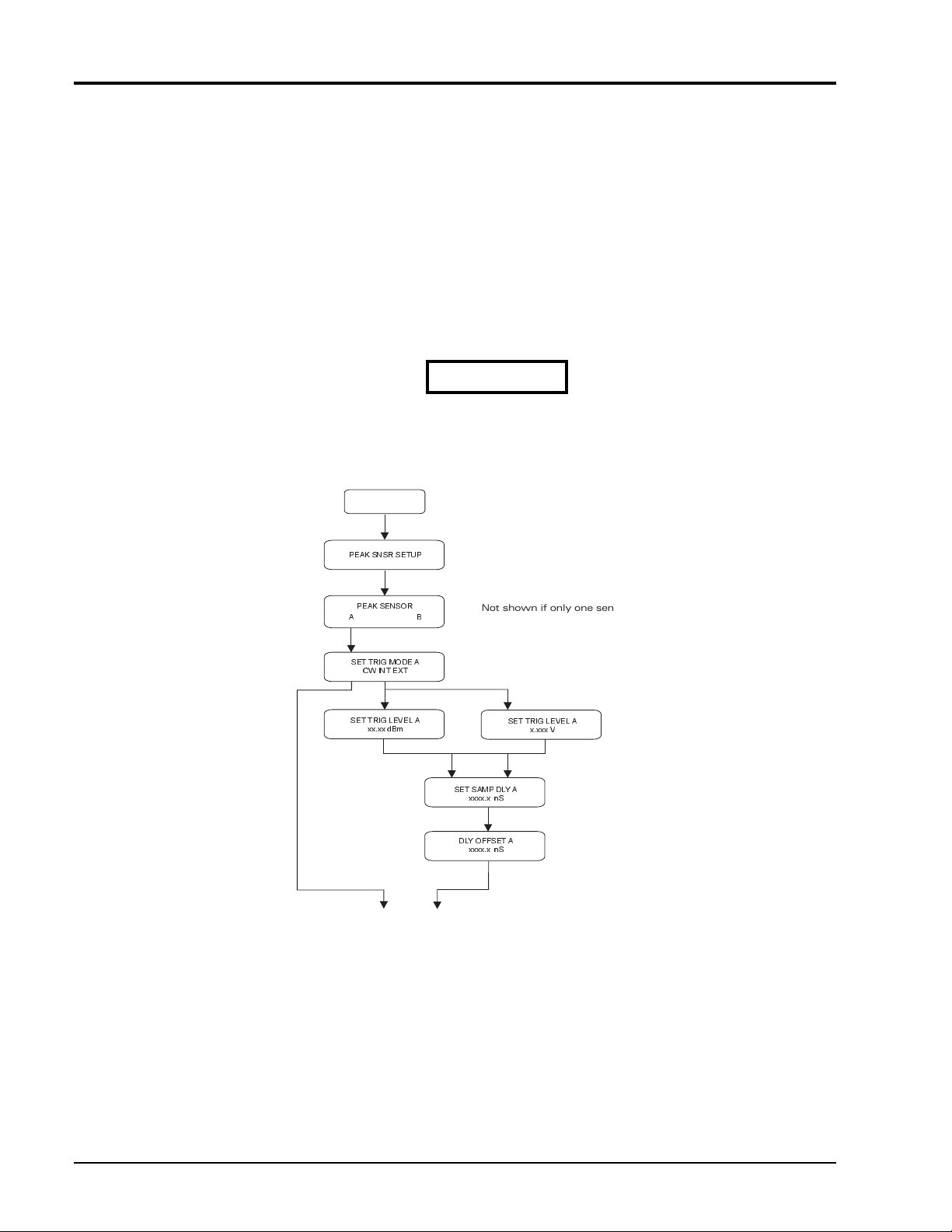

SET UP

PEAK SNSR SETUP

PEAK SENSOR

A

SET TRIG MODE A

CW INT EXT

SET TRIG LEVEL A

xx.xx dBm

To default display

B

Not shown if only one sensor is attached

or if the power meter is single- channel (8541)

SET TRIG LEVEL A

x.xxx V

SET SAMP DLY A

xxxx.x nS

DLY OFFSET A

xxxx.x nS

Figure 2-1: Sensor Setup Menu Tree

2-2 Manual 21568, Rev. F, March 2008

Page 27

2.2.2 Triggering

The 8540 power meters will not display a new peak power reading until the 8035XA sensor is

triggered. The default configuration is internal triggering (INT) at -20 dBm. Press [MENU],

select SETUP MENU, select PEAK SNSR SETUP, (select sensor A or B if necessary), and then

select INT triggering. You can then enter a new internal trigger level. Be sure that the value is 3

dB or greater below the peak powe r level of the signal being measured. If you are attemptin g to

trigger at excessively low power levels, measurement repeatability and noise performance can

be improved by using external (EXT) triggering.

INT Trigger Level

Operation

Amplitude Profile of

Meaured Signal.

Figure 2-2: Internal Triggering Levels

Manual 21568, Rev. F, March 2008

Page 28

Series 8035XA Peak Power Sensors

This is a pproximately 0.0 ns delay.

A built in delay line provides at least

20 ns look-ahead capability.

Sample Delay Pulse

10 sµ

Delay

58542 VXIbus Power Meter SCPI Compatible Commands

OUTPUT @Pwr_MTR;SENS1:TRIG:SOUR INT

OUTPUT @Pwr_mtr, SENS1: TRIG: DEL 10E-06

WAIT 200

OUTPUT @Pwr_mtr, MEAS1?

ENTER @Pwr_mtr: Peak_pwr_rdg

! Selects Internal Triggering

! Sets Sample Delay Position to 10 s

! Wait 200 ms for Sample Time Set

! Take a Measurement

µ

RF

Envelope

Trigger Level

(Int. or Ext.)

2.2.3 Zeroing

Zero the sensor before taking critical measurements in the bottom 10 dB of the peak power

sensor’s dynamic range. For standard peak power sensors, this level is -10 dBm.

When making dual channel power measurements, zero the sensors whenever another sensor

is attached or disconnected. Use the following steps:

1. Turn off the RF source.

2. Press [CAL/ZERO].

The sensors will zero automatically. The 8540 power meters detect when a sensor is attached

to the calibrator port. When a sensor is not attached to the power sweep calibrato r, the power

meter automatically initiates the zeroing procedure (if only one sensor is connected to the

meter). Be sure to deactivate the RF source for zeroing. Leaving the sensor attached to your

measurement test ports during zeroing properly accounts for test setup ground noise an d metal

to metal contact thermal EMF.

The 8035XA Series EXT trigger port is on the back of the sensor , not the power meter. A set of

three SMB(f) to BNC(m) cables are included with each 80 35XA Series senso r. The EXT tr igger

input impedance is 110 kΩ. This allows you to use TTL level signals without damaging the inp ut

circuit. However, the input impedance match might cause triggering line reflections and

potential false triggering when fast (50 Ω) trigger sources are used.

This can be resolved by setting the EXT trigger level (see Figure 2- 1).

The CW power measurement mode is also selected in the Peak Sensor Setup menu. CW

measurements are automatica lly performed on a continuous basis.

2-4 Manual 21568, Rev. F, March 2008

Figure 2-3: 8035XA Sensor Timing Diagram

Page 29

2.2.4 Sensor Triggering

A measurement will not be possible until the peak power sensor is triggered. The Series 8540

Power Meters will display

verification technique is valid for both Series 8540 and 58542 VXI Power Meters:

1. If you need to verify triggering, connect the Sample Delay output on the back of the

8035XA Series sensor to an oscilloscope using one of the SMB(plug) to BNC(m)

cables provided with the sensor. Set the scope channel to dc coupling, 1.0 µs per

division. Use rising edge (Normal) triggering at about 0.5 V trig ger level. Set the sens or

sample delay to 2.0 µs.

2. The sample delay pulse will appear each time the sensor is triggered. If a pulse does

not appear on the scope display, the sensor is not triggering. Check the triggering

configuration and adjust it if necessary. An analog oscilloscope may show a dim trace

when the repetition rate is low.

3. A quick check that can be made on the 8540 power meter for triggering without using

an oscilloscope is to press [dB/mW] twice. This will clear the current reading and

display

NO TRIG until a valid trigger is received.

Operation

NO TRIG until a valid trigger is received. The following trigger

Manual 21568, Rev. F, March 2008

Page 30

Series 8035XA Peak Power Sensors

2.3 Sample Delay

Sample Delay is the time value in nano-, micro-, or milliseconds that appears on the Series

8540 display after an 8035XA Series sensor has been calibrated. This is the length of time

between the trigger point and the sample point on the pulsed signal. This capability allows you

to measure the power level of your pulsed sig nal at any time point along its amplitude path. The

power level displayed is the true, sampled signal level at the time position that you specified;

the pulse level is not interpolated from two adjacent samples as is com mon in random sampling

oscilloscope-type peak power meters.

Sample delay is fully adjustable from -20 ns to 100 ms. On the 8541/2 front panel, use the

arrow keys to position the cursor and adjust the time values. Seven digits, four to the left of the

decimal and three to the right of the decimal, can be edited in the microsecond (ns) and

millisecond (ms) ranges (see Figure

allows four digits to the left of the decimal, but only a .0 or .5 to the right of the decimal.

The 0.0 ns time delay setting will be close to the trigger level when internal triggering is used. If

your measurements require definition of the 0.0 ns position, use Sample Delay Offset to adjust

for small triggering variations.

2-4 for an example.) The nanosecond range

Figure 2-4: Sample Delay Adjustment Display

Full 0.5 ns resolution is always possible regardless of the front panel units disp lay. On the

millisecond ranges, small nanosecond level increments in sample delay can be performed by

incrementing Sample Dly Offset in the Peak Sensor Setup menu tree. In addition to allowing

control of small nanosecond range sample delay increments while currently displaying

millisecond ranges, sample delay offsets allow you to compensate for cabling and circuit time

delays in your test setup. The sensor delay is the sum of DLY

and DLY OFFSET

)

B

and DLY OFFSETA (or DLYB

A

2-6 Manual 21568, Rev. F, March 2008

Page 31

2.3.1 Sample Delay Display

With a single peak power sensor attached, the default display after attachment and calibr ation

of the sensor will have the power displayed on one line and the sample delay displayed on the

other line. The default for channel A will be as shown in Figure

The default for channel B will be as shown in Figure 2-6.

Operation

2-5.

Figure 2-5: Channel A Default Sample Delay

Figure 2-6: Channel B Default Sample Delay

The default displays will also be used when the meter is preset. The default for two sensors will

display power readings on both lines as shown in Figure

Figure 2-7: Channel A & B Default Sample Delay

2-7.

If a sensor is uncalibrated, the word UNCALIBRATED will be displayed for the channel as

shown in Figure

2-8.

Figure 2-8: Sample Delay with Uncalibrated Sensor

Manual 21568, Rev. F, March 2008

Page 32

Series 8035XA Peak Power Sensors

The default display will be presented after attachment of a new sensor. Sample delay offsets

are available for each sensor. The use of a non-zero offset will be indicated by an asterisk

between the last digit and the units as shown below. The delay displayed is the sample delay

before the application of any offset.

DLYA 56.345*uS

The Sample Delay display line interacts with the Min/Max display line. If Min/Max is turned on

for a line that Sample Delay was tracking, Min/Max will be displayed instead of Sample Delay.

2.3.2 Setting Sample Delay

The sample delay can be set from two locations within the menu structure. One location is at

the default display where sample delay information is displayed. The other is in the menu

structure where the peak sensor setup is configured.

Sample Delay Operation

You will be presented with a display with a decimal point fixed in the display. Normally, four

digits are available to the left of the decimal point and three digits to the right as shown below.

Leading zeros will be suppressed.

XXXX.XXX uS

When the units are set to nS, only one digit will be available to the right of the decimal.

The right and left arrow keys move a cursor to select a digit or unit to be changed. The cursor

will stop only at valid digit or unit locations (valid digits are shown by ^ below). The cursor will

stop under valid blank spaces so that large numbers can be entered quickly.

XXXX.XXX uS

^^^^ ^^^ ^

Press the up key to increment the digit value b y 1, or the down key to decrement the digit value

by 1. If a digit is incremented past 9, a carry is propagated to the next higher digit (odometer

mode). Similarly, if a digit is decremented past 0, a borrow will be made from the next higher

digit. You can decrement the delay to a negative number.

An exception is made when the cursor is moved to the 10 ths of n anose co nd s ran ge. The up or

down arrows will change the display in .5 nS increments. This is the maximum resolution of the

sensor.

Press the up or down keys while the cursor is und er the units display to cycle through th e units.

You will be offered a choice of nS, uS, or mS. The units display does not wrap around.

The units selected will be used in all displays for the delay for the sensor to which they are

assigned.

If a peak measurement parameter is changed, e.g. sample delay or trigger level, the power

display will display NO TRIG (see Figure

parameters in effect. If the sensor triggers quickly, the message may not be seen. In the TR2

2-8 Manual 21568, Rev. F, March 2008

2-9) until a new measurement is made with the new

Page 33

mode, the display may show MEAS* with the asterisk lines rotating as each measurement is

made.

The GPIB will return numerical data in the No Trig state, depending on the GPIB measurement

mode. See the GPIB Commands in Section

2.3.3 Sample Delay Limits

There is no automatic units scaling for the sample display. You can enter an y number up to

9999.999 and then set the units, with the exception of the nS range , which allows only one digit

to the right of the decimal. If the sample delay plus the offset exceed the range of the attached

sensor, the

Figure

is too low.

S at the end of the line will be replaced with an arrow indicating a range error (see

2-10). An up arrow indicates that a delay is too high, a down arrow indicates that a delay

Operation

Figure 2-9: Sample Delay with No Trigger Display

2.4 for more details on Trigger Modes.

Figure 2-10: Sample Dely Over-Range Indication

When the arrow keys are used to change the units, the digits in the display will simply use the

new units. The only exception is going from µS to nS. The digits to the right of the decimal point

will be reduced to one digit, and that last digit will be either 0 or 5 as shown in the following

example:

Starting Display Action Resulting Display

15.678 uS ↓ 15.5 nS

Setting Delay from the Default Display

A cursor will be displayed on the sample delay in the default display. When you change the

sample delay by pressing an up or down arrow key, the associated sensor will be immediately

programmed with the new delay. The power display may be repla ced with NO TRIG until a new

power measurement can be made with the new sample delay.

If an over-range sample delay is entered, no measurement will be made until the over-range

condition is corrected (over-range includes delay plus offset).

If there is more than one delay display line, the left and right arrows will move the cursor off the

end of one display line and onto the next.

Manual 21568, Rev. F, March 2008

Page 34

Series 8035XA Peak Power Sensors

Setting Delay from the Peak Setup Menu

The cursor will be available immediately upon entering this menu. The sensor will not be

updated with the new delay setting until the peak menu sequence is completed. This requires

selecting the trigger mode, setting the trigger level, setting the sample delay, and setting the

sample delay offset. The display will exit to the default measurement display when you press

[ENTER] on the last menu in the sequence.

2.3.4 Setting Sample Delay Offset

The sample delay offset is settable from the menu following the SET SAMP DLY menu (see the

Menu Tree in Figure

to enter the sample delay. You can change a set of digits (XXXX.XXX), plus units.

The offset will be range checked together with the sample delay so that the total of sample

delay plus offset does not exceed the range of the sensor. If the range of the sensor is

exceeded, a beep may sound and an arrow will replace the S at the end of the line (see Figure

2-11) to indicate an out of range condition. If you exit the menu without correcting the out of

range condition, no power measurement will be made.

2-1). The method to enter the delay offset will be the same as the method

Figure 2-11: Sample Delay Over-Range Offset Display

For example, if the max delay available from a sensor is 100 mS and the samp le delay is set to

75 mS, the maximum offset permitted is 25 mS. Anything larger will cause an arrow to be

displayed.

Each sensor has its own delay offset paramet er.

2.3.5 Single Peak Sample Measurements

Measurements for a peak sensor will be performed over a number of single samples. A single

sample is defined as follows:

1. The sensor is armed.

2. A pulse is triggered and sampled by the sensor. The sensor informs the meter via handshaking

that a measurement voltage is available.

3. The meter measures the voltage and computes the power from this one trigger sample.

When averaging is turned on, the averaging will be done over a number of single samples. Auto

averaging will use an increasing averaging number as the power level being measured

declines. For example, the number of sam ples req u ire d fo r me as ur em e nt s at 20 dBm is 1. At 20 dBm, the number of samples will be about 32 (this could change depending on mode or

software version).

2-10 Manual 21568, Rev. F, March 2008

Page 35

2.3.6 Real Time Pulse Profile and Sample Position Display

The Detector Out connector on the rear of the 8035XA Series Peak Power Sensor can be

connected to any common oscilloscope for a real-time amplitude profile of your signal, delayed

by about 120

Connect the SMB to BNC cables to your oscilloscope (digital scope preferred - especially for

sample delay setting >500 µs) as shown in Figure

ns.

2-12.

Operation

Figure 2-12: Pulse Profile and Sample Delay Test Setup

Use the Sample Delay output as an oscilloscope trigger source. This waveform rises at the

trigger point and falls at the sample point; thus, it provides both a stable scope trigger source

and a precise indicator of the trigger point and sample point.

The time length of the sample delay pulse is the sum of the sample delay which is displayed on

the Series 8540 power meter front panel, and the sample delay offset which is available

through the menu.

Manual 21568, Rev. F, March 2008

Page 36

Series 8035XA Peak Power Sensors

2.3.7 Sample Delay Offset

In addition to compensating for delay line triggering variations or external triggering cables,

sample delay offset can be used to set a 0.0 ns time refe rence p oint a fter the tr igger poi nt (see

Figure

2-13).

t

total

t

total = sample delay + sample delay offset

t

total = 20,000 s + 0.120 s = 200 120 sµµ µ

or

t

total = 200,000 s + (-0.010 s) = 199.990 sµµ µ

Figure 2-13: Sample Delay

The use of a digital oscilloscope can permit better viewing of data. There are two small markers

injected onto this waveform. The first is a small triggering marker which is added slightly after

the trigger point. The second marker on the waveform is the sample marker. The sample

marker is located slightly behind the actual sample point. There may be small markers at the

end of the sample transfer and when the trigger signal occurs. Because the visibility of these

markers varies greatly with signal level and horizontal sweep rate, the use of the SAMPLE

DELAY output is recommended.

In Figure 2-14, triggering occurs at the frame start of a pulsed TDMA communications signal.

The trigger level is set such that triggering can only occur on the highest amplitude pulse; this

provides stable triggering. A sample delay offset is used to set a 0.0 ns reference point at the

start of the third data burst pulse.

Sample

Delay

Sample

Delay

Detector Out

Connection

Internal

Trigger

Level

Sample Delay Offset

Sample Delay

Connection

Figure 2-14: Using SD to Offset a 0 ns Time Refer ence

2-12 Manual 21568, Rev. F, March 2008

Page 37

2.3.8 Measuring Pulse Droop

Detector Out

Trigger Level

t

1

t

2

Pulse characteristics such as droop, ripple, and overshoot can be measured quickly using

referenced measurements. This involves the use of the fron t panel REL key for the Series 85 40

power meter users, or the CALC#:REF:COLL function for 58542 power meters.

1. Connect the 8035XA Peak Power Sensor to the power meter and the CALIBRATOR

output.

2. Press [CAL/ZERO] to calibrate the sensor to the meter.

3. Upon successful completion of power sweep calibration, connect the sensor to a pulsed signal

source. The power level must be above the trigger level.

4. Connect the 8035XA Detector Out and Sample Delay leads to a digital oscilloscope.

5. Set the sample delay ( DLYA) to the t1 position just after the rising edge as shown in Figure

2-15.

6. Press [REL]. The display should now read approximately 0.00 dBm or 100%.

7. Set the sample delay to the t2 position just before the falling edge of the pulse.

Operation

The display is now reading the pulse-top amplitude variation.

Figure 2-15: SD Setting for Measuring Pulse Droop

Manual 21568, Rev. F, March 2008

Page 38

Series 8035XA Peak Power Sensors

100% Reference Level

3 dB down (50%)

3 dB down (50%)

Sample Delay

Offset

Total Delay

Trigger Level

Sample Delay = Pulse Width

t

t

=

2.3.9 Measuring 3 dB Pulse Width

Pulse width and other pulse timing parameters can be measured using the REL key and the

sample delay offset control (see Figure

1. Preset the delay offset to 0 nS.

2. Set the sample delay equal to about half the pulse width.

3. Press [REL] to set the 0.0 dB reference level (100% for Watts display).

4. Set the sample delay to a position on the rising edge of the pulse. Increment or decrement the

sample delay value until the power level display reads approximately -3.00 dBr.

5. Remember or write down the sample delay value.

6. Press [MENU], and use the up/down arrow keys to display SETUP MENU. Press [ENTER].

Select PEAK SNSR SETUP, then select the current tri ggering m e tho d (INT or EX T). When

DLY Offset appears, set the offset value to the same time value from Step 4. This sets the 3 dB

down time point to a 0.0 ns reference position.

7. Press [ENTER] to return to the measurement display.

2-16).

8. Set the sample delay to a position on the falling edge of the pulse. Increment or decrement the

sample delay value until the display again reads approximately -3.00 dBr.

The sample delay currently displayed is the signal’s 3 dB pulse width.

Figure 2-16: Using SD to Measure a 3 dB Pulse Width

2-14 Manual 21568, Rev. F, March 2008

Page 39

2.3.10 Measuring Rise-Time

Rise time measurements can be performed using a technique similar to the pulse width

measurement. This example uses a linear Watts display readout rather than the more common

logarithmic dBm readout for convenient identification of the 10% and 90% levels.

1. Preset the delay offset to 0 ns.

2. Press [dBm/mW] to obtain a linear, Watt, display readout.

3. Set the sample delay equal to about half the pulse width.

4. Press [REL] to set the 100% reference level.

5. Set the sample delay to a position on the rising edge of the pulse. Increment or decrement the

sample delay value until the power level display reads approximately 10%.

6. Remember or write down the sample delay value.

7. Press [MENU]. Select SETUP MENU then PEAK SNSR SETUP. Proceed to the SAMPLE

DELAY OFFSET selection. Set the offset value to the same value from Step 6.

Operation

8. Return to the measurement display and increment the sample delay until the display reads

approximately 90%.

The sample delay currently displayed is the 10% to 90% rise time.

2.4 GPIB Commands

These commands supplement the commands given in the Series 8540C Universal Power

Meter Operation and Maintenance Manual.

2.4.1 Setting Trigger Modes

These commands set the trigger method for the 8035XA sensor. The sensor can be set to

trigger on the rising RF envelope of the power signal. This is the internal trigger mode. An

external TTL trigger can be used, or the sensor can “free run” and allow a CW measurement

mode with no trigger required.

The terms digital filter (as used in some instrument instructions) and averaging buffer (as used

here) are interchangeable.

Examples:

OUTPUT 713;PEAK A INT TRIG -10.00 ! Configure sensor A for internal trigger at

! -10.00 dBm trigger level

OUTPUT 713;PEAK B EXT TRIG 1.50 ! Configure sensor B for external trigger at

OUTPUT 713;PEAK A CW ! Configure sensor A for CW measurements

In this example, the address 713 means "Type 7" GPIB instrument, and address 13 for the

power meter. The GPIB control command (the portion to the left of the semicolon) may vary.

Trigger Modes With a Peak Sensor

Manual 21568, Rev. F, March 2008

! 1.50 Vdc trigger leve l

Page 40

Series 8035XA Peak Power Sensors

Examples:

OUTPUT 713;TR3 ! Last measured value will be returned

OUTPUT 713;TR2 ! Refill averaging buffer before measurement display

OUTPUT 713;TR1 ! Wait for trigger before returning measurement

OUTPUT 713;TR0 ! Measure, but no display

TR0

The meter will measure power, but the display of measured data will be suppressed and the

GPIB bus will not be updated with measurement data.

TR1

This mode will wait until the sensor triggers before returning a measurement. The

measurement returned will be after the application of any averaging. The display for the

channel will follow the TR1 mode. When TR1 is received over the bus, NO TRIG will be

displayed until the sensor has triggered and measurement data is available.

TR2

This mode will wait until enough measurements are made to completely refill the averaging

buffer. The measurement returned will be the average of all measurements in the buffer.

MEAS* will display with one of the asterisk lines rotating for each measurement) while the

averaging buffer is being filled.

TR3

The last measured value will be returned. This mode will not wait for the peak sensor to trigger.

2.4.2 Setting Delays

When the sensor is configured for internal triggering, the delay from trigger to measu rement

sample must be set. The valid range of delays is -20 ns to 100 ms, expressed in a floating point

number. The smallest delay increment is 0.5 ns. Setting delays in CW trigger mode are invalid

and ignored.

Examples:

OUTPUT 713;PEAK A DELAY 1.20E-6 ! Configure sensor A for a delay of 1.20 µs

OUTPUT 713;PEAK B DELAY 33.5E-9 ! Configure sensor B for a delay of 33.5 ns

The offset command adds a known offset to the trigger delay value. The actual value of delay

would be the DELAY set plus the OFFSET set. The default value of offset is 0. The valid range

of offset is -20 ns to 100 ms, expressed in a floating point number.

Example:

OUTPUT 713;PEAK A OFFSET 1.00E-6 ! Configure sensor A for a delay offset of 1.00 µs

2-16 Manual 21568, Rev. F, March 2008

Page 41

2.4.3 Reading Values

These commands read the current settings of delay or offset.

Examples:

OUTPUT 713;PEAK A? ! Query the current sensor A trigger setting

ENTER 713;TRIG$ ! Query the trigger mode setting of the sensor, and return:

CW

or

INT_TRIG

or

EXT_TRIG

OUTPUT 713;PEAK A DELAY? ! Query the current sensor A delay setting

ENTER 713;Delay

OUTPUT 713;PEAK B OFFSET? ! Query the current sensor B offset

ENTER 713;Offset

Operation

Manual 21568, Rev. F, March 2008

Page 42

Series 8035XA Peak Power Sensors

2.4.4 Commands for the 58542

The following peak power sensor GPIB commands are used with the Model 58542 VXI

Universal Power Meter. Refer also to the Model 58542 Operation and Maintenance Man ual for

additional details.

SENSe<sensor 1 or 2>:TRIGger:SOURce<INTernal|EXTernal|CW>

This command sets the sensor (1 or 2) peak trigger mode to either the INTernal, EXTernal, or

CW mode.

SENSe<sensor 1 or 2>:TRIGger:DELay[:MAGnitude]<1e-6, -20e-9,100e-3>

This command sets the sensor (1 or 2) peak delay value to any desired time from -20e-9 to

100e-3 seconds, with 1e-6 seconds being the default setting.

SENSe<sensor 1 or 2>TRIGger:OFFSet[:MAGnitude]<0, -20e-9,100e-3>

This command sets the sensor (1 or 2) trigger offset time to any desired value from -20e-9 to

100e-3 seconds, with 0 seconds being the default setting.

SENSe<sensor 1 or 2>TRIGger:LEVel[:MAGnitude]<-10 dBm, -30 dBm, 20 dBm>

When the INTernal trigger mode is in use, this command sets the trigger level to any desired

power level setting from -30 to +20 dBm. Default is -20 dBm.

SENSe<sensor 1 or 2>TRIGger:LEVel[:MAGnitude]<1.700, -0.100, 5.000>

When the EXTernal trigger mode is in use, this command sets the trigger level to any desired

voltage level from -0.100 to 5.000 V. Default is 1.700 V.

2-18 Manual 21568, Rev. F, March 2008

Page 43

3.1 Introduction

This chapter describes the electrical operation of the Series 803 5XA Peak Power Sensors.

Refer to the block diagram in Figure 3-1 to follow the general function of the sensor. The RF

signal is rectified in the sensor element, and the video envelope is buffered and de layed by the

input amplifier and delay buffers. This buffered envelope is available at the Detector Out

connector. The Track and Hold (T&H) function tracks and follows the signal and then holds it for

hundreds of microseconds. The Sample and Hold (S&H) function acqu ires the S&H o utput and

holds it for hundreds of milliseconds.

The timing circuitry generates the sample pulses from the trigger input or, if the sensor is in the

free run mode, from an internal oscillator.

The block diagrams, circuit descriptions, and the troubleshooting information in Chapter 4 are

written around the circuit test points. The delay lines shown in Figure

Analog Timing Diagram in Figure 3-3. Delay lines match the delay through the analog channel

to the sample point, and the delay through the timing circuitry to the sample generator. Since

fixed lumped constant delay lines are used, the match is not perfect. The delay through the

3

Theory of Operation

3-1 are illustrated in the

Manual 21568, Rev. F, March 2008

Page 44

Series 8035XA Peak Power Sensors

INTernal trigger is slightly longer than the delay through the EXTernal trigger due to the delay of

the input differential preamp.

Figure 3-1: 8035XA High Level Block Diagram

3.2 Analog Assembly Description

Refer to Figure 3-2, the Analog Timing Diagram in Figure 3-3, and schematic diagram #21351

in Chapter 7 to follow the discussion of the Analog PC assembly circuit operation.

The rectified signal from the detector goes into the resistors R1 or R2 (TP1 and TP2). The

signal sees 2 kΩ to ground from either input (the negative input sees 2 kΩ to a virtual ground

inside R100). R3 helps to balance the input bias current. U1 and U2 delay the signal so the

trigger output and video output may be viewed close together. U4 and U5 are buffers for the

delay lines (TP3).

3-2 Manual 21568, Rev. F, March 2008

Page 45

Theory of Operation

U10C and U7A provide a fast Track and Hold (T&H). U7A buffers the T&H capacitor C21, and

U7B buffers the S&H capacitors, C1 & C2.

Figure 3-2: Analog PC Assembly Block Diagram

A track and hold differs from a sample and hold in the manne r in w hic h the sign al pr ior to the

hold is manipulated. In a sample and hold, the sample gate turns on and the holding capacitor

is charged to the signal potential, then the sample gate turns off and the hold capacitor

maintains the value of the input at the time of the sample. In a track and hold circuit, the voltage

on the hold capacitor is the same as the input (tracks) until the track gate goes off, after which

the level is held until the track goes on and the hold capacitor again follows the input.

The INTernal or EXTernal trigger source is selected by U10D and U11A. U11B functions as a n

inverter for HIGHGAIN. U6 amplifies the trigger signal by 1 or 41. Trigger DAC U9 is loaded

with a count from the serial chain. The DAC needs the data signal held after the clock for at

least 80 ns. A2R12 and A2C25 on the Digital board take care of that requirement. That cou nt

gets translated into a voltage between - 0.1 V and about +5 V by U8A. Digital bo ard comparator

A2U18 provides the TRIG-IN pulse (A2TP25). A2R42 provides hysteresis for A2U18.

*

NOTE: All times shown in Figure 3-3 are referenced to TP3, and are not to scale.

Manual 21568, Rev. F, March 2008

Page 46

Series 8035XA Peak Power Sensors

NEG INPUT

TP1

POS INPUT

TP2

DIF - AMP

TP3

1ST DELAY

TP4

2ND DELAY

TP5

MONITOR

TP9

TRACK&HOLD

TP7

OUTPUT

TP12

TRIG AMP

TP6

SAMP

J2-5

DELAY TIME

TRANSFER TIME

Figure 3-3: Analog Circuit Timing Diagram

3-4 Manual 21568, Rev. F, March 2008

Page 47

3.3 Digital Assembly Description

3.3.1 Overview

Refer to the Digital PC block diagram in Figure 3-4, an d the Digital Timing Diagra ms in Figur es

3-5, 3-6 and 3-7.

The digital board provides the timing functions for delays between a small negative time (with

respect to either the video monitor, or the sampled pulse) and >100 ms. In the CW mode, the

digital board is not reset, but continues to generate clocks and samples at about 70 µs

intervals. In either the INTernal or EXTernal modes, an acquisition is requested by the host (the

power meter to which the sensor is connected is the host) which causes READY to be set.

When an input trigger is received, it is latched and delayed by a FINE delay, and then starts a

10-MHz clock. The clock increments a COARSE counter until it reaches FFFFF or all ones, and

then outputs a Ripple Carry Out (RCO) signal. This is latched as SAMPle, delayed by one

count, and then compared to the count of 51µs out of the counter to allow the SAMPle to be

51µs wide. Then the COARSE counter is reLOADed for about 5µs, the 10-MHz clock is

stopped for about 5µs, the

reset for about 1µs. A 48-bit serial stream provides the 80350A configuration infor mation. When

the serial clock is running, CLKHOLD resets the TRIG loop and loads the counter.

LOAD unasserted, and the TRIGger, SAMPle, and READY flip-flops

Theory of Operation

*

NOTE: Over-score indicates a logic-NOT condition.

Manual 21568, Rev. F, March 2008

Figure 3-4: Digital PC Assembly Block Diagram

Page 48

Series 8035XA Peak Power Sensors

3.3.2 Description

When READY (TP17) is true, U8B flip-flop (TP14 - TRIG) is set after TRIG-IN goes high. U13

delays the TRIGgered signal by a delay programmed in 1/2 ns intervals. U3 is a 10-MHz gated

delay line oscillator which, when enabled by the fine delay, clocks (TP1) the coarse counter U1,

U5, U6, U15 and U16, and the SAMPLE flip-flops U7B and U8A. Unlike conventional oscillators

which free run, a gated delay line oscillator beginning time period is the same length as all of its

other time periods with the possible exception of the last period when enable is unasserted.

When RCO (TP8) is true for one clock cycle (ignores pulses less than 100 ns), U7B is latched

as SAMPle (TP11). SAMPle is delayed by one count because 51µs (TP7) can still be true when

SAMPle goes true, and AND’d with 51µs from U1. When true (when SAMPle has been on for

51µs), the U10A loader receives a negative edge clock.

asserted and held low via U9C, R34, and C27 until the 10-MHz clock (U3) stops via U12A,

U10B, (TP9), U4A, and U4C. Note the sequence:

1. CTR-CLK (TP1) must be running.

2. LOAD-CTR (TP9) goes low and stays low while CTR-CLK continues for at least one cycle.

This loads the COARSE counter.

3. CTR-CLK (TP1) stops. LOAD-CTR is still low. CTR-CLK continues in the CW mode.

LOAD for the COARSE counter is

4. LOAD-CTR returns high at least 200 ns before POST (TP5) returns high. The same FINE delay

which delayed the start of the 10-MHz clock now works against turning the 10-MHz clock off.

SAMP (TP11) going high turns the Track and Hold (T&H) to Hold on the Analog board, and

turns the Sample and Hold (S&H) to Sample. When it goes low, the T&H goes back to tracking

the input and the S&H holds the sampled signal level. U10B POST (TP5), the major reset

circuit, resets READY (TP17) to prevent the trigger circuit from restarting, continues to rese t

TRIG (TP14) (except in the CW mode) which started in PRE-POST, and resets SAMP (TP11).

When the host has read the data, the DATA-IN line is momentarily pulsed low by the host which

sets READY (TP17), and pulls the DATA-IN line (TP20) low via diode CR3. Note that the

DATA-IN — READY handshake does not occur in the CW mode.

EEPROM U11 stores the sensor type, serial number, and calibration constants. This IC is only

accessed by the host. Except for device start and stop conditions, DATA-IN can change states

only when CLK is low. After device stop has been sent, the host sends a 48-bit serial str eam to

set up the 80350A sensor. Four zeros are sent followed by the 12 DAC tr igger bits, followed by

the fine counter 8 bits, 20 bits for the COARSE counter (with FFFFF meaning zero delay), and

finally the 4 control bits (INTernal, EXTernal, CW, and HIGHGAIN). Because the serial DAC on

the ANALOG board has a data hold requirement of 80 ns minimum, DATA-4 (TP2) must be

delayed by R12 and C25.

Incoming CLK turns on U3 (10 MHz - TP1) and U9C (LOAD) (TP9) via U12B (CLKHOLD)

which loads the COARSE counter with the new delay.

The test points are essentially in order across the len gth of bo th the Analog and Digital boar ds

in the approximate order of signal progression to aid in troubleshooting. In addition, the

between-the-board connectors can be used as test points.

3-6 Manual 21568, Rev. F, March 2008

Page 49

Theory of Operation

Figure 3-5: Digital Timing Diagram, INT/EXT Trig Mode

Manual 21568, Rev. F, March 2008

Page 50

Series 8035XA Peak Power Sensors

Figure 3-6: Digital Timing Diagram, CW Mode

Figure 3-7: Digital Serial Data Cycle Timing Diagram

3-8 Manual 21568, Rev. F, March 2008

Page 51

4.1 Introduction

Information in this section is useful for periodic evaluation of the performance and/or r eceiving

inspection testing of the 8035XA Series Peak Power Sensors. These tests assume that the

operation of the particular 8540, 8650, Series Power Meter or Model 58542 VXI Power Meter

being used with the sensor has already been verified as described in the power meter’s

Operation & Maintenance Manual. Verifying the Frequency Cal factors stored in the sensor

EEPROM is not covered in this procedure. If necessary, the Cal Factors should be verified with

a Vector Network Analyzer using similar procedures as for standard power meter sensors.

Before starting these tests, connect the Peak Power Sensor(s) to the compatible power meter,

and allow at least 24 hours for warm-up. These tests will only be valid if the power meter and

the sensor(s) have been calibrated at an ambient temperature between +20 °C and +30 °C

(+68 °F to +86 °F), and are operating within ±3 °C (±5.4 °F) of the calibration temperature.

4.2 Equipment Required

4

Calibration and Testing

The following items of test equipment (or equivalent) are required for completing the

Performance Tests described in this chapter.

Description Instrument Model Requirements

Power Meter Giga-tronics 8650, 8540 or

58542 Series

RF Source Wavetek Model 2510 (Hi

Power Opt.) or equivalent

Oscilloscope (DSO) LeCroy 9400 Bandwidth 125 MHz

CW Thermistor Power

Meter

Thermistor Mount Agilent/HP 478A-H75 0 to +10 dBm range <1.1 SWR

Pulse Generator Wavetek Model 278 or

Attenuators 10, 20, 30 and

40 dBm

Directional Coupler Narda Model 3002, 10 dB

Low Pass Filter Integrated Microwave Model

Agilent/HP Model 432B Inst. Acc. of at least 0.5%

equivalent

Weinschel Model AC118A-

90-33

904 881

Compatible with 8035XA Sensor

+20 dBm @ 50 MHz

Delay and pulse width control

Type N, 0.5 dB accuracy

VSWR <1.20 @ 50 MHz

>50 dB Atten. @ 100 MHz

Manual 21568, Rev. F, March 2008

Page 52

Series 8035XA Peak Power Sensors

4.3 Power Linearity Test

The linearity will be tested in a series of 10 dB steps over the range of the sensor. At low power

levels, the measurements will reflect the uncertainty due the noise and zeroing specifications.

Make a copy of the Performance Verification Data Sheets at the end of this chapter to record

the data from this test.

4.3.1 CW Linearity Test

1. Connect the test setup as shown in Figure 4-8. Set the RF source to 50 MHz. Be sure the sensor

has had at least 24 hours of warm-up time. To take accurate measurements, it is essential to take

out any drift that might occur.

a. Calibrate the Peak Power Sensor as described in the applicable Power Meter Operation and

Maintenance manual.

b. Place the peak sensor into the CW mode.

c. Set the power meter to display power in lin ear units (mW).

d. Set Averaging to 4.

e. Set the CW frequency to 50 MHz.

2. Start with no attenuation between the coupler and the Peak Power Sensor. Record results on the

first row of the linearity data recording sheet. If the sensor being tested is an 80351A, 80352A

or 80355A model, remove the attenuator from the sensor.

3. Turn the RF source off and zero the Peak Power Sensor by pressing [ZERO/CAL].

Figure 4-8: Power Linearity Test Setup

4. Zero the thermistor power meter.

5. Turn the RF source on.

4-2 Manual 21568, Rev. F, March 2008

Page 53

Calibration and Testing

6. Adjust the RF source until the thermistor power meter reads 10.0 mW ±0.25 mW.

7. Record the thermistor power meter reading, P1, and the power meter reading, R1, on the data

sheet.

8. Adjust the RF source until the thermistor power meter reads 1.0 mW ±0.025 mW.

9. Record the power meter reading, P2, and the power meter reading, R2, on the data sheet.

10. Calculate and record the reference power ratio P1/P2, and the DUT reading ratio, R1/R2.

11. Calculate and record the Linearity Error using the formula:

12. Add an additional -10 dB of attenuation between the coupler and the Peak Power Sensor and

repeat Steps 3 through 9, filling in the 10 dB through 40 dB (through 30 dB in Peak Mode)

attenuation rows of the data sheet. On these rows, add the current linearity error to the

accumulated linearity error in the row above. Verify that this accumulated error is less than the

specified values given on the data sheet.

4.3.2 Peak Linearity Test

Set the sensor to EXT, 1.7 V, 10 µs, 0 offset, and connect the TRIGGER IN (black lead) to the

pulse generator. Set the pulse generator to 1 kHz, and repeat all of the steps in the CW

Linearity Test for this Peak Linearity verification test. Record the readings on the Peak Linearity

Data recording sheet at the end of this chapter.

Manual 21568, Rev. F, March 2008

Page 54

Series 8035XA Peak Power Sensors

4.4 Trigger Modes Tests

Connect the test setup as shown in Figure 4-9. Set the pulse generator for a 100 Hz pulse

repetition frequnecy. Set the RF source to generate a 2 ms wide pulse. Set the power me ter to

display power in linear units (mW). Set teh source to 50 MHz with a power output to

approximately 1 mW (0 dBm).

1. Set the delay of the pulse generator to 0 ms.

2. Set the peak Power Sensor to EXT trigger mode with the following parameters:

Trigger level: 1 V

Trigger Delay: 1 mS

Delay Offset: 0 mS

NOTE: If the sensor under test is has an external attenuator, remove it before

connecting to the sensor to the RF source.

DC

Figure 4-9: Detector Output and Trigger Level Setup

4.4.1 Detector Output Test

Leave the test setup as shown in Figure 4-9. Connect the 1 MΩ oscilloscope input to the

Detector Output. Verify that the pulse has an amplitude of approximately 200 mV peak to p eak

for an applied signal level of 0 dBm.

4.4.2 Trigger Level Test

The following tests check for trigger sensitivity. Each section refers to a specific sensor group

arranged by power capability. Refer to the appropriate section based on the sensor model

being verified.

4.4.2.1 100 mW Power Peak Sensors

Set the RF source to the following settings:

4-4 Manual 21568, Rev. F, March 2008

Page 55

50 MHz, -30 dBm

Pulse output settings:

PRF 100 Hz

Width: 2 msec

Pulse State: ON

NOTE: Applies to 80350A, 80353A and 80354A sensors only.

1. Set the Pulse Sensor trigger to Internal and sample delay to 1 ms.